Patents

Literature

77 results about "Normal filter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Backwash flushing filter

Owner:THE SOURCE RCO PARTS INC

Back-flush-type preposed water filter

ActiveCN103372341ARealize self-cleaningAchieve conversionStationary filtering element filtersWater filterWater flow

The invention provides a back-flush-type preposed water filter. The back-flush-type preposed water filter comprises a water inlet, a water outlet, a shell, a filter screen and a water flow direction conversion device, wherein a filter cavity body is defined by the shell, and water flowing from the water inlet passes through the filter cavity body, and then flows out of the water outlet; the filter screen is arranged in the shell and separates the filter cavity body into an internal filter cavity body and an external filter cavity body, and water flows between the internal filter cavity body and the external filter cavity body through the filter screen; the water flow direction conversion device enables water flow to be converted between normal filter operation and back flush operation; when the water flow direction conversion device is converted to the normal filter operation, water flowing from the water inlet is filtered by the filter screen from the internal filter cavity body, enters the external filter cavity body, and flows out of the water outlet; when the water flow direction conversion device is converted to the back flush operation, water flowing from the water inlet flows to the internal filter cavity body through the filter screen from the external filter cavity body, and flushes impurities adhering to the filter screen, thereby flushing the filter screen.

Owner:3M INNOVATIVE PROPERTIES CO

Backwash flushing filter

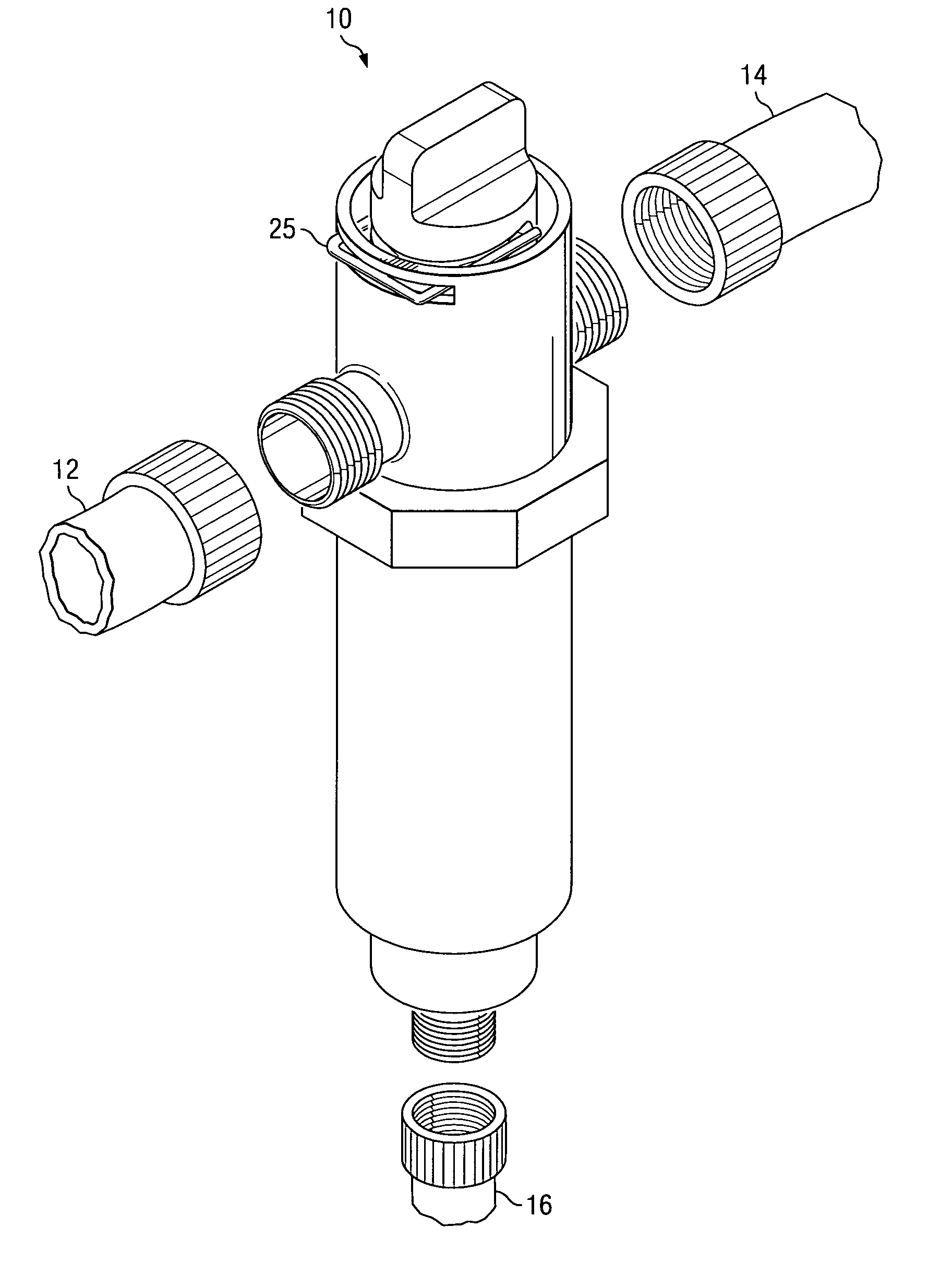

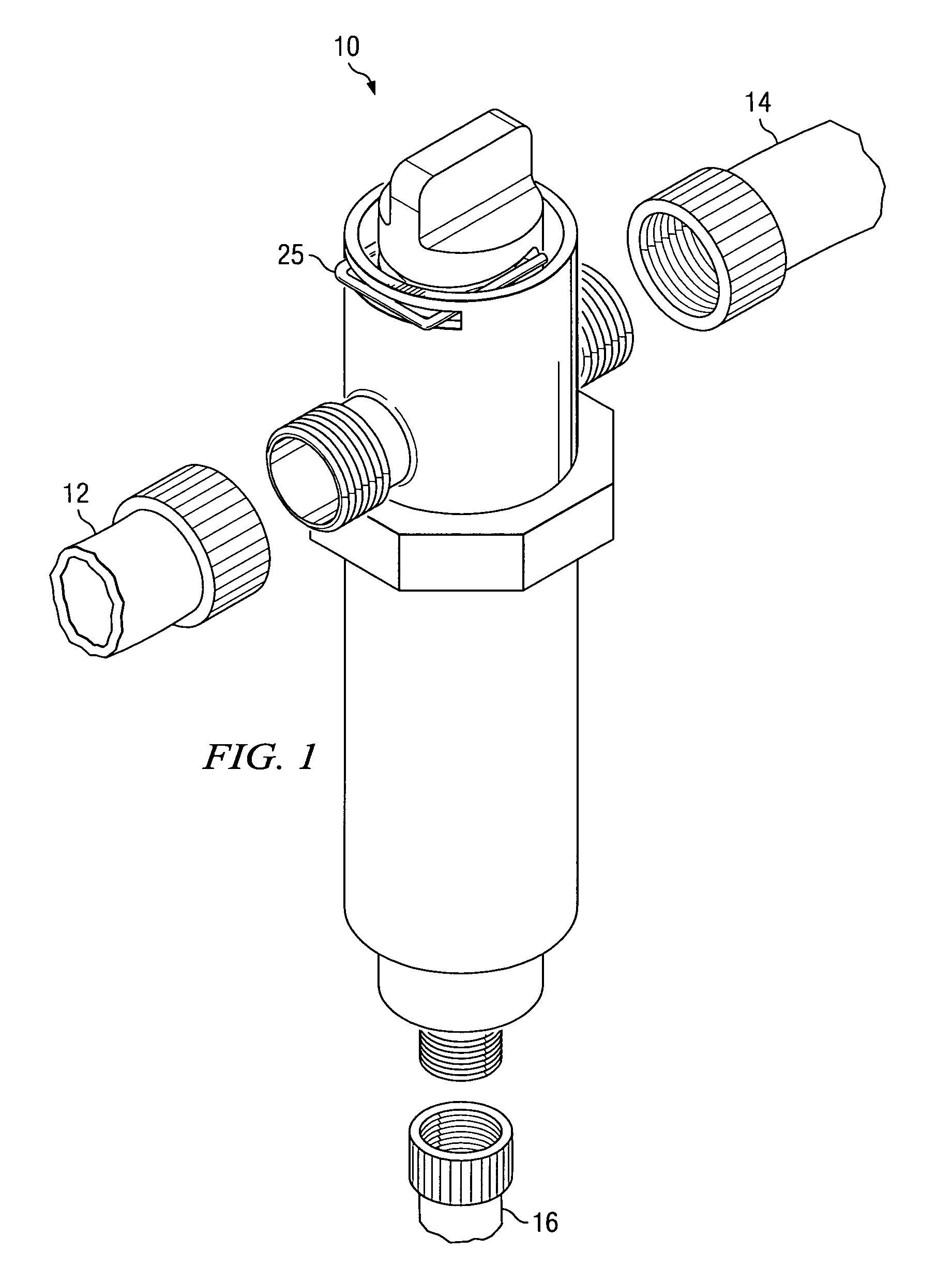

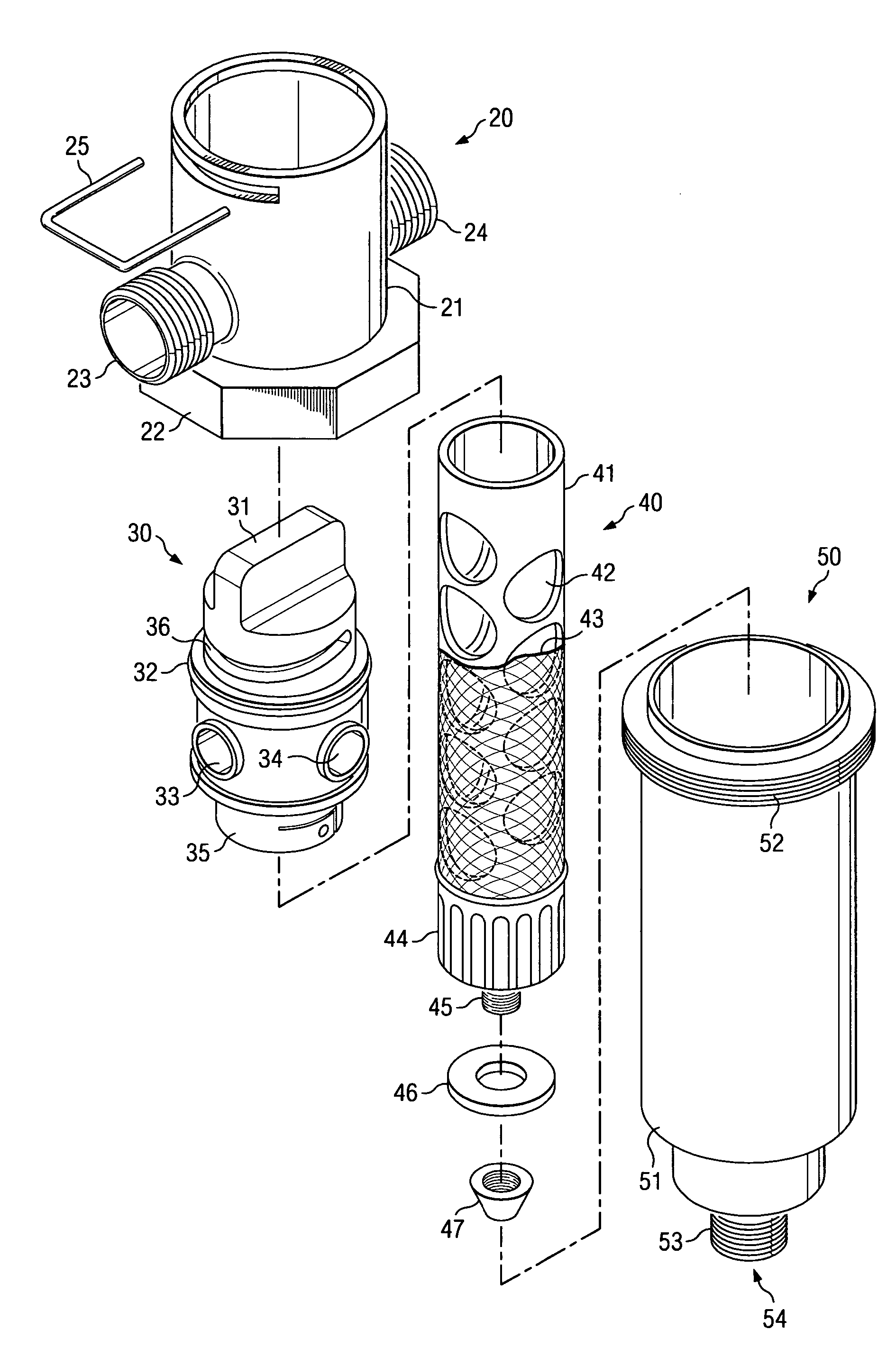

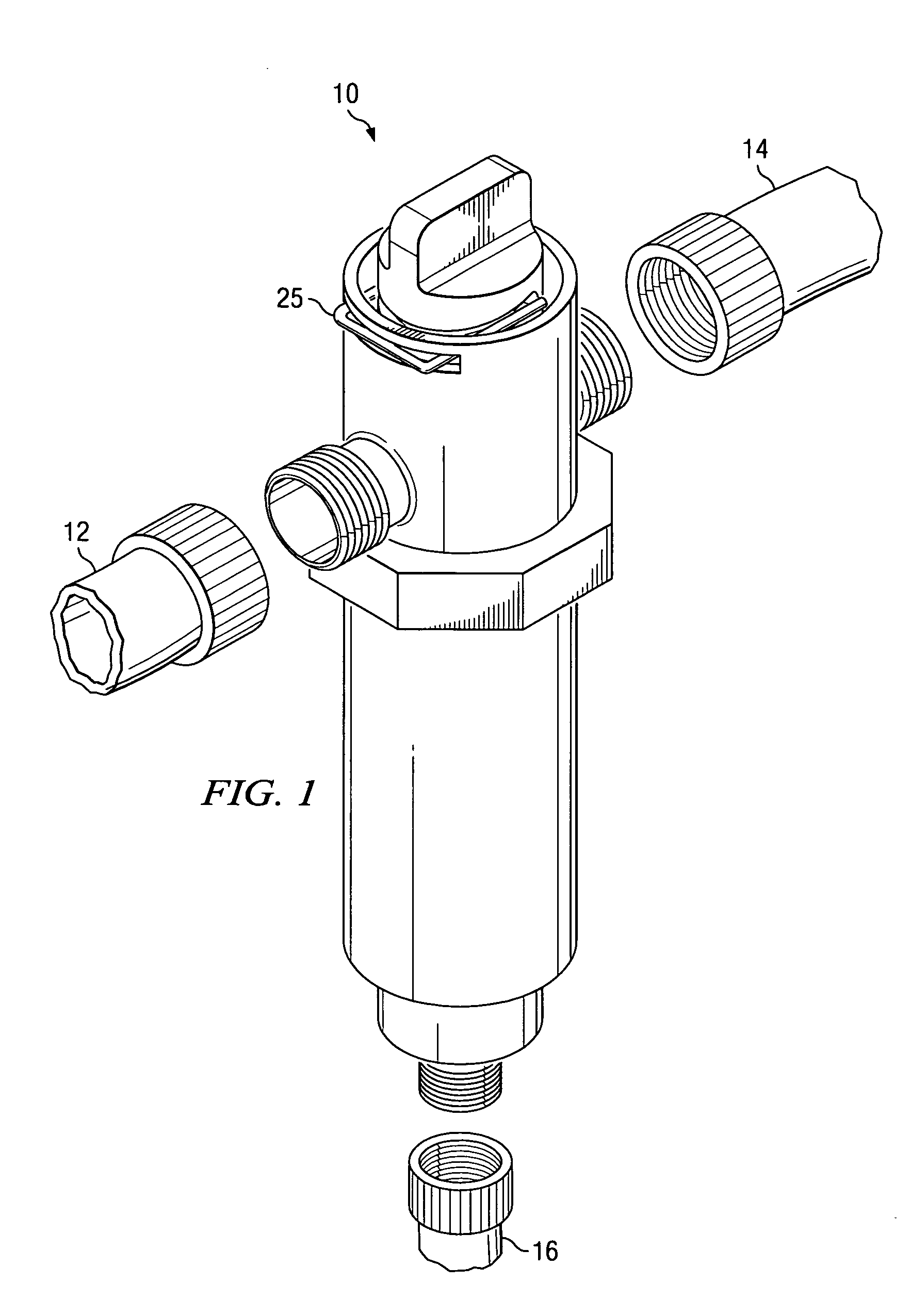

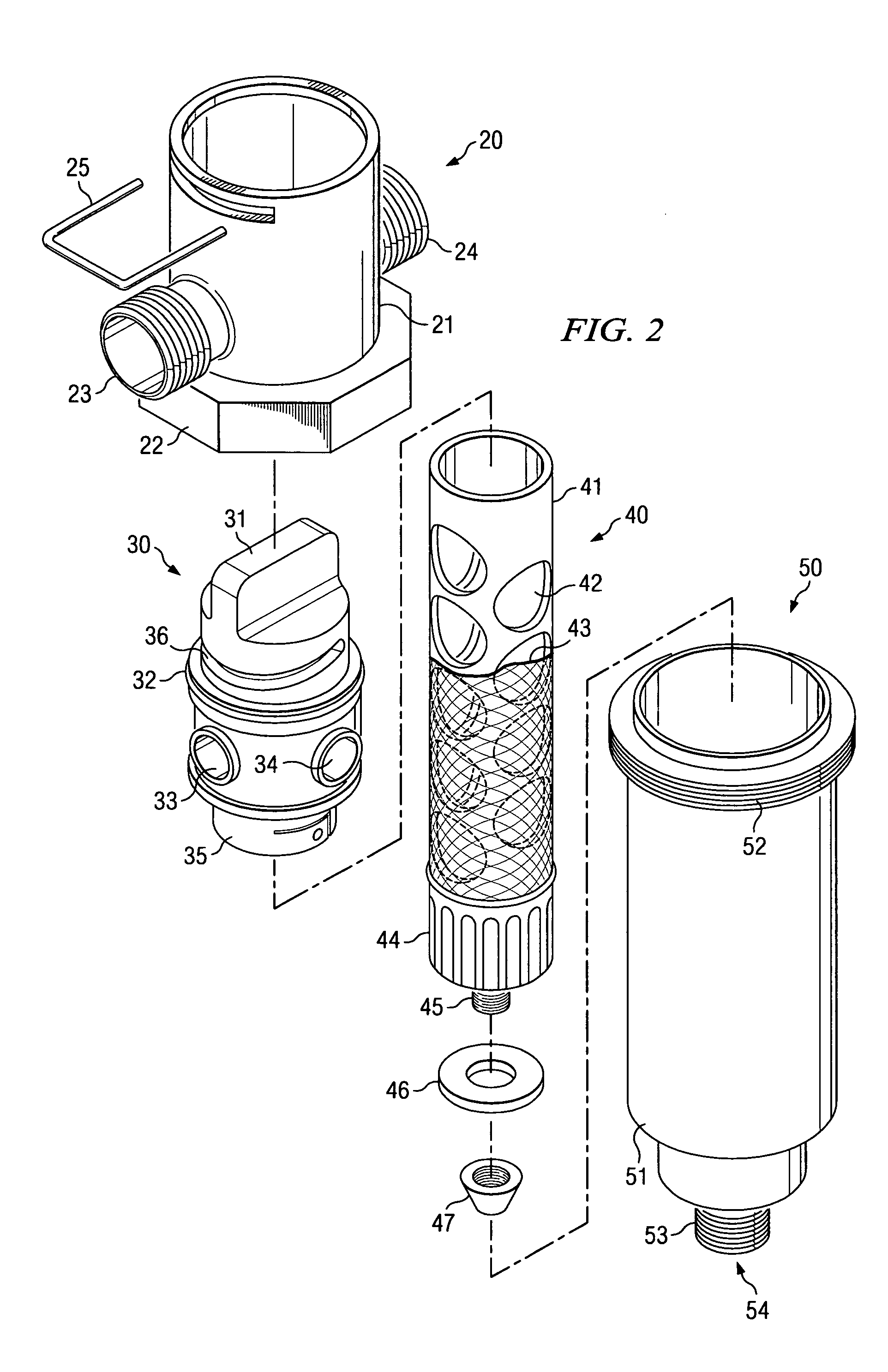

