Heat exchanger

A technology of heat exchangers and fins, applied in the field of heat exchangers, can solve the problems of increased air flow resistance and reduced heat exchange performance, and achieve the effects of improved fin efficiency, easy manufacturing and management, and prevention of hole clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Next, embodiments of the present invention will be described based on the drawings.

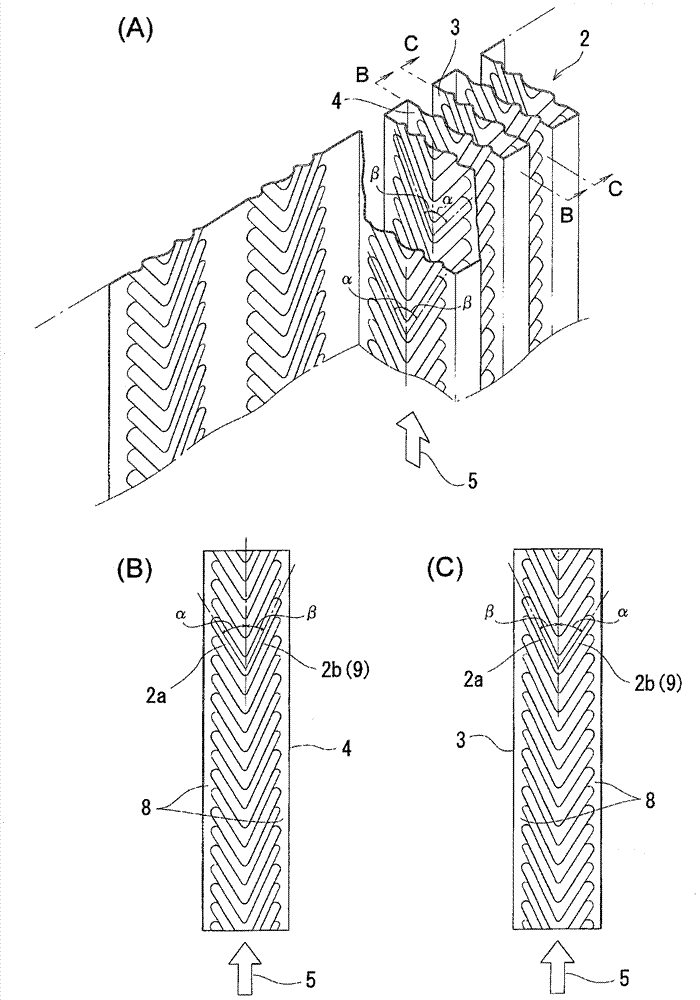

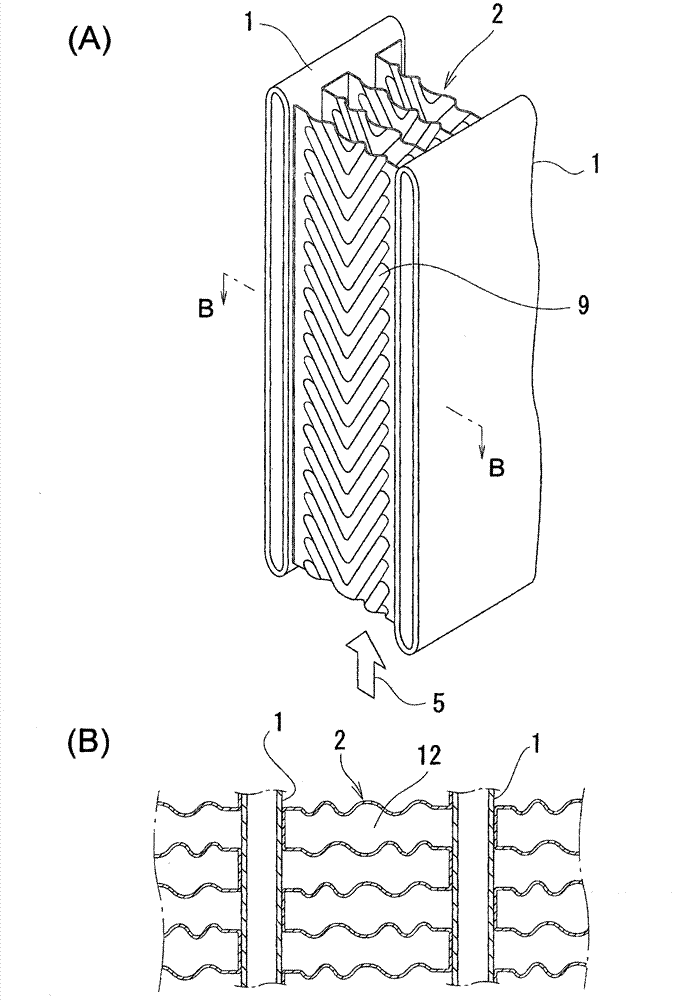

[0051] figure 1 It is explanatory drawing of the corrugated fin of this invention, (A) is its perspective schematic view, (B) is the top view of the 1st plane 4 of (A), (C) is the top view of the 2nd plane 3 of (A). in addition, figure 2 (A) is a perspective view of main parts of the heat exchanger, and (B) is a cross-sectional view thereof viewed along the direction of B-B.

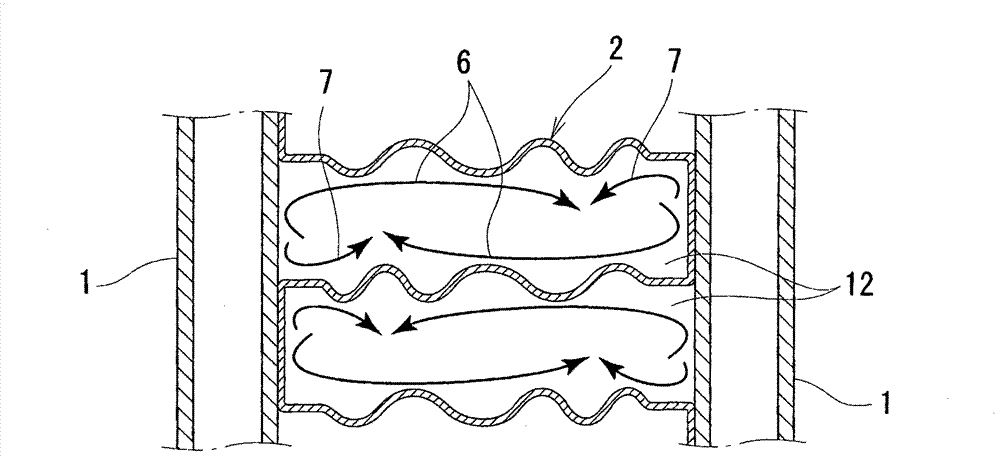

[0052] Such as figure 2 As shown in (A), in the heat exchanger of this example, corrugated fins 2 are fixed in contact with each other between a plurality of parallel flat tubes 1 . In this example, the entire fin 2 is bent into a rectangular wave shape, and the bent top and bottom of the fin 2 are soldered and fixed to the flat tube 1 . And, there is a flat first plane 4 and a second plane 3 facing it between the top and the valley, and on each of the planes 3, 4, there are a plurality of parallel planes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com