Pulse tube refrigerator

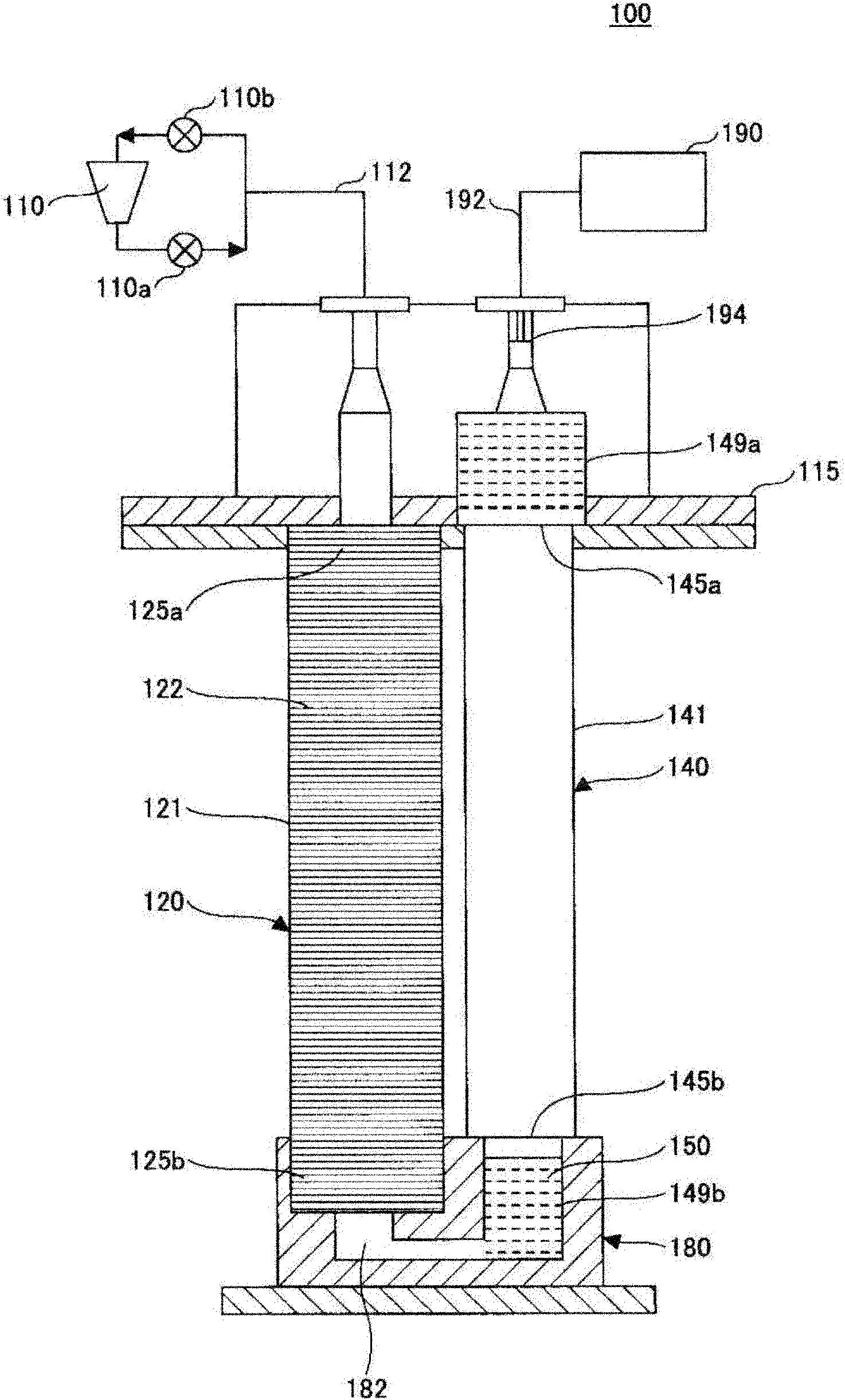

A pulse tube and refrigerator technology, which is applied to refrigerators, gas cycle refrigerators, compressors, etc., can solve the problems of large changes in thermal resistance, deviation of heat exchange performance, and degradation of heat exchange performance of pulse tube refrigerators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

