Patents

Literature

54results about How to "Improve heat exchange performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

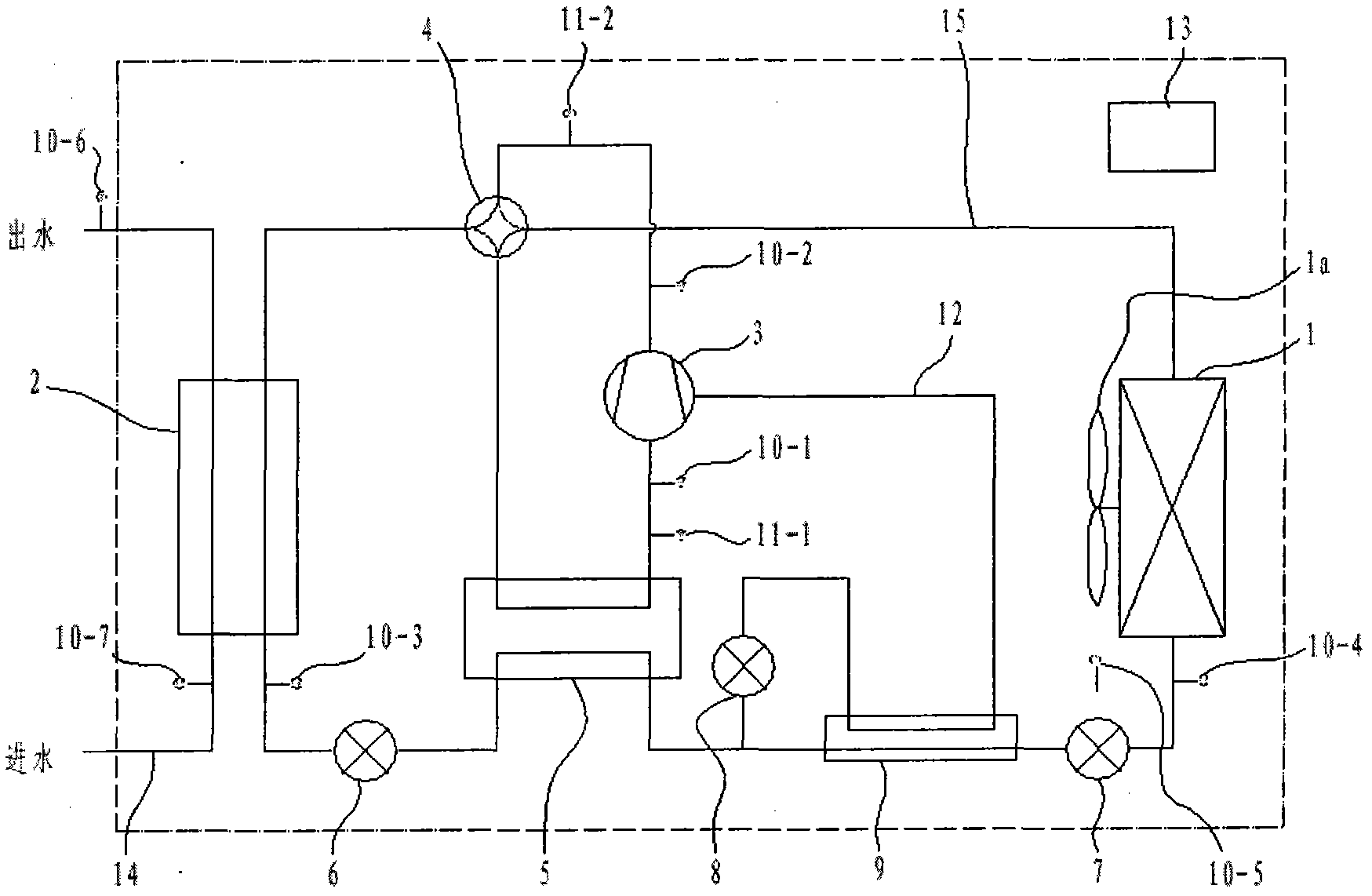

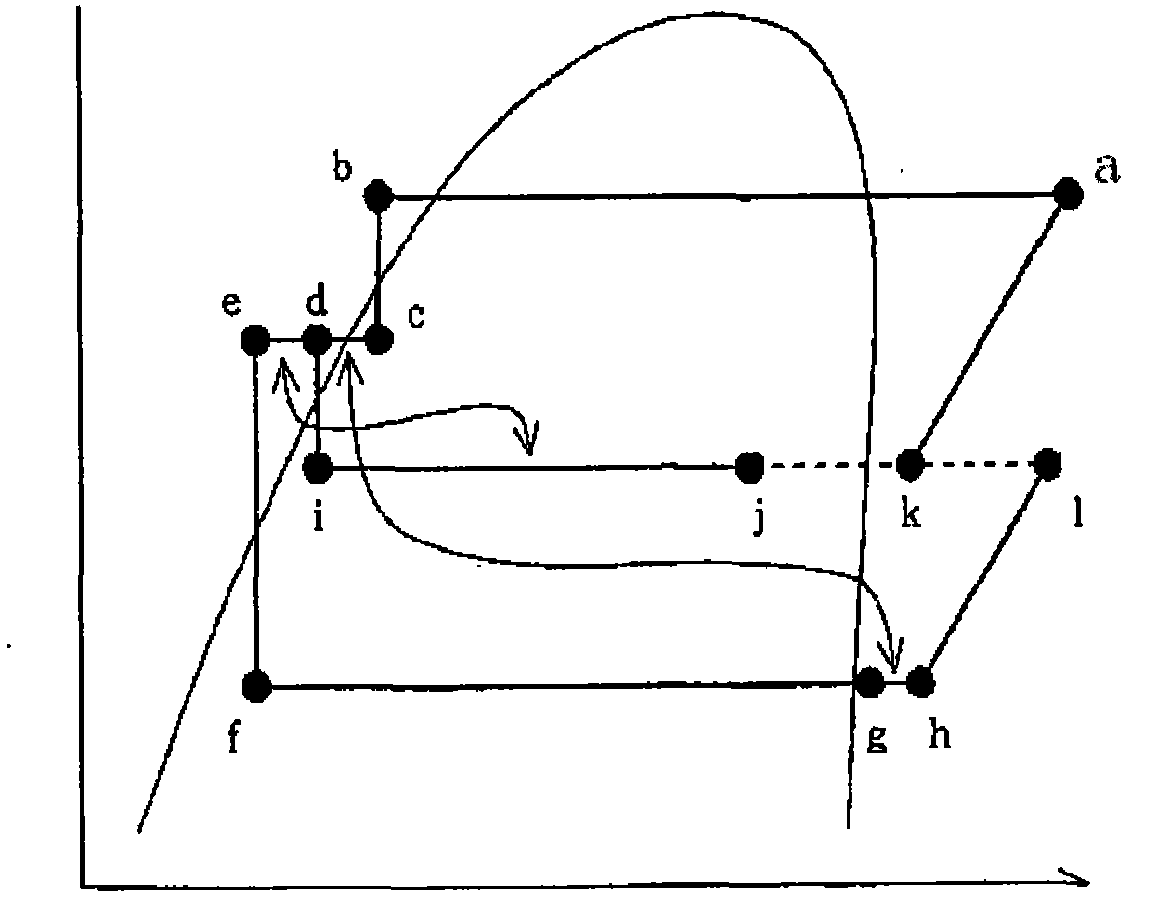

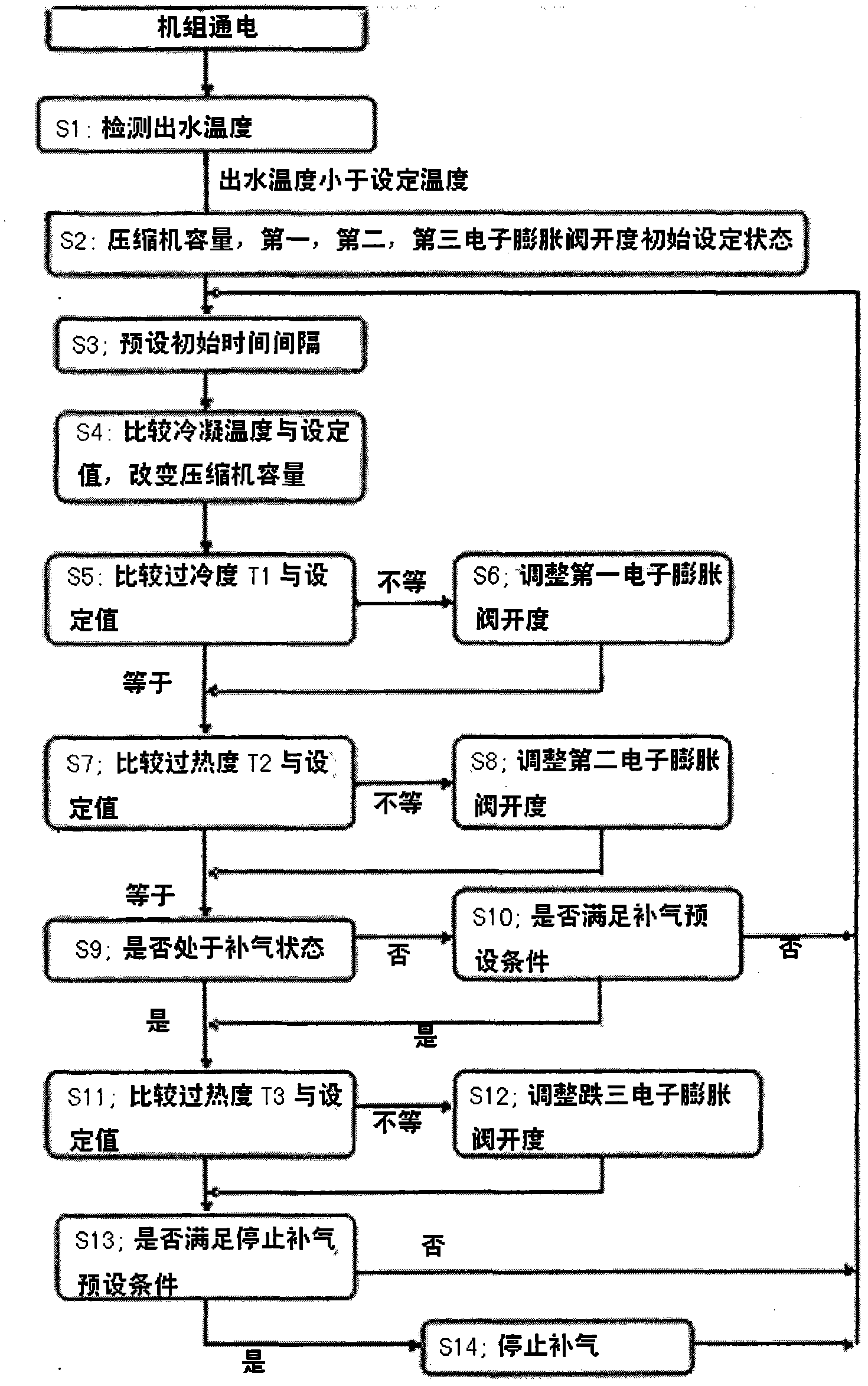

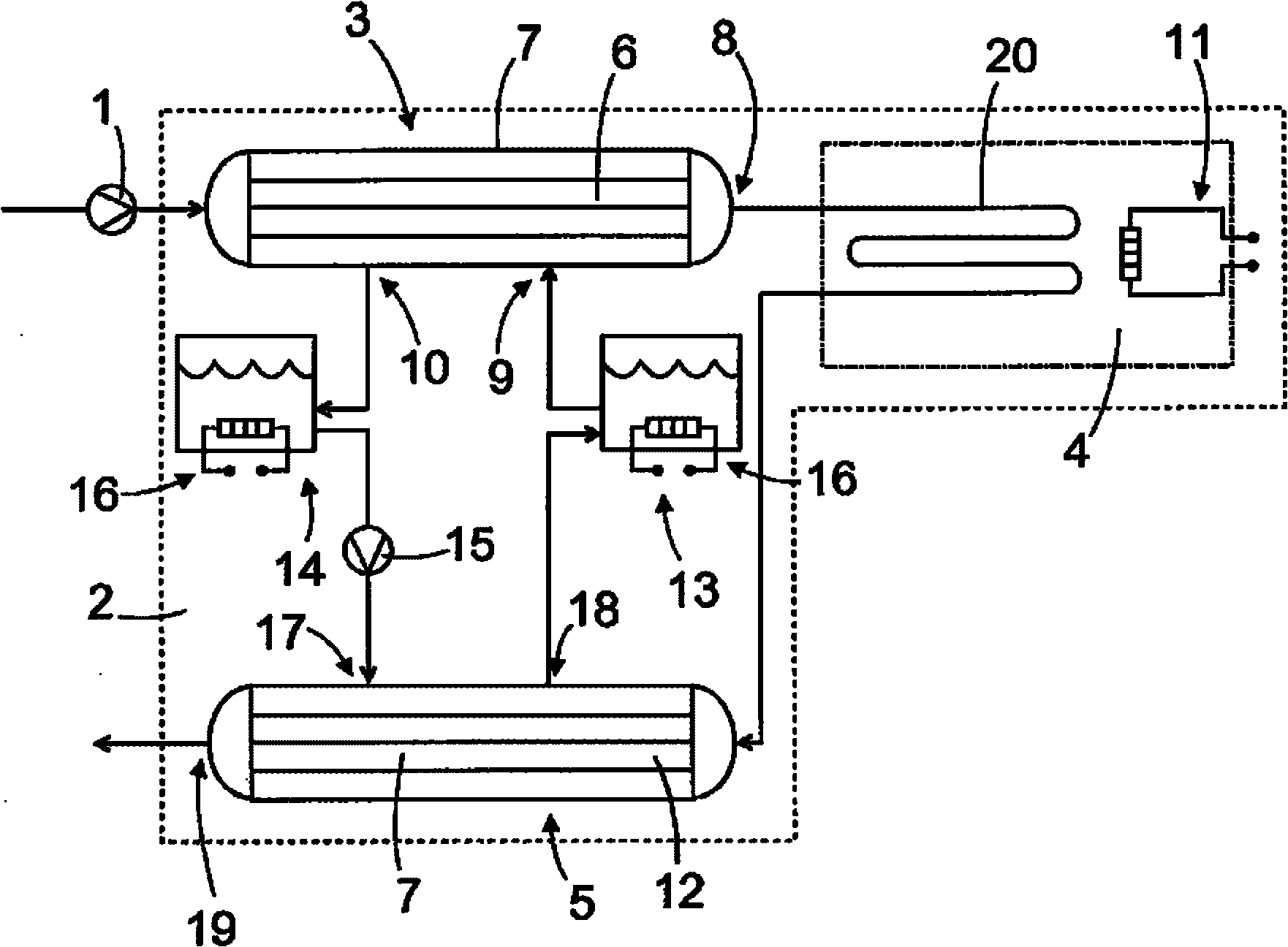

Self-regulating steady-state low-temperature heat-pump water heater and operating method thereof

ActiveCN101936600AGuaranteed heating efficiencyIncrease circulation flowFluid heatersRecuperatorEngineering

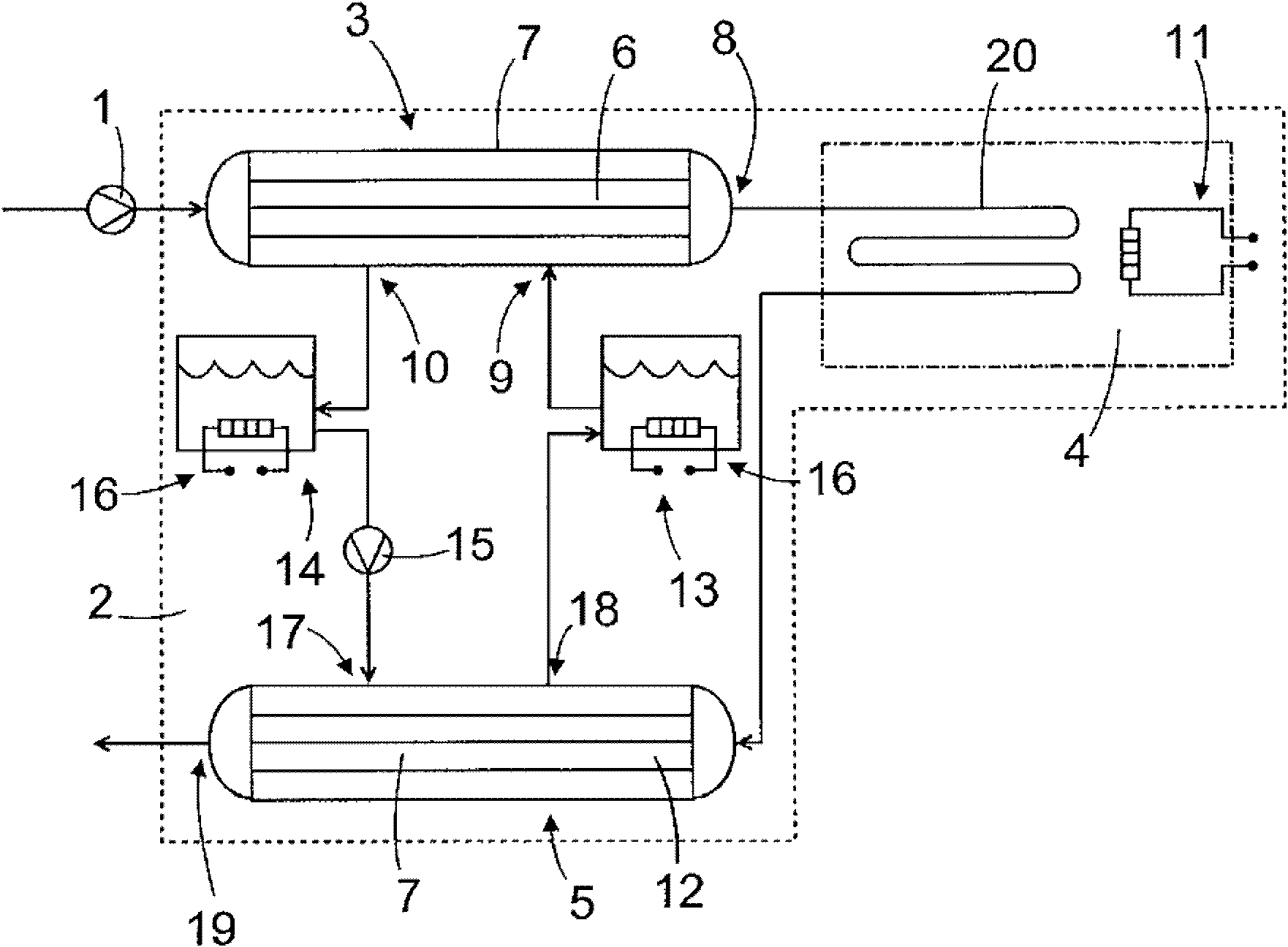

The invention relates to a self-regulating steady-state low-temperature heat-pump water heater comprising an evaporator, a condenser, a compressor, a control device, a four-way reversion valve, a medium-pressure receiver and an intermediate heat exchanger which can form a closed main loop, wherein the four-way reversion valve is positioned on a connection access arranged between the evaporator and the condenser, the medium-pressure receiver and the intermediate heat exchanger are arranged on the other connection access arranged between the evaporator and the condenser, and a temperature sensor, an electronic expansion valve and a pressure sensor are positioned on the closed main loop. The self-regulating steady-state low-temperature heat-pump water heater is characterized in that an air-supply loop is arranged between the compressor and the intermediate heat exchanger. The self-regulating steady-state low-temperature heat-pump water heater has a main purpose of preventing hot-water preparation capacity reduction at low environmental temperature and a secondary purpose of ensuring the stable state of a refrigerant when heat load changes in the condenser and realizing higher heat-exchange performance in the condenser.

Owner:JIANGSU TENESUN ELECTRICAL APPLIANCE

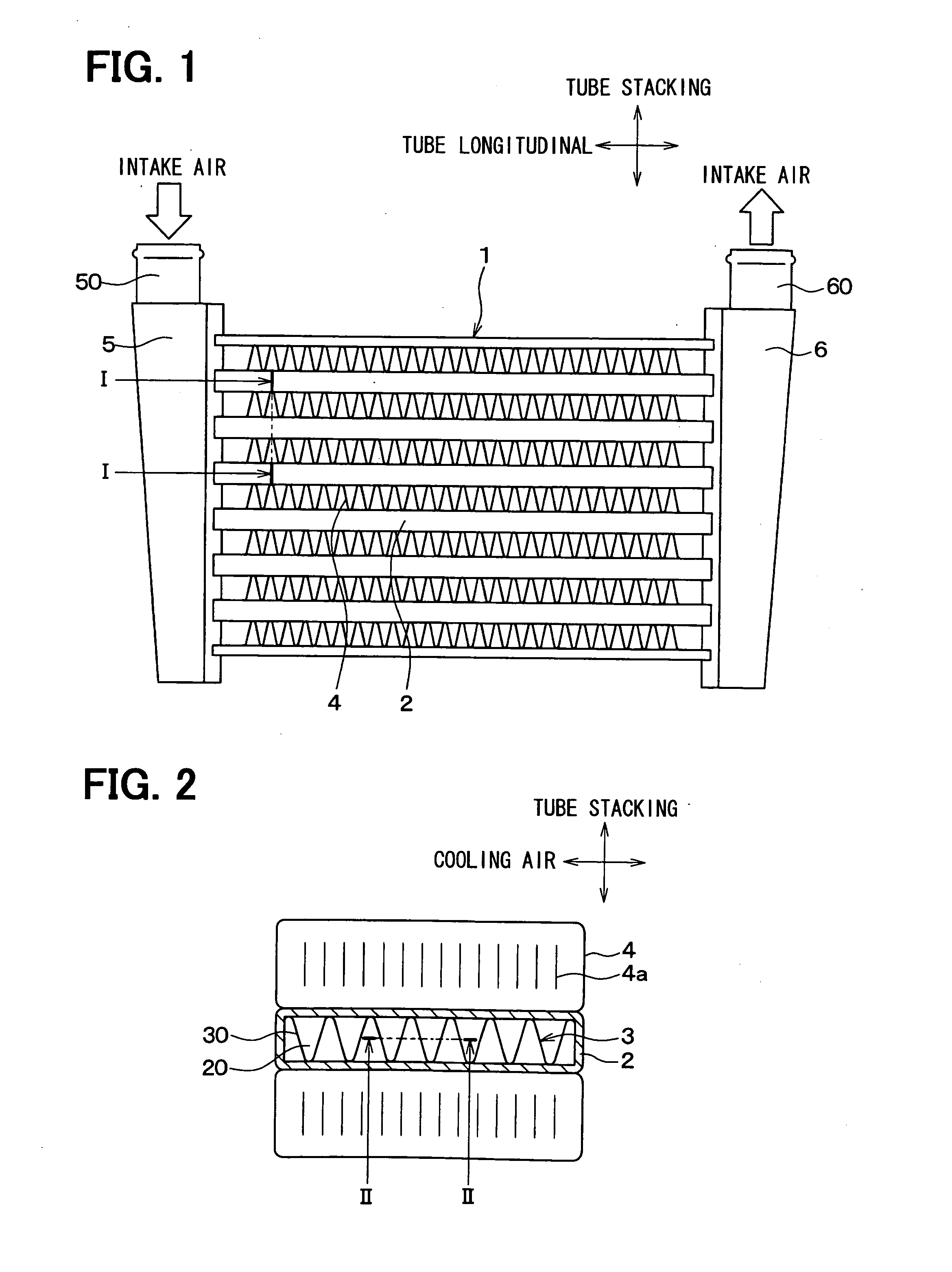

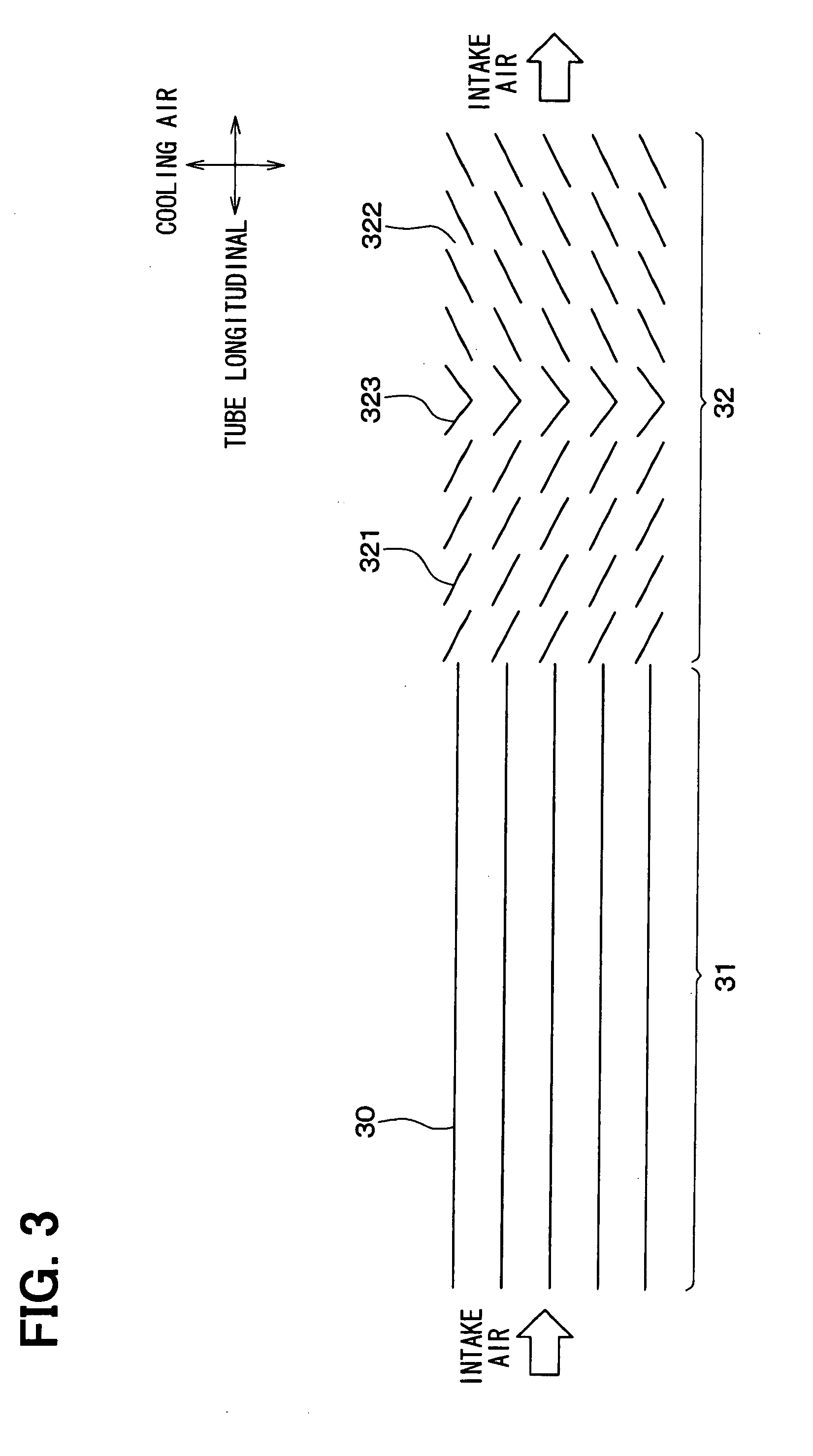

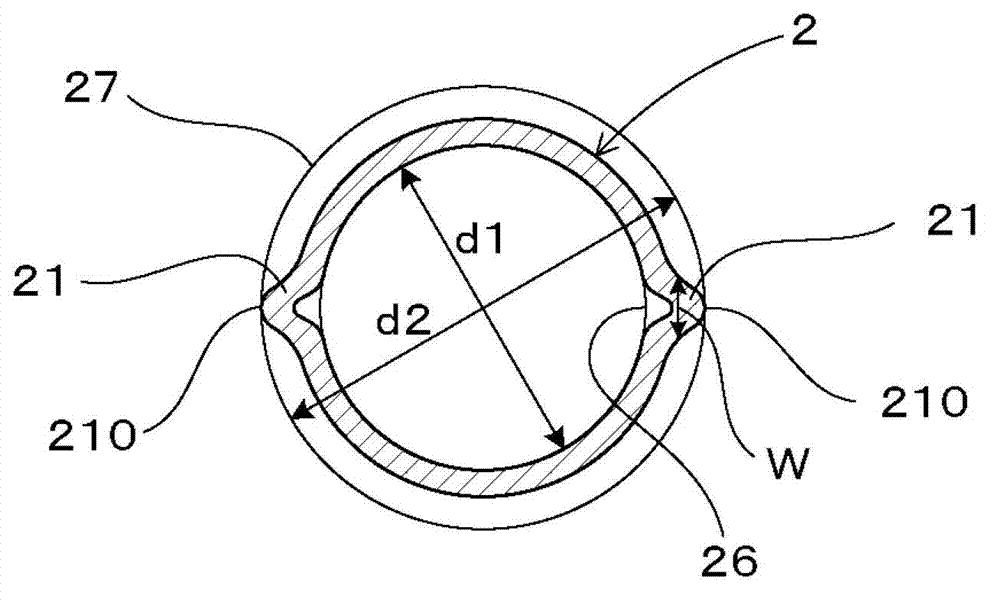

Heat exchanger

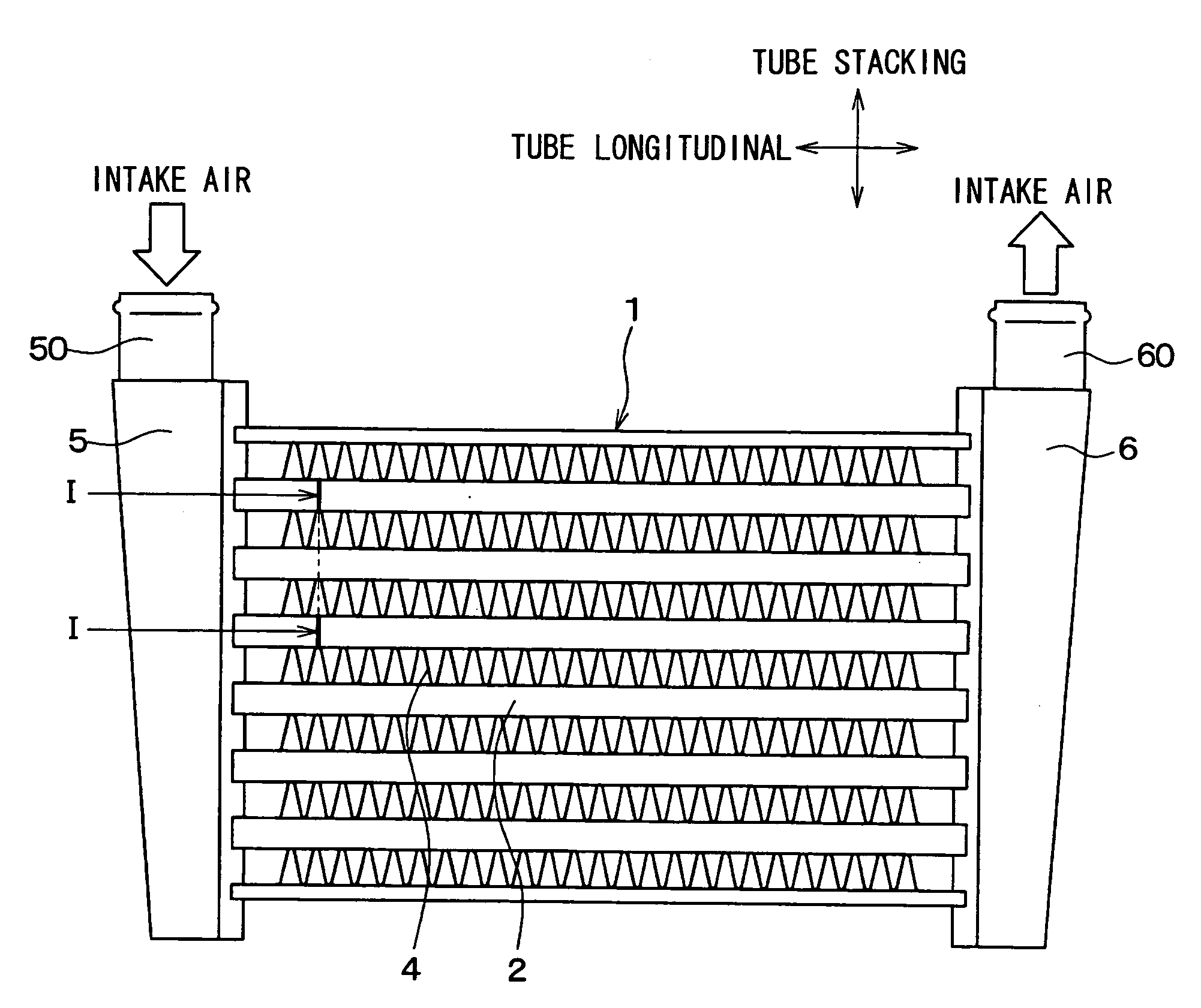

InactiveUS20090133860A1Improve heat exchange performanceImprove heat transfer effectStationary conduit assembliesStationary tubular conduit assembliesEngineeringPlate heat exchanger

In a heat exchanger, a tube is adapted to exchange heat between a first fluid flowing therein and a second fluid flowing through outside of the tube, and an inner fin is disposed in the tube to divide a flow passage in the tube into a plurality of flow paths. The inner fin includes a plurality of fin portions with different specifications, and the fin portions are arranged in series with respect to a flow direction of the first fluid. Furthermore, the fin portion with the smallest flowing resistance of the first fluid among the plurality of fin portions is arranged on an upstream side of the flow direction of the first fluid with respect to at least an another fin portion. Accordingly, heat exchange performance in the entire heat exchanger can be effectively improved.