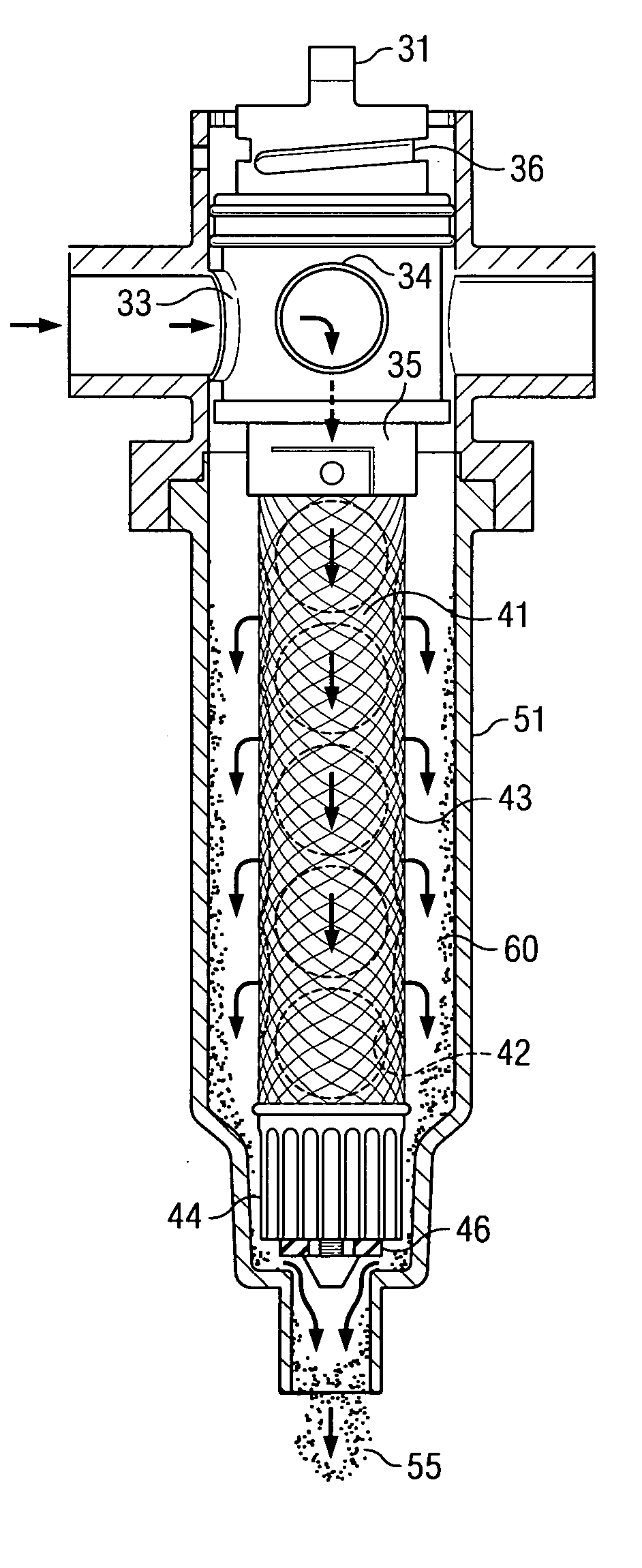

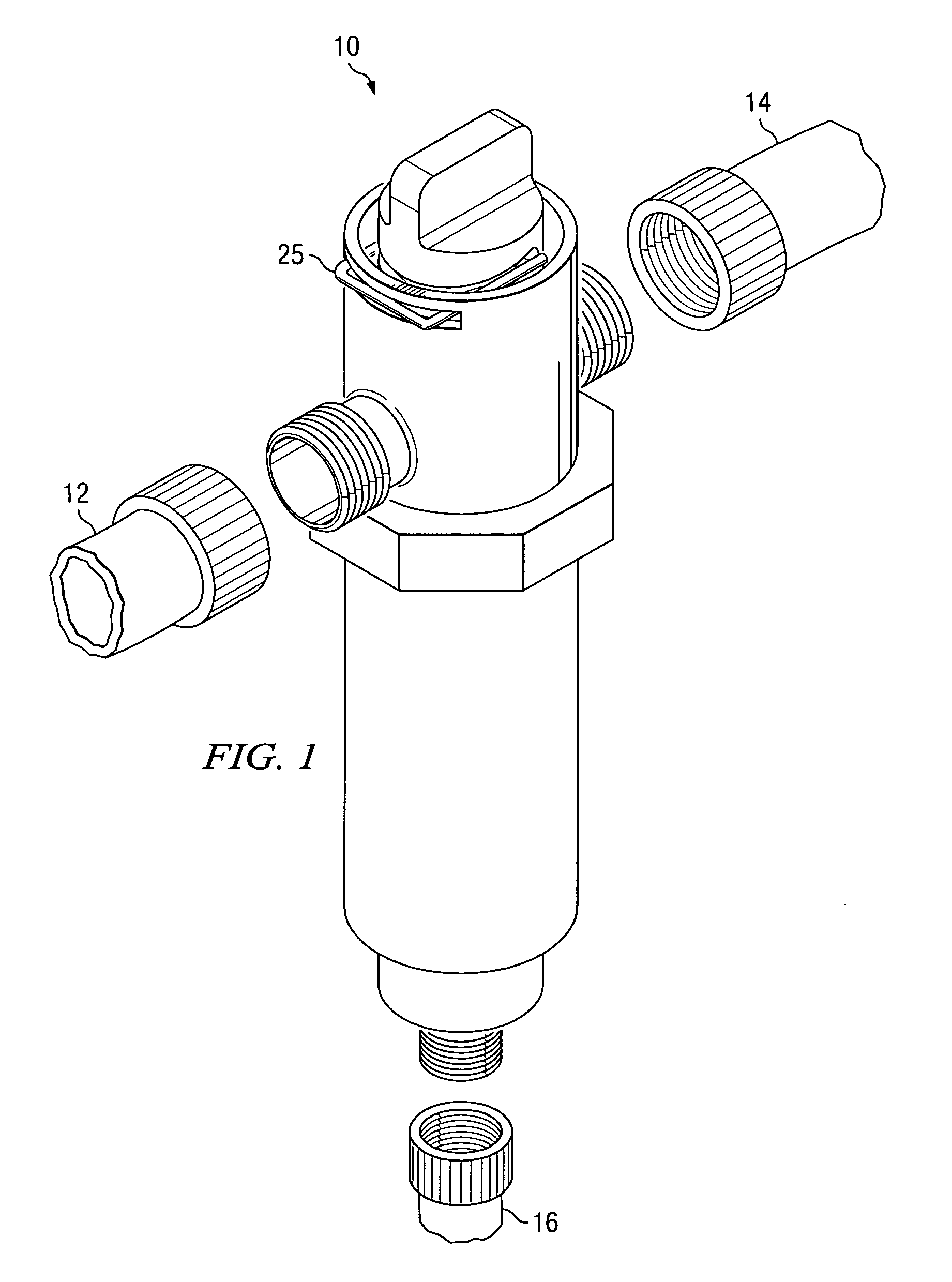

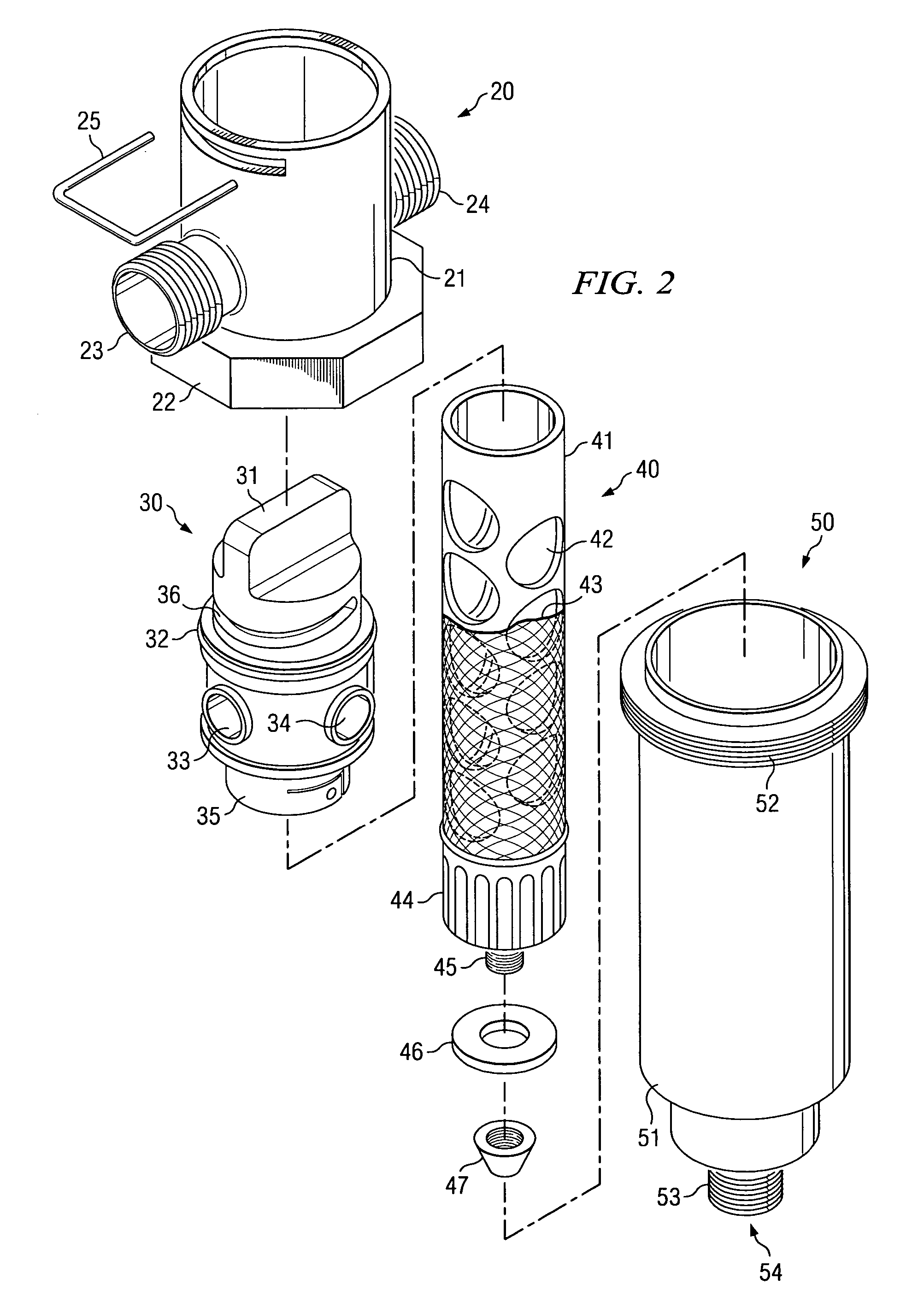

An inline backwash, flushing filter assembly comprising a header assembly, a rotatable valve assembly, and a filter element assembly disposed within a filter housing assembly. In operation, the controller moves the turn knob of the rotatable valve assembly a one-quarter turn which results in the reversal of fluid flow through the assembly to periodically back flush the filter utilizing fluid from the system inlet. Debris removed from the filter element during the backwash process are immediately discharged from the system through a drain port. Simultaneously, the hydraulic shearing mechanism of the backwash process dislodges and drains debris which may have accumulated on the screen and at the bottom of the lower filter assembly during normal filter operations. The controller then returns the filter assembly to filtration operation by a reverse one-quarter turn of the turn knob of the rotatable valve assembly.

Owner:CLAUDE LAVAL

Backwash flushing filter

An inline backwash, flushing filter assembly comprising a header assembly, a rotatable valve assembly, and a filter element assembly disposed within a filter housing assembly. In operation, the controller moves the turn knob of the rotatable valve assembly a one-quarter turn which results in the reversal of fluid flow through the assembly to periodically back flush the filter utilizing fluid from the system inlet. Debris removed from the filter element during the backwash process are immediately discharged from the system through a drain port. Simultaneously, the hydraulic shearing mechanism of the backwash process dislodges and drains debris which may have accumulated on the screen and at the bottom of the lower filter assembly during normal filter operations. The controller then returns the filter assembly to filtration operation by a reverse one-quarter turn of the turn knob of the rotatable valve assembly.

