Ground source heat pump tube embedment method based on piling process

A technology of ground source heat pump and pile planting, which is applied to geothermal energy, heating devices, geothermal energy power generation, etc., can solve the problems of weak heat exchange performance, affecting the bearing capacity of pipe piles, and troublesome construction, so as to achieve good heat exchange performance and reduce The risk of breakage and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

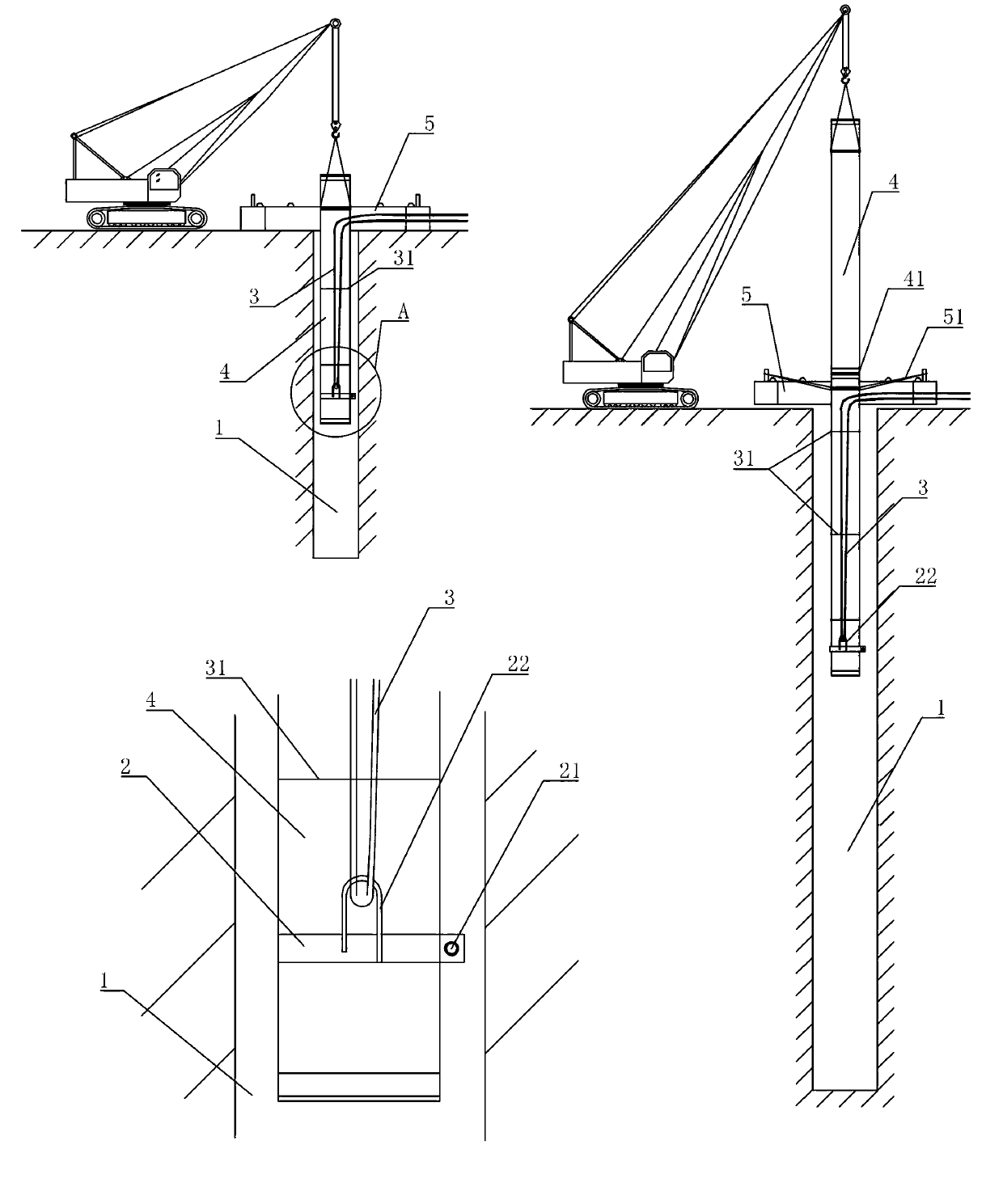

[0024] Embodiment 1: A ground source heat pump tube embedding method based on pile planting process, comprising the following steps:

[0025] 1): Use a special spiral drilling machine to drill into the soil to break the soil structure. After the soil is loosened, inject high-pressure water and use a special spiral drilling machine to stir the soil into mud. After the hole reaches the design depth Then inject the cement slurry and stir it with a special screw drilling machine, and after putting away the special screw drilling machine, a pile planting hole 1 is formed, and the inner diameter of the pile planting hole 1 is greater than the outer diameter of the pipe pile;

[0026] 2): Fix and install a steel ferrule around the outer surface of the pipe pile near the bottom. The steel ferrule is a ring-shaped steel plate 2, and the hook 22 is welded on the ring-shaped steel plate 2. The two ends of the ring-shaped steel plate 2 are screwed and fixed with bolts 21. The ring-shaped s...

Embodiment 2

[0034] Embodiment 2: The remaining parts are the same as Embodiment 1, the difference is that the joint joint 41 is a connection formed by mechanically fixing two adjacent unit pile sections 4 together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com