Owner:DENSO CORP

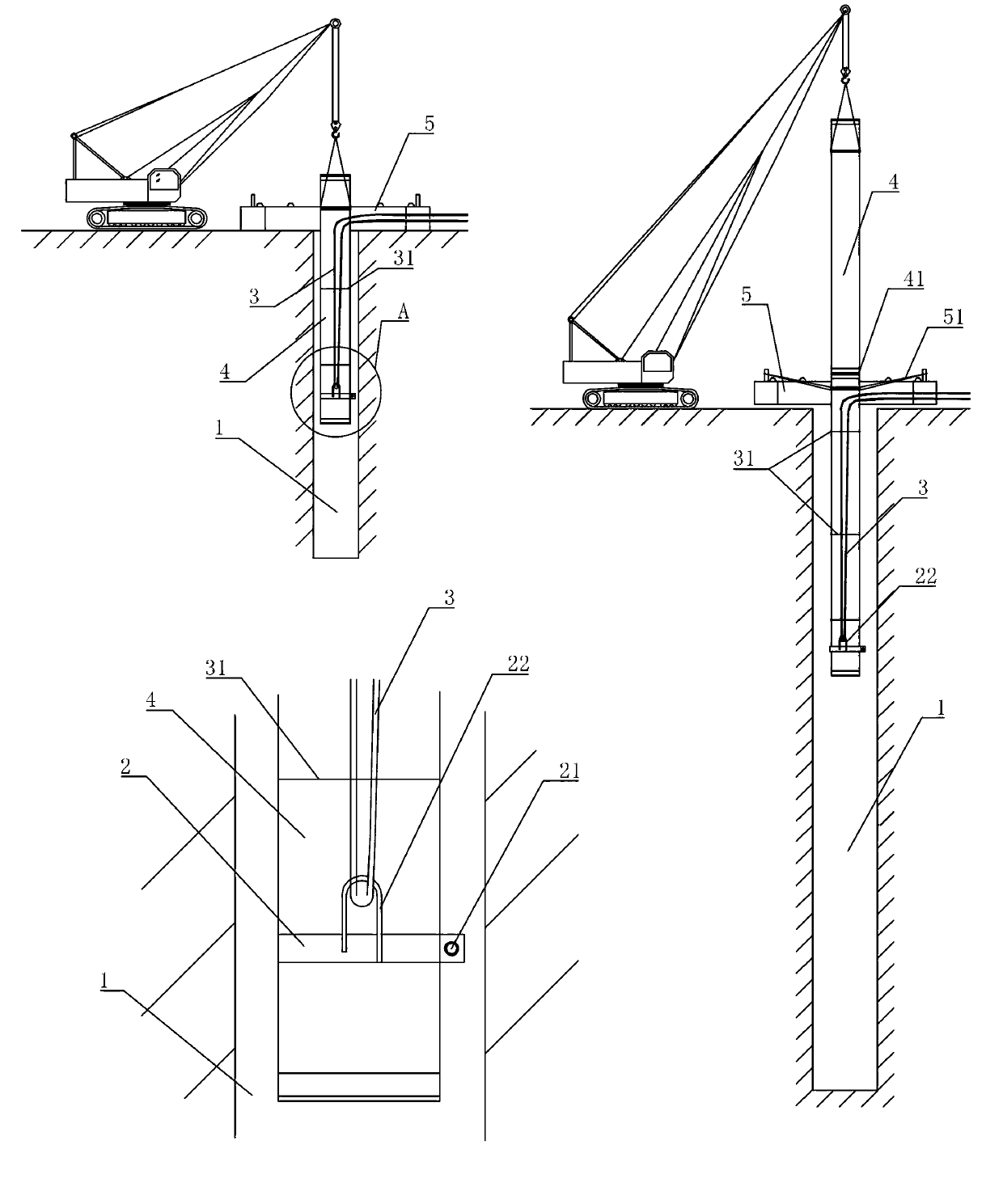

Ground source heat pump tube embedment method based on piling process

ActiveCN103103985AReduced risk of breakageFully contactedCollector components/accessoriesOther heat production devicesEngineeringEmbedment

The invention discloses a ground source heat pump tube embedment method based on a piling process. The ground source heat pump tube embedment method based on the piling process is characterized by comprising steps as below: forming piling holes by using a piling machine, wherein the inner diameter of the piling holes is larger than the outer diameter of a tubular pile; installing at least one hook at the position near the bottom of the outer surface of the tubular pile, preparing ground source heat pump tubes according to a preset length and a preset amount, fixing the ground source heat pump tubes on the hook, and fixing the ground source heat pump tubes on the tubular wall of the tubular tubes; hanging the tubular piles right above the piling holes in a perpendicular mode; putting the tubular piles into the piling holes, utilizing self weights of the tubular piles to enable the tubular tubes to sink, burying the ground source heat pump tubes underground through the traction of the hook, wherein the part, buried underground, of the ground source heat pump tubes is low in breaking risks, low in disturbance of the piling process of the tubular tubes, and therefore a plurality of ground source heat pump tubes can be buried at the same time under the condition permitted by engineering design.

Owner:黄吉永

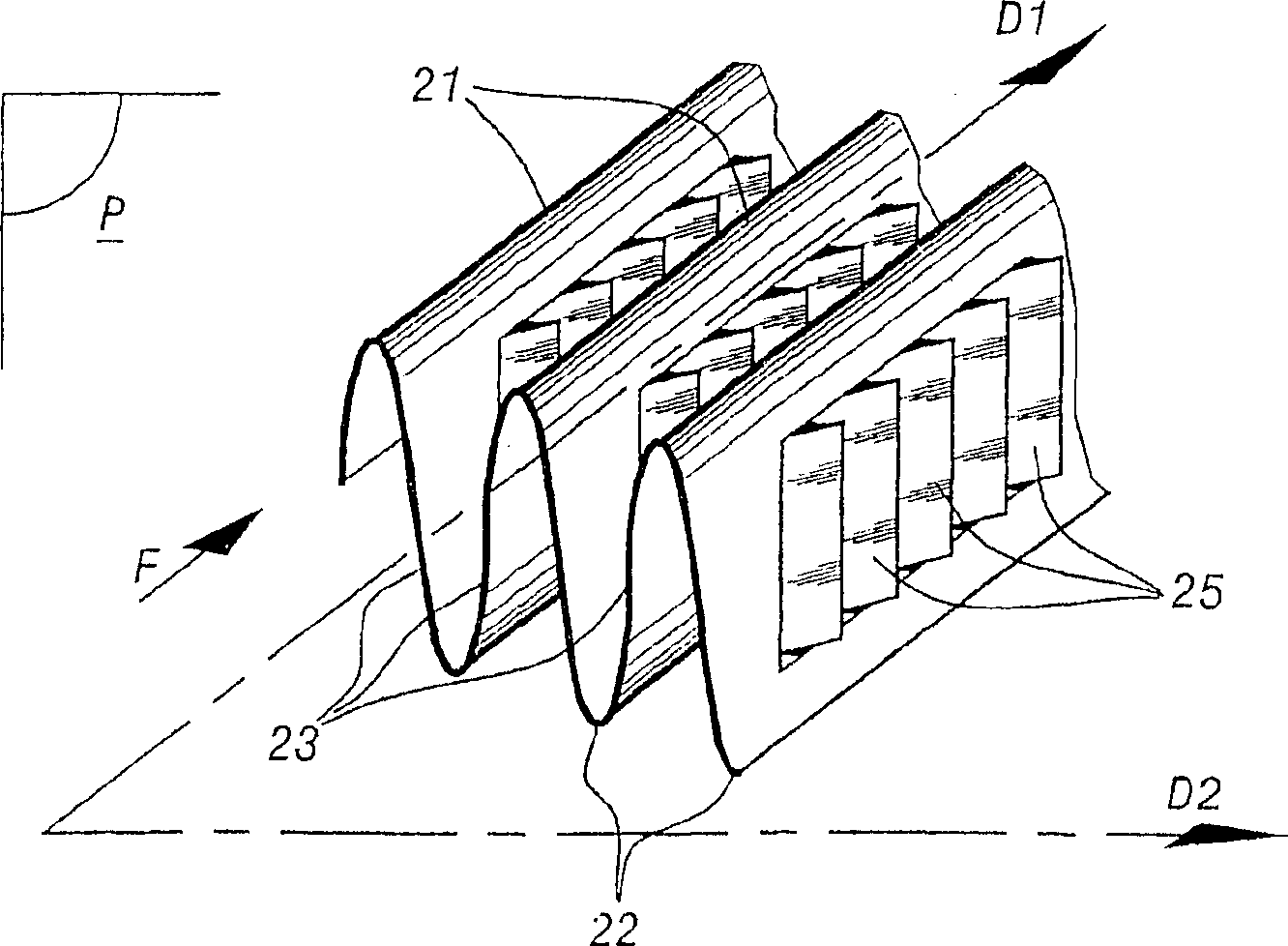

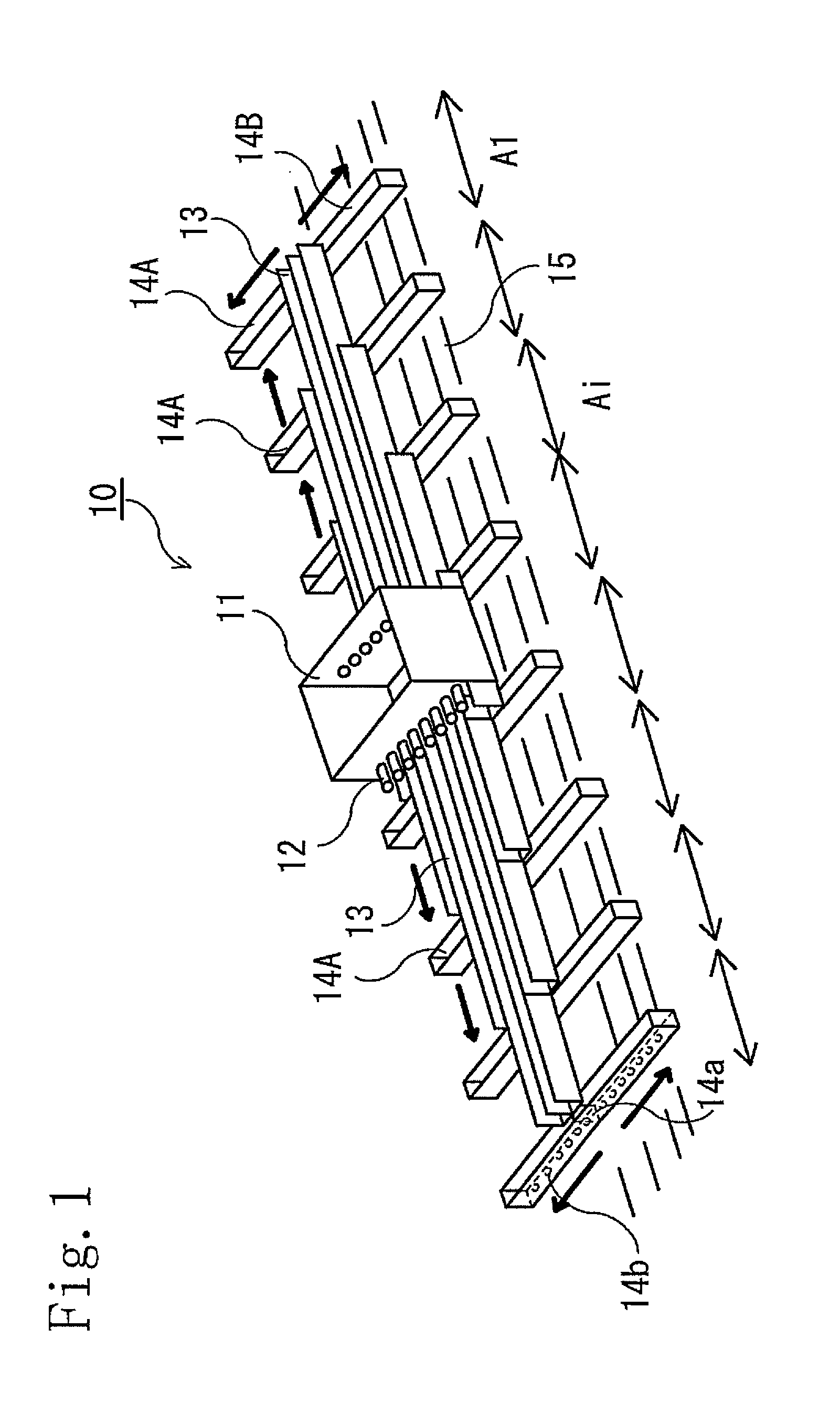

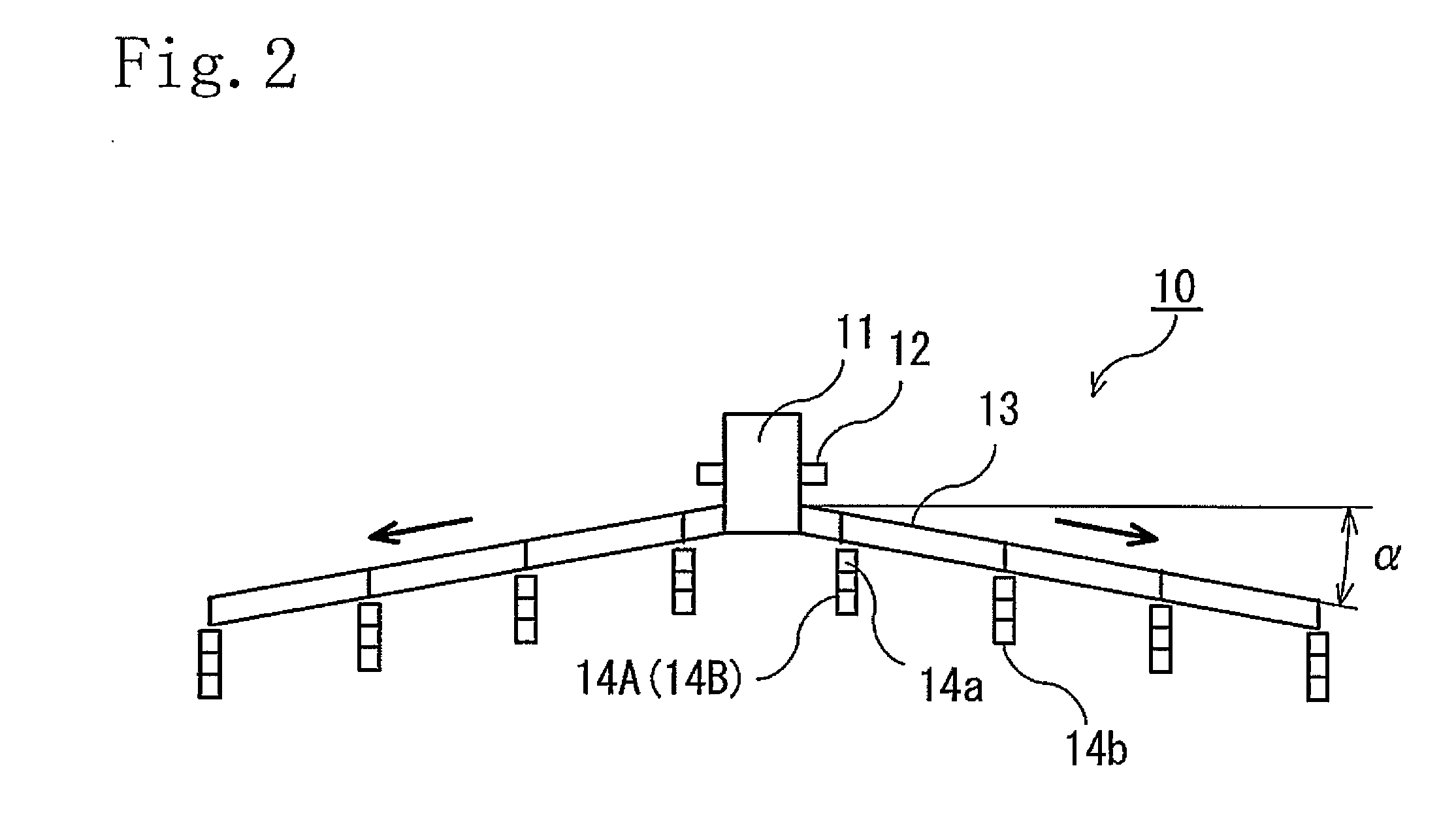

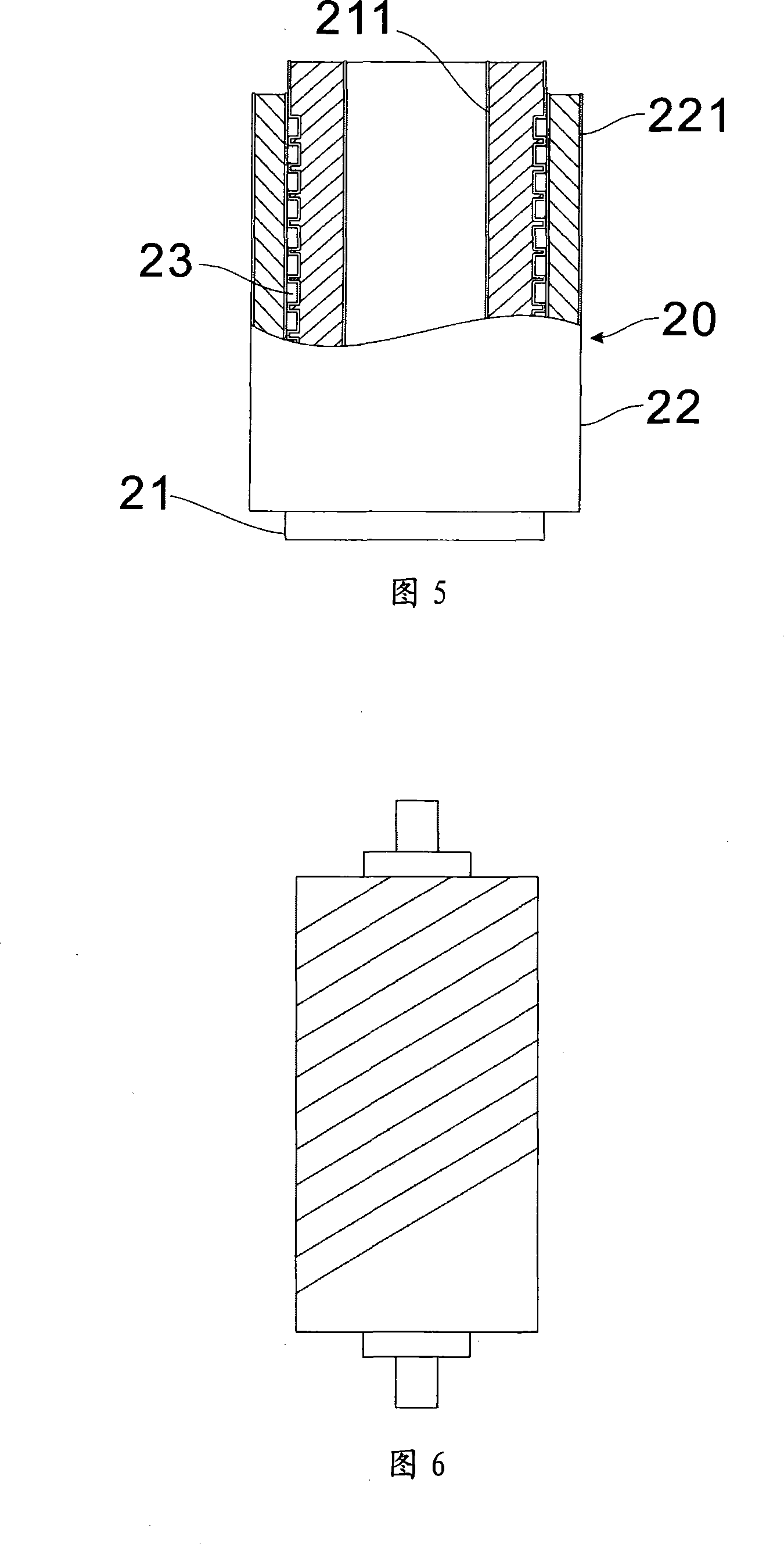

Louvered fins for heat exchanger

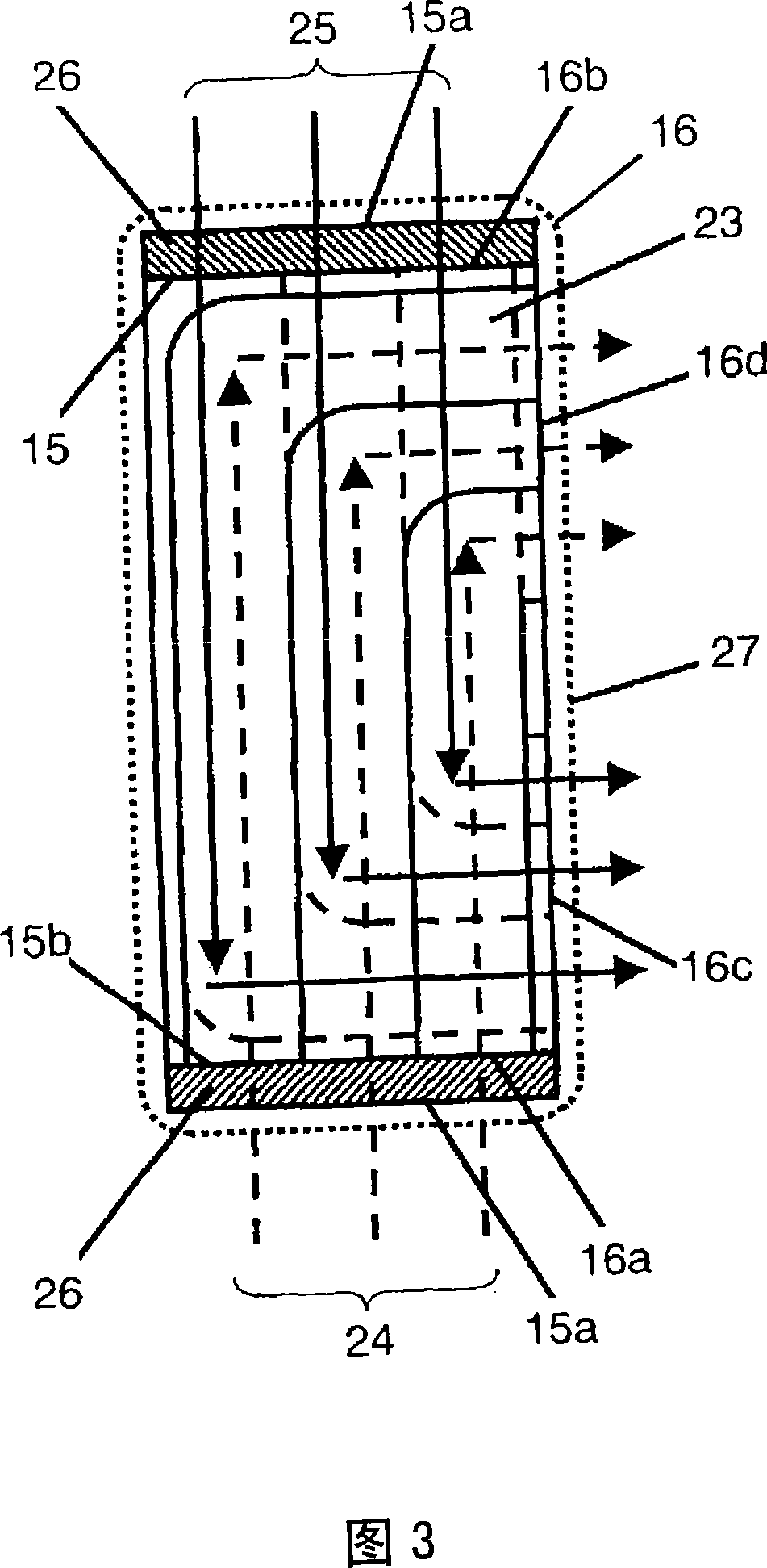

InactiveCN1509403ALimit pressure dropImprove heat exchange performanceSolidificationLiquefactionEngineeringMechanical engineering

The fin comprises a set of undulating legs (23) connected alternately by an undulating top and by an undulating base. The legs are provided with flaps (25) cut in the legs and inclined at an angle (alpha ) relative to the principal undulating direction (D1). The legs have a thickness (e), an average transverse spacing (w) which define the width of the passage channel and the flaps have a length (ls) greater than the pitch (p). An independent claim is included for a heat exchanger utilizing the fins.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

Double pipe for heat exchanger

ActiveCN103245242AIncrease heat exchange rateEfficient heat exchangeStationary tubular conduit assembliesTubular elementsPlate heat exchangerEngineering

