Novel process for making synthetic natural gas by using coke-oven gas

A technology for synthesizing natural gas and coke oven gas, which is applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of insufficient utilization of hydrogen, high investment, high operating costs, and low utilization of hydrogen resources, so as to prevent sulfur poisoning and improve Recovering waste heat and strong heat removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

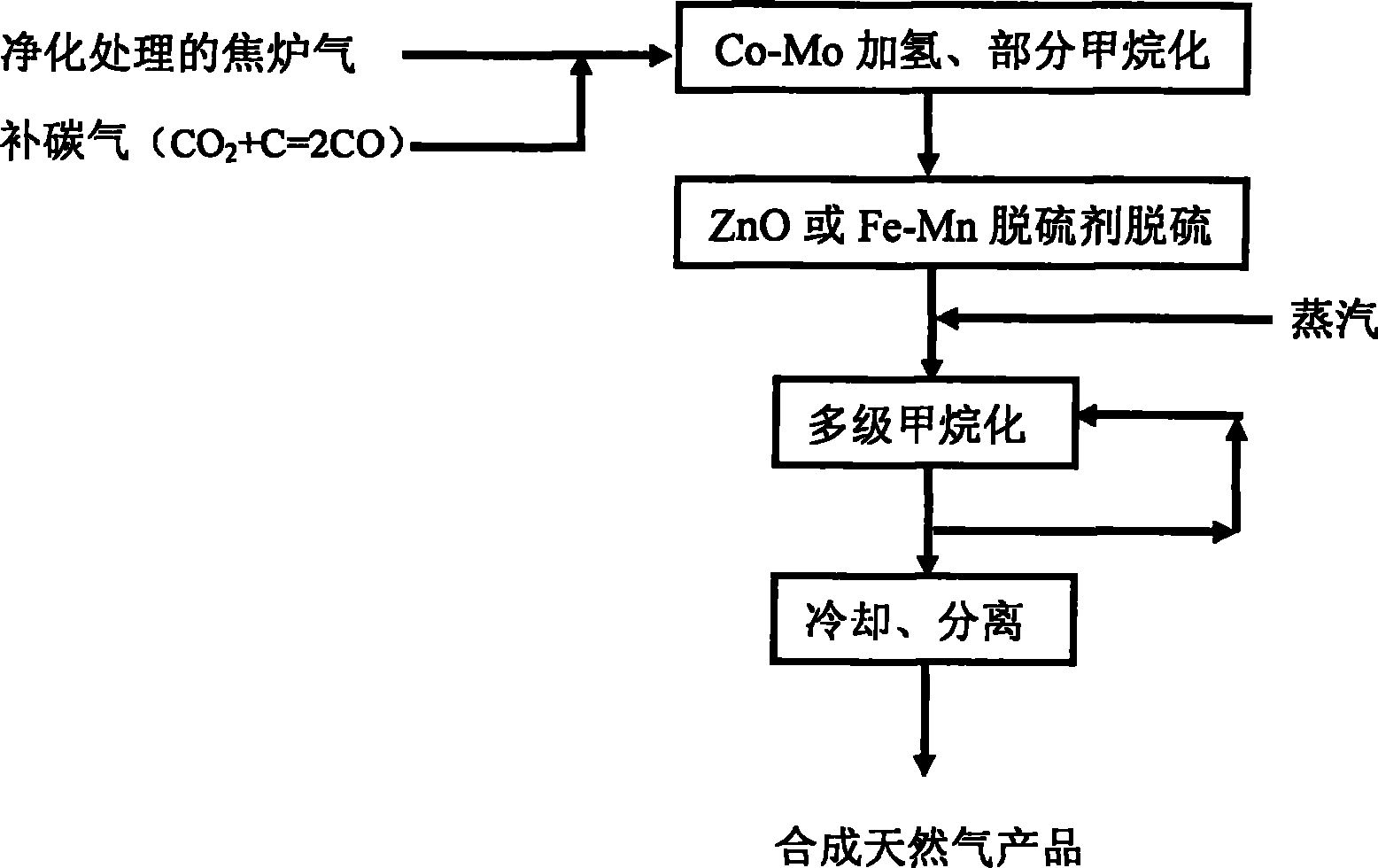

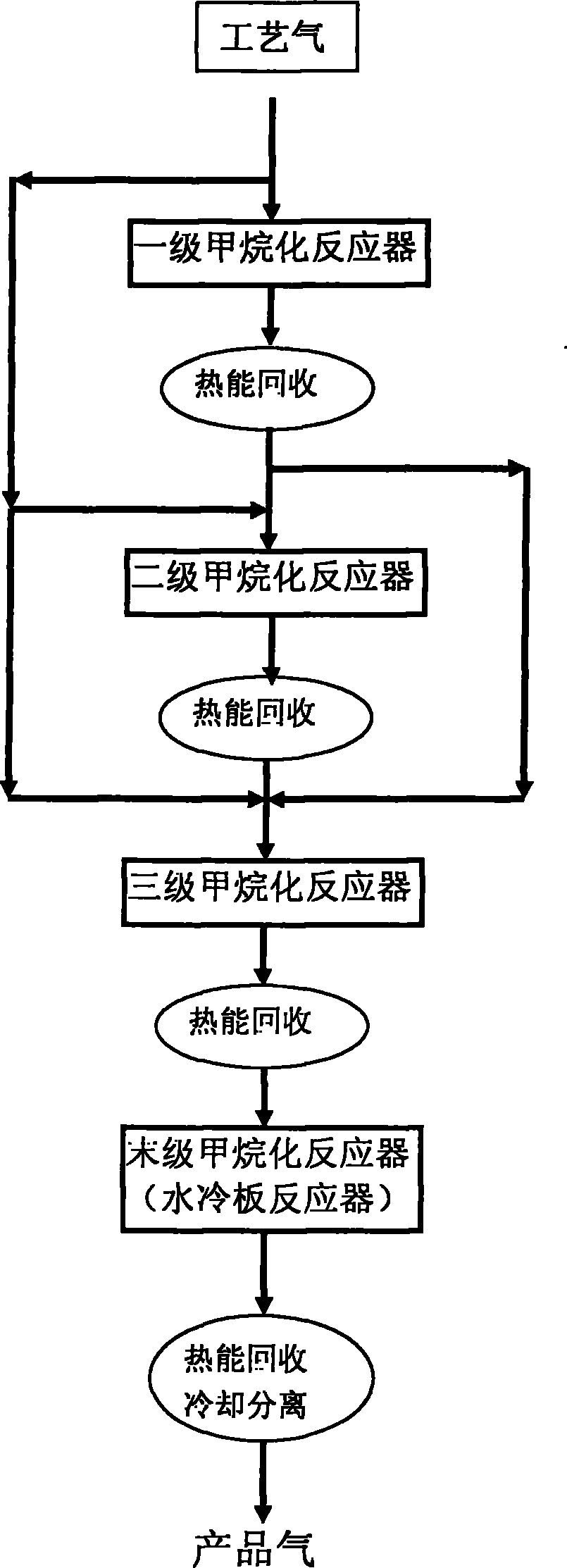

[0038] In this embodiment, the process for preparing synthetic natural gas by using coke oven gas is as follows, and the flow chart is shown in figure 1 .

[0039] Coke oven gas treated by conventional purification methods (referring to detarring, crude desulfurization, deammonization, benzene washing and benzene removal, final naphthalene removal, etc., the same below) is mixed with carbon replenishing gas. The gas composition after mixing (v% ): H 2 54.04, CO 13.14, CO 23.07, CH 4 24.22, C 2 h 4 2.10,N 2 3.03, O 2 0.28,H 2 O 0.12, H 2 S25ppm, COS 12ppm; After heat exchange, the temperature of the gas reaches 250°C and enters the Co-Mo hydrogenation reactor, where the Co-Mo hydrogenation conversion