Patents

Literature

48results about How to "Good recovery of waste heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

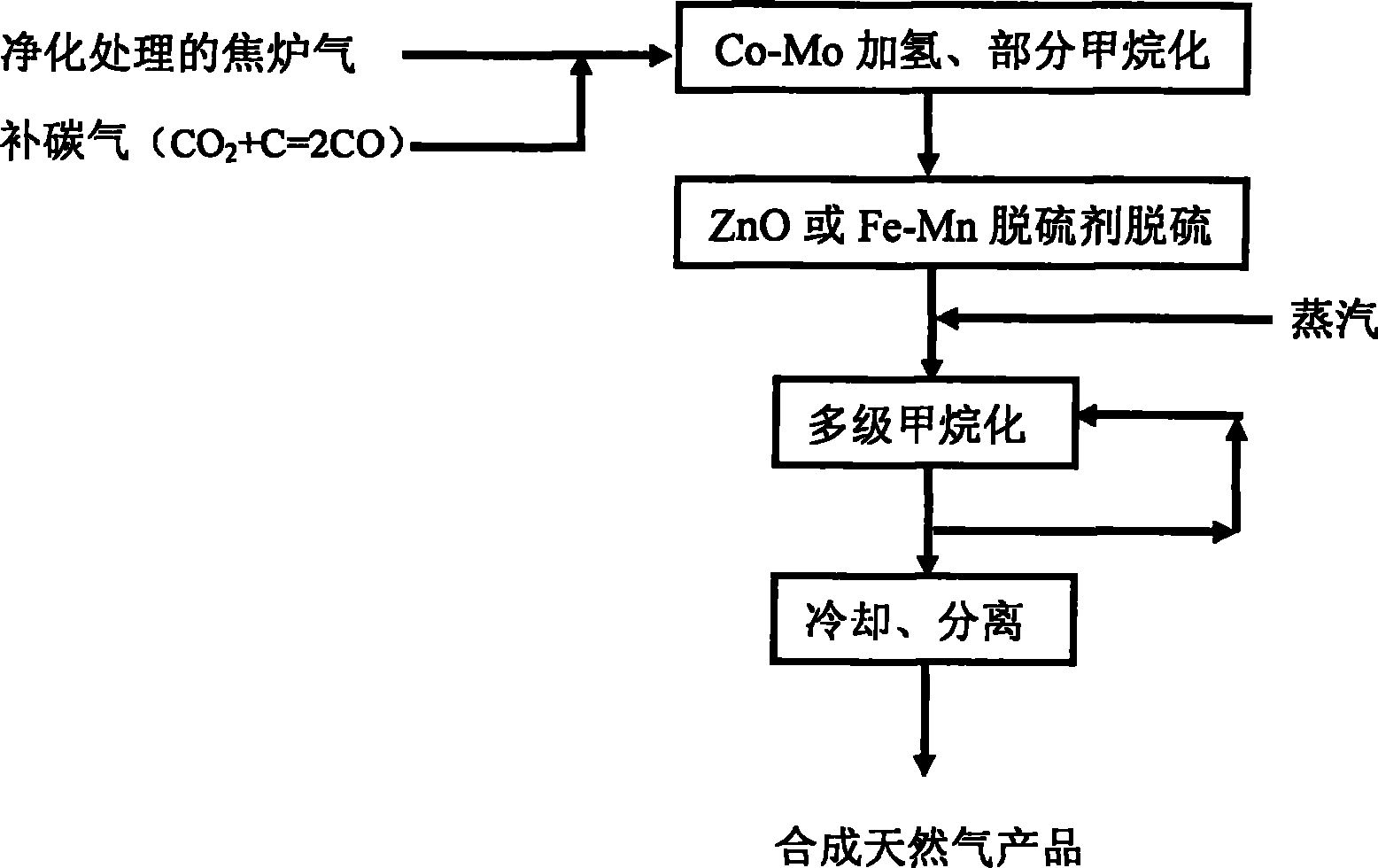

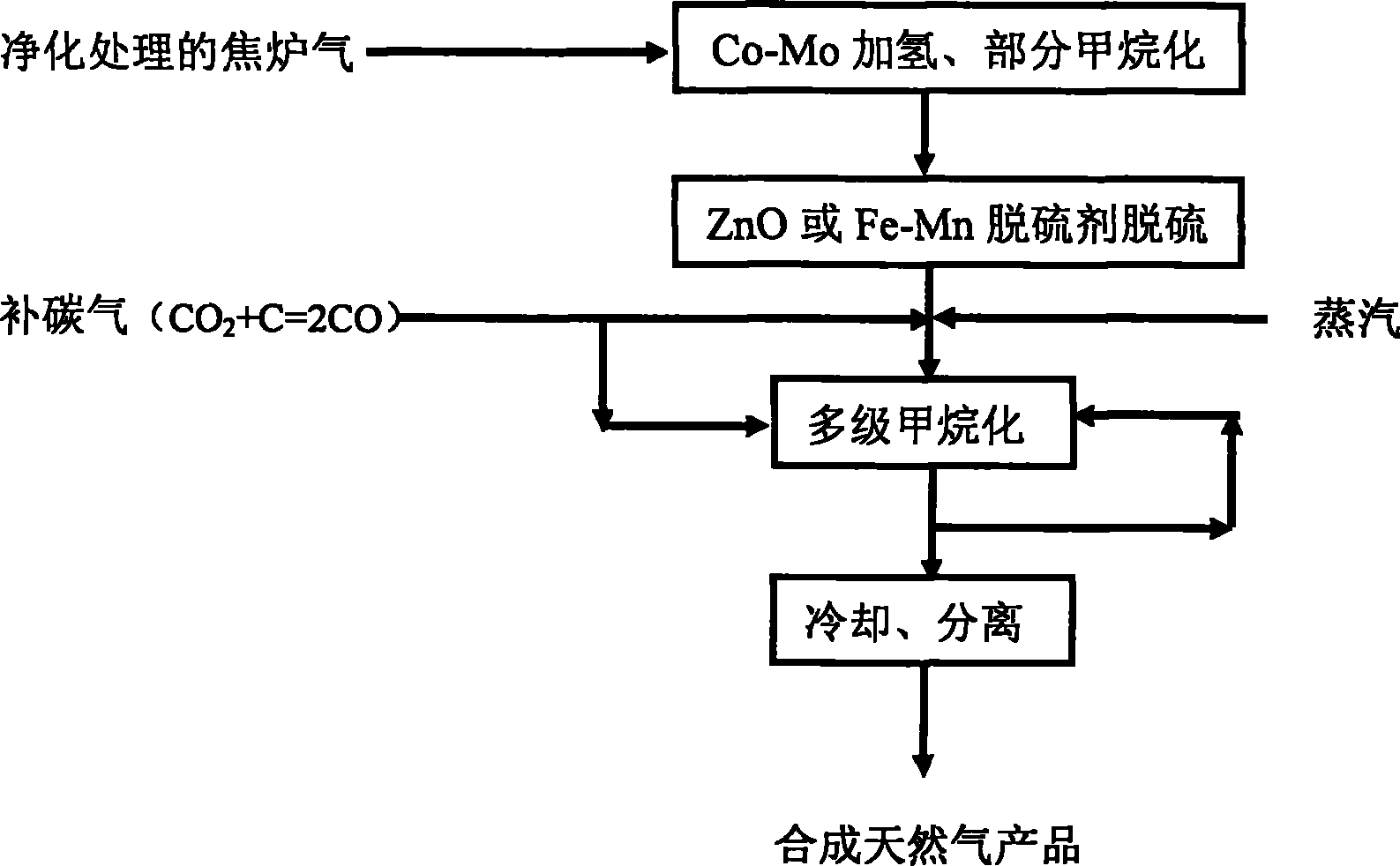

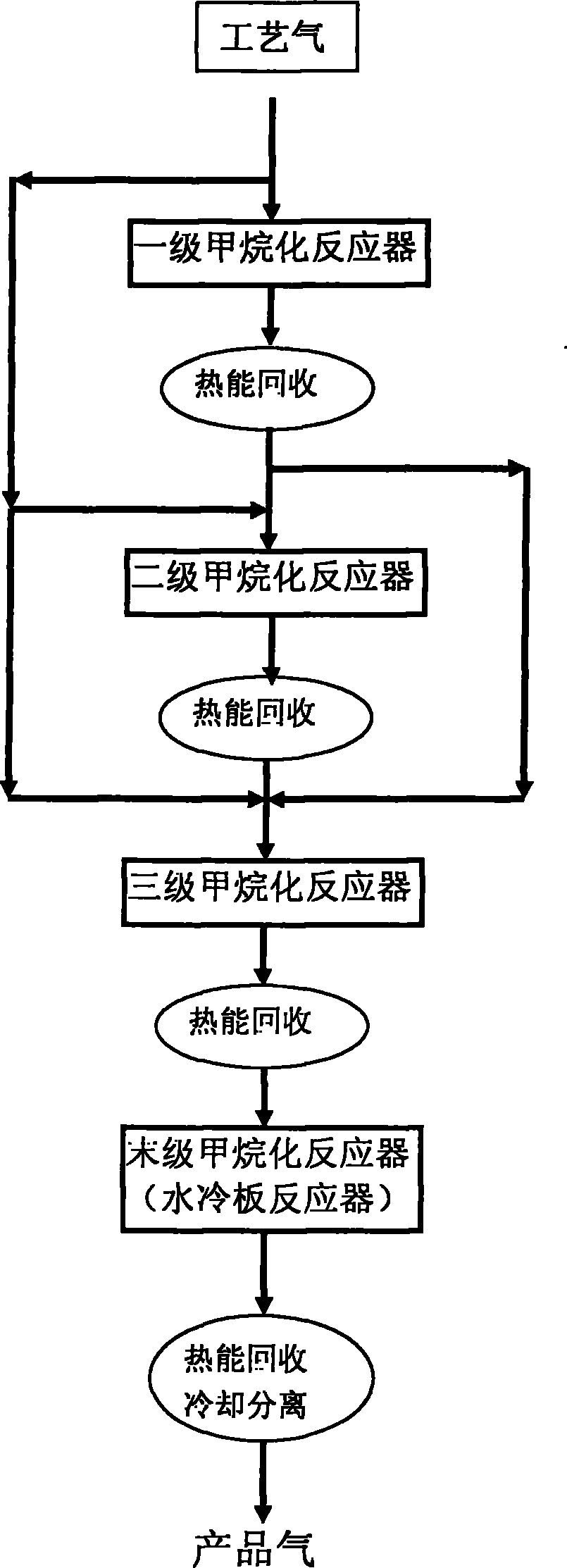

Novel process for making synthetic natural gas by using coke-oven gas

ActiveCN101818087APrevent sulfur poisoningGood recovery of waste heatGaseous fuelsChemistryCoke oven gas

The invention belongs to the field of the comprehensive utilization of coke-oven gas, and discloses a novel process for making synthetic natural gas by using the coke-oven gas. The qualified synthetic natural gas product is produced by the process comprising the steps of hydrodesulfurization, carbon compensation, multi-level methanation, cooling, separation and the like. The process can effectively prevent the temperature runaway phenomenon of a methanation reactor, can reasonably distribute the load of the methanation reactor, improves the conversion rate of CO and CO2, and provides a new method for making the synthetic natural gas by using the coke-oven gas.

Owner:NANJING GOODCHINA CHEM TECH

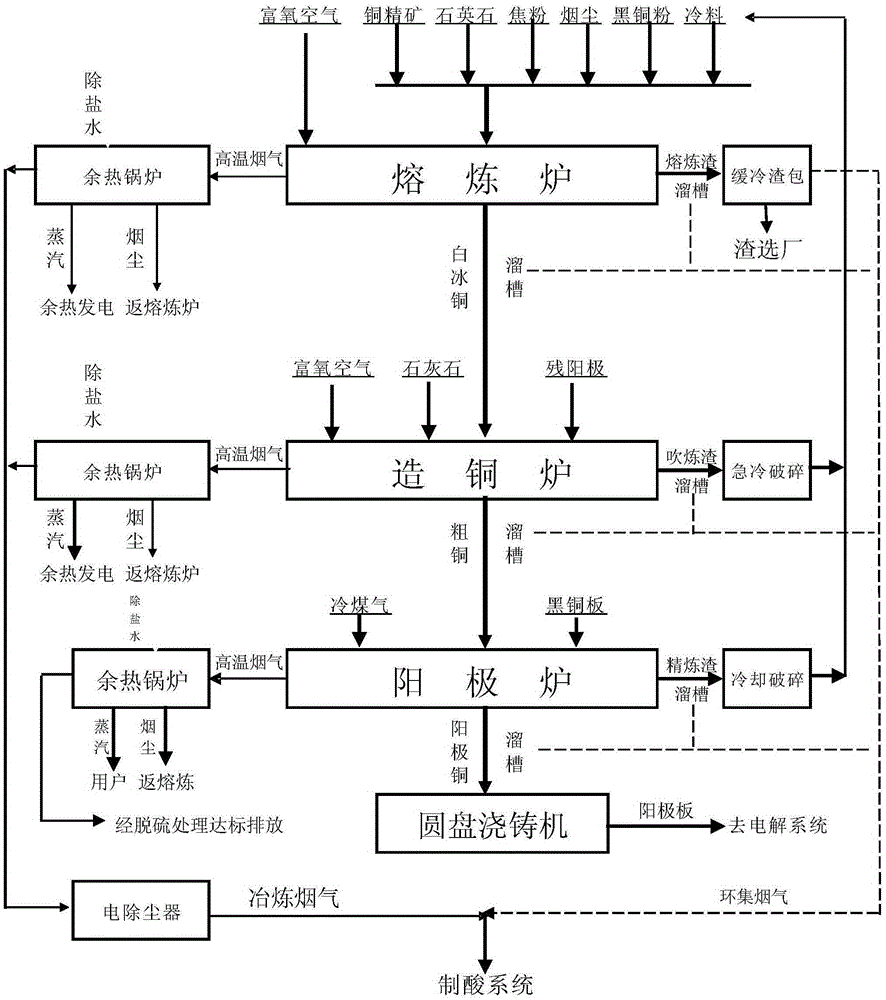

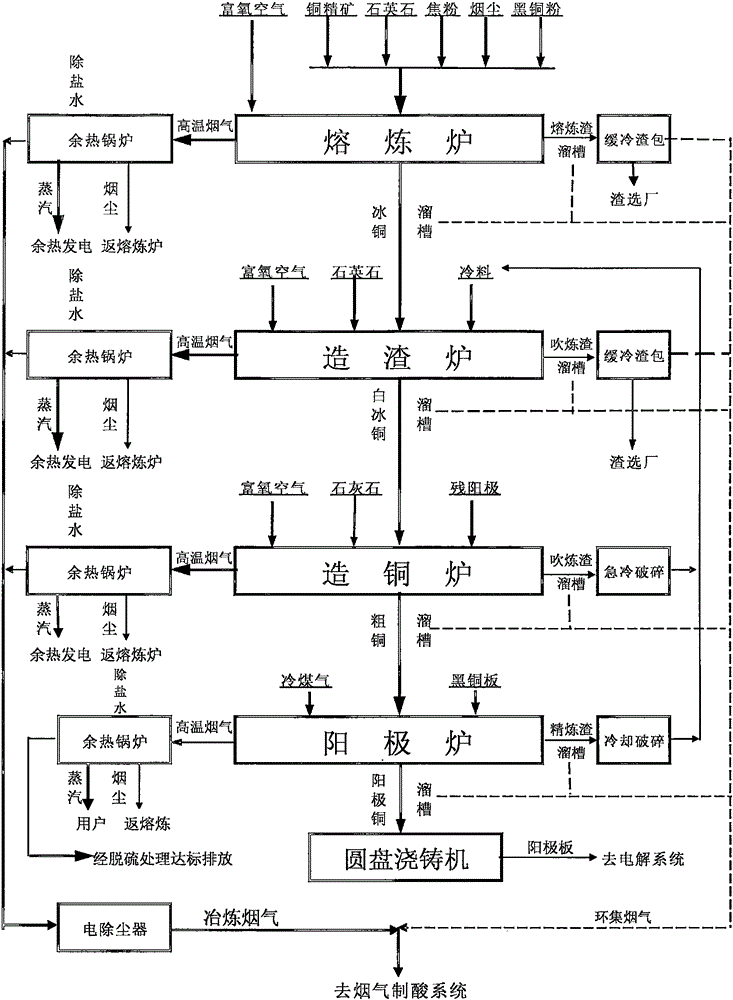

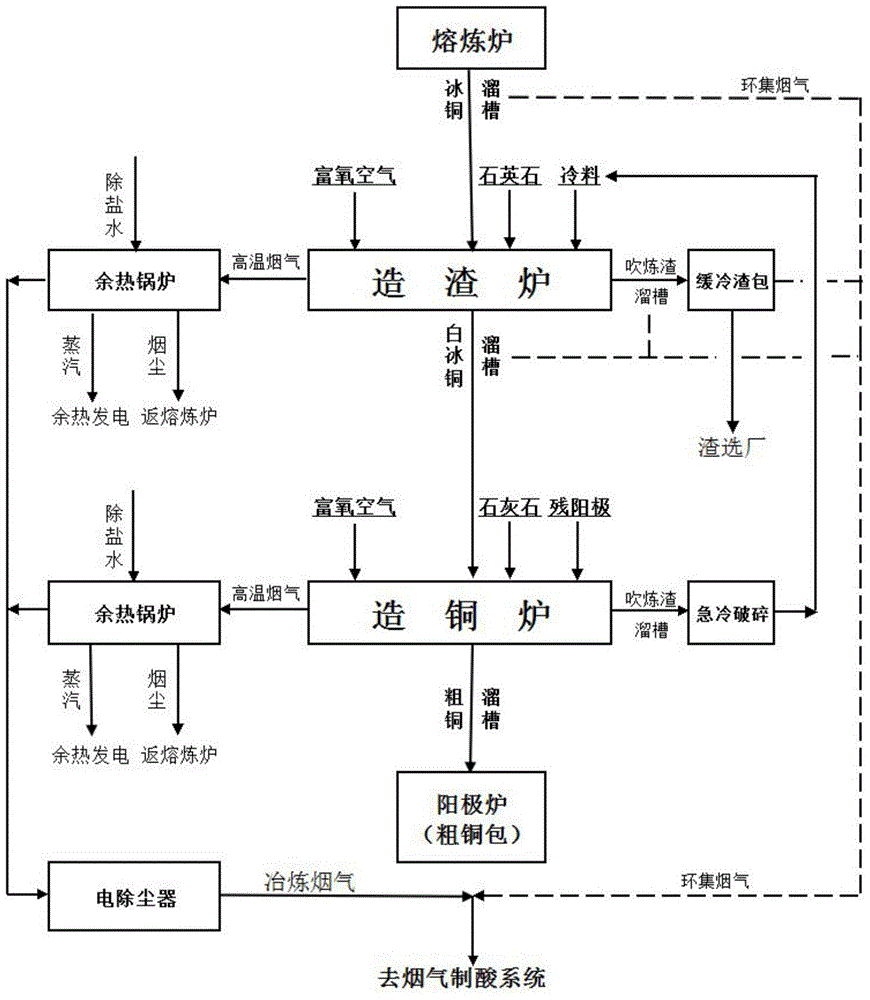

Three continuous furnace technology for continuous production of anode copper with copper concentrate

InactiveCN105238938AReduce metallurgical equipment and plant investmentAvoid sensible heat lossRotary drum furnacesCrucible furnacesSlagContinuous operation

The invention provides a three continuous furnace technology for continuous production of anode copper with copper concentrate. The technology is particularly characterized in that a smelting furnace, a copper making furnace and an anode furnace are in tandem arrangement successively, and kilns are connected by chutes. The technology comprises the steps that the copper concentrate and flux enter the smelting furnace and react with oxygen-enriched air to generate white matte, smelting slag and high-temperature smoke; the smelting slag overflows continuously; a slow cooling slag ladle is put through the chutes for floatation and depletion; the white matte continuously flows into the copper making furnace via siphon through the chute and reacts with the flux and the oxygen-enriched air to generate raw copper, copper converting slag and high-temperature smoke; the raw copper continuously or intermittently flows into the anode furnace via siphon through the chute; the anode furnace alternately operates and produces the anode copper via oxygenation and reduction; and the converting slag is regularly discharged, chilled, broken and returned to the smelting furnace. The technology achieves continuous operation of smelting production of the raw copper with the copper concentrate.