Owner:THE SOURCE RCO PARTS INC

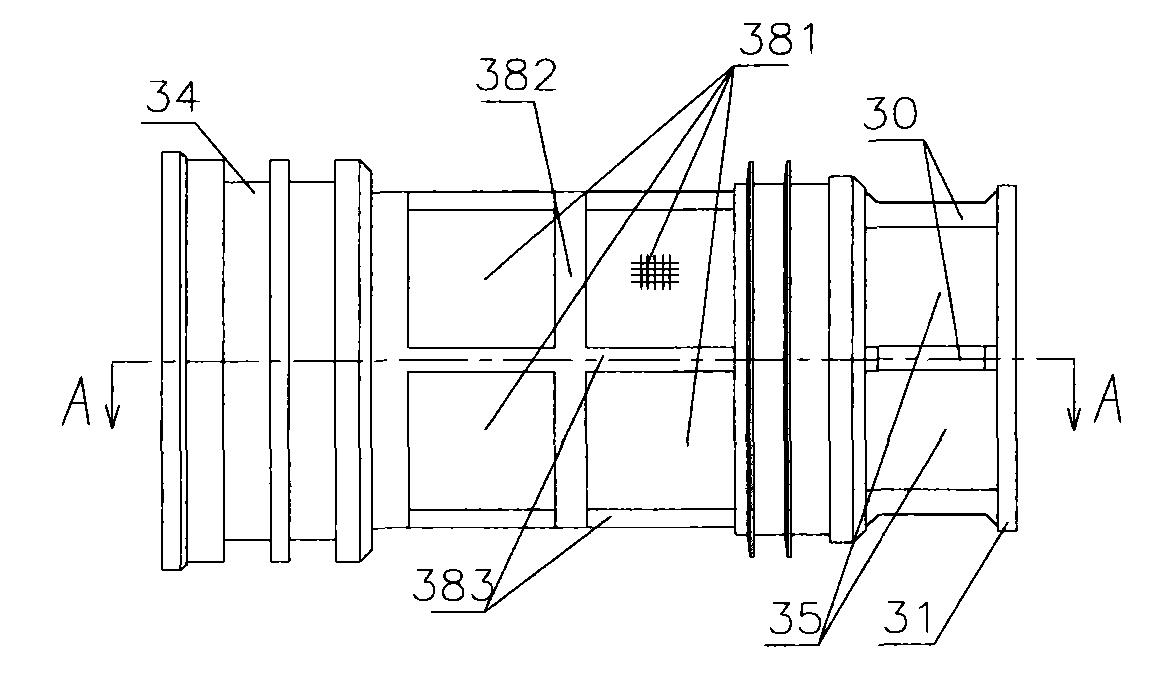

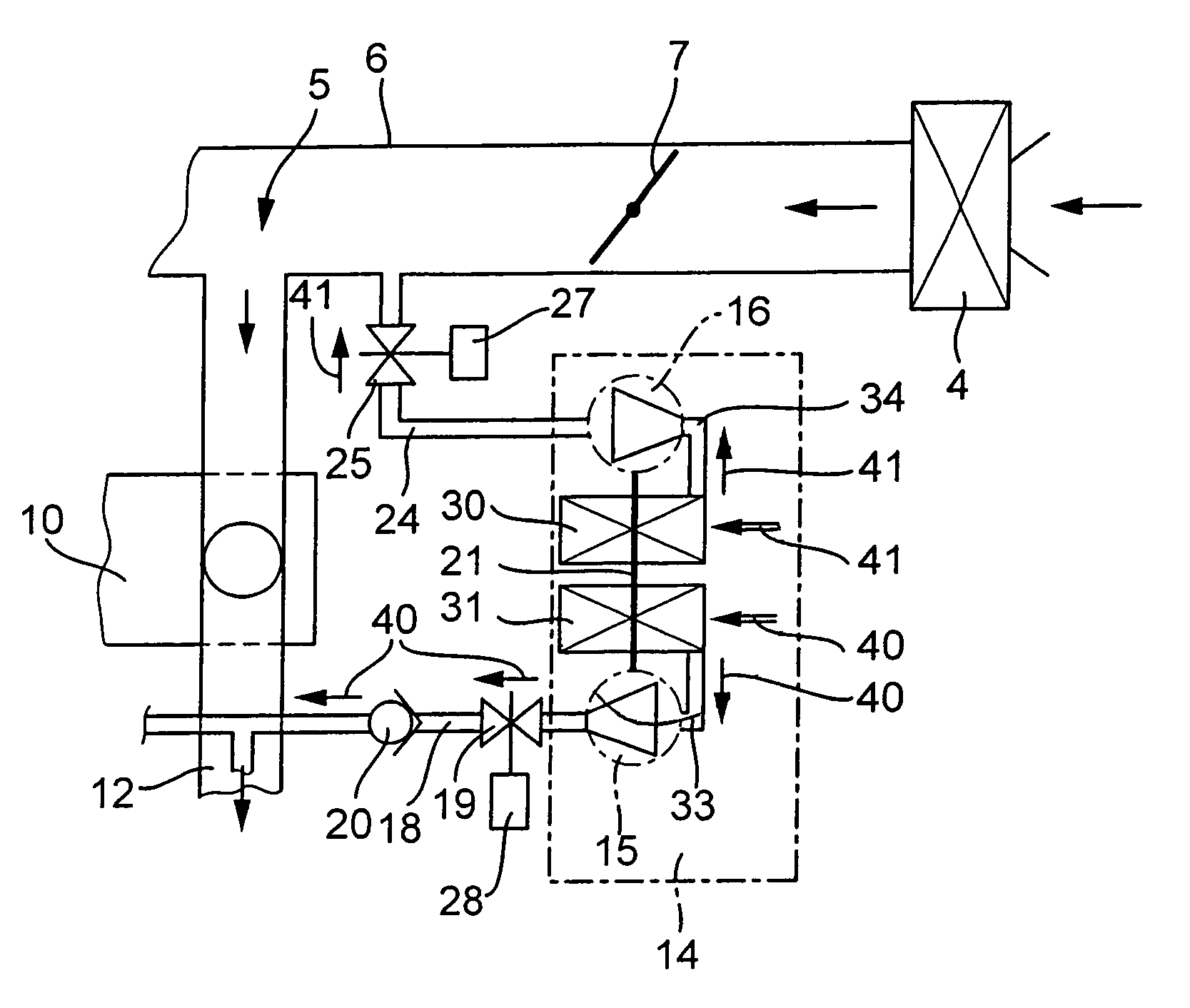

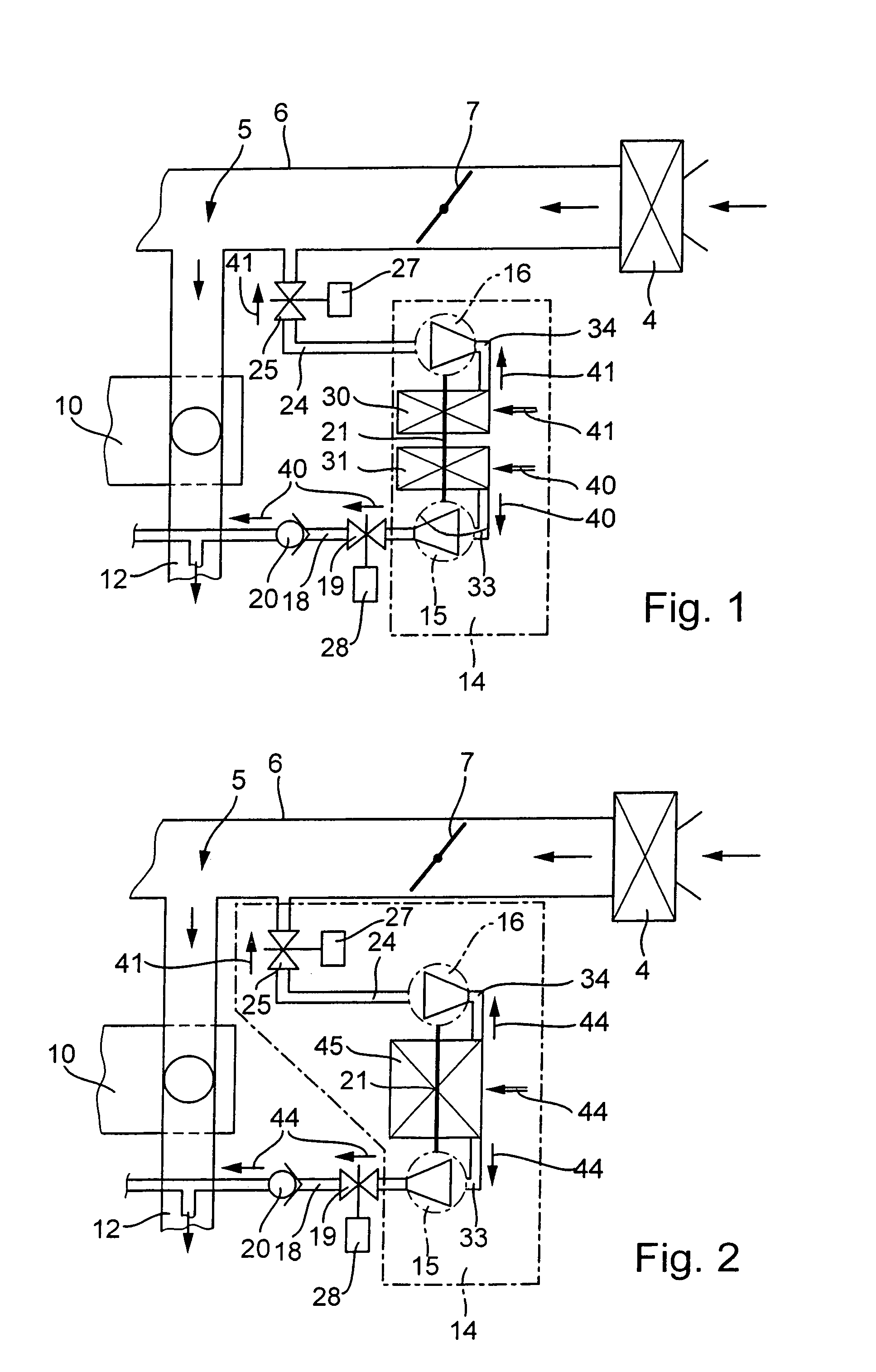

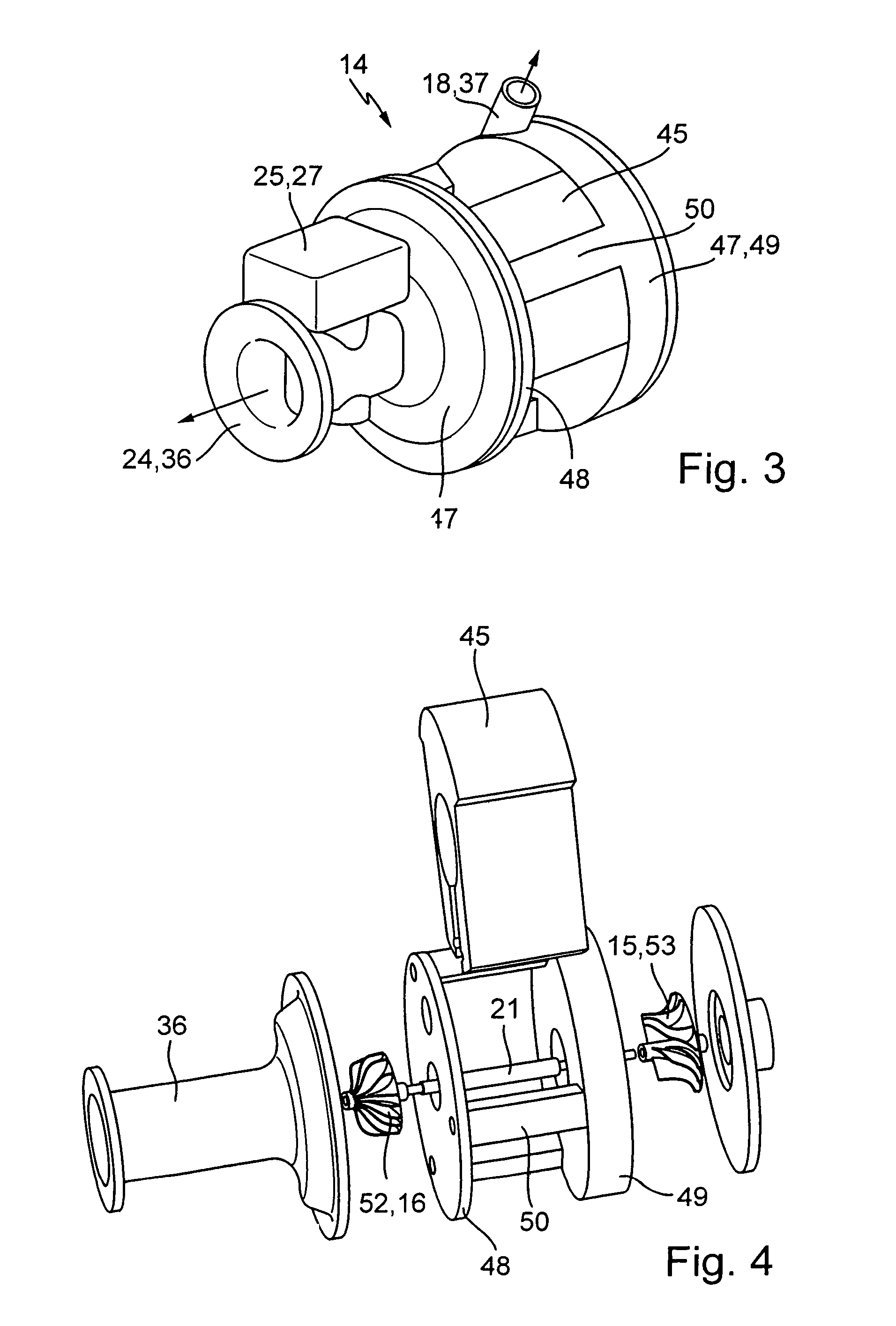

Air supply device for an internal combustion engine

ActiveUS20060150928A1Simple inexpensive sealing arrangementEasy to manufactureInternal combustion piston enginesPump componentsImpellerTurbine wheel

In a secondary air supply device comprising a turbine and a compressor with turbine and compressor wheels having blades which are covered by wheel covers and an air filter structure disposed between the turbine and compressor wheels, so that air is supplied to the compressor and to the turbine from a common filter structure disposed between the compressor and the turbine wheels.