catalyst (active component: CoO 3-4%wt, MoO 3 11~13%wt, the rest is carrier γ-Al 2 o 3 ) under the action of organic sulfur into inorganic sulfur, while hydrogenating unsaturated hydrocarbons into alkanes, a small amount of O 2 with H 2 React (generate water) and...

Embodiment 2

[0043] In this embodiment, the process for preparing synthetic natural gas by using coke oven gas is as follows, and the flow chart is shown in figure 1 .

[0044] The coke oven gas treated by conventional purification methods is mixed with carbon replenishing gas, and the gas composition after mixing (v%): H 2 54.05, CO 13.14, CO 2 3.07, CH 4 24.22, C 2 h 4 2.10,N 2 3.03, O 2 0.28,H 2 O0.11, H 2 S 25ppm, COS 12ppm; the temperature of the gas reaches 255°C after heat exchange and enters the Co-Mo hydrogenation reactor. 3 11~13%wt, the rest is carrier γ-Al 2 o 3 ) under the action of organic sulfur into inorganic sulfur, while hydrogenating unsaturated hydrocarbons into alkanes, a small amount of O 2 with H 2 React (generate water) and complete partial methanation, then enter the desulfurization reactor to remove inorganic sulfur under the action of zinc oxide desulfurizer, the pressure of the hydrodesulfurization reaction is about 3.3MPa, the temperature is ...