Owner:CHIFENG JINFENG METALLURGICAL TECH DEV

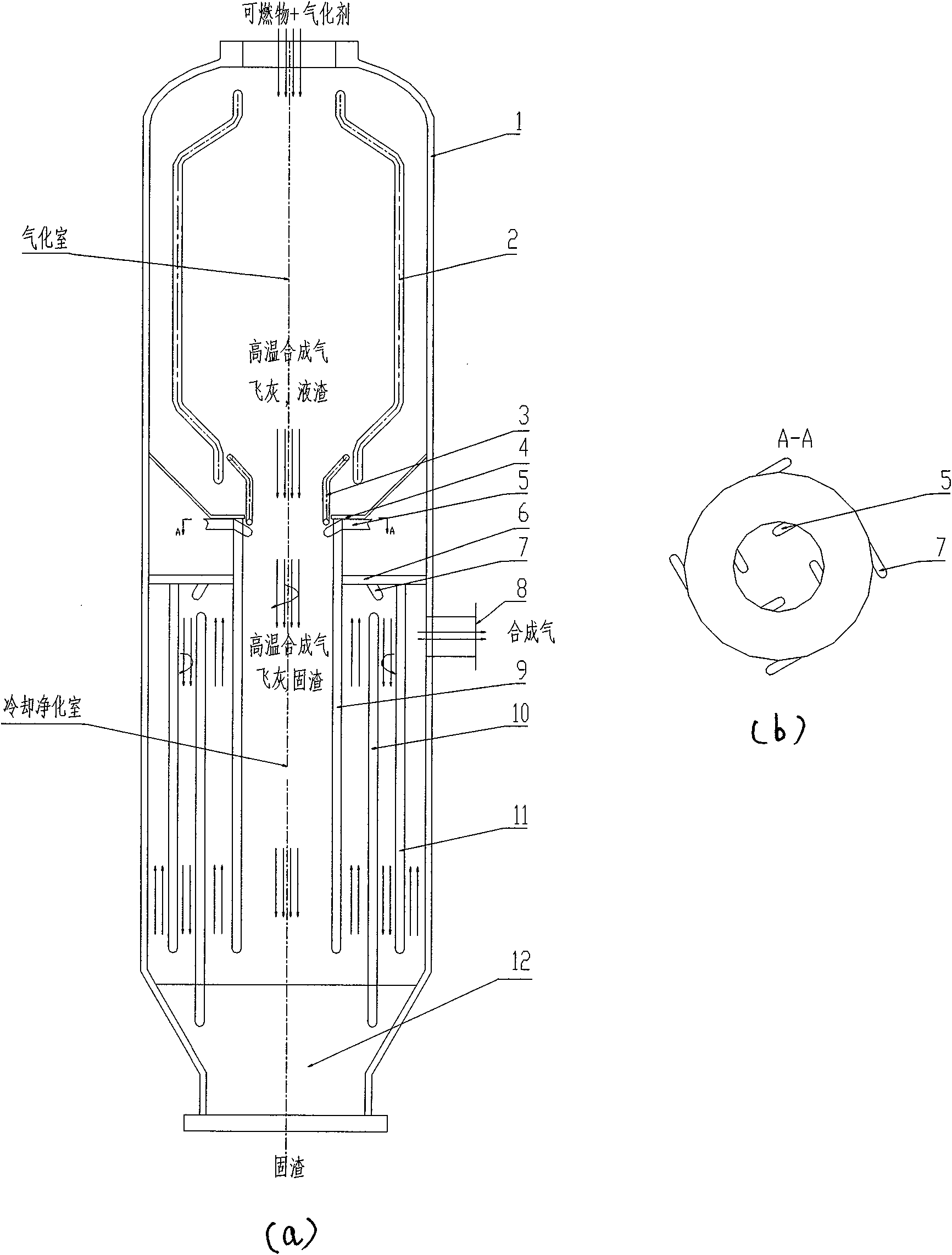

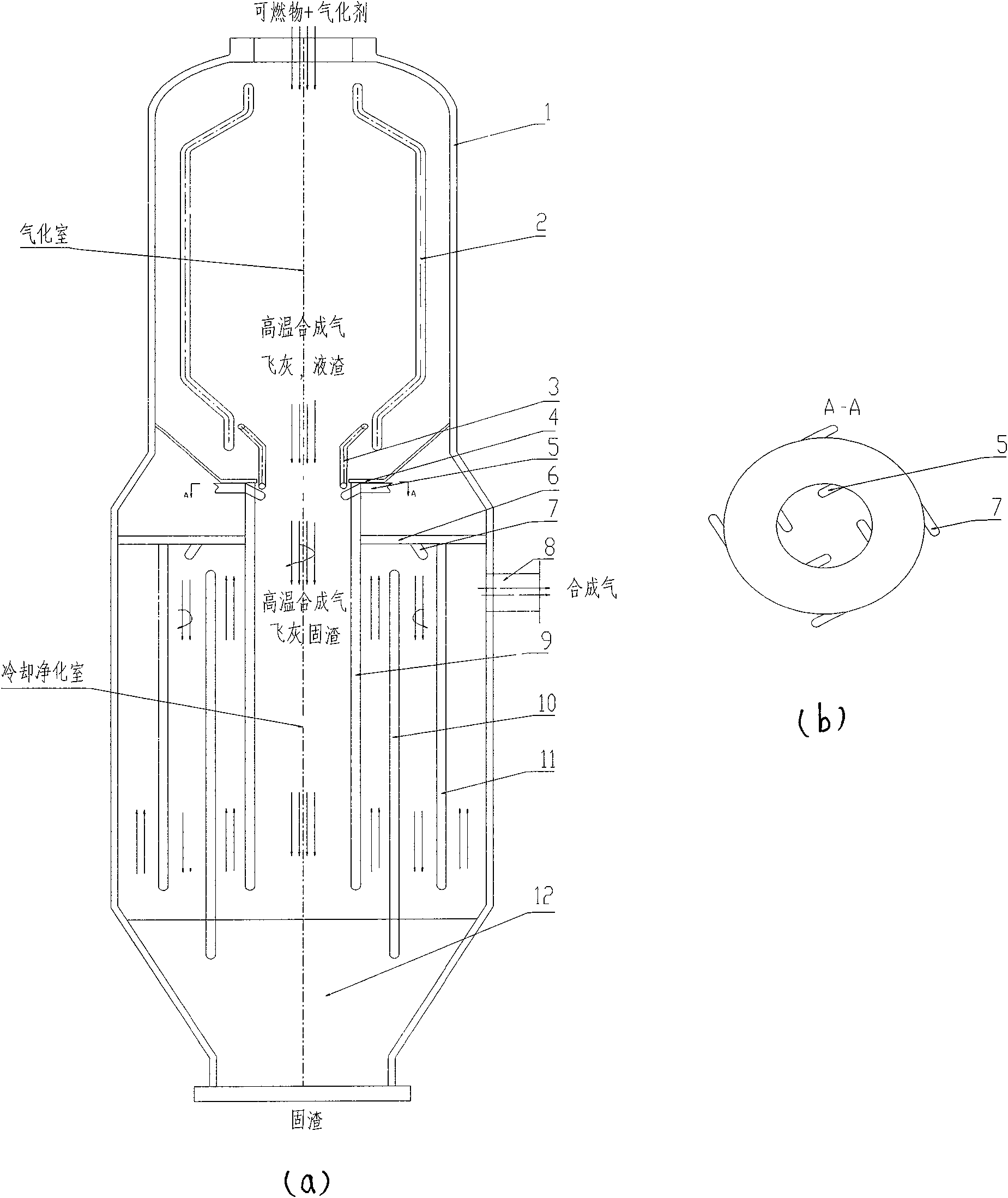

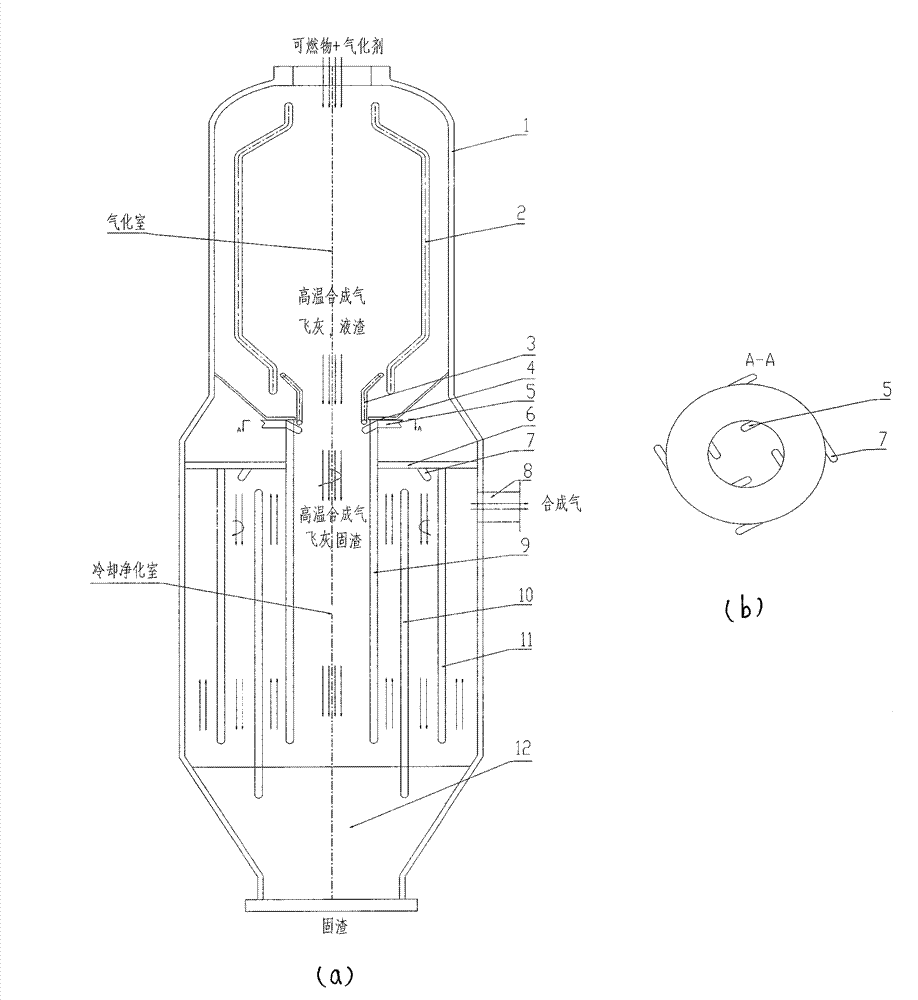

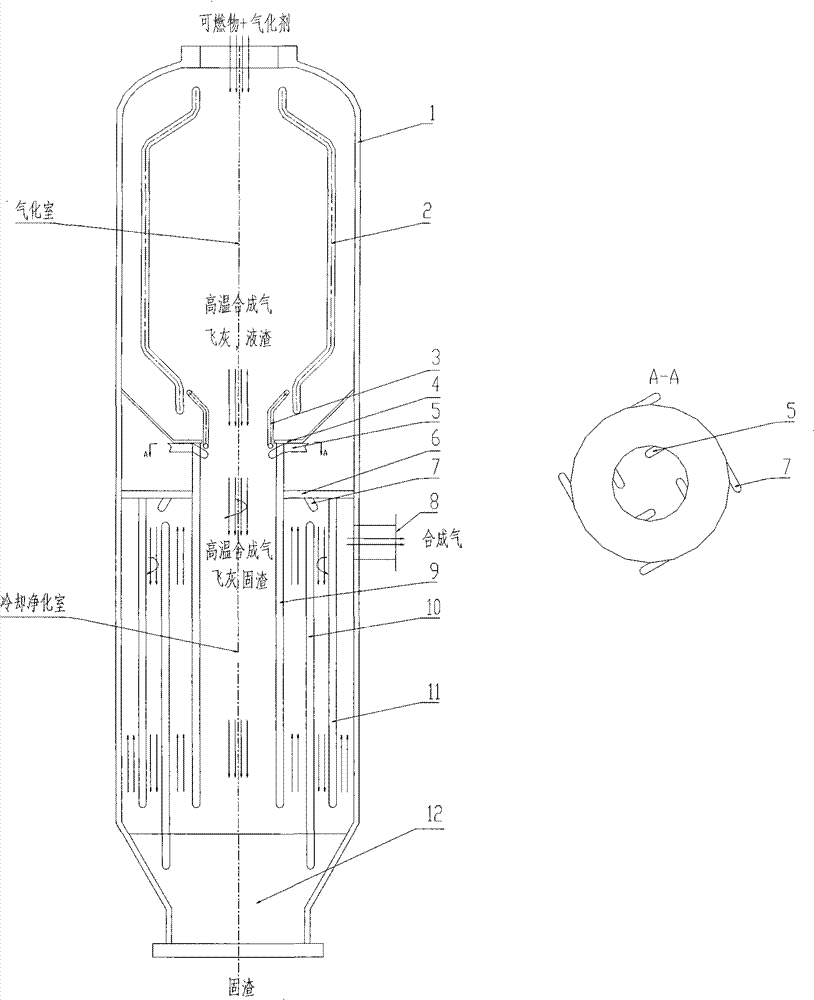

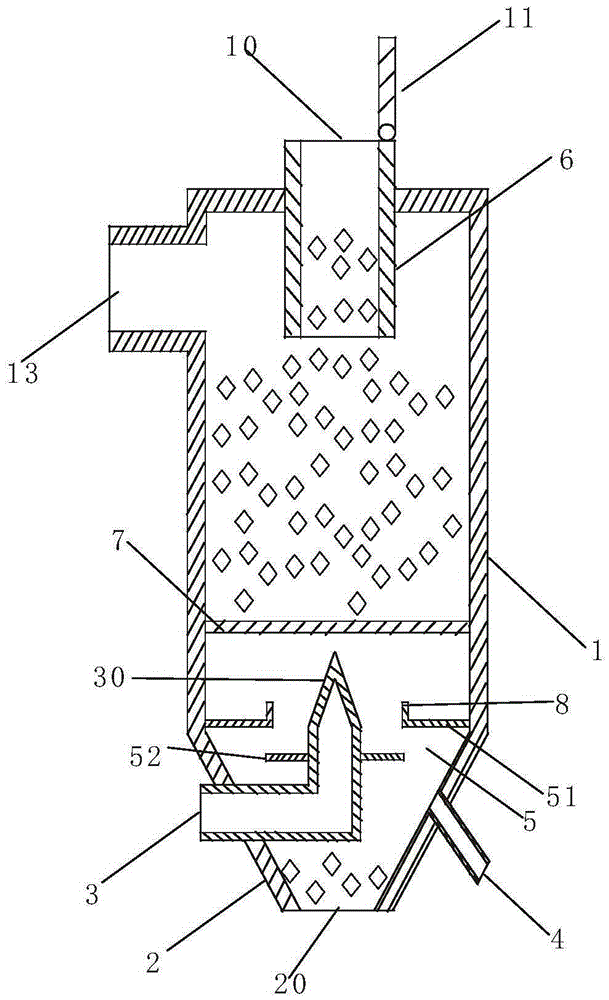

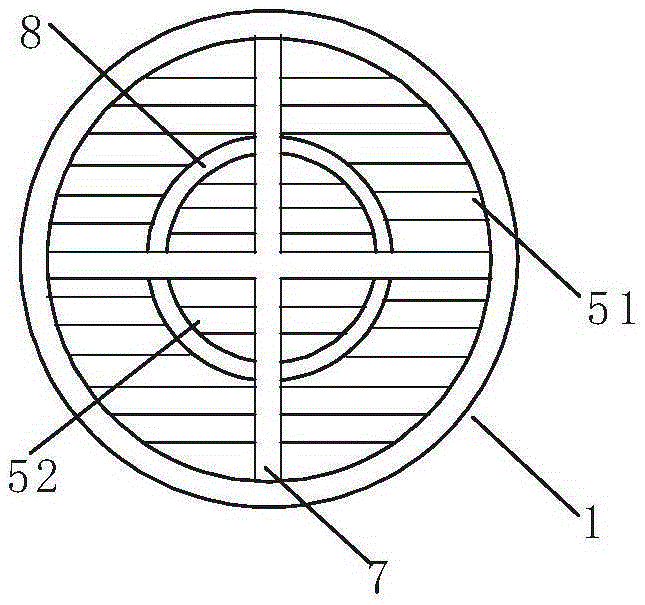

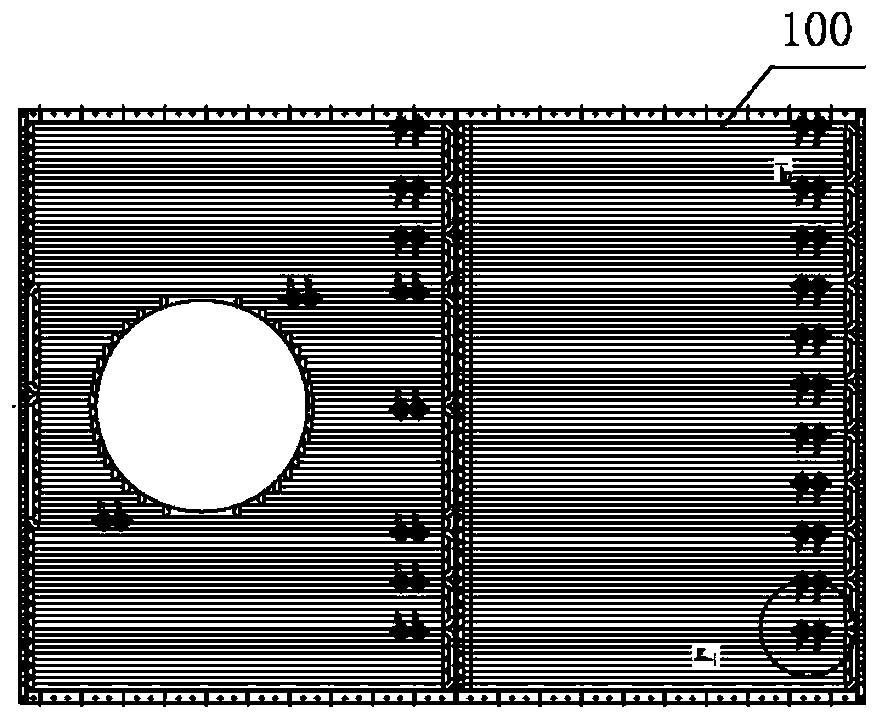

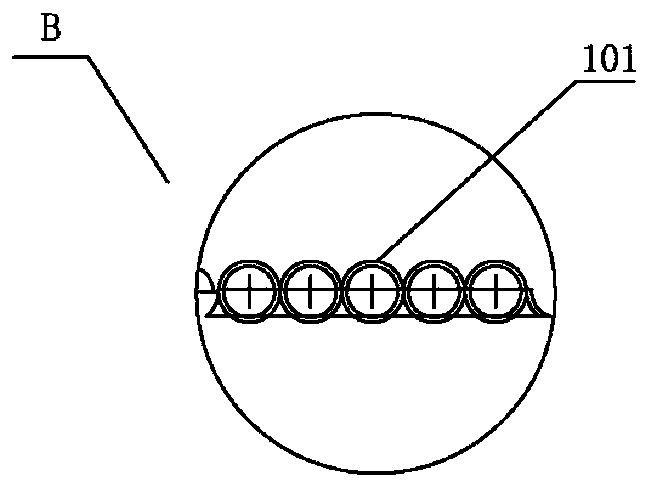

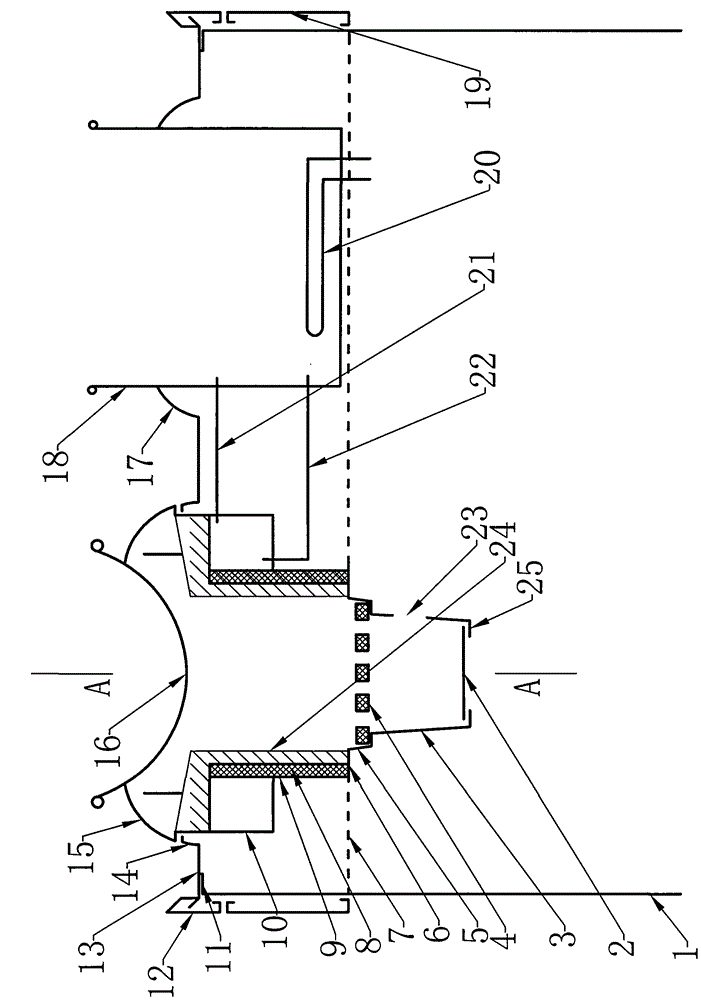

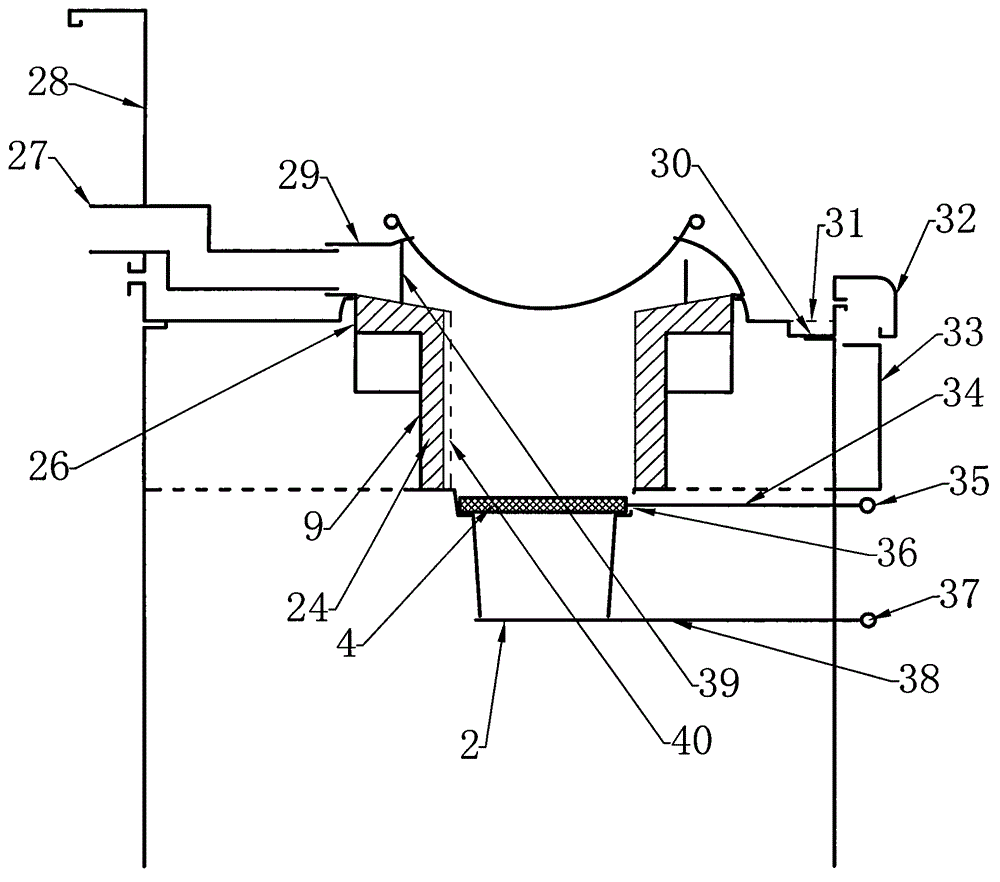

Gasification device for solid fuel and method for producing synthetic gas

ActiveCN101570699AImprove carbon conversionReduce water consumptionEnergy inputCombined combustion mitigationForming gasHigh carbon