Owner:CHEMTRON RES

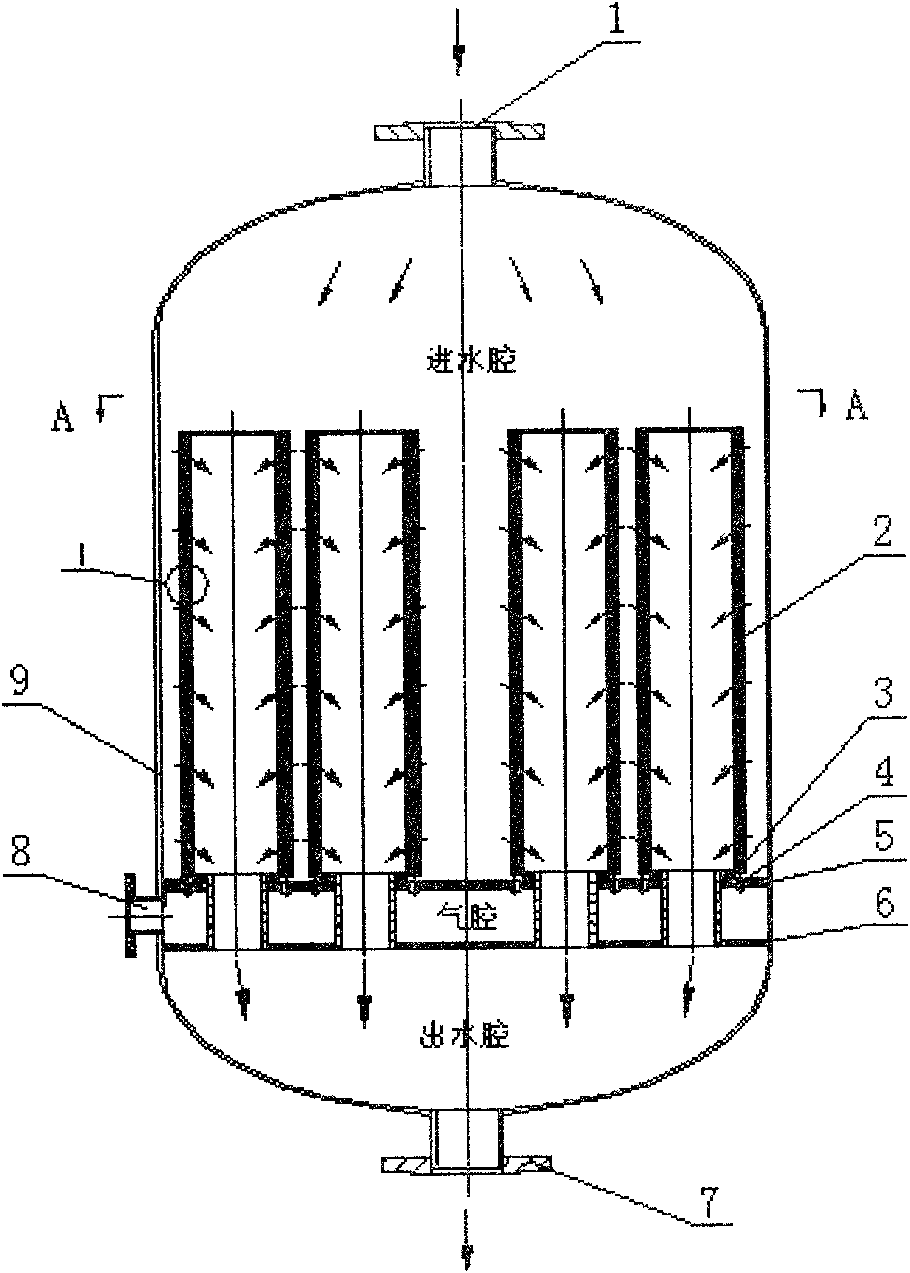

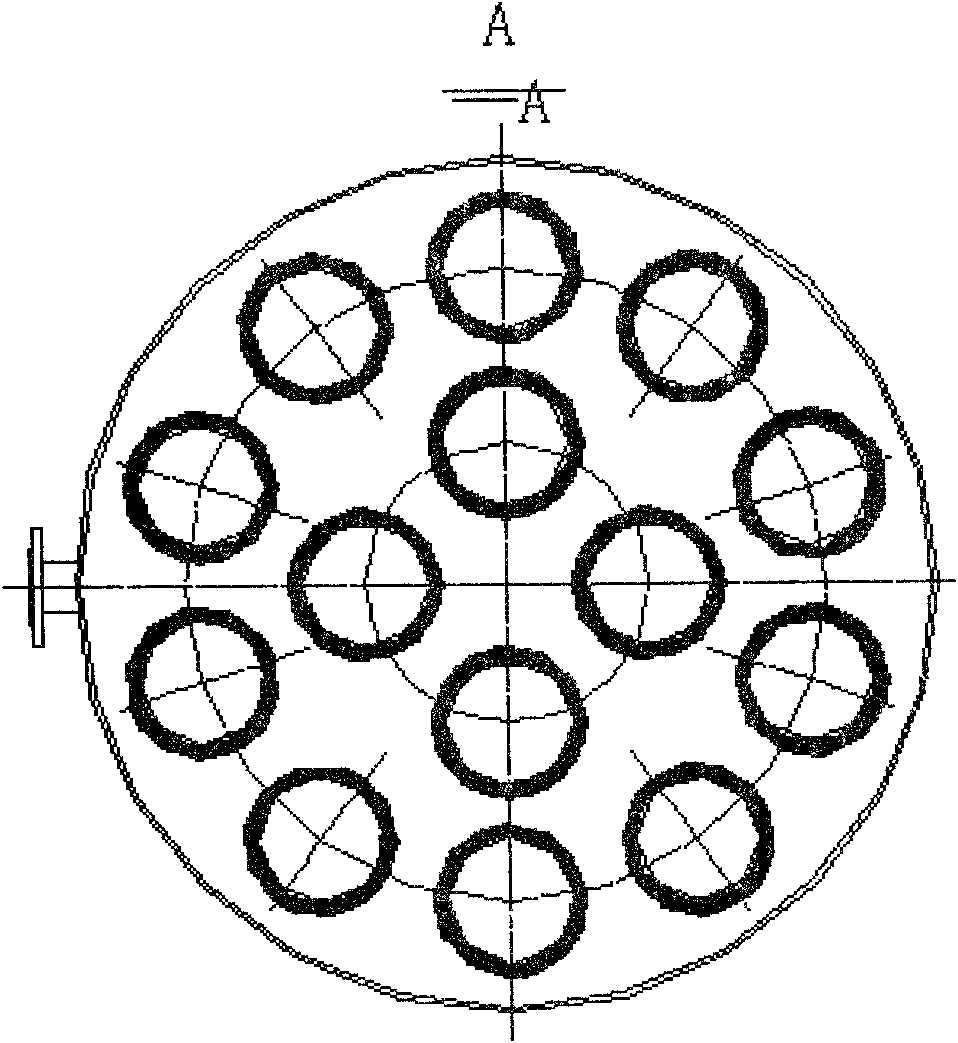

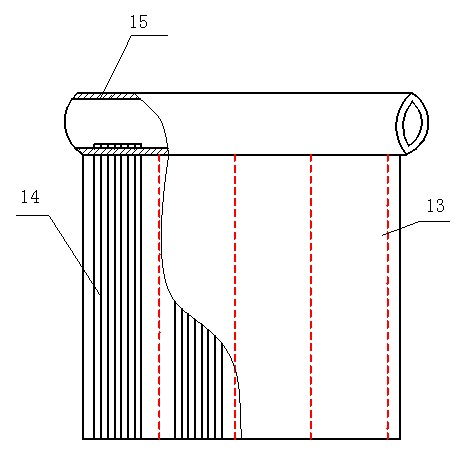

Highly Integrated Hollow Fiber Column Filter

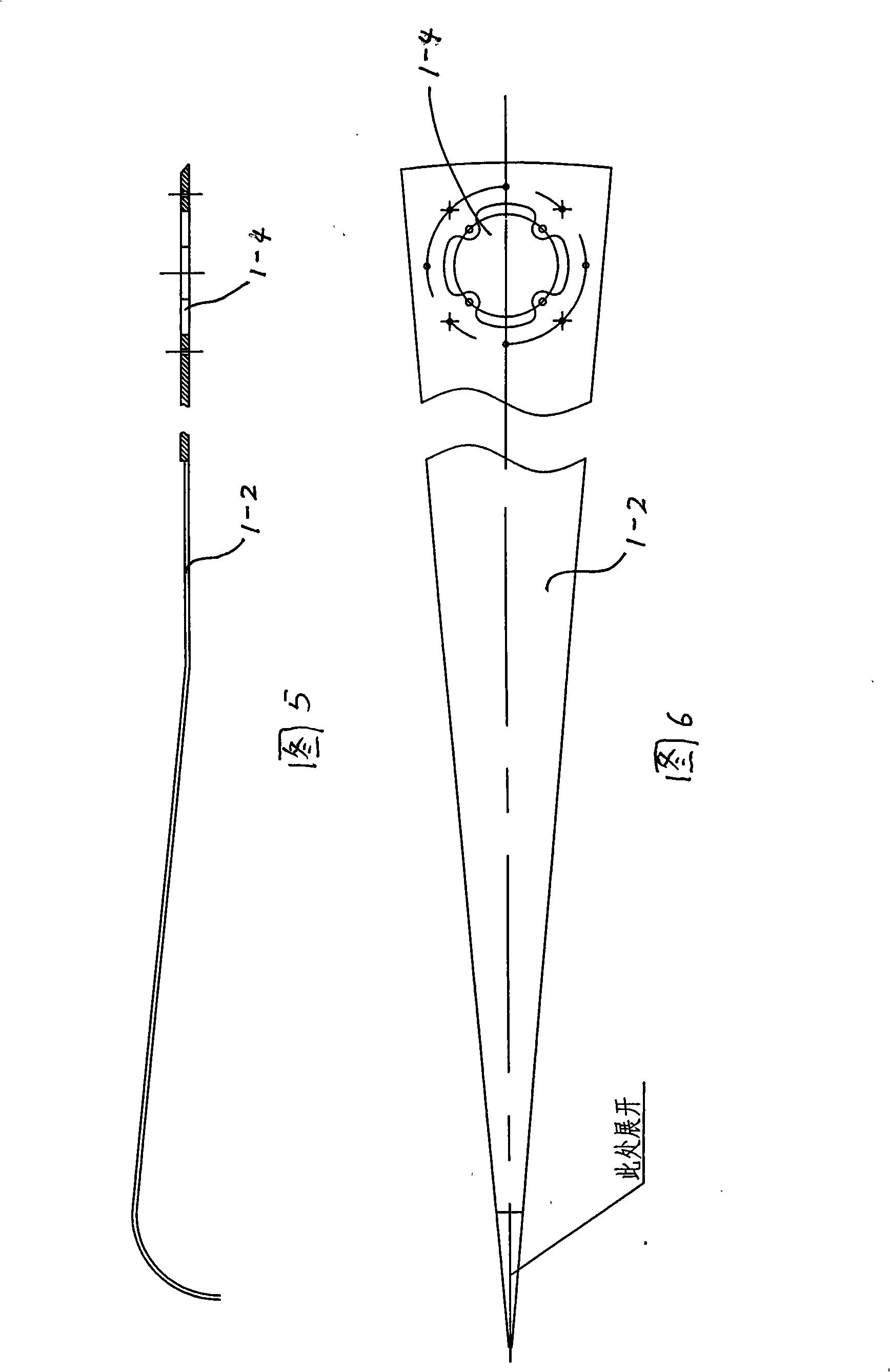

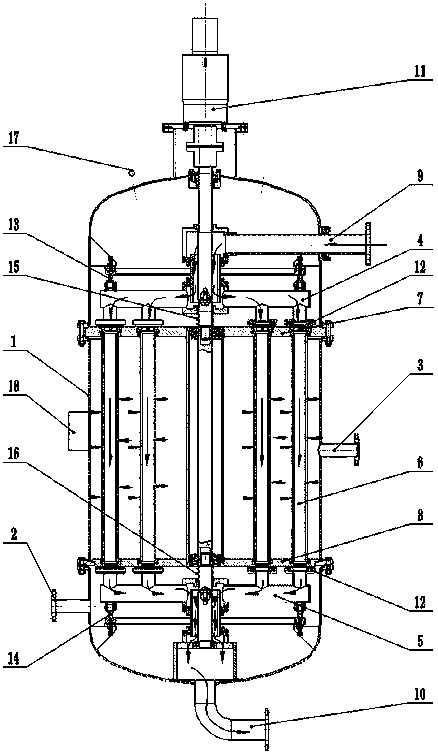

InactiveCN102274650AThe same capacityGas distributionStationary filtering element filtersFiberHollow fibre

The invention discloses a highly integrated hollow fiber column filter, which belongs to the technical field of filtration in water treatment, and mainly includes a water inlet, a shell, a hollow fiber column, a water outlet, an air inlet, a first partition, and a second partition. Several hollow fiber columns are distributed in a circle in the housing. During normal filtration, the water inlet and outlet are opened, and the air inlet is closed. The filtered water passes through the hollow fiber columns covered with filter cloth from outside to inside, and impurities in the water are retained when passing through the filter cloth. . When backwashing, the clean water flow is opposite to that of filtration, and the filter cloth is backwashed from the inside to the outside, and the air inlet is opened at the same time, the backwashing gas enters the air cavity from the air inlet, and is distributed through the air distribution pipe on the second partition to the The air in each hollow fiber column and the air distribution pipe strongly sweeps the fibers on the filter cloth, and the backwashing of the backwashing water flow and the strong sweeping of the air flow are carried out at the same time, resulting in a good backwashing effect. Compared with the prior art, the invention has many advantages such as good regeneration effect and good effluent quality.

Owner:HEFEI SANFAN WATER TREATMENT EQUIP

Method and formulation using passive electrostaticity for improving filter performance

InactiveUS6924326B2Improve performanceHigh retention rateAntifouling/underwater paintsOther chemical processesParticulatesIndoor air quality

A method treats ordinary filters with an electrostatic material that will turn any filter into a passive electrostatic filter. A formulation is sprayed or otherwise applied onto the filter to increase the filter's ability to effectively reduce indoor air particulates and improve indoor air quality. The formulation includes a water-soluble dielectric formulation and can also be combined with a biocide.

