Centralized heating method and system

A technology for central heating and water supply temperature, applied in heating systems, hot water central heating systems, heating methods, etc., can solve the problems of increased operating costs, increased pressure difference between supply and return water, pressure on pipes and equipment, etc. problems, to achieve the effect of reducing transformation investment, reducing operating pressure, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

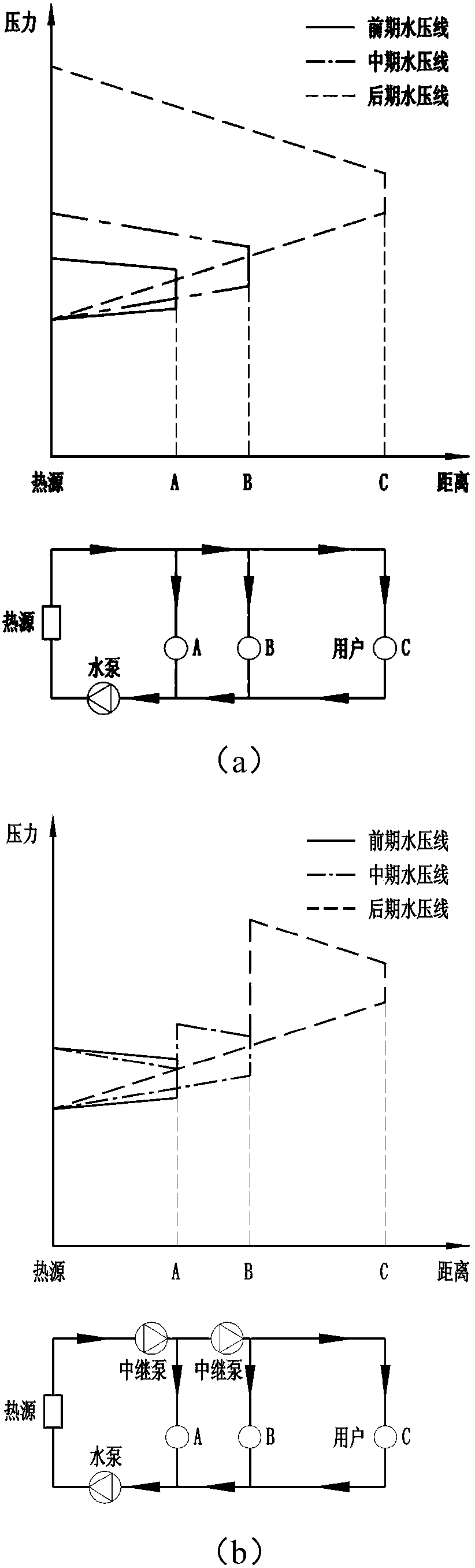

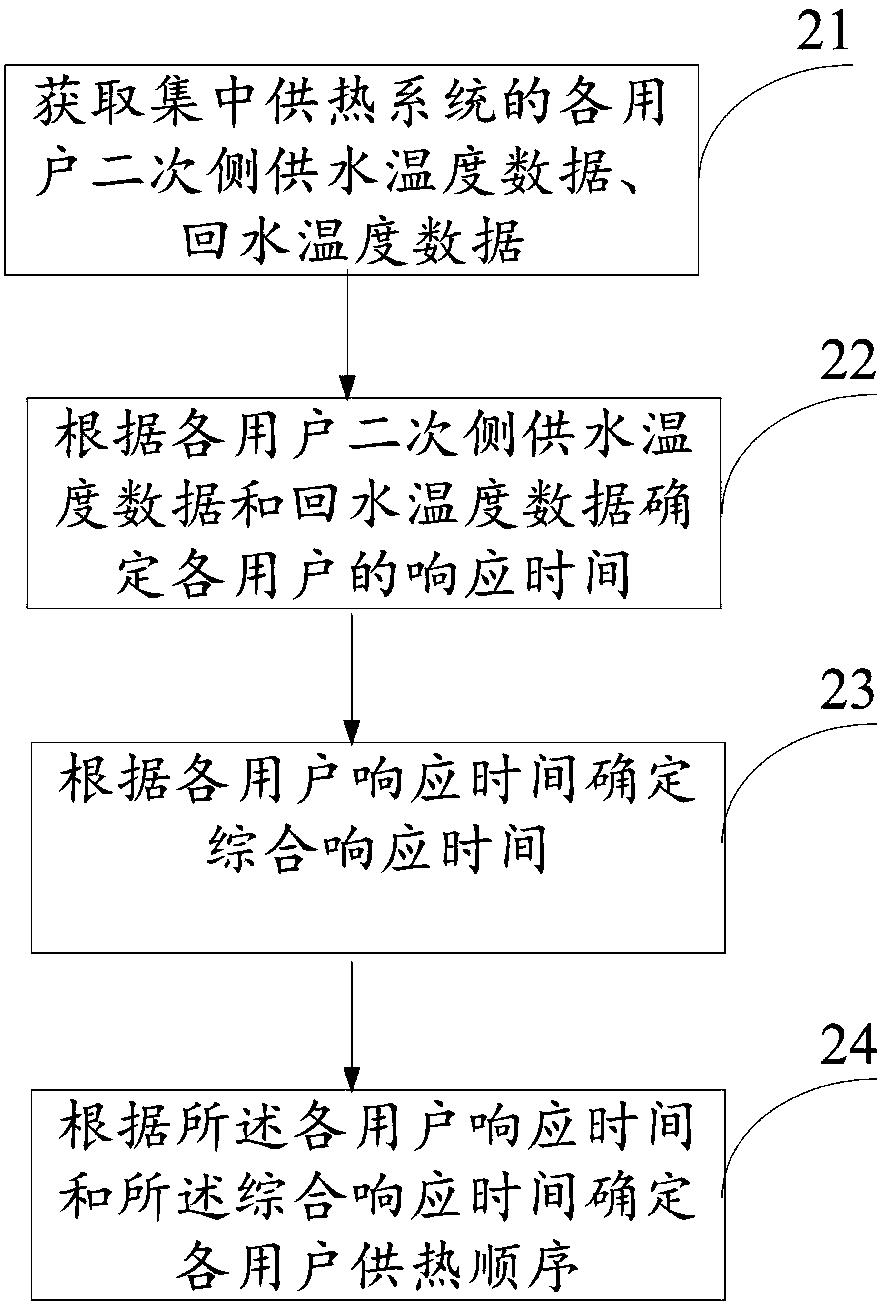

[0072] figure 2 It is a flow chart of the central heating method of the embodiment of the present invention, image 3 (a) in the embodiment of the present invention is a flow chart of the method for determining the heating order of each user, such as figure 2 and image 3 Shown in (a), the present invention provides a kind of central heating method, and described method comprises:

[0073] Step 21: Obtain the secondary side water supply temperature data and return water temperature data of each user in the central heating system.

[0074] Step 22: Determine the response time of each user according to the secondary side water supply temperature data and return water temperature data of each user; the specific steps include:

[0075] According to the water supply temperature data and return water temperature data of each user's secondary side, determine the cooling rate of each user when the heat is stopped;

[0076] Determine the temperature drop value of each user within...