The invention provides a gasification device for solid fuel, which comprises a gasification chamber and a cooling purification chamber. A first cooling medium distributor (5) is arranged at an inlet of the cooling purification chamber, and is used for injecting a low-temperature cooling medium into high-temperature synthetic gas from the gasification chamber along the circumferential direction, thereby making the high-temperature synthetic gas cooled and removing solid impurities from the high-temperature synthetic gas. The invention also provides a method for producing synthetic gas, which comprises the steps: ensuring that the quick incomplete reaction of the solid fuel and an oxidizing agent is performed to generate the high-temperature synthetic gas; and injecting the low-temperature cooling medium into the high-temperature synthetic gas along the circumferential direction to purify the high-temperature synthetic gas and make the temperature of the high-temperature synthetic gas reduced. The device and the method improve the purity of the synthetic gas which is finally obtained by temperature reduction, impurity removal and heat recovery for multiple times; and the device has high carbon conversion rate, and also has good complementary energy and waste heat recovery effect, low water consumption and no pollution.

Owner:CHANGZHENG ENG

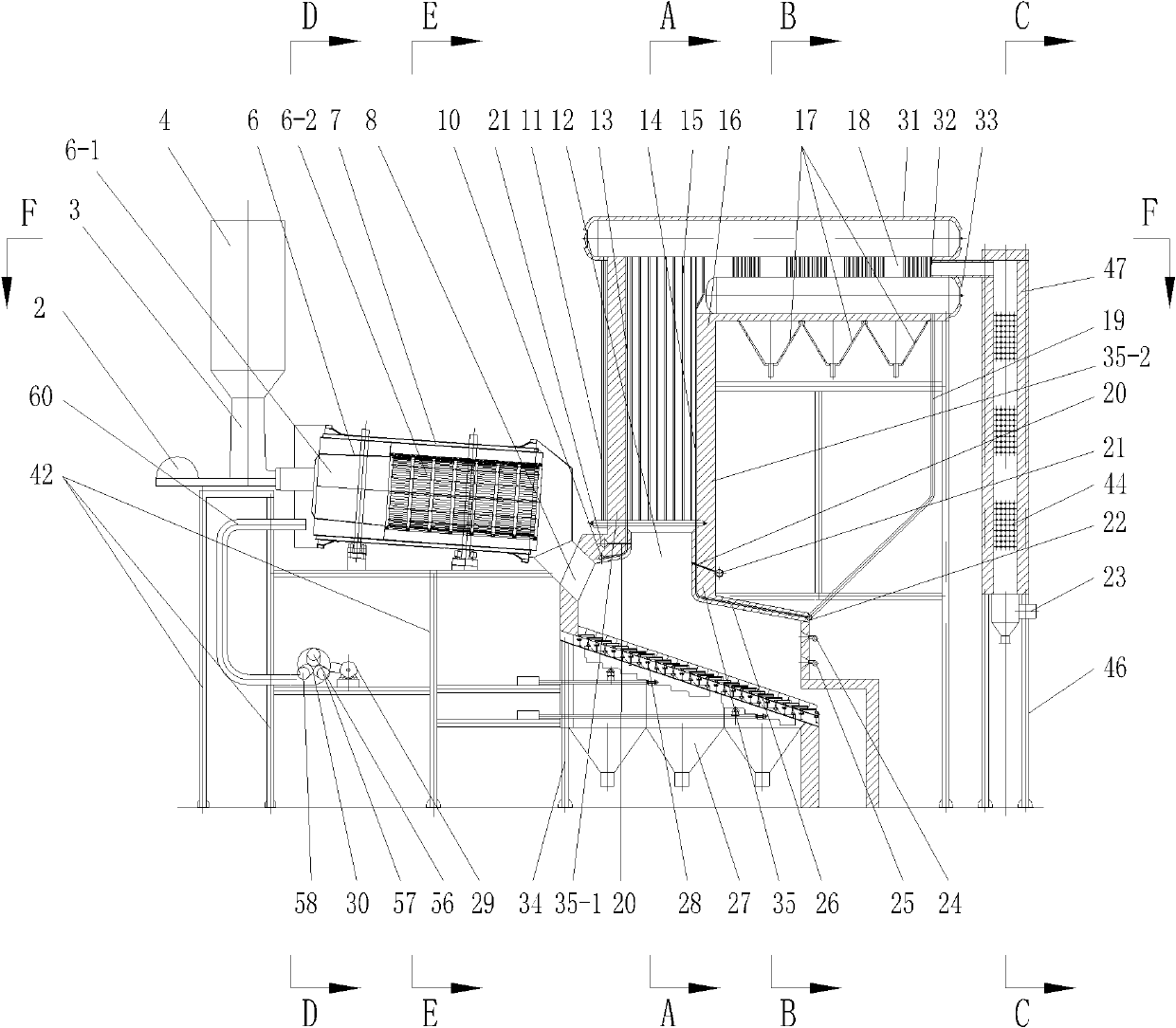

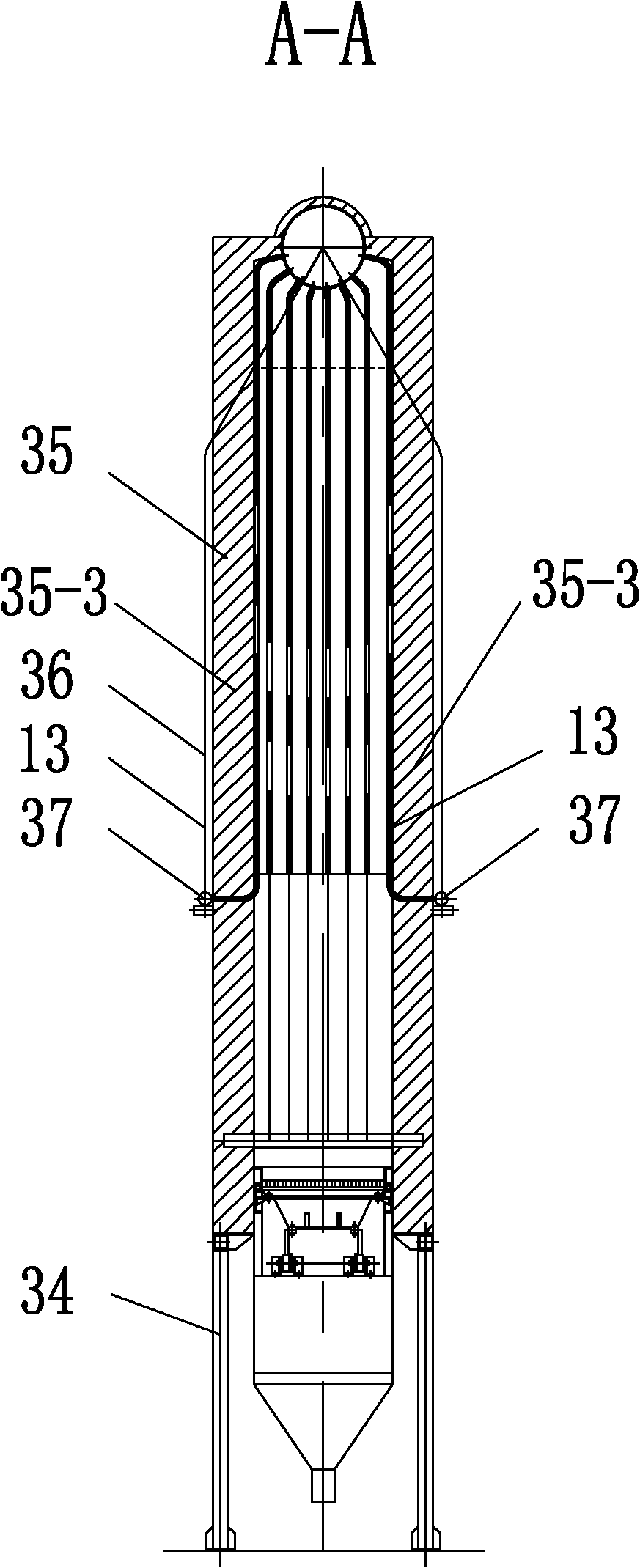

Three-dimensional hierarchical air supply combined waste incinerator

InactiveCN102168853ASmall granularityLow shape requirementIncinerator apparatusAir preheaterAir interface

The invention relates to a three-dimensional hierarchical air supply combined waste incinerator, in particular to a waste incinerator. The waste incinerator provided by the invention solves the problems of single function and narrow application range of the traditional waste incinerator. In the waste incinerator provided by the invention, the lower end of a feeding device is communicated with one end of a rotary drying pyrolysis device; the other end of the rotary drying pyrolysis device is communicated with a grate type incinerator; the feeding device and the rotary drying pyrolysis device are fixedly installed on a first bracket; two groups of secondary air spray pipes are both communicated with a secondary air main pipe; one group of the two groups of secondary air spray pipes is positioned above a rear arch and arranged on the outer side wall of a rear wall, and the other group of secondary air spray pipes are arranged at the lower end of a front wall; each group of secondary air spray pipes is communicated with a hearth; a high-temperature smoke interface is communicated with a horizontal flue through a pipeline; an intermediate-temperature smoke interface is communicated with a tail flue through a pipeline; and an air interface is communicated with the air outlet of an air preheater through a pipeline. The waste incinerator provided by the invention is used for incinerating waste.

Owner:HARBIN INST OF TECH

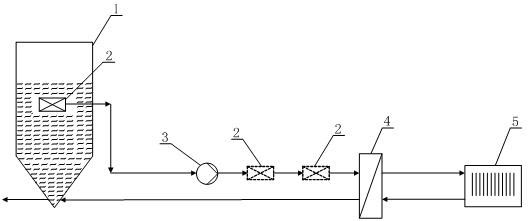

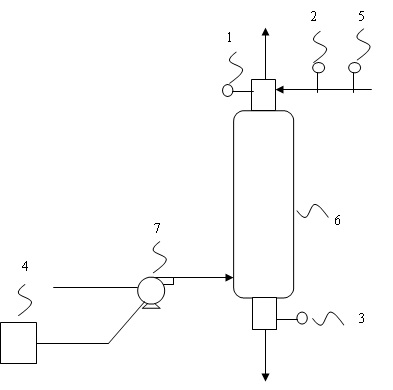

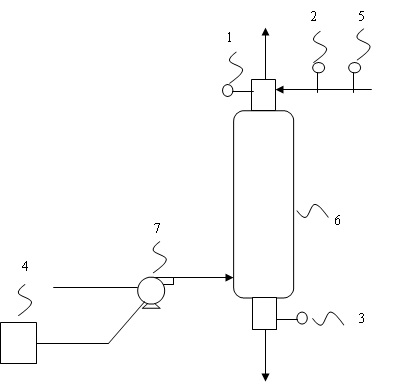

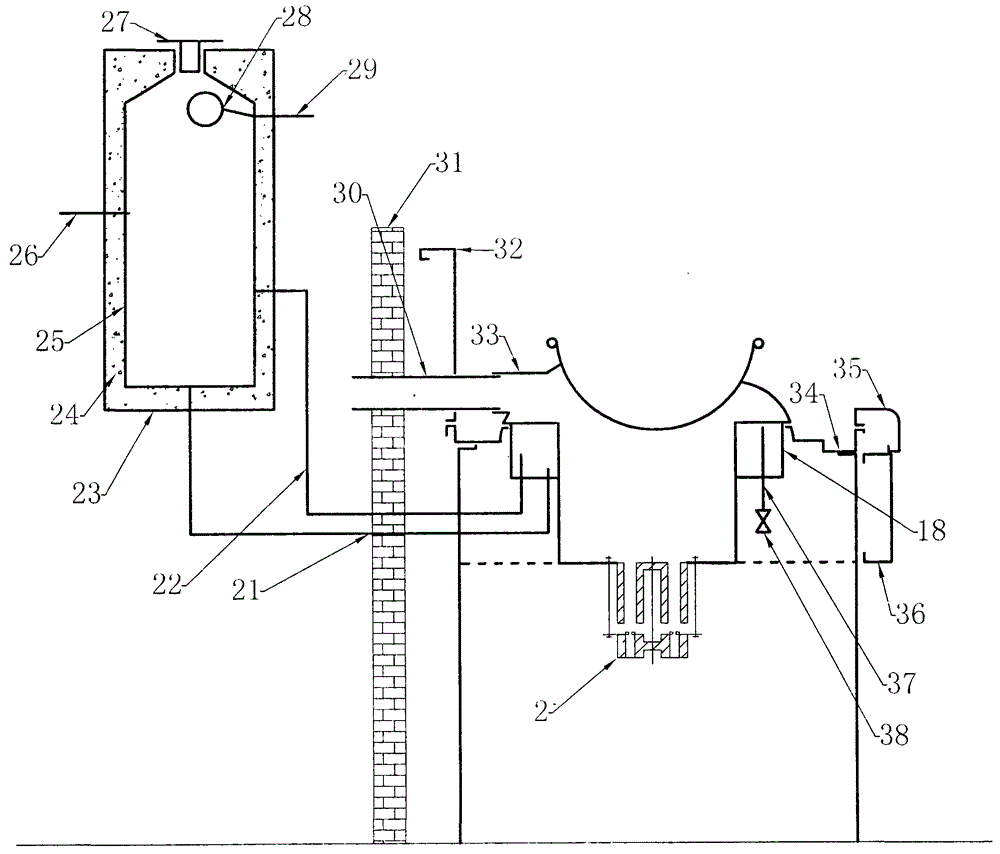

Method and system for recovering waste heat from INBA slag washing water of blast furnace

InactiveCN102676711AGuarantee the effect of flushing slag againReduce wearProcess efficiency improvementWater useSlag

The invention discloses a method and a system for recovering waste heat from IBNA slag washing water of a blast furnace. The system is formed by the connection of a filter, a water pump, a heat exchanger and a matched electric power meter, and the recovering method is that the high temperature slag washing water in a hot water tank is subjected to filtering and pressurizing and then flows into the heat exchanger for heat exchanging with water used by heat consumers. The method and the system have the advantages that short-process INBA slag washing water is high in temperature, and recovering and utilizing effects are good; water qualities of the filtered slag washing water are good, pipelines are protected from being abraded, and the heat exchanger is protected; and the water used by the heat consumers is clean water and is subjected to heat exchanging with the slag washing water by means of the heat exchanger, and the safety and stability of facilities of the heat consumers are guaranteed.

Owner:涉县亿玮坤节能科技有限公司

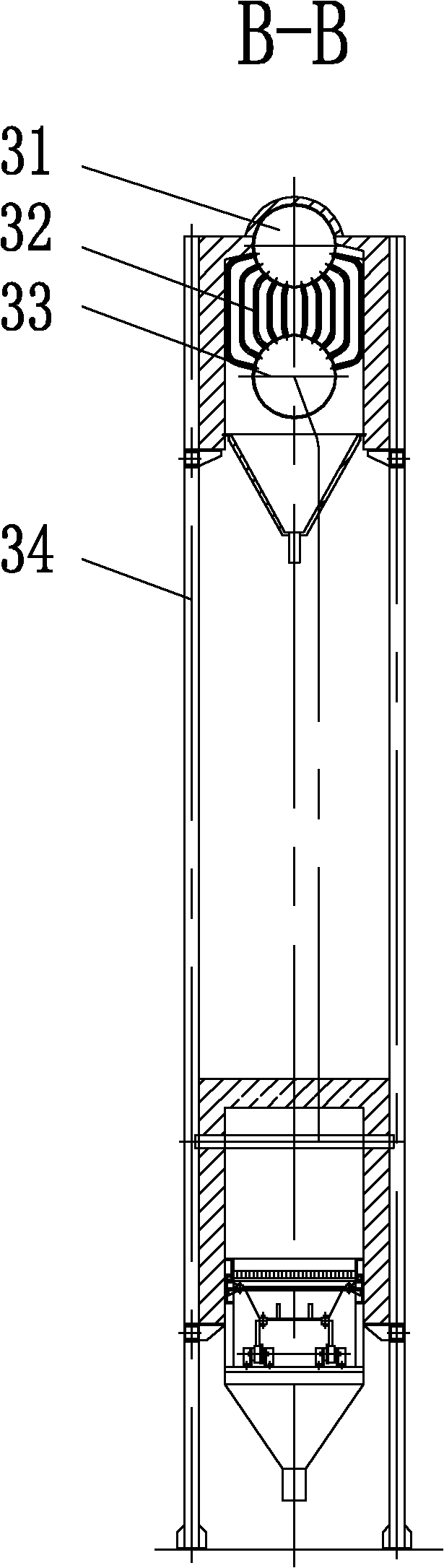

Process for producing anode copper by adoption of four connected furnaces

InactiveCN105002371AAchieve separationInto continuous stabilityRotary drum furnacesCrucible furnacesSlagSlow cooling

The invention provides a process for producing anode copper by adoption of four connected furnaces. The process is particularly characterized in that a smelting furnace, a slagging furnace, a copper preparation furnace and an anode furnace are connected in series from front to back and are connected through chutes. The process mainly comprises the steps that copper concentrate and flux enter the smelting furnace to react with oxygen-enriched air to generate smelting slag and copper matte, and the smelting slag continuously overflows and is put into a slow cooling slag bag through the corresponding chute; the copper matte is siphoned to continuously flow into the slagging furnace through the corresponding chute and reacts with flux and oxygen-enriched air to generate converting slag, white matte and high-temperature smoke; the converting slag continuously overflows and is put into the slow cooling slag bag through the corresponding chute; the white matte is siphoned to continuously flow into the copper preparation furnace through the corresponding chute and reacts with flux and oxygen-enriched air to generate converting slag, crude copper and high-temperature smoke; copper preparation slag is discharged regularly and is quenched and broken to return to the slagging furnace; crude copper is siphoned and continuously or discontinuously flows into the anode furnace through the corresponding chute, the anode furnace operates alternately, and anode copper is obtained through oxidation and reduction. The process achieves continuous operation of the crude copper production process.

