Methods, systems and applications for heat exchange

A technology for heat exchangers and heat exchange media, applied in the fields of heat exchange, systems and applications, can solve problems such as channel blockage, heat exchanger inoperability, increased flow resistance, etc., to increase heating rate, efficient productivity, The effect of shortening the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

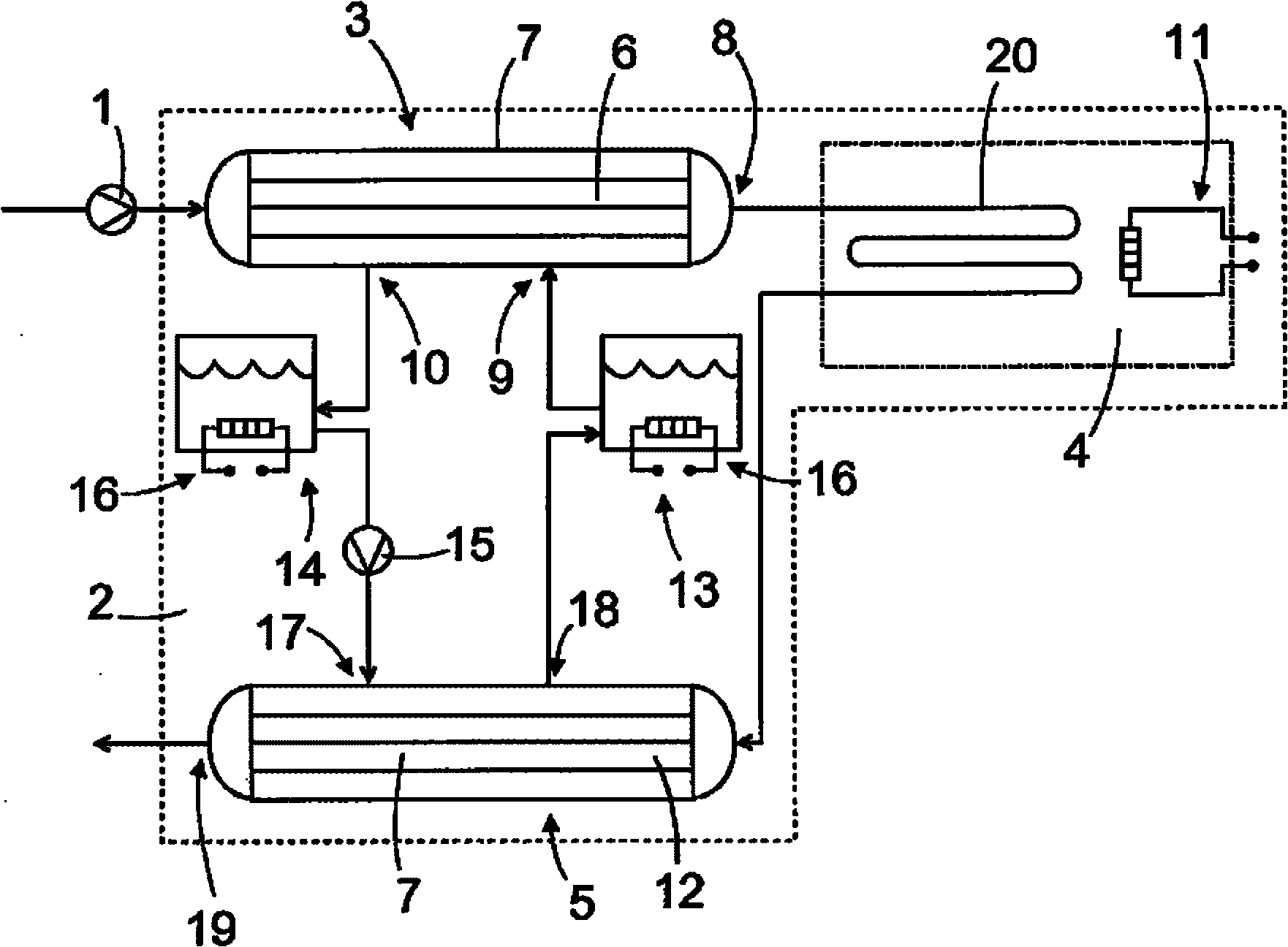

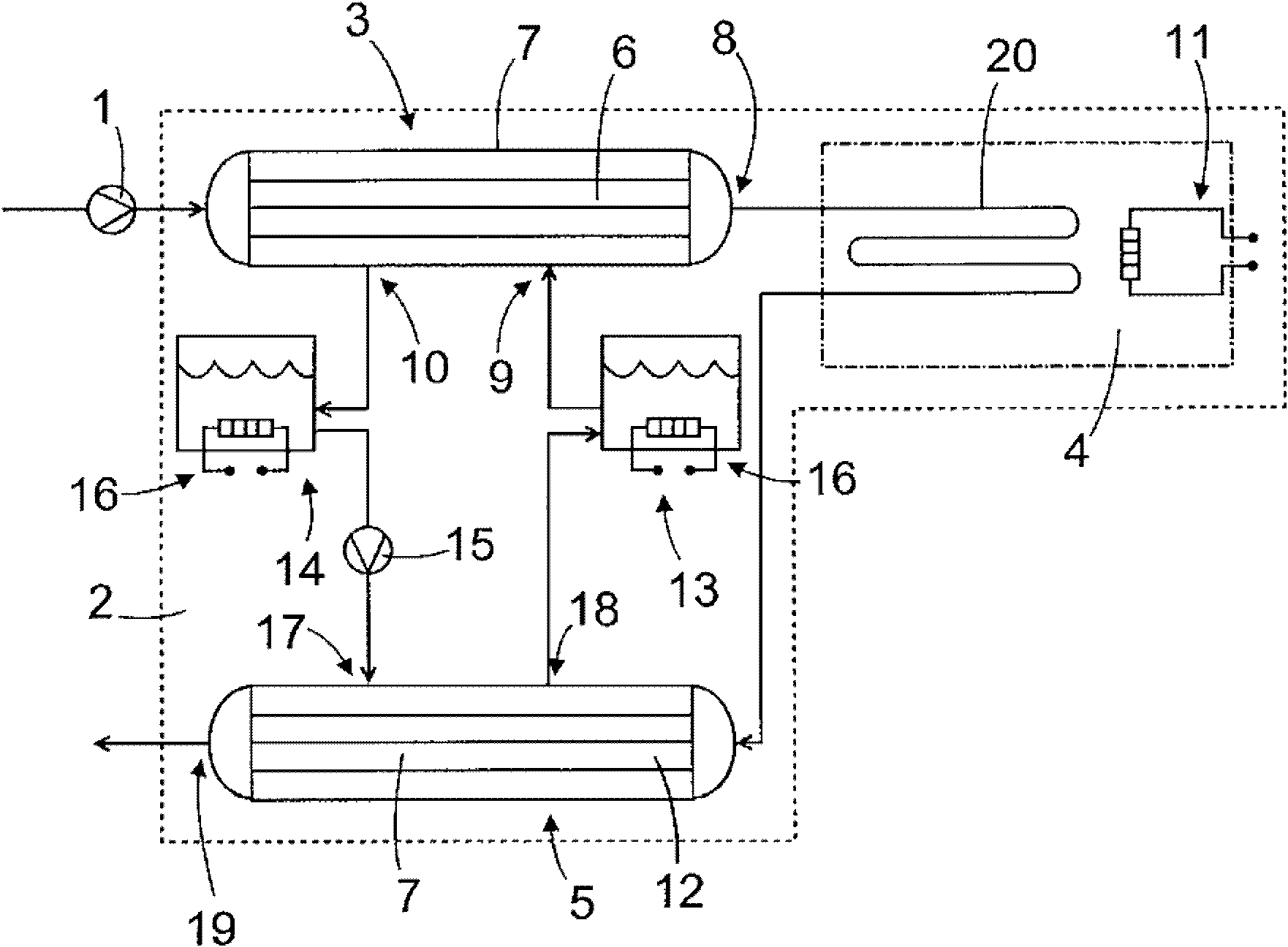

[0023] figure 1 is a schematic diagram showing the system and method of the present invention in the form of a flowchart.

[0024] First, biomass optionally mixed with additives and / or catalysts is pressurized to a predetermined pressure (for example in the range of 150-400 bar) by a pressurization device 1 and fed to a reactor system 2 . exist figure 1 The pressurizing device 1 shown in includes a pump. Pressurization to the desired pressure can be achieved in one step, eg by one pump, or can be achieved stepwise, eg by several pumps connected in series.

[0025] In another embodiment of the invention, there are two or even more biomass, additive and / or catalyst streams, which are fed to the reactor system 2 separately. The streams are mixed in the reactor system 2 and form a reaction mixture.

[0026] Biomass typically contains at least 70% by weight (weight percent) water. The water may preferably be predominantly moisture, ie water already present in the biomass. Mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com