Ultra-low phosphorus steel smelting method

A smelting method, ultra-low phosphorus steel technology, applied in the field of metal material smelting, can solve problems such as environmental pollution, converter lining erosion, etc., and achieve the effects of improving production efficiency, low cost, and saving transformation investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

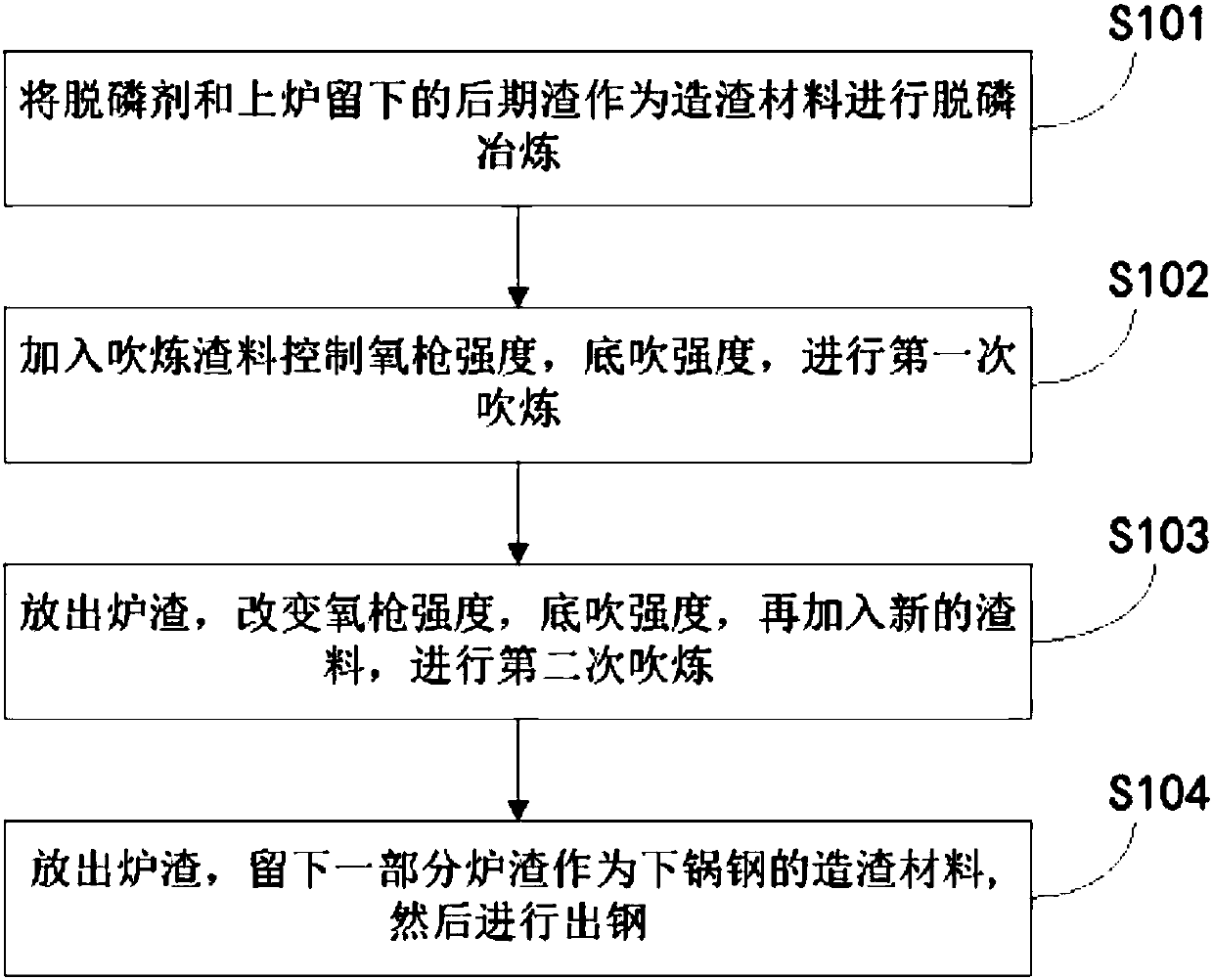

Method used

Image

Examples

Embodiment Construction

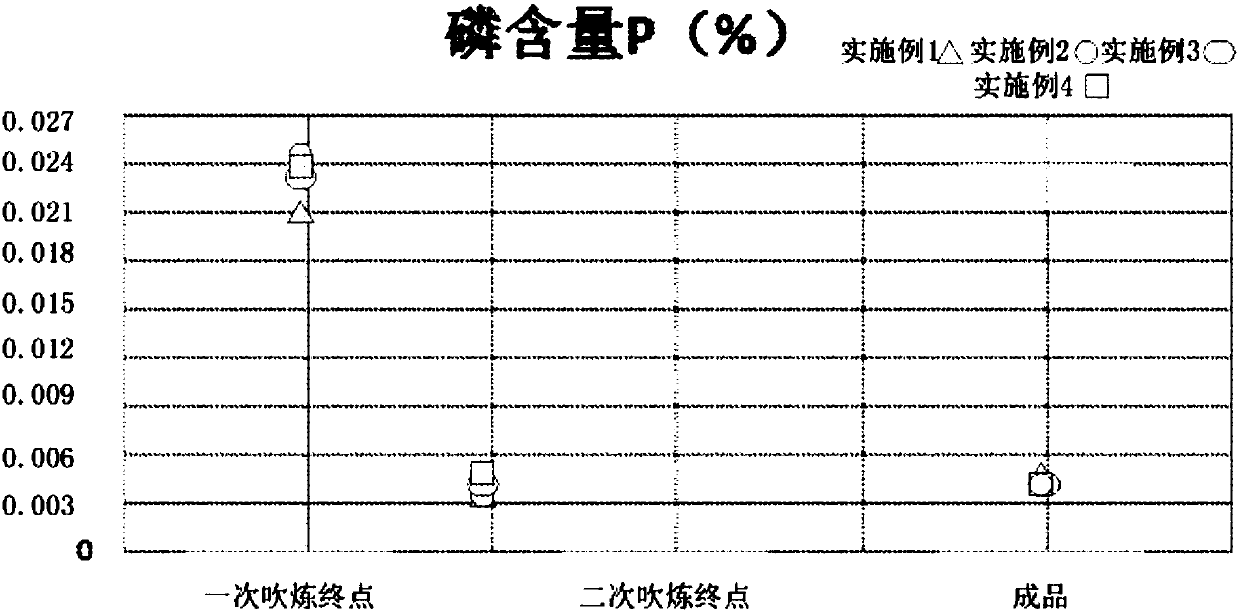

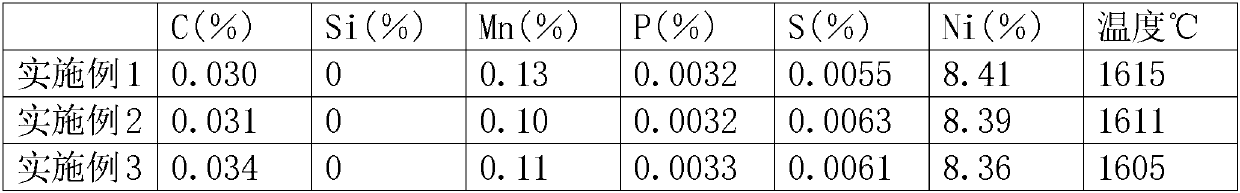

[0021] Smelting steel type: 9Ni

[0022] Specifically, in the dephosphorization period, the dephosphorization agent containing lime, light-burned dolomite and mica ore is added into the converter and smelted together with the late slag left by the steel in the previous furnace as slag-making materials, and at the end of the dephosphorization period When the slag is dumped. According to an exemplary embodiment of the present invention, the added dephosphorization agent may include 10-35 kg of lime per ton of steel, 2-10 kg of lightly burned dolomite per ton of steel, and 2-8 kg of mica ore per ton of steel.

[0023] Converter primary blowing: Put the tap hole in the special slag stopper. Adjust the converter bottom blowing flow rate to 410Nm before blowing 3 / h, the oxygen supply flow rate is 27000Nm when the blowing is started 3 / h, gun position 1.4m. After hmin, raise the gun position to 1.6~1.8m, and reduce the flow rate to 21000Nm 3 / h. The amount of lime is added acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com