Embodiment 2

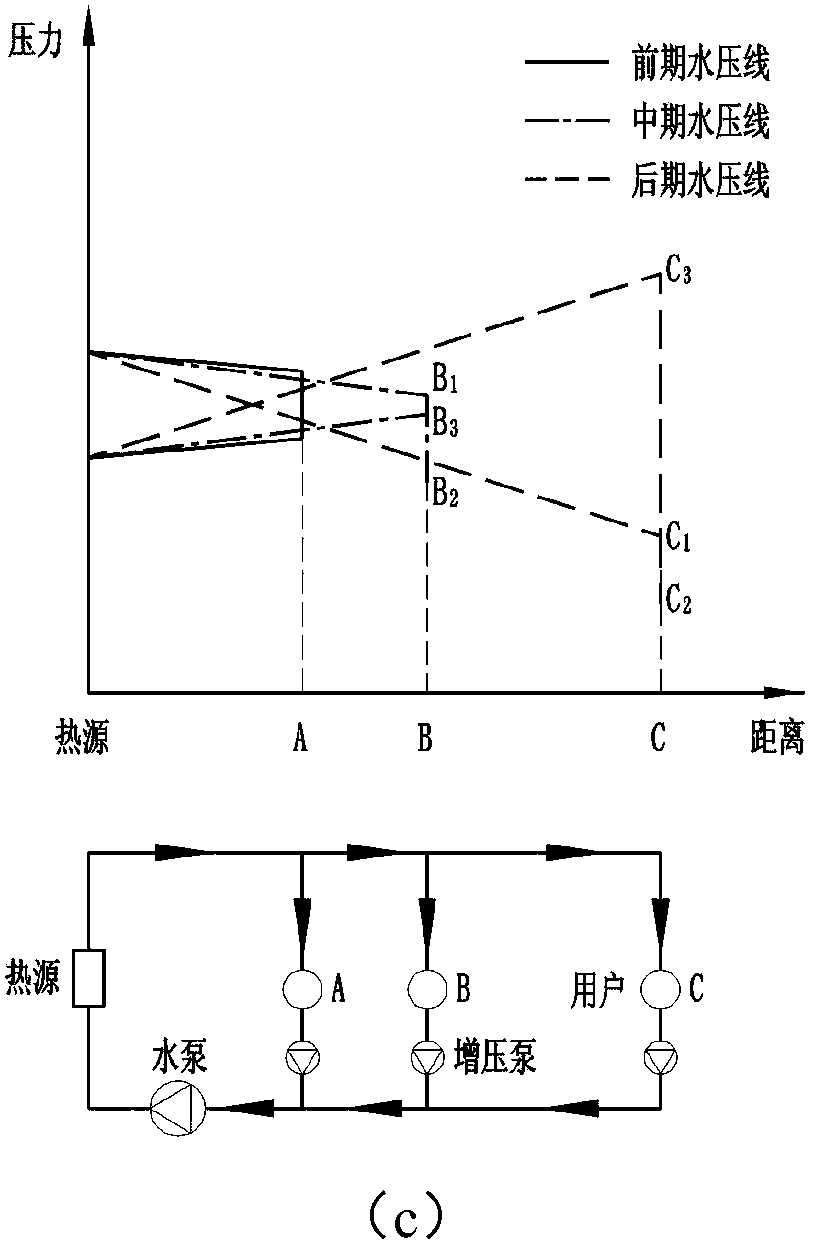

[0097] figure 2 It is a flow chart of the central heating method of the embodiment of the present invention, image 3 (b) is a flow chart of the method for determining the heating order of each user in the embodiment of the present invention, such as figure 2 and image 3 Shown in (b) in, the present invention provides a kind of central heating method, described method comprises:

[0098] Step 21: Obtain the secondary side water supply temperature data and return water temperature data of each user of the central heating system;

[0099] Step 22: Determine the response time of each user according to the secondary side water supply temperature data and return water temperature data of each user; the specific steps include:

[0100] According to the water supply temperature data and return water temperature data of each user's secondary side, determine the cooling rate of each user when the heat is stopped;

[0101] Determine the temperature drop value of each user within th...

Embodiment 3

[0124] Figure 4 It is the structural diagram of the central heating system of the embodiment of the present invention, as Figure 4 As shown, the present invention provides a centralized heating system, which includes: an acquisition module 41 , a module 42 for determining the response time of each user, a module 43 for determining the comprehensive response time, and a module 44 for determining the order of heating for each user.

[0125] The acquiring module 41 is configured to acquire secondary side water supply temperature data and return water temperature data of each user in the central heating system.

[0126] Each user response time determination module 42 is used to determine the response time of each user according to the secondary side water supply temperature data and return water temperature data of each user; the each user response time determination module 42 specifically includes:

[0127] The cooling rate determination unit is used to determine the cooling r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com