Owner:FURUKAWA SKY ALUMINUM CORP

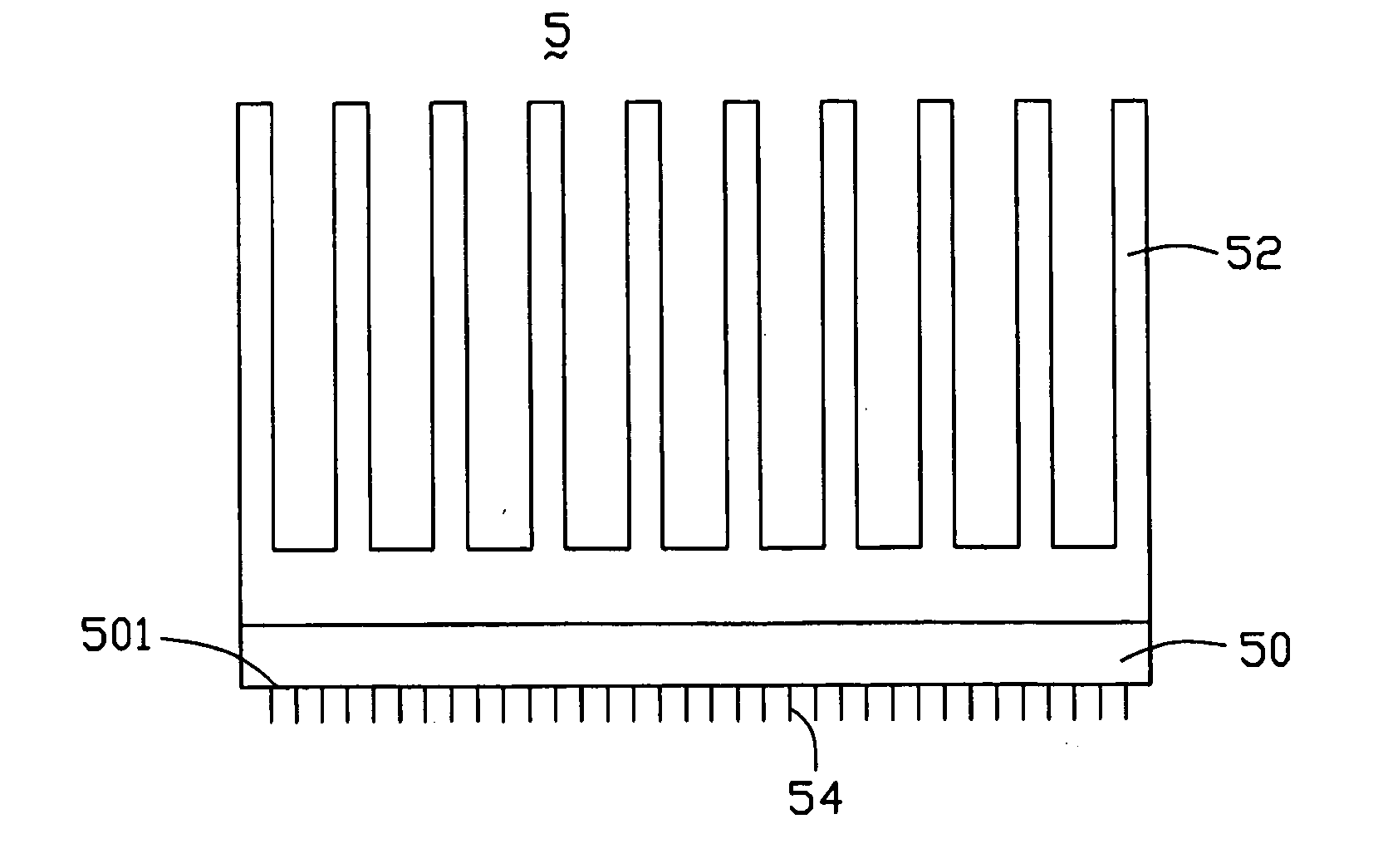

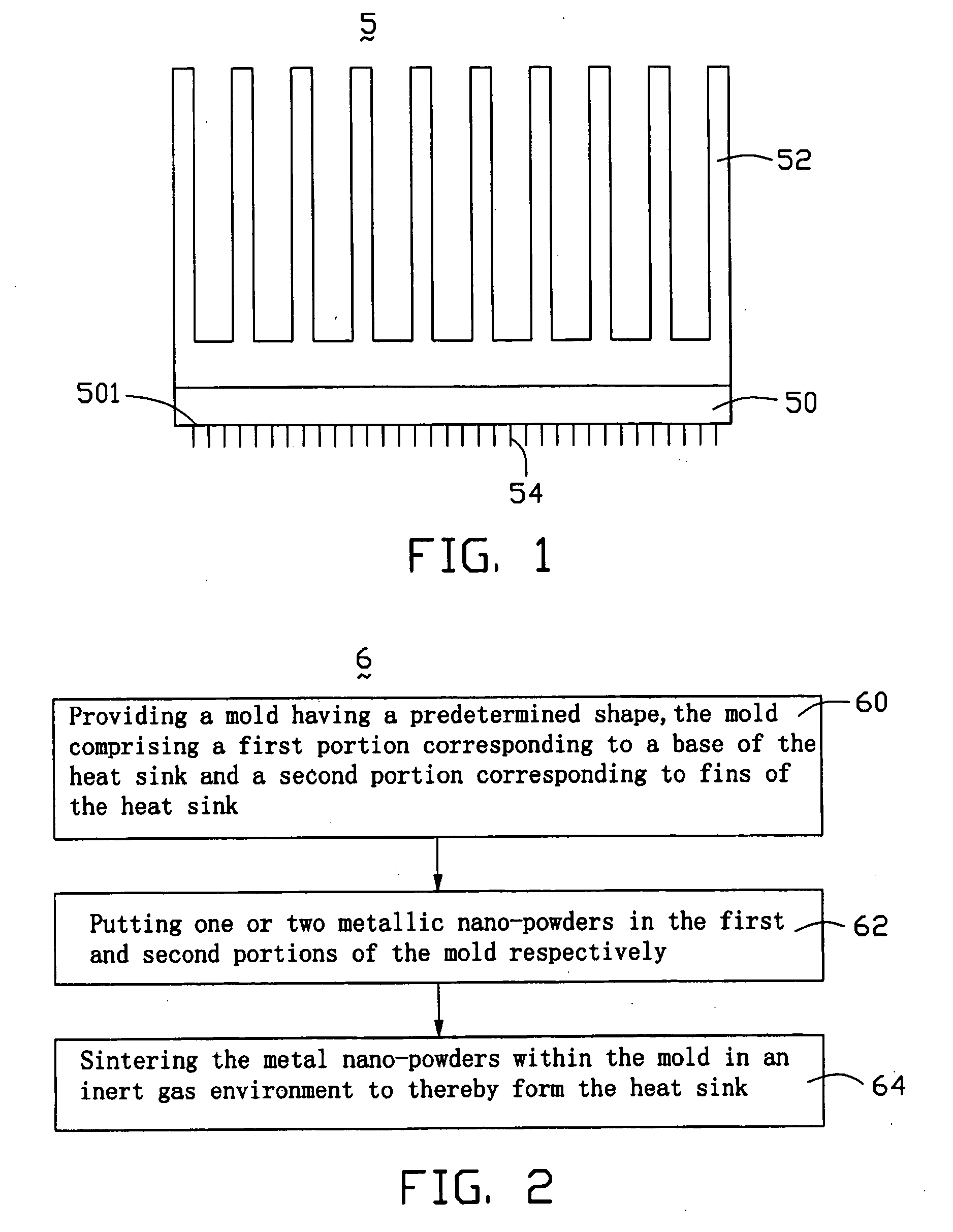

Heat sink and method for making same

InactiveUS20050252637A1Thermal resistanceImprove thermal conductivitySemiconductor/solid-state device detailsNanoinformaticsHeat transfer efficiencyEngineering

A heat sink (5) for dissipating heat from an electronic component includes a base (50), and a plurality of fins (52) formed on the base. The base and the plurality of fins are integrally formed by sintering one or two metallic nano-powders. Since the heat sink is integrally formed by sintering, any thermal resistance between the base and the fins is minimized. In addition, because the base and the fins of the heat sink are all made from one or more metallic nano-powders having good thermal conductivity, a surface area of the heat sink is larger than that of a comparable heat sink made by extrusion. Therefore, a heat transfer efficiency of the heat sink is improved.

Owner:HON HAI PRECISION IND CO LTD

Methods, systems and applications for heat exchange

InactiveCN102264873AImprove heat exchange performanceAvoid accumulationPulp liquor regenerationHeat storage plantsThermal energyMolten salt

Disclosed are a method, a system and use for heat exchange in super-critical or near-critical water gasification process of biomass. The method comprises the steps of: heating a biomass in a first heat exchanger (6) by thermal energy of a heat transfer medium, reacting the biomass in said super-critical or near-critical water gasification process and producing reaction products, cooling the reaction products of the biomass in a second heat exchanger (12) by absorbing the thermal energy of the reaction products to said heat transfer medium, and circulating said heat transfer medium between the first heat exchanger (6) and the second heat exchanger (12), wherein molten salt is used as the heat transfer medium.

Owner:UPM-KYMMENE OYJ

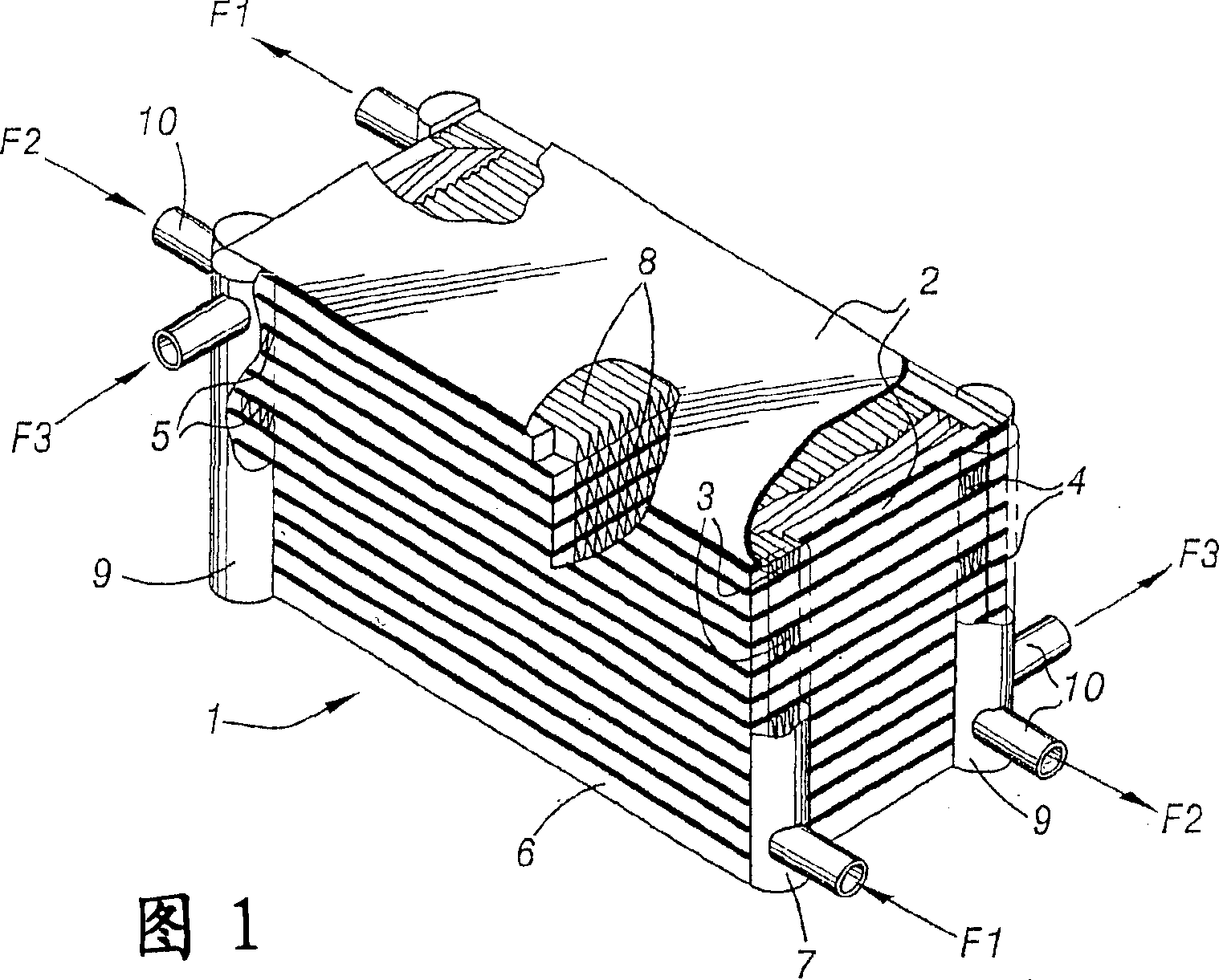

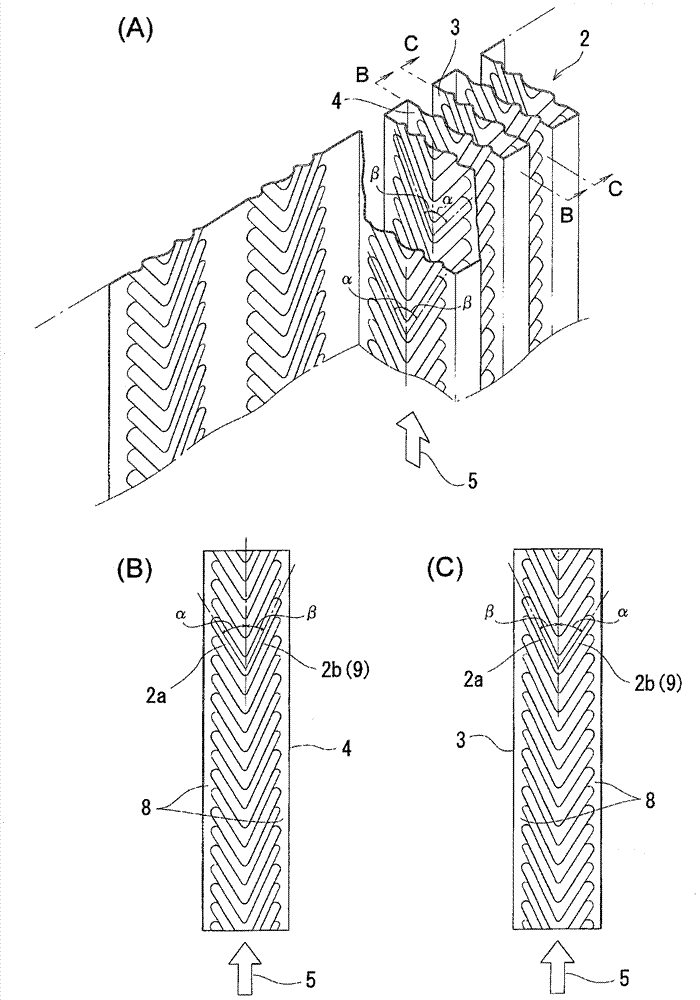

Heat exchanger

ActiveCN103090713APrevent adhesionAvoid cloggingNon-fuel substance addition to fuelInternal combustion piston enginesPlate heat exchangerMechanical engineering

The invention provides a heat exchanger. A plurality of V-shaped strip portions (9) are parallelly arranged on surfaces of fins of the heat exchanger, dust or coal and the like are difficult to attach to each portion of the fins (2), and the thermal efficiency is good. In a first plane (3) of each fin (2), a pair of inclined strip portions (2a and 2b) forms a V shape, one inclined strip portion in the pair of inclined strip portions (2a and 2b) is configured at an inclined angle (alpha) towards a front side in a direction opposite to the circulating direction of gases, the other inclined strip portion in the pair of inclined strip portions (2a and 2b) is configured at an inclined angle (beta) towards a back side in a direction opposite to the circulating direction of the gases, and thereby the inclined strip portions (2a and 2b) form a right and left asymmetrical angle. Besides, a right and left asymmetrical angle in a second plane (4) opposite to the first plane (3) is opposite to that of the first plane (3) in a direction relative to the circulating direction of the gases.