Owner:CHIFENG JINFENG METALLURGICAL TECH DEV

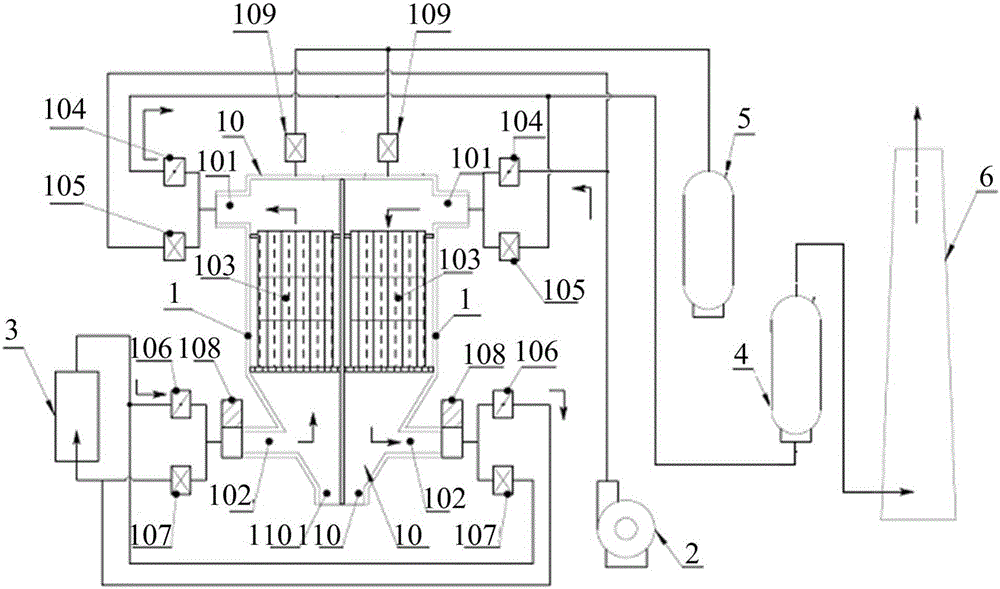

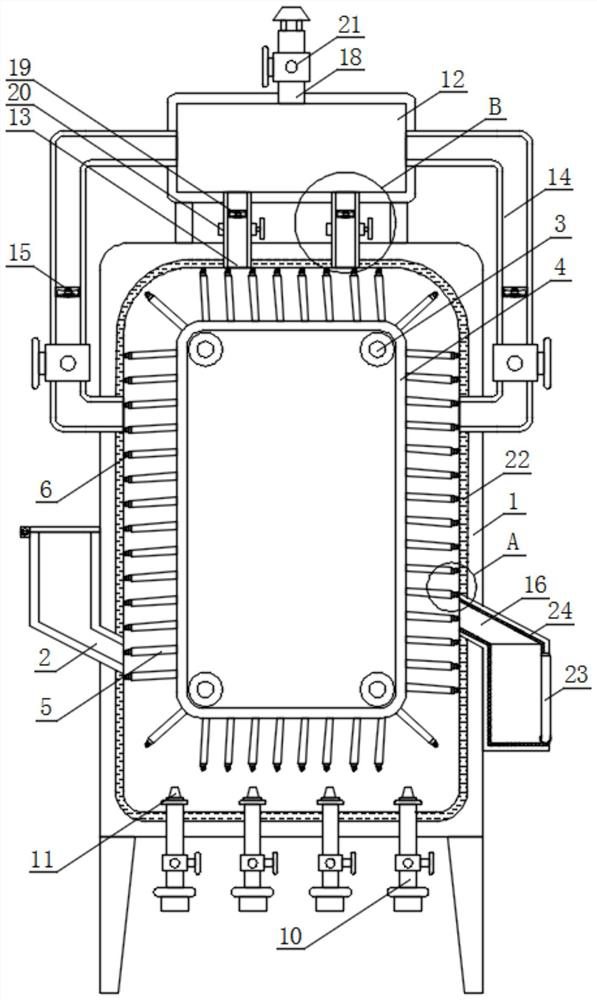

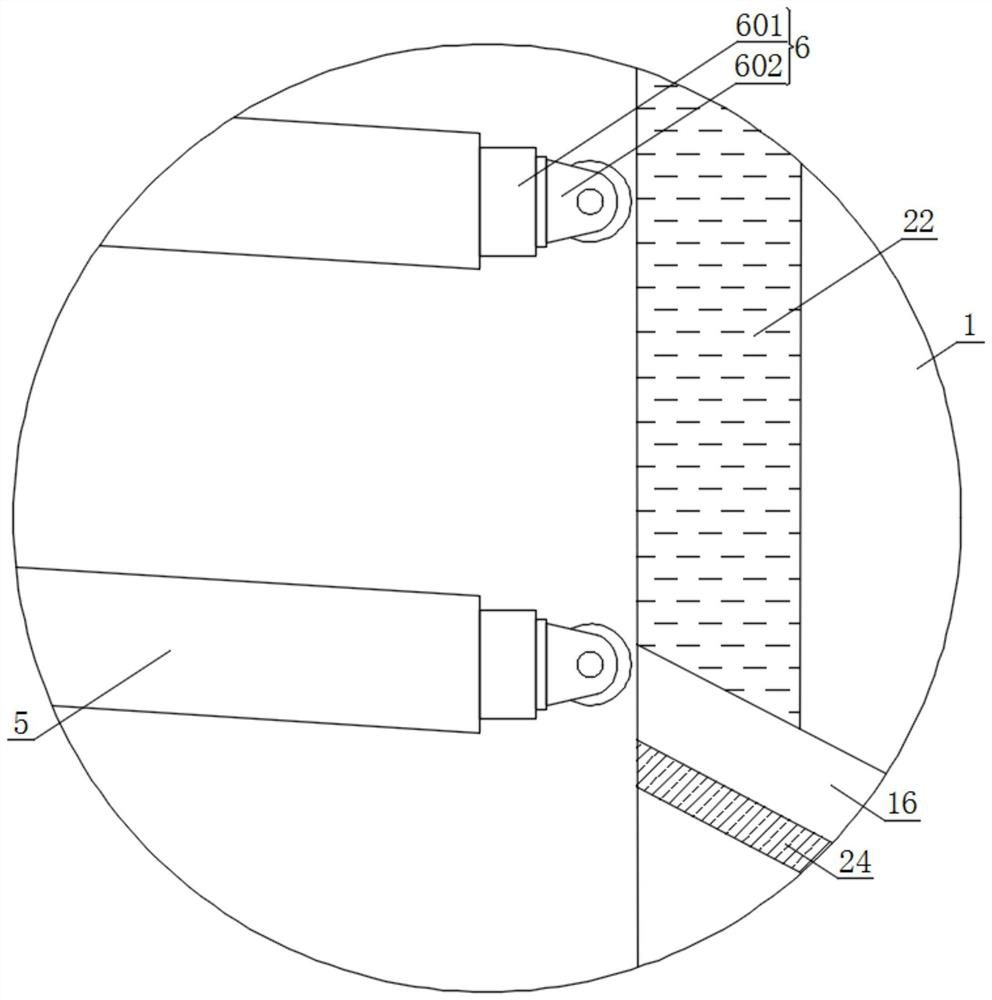

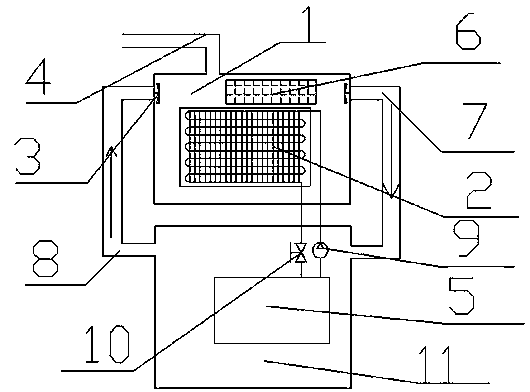

High-temperature wastewater dust removal filter device with waste heat recovery function

ActiveCN105999909AEasy to captureExcellent shooting down performanceDispersed particle filtrationHeat storage plantsWaste heat recovery unitCombustion

The invention provides a high-temperature wastewater dust removal filter device with a waste heat recovery function. The device used for removing dust in waste gas produced through combustion of a combustion furnace and guiding the waste gas into a denitration reaction tower for denitration. The device comprises at least two dust removal working chambers and a combustion fan. The dust removal working chambers are sequentially opened and closed according to preset rules. Each dust removal working chamber comprises an upper air through hole, a lower air through hole and a filter body, wherein the upper air through hole is made communicated with the denitration reaction tower, the lower air through hole is made communicated with the combustion furnace, and the filter body is arranged between the upper air through hole and the lower air through hole. The combustion fan is made communicated with the upper air through holes and injects combustion air into the combustion furnace according to a preset rule. The combustion air passes through the dust removal working chambers to bring heat of the dust removal working chambers to the combustion furnace. According to the high-temperature wastewater dust removal filter device with the waste heat recovery function, dust catching and knocking-down performance is excellent, and heat storage performance and waste water recovery performance are excellent.

Owner:德州奥深节能环保技术有限公司

Fluoroplastic waste heat recycling and ultra-low emission integrated device

InactiveCN105157051AGood heat exchange performancePromote absorptionEnergy industryIncreasing energy efficiencyEngineeringRecuperator

The invention relates to a fluoroplastic waste heat recycling and ultra-low emission integrated device which is located above a catalytic reaction area in a desulfurizing tower and below a demister. The fluoroplastic waste heat recycling and ultra-low emission integrated device comprises a heat exchanger used for carrying out smoke waste heat exchange and capturing dust, a water flushing assembly used for flushing the surface of the heat exchanger, and a water collecting assembly used for collecting waste water and dust falling down from the surface of the heat exchanger. The water flushing assembly and the water collecting assembly are located above and below the heat exchanger respectively. The heat exchanger is a fluoroplastic plate type heat exchanger with a water inlet and a water outlet. The water inlet is connected with a low-temperature demineralized water feed pump. The water outlet s connected with a boiler system or a heating system. Compared with the prior art, the fluoroplastic waste heat recycling and ultra-low emission integrated device has good smoke waste heat recycling performance and dust and mist removing performance, and the purpose of integration of waste heat recycle and ultra-low emission is achieved. The fluoroplastic waste heat recycling and ultra-low emission integrated device has the beneficial effects of being resistant to corrosion, stable, reliable, low in water consumption and the like.

Owner:SHANGHAI HUAXIANG ENERGY SAVING & ENVIRONMENTAL PROTECTION CO LTD

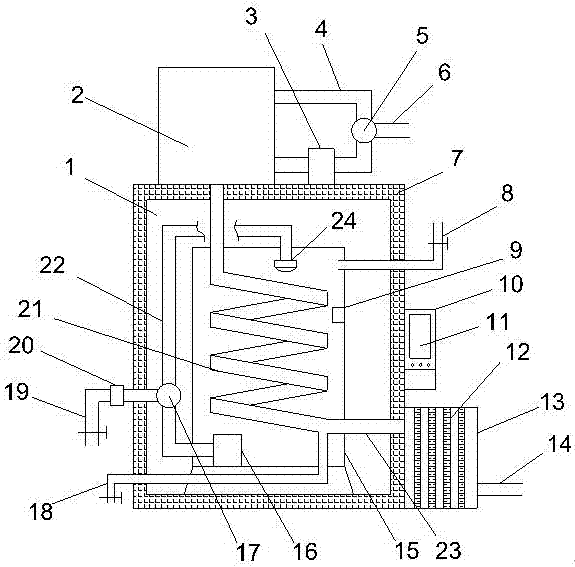

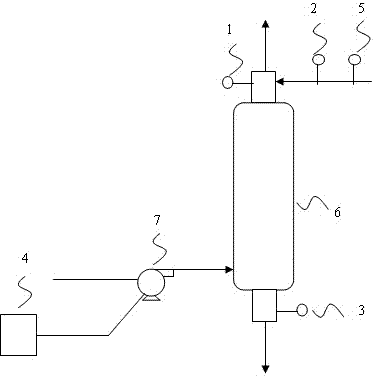

Environment-friendly industrial exhaust gas waste heat recycling device

InactiveCN107449293AIncrease the heat exchange areaGood recovery of waste heatHuman health protectionDispersed particle filtrationExhaust fumesProduct gas

An environment-friendly industrial exhaust gas waste heat recycling device comprises a body and is characterized in that a heat exchange box is arranged inside the body and internally filled with tap water; a heat exchange pipe is arranged inside the heat exchange box, and the inlet end of the heat exchange pipe communicates with a connecting pipe; a condensing pipe is arranged on the heat exchange pipe; a gas purifying box is arranged on the top of the body; a circulating gas pipe is arranged on the right side of the gas purifying box; an air quality detecting instrument is arranged on the circulating gas pipe; the space between the body and a liquid level sensor is vacuum; the body is wrapped with heat preservation cotton; a water inlet pipe is arranged on the body; a submerged pump is arranged at the bottom of the heat exchange box; a second reversing valve is mounted on a circulating water pipe; a hot water pipe is arranged on the second reversing valve; and a water temperature sensor is arranged on the hot water pipe. A rough filter box roughly filters industrial exhaust gas, and the situation that dust in the exhaust gas blocks the heat exchange pipe is avoided; the heat exchange area is increased through the spiral heat exchange pipe, so that the waste heat recycling effect of the exhaust gas is better; and gas discharging of the device is more environmentally friendly, heat dissipation is little, and the heat exchange efficiency is high.

Owner:盐城千之诺机械有限公司

Double-furnace blister copper continuous converting process

InactiveCN104532015ALow running costHigh recovery rateRotary drum furnacesCrucible furnacesChemical reactionSlag

The invention relates to the production process technology of double-furnace blister copper continuous converting. According to the technical scheme, a double-furnace blister copper continuous converting process is uniquely characterized in that two furnace kilns which are arranged front and back continuously complete the process of forming blister copper through copper matte by means of converting, and the two furnace kilns are named as a slag formation furnace and a copper formation furnace. The process flow includes the steps that the copper matte produced by a smelting furnace continuously flows into the slag formation furnace, and in the slag formation furnace, the copper matte chemically reacts with solvent added into the slag formation furnace and oxygen-enriched air blown into the slag formation furnace, so that converting slag, white copper matte and high-temperature gas are generated; the converting slag is continuously discharged out of a slag discharge opening in an overflow mode, and placed in a slow cooling slag ladle through a chute, the white copper matte sinks to the furnace bottom, is discharged through siphoning and continuously flows into the copper formation furnace through the chute, and the high-temperature gas enters a waste heat boiler; in the copper formation furnace, the white copper matte chemically reacts with the solvent and the oxygen-enriched air which is blown in, so that the blister copper, a trace of converting slag and the high-temperature smoke are generated; the blister copper is continuously or intermittently discharged through siphoning by means of the chute, the converting slag is regularly discharged out of the slag discharge opening in the overflow mode, and the high-temperature gas enters the waste heat boiler.

Owner:CHIFENG YUNTONG NONFERROUS METALS +1

Method for recycling flue gas waste heat of alumina roasting furnace

ActiveCN101915515AEffective temperature controlTemperature controlHeat exchange apparatusFlue gasEngineering

The invention relates to a method for recycling the flue gas waste heat of an alumina roasting furnace. In a recycling process, a way of performing direct heat exchange between water and flue gas is adopted. The method is characterized in that: in the recycling process, difference between the temperature of water on which the direct heat exchange is performed together with the flue gas and the temperature of exhausted flue gas after the heat exchange is controlled to between 0 and 2 DEG C; and the volume ratio of the amount of the flue gas to the dosage of the water is 100:1-250:1. The method for recycling the flue gas waste heat of the alumina roasting furnace of the invention has the advantages of effectively controlling the parameters of the recycling process, achieving good waste heat recycling effects, effectively avoiding effects caused by the fluctuations of the moisture content and the temperature of the flue gas and effectively controlling the temperature of generated hot water.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

