A kind of hydrogenation catalyst and its preparation and application

A hydrogenation catalyst and hydrogenation catalysis technology, applied in catalyst activation/preparation, molecular sieve catalyst, physical/chemical process catalyst, etc., can solve problems such as poor sulfur resistance, avoid sulfur poisoning, reduce the generation of carbon deposits, Good for entry and exit and diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

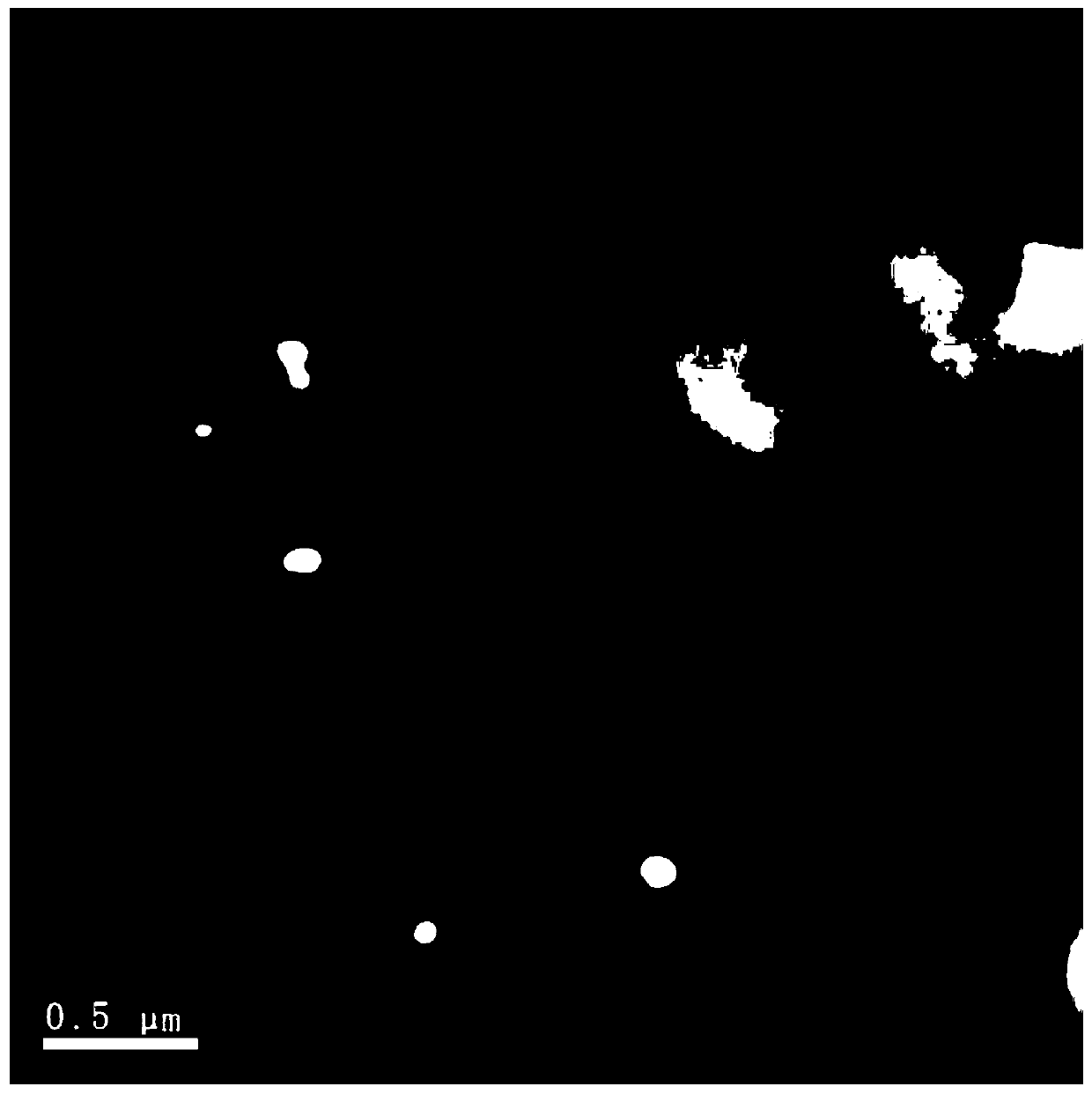

Embodiment 1

[0055] 4g solid sodium hydroxide (NaOH≥96%), 1.7g potassium hydroxide (KOH≥96%) and 14g potassium silicate (K 4 SiO 4 ≥98%) is dissolved in the mixed solution of 27g water preparation, 13g pseudo-boehmite (Al 2 o 3 ≥60%) solids were dissolved in the above mixed solution, and then transferred to the crystallization kettle, and the crystallization kettle was placed in an oven at 100°C for crystallization for 1 hour, and then the crystallization kettle was taken out and cooled to 80°C, and then 10 g of Boehmite and 4.2g of silicon oxide were uniformly added to the mixed solution within 1 hour. After mixing evenly, a mixed solution of 0.5g of chloroplatinic acid and 3g of citric acid was added to the mixed solution, and the constant temperature crystallization was continued at 100°C 2h, finally filtering and drying the crystallized product to obtain a Pt-containing small-pore molecular sieve material 1Pt-A with a pore size of less than 0.3 nm, wherein the mass content of Pt in t...

Embodiment 2

[0059] 4g solid sodium hydroxide (NaOH≥96%), 1.7g potassium hydroxide (KOH≥96%) and 14g potassium silicate (K 4 SiO 4 ≥98%) is dissolved in the mixed solution of 27g water preparation, 13g pseudo-boehmite (Al 2 o 3 ≥60%) solids were dissolved in the above mixed solution, and then transferred to the crystallization kettle, and the crystallization kettle was placed in an oven at 100°C for crystallization for 1 hour, and then the crystallization kettle was taken out and cooled to 80°C, and then 10 g of Boehmite and 4.2g of silicon oxide are uniformly added to the mixed solution within 1 hour, after mixing evenly, then a mixed solution of 0.4g of palladium chloride and 3g of citric acid is added to the mixed solution, and the constant temperature crystallization is continued at 100°C 2h, finally filtering and drying the crystallized product to obtain a Pd-containing small-pore molecular sieve material 1Pd-A with a pore size of less than 0.3 nm, wherein the mass content of Pd in ...

Embodiment 3

[0063] 4g solid sodium hydroxide (NaOH≥96%), 1.7g potassium hydroxide (KOH≥96%) and 14g potassium silicate (K 4 SiO 4 ≥98%) is dissolved in the mixed solution of 27g water preparation, 13g pseudo-boehmite (Al 2 o 3 ≥60%) solids were dissolved in the above mixed solution, and then transferred to the crystallization kettle, and the crystallization kettle was placed in an oven at 100°C for crystallization for 1 hour, and then the crystallization kettle was taken out and cooled to 80°C, and then 10 g of Boehmite and 4.2g of silicon oxide were uniformly added to the mixed solution within 1 hour, and continued constant temperature crystallization at 100°C for 1 hour, then took out the crystallization kettle and cooled it down to 80°C, opened the crystallization kettle and added 0.4g into the mixed solution A mixed solution of palladium chloride and 3g of citric acid was continued to be crystallized in an oven at 100°C for 2 hours, and finally the crystallized product was filtered ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com