Owner:T RAD CO LTD

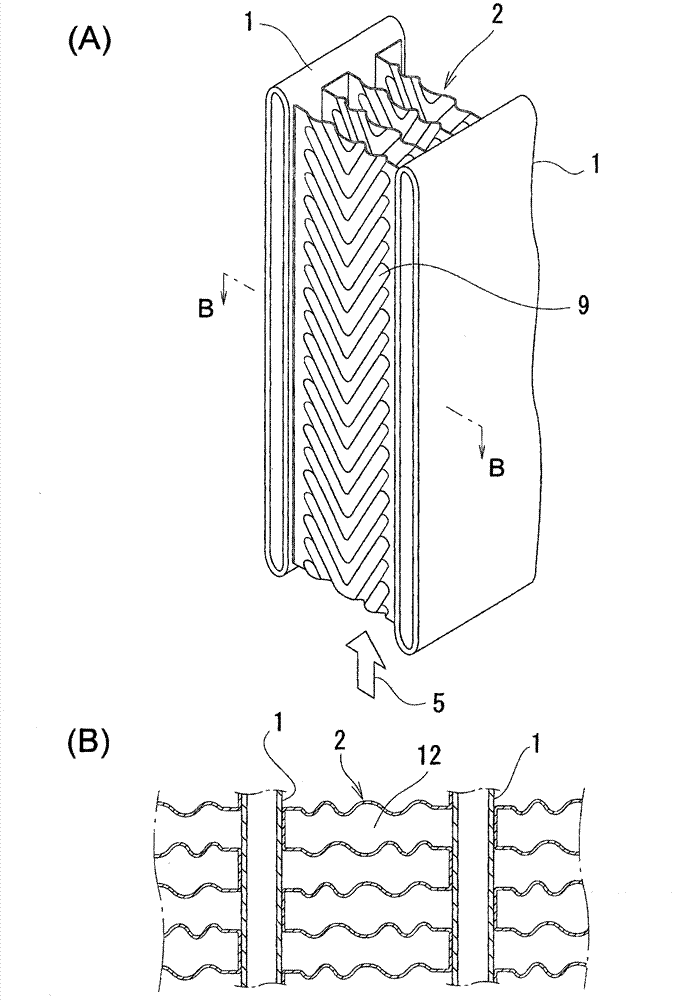

Heat exchanger

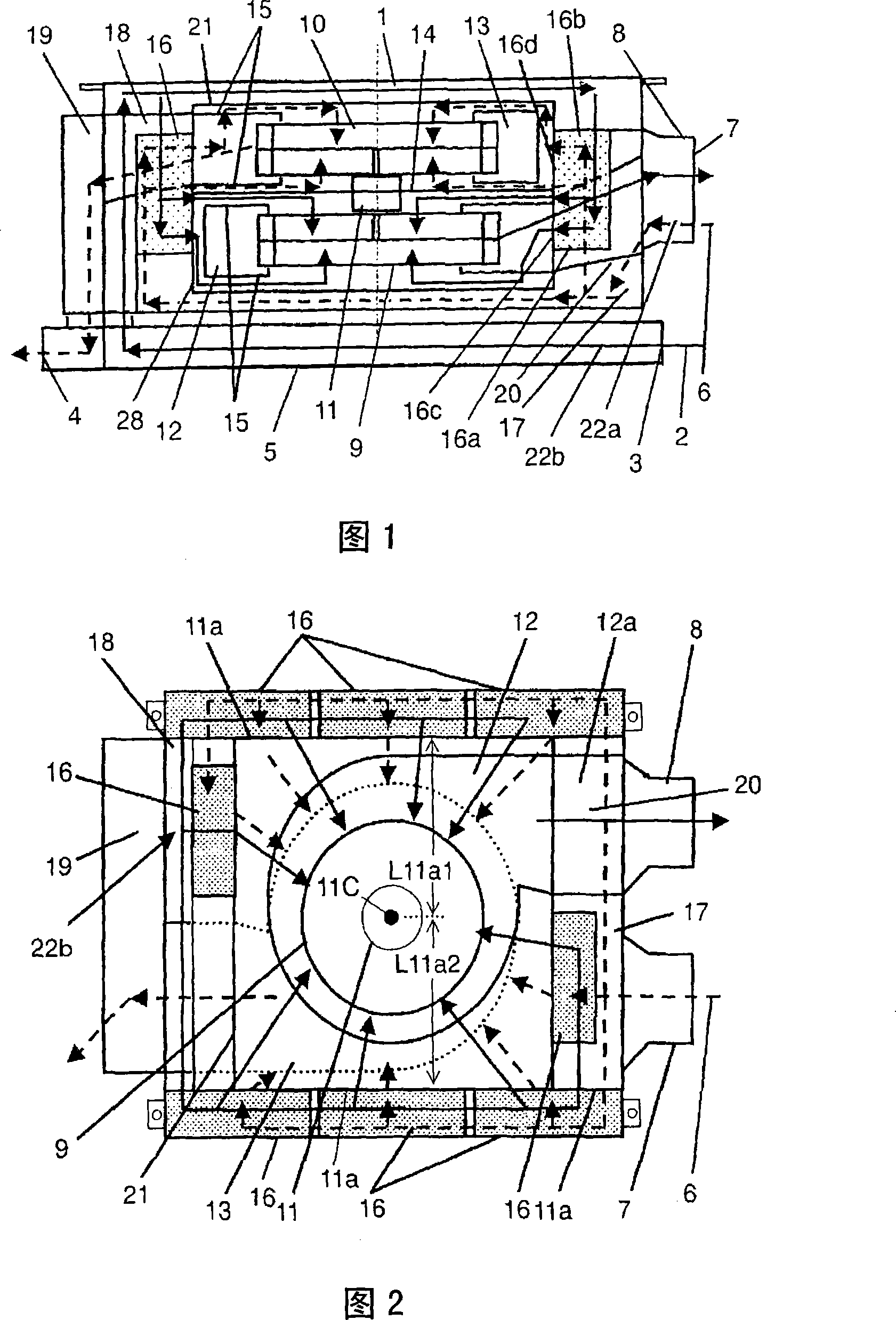

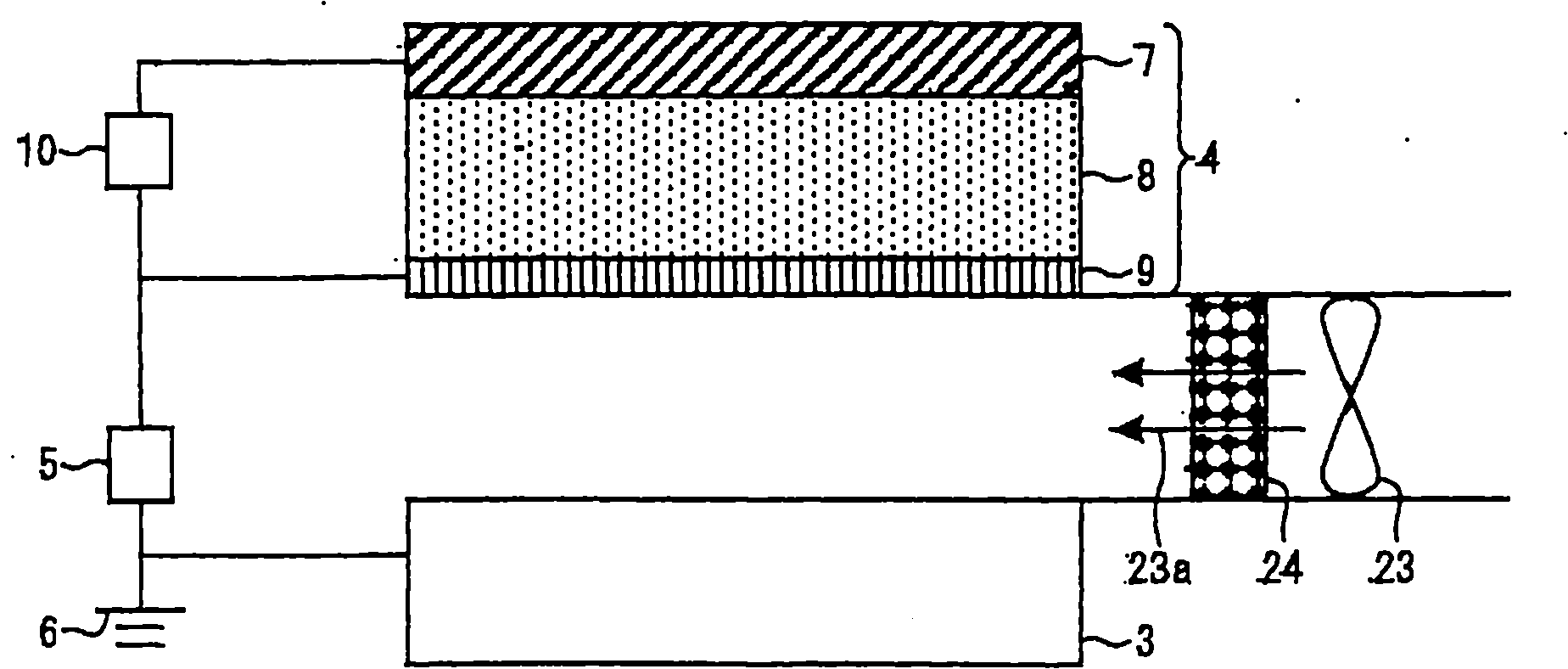

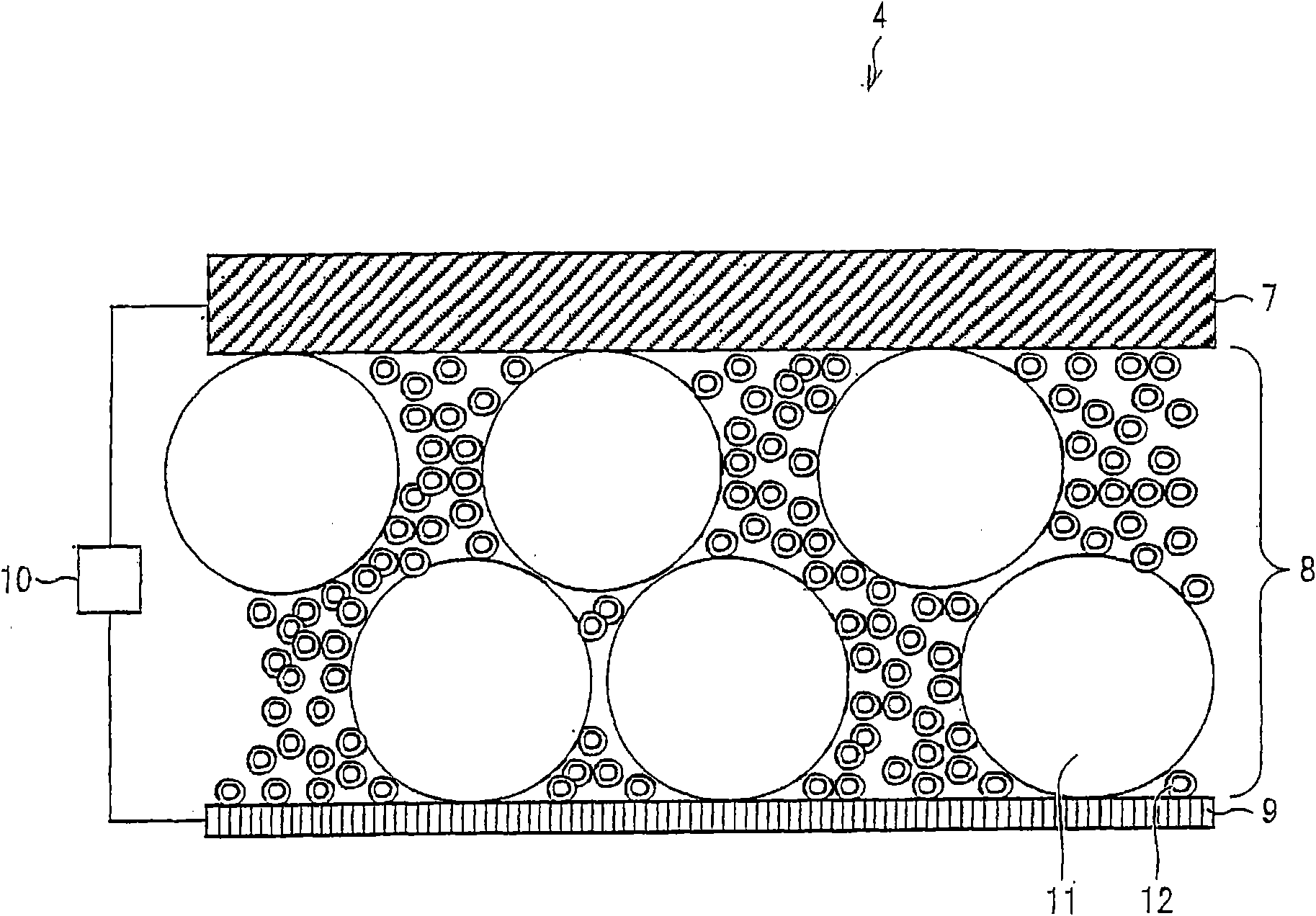

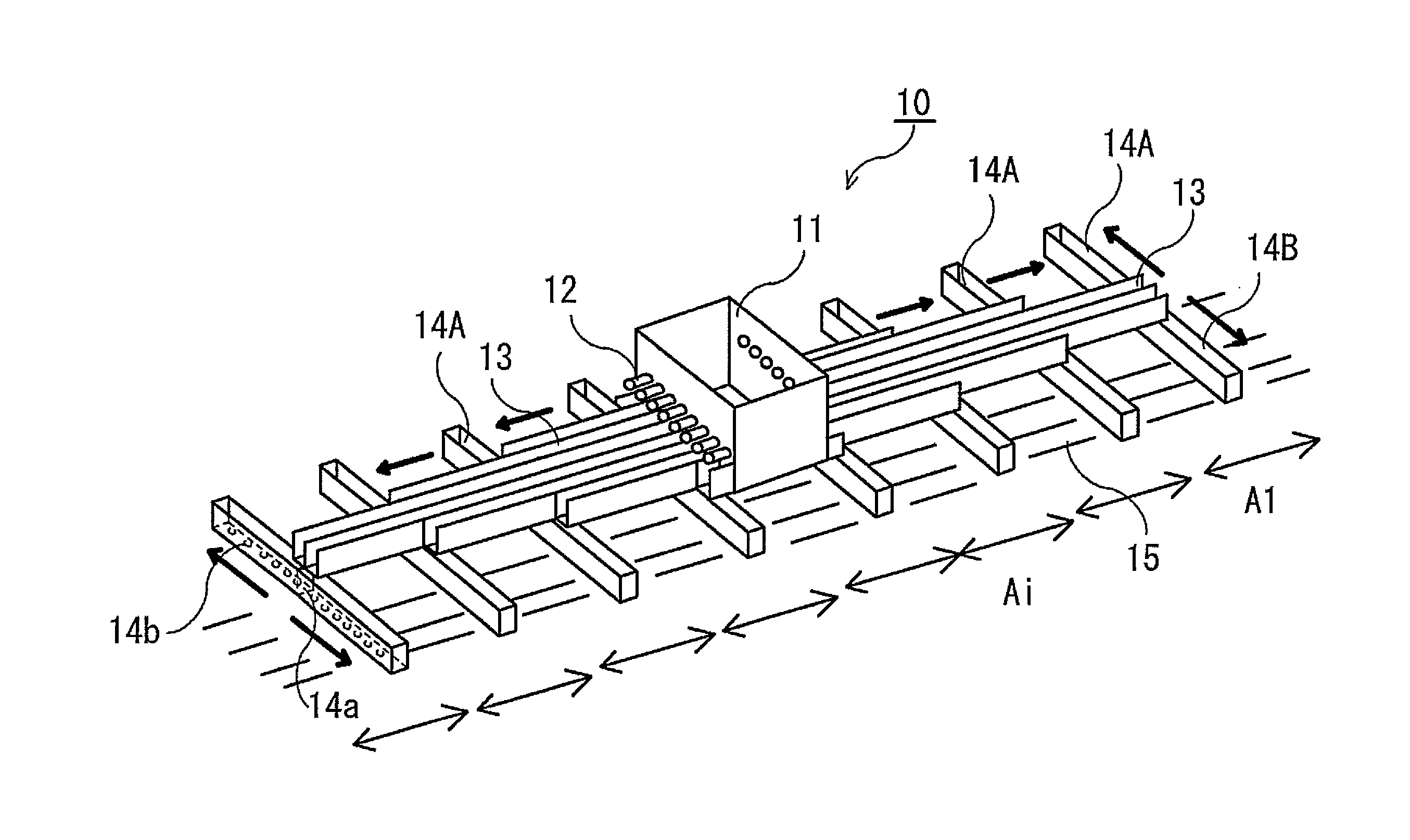

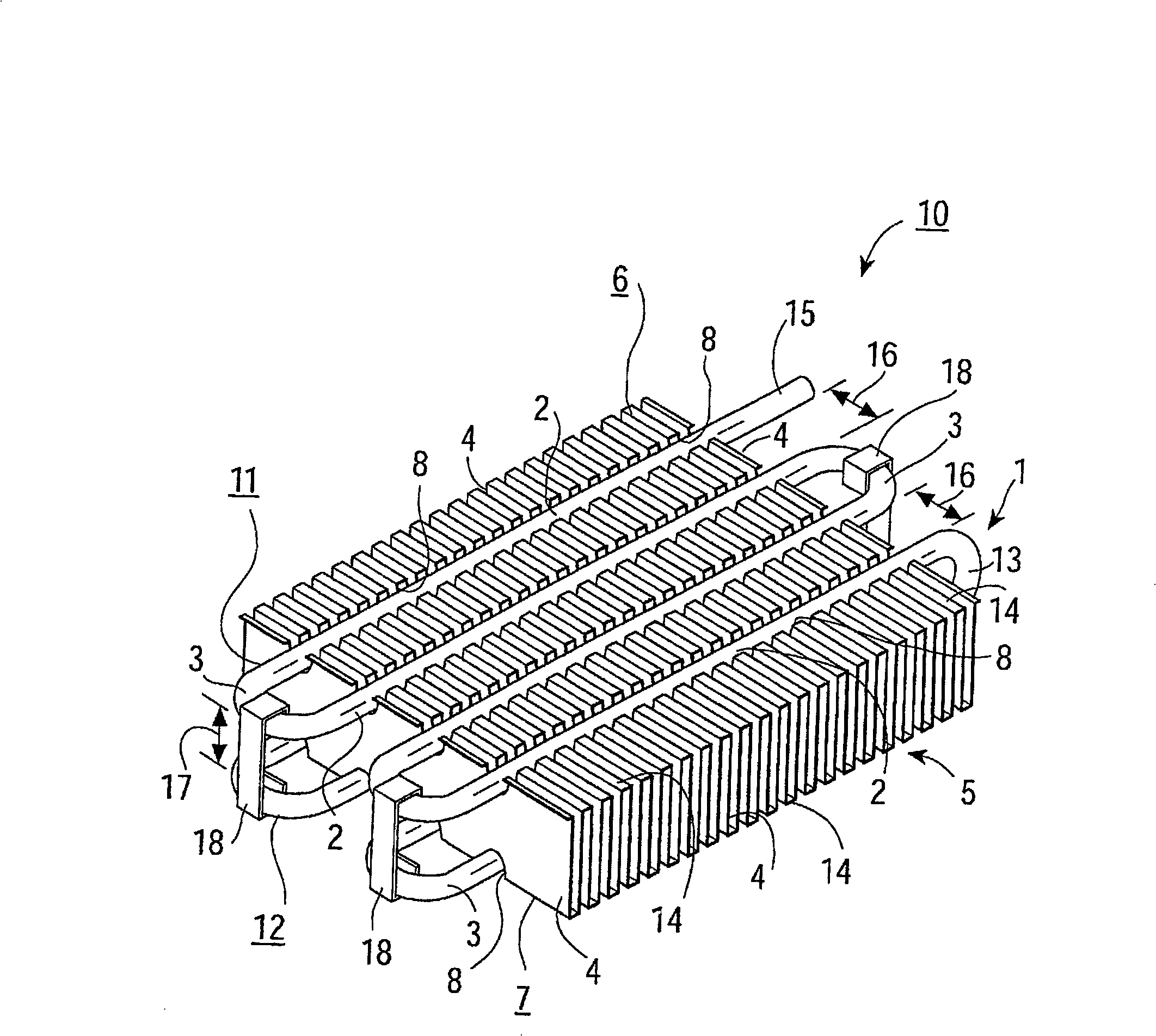

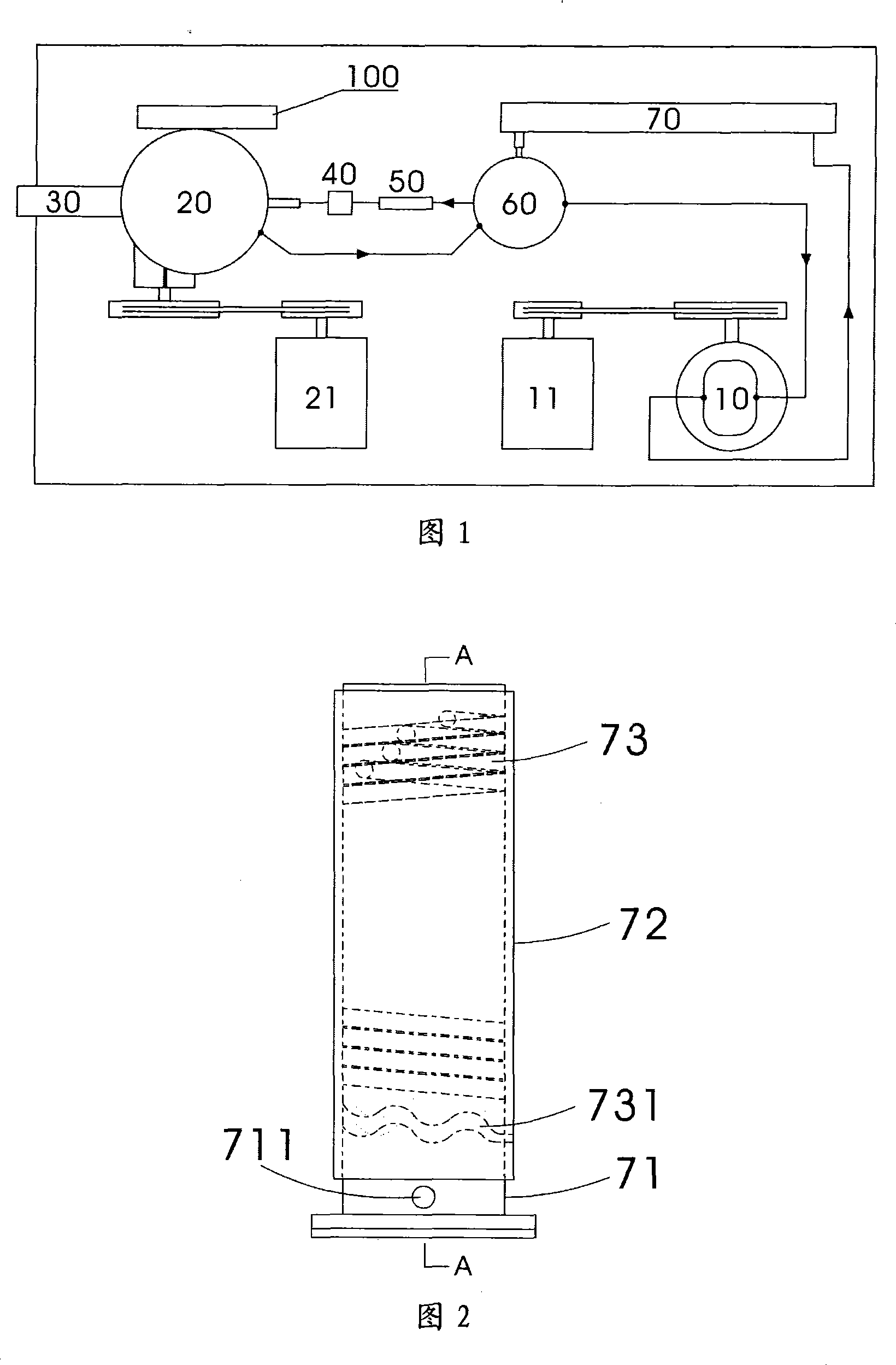

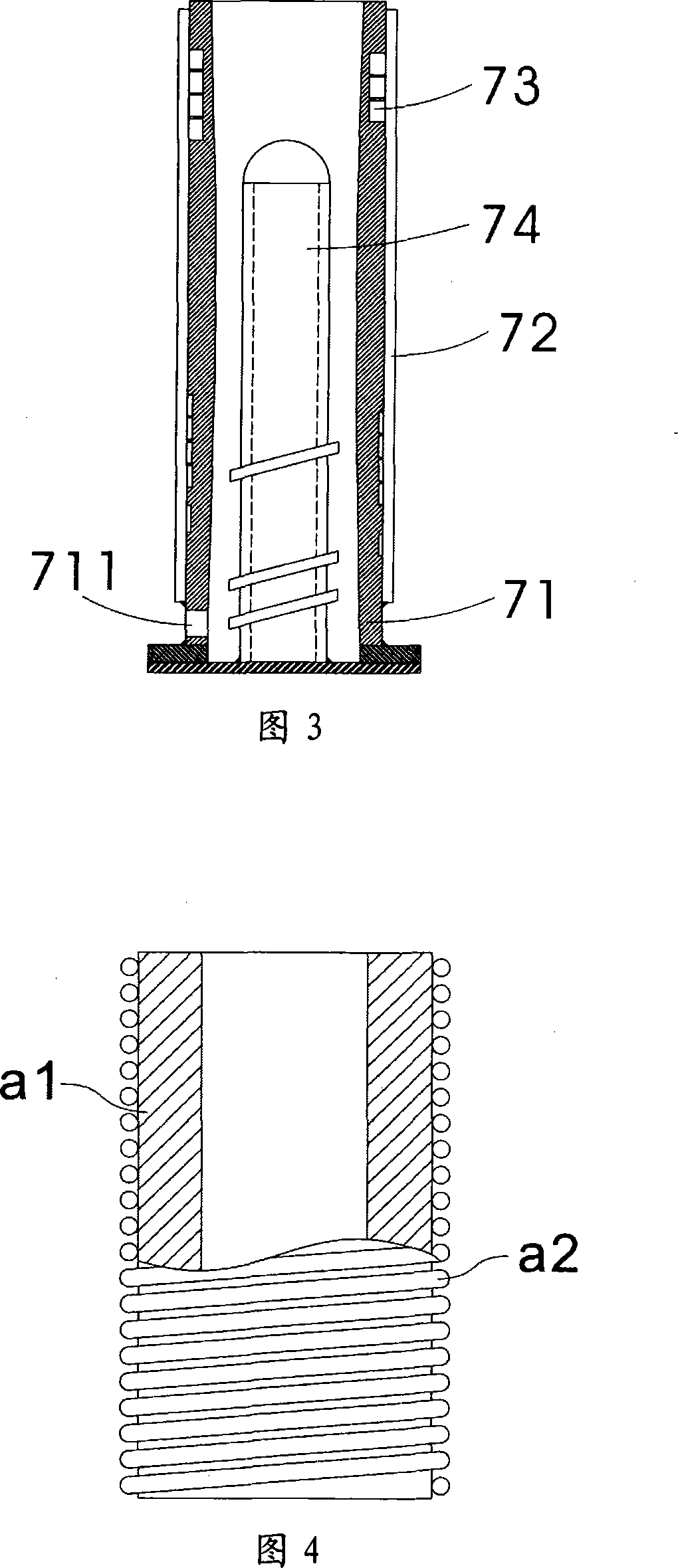

InactiveCN101198825AImprove heat exchange performanceSmall pressure lossEnergy recovery in ventilation and heatingHeat recovery systemsIndoor airEngineering

A heat exchanger of small size and thin type is provided. It includes a machine body (1), an indoor suction port (3) for sucking indoor air (2), an indoor diffuser (4), an outdoor suction port (7) for sucking in outdoor air (6), an outdoor diffuser (8), a motor (11) provided inside the machine body (1), an exhaust blade (9) and an intake blade (10) disposed at the motor (11), an exhaust fan casing (12) provided around the exhaust blade (9), an intake fan casing (13) provided around the intake blade (10), and a plurality of heat exchange elements (16) disposed around the exhaust fan casing (12) and intake fan casing (13).