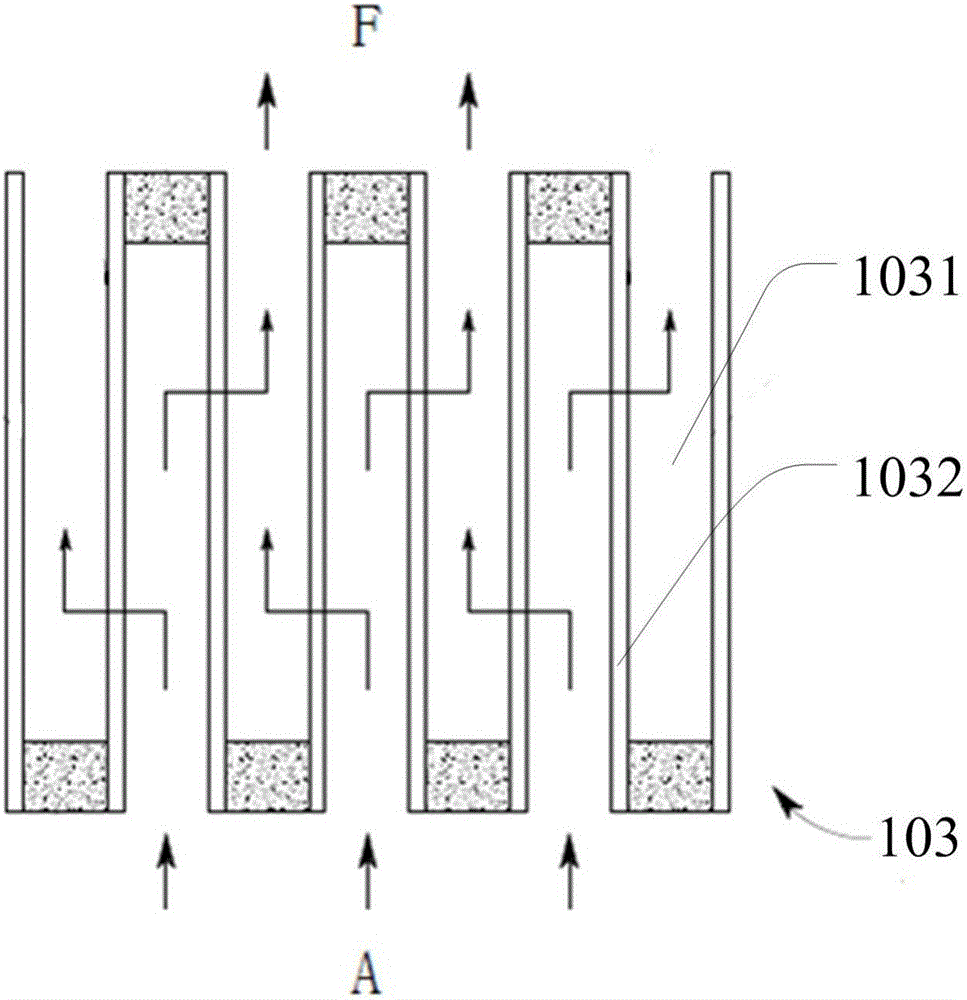

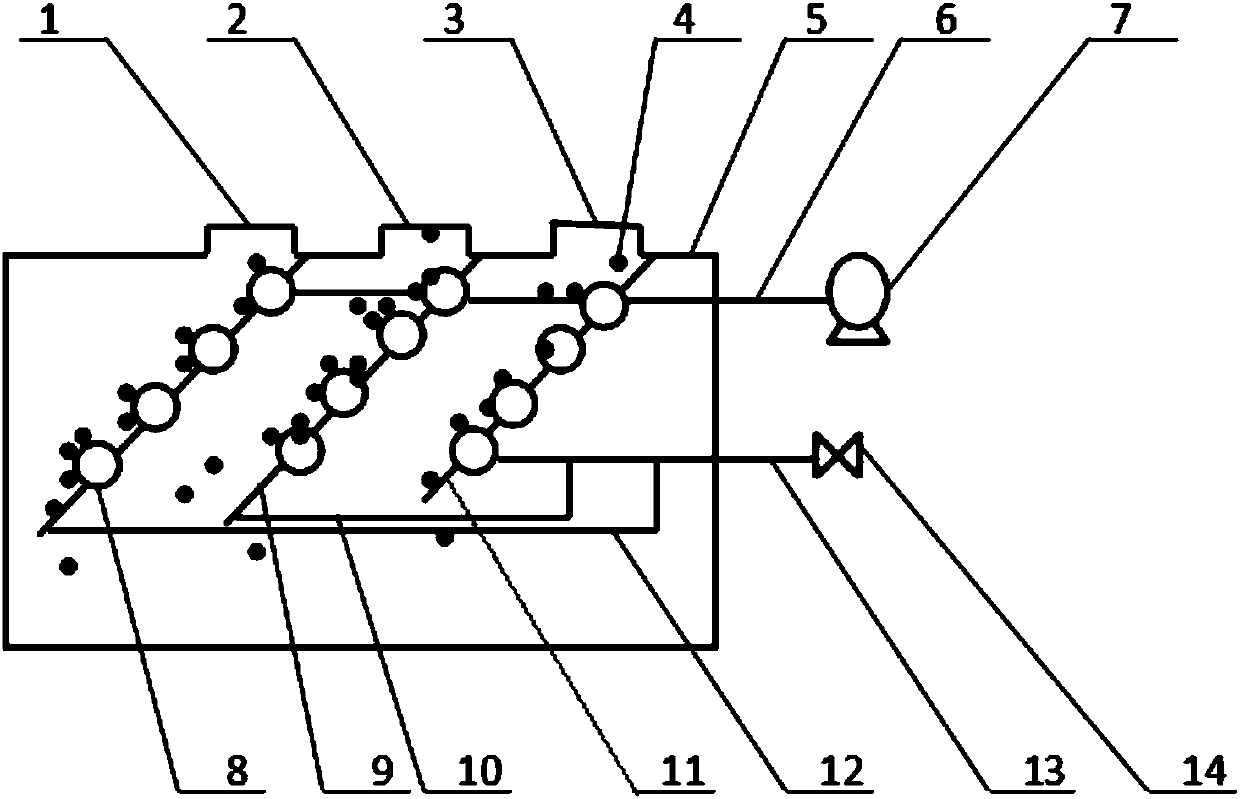

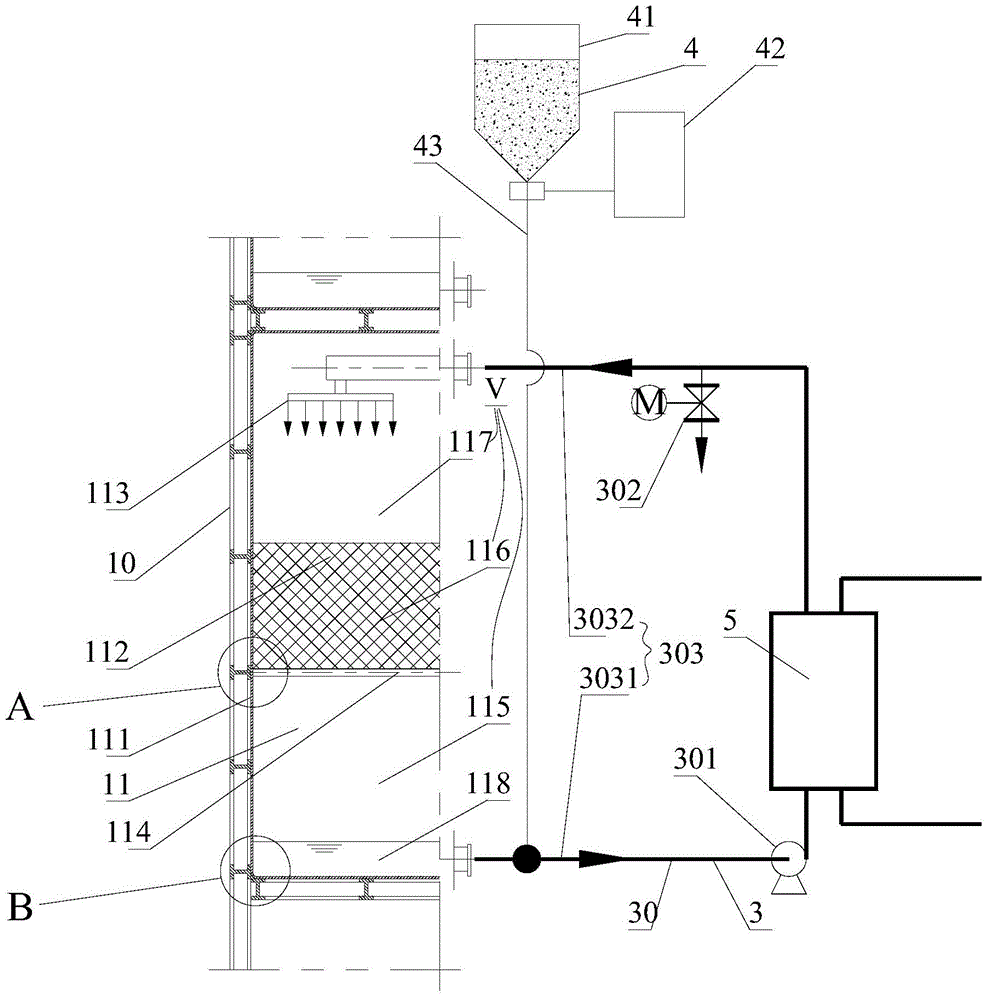

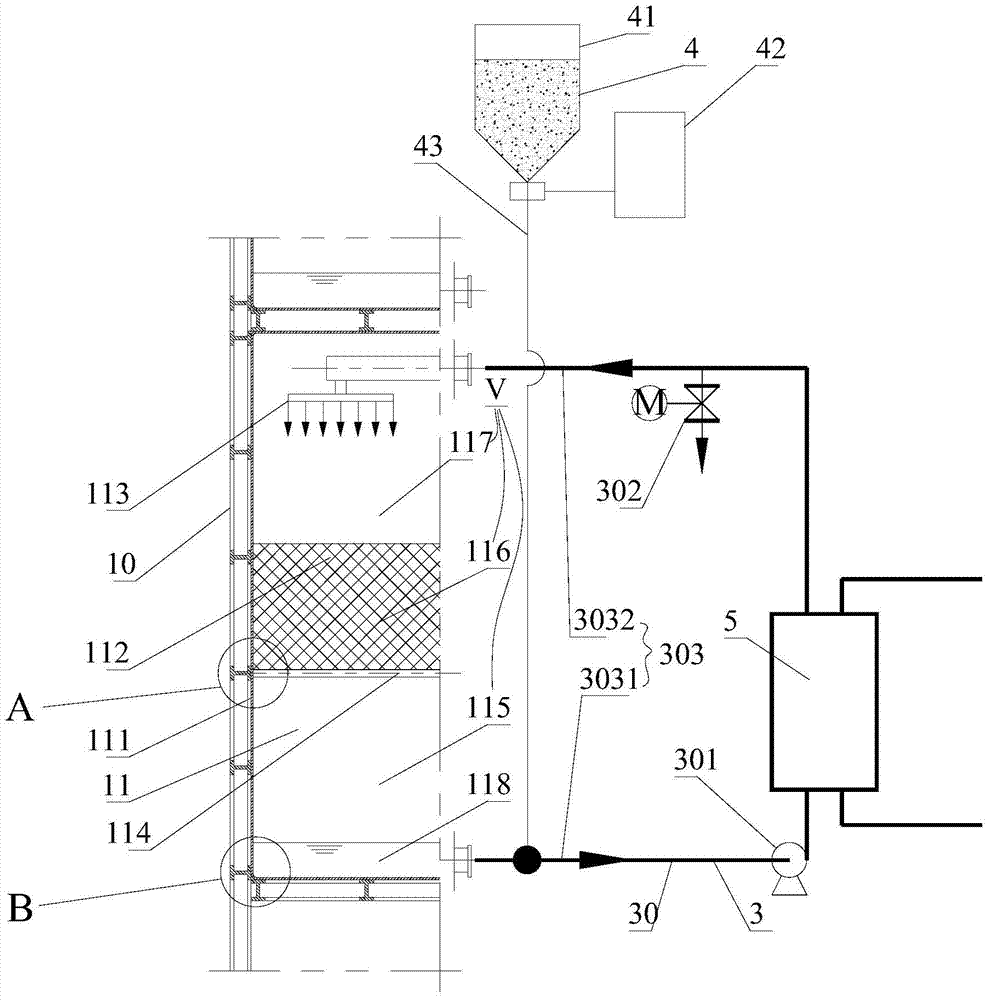

Film type evaporator for recovering waste heat of semi-coke quenching

PendingCN107794062AMake full use of waste heatFully absorbedCoke quenchingEnergy inputRelease timeCoal chemical industry

The invention discloses a film type evaporator for recovering the waste heat of semi-coke quenching, and belongs to the technical field of coal chemical industry. The film type evaporator comprises acoke quenching tank. Multiple coke inlets are arranged in the top of the coke quenching tank. Multiple film type tubes are arranged in the coke quenching tank and are arranged under the coke inlets one to one. The top end of each film type tube is provided with a water inlet pipe and the bottom end is provided with a steam pipe. The film type tubes can be heated from both sides, the heating effectis good, the heating speed is fast, high temperature semi-cokes slide down along with the film type tubes, the heat releasing time in a furnace is prolonged, and the waste heat of semi-cokes can be fully absorbed. The film type evaporator has the advantages of low cost, energy saving and environment-friendly property, and good waste heat recovering effect.

Owner:YULIN UNIV

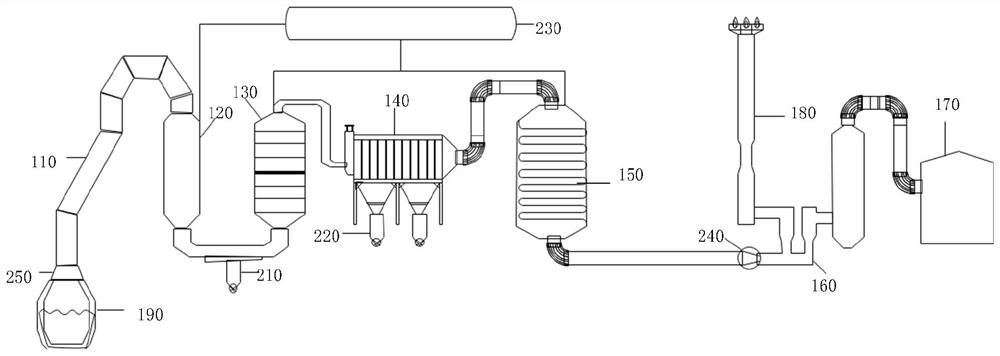

Converter flue gas waste heat recovery system and method

PendingCN113073170AEfficient removalAvoid cloggingIncreasing energy efficiencyExhaust gas handlingThermodynamicsFlue gas

The invention provides a converter flue gas waste heat recovery system and method. The converter flue gas waste heat recovery system comprises an evaporative cooling flue, a waste heat boiler radiation section, a waste heat boiler evaporation section, a ceramic fiber filter, a waste heat boiler economizer section, a three-way switching valve, a coal gas recovery system, a diffusion chimney and a converter; the inlet end of the evaporative cooling flue communicates with the converter, and the outlet end of the evaporative cooling flue communicates with the inlet end of the waste heat boiler radiation section; the outlet end of the waste heat boiler radiation section communicates with the inlet end of the waste heat boiler evaporation section, and the outlet end of the waste heat boiler evaporation section communicates with the inlet end of the ceramic fiber filter; and the outlet end of the ceramic fiber filter communicates with the inlet end of the waste heat boiler economizer section, the outlet end of the waste heat boiler economizer section communicates with the inlet end of the three-way switching valve, and the two outlet ends of the three-way switching valve are connected with the coal gas recovery system and the diffusion chimney respectively. Dust can be effectively removed while waste heat of converter flue gas is fully absorbed.

Owner:WISDRI ENG & RES INC LTD

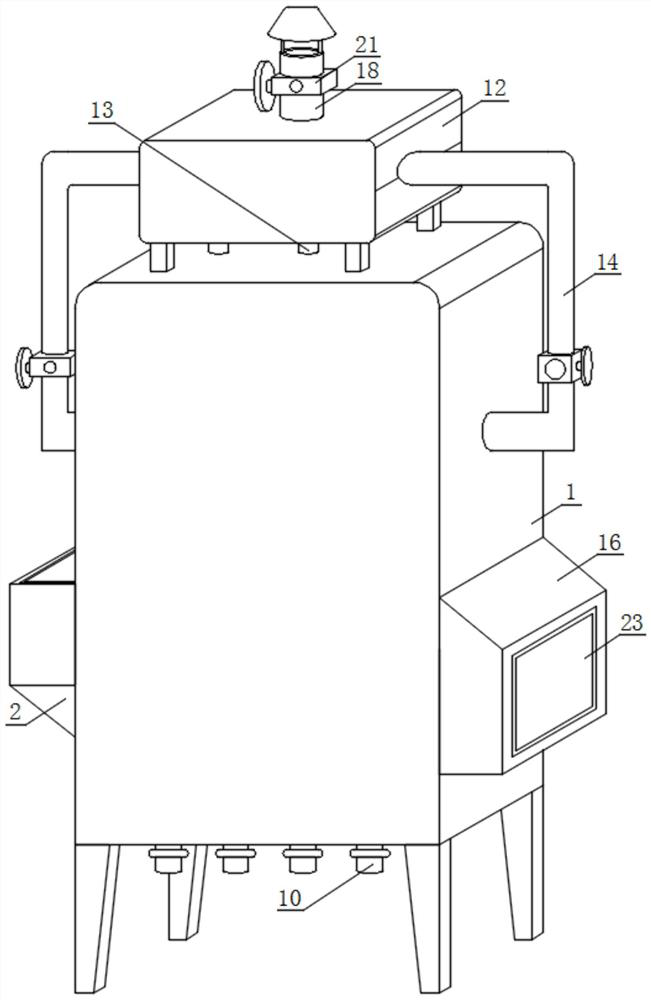

Heating furnace for aluminum rod production

InactiveCN111854427AHeating evenlyHeating evenly and efficientlyCharge composition/stateFurnace typesFlue gasExhaust fumes

The invention discloses a heating furnace for aluminum rod production, and belongs to the technical field of aluminum rod production. The heating furnace comprises an aluminum rod heating furnace, wherein a feeding hopper communicating with the aluminum rod heating furnace is fixedly mounted on the right side of the aluminum rod heating furnace, four transmission rollers are rotationally connectedinside the aluminum rod heating furnace, and an integrated high-temperature-resistant transmission belt is in transmission connection with the exteriors of the four transmission rollers. According tothe heating furnace for aluminum rod production, by operating an electric motor, the high-temperature-resistant transmission belt and heat-resistant placement plates can be driven by the transmissionrollers, aluminum rods can be driven by the high-temperature-resistant transmission belt for transmission, and the aluminum rods inside the aluminum rod heating furnace can be uniformly heated at high temperature through heating burners at the tops of fuel gas outer pipes, so that the heating of the aluminum rods is relatively efficient and uniform; and high-temperature waste gas after heating ofthe aluminum rod heating furnace is re-conducted to the interior of the aluminum rod heating furnace through lower air pipes on the two sides of a waste heat recovery furnace, so that the heating quality and efficiency of the aluminum rods in the aluminum rod heating device are relatively high, and the waste heat recovery effect on the fuel-gas flue gas is good.

Owner:恒吉集团实业有限公司

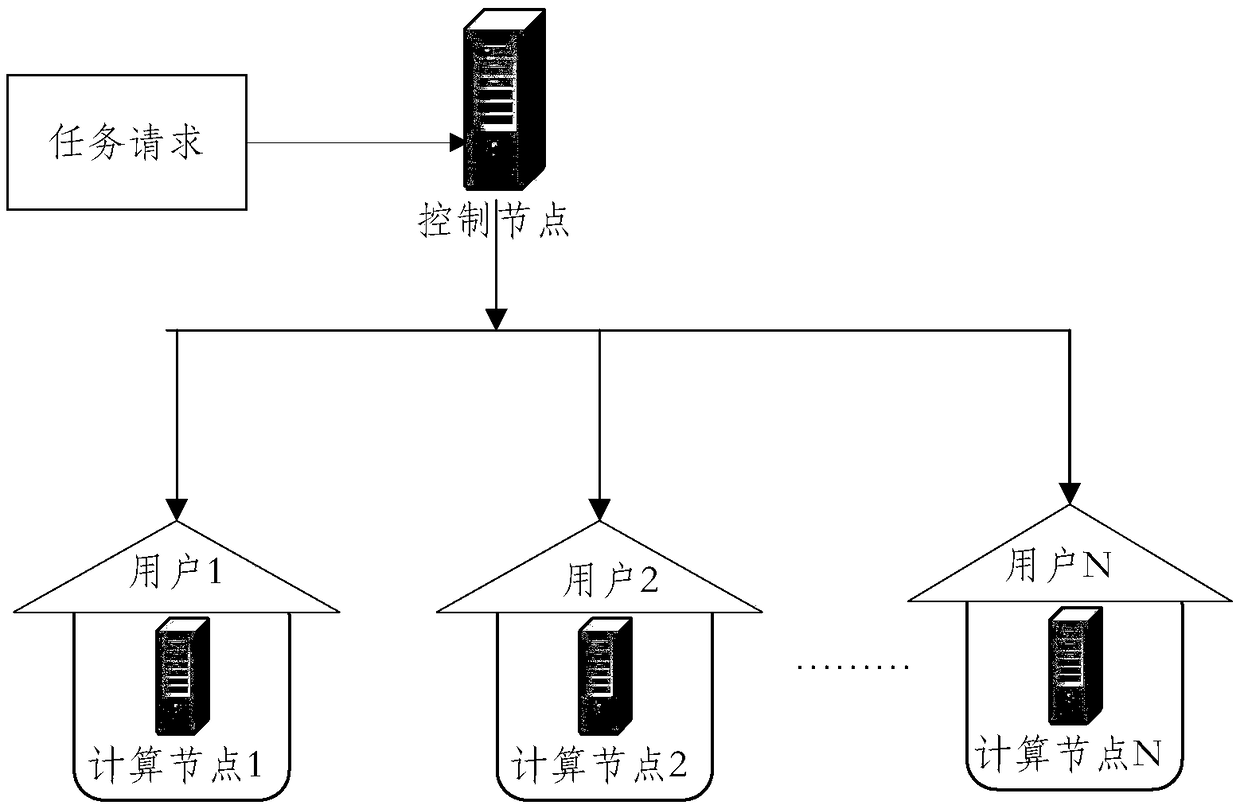

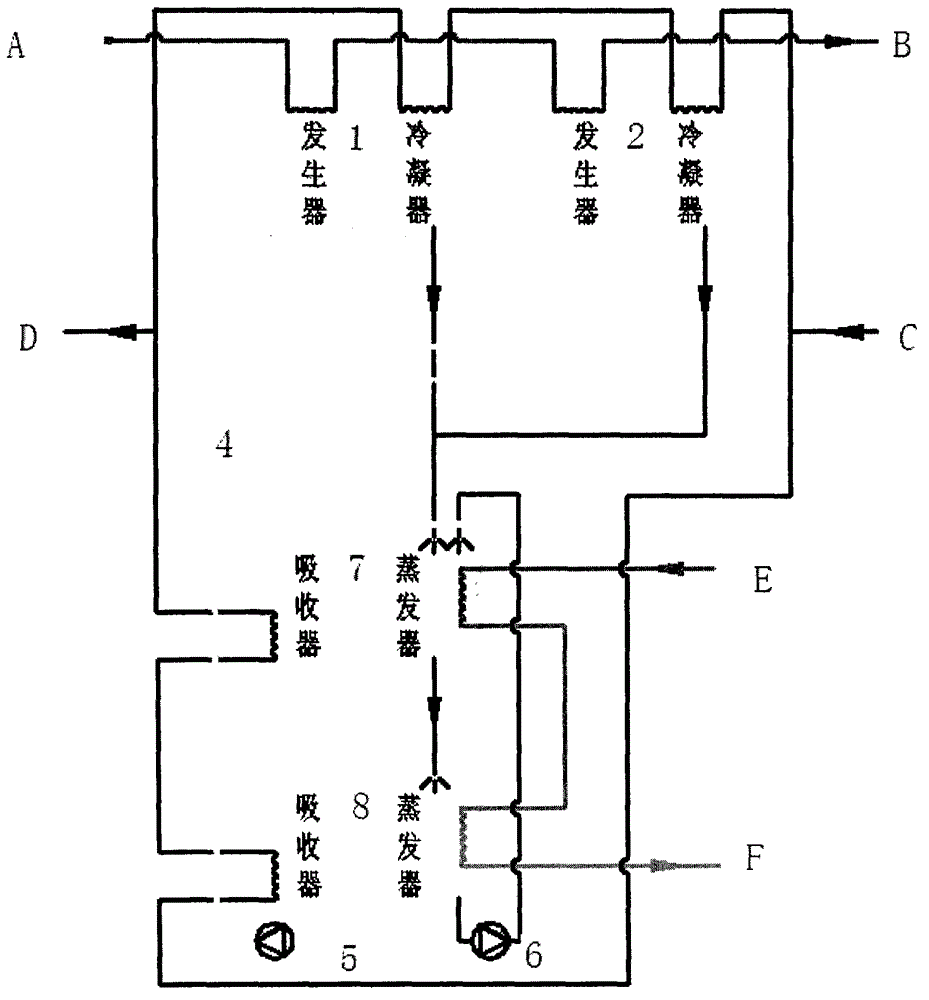

Waste heat energy supply devices for distributed type cloud computing system

InactiveCN108758786AGuaranteed Cooling TargetFlexible operationLighting and heating apparatusSpace heating and ventilation detailsWaste heat recovery unitEnergy supply

The invention relates to waste heat energy supply devices for a distributed type cloud computing system and relates to the technical field of waste heat recovery. The distributed type cloud computingsystem comprises at least one control node and computing nodes interacting with the control nodes. All the computing nodes are divided into multiple sets, and one set comprises one or more computing nodes. Each set of computing nodes are located in houses with heating needs in a first area. Each house corresponds to one waste heat energy supply device, and each waste heat energy supply device comprises a waste heat recovery unit corresponding to the corresponding set of computing nodes and used for absorbing heat of the set of computing nodes, and a heating unit in the house to which the set of computing nodes belong, wherein the waste heat recovery unit and the heating unit form a heat cycle system, and thus heat is supplied to the house. Servers are independently installed in the houseswith the heating needs flexibly, waste heat of the servers is recovered and reused, and the utilization rate of energy is increased.

