Fluoroplastic waste heat recycling and ultra-low emission integrated device

A technology of waste heat recovery and fluoroplastics, applied in waste heat treatment, greenhouse gas reduction, lighting and heating equipment, etc., can solve the problems of ignoring heat energy recovery and inability to realize heat energy recovery, so as to reduce water consumption, good waste heat recovery performance, and avoid The effect of shaking deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

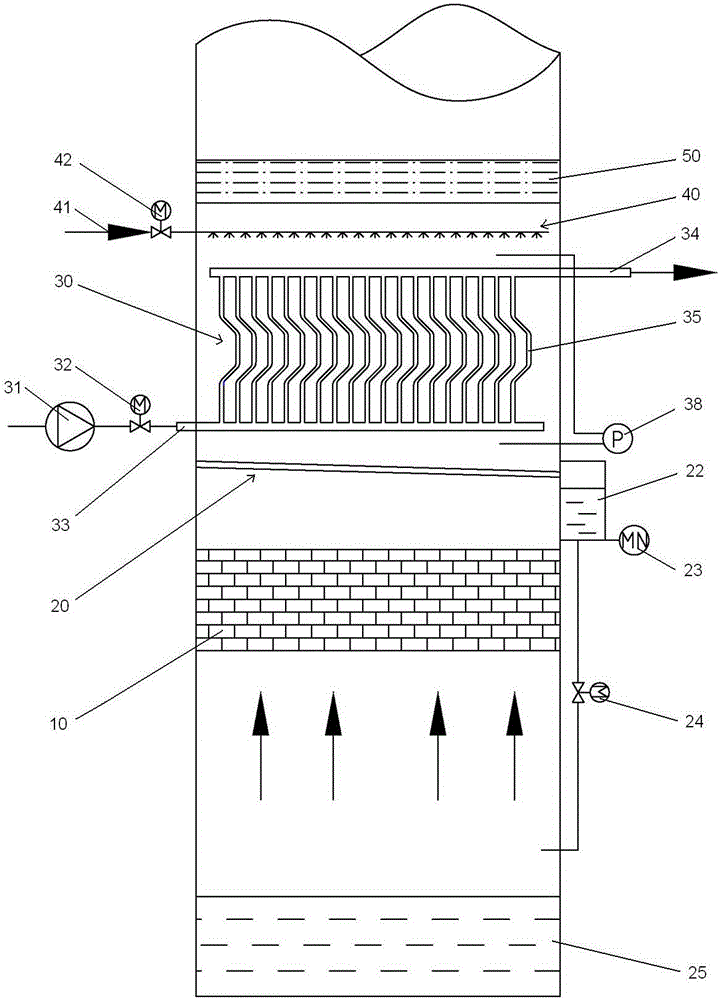

[0029] Such as figure 1 As shown, a fluoroplastic waste heat recovery and ultra-low emission integrated device is located above the catalytic reaction zone 10 in the desulfurization tower and below the demister 50, including a heat exchanger 30, a water flushing assembly 40, and a water collection assembly 20 , the water flushing assembly 30 and the water collecting assembly 20 are respectively located above and below the heat exchanger 30 .

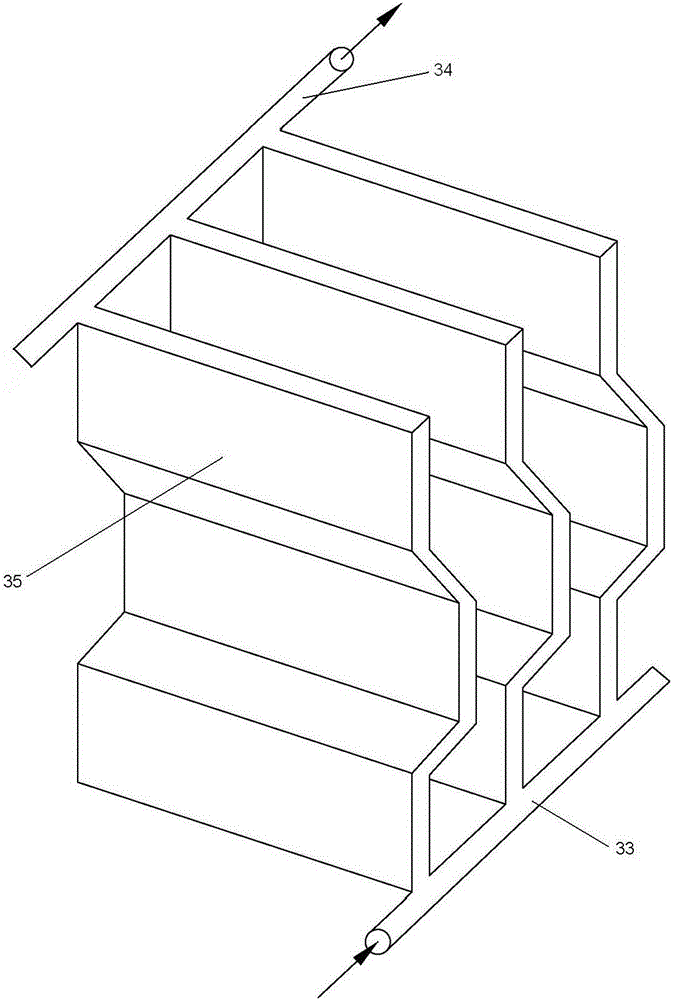

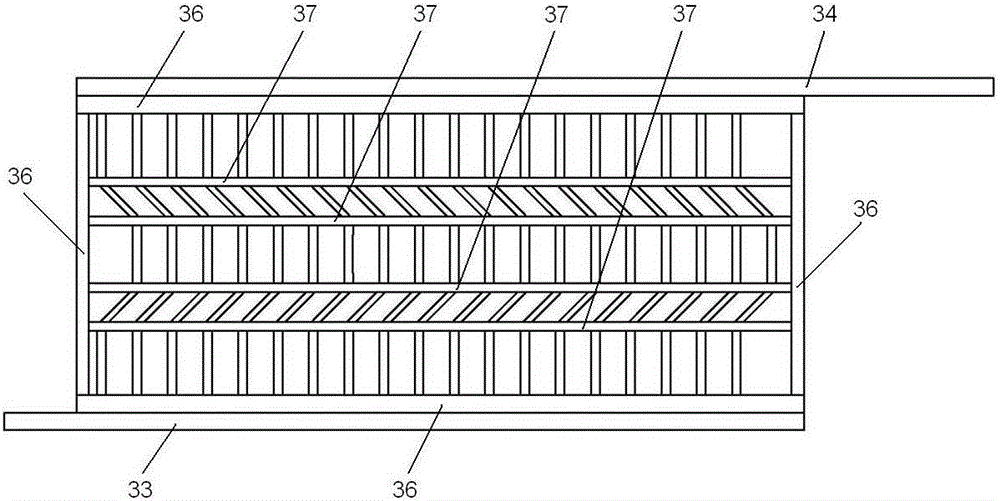

[0030] The heat exchanger 30 is a main component for realizing functions such as waste heat exchange of flue gas, dust collection, acid dew condensation, and demisting. The heat exchanger 30 is provided with a water inlet 33 and a water outlet 34, wherein the water inlet 33 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com