Owner:PANASONIC CORP

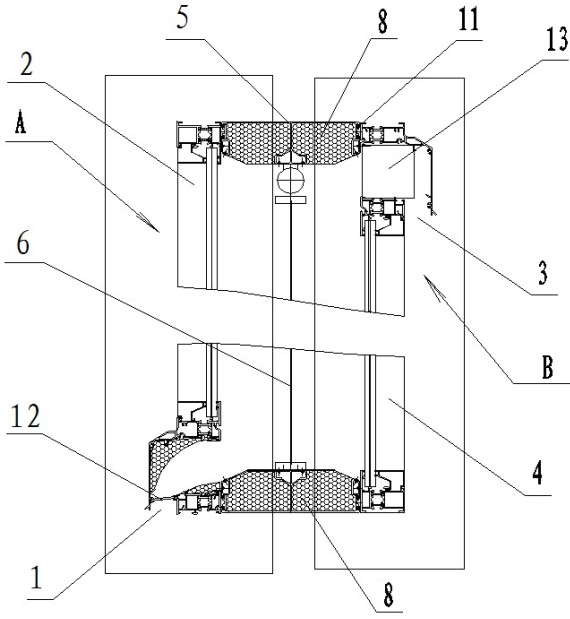

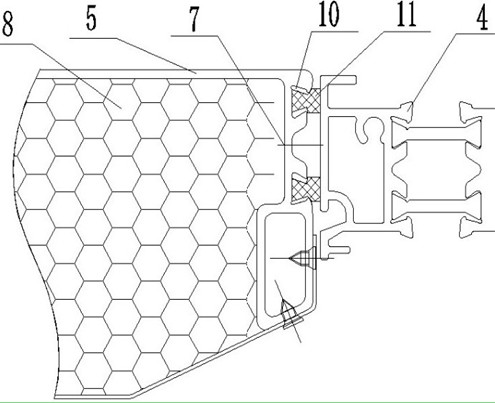

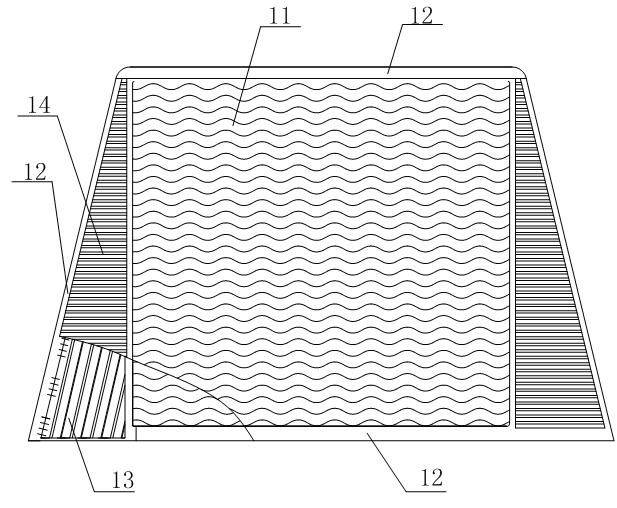

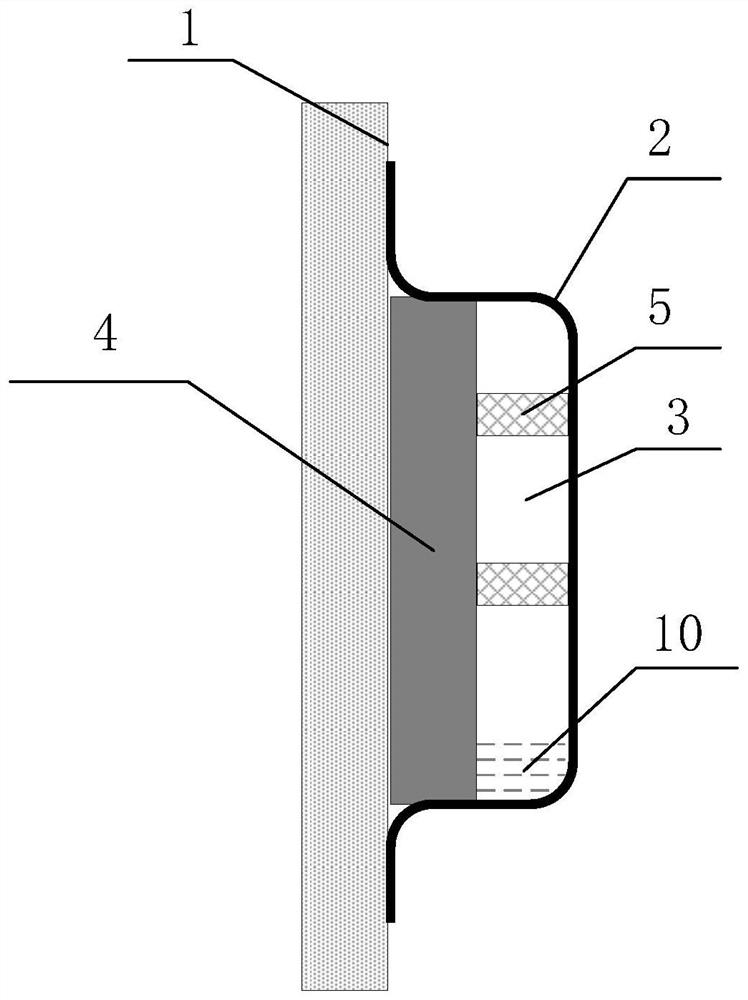

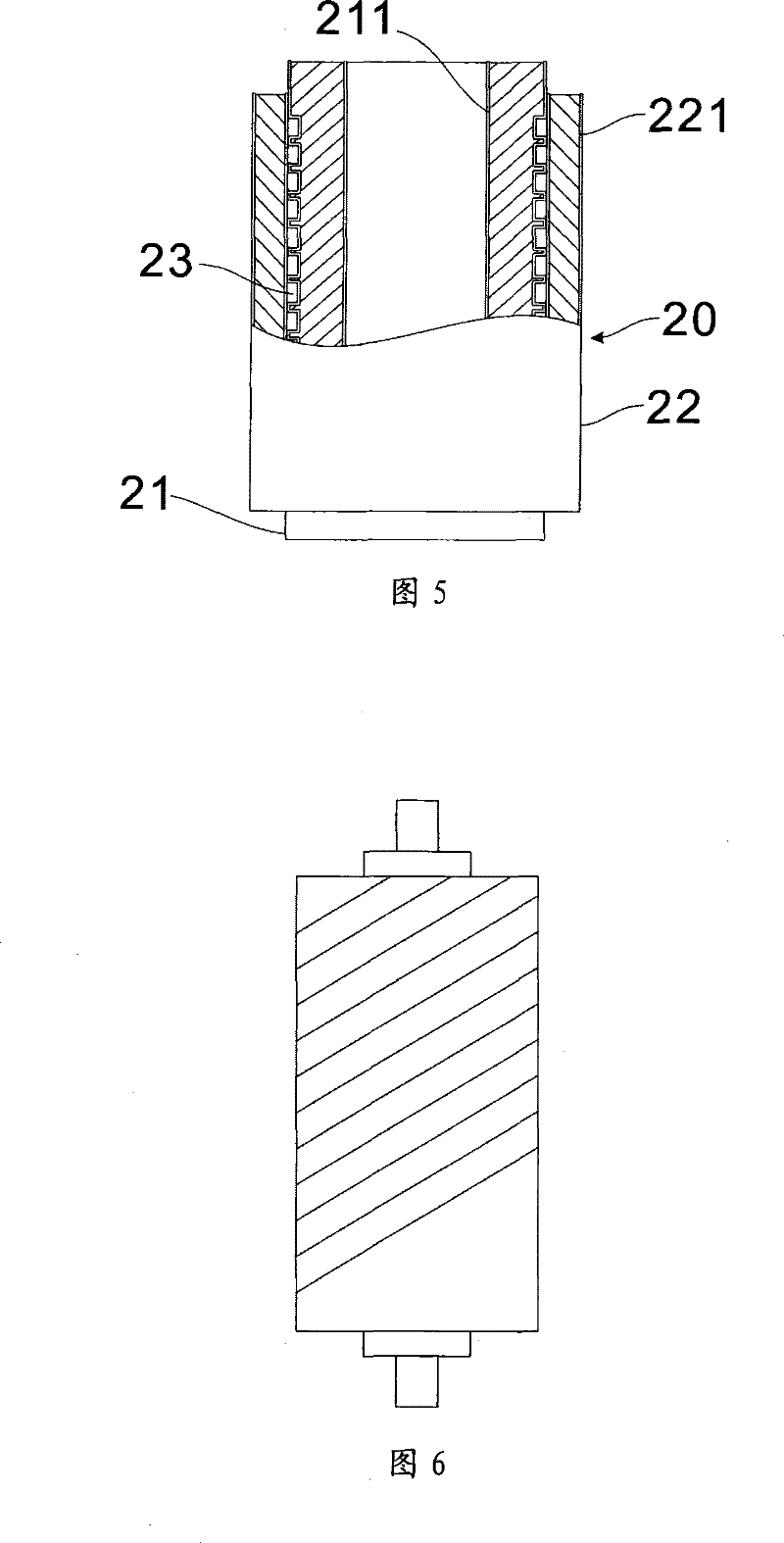

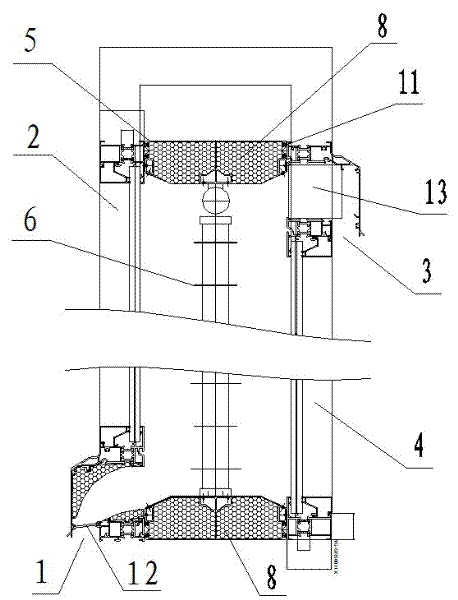

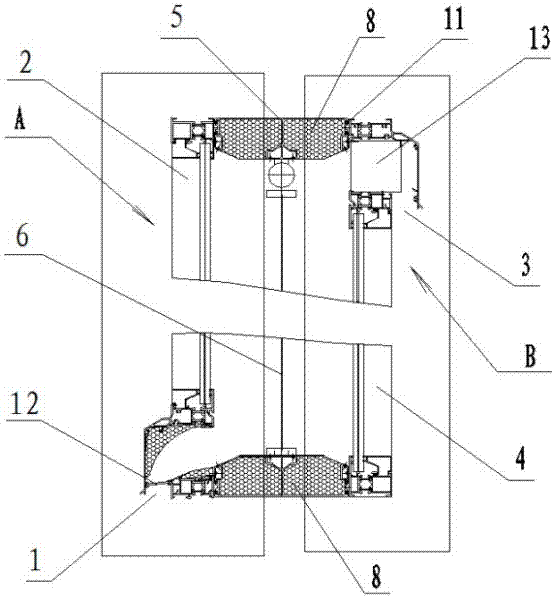

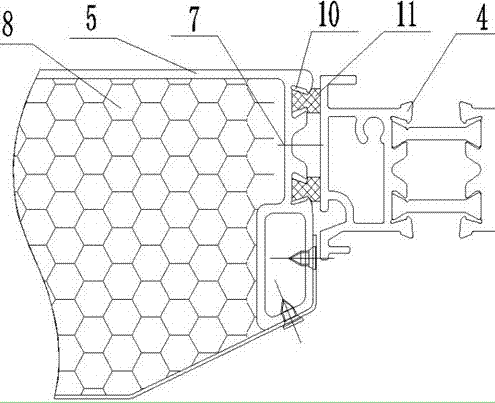

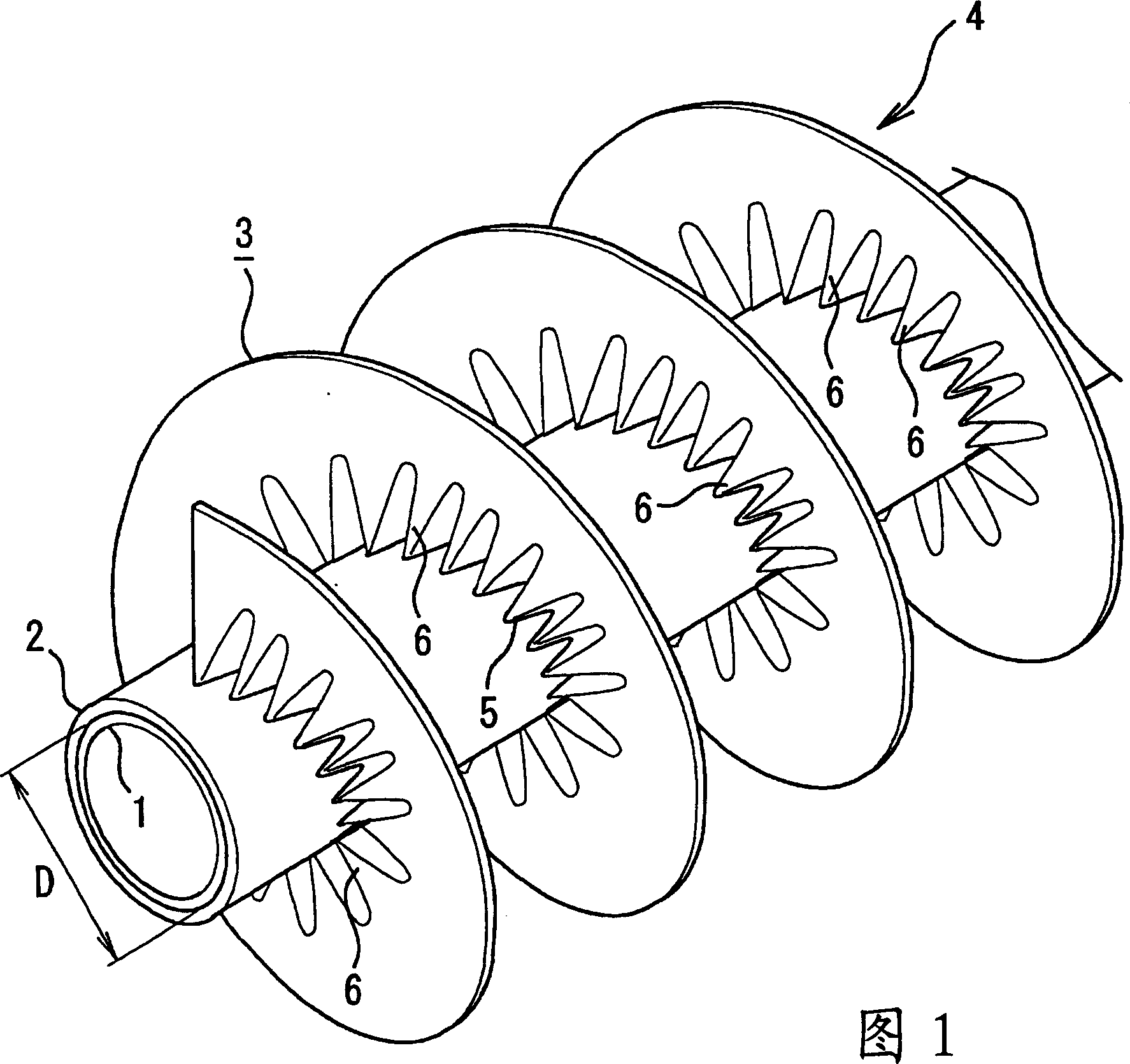

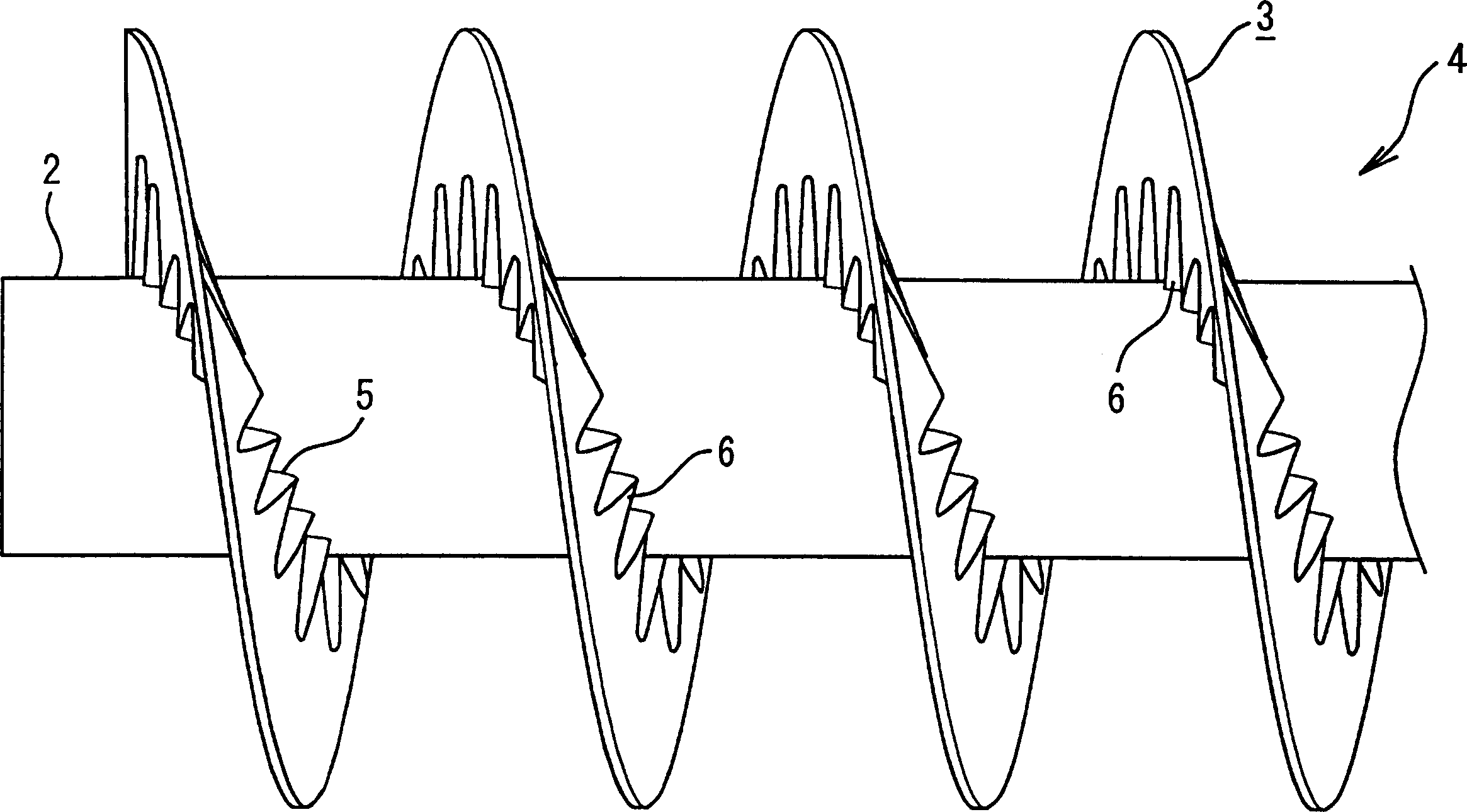

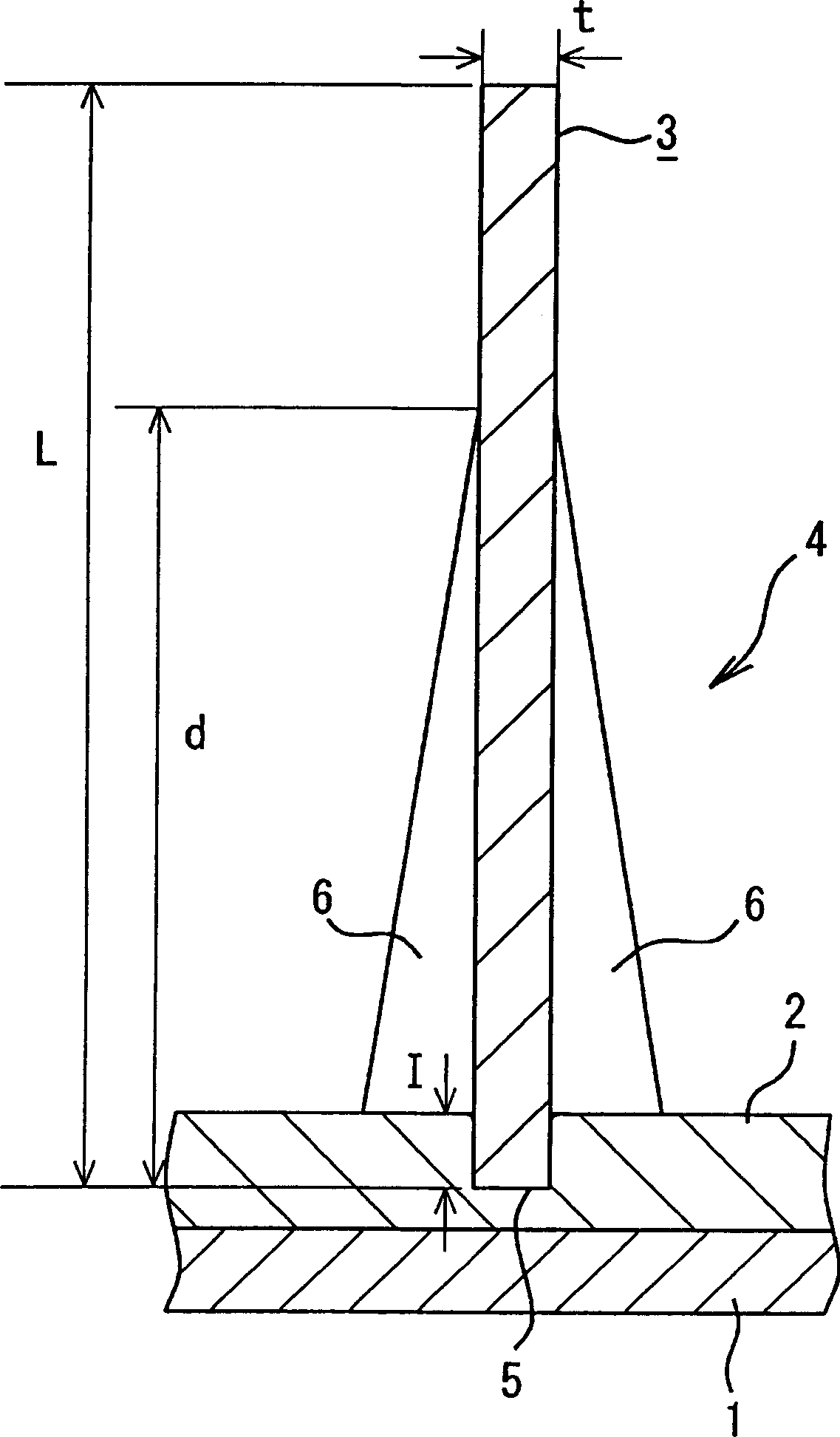

Sound insulation ventilating window

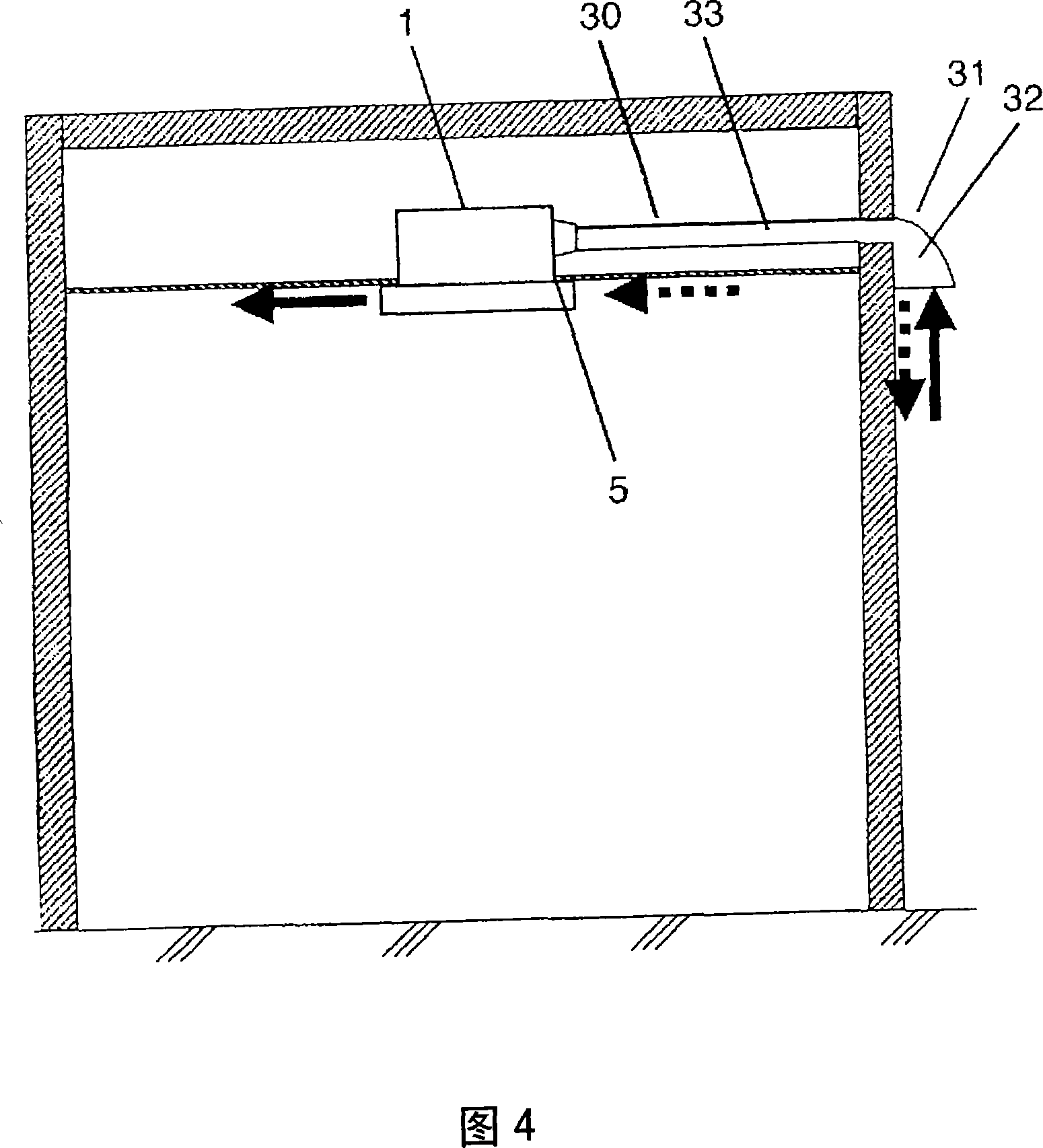

ActiveCN102116126AGuaranteed ventilation effectOvercoming Difficult-to-Block Low-Frequency NoiseVentilation arrangementNoise insulation doors/windowsLow frequency bandEngineering

The invention discloses a sound insulation ventilating window. The sound insulation ventilating window comprises an external window (2) with an air inlet (1), an internal window (4) with an air outlet (3), and a muffling cavity body (5) which is positioned between the internal window (4) and the external window (2), and connected with the external window (2) and the internal window (4); louver muffling sheets (6) controlled by a motor are suspended inside the muffling cavity body (5); and the louver muffling sheets (6) are rotated or gathered under the action of the motor. The sound insulation ventilating window can stop low frequency band noises of which the frequency is lower than 500Hz so as to further weaken the noises from the outside of the window to the inside of the window; meanwhile, the ventilating performance of the sound insulation ventilating window can be guaranteed; the daylighting effect of the sound insulation ventilating window is better, the requirements of indoor noise reduction, heat insulation and daylighting of people can be met, and the structure is simple.

Owner:ZISEN ENVIRONMENTAL TECHNOLOGY CO LTD

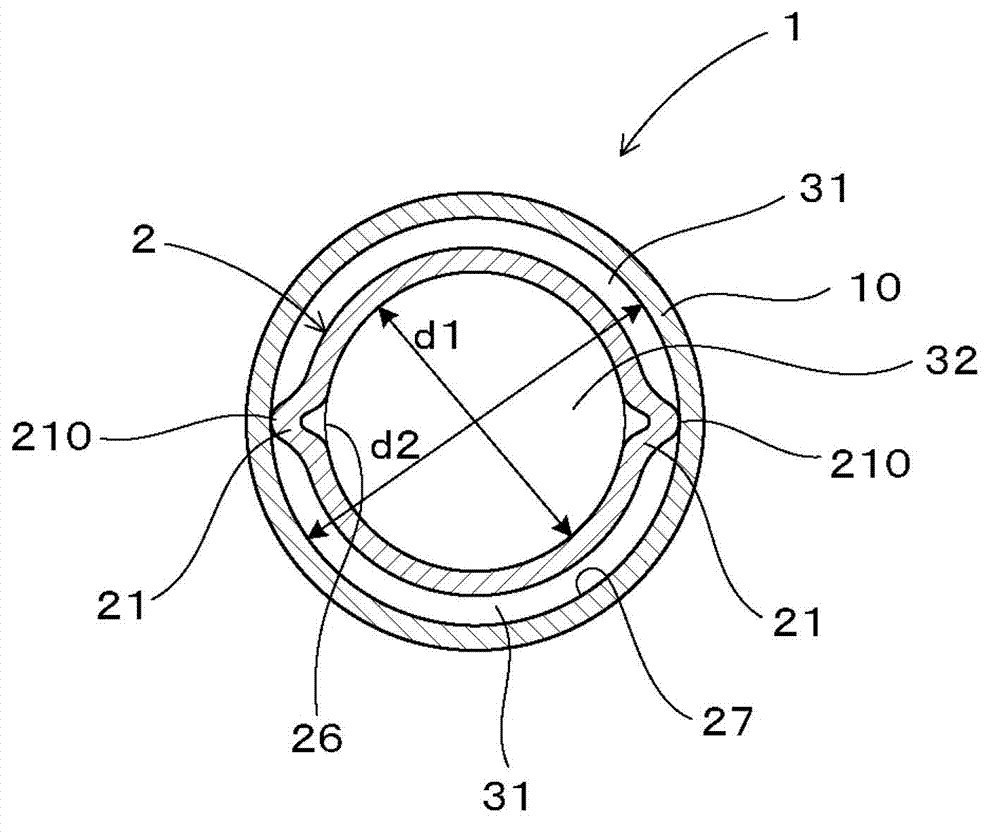

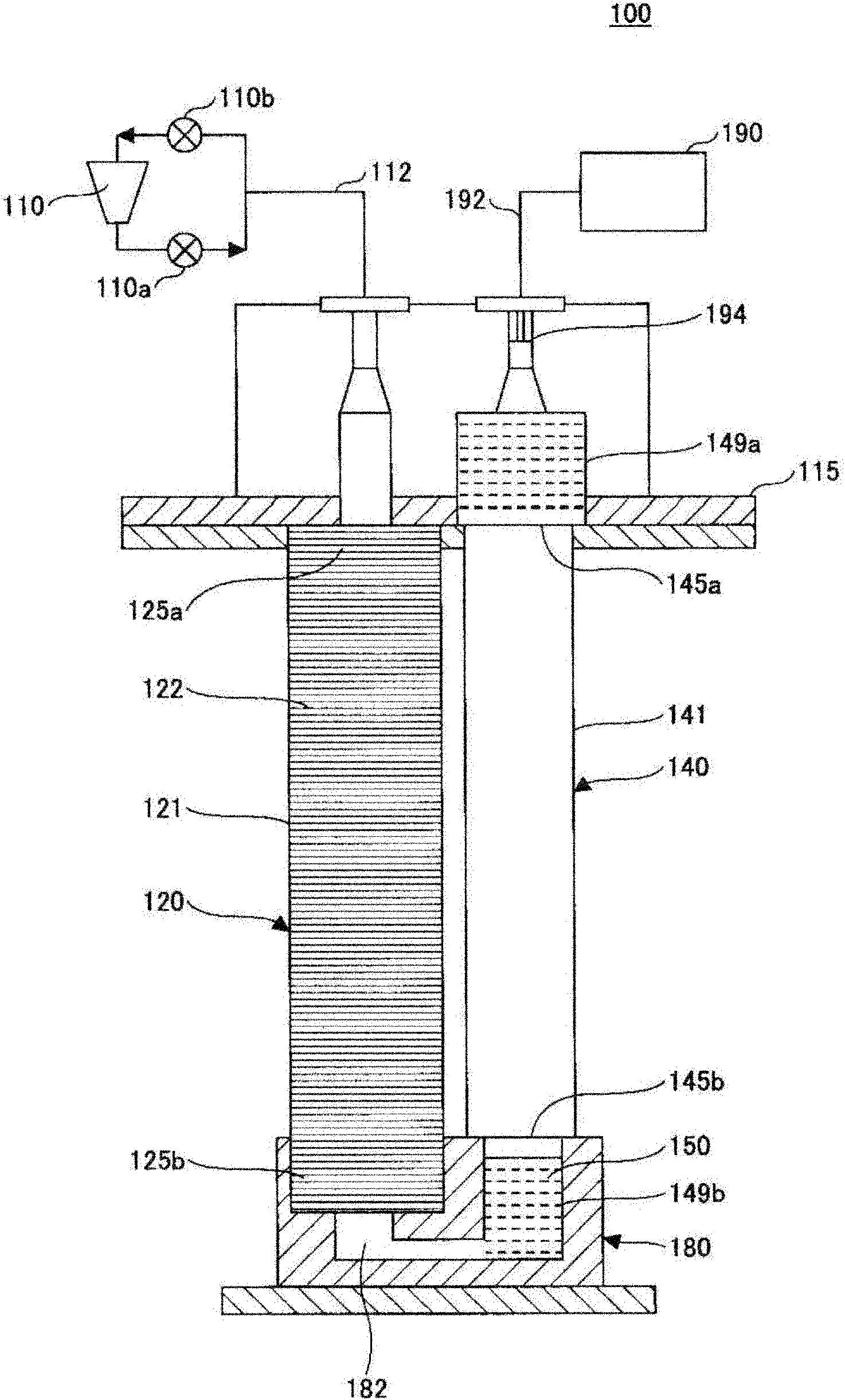

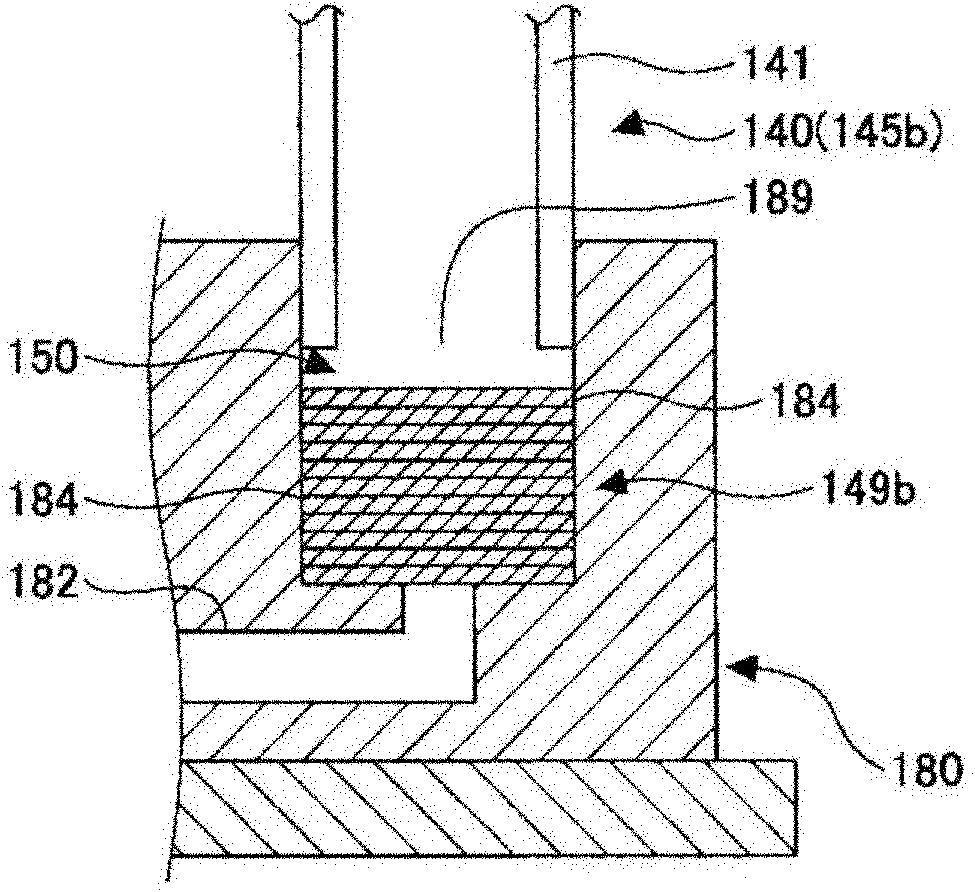

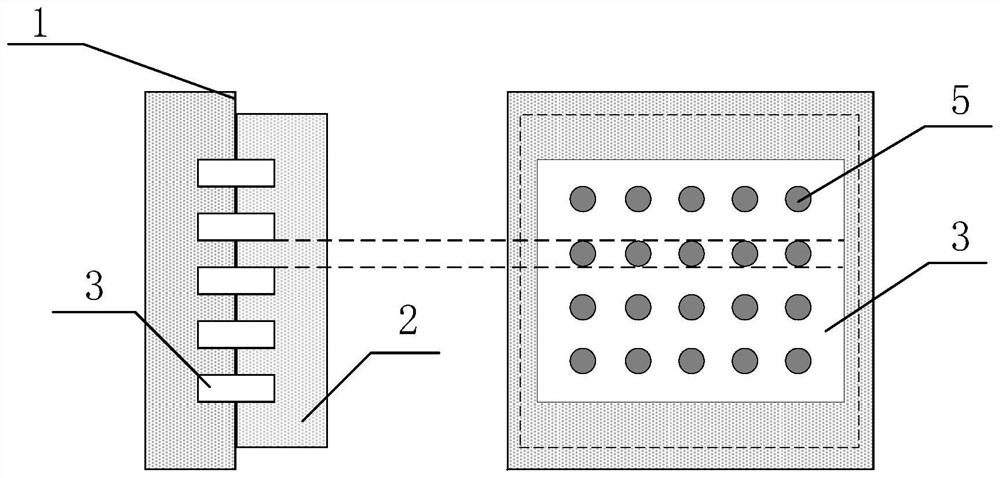

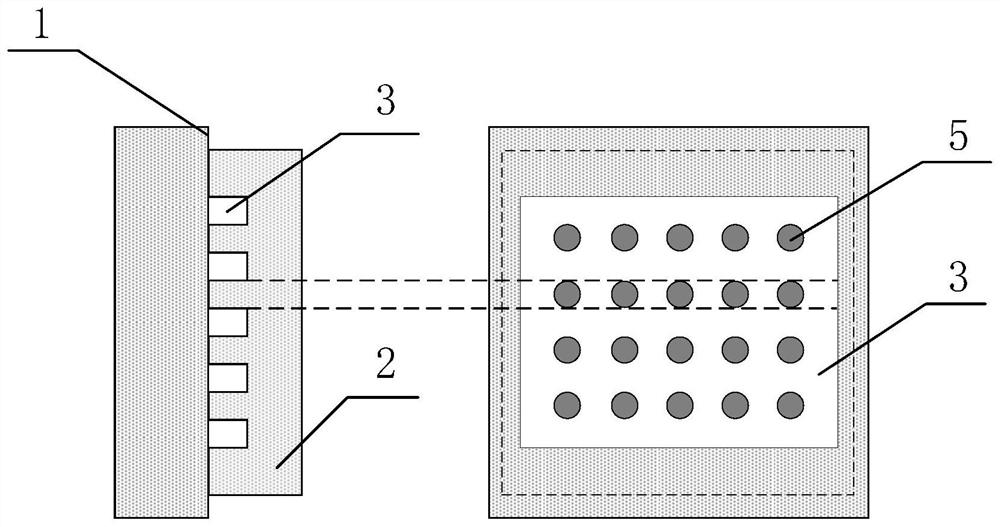

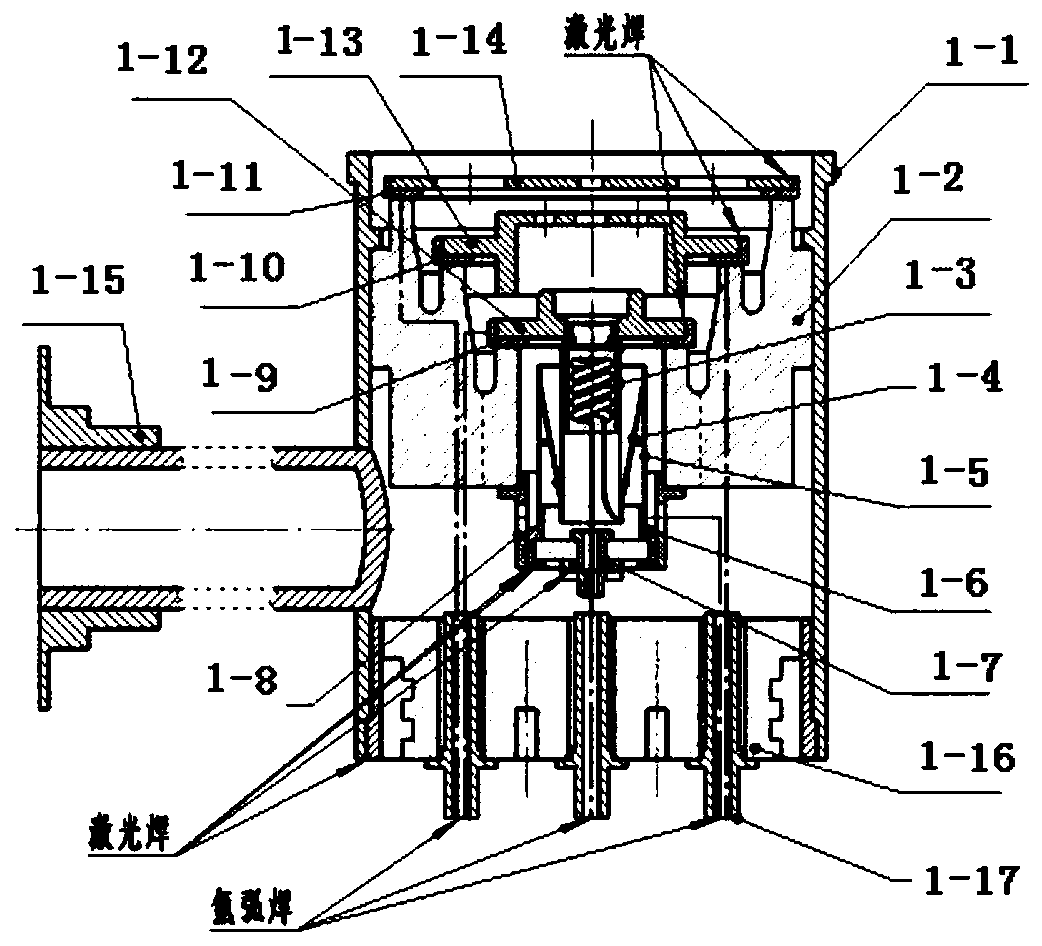

Pulse tube refrigerator

InactiveCN102128510AImprove heat exchange performanceMagnetic measurementsCompression machinesPulse tube refrigeratorEngineering

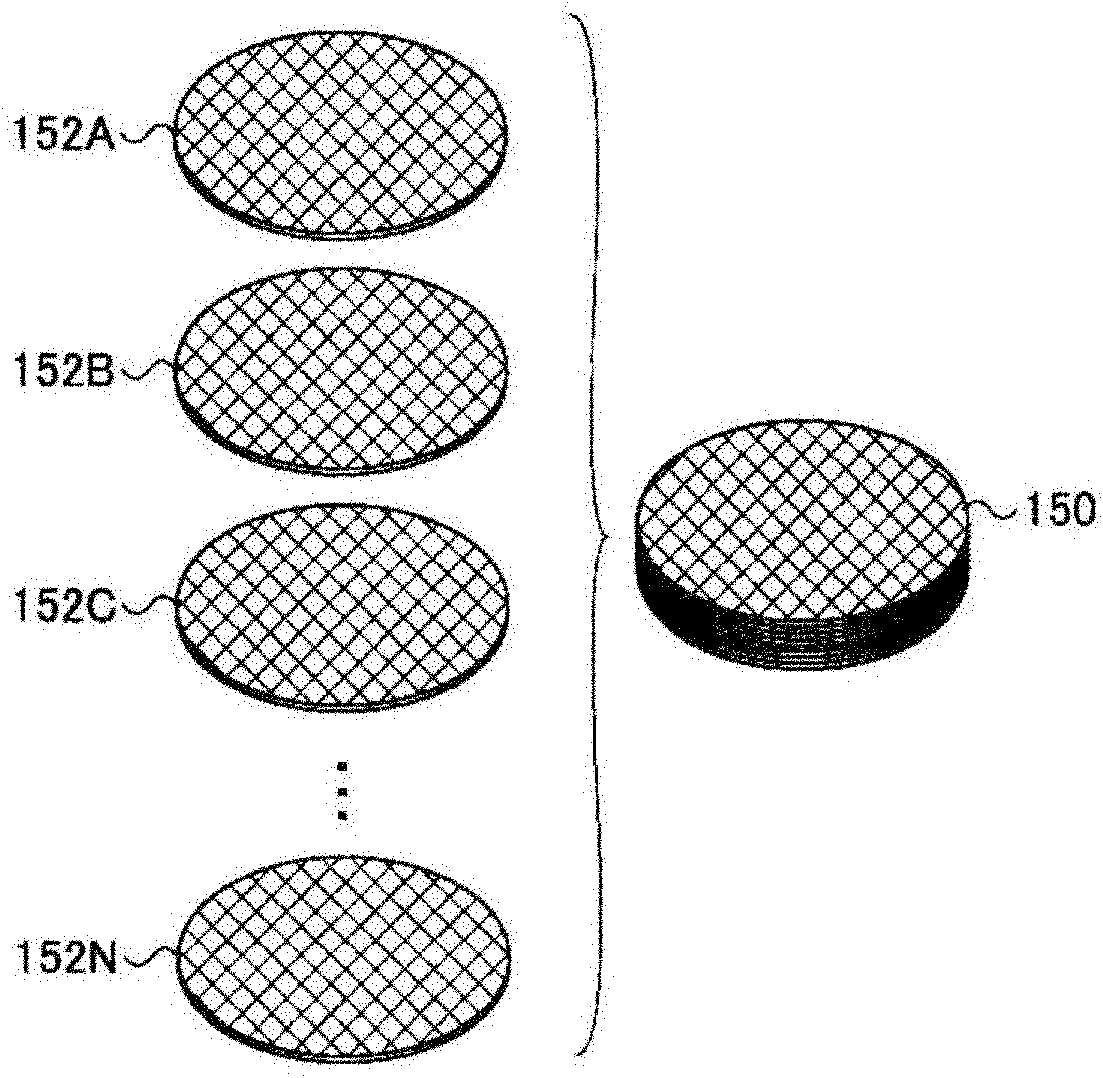

The invention provides a pulse tube refrigerator including a heat exchanger having heat exchangeability better than that of the conventional art. The pulse tube refrigerator, includes a pulse tube; and a regenerator having a low temperature end, the low temperature end being in communication with a low temperature end of the pulse tube via a communicating path, wherein a heat exchanger is provided at the low temperature end side of the pulse tube in the communicating path; the heat exchanger includes a laminated body, the laminated body including at least first and second metal gauzes; the first and second metal gauzes include copper or a copper alloy; interfaces of the metal gauzes are diffusion-bonded to each other; and a side surface of the laminated body is diffusion-bonded to an internal wall forming the communicating path.