Owner:NORTHEASTERN UNIV

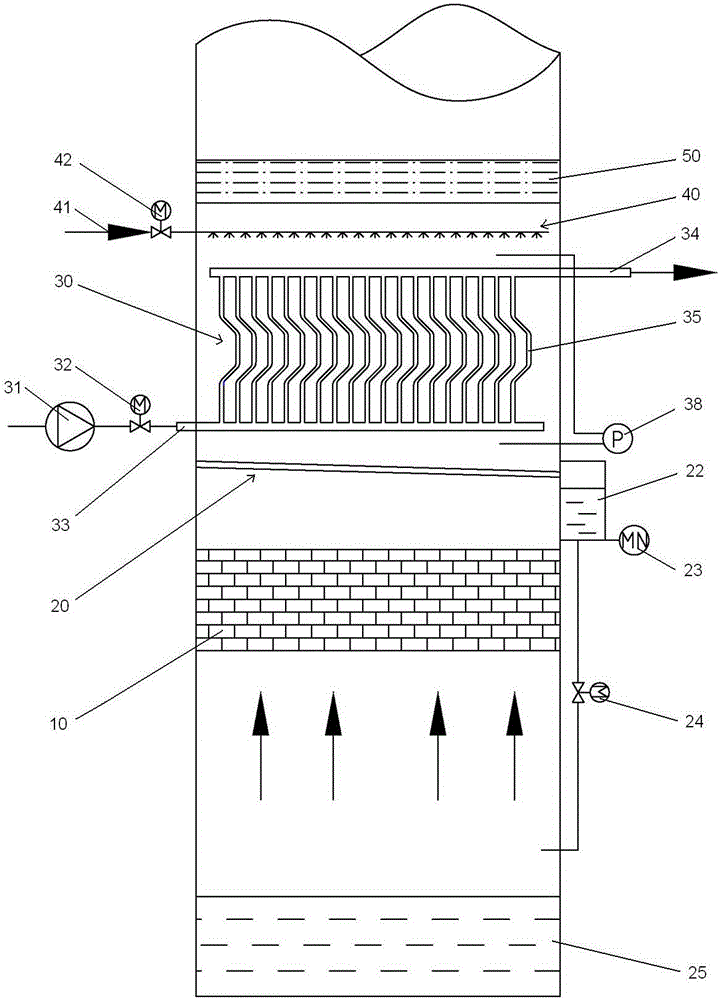

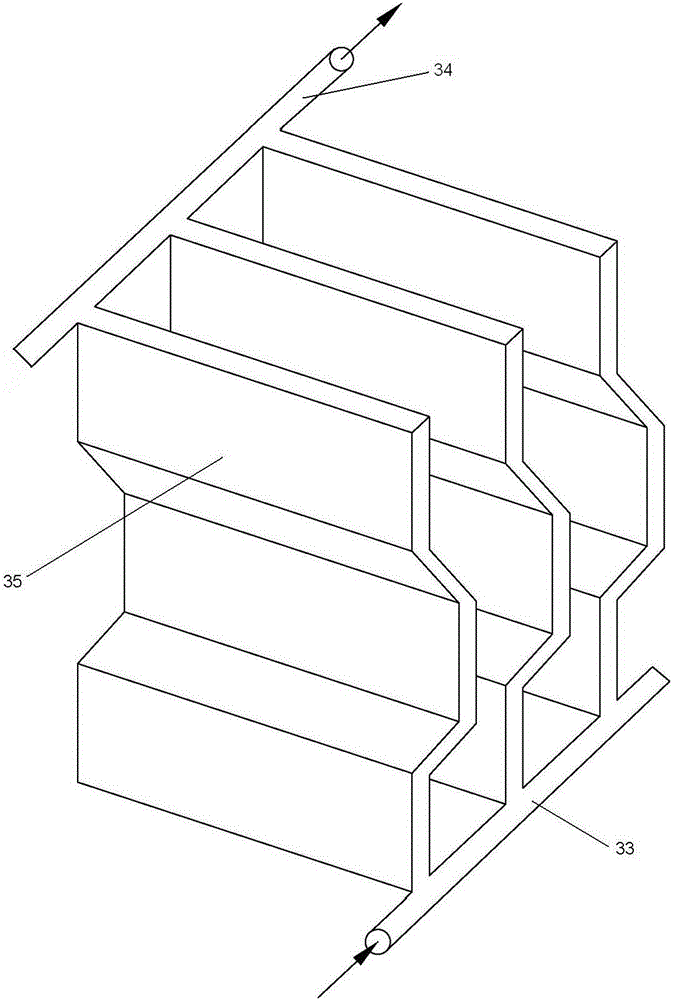

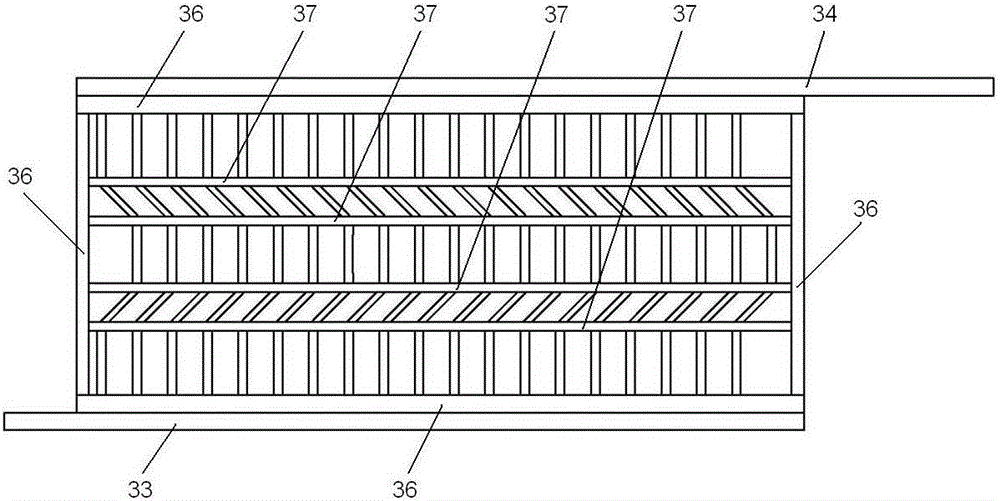

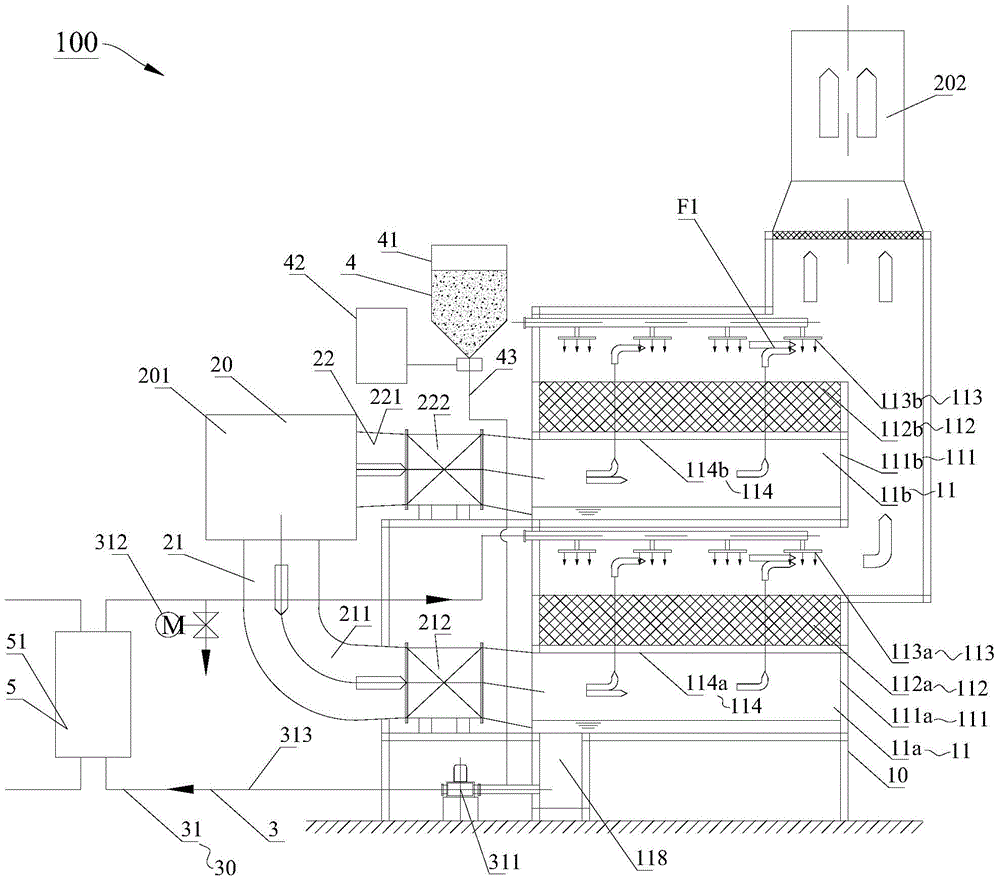

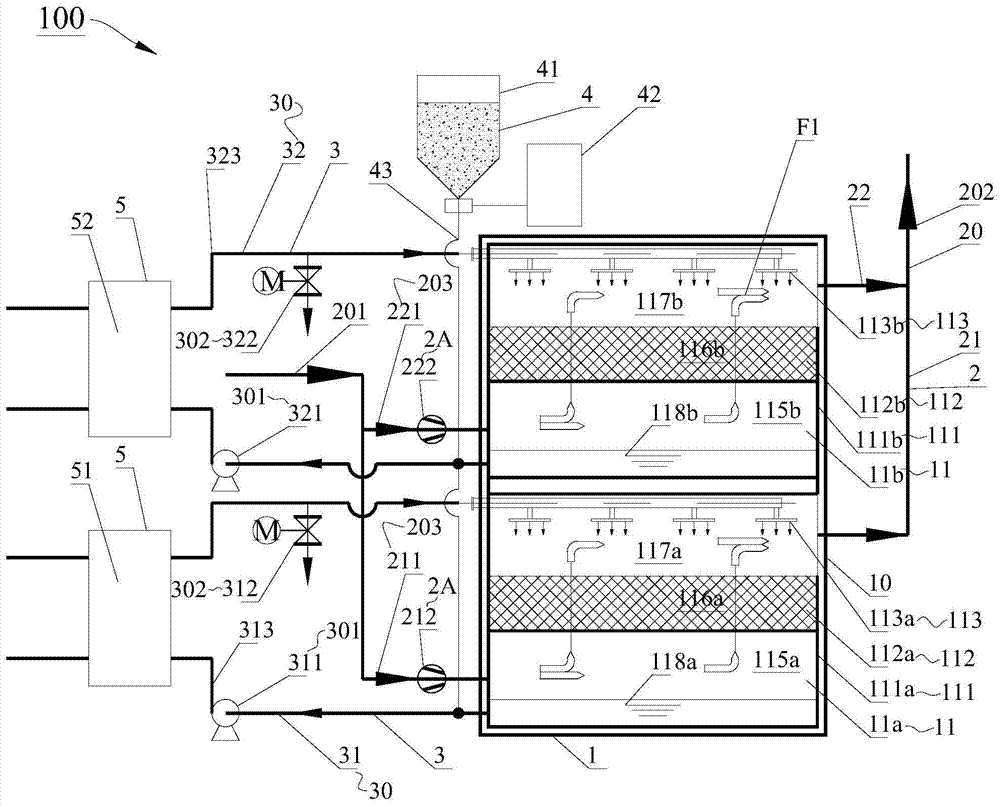

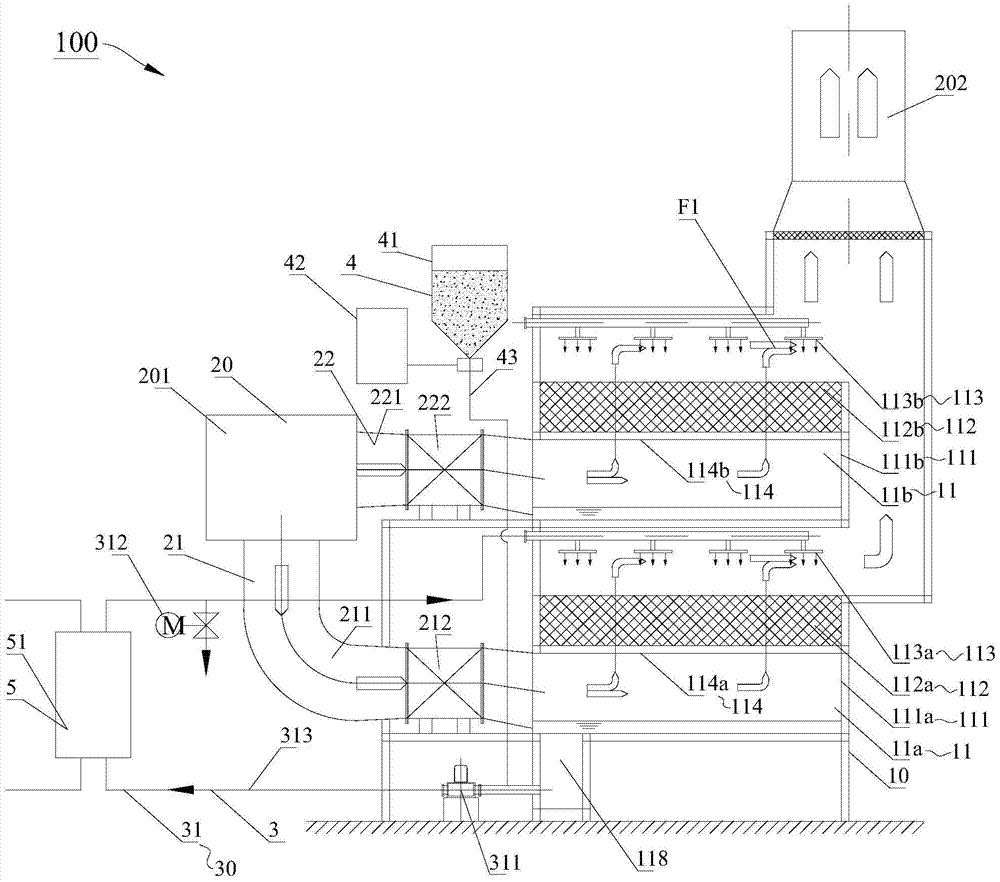

Multi-layer parallel-connection overlaid frame type spraying flue gas waste heat recovery and heat exchange device

ActiveCN104791822AReduce processingLow flow resistanceCombustion technology mitigationTrickle coolersThermal energyFlue gas

The invention discloses a multi-layer parallel-connection overlaid frame type spraying flue gas waste heat recovery and heat exchange device. The device comprises a flue gas waste heat recovery and heat exchange tower, a multi-layer overlaid parallel-connection flue gas system, a multi-layer overlaid spraying and delivering loop system, an alkaline adding neutralization system and a waste great recovery heat energy utilizing system. A plurality of overlaid spraying flue gas waste heat recovery and heat exchange assemblies are arranged in the flue gas waste heat recovery and heat exchange tower, supported and connected into a whole through a heat exchanger tower frame structure and connected in parallel on a flue gas circulating loop. According to the multi-layer parallel-connection overlaid frame type spraying flue gas waste heat recovery and heat exchange device, the heat exchange performance of the device is remarkably enhanced, and recovered waste heat can be increased by 20-40%; flue gas flowing resistance and the power consumption of a draught fan are remarkably reduced, all the spraying flue gas waste heat recovery and heat exchange assemblies can independently run, and running is more economical and more flexible; the acidoid absorbing performance can also be remarkably improved, and therefore the desulfurization and denitration dust removal effects of flue gas can be greatly enhanced; meanwhile, the occupied area can also be remarkably reduced, cost of investment is saved, the quality of equipment can be monitored conveniently, and potential safety hazards of site construction are reduced.

