Heat transfer pipe with radiating fin parts

一种散热片、传热管的技术,应用在传热管领域,能够解决不能很好地实现散热片部件金属管的外周面紧密接合、不能获得金属管和散热片部件传热性、散热特性和吸热特性有问题等问题,达到良好热交换性能、保持热交换性能、提高耐冲击性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

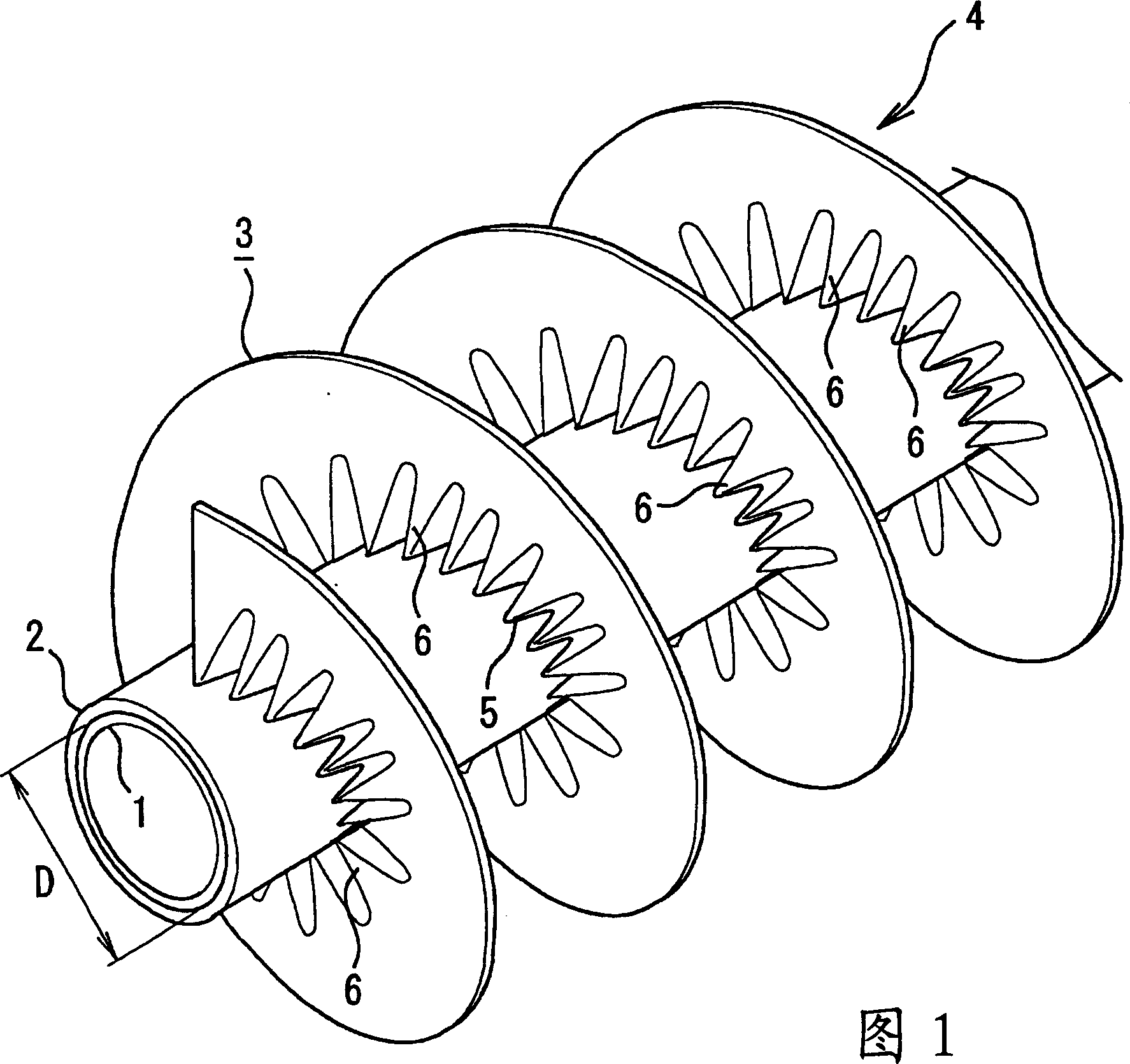

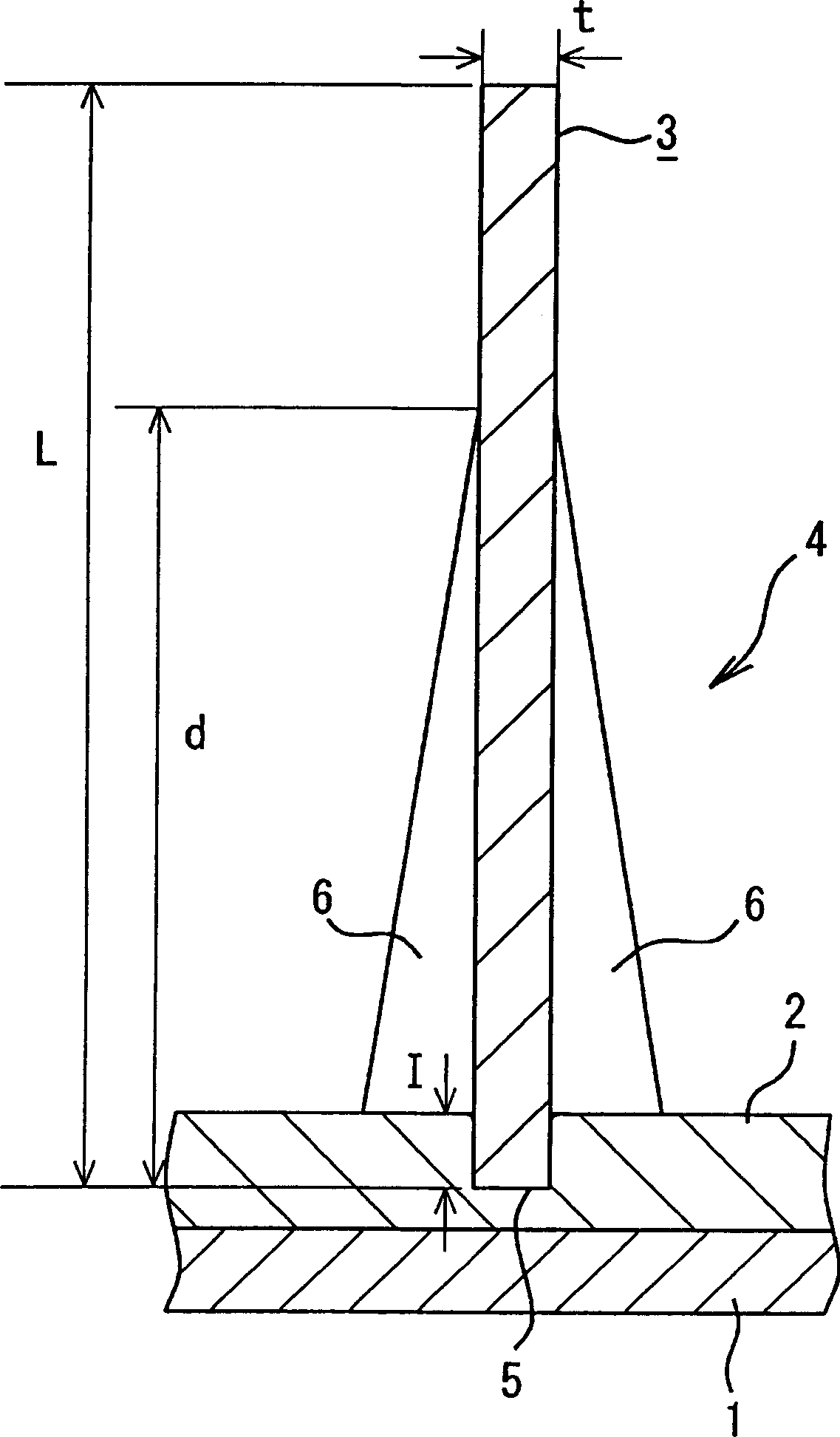

[0062] First, let’s describe Figures 1 to 1 in detail. Figure 4 The shown embodiment 1, 1 represents a metal pipe, using a single-layer wound steel pipe with an outer diameter of 8mm, a wall thickness of 0.7mm, and no copper plating on the outer surface, a composite wound steel pipe, an aluminum pipe, etc. with a copper outer surface. This metal pipe 1 can obtain corrosion resistance by setting the resin film layer 2 as described later, so it can be used directly, but in this embodiment, an alternative corrosion-resistant coating ( not shown), it can exhibit good corrosion resistance even in harsh corrosive environments.

[0063] The above-mentioned anti-corrosion coating can be a layer of coatings such as zinc, tin, tin-zinc alloy, nickel, zinc-nickel alloy, zinc-aluminum alloy, etc., and can also be nickel-plated on the outer surface of the metal pipe 1). The outer peripheral surface is plated with zinc-nickel alloy to form a multi-layer coating such as a two-layer structu...