Owner:SUMITOMO HEAVY IND LTD

Superconducting cable

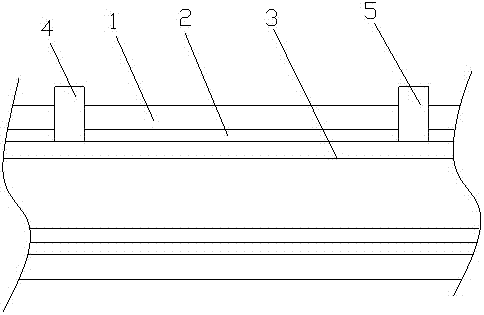

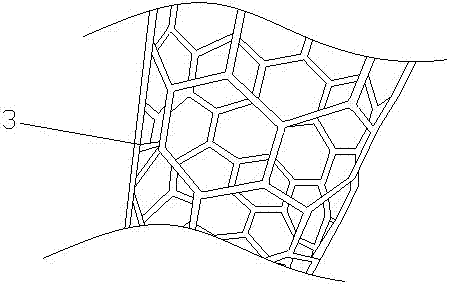

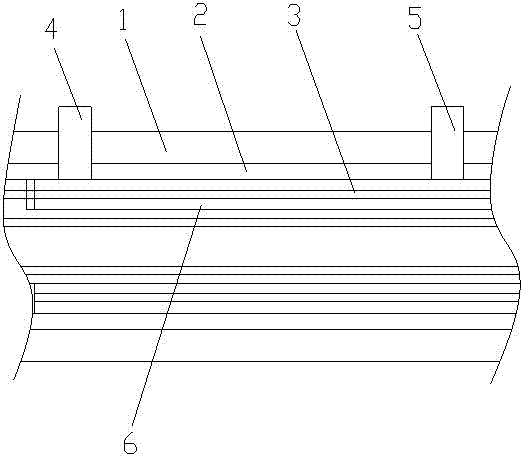

ActiveCN107103958AImprove heat exchange performanceShorten pre-cooling timeSuperconductors/hyperconductorsSuperconductor devicesEngineeringNitrogen

The invention discloses a superconducting cable. The cable comprises an external wrapping insulating protective layer, a conduit arranged in the external wrapping insulating protective layer and a superconductor arranged in the conduit, the conduit is provided with a nitrogen inlet tube and a nitrogen outlet tube, both the nitrogen inlet tube and the nitrogen outlet tube penetrate the external wrapping insulating protective layer, and the superconductor is of a hexagonal grid type and forms a tubular spatial topology structure. Precooling time, before use, of the superconducting cable is short.

Owner:广州市壹缆电缆实业有限公司

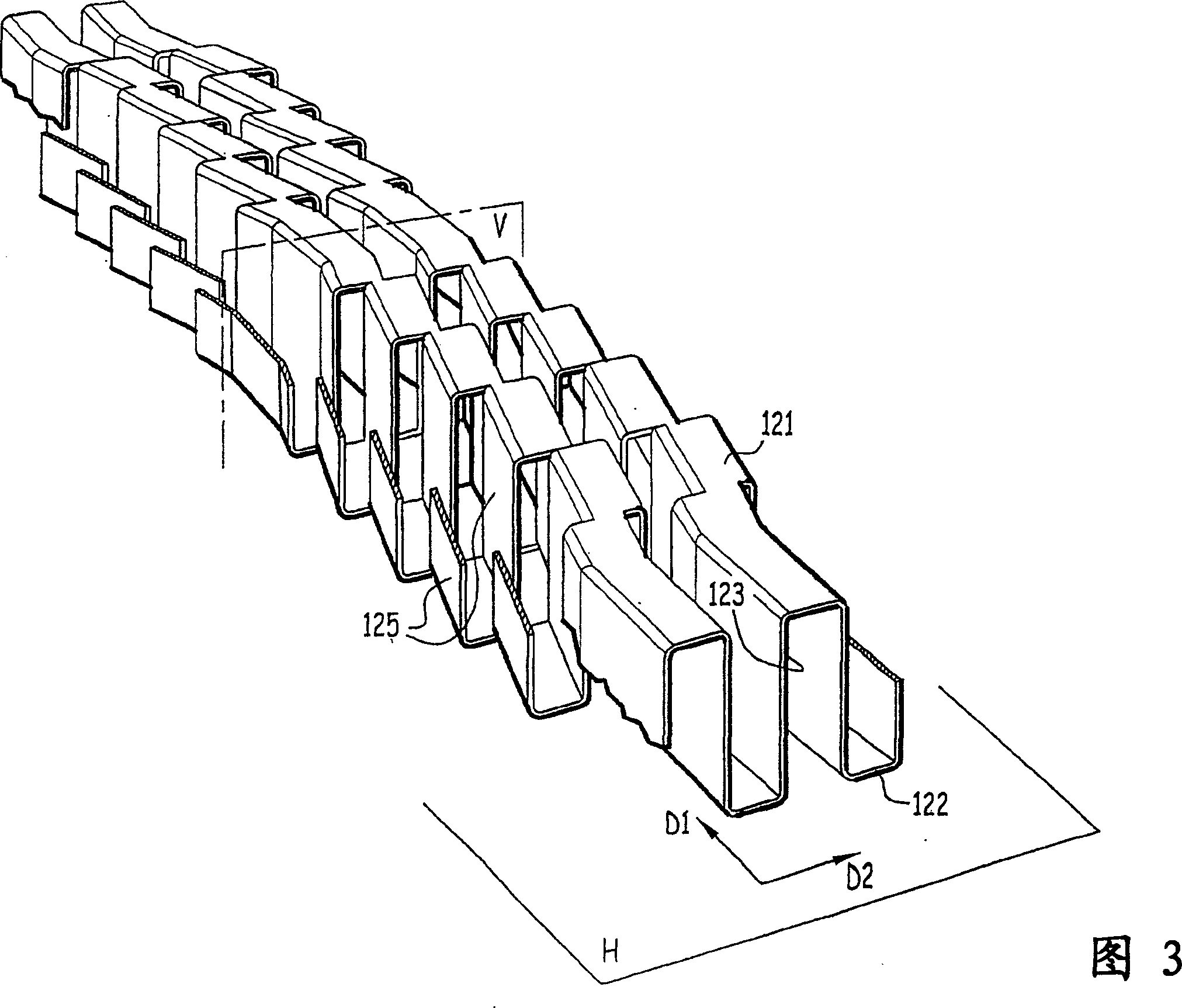

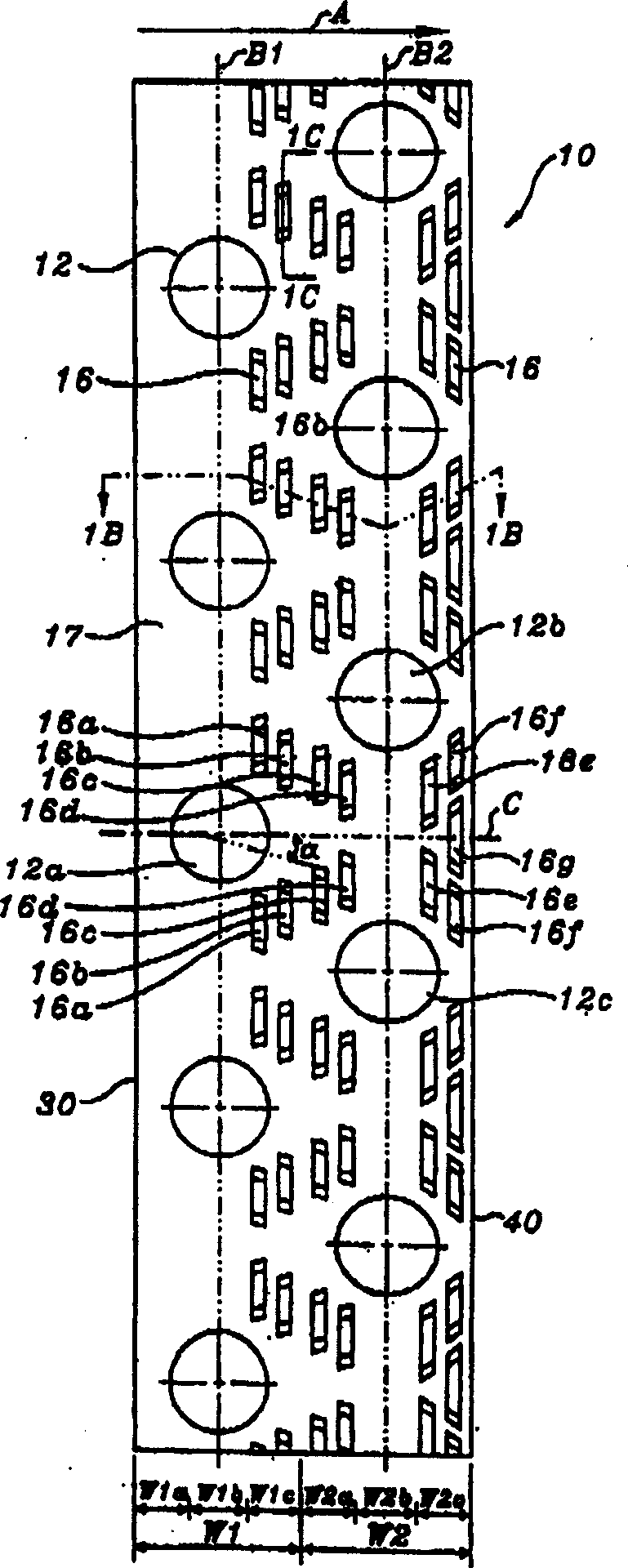

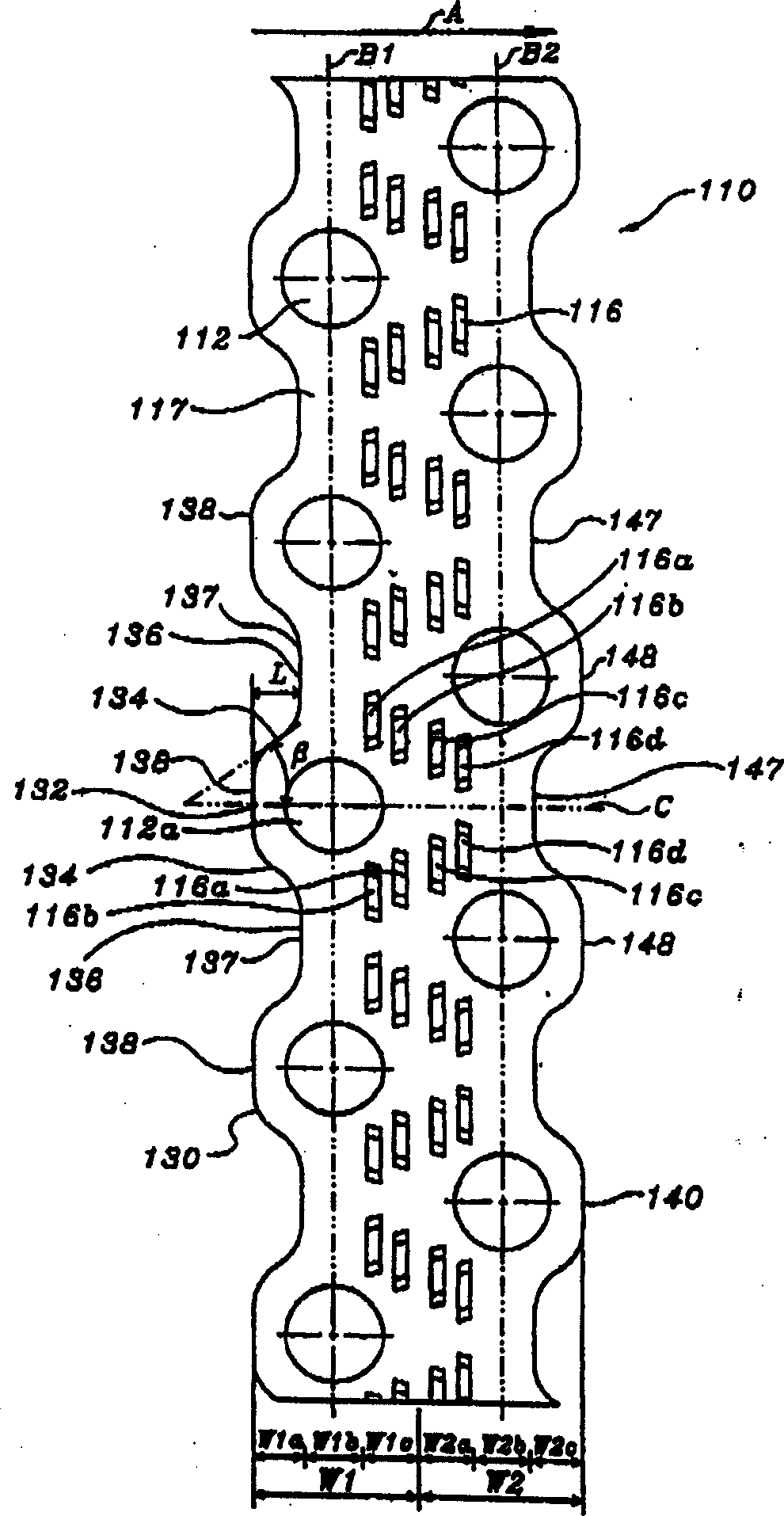

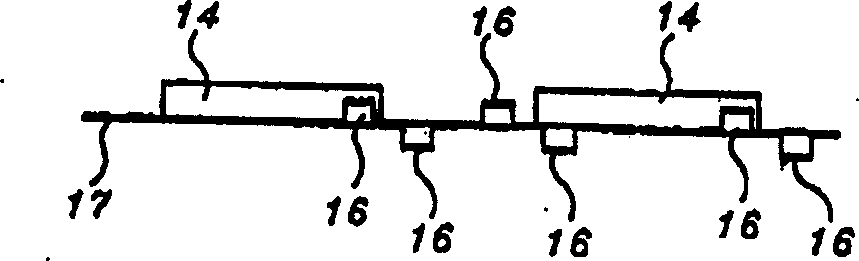

Fin tube heat exchanger

InactiveCN1354829AReduce resistanceImprove heat exchange performanceStationary conduit assembliesTubular elementsFront edgeHeat exchanger

A fin tube heat exchanger includes a plurality of plate-shaped elongated fin members(110)spaced at regular intervals in parallel with one another. Each fin member has a fin base, a plurality of through-holes(112)in two rows in a longitudinal direction of the fin member and a plurality of raised portions with legs. A plurality of heat exchanger tubes are inserted into the through-holes. Each fin member has flat areas at a front and middle regions of a front half and a middle region of a rear half. The raised portion disposed at a rear region of the front half and a front region of the rear half has the legs inclined by a predetermined angle with respect to a traverse centerline which passes through the center of an adjacent through-hole of the front row. The distance from the centerline is generally increased. Each fin member has a front edge and a rear edge. The front edge has protruded portions and recessed portions and the rear edge has protruded portions and recessed portions. The protruded portion of the front edge substantially corresponds to the recessed portion of the rear edge disposed on the same traverse centerline.

Owner:POSTECH ACAD IND FOUND +1

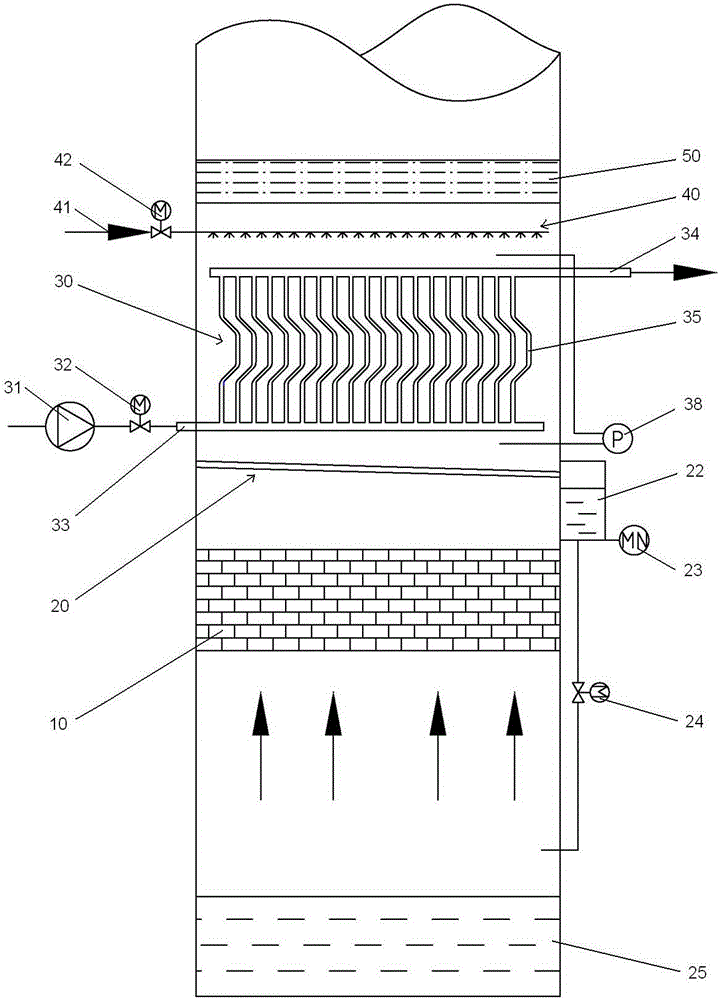

Fluoroplastic waste heat recycling and ultra-low emission integrated device

InactiveCN105157051AGood heat exchange performancePromote absorptionEnergy industryIncreasing energy efficiencyEngineeringRecuperator

The invention relates to a fluoroplastic waste heat recycling and ultra-low emission integrated device which is located above a catalytic reaction area in a desulfurizing tower and below a demister. The fluoroplastic waste heat recycling and ultra-low emission integrated device comprises a heat exchanger used for carrying out smoke waste heat exchange and capturing dust, a water flushing assembly used for flushing the surface of the heat exchanger, and a water collecting assembly used for collecting waste water and dust falling down from the surface of the heat exchanger. The water flushing assembly and the water collecting assembly are located above and below the heat exchanger respectively. The heat exchanger is a fluoroplastic plate type heat exchanger with a water inlet and a water outlet. The water inlet is connected with a low-temperature demineralized water feed pump. The water outlet s connected with a boiler system or a heating system. Compared with the prior art, the fluoroplastic waste heat recycling and ultra-low emission integrated device has good smoke waste heat recycling performance and dust and mist removing performance, and the purpose of integration of waste heat recycle and ultra-low emission is achieved. The fluoroplastic waste heat recycling and ultra-low emission integrated device has the beneficial effects of being resistant to corrosion, stable, reliable, low in water consumption and the like.

Owner:SHANGHAI HUAXIANG ENERGY SAVING & ENVIRONMENTAL PROTECTION CO LTD

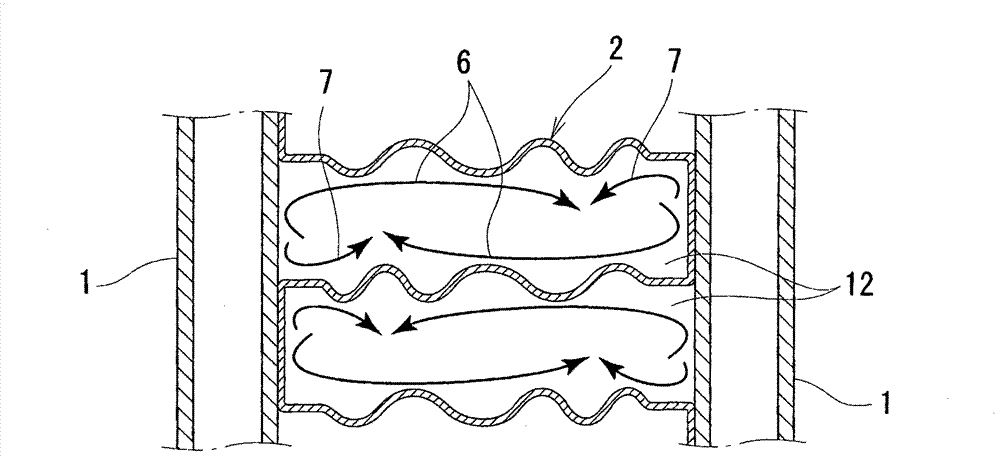

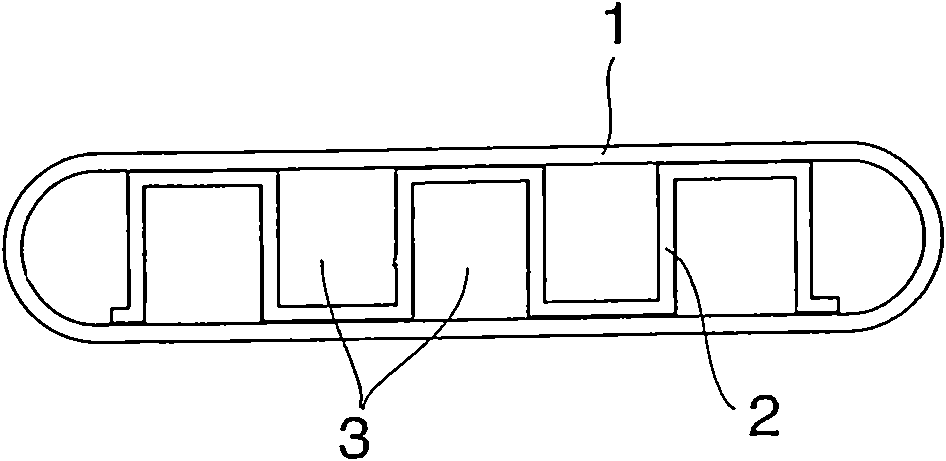

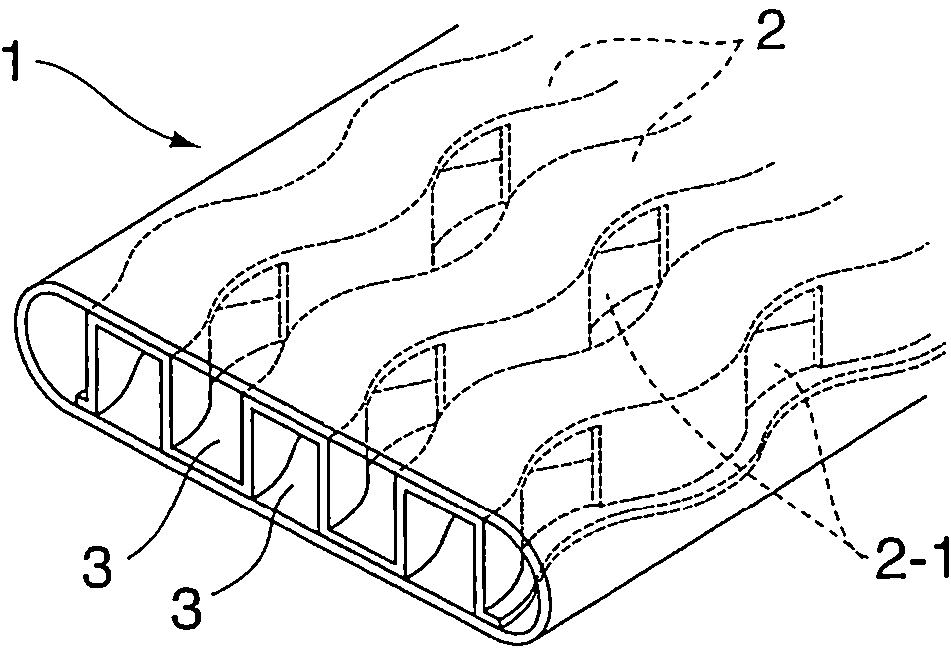

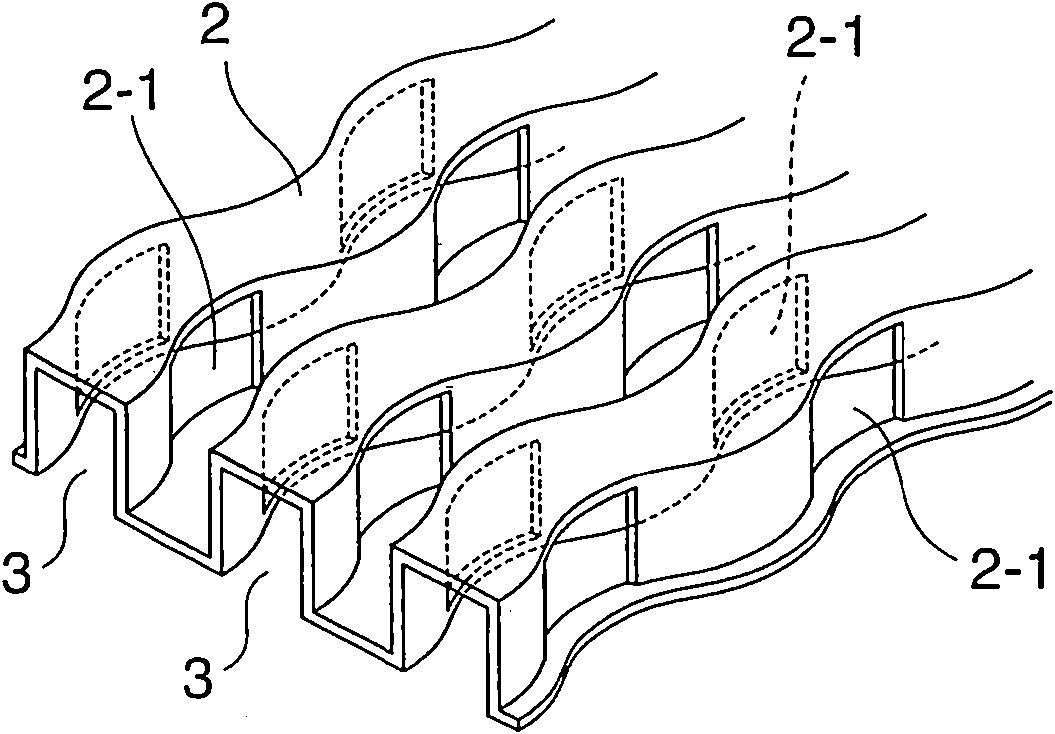

Fin structure

InactiveCN102032829AEasy to installImprove heat exchange effectRecuperative heat exchangersStationary tubular conduit assembliesEngineeringCooling medium

The invention discloses a fin structure disposed in heat transfer pipe, which divides the fluid channel into a plurality of small channels. The fluid includes cooling medium or refrigerant flowing in a heat transfer pipe; the cross sections of the small channels of the fin structure are squares or rectangles; the longitudinal plane of the small channels of the fin structure are corrugated shaped with same corrugation width; at least one rising section is formed on the side surface, or upper wall, or lower wall of the small channel of the fin structure, in order that at least one rising section is formed extending toward the upstream of the small channel by a tongue shape.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

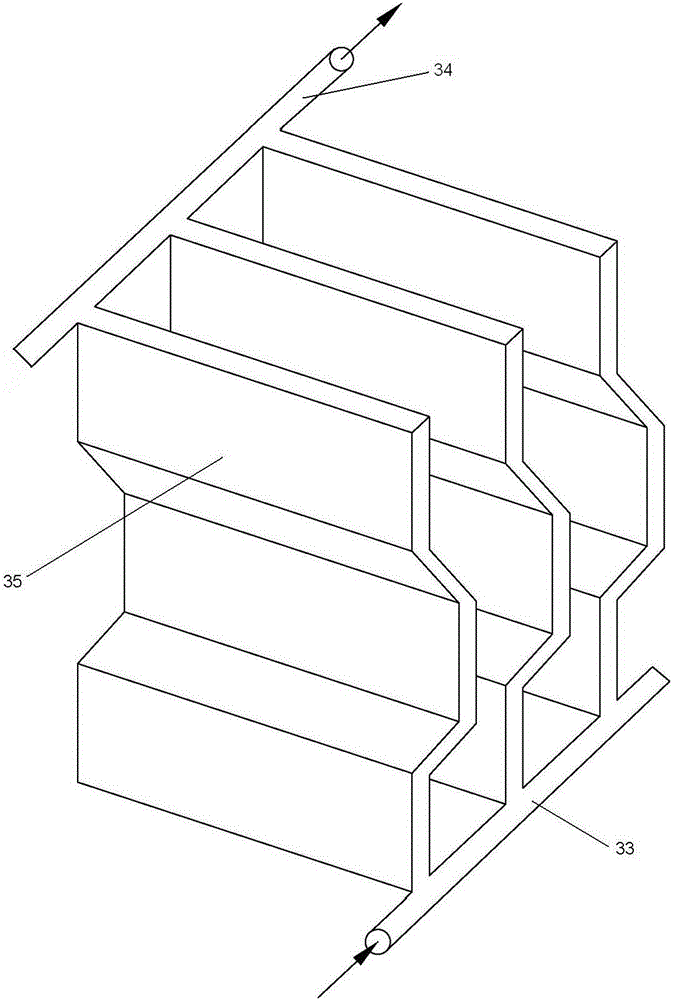

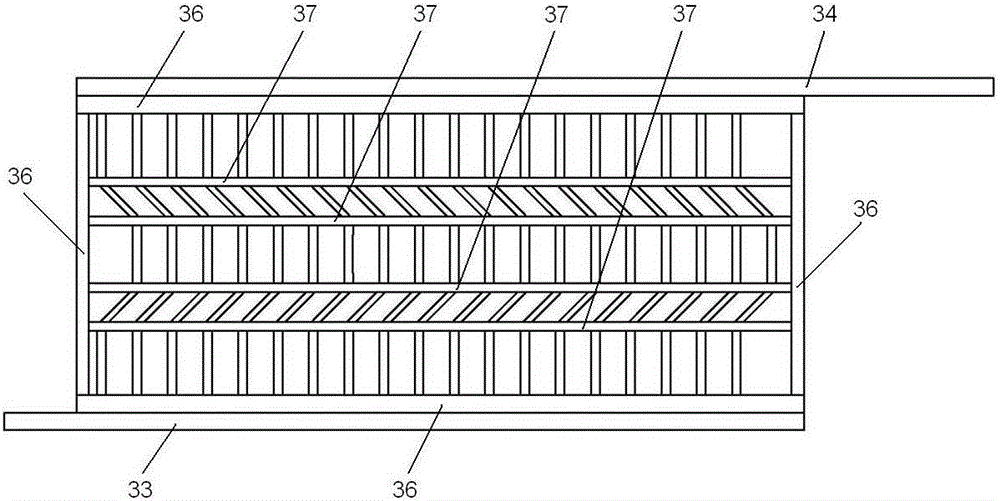

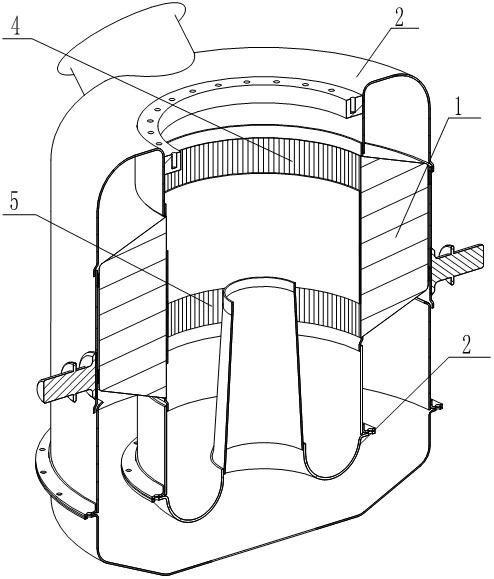

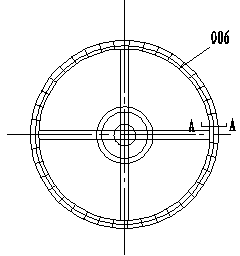

Primary surface type regenerator

InactiveCN102072023AIncrease the heat exchange areaIncrease the lengthGas turbine plantsJet propulsion plantsEngineeringSurface type

The invention discloses a primary surface type regenerator, which comprises a shell (2) and is characterized in that the shell (2) comprises an inner shell and an outer shell, a heat exchange core (1) is arranged between the inner shell and the outer shell and comprises an inner barrel (7) and an outer barrel (8) which are sheathed coaxially, and at least two heat exchange units (3) are arranged between the inner barrel (7) and the outer barrel (8). In the primary surface type regenerator disclosed by the invention, corrugated plates with air ducts being distributed in a cosine line shape are adopted, so that heat exchange area and length are increased, and high-temperature hot air after being combusted is utilized as much as possible to heat air; high-temperature tail gas is utilized to heat air, so that energy consumption is reduced, and heat efficiency of fuel gas is improved; since air involving in combustion has high temperature, the generated quantity of exhaust gases such as oxynitride, CO (carbon monoxide) and the like can be greatly reduced, and thus the goal of energy saving and emission reduction is realized; and the discharge temperature of a host machine can be reduced to 300 DEG C from 600 DEG C, and the heat exchange effect is remarkable.

