Prefabricated capillary energy-storage heat-dissipation wall

A heat dissipation wall and capillary technology, applied in the direction of wall, dispersed particle filtration, dispersed particle separation, etc., can solve the problems of increasing the cost of use, and achieve the effects of energy saving, uniform water flow distribution, and convenient temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

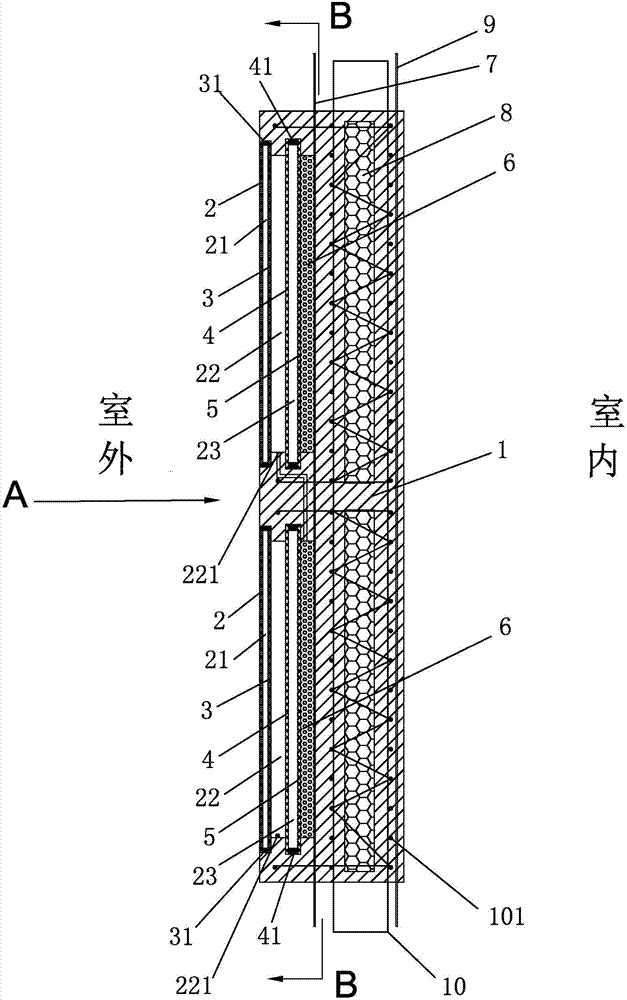

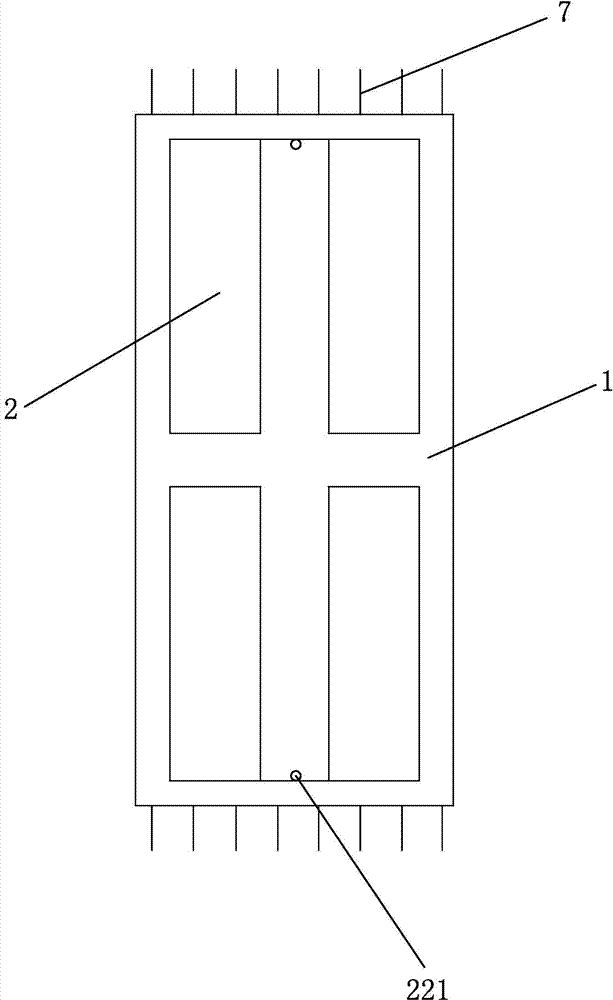

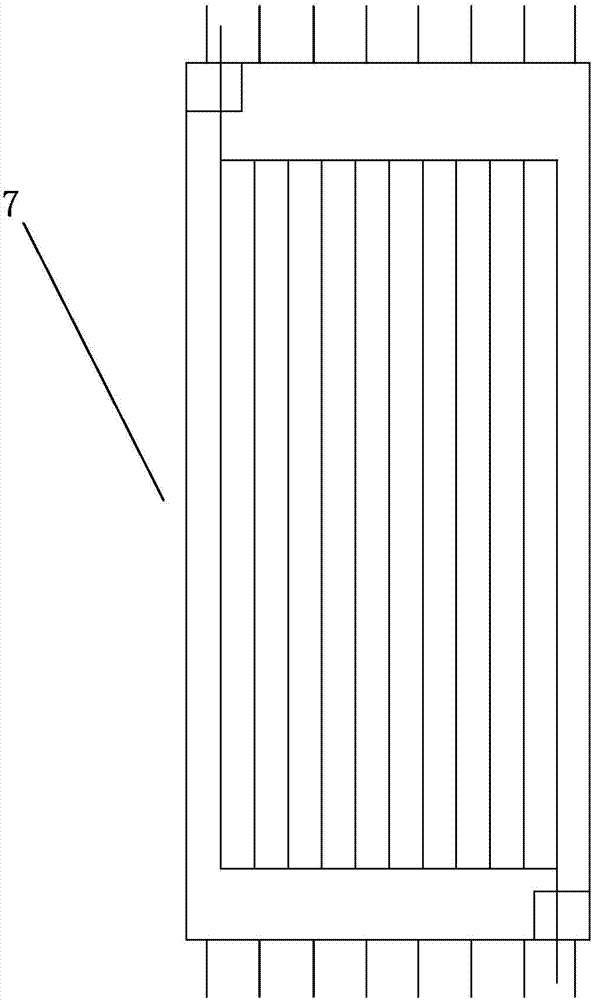

[0020] like Figure 1 to Figure 3 As shown, the prefabricated capillary energy storage heat dissipation wall of the present invention includes a concrete wall 1, on which the first tempered glass layer 2, the second tempered glass layer 3, the first tempered glass layer 2, The second toughened glass layer 3 is four pieces, and two pairs are symmetrically distributed up and down. The first toughened glass layer 2 and the second toughened glass layer 3 are sealed by the first sealant 31 to form two closed upper and lower symmetrical first glass layers. An air layer 21, the inner side of the second tempered glass layer 3 is provided with a first-level dust removal filter 4, the inner side of the first-level dust removal filter 4 is provided with a second-level dust removal filter 5, a first-level dust removal filter 4 and a second-level dust removal filter 5 There are two of them, and they have the same structure and are symmetrically distributed up and down. Two closed second a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com