Owner:TSINGHUA UNIV +1

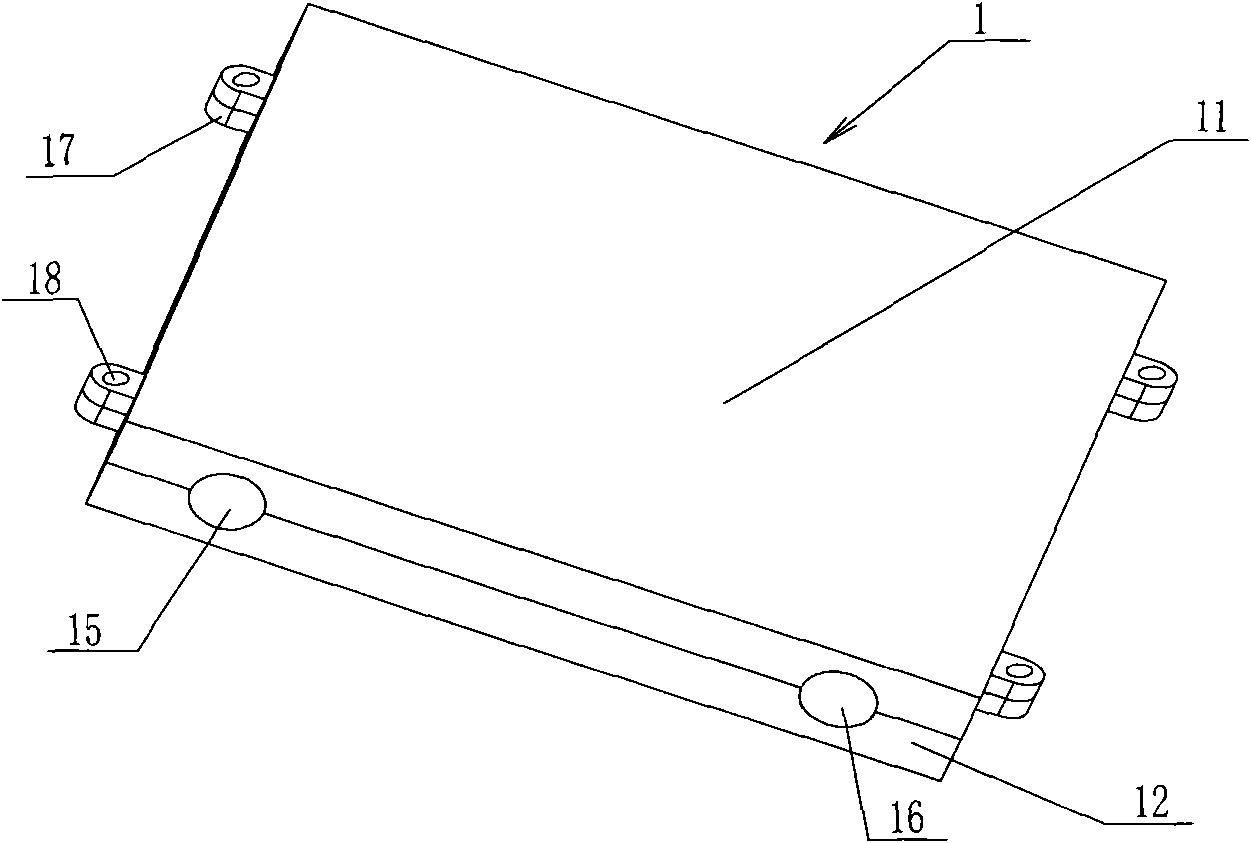

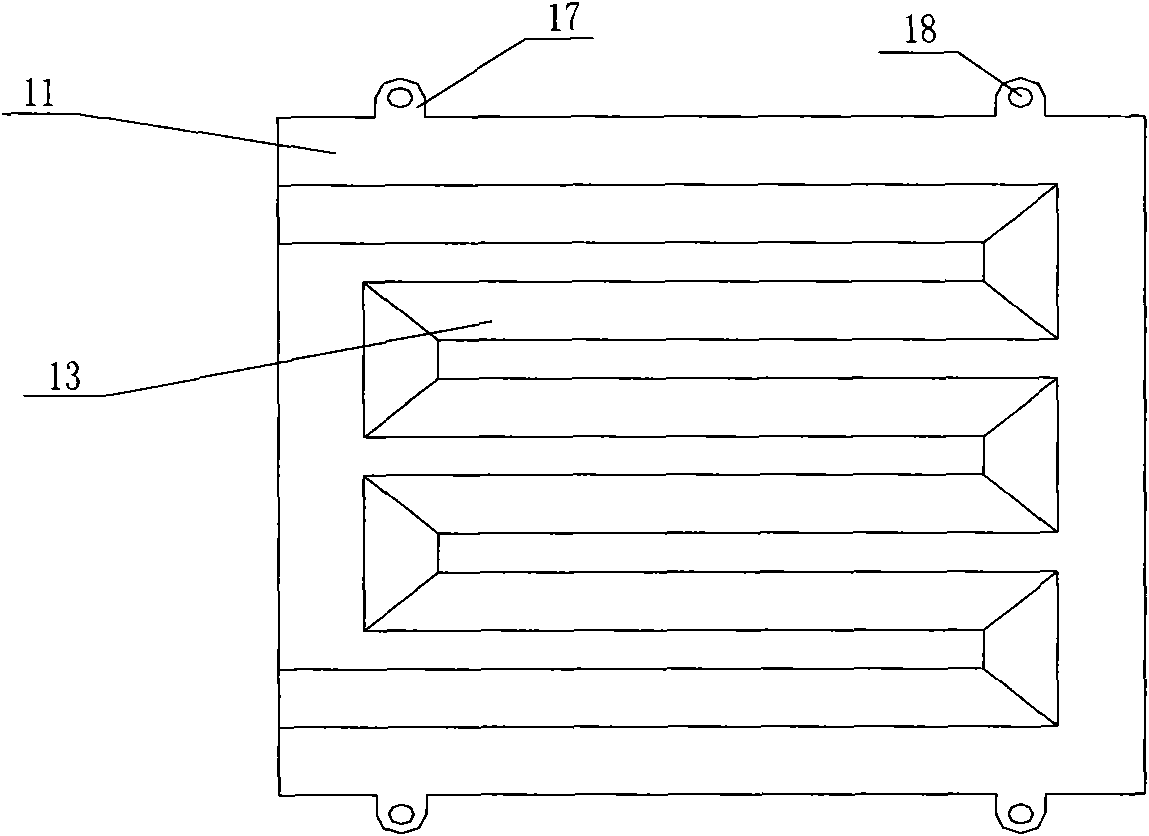

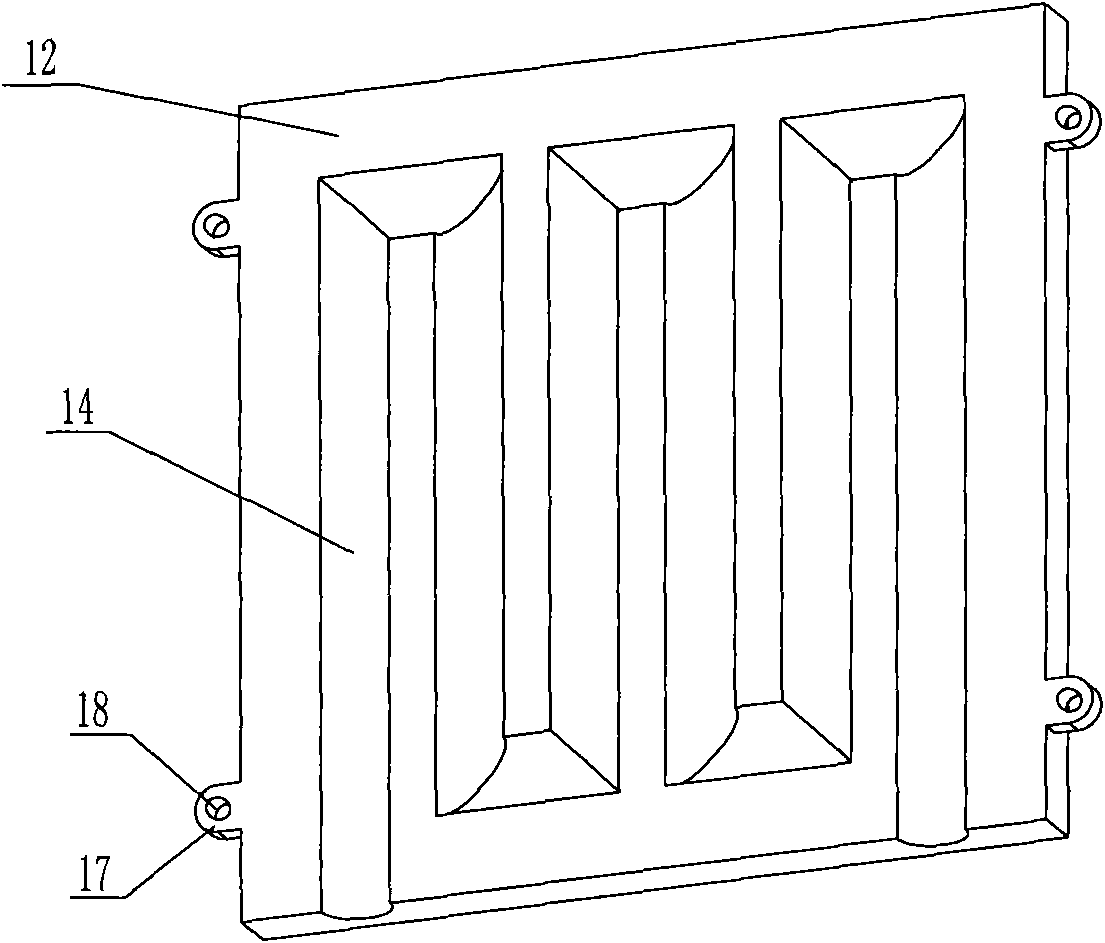

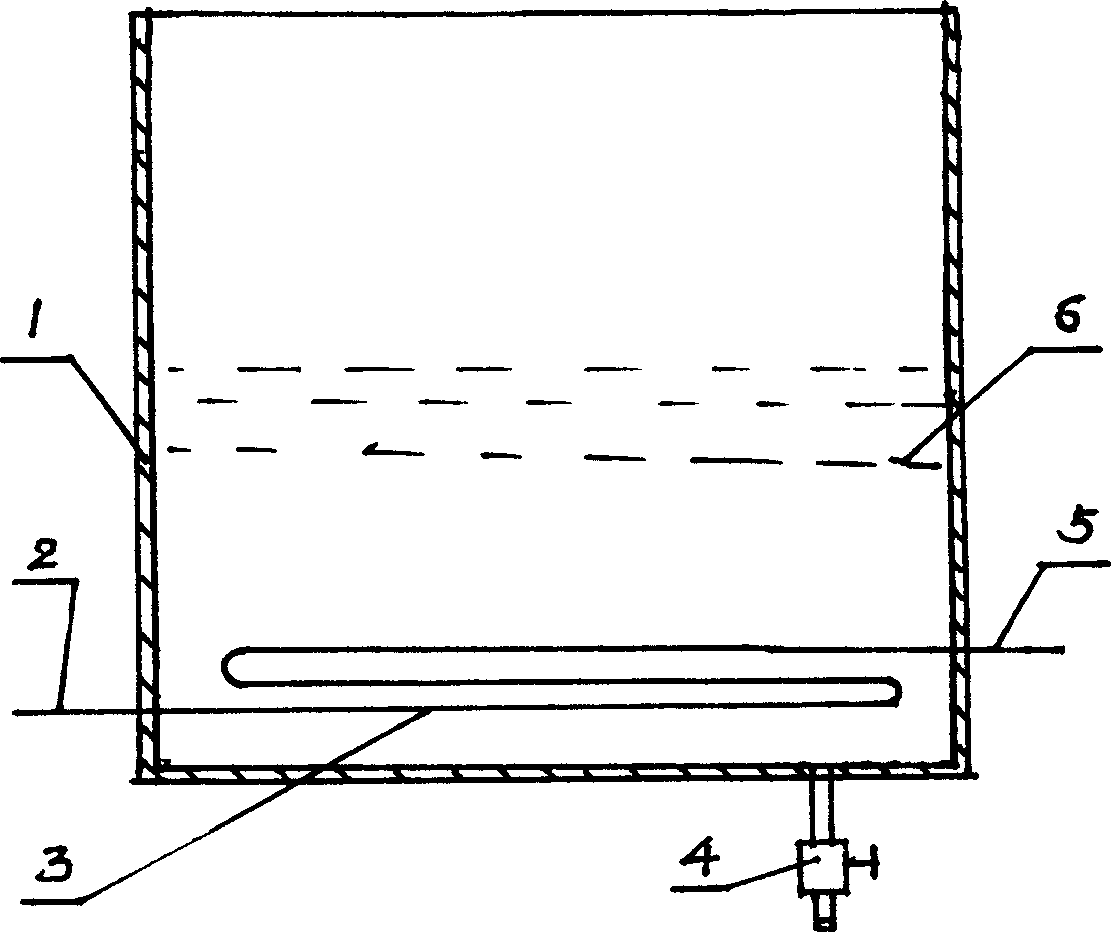

Heat exchanger and energy-saving shower

InactiveCN102374798AExtended flow timeEasy to processStationary conduit assembliesHeat exchanger casingsPlate heat exchangerWater flow

The invention provides a heat exchanger and an energy-saving shower. The heat exchanger comprises a main body heat exchanging part, wherein the main body heat exchanging part is in a split-type structure, and a circuitous water flow passage is formed inside the main body heat exchanging part. Water flow passages or water flow grooves are respectively processed on the branch parts of the main body heat exchanging part to be assembled into the circuitous water flow passage inside the main body heat exchanging part, so the flowing time of the water stream inside a pipeline can be increased, and the heat exchanger is convenient to process. In addition, all branch parts can be integrally molded, or the branch parts are connected with one another after partial branch parts are integrally molded, so the mass production can be facilitated, the service life is long, the reliability is high, and the surplus heat recycling efficiency is high.

Owner:HAIER GRP CORP +1

Gasification device for solid fuel and method for producing synthetic gas

ActiveCN101570699BImprove carbon conversionReduce water consumptionEnergy inputCombined combustion mitigationForming gasHigh carbon

The invention provides a gasification device for solid fuel, which comprises a gasification chamber and a cooling purification chamber. A first cooling medium distributor (5) is arranged at an inlet of the cooling purification chamber, and is used for injecting a low-temperature cooling medium into high-temperature synthetic gas from the gasification chamber along the circumferential direction, thereby making the high-temperature synthetic gas cooled and removing solid impurities from the high-temperature synthetic gas. The invention also provides a method for producing synthetic gas, which comprises the steps: ensuring that the quick incomplete reaction of the solid fuel and an oxidizing agent is performed to generate the high-temperature synthetic gas; and injecting the low-temperature cooling medium into the high-temperature synthetic gas along the circumferential direction to purify the high-temperature synthetic gas and make the temperature of the high-temperature synthetic gas reduced. The device and the method improve the purity of the synthetic gas which is finally obtained by temperature reduction, impurity removal and heat recovery for multiple times; and the device has high carbon conversion rate, and also has good complementary energy and waste heat recovery effect, low water consumption and no pollution.

Owner:CHANGZHENG ENG

Flue gas waste heat recovery method

ActiveCN104089266AAvoid discharge overheatingEfficient use ofChemical industryHeat-exchange elementsRecovery methodCooling tower

The invention discloses a flue gas waste heat recovery method. The processing steps of the recovery method are as follows: heat exchange is carried out through a high-temperature waste heat carrier and low-temperature saturated steam in a steam heat exchange mode for pre-heat-exchange first, then the high-temperature waste heat carrier enters a water cooling tower, heat transfer and heat exchange are conducted by means of heat-transfer media, a more reasonable multi-return-stroke heating method is adopted to carry out stepped heat transfer and temperature reduction ultimately on the basis that the heat-transfer media are utilized, heat of different potential temperatures of the high-temperature waste heat carrier is reasonably used, the high-temperature waste heat carrier is prevented from discharging overtemperature, and waste heat can be made full use of. According to the flue gas waste heat recovery method, high-temperature waste heat consumption of waste heat products of unit weight becomes low, efficient and comprehensive utilization of high-temperature waste heat and low-temperature waste heat is achieved, the waste heat recovery effect is good, influences of flue gas moisture content and flue gas temperature fluctuation are effectively eliminated, and a satisfying waste heat recovery effect can be reached; the stepped heat transfer and temperature reduction method is adopted, the high-temperature waste heat carrier is prevented from discharging overtemperature, and the waste heat is made full use of.

Owner:NANJING HUADIAN ENERGY SAVING & ENVIRONMENTAL PROTECTION EQUIP

Waste heat recovery furnace

ActiveCN104121786BEfficient recyclingReduce dosageEnergy industryWaste heat treatmentRecovery boilerWaste management

The invention provides a waste heat recycling furnace. According to the waste heat recycling furnace, waste heat of sintered ore can be sufficiently and efficiently recycled. The waste heat recycling furnace comprises a cooling cylinder. A feeding opening is formed in the upper surface of the cooling cylinder, a sealing cover for sealing the feeding opening is arranged on the feeding opening, an air outlet is formed in the upper end of the side wall of the cooling cylinder and connected with an induced draft fan, a conical cold feeder is connected to the lower end of the cooling cylinder, a discharging opening is formed in the lower end of the cold feeder, a vibration discharging machine is installed in the discharging opening, a center cooling air pipe extending to the center of the cooling cylinder is installed on the waste heat recycling furnace, a conical center air cap with the upward top end is connected to the upper end of the center cooling air pipe, a plurality of air holes are formed in the conical wall of the center air cap, one or more peripheral cooling air pipes are formed on the conical wall of the cold feeder in the mode of surrounding the conical wall, a discharging mechanism is arranged between the cooling cylinder and the cold feeder and comprises an upper discharging plate and a lower discharging plate, and the upper discharging plate and the lower discharging plate can be opened and closed and can achieve discharging through reciprocating movement.

Owner:TIANJIN ZHENGYUANHE TECH DEV CO LTD

Cooling structure for settling chamber top of electric furnace and manufacturing method of cooling structure

InactiveCN102840760AEliminates prone to leaksReduce heat lossFurnace cooling arrangementsSteel platesElectric furnaces

The invention discloses a cooling structure for the settling chamber top of an electric furnace and a manufacturing method of the cooling structure. The aim of cooling the settling chamber top is fulfilled by hanging a stainless steel top and spraying. The technical scheme of the invention is specifically as follows: a plurality of riveting pieces are fixedly connected on the bottom surface of a water cooling plate on the settling chamber top, and are fixedly connected into a whole through a diamond-shaped steel plate net; heat insulating coatings are coated on the riveting pieces and the diamond-shaped steel plate net; the riveting pieces are preferably fixed with the bottom surface of the water cooling plate on the settling chamber top and the diamond-shaped steel plate net in a welding way; moreover, the riveting pieces are preferably V-shaped riveting pieces; the thickness of the diamond-shaped steel plate net is preferably over 6 millimeters; and the thicknesses of the heat insulating coatings are preferably over 50 millimeters. Due to the adoption of the cooling structure, the conventional tubular water cooling plate is eliminated, the defects of easy water leakage, easy agglomerating of a dust-removing cloth bag, large heat loss, high equipment maintenance cost and the like existing in the prior art are overcome, the residual heat recovering effect and the dust-removing effect can be improved effectively, environmental friendliness is facilitated, and the equipment maintenance cost can be reduced greatly.

Owner:SHAGANG GROUP

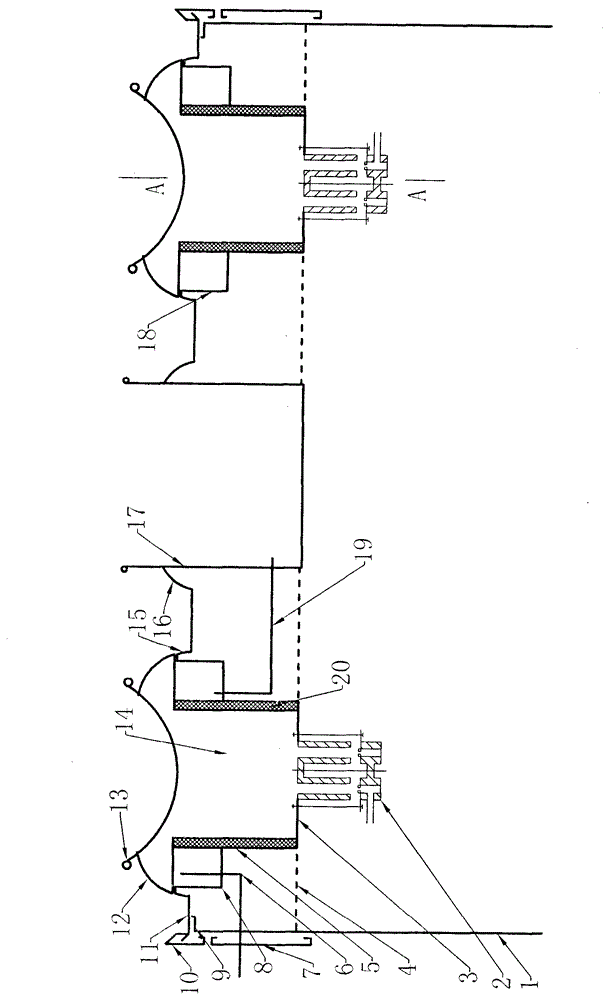

Low-noise maintenance-free energy-saving kitchen range

InactiveCN105318371AImprove efficiencyGood recovery of waste heatLighting and heating apparatusWater heating stoves/rangesBurning outCombustion chamber

A low-noise maintenance-free energy-saving kitchen range is mainly composed of a support, a waste heat recycler, a combustor, a water barrel and a heat-preservative water tank. High-temperature waste flame and high-temperature waste smoke are contacted with the waste heat recycler at first time and in first space so that the heat efficiency is greatly increased. A tubular wing plate and a waste heat recycler battery are connected to the main body of the waste heat recycler. The waste heat recycler has enough heat change area to achieve excellent waste heat recycling effect. During normal cooking, waste heat is employed to generate large amounts of hot water, boiled water and vapor, so that the kitchen range can solve a difficult problem that a kitchen range hearth is liable to be burned-out in a water-cooling-type flue and a water-cooling-type hearth. The kitchen range employs a sealed combustion operation manner so that waste smoke and combustion noise from the combustion chamber are discharged to outdoor through a flue duct, so that noise in a kitchen is reduced. The kitchen range is low in production cost, is long in service life, is high in reliability, is free of maintenance, is simple in production process, allows large-scale industrial production and has a wide market prospect.

Owner:侯国山

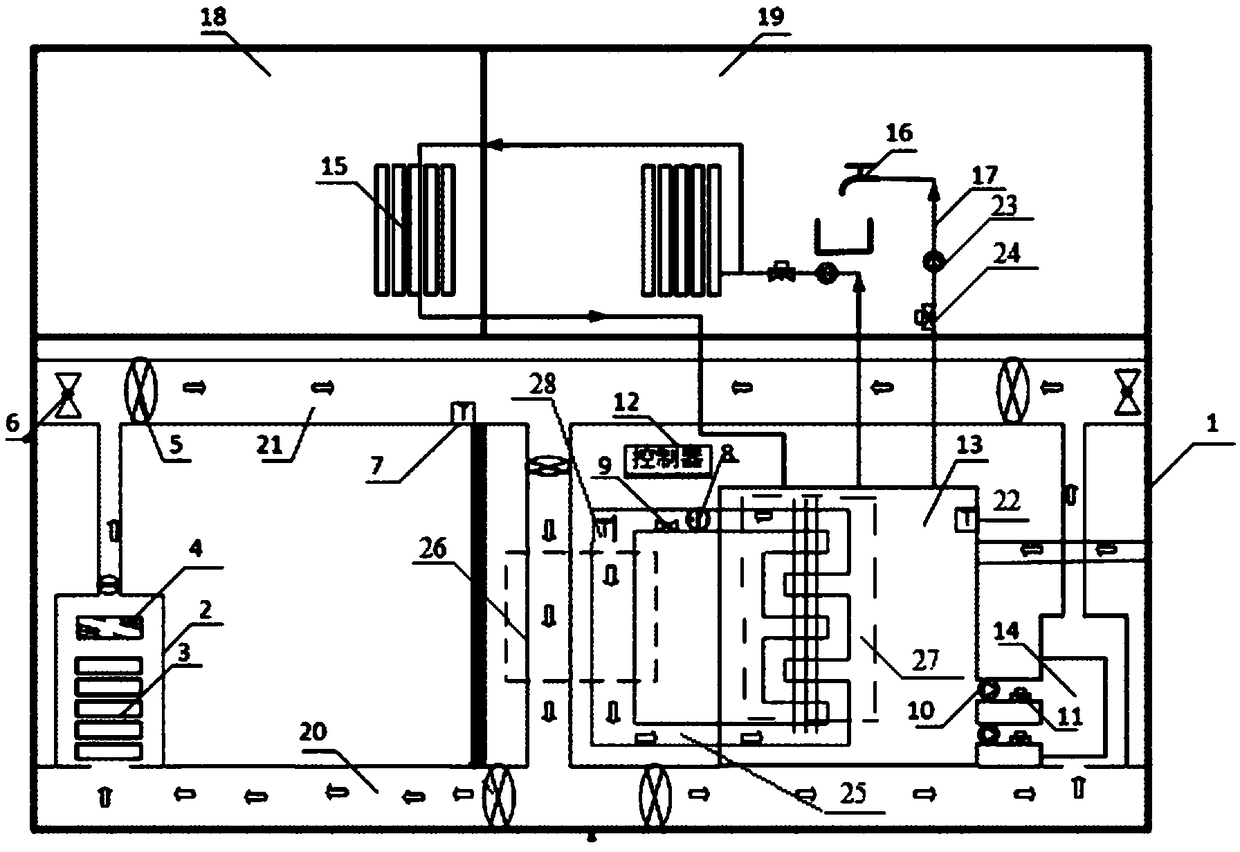

Equipment waste heat utilization system

InactiveCN103453631AGood recovery of waste heatRealize heating in winterEnergy recovery in ventilation and heatingDucting arrangementsSecondary loopEngineering

The invention discloses an equipment waste heat utilization system, which comprises an air-conditioned room, a heat exchanger, a motor, a fan, a ventilating duct, spinning equipment and auxiliary heating equipment, wherein the spinning equipment and the heat exchanger form a primary loop; the air-conditioned room and the ventilating duct form a secondary loop; a heat absorption end of the heat exchanger is arranged in the spinning equipment; a heat radiation end of the heat exchanger is arranged in the air-conditioned room; the heat absorption end is connected with the heat radiation end through a pipeline; the ventilating duct is arranged in the air-conditioned room; the motor and the fan are arranged at a pipeline port; the auxiliary heating equipment is arranged in the air-conditioned room; the ventilating duct is communicated with a workshop. Through the manner, the equipment waste heat utilization system has the advantages of high reliability, compact structure, good adaptability, energy conservation, heat radiation of auxiliary equipment, and the like, and meanwhile, the system has wide market prospect in the commercial unit field.