Owner:SICHUAN AEROSPACE ZHONGTIAN POWER EQUIP CO LTD

Heat exchanger

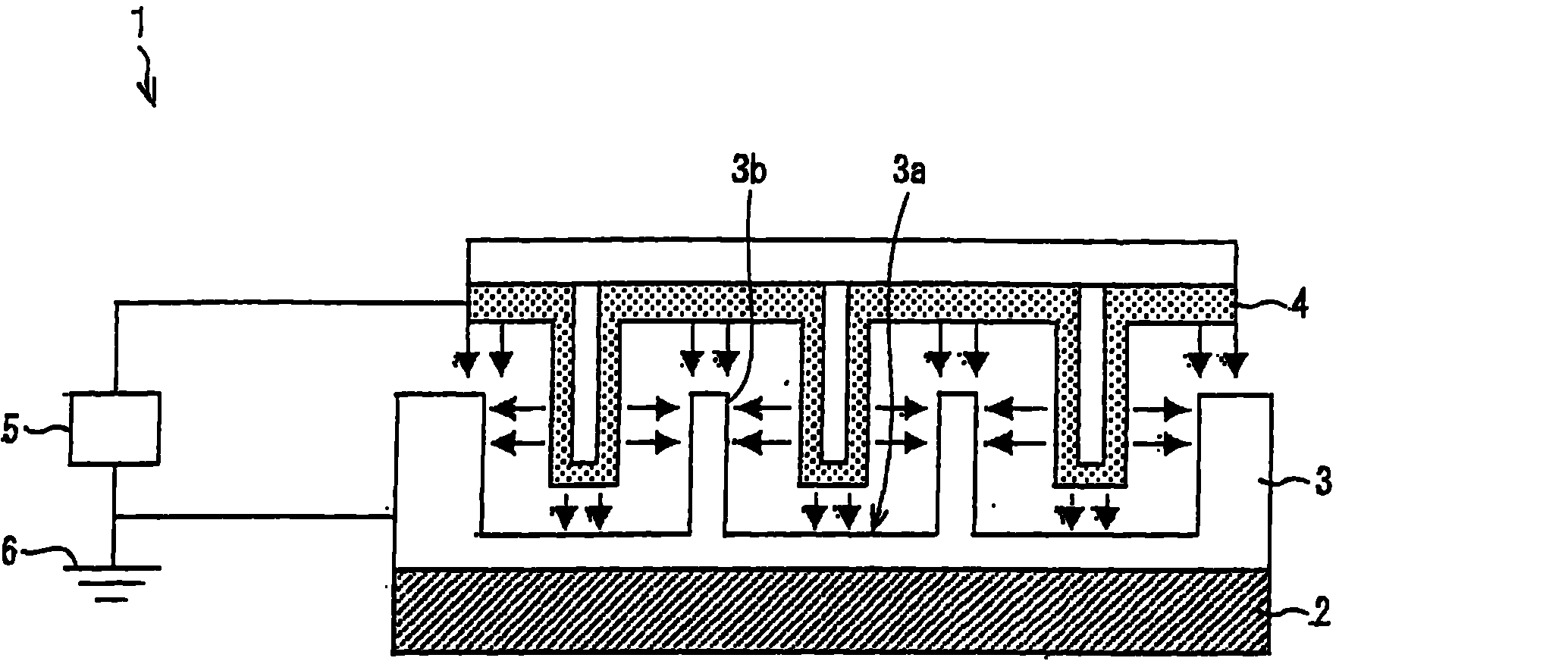

InactiveCN102110561ASuppresses degradation of heat exchange performanceGood heat exchange performanceDigital data processing detailsSolid cathode detailsThin film electrodeAir filter

In order to alleviate reduction in a heat exchange capability and to further improve the heat exchange capability, a heat exchanger of the present invention includes: a heat sink; and an electron emitting element which is provided so as to be separated from the heat sink by a space and which provides electrons to the heat sink via air in the space. The electron emitting element includes: an electrode substrate; a thin-film electrode; a power supply which applies a voltage between the electrode substrate and, the thin-film electrode; and an electron acceleration layer which accelerates electrons inside the electron acceleration layer in response to the voltage applied by the power supply so that the electrons are emitted from the thin-film electrode. The electron acceleration layer is made at least partially of an electric insulating material. The heat exchanger includes an air filter through which air flows onto a surface of the thin-film electrode. This can alleviate reduction in the heat exchange capability, caused by dust that adheres to a surface of the electron emitting element and therefore can attain an excellent heat exchange capability for long periods.

Owner:SHARP KK

Falling film heat exchanger, absorption refrigerator system, ship, offshore structure and underwater offshore structure

ActiveUS20140231058A1Improve heat exchange performanceAuxillariesEvaporators/condensersLeft directionMarine engineering

A guide plate having depressed portions is provided between an array of heat exchanger tubes, herein after “tubes”, arranged horizontally side-by-side and a next lower array of tubes arranged horizontally side-by-side, and is positioned with the lowest parts of the depressed portions near crest portions of respective lower tubes. The guide plate conveys a liquid D on outer surfaces of respective upper tubes onto similarly positioned lower tubes even when the tubes move in a right-and-left direction. A falling film heat exchanger installed in a ship, an offshore structure or the like can avoid reduction in heat exchange performance, even when the ship or the like inclines and swings, by substantially evenly distributing and dropping a liquid onto the crests of the tubes and causing the liquid dropped from the tubes located in an upper array to fall onto the tubes located in the next lower array.

Owner:MODEC

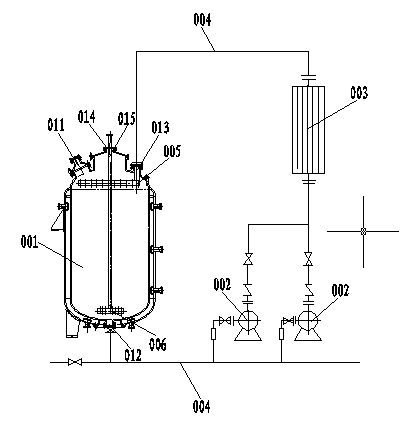

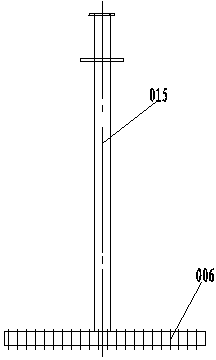

Circulation flow reaction device for producing phosphorus oxychloride by oxygen oxidation process

InactiveCN102826522AFully contactedImprove thermal conductivityPhosphorus halides/oxyhalidesEngineeringOxygen

The invention relates to a circulation flow reaction device for producing phosphorus oxychloride by an oxygen oxidation process. The circulation flow reaction device comprises a reaction kettle, a circulating pump and a heat exchanger, wherein a feed port is arranged in the left side of the top of the reaction kettle and a discharge port is arranged in the bottom end of the reaction kettle; the discharge port is provided with a connecting pipeline which is connected with the bottom end of the heat exchanger; the connecting pipeline, which is positioned between the discharge port in the bottom end of the reaction kettle and the bottom end of the heat exchanger, is provided with the circulating pump; the top of the heat exchanger is provided with a connecting pipeline which extends into a feed port arranged in the right side of the top of the reaction kettle and is connected with a material spray distributor arranged in the reaction kettle; and an air inlet is drilled in the center of the top of the reaction kettle and is internally provided with a vertical pipeline which extends into the near bottom of the reaction kettle and is connected with an oxygen distributor. According to the circulation flow reaction device, as the material spray distributor and the oxygen distributor are arranged in the reaction kettle, oxygen molecules can be effectively and fully in contact with phosphorus oxychloride molecules, therefore, the reaction probability is increased, the reaction time is shortened, and the yield and the device availability are increased.

Owner:滨海雅克化工有限公司

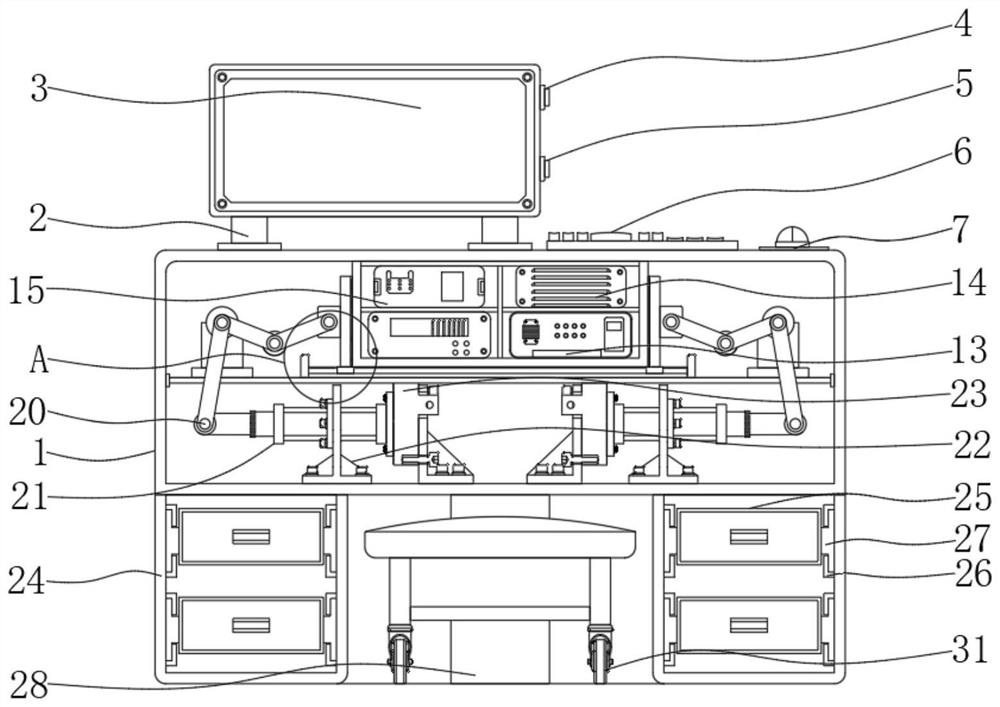

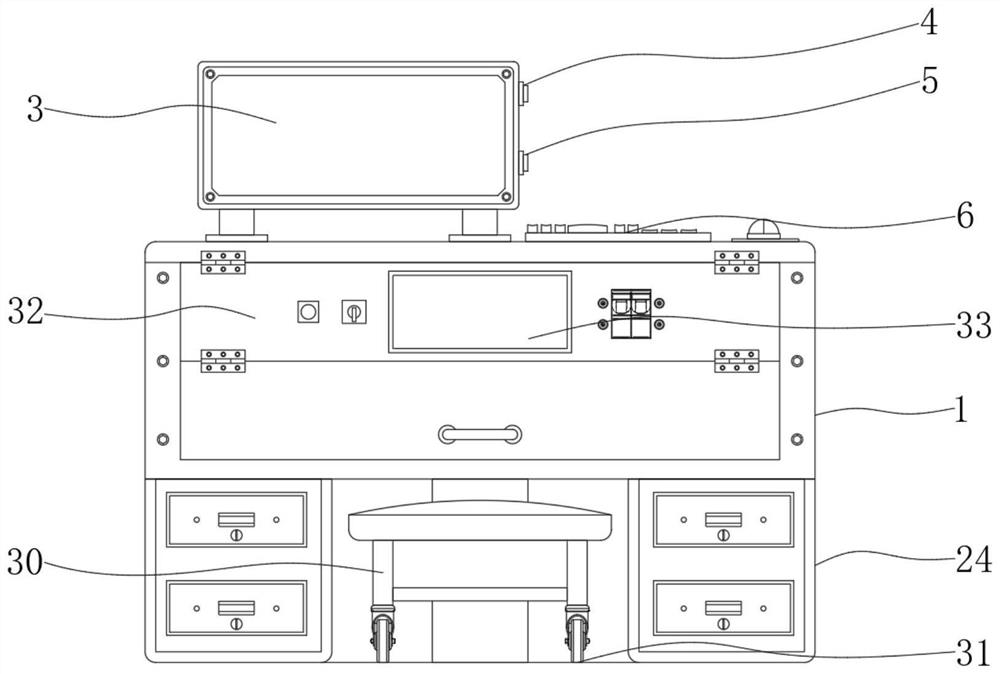

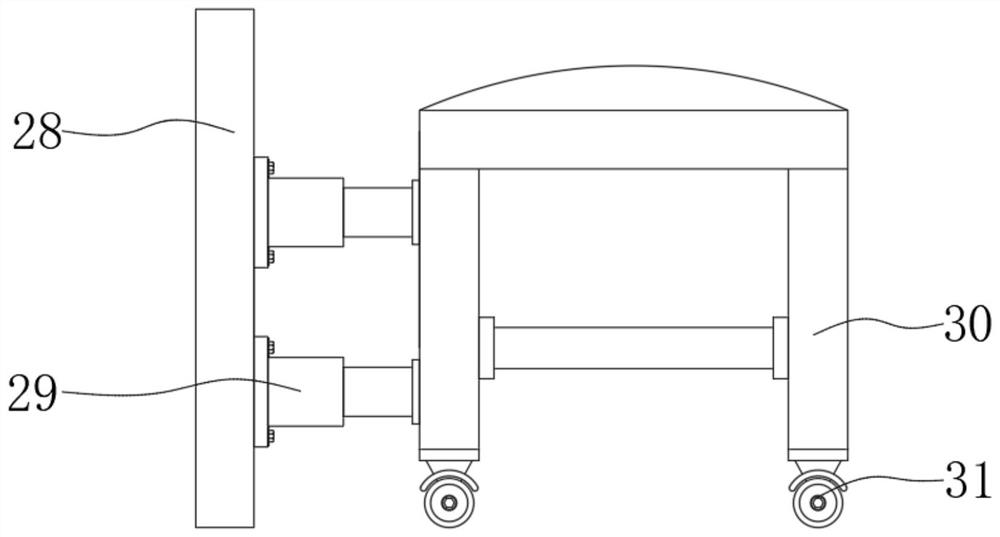

Information acquisition and fusion device based on spindle system thermal design and method of information acquisition and fusion device

InactiveCN112192250AAccurate acquisitionFull accessMeasurement devicesMeasurement/indication equipmentsComputer hardwareElectrical control

The invention belongs to the technical field of information acquisition and fusion, and particularly discloses an information acquisition and fusion device based on spindle thermal design and a methodof the information acquisition and fusion device. The information acquisition and fusion device comprises an equipment box and a detection module, wherein supporting rods are fixedly connected to theupper part of the equipment box; a host is fixedly connected to the upper parts of the supporting rods; a data integration unit is arranged below the detection module; the detection module is arranged on the right side of the host; a keyboard is arranged on the right side of the supporting rods; and a mouse is arranged on the right side of the keyboard. According to the information acquisition and fusion device based on the spindle thermal design and the method of the information acquisition and fusion device, compared with an existing common information acquisition and fusion device and a method thereof, the information acquisition and fusion device based on the spindle thermal design can well clamp electric control parts in the using process and are not prone to causing the shifting ofthe electric control parts in the long-term use process, circuits cannot drop, and instruments frequently used in the information collection process can be collected well in a centralized manner.

Owner:QUZHOU UNIV +1

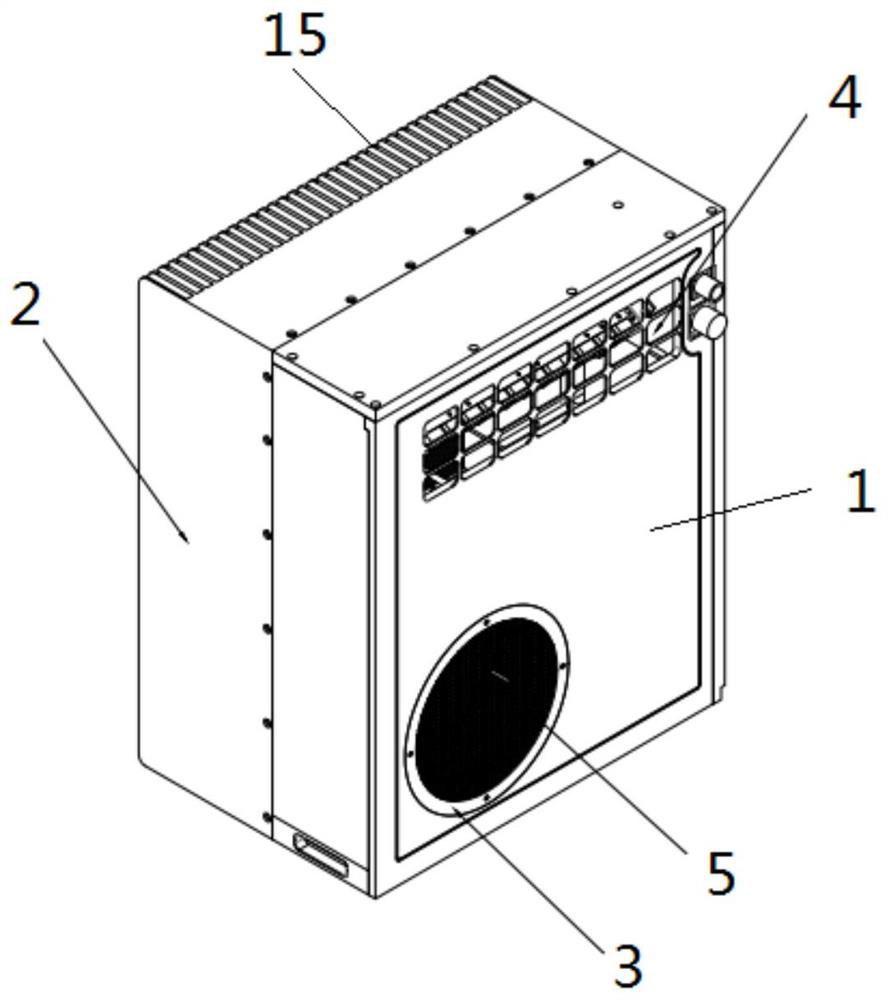

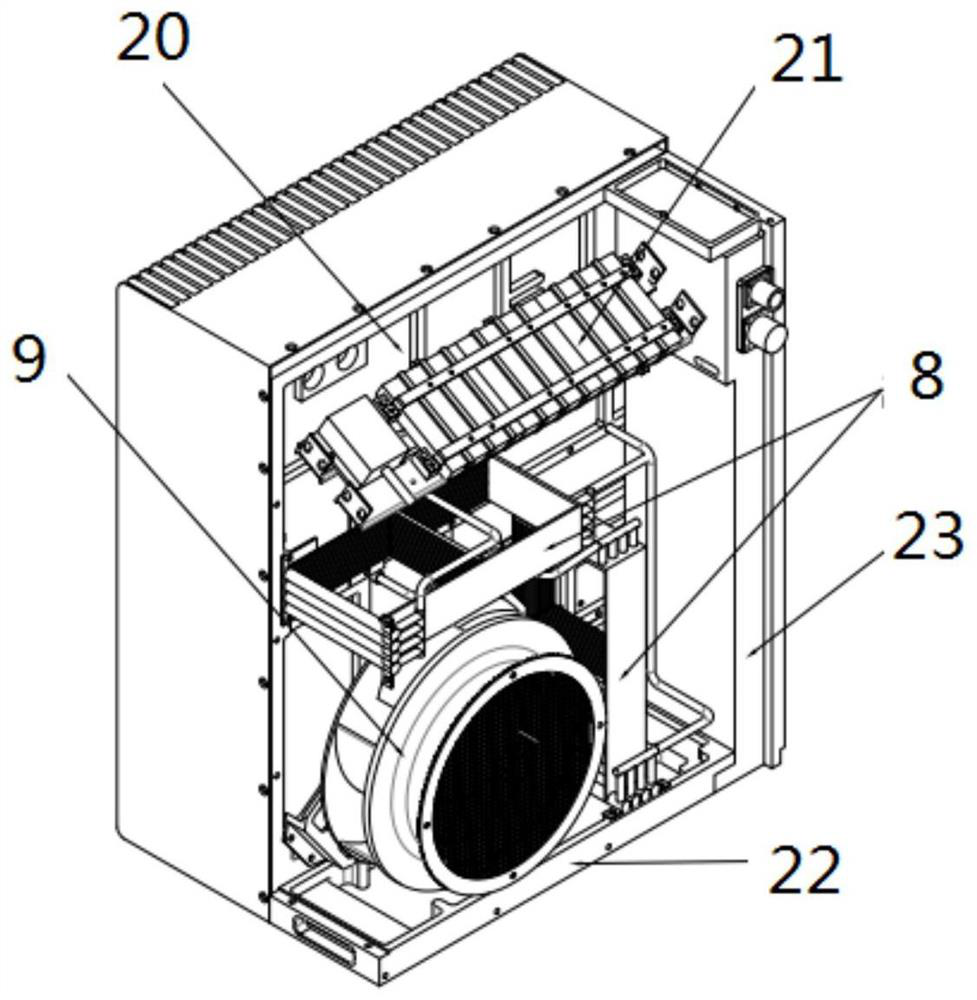

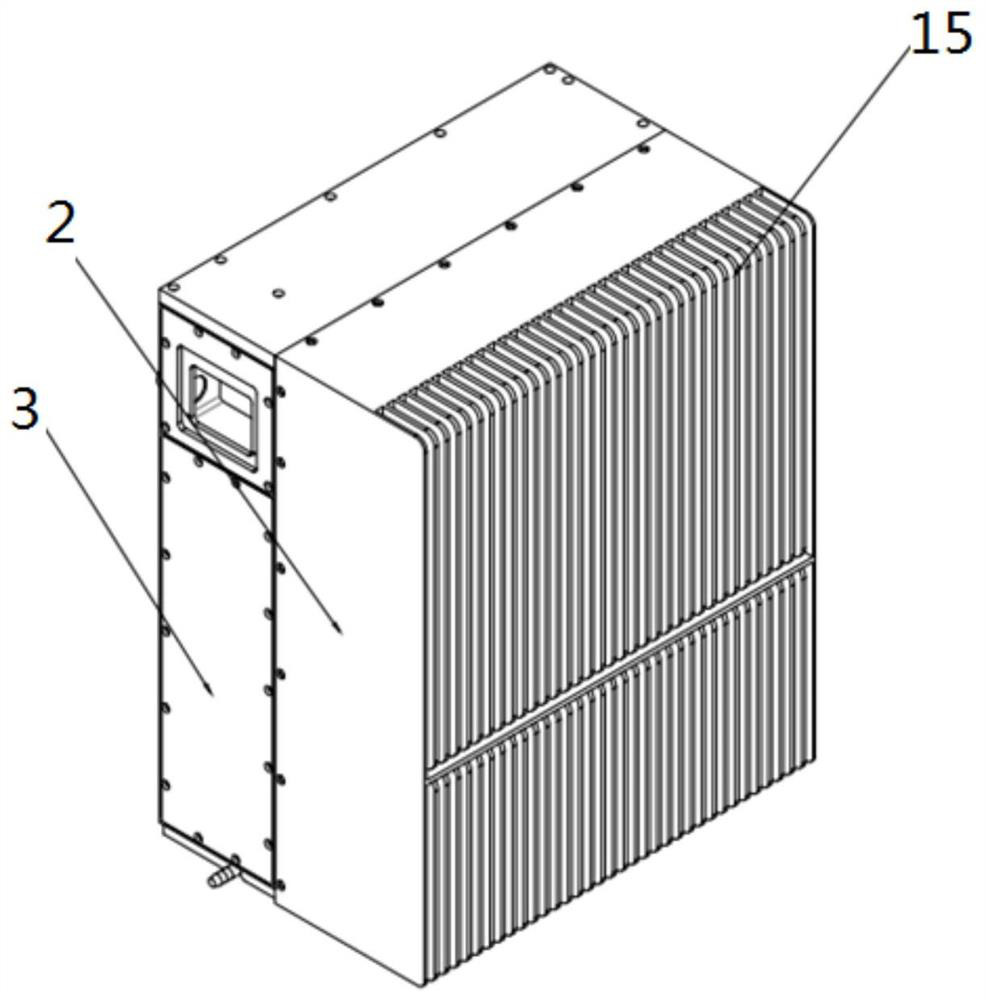

Cabinet air conditioner

PendingCN112004374AEasy to cleanImprove heat transfer effectCooling/ventilation/heating modificationsEngineeringRefrigerant

The invention relates to a cabinet air conditioner. The cabinet air conditioner comprises a partition plate, a front cover and a rear cover, the front cover and the rear cover are oppositely buckled on the front side and the rear side of the partition plate respectively, an inner circulation heat exchange cavity is formed between the front cover and the partition plate, an outer circulation heat exchange cavity is formed between the rear cover and the partition plate, and the inner circulation heat exchange cavity and the outer circulation heat exchange cavity are isolated through the partition plate. A base plate in an outer circulation system is provided with a flow channel for a refrigerant to flow, the outermost side of the base plate is provided with heat dissipation fins directly exposed to the outside space, and heat dissipation is conducted through natural convection of air. The cabinet air conditioner is reasonable and compact in structural layout, corrosion-resistant in material, simple and convenient in modular design and processing, relatively low in cost, easy to mount and maintain, relatively low in noise during working, attractive in appearance and excellent in heatexchange effect.

Owner:CHANGZHOU UNIV

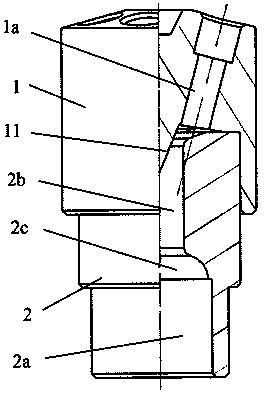

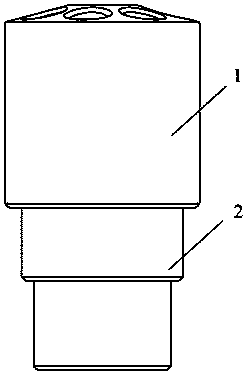

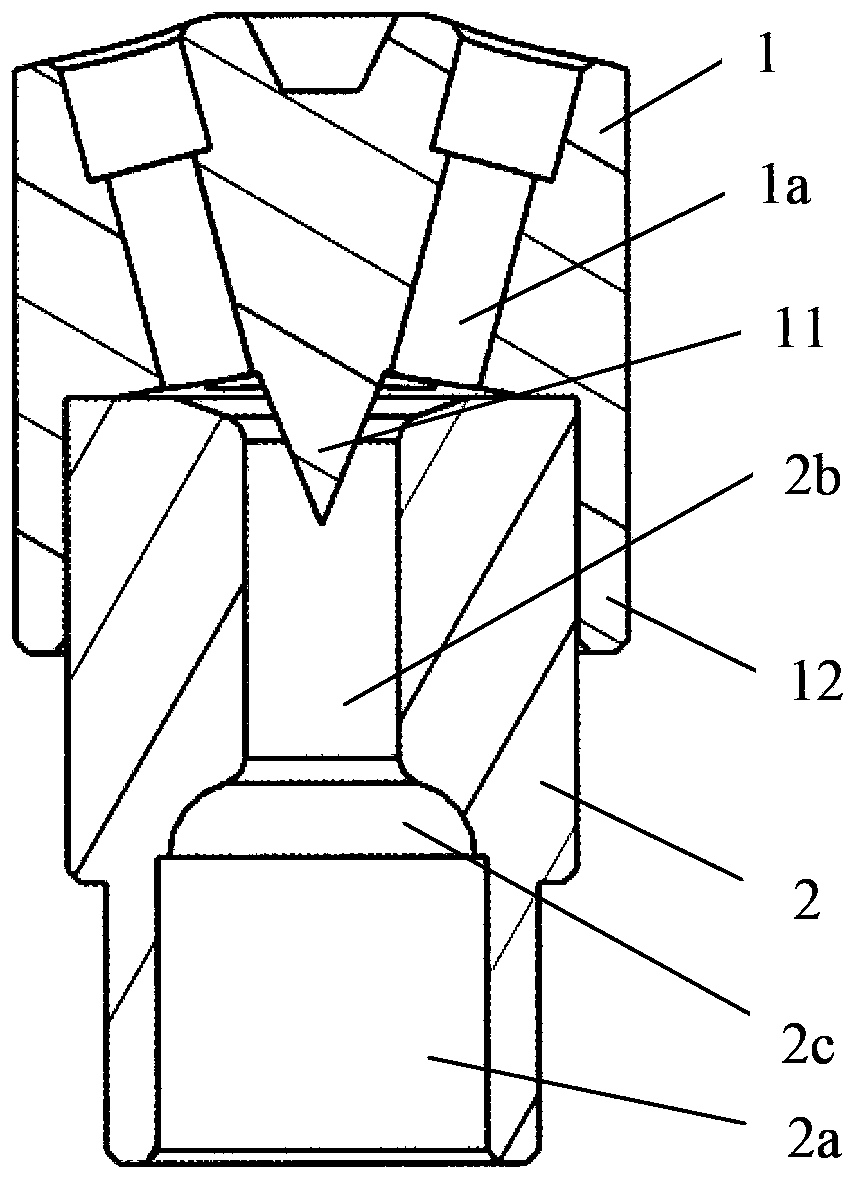

Liquid distributor and air conditioner equipped with liquid distributor

ActiveCN104061722AIncrease the lengthEvenly distributedFluid circulation arrangementEngineeringDistributor

The invention discloses a liquid distributor and an air conditioner equipped with the liquid distributor. The liquid distributor comprises a distributing part at the upper end and a liquid inlet part at the lower end, wherein a drainage port is formed in the inner side of the lower part of the liquid inlet part, a flow stabilizing hole communicated with the drainage port is formed in the drainage port, the diameter of an inlet of the flow stabilizing hole is smaller than that of the drainage port, the flow stabilizing port extends to the top end of the liquid inlet part, a plurality of distributing ports at equal intervals are formed in the upper end of the flow stabilizing hole, and the distributing part is provided with a plurality of distributing channels communicated with the distributing ports; and the air conditioner is equipped with the liquid distributor. Liquids entering the liquid distributor are uniformly distributed, non-uniform turbulent flow is prevented from being formed, noise produced when a liquid flows is reduced, and the refrigerating capacity of the air conditioner is effectively improved.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

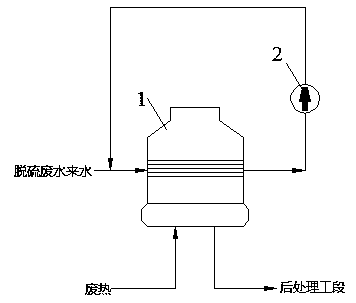

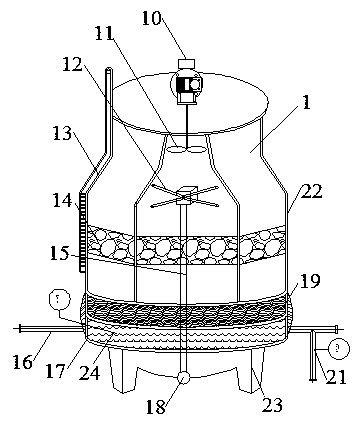

Efficient energy-saving concentration treatment device for desulfurization wastewater

PendingCN110316778AEven distribution of water flowImprove heat exchange performanceWaste water treatment from gaseous effluentsWater/sewage treatment by heatingEfficient energy useHigh concentration

Owner:国能浙江北仑第一发电有限公司 +1

Square battery shell, battery adopting same, battery pack and automobile

PendingCN113823865AHeating fastReduce energy densitySecondary cellsCell component detailsThermodynamicsHeat management

The invention relates to a square battery shell, a square battery adopting the same, a battery pack and an automobile. The square battery shell is characterized in that a flat sealing cavity is formed in at least one shell surface of the square battery shell, no interface thermal resistance exists between at least one cavity wall of the sealing cavity and the shell connected with the cavity wall, a liquid absorption core is arranged in the sealing cavity, and the sealing cavity is vacuum and is filled with a phase change heat transfer working medium. The sealing cavity enables any local heat on the shell surface where the sealing cavity is located to be quickly and uniformly dispersed to the periphery, and heat exchange of quick heat dissipation and quick heat absorption with the external environment can be carried out only by contacting the surface of the sealing cavity, any area of the shell surface where the sealing cavity is located or an adjacent area with the external environment, thus the technical problems that the energy density of the battery pack is obviously reduced, the assembly cost is increased and the reliability is reduced due to the fact that a refrigerant pipeline needs to be arranged on the battery shell and the battery shell is connected with an external refrigerant system through a connector in order to achieve rapid heat management of the battery in the battery pack composed of batteries manufactured through an existing battery shell are solved.