Embodiment 2

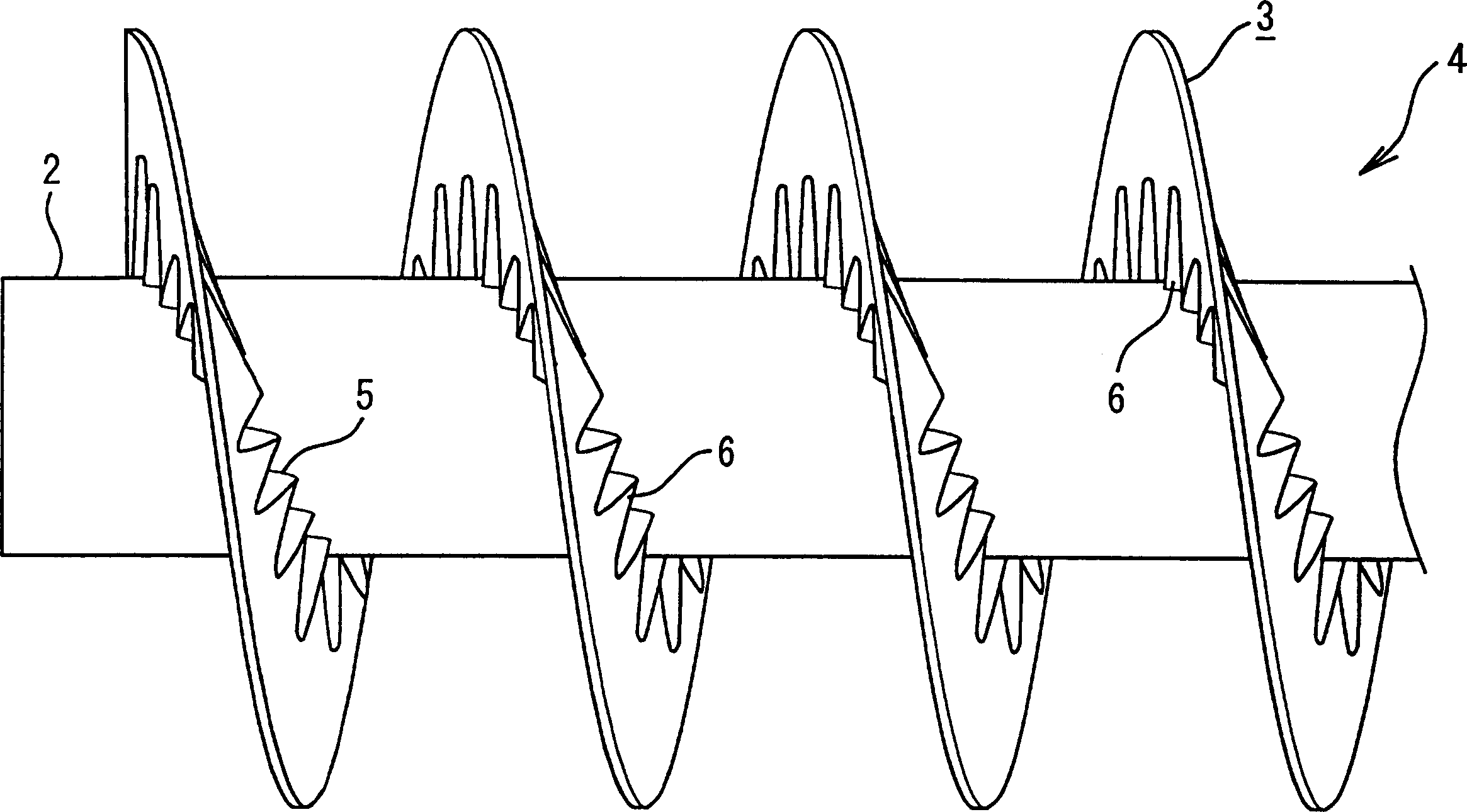

[0081] In the above-mentioned Embodiment 1, before the fin member 3 provided with the corrugated corrugations 6 covering the entire width is prepared to be installed on the metal tube 1, the fin member 3 is wound in a helical shape on the outer periphery of the metal tube 1 easily. , and the diameter of the inner peripheral side is reduced to increase the undulation of the corrugated pleats 6, and the corrugated pleats 6 on the outer peripheral side are stretched and formed into a flat shape, and the fin member 3 is curved into an arc shape. In contrast, in Example 2, as Figure 6 As shown, the heat sink member 3 provided with a plurality of corrugated corrugations 6 over the entire width is wound on the metal tube 1 in a spiral shape, while the inner peripheral side is reduced in diameter and the undulations of the corrugated corrugations 6 are increased. on the peripheral side as Figure 6 As shown, the corrugated pleats 6 are not stretched into a flat shape, but only the p...

Embodiment 3

[0086] exist Figure 7 In Example 3 shown, the cationic electrodeposition coating is applied to the entire outer surface of the heat transfer tube 4 . In the process of making the heat transfer tube 4, first, the outer circumference of the iron metal tube 1 is electroplated with zinc series to improve corrosion resistance, and after the epoxy resin as a primer is provided on the outer circumference, the outer circumference of the epoxy resin is PA is extruded to form the resin coating layer 2 . Then, on the outer periphery of the metal pipe 1 provided with the resin film layer 2, the iron fin member 3, which is electroplated with zinc to improve corrosion resistance, is provided in a spiral shape to form the heat transfer pipe 4. The helical configuration of the heat sink component 3 can be Figure 4 When the shown fin member 3 provided with corrugated corrugations 6 covering the entire width is wound on the metal tube 1, as Figure 5 As shown in Example 1, it is arranged w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com