Owner:ZHONGRUN SCI & TECH

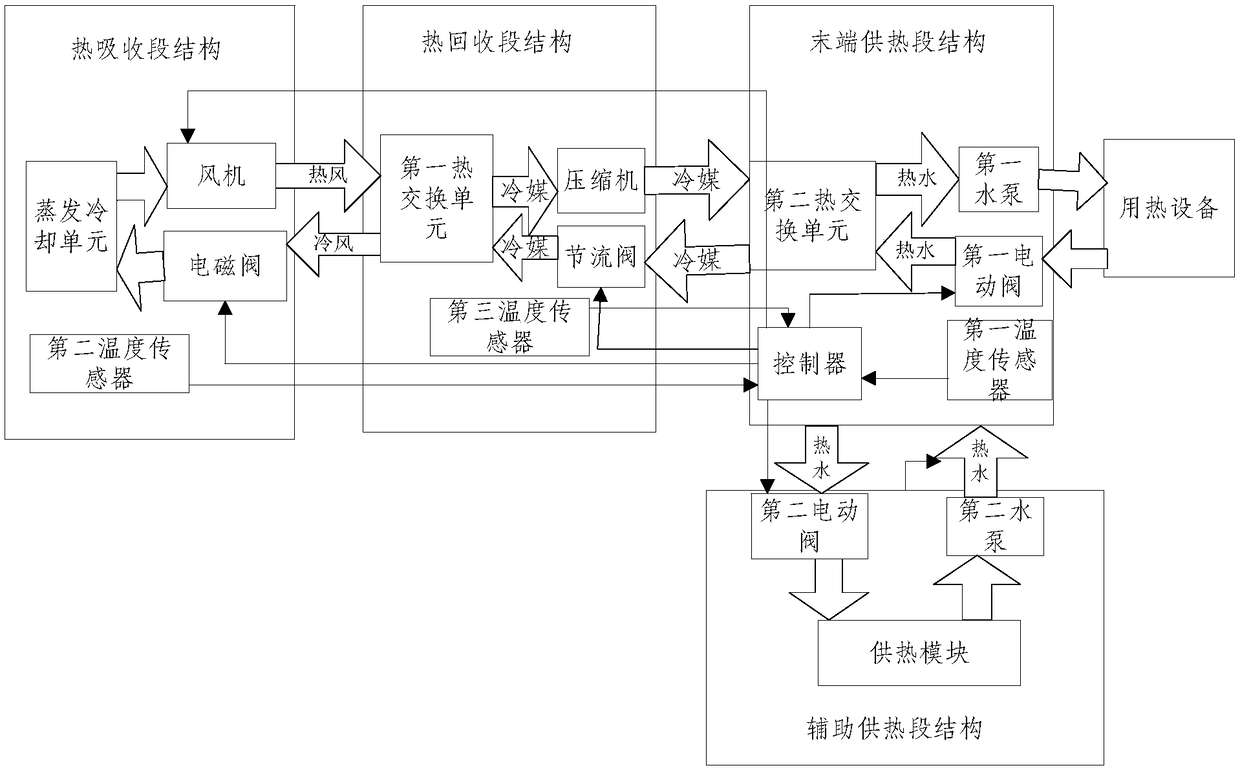

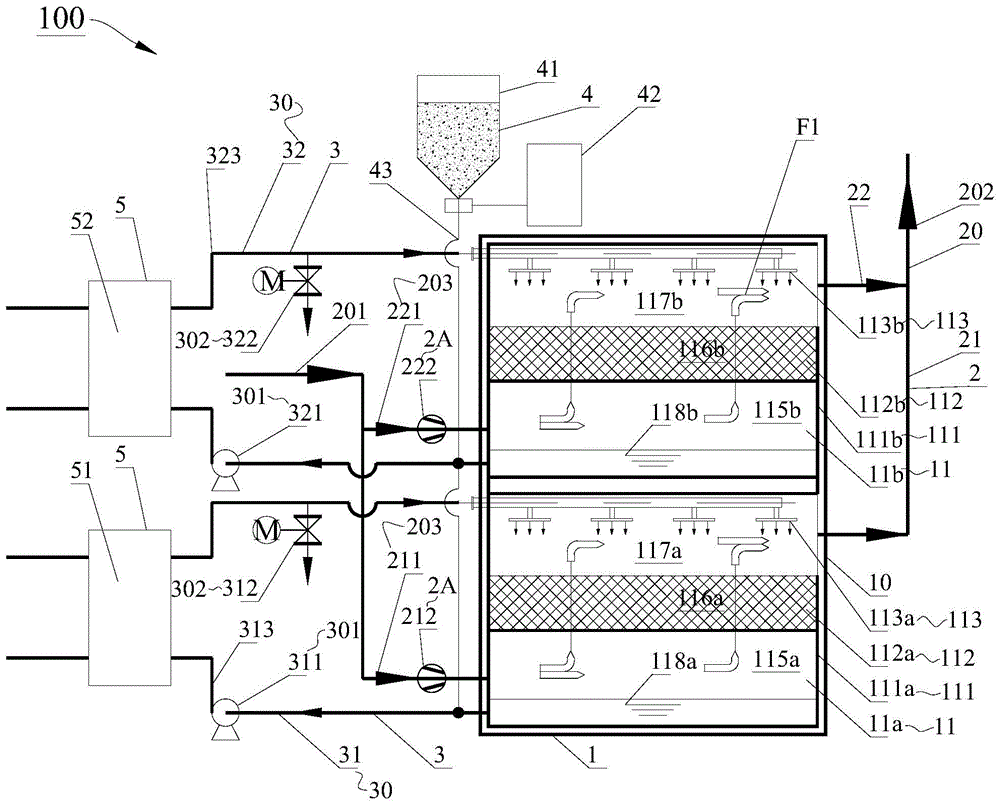

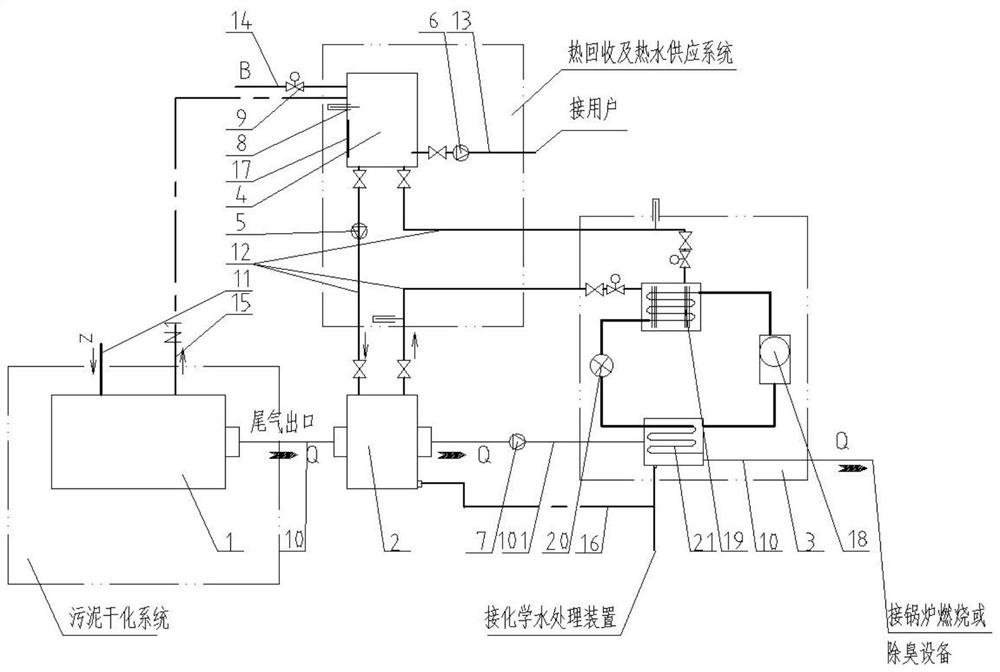

Condensation heat recovery heat pump hot water system for sludge drying system

PendingCN113606781AEasy to produceEasy to install on siteFluid heatersSludge treatment by de-watering/drying/thickeningSludgeWater circulation

The invention provides a condensation heat recovery heat pump hot water system for a sludge drying system. The condensation heat recovery heat pump hot water system comprises the sludge drying system and a heat pump hot water unit, wherein a steam outlet of the sludge drying system is connected with a hot water tank; a tail gas outlet of the sludge drying system is connected with a condensation heat recovery device; the heat pump hot water unit comprises a compressor, a condenser, a throttling valve and an evaporator which are connected in sequence; and the hot water tank, the condensation heat recovery device and the condenser are connected through a pipeline to form a water circulation heating pipeline. Compared with the prior art, the condensation heat recovery heat pump hot water system is simple, easy to produce and mount on site, good in waste heat recovery effect and high in waste heat utilization rate, and has obvious environmental friendliness. By the condensation heat recovery heat pump hot water system, the problem of generation of condensate water in a tail gas conveying process after sludge drying can be effectively solved, and waste heat in a drying process can be effectively recovered.

Owner:CEEC HUNAN ELECTRIC POWER DESIGN INST

Multi-layer parallel stacked frame type spray flue gas waste heat recovery heat exchange device

ActiveCN104791822BLow flow resistanceLow running costCombustion technology mitigationTrickle coolersFlue gasProcess engineering

The invention discloses a multi-layer parallel-connection overlaid frame type spraying flue gas waste heat recovery and heat exchange device. The device comprises a flue gas waste heat recovery and heat exchange tower, a multi-layer overlaid parallel-connection flue gas system, a multi-layer overlaid spraying and delivering loop system, an alkaline adding neutralization system and a waste great recovery heat energy utilizing system. A plurality of overlaid spraying flue gas waste heat recovery and heat exchange assemblies are arranged in the flue gas waste heat recovery and heat exchange tower, supported and connected into a whole through a heat exchanger tower frame structure and connected in parallel on a flue gas circulating loop. According to the multi-layer parallel-connection overlaid frame type spraying flue gas waste heat recovery and heat exchange device, the heat exchange performance of the device is remarkably enhanced, and recovered waste heat can be increased by 20-40%; flue gas flowing resistance and the power consumption of a draught fan are remarkably reduced, all the spraying flue gas waste heat recovery and heat exchange assemblies can independently run, and running is more economical and more flexible; the acidoid absorbing performance can also be remarkably improved, and therefore the desulfurization and denitration dust removal effects of flue gas can be greatly enhanced; meanwhile, the occupied area can also be remarkably reduced, cost of investment is saved, the quality of equipment can be monitored conveniently, and potential safety hazards of site construction are reduced.

Owner:TSINGHUA UNIV +1

Series water tank recovering waste heat in air radiation type refrigerating system

InactiveCN1749667AGuaranteed working temperatureSimple designEnergy recovery in ventilation and heatingLighting and heating apparatusWarm waterEngineering

The refrigerating system of the present invention has snakelike or spiral long high pressure refrigerant liquid pipeline between the high pressure end of the compressor and refrigerating radiator set inside a water tank, and can recover the afterheat and ensure the normal continuous operation of the compressor. The present invention makes it possible for the air conditioner to produce hot water with its afterheat, for refrigerator to produce warm water with its afterheat and for refrigerated warehouse to produce hot with its afterheat water for bathing.

Owner:刘佰林

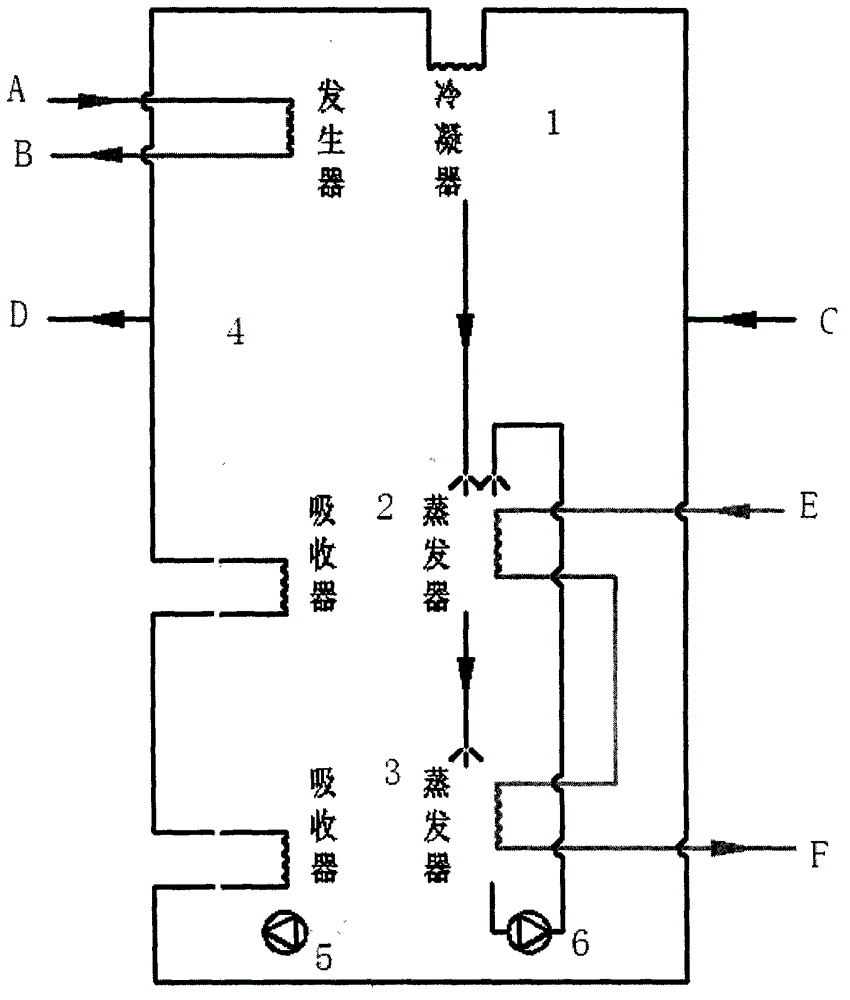

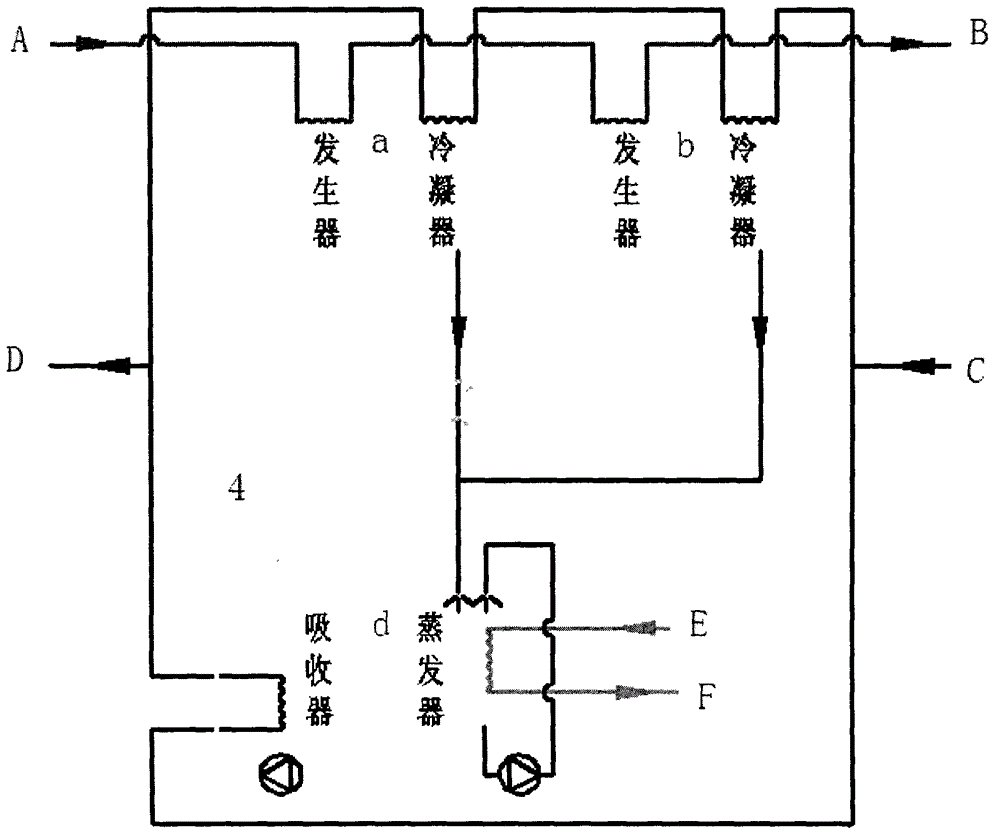

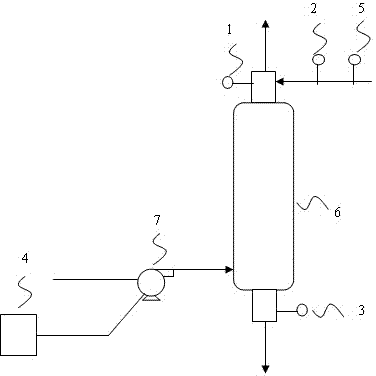

Unit type hot water heat pump

ActiveCN104089434AGood recovery of waste heatHeat pumpsHot-water central heatingEvaporationEngineering

The invention provides a unit type hot water type heat pump which comprises m generation-condenser modules, n absorption-evaporator modules and a solution heat exchanger. The unit type hot water type heat pump is characterized in that the standard unit modules are designed, and through different combinations, the heat pump adapts to requirements of different conditions. The modules are respectively and independently designed, manufactured and formed with generation-condensing and evaporation-absorption as unit levels, and the matched assembling modes of the unit levels can be selected according to different conditions so that the heat pump can achieve the optimum waste heat recycling effect. Through the unit module type, the design workloads are reduced, the production material supply period is shortened, the different station requirements can be met, and possibility is provided for mass production and application of the heat pump.

Owner:CES BEIJING ENERGY SAVING INVESTMENT

Maintenance-free waste heat utilization commercial charcoal stove

InactiveCN105222171AImprove efficiencyGood recovery of waste heatStove/ranges for heating waterSteam generation plantsBurning outHeating efficiency

The invention discloses a maintenance-free waste heat utilization commercial charcoal stove. The maintenance-free waste heat utilization commercial charcoal stove mainly comprises a bracket, a waste heat recycling device, an electric heater and a water bucket. According to the maintenance-free waste heat utilization commercial charcoal stove, the high-temperature waste flame and the high-temperature waste smoke are in contact with the waste heat recycling device in a first space at first time, so that the heating efficiency can be greatly improved. A waste heat recycling device main body is connected with a wing plate, a ring-shaped wing plate and a fort, wherein the waste heat recycling device has large enough heat exchange area, so that the excellent waste heat recycling effect is implemented. When the maintenance-free waste heat utilization commercial charcoal stove is capable of generating a large amount of hot water, boiled water or steam by using the waste heat while normally cooking rice and cooking dishes; the electric heater is matched with the water bucket, the maintenance-free waste heat utilization commercial charcoal stove still can be used as an electric steamer or an electric water heater even if not cooking rice and cooking dishes; according to the maintenance-free waste heat utilization commercial charcoal stove, the serious and long-standing problem that the hearth is easy to burn out of all time of a water-cooling type smoke channel and a water-cooling type hearth can be solved; a system of the maintenance-free waste heat utilization commercial charcoal stove is low in manufacturing cost, long in service life, high in reliability and simple in production process; the large-scale industrial production can be implemented; the maintenance-free waste heat utilization commercial charcoal stove has a broad market prospect.

Owner:侯国山

Method for recycling flue gas waste heat of alumina roasting furnace

ActiveCN101915515BEffective temperature controlTemperature controlHeat exchange apparatusFlue gasEngineering

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

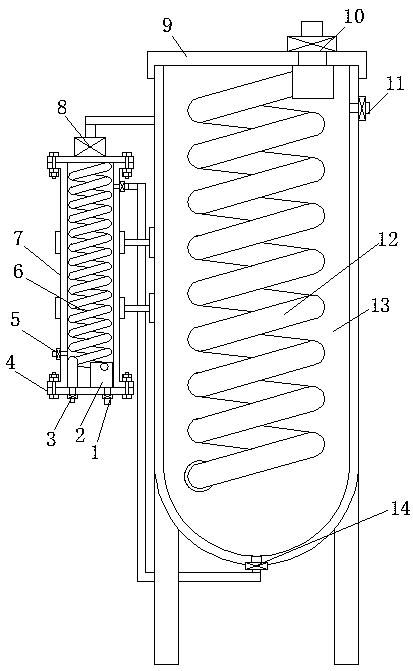

Exhaust gas afterheat recycle device

InactiveCN108050867AAchieve recyclingNovel structureVapor condensationStationary tubular conduit assembliesOrganic solventEngineering

The invention provides an exhaust gas afterheat recycle device. The device comprises a condensation tank, an upper end and lower end of the condensation tank are provided with end covers, the condensation tank is internally provided with a spiral condensation pipe, a lower end of the spiral condensation pipe is respectively connected with a gas inflow joint and a liquid collecting tank, an upper end of the spiral condensation pipe is connected with a gas discharging pipe joint, one side at a lower end of the condensation tank is connected with a water inflow joint, one side of the upper end ofthe condensation tank is connected with a water outflow joint, one side of the condensation tank is provided with a heat recycle tank, the heat recycle tank is internally provided with a spiral gas pipe, a lower end of the heat recycle tank is connected with the water outflow joint through a joint and a water pipe, a lower end of the spiral gas pipe is connected with the gas discharging pipe joint through a three-way valve and the gas pipe. The exhaust gas afterheat recycle device is novel in structure and stable in operation, can be used for realizing recycle of a volatile organic solvent inexhaust gas and second-level heat recycle treatment, is good in afterheat recycle effect, and meets current application requirement.

Owner:CHANGSHU YUTONG PHOTOELECTRIC TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com