Owner:陈巍

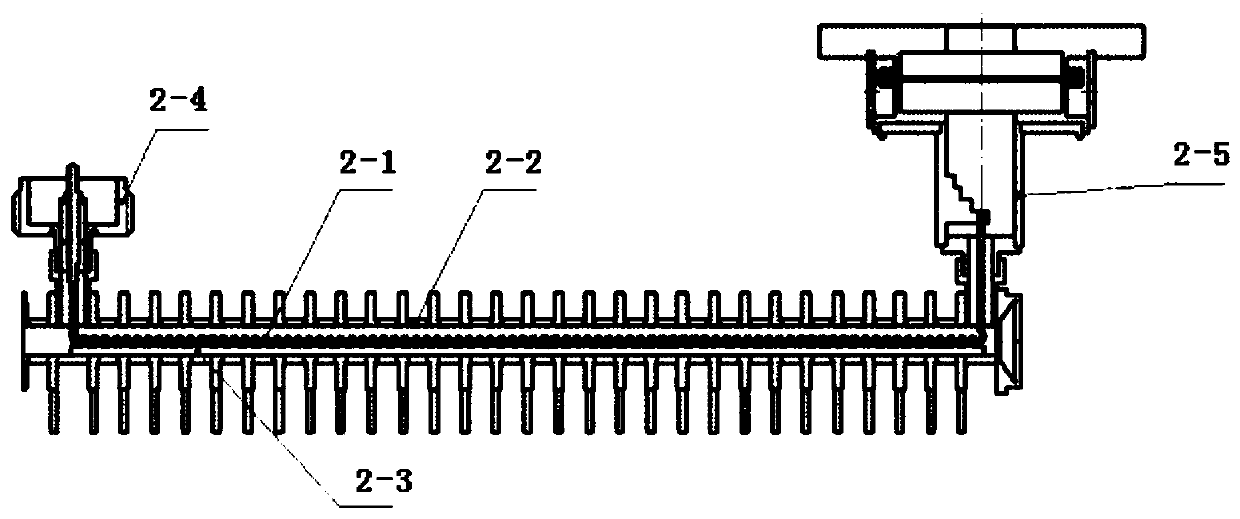

Miniaturized and light-weight Ka waveband space traveling wave tube

ActiveCN110620028AIdeal structural designImprove performanceTransit-tube electron/ion gunsTravelling-wave tubesDBcLinearity

The invention discloses a miniaturized and light-weight Ka waveband space traveling wave tube. The traveling wave tube comprises a double-anode electron gun (1), a spiral line slow wave circuit (2) connected with the double-anode electron gun (1), and a four-stage step-down collector (3) connected with the spiral line slow wave circuit (2). The device is reasonable in structural design, high-performance miniaturized electron guns are screened out through a large number of experiments, the spiral line slow wave circuit has high linearity and high efficiency, the whole pipe heat dissipation structure is for rapid cooling, and the four-stage depressed collector is excellent in heat exchange performance and low in backflow. The device is advantaged in that experimental detection results show that the total length of the traveling wave tube is smaller than 200 mm, the weight is smaller than 350 g, the power is larger than 55 W, the work ratio is 100%, the phase shift curve is monotonous andsmaller than 45 degrees, third-order intermodulation is larger than 18.5 dBc, and the traveling wave tube has excellent performance, good work stability and a wide application range.

Owner:NANJING SANLE GROUP

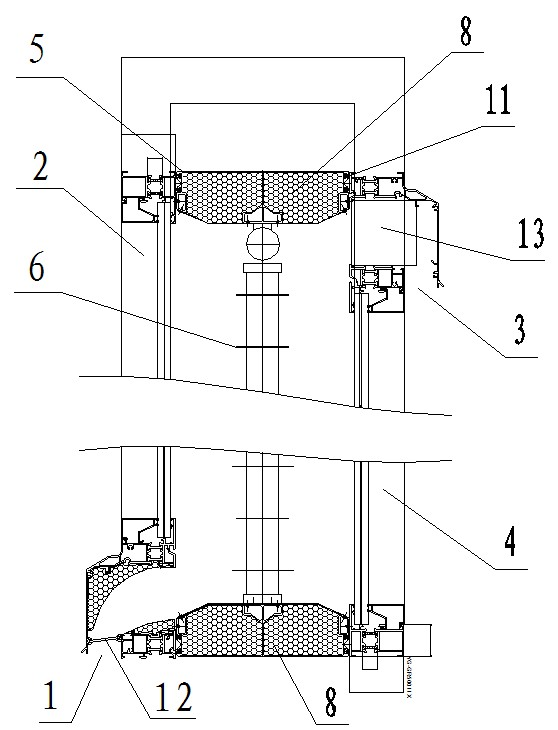

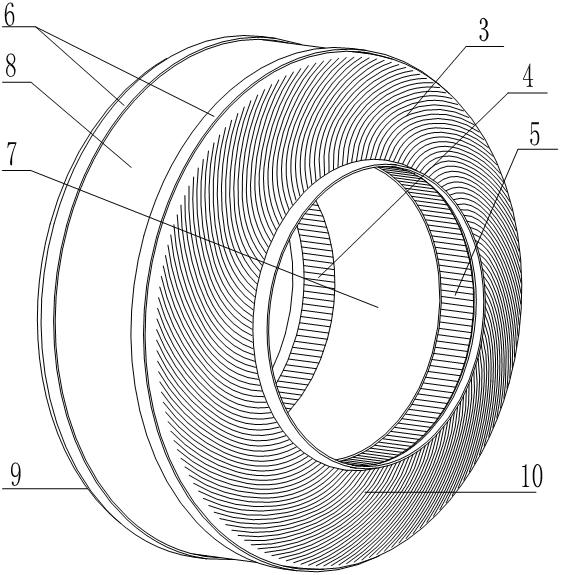

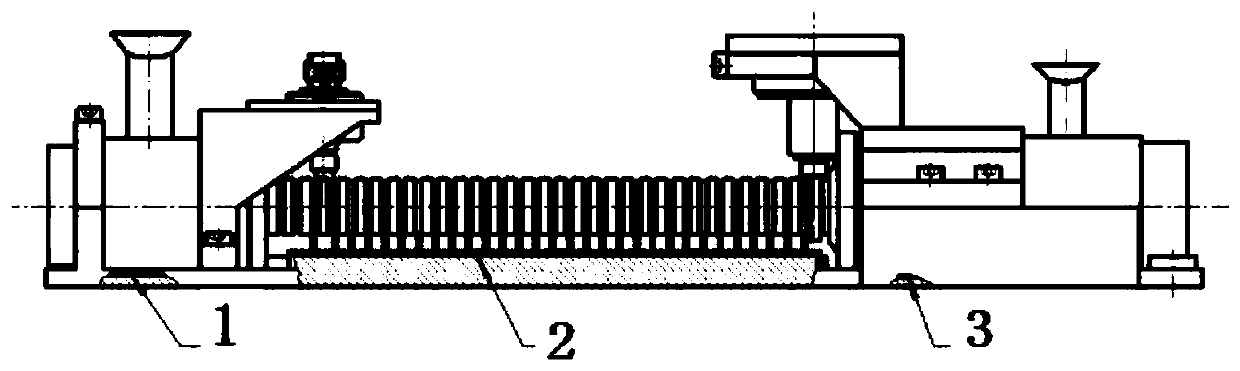

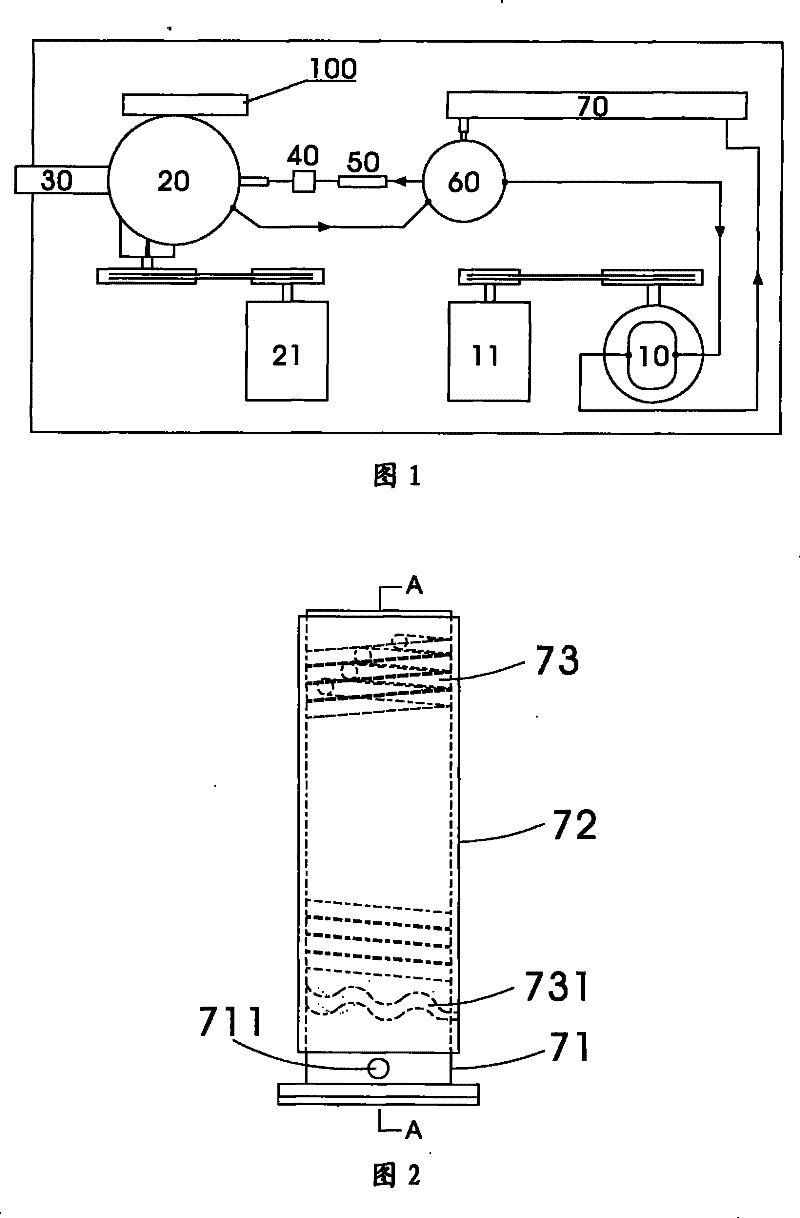

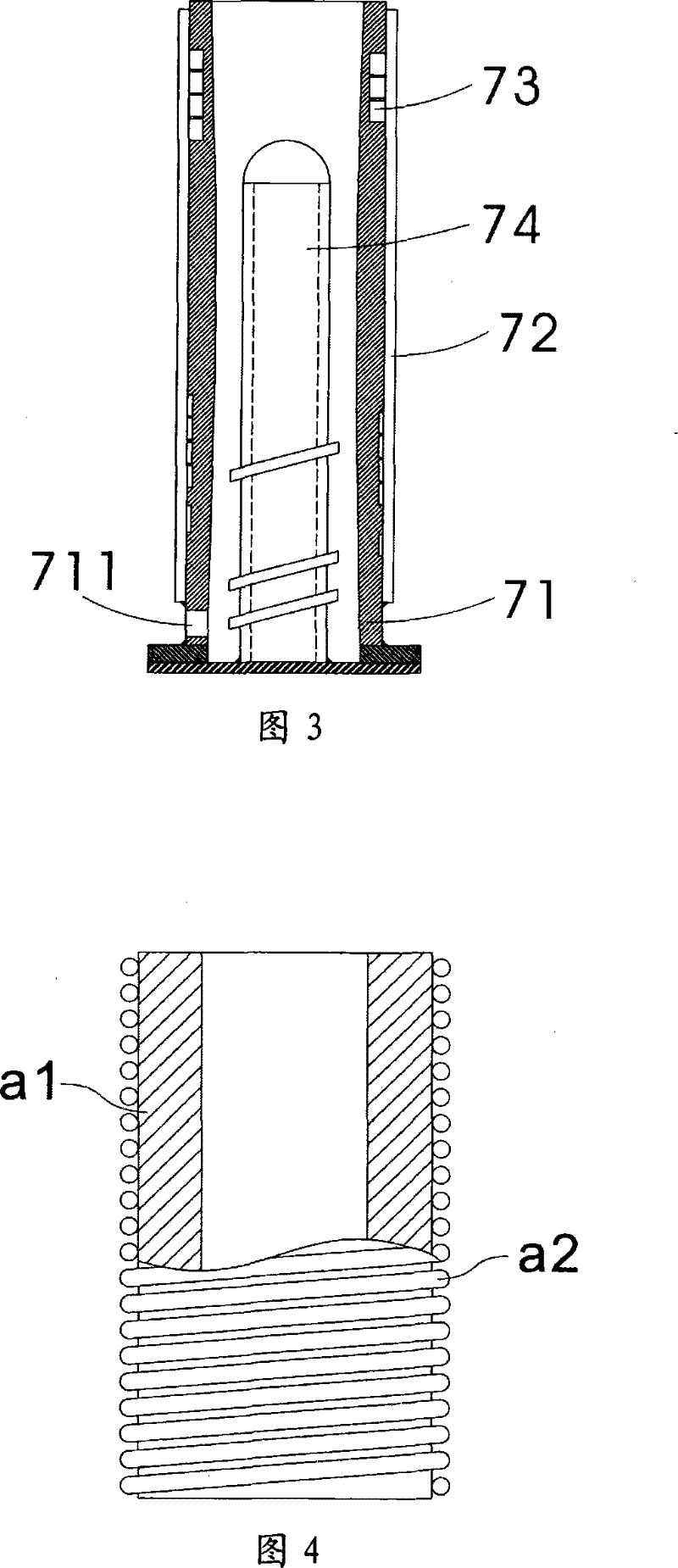

A sea/fresh water dual-purpose ice-making machine

InactiveCN101251324BSimple structureCompact structureLighting and heating apparatusIce productionVapor–liquid separatorFresh water organism

The invention relates to an ice maker, in particular to a sea / fresh water dual-purpose continuous ice-discharging ice maker. It includes: compressor, ice making cylinder, ice outlet pipe, thermal expansion valve, dry filter, gas-liquid separator, condenser. The machine and the ice making cylinder are driven by the motor respectively, the compressor is connected with the ice making cylinder through the condenser, gas-liquid separator, dry filter, and thermal expansion valve, and the ice making cylinder and the compressor form a circuit through the gas-liquid separator, The ice outlet pipe is arranged on one side of the ice making cylinder. The invention has the advantages of simple and compact structure, low heat resistance, superior heat exchange performance, high ice making efficiency and safe production process.

Owner:广州长璟科技开发有限公司

Sound insulation ventilating window

ActiveCN102116126BGuaranteed ventilation effectOvercoming Difficult-to-Block Low-Frequency NoiseVentilation arrangementNoise insulation doors/windowsLow frequency bandElectric machinery

The invention discloses a sound insulation ventilating window. The sound insulation ventilating window comprises an external window (2) with an air inlet (1), an internal window (4) with an air outlet (3), and a muffling cavity body (5) which is positioned between the internal window (4) and the external window (2), and connected with the external window (2) and the internal window (4); louver muffling sheets (6) controlled by a motor are suspended inside the muffling cavity body (5); and the louver muffling sheets (6) are rotated or gathered under the action of the motor. The sound insulation ventilating window can stop low frequency band noises of which the frequency is lower than 500Hz so as to further weaken the noises from the outside of the window to the inside of the window; meanwhile, the ventilating performance of the sound insulation ventilating window can be guaranteed; the daylighting effect of the sound insulation ventilating window is better, the requirements of indoor noise reduction, heat insulation and daylighting of people can be met, and the structure is simple.

Owner:ZISEN ENVIRONMENTAL TECHNOLOGY CO LTD

Heat transfer pipe with radiating fin parts

InactiveCN1590946AAvoid distortionImprove heat transfer performancePipe heating/coolingCoatingsMetallic materialsResin coating

It is an object of this invention to obtain a heat conduction pipe superior in corrosion resistance as well as heat exchange efficiency between fluid flowing respectively through an inside and an outside for great heat radiation property and endothermic characteristics. It is also object of this invention to form the heat conduction pipe superior in the corrosion resistance as well as the heat radiation property and endothermic characteristics at inexpensive price. To achieve the above, at least single resin coating layer is formed on an outer circumferential surface of a metal pipe, a metal fin member is spirally wound on an outer circumferential surface of the resin coating layer with a side end surface the metal fin member in contact. The winding contact portion is made to encroach a surface of the resin coating layer to form the heat conduction pipe.

Owner:USUI CO LTD

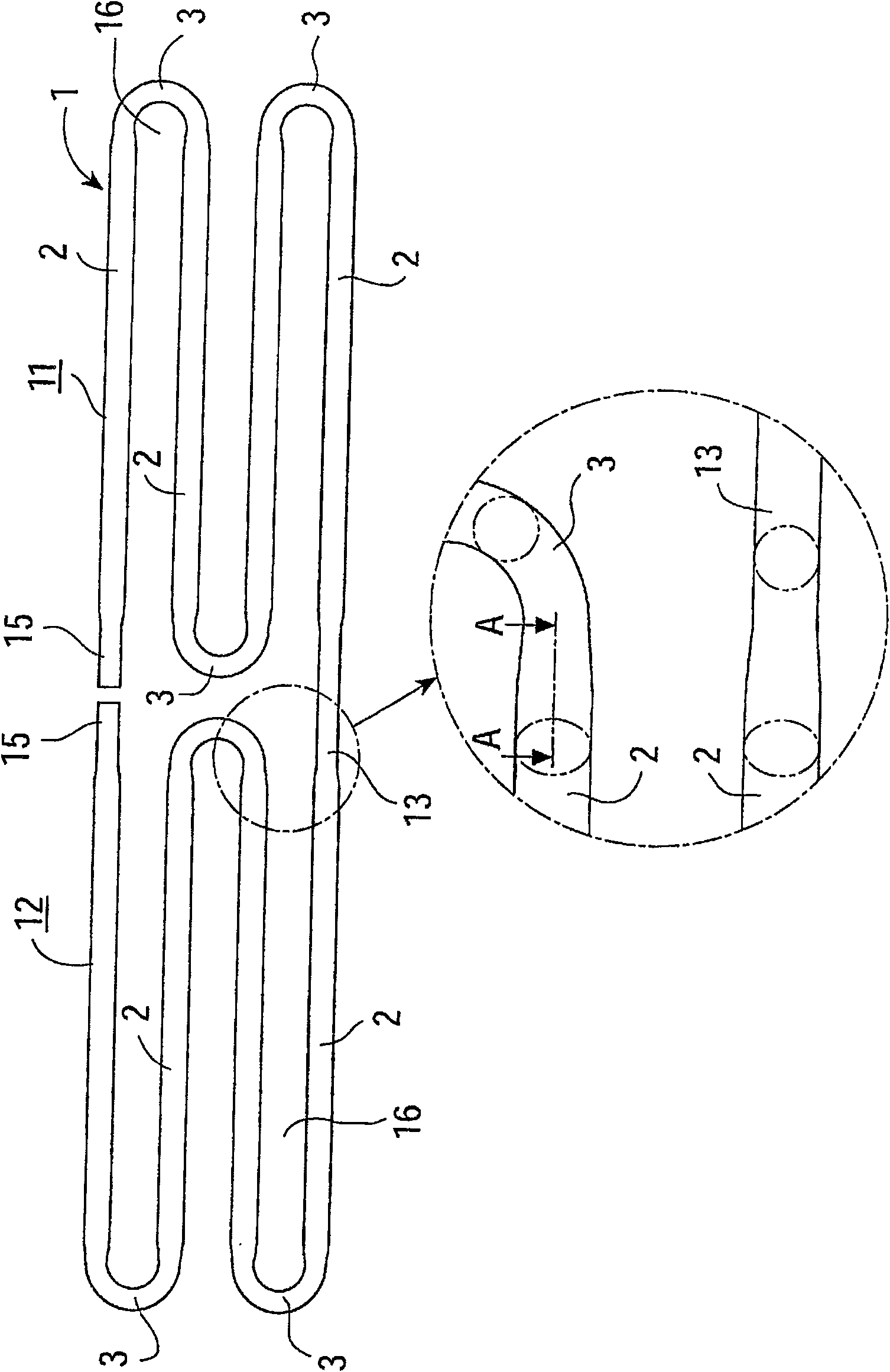

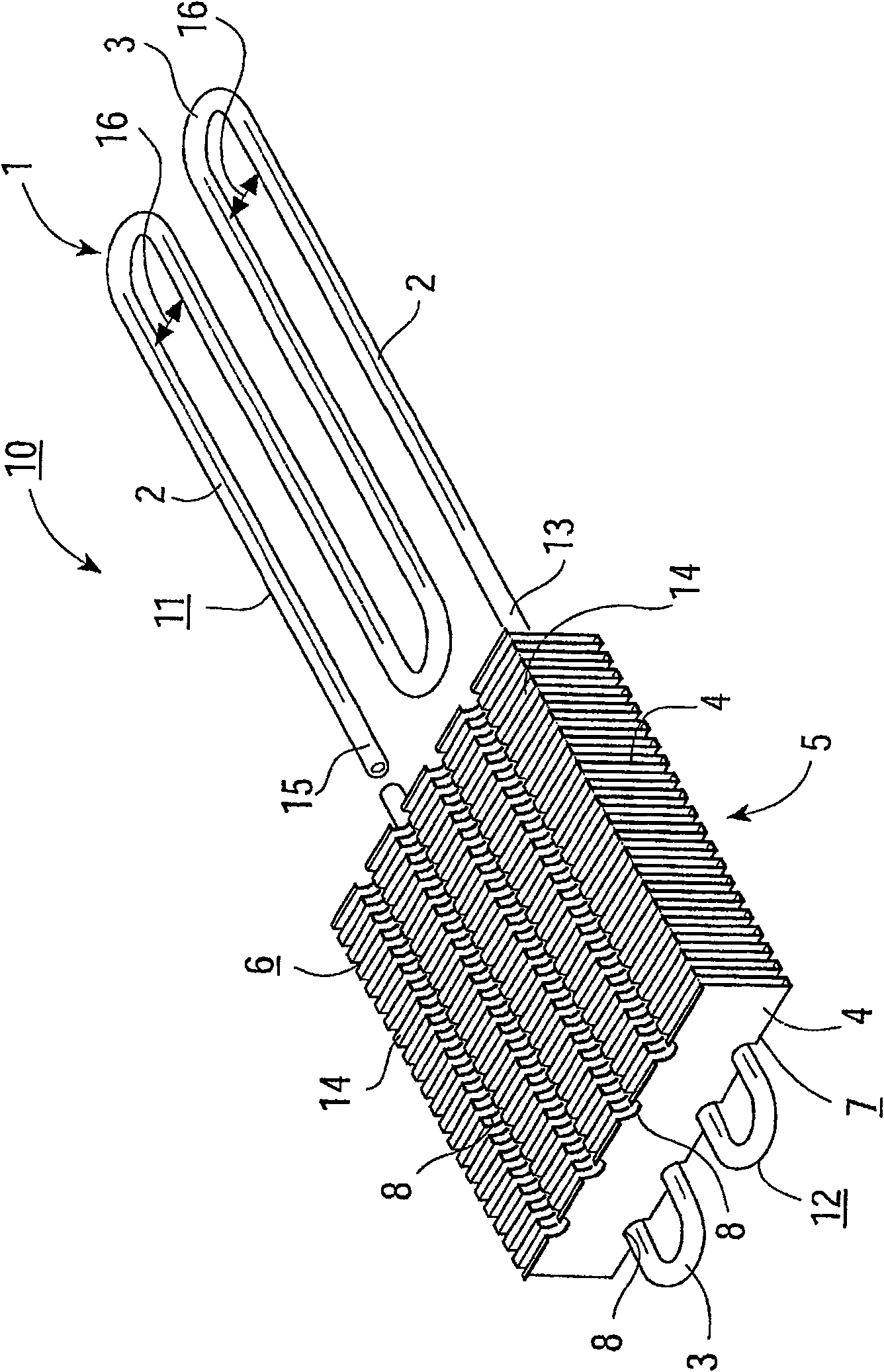

Heat exchanger

ActiveCN100541104CImprove heat exchange performanceIncrease contact frequencyEvaporators/condensersStationary conduit assembliesManufacturing technologyStraight tube

The invention provides a heat exchanger, which is provided with a fin member, so that the thermal conductivity between the fin member and the main body of the serpentine tube is improved, and a heat exchanger with excellent heat exchange performance can be obtained cheaply through simple manufacturing technology and process . In addition, a compact heat exchanger can be formed, and it can be installed in a narrow space, etc., and a product with a high degree of freedom of arrangement can be obtained. The fin member (5) has a plurality of fins (4) arranged in parallel, and a plurality of engagement grooves (8) are provided on opposite end surfaces (6) (7) of the fin member (5). Separate the opposing intervals (16), arrange the plurality of straight pipe parts (2) in parallel in the engaging groove (8) for disposing the fin member (5), and use the bent part (3 ) connect the plurality of straight pipe parts (2), separate the insertion gap (17) of the fin member (5), arrange a pair of serpentine parts (11), (12) opposite to each other, pass through the connecting pipe (13), One serpentine part (11) and the other serpentine part (12) are connected to form a serpentine pipe main body (1). In the insertion gap (17) between one meandering part (11) and the other meandering part (12) of the meandering pipe main body (1), a fin member (5) is inserted and arranged, and the fin member (5) In the engagement groove (8) of one end surface (6) of ), the straight pipe portion (2) of one serpentine part (11) is arranged, and in the engagement groove (8) of the other end surface (7), A straight pipe part (2) is arranged to fix the other side of the meandering part (12).

Owner:USUI KOKUSAI SANGYO KAISHA LTD

Sea-fresh water dual-purpose continuous ice-supply type ice maker

InactiveCN101251324ASimple structureCompact structureLighting and heating apparatusIce productionVapor–liquid separatorEngineering

The invention relates to an ice machine, in particular to a seawater / freshwater continuous ice-outlet type ice machine. The ice machine comprises a compressor, an ice barrel, an ice outlet pipe, a thermal expansion valve, a drier filter, a gas-liquid separator and a condenser, wherein, an ice outlet opening of the ice outlet pipe is provided with an ice knife with an ice scoop; the compressor and the ice barrel are respectively driven by a motor; the compressor is connected with the ice barrel via the condenser, the gas-liquid separator, the drier filter and the thermal expansion valve; the ice barrel forms a loop together with the compressor via the gas-liquid separator; the ice outlet pipe is arranged on one side of the ice barrel. The ice machine has the advantages of compact structure, low thermal resistance, good heat exchanging performance, high ice making efficiency and safe course of production.

Owner:广州长璟科技开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com