Fin tube heat exchanger

A finned tube and fin technology, applied in the field of heat exchangers, can solve problems such as short die life, insufficient heat exchange performance, and blocked airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Detailed description of the preferred embodiment

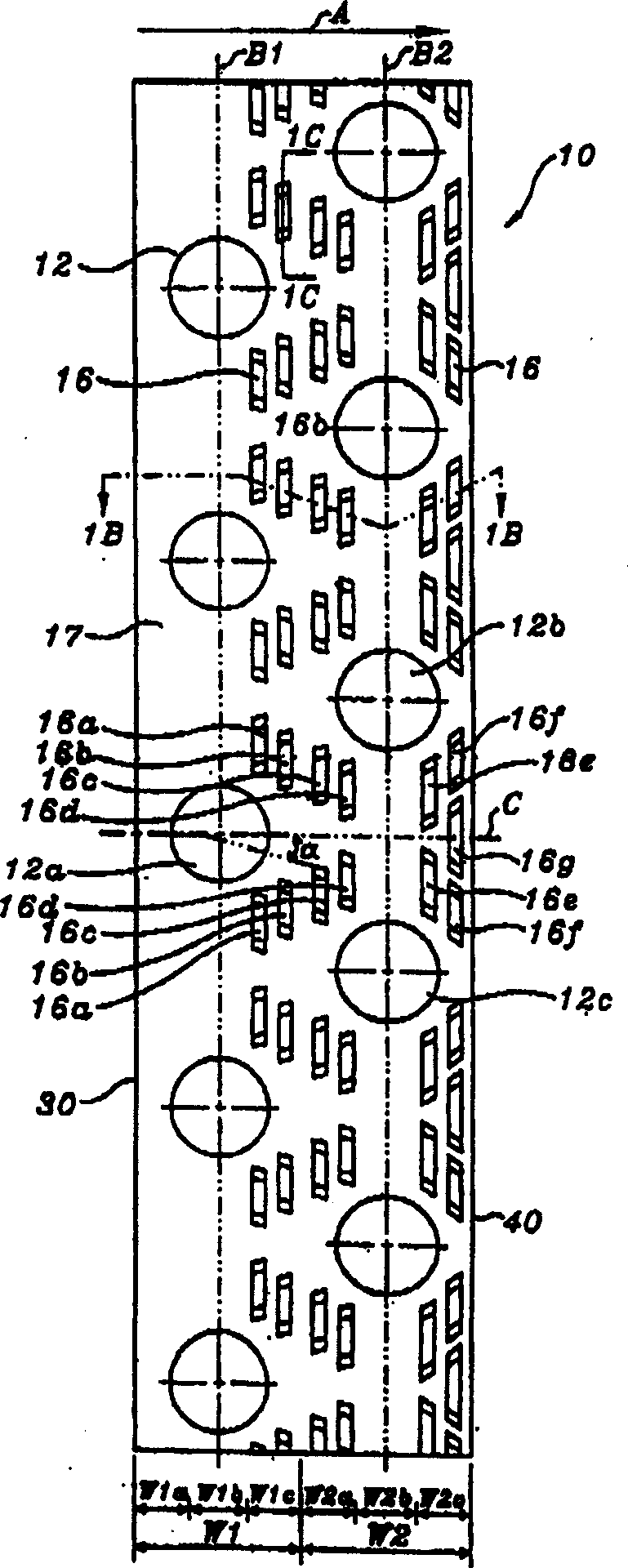

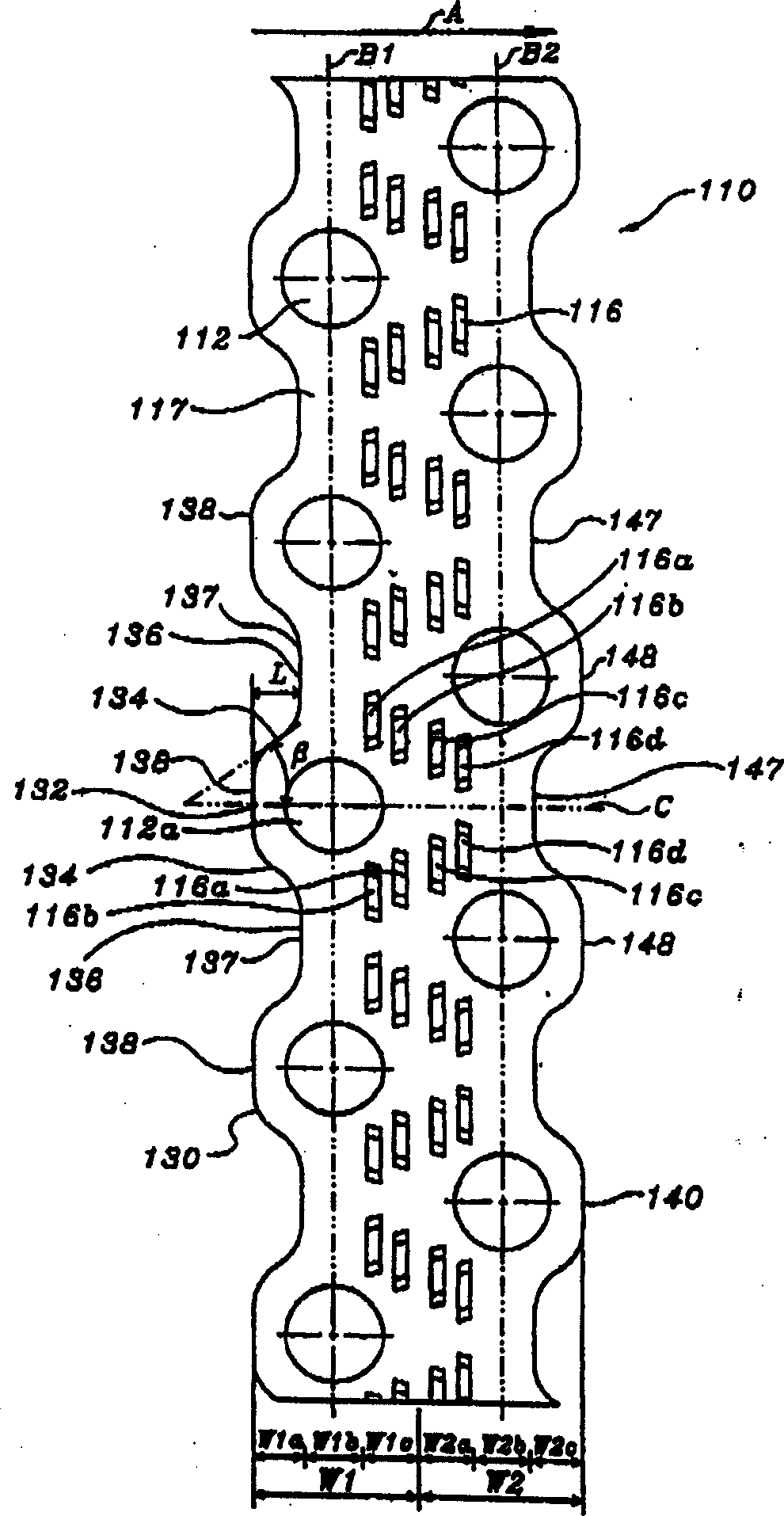

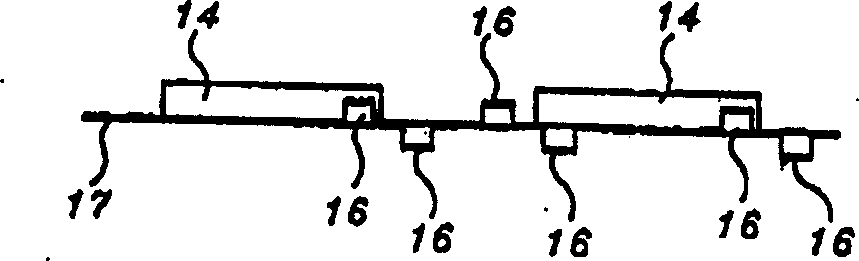

[0023] refer to Figure 1A-Figure 1C , The finned tube heat exchanger according to the first embodiment of the present invention has a plurality of thin plate-shaped aluminum fin members 10 . The fin members 10 are spaced at regular intervals and parallel to each other. Two rows B1 and B2 of a plurality of through holes 12 regularly spaced apart are formed in each plate-shaped fin member 10 along its length. A heat exchange tube is inserted into each through hole 12 . The through-holes 12 of the rear row B2 are offset in the airflow direction A from the through-holes 12 of the front row B1 and are located therebetween. Preferably, each through-hole 12 of the rear row B2 is arranged on a direction line passing through the middle between adjacent through-holes of the front row B1. An annular fin ring 14 is integrally formed on the fin member around each through hole 12 so that heat exchange between the tubes and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com