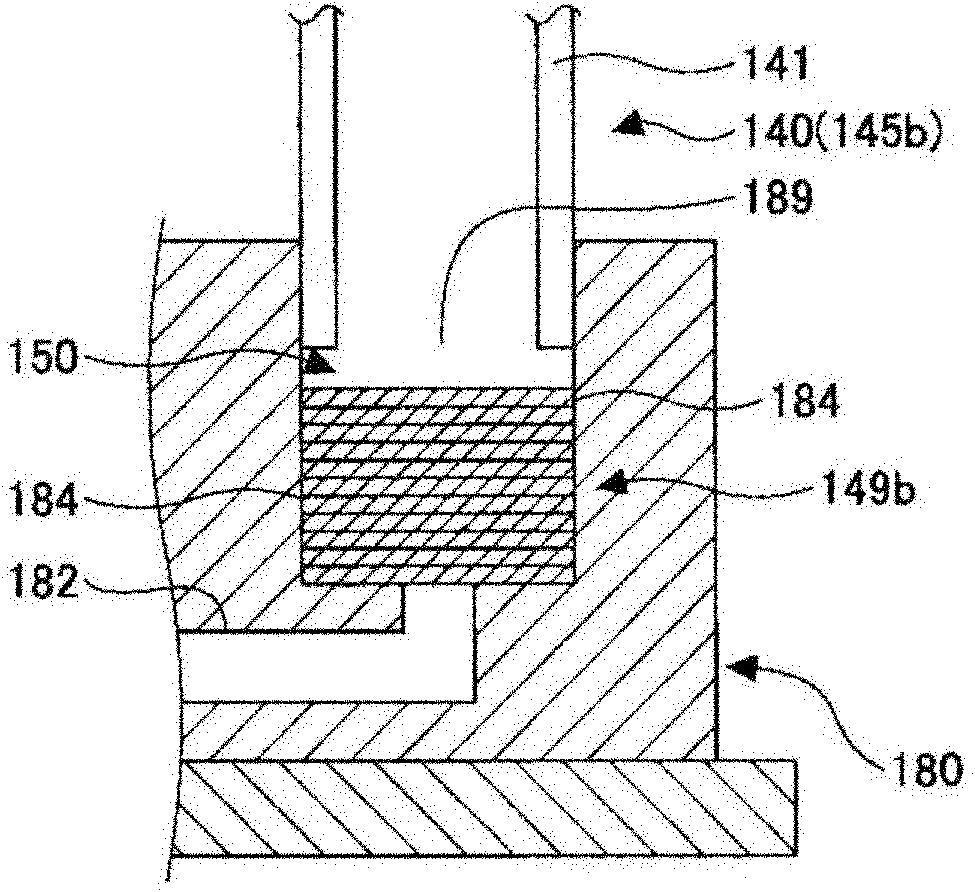

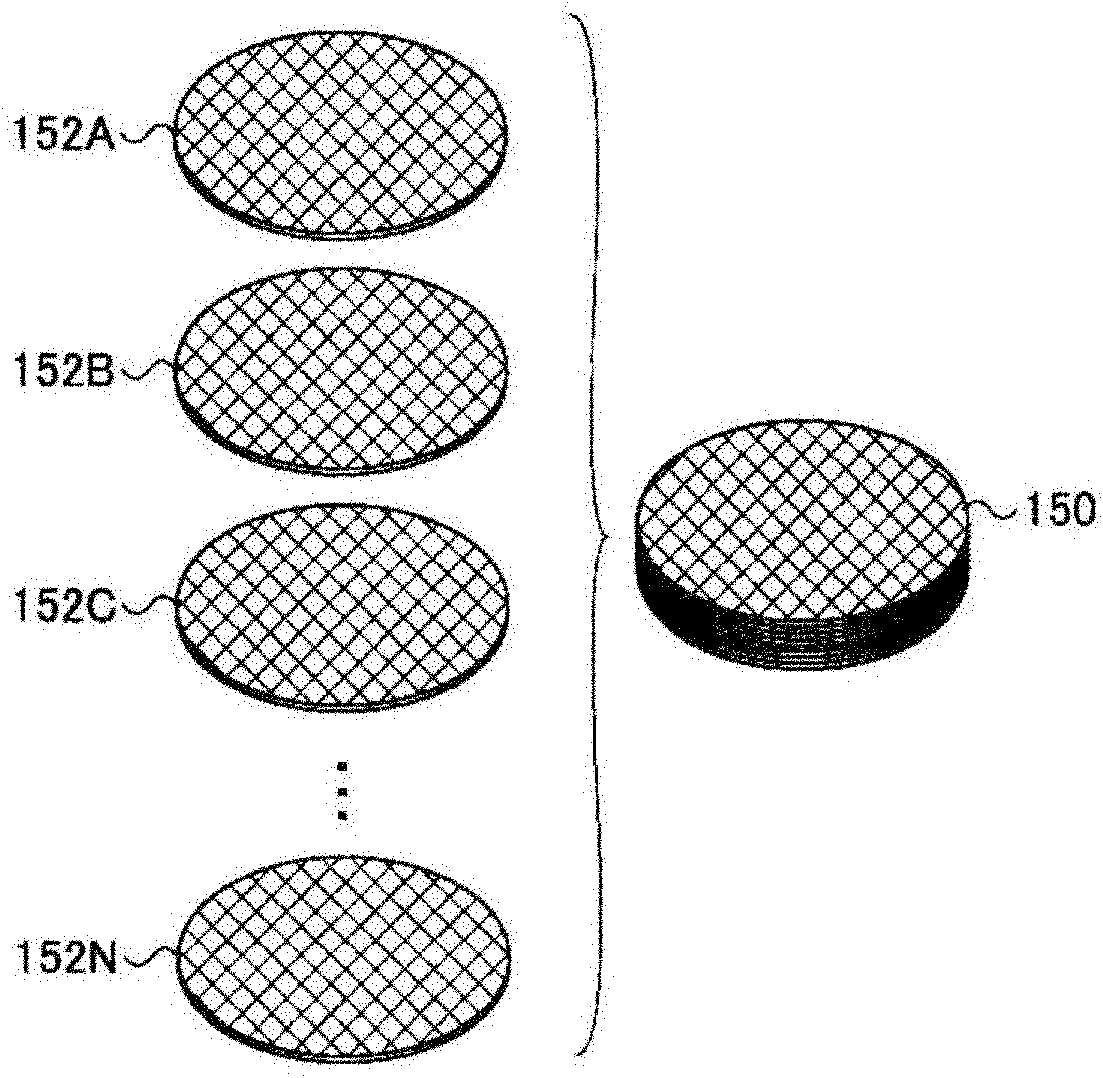

[0111] In fact, in the tank of the cooling table, under normal conditions, the above-mentioned figure 2 A pulse tube refrigerator with heat exchanger 149b is shown to measure the temperature of the cooling stage. The stack of heat exchangers 149b uses Figure 5 Laminate 150A of the structure shown. As the uppermost wire mesh 153A, a mesh made of SUS304 of #250 was used. In addition, copper wire mesh with mesh #80 is used for the wire mesh after the second grade.

[0112] As a result of the measurement, the temperature of the cooling stage was about 36.4K (Kelvin). On the other hand, in a pulse tube refrigerator equipped with a conventional heat exchanger (having a #80 copper laminated body with a mesh of #80, and the side portion of the laminated body is not diffusely bonded to the inner wall of the tank) in the tank of the cooling stage, the The same measurement was carried out, and the temperature of the cooling stage was about 40.2K (Kelvin).

[0113] From this result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com