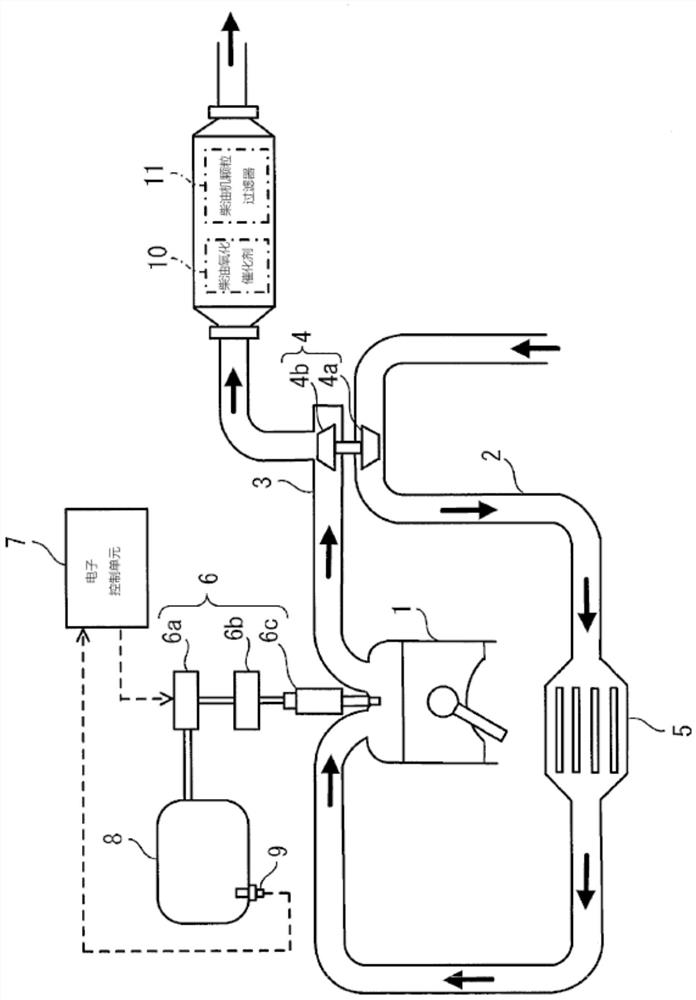

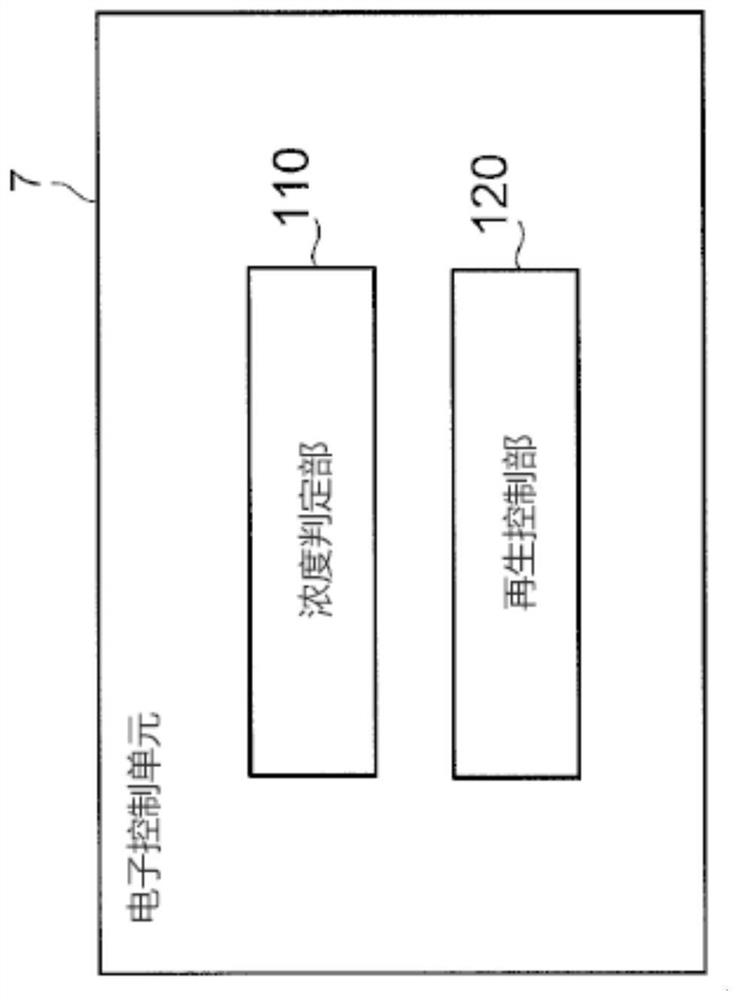

Filter regeneration control device and filter regeneration control method

A regenerative control and filter technology, applied in exhaust devices, mufflers, machines/engines, etc., can solve problems such as DPF damage, diesel engine output reduction, fuel consumption deterioration, etc., and achieve the effect of preventing sulfur poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

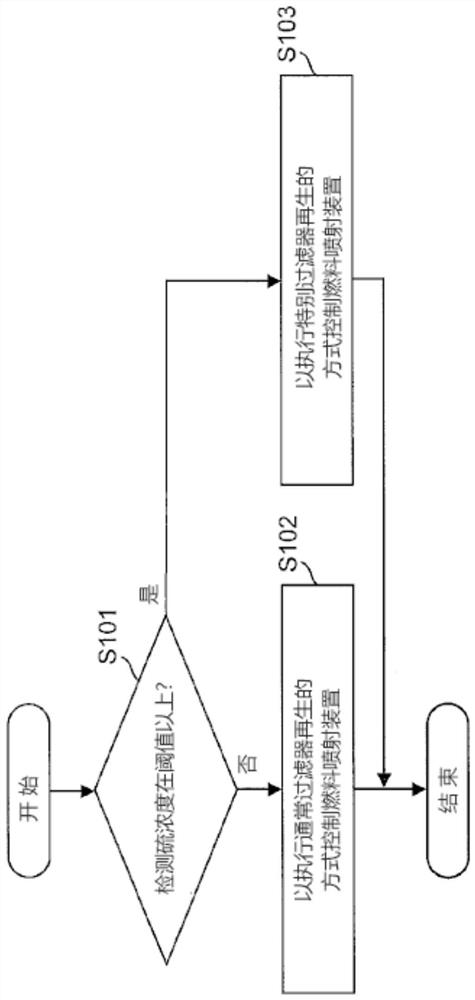

Method used

Image

Examples

Deformed example 1

[0060] In the above embodiment, the fuel injection when the filter regenerated is the case where the fuel injection is taken as an example, but fuel injection can be performed by a fuel injection valve (omitted) provided in the exhaust passage 3 (so-called " Exhaust pipe spray).

Deformed example 2

[0062] In the above embodiment, the case where the sulfur concentration of the fuel by the concentration sensor 9 is mentioned, but is not limited thereto. For example, the ECU 7 can also calculate (measure, estimated) of the sulfur concentration contained in the exhaust gas.

Deformed example 3

[0064] In the above embodiment, the case where the upstream side of the DPF 11 is set to be described as an example, but is not limited thereto. For example, figure 1 In, it is also possible to have an absorbent nitrogen oxide reduction catalyst (Lean NOx TRAP: LNT) instead of DOC10. In this case, the sulfur poisoning of LNT can be prevented.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com