Embodiment 3

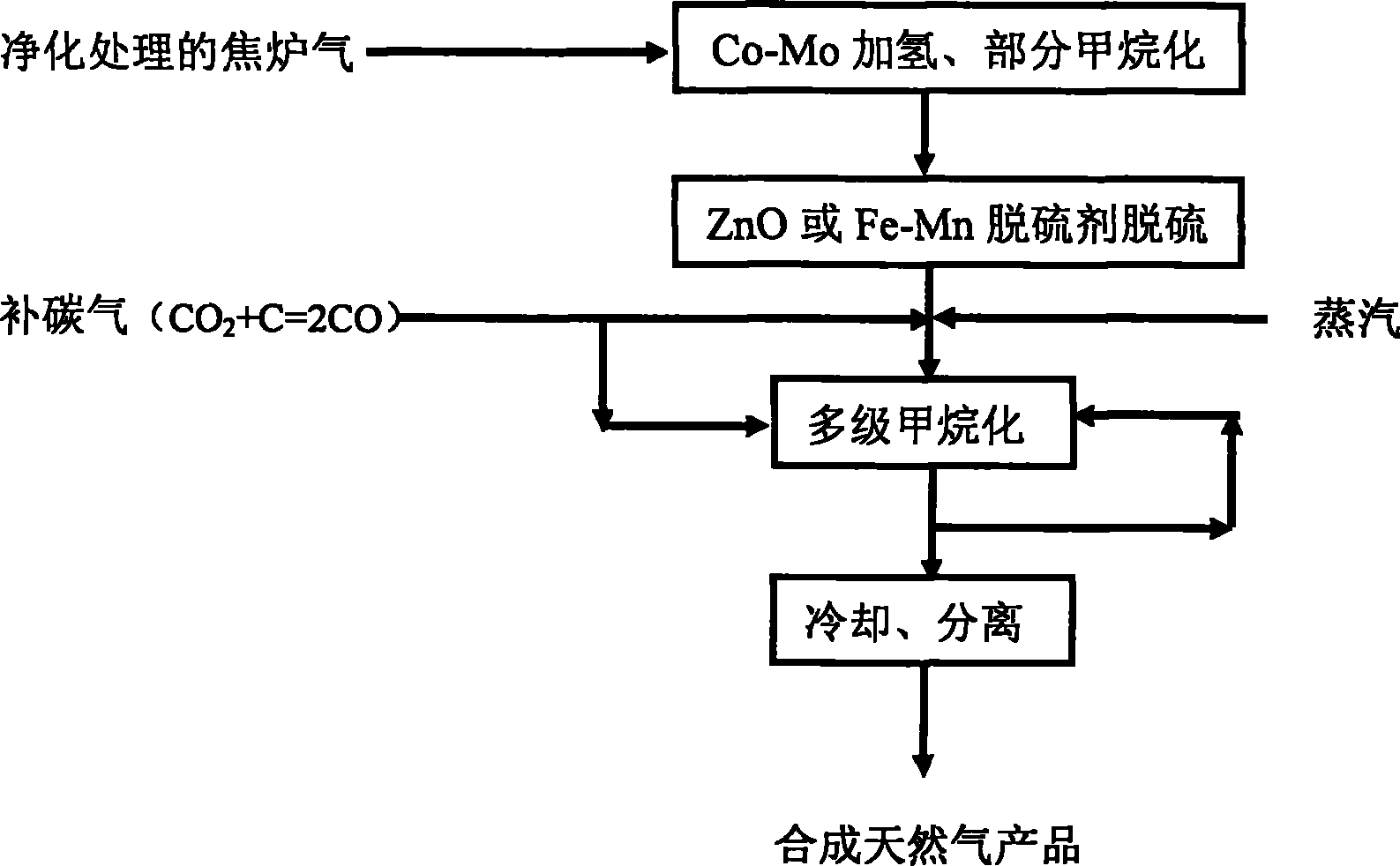

[0047] In this embodiment, the process for preparing synthetic natural gas by using coke oven gas is as follows, and the flow chart is shown in figure 2 .

[0048] Coke oven gas treated by conventional purification methods, gas composition (v%): H 2 58.72, CO 7.29, CO 2 2.30, CH 4 25.56, C 2 h 4 2.10,N 2 3.50,O 2 0.40,H 2 O 0.13, H 2 S 53ppm, COS 27ppm: The gas temperature reaches 250°C after heat exchange and enters the Co-Mo hydrogenation reactor, where the Co-Mo hydrogenation conversion catalyst (active component: CoO 3-4%wt, MoO 3 11~13%wt, the rest is carrier γ-Al 2 o 3 ) under the action of organic sulfur into inorganic sulfur, while hydrogenating unsaturated hydrocarbons into alkanes, a small amount of O2 with H 2 React (generate water) and complete partial methanation, then enter the desulfurization reactor to remove inorganic sulfur under the action of iron-manganese desulfurizer, the pressure of hydrodesulfurization reaction is about 2.8MPa, the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com