Owner:MAINSTREAM ENG

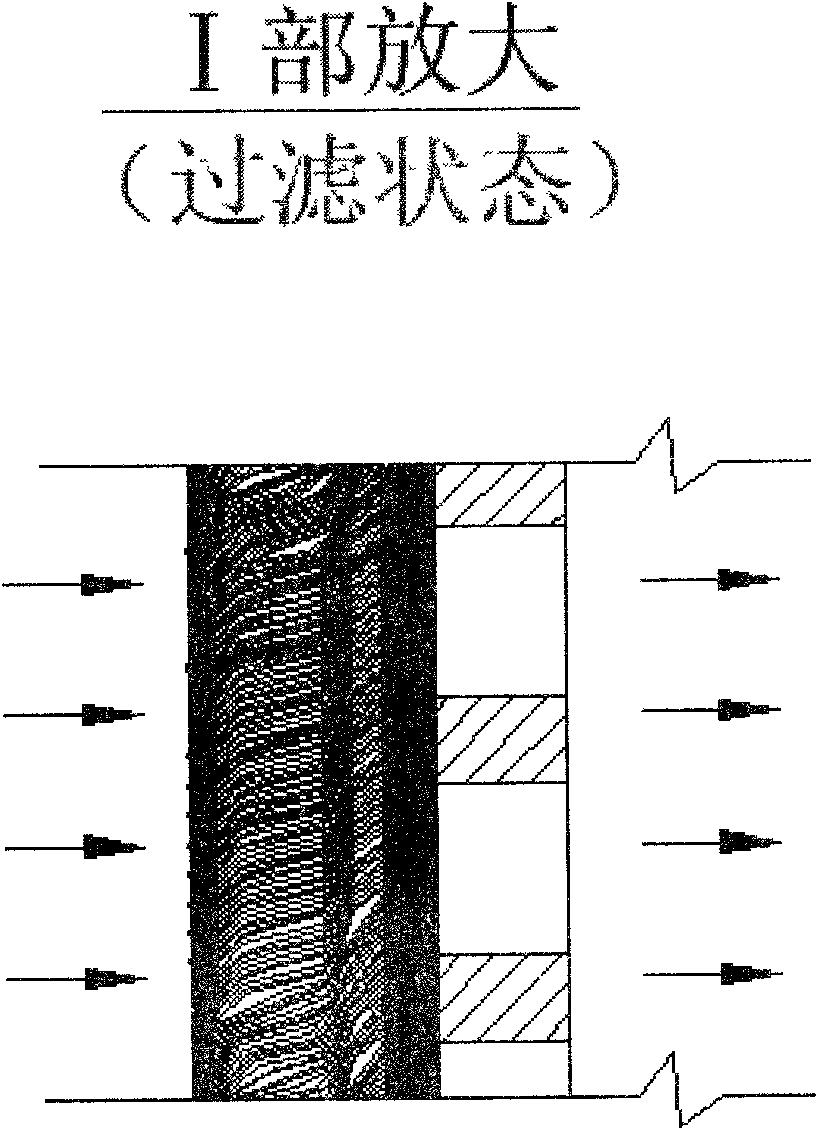

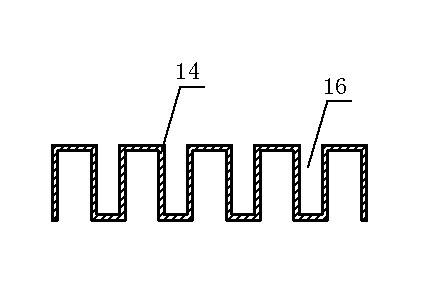

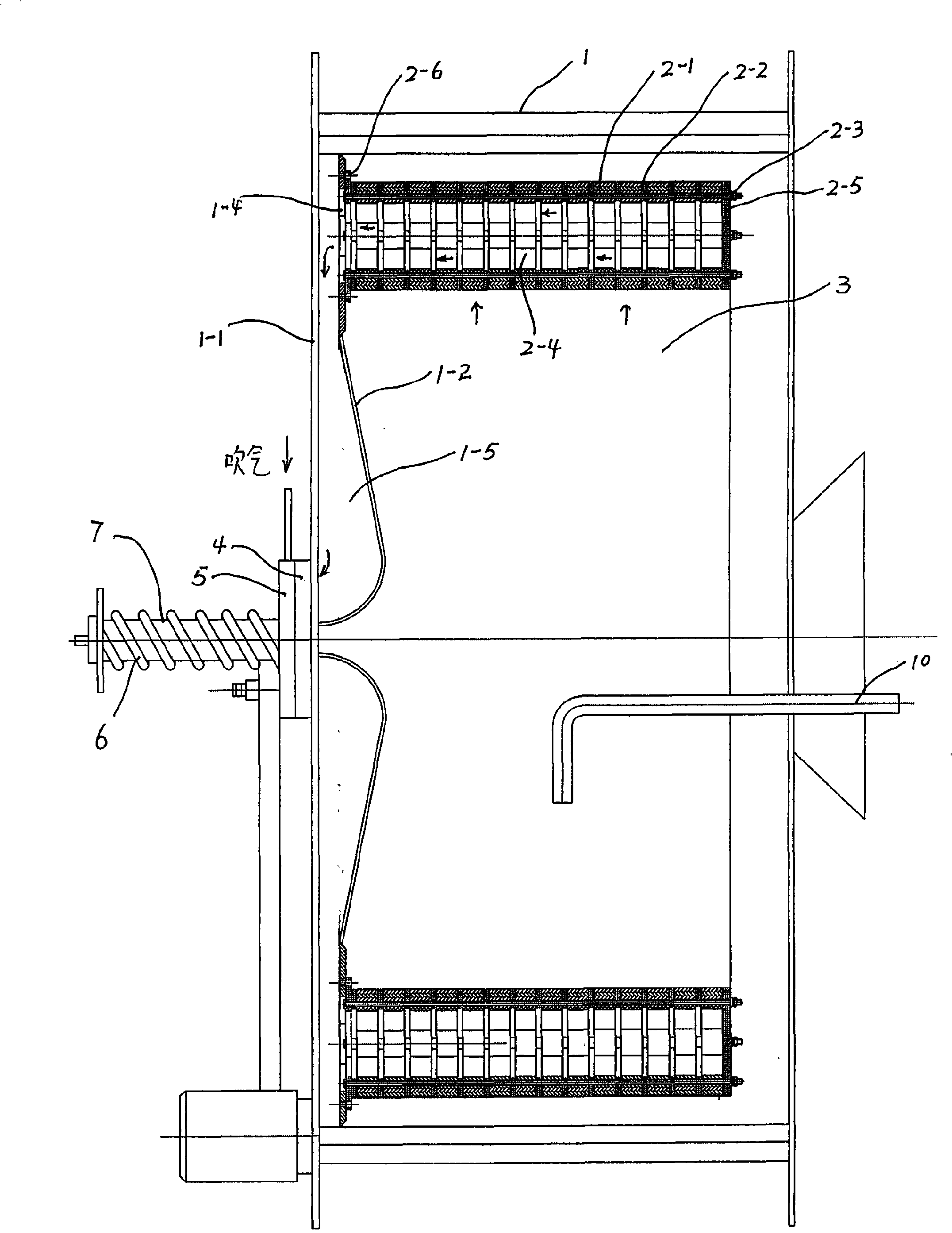

Vertical leaf filter filtering device and filter method and application thereof

InactiveCN101982218AEasy to transformSimple cuttingStationary filtering element filtersAluminium oxides/hydroxidesNormal filterEconomic benefits

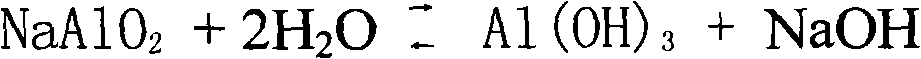

The invention relates to a vertical leaf filter filtering device and a filter method and application thereof. The filtering device comprises a filter shell, a filter plate, a head tank, a raw liquor tank, a filter cake tank, a fine liquor tank and a pressure pump, wherein raw liquor is filtered by the filter plate of the filter to obtain fine liquor which enters the head tank via a collector tube; the filter plate comprises a bar-shaped bracket and stainless steel filament filter cloth, wherein the bar-shaped bracket is installed between two layers of filter cloth and is provided with filter tanks which alternately arranged convexly and concavely; the collector tube is provided with a horizontal groove; the bar-shaped bracket is communicated with the collector tube by the horizontal groove; and the filter cloth is covered on the collector tube. The filter method is in periodic operation and is divided into the following steps: the step of feeding and hanging mud: lasting for 4-7 min; sodium aluminate raw liquor enters the leaf filter from the raw liquor tank and forms a filter layer on the filter plate by filter pressing; turbid liquid penetrating through the filter layer returns to the raw liquor tank by a reflux valve; the normal filter step: filtrate penetrating through the filter layer is fine liquor, and the fine liquor enters the head tank; and the final step of removing cakes under decompression and recovery. The invention uses stainless steel filament filter cloth to replace polypropylene monofilament cloth, so that the service life of the filter cloth is greatly prolonged; meanwhile, the stainless steel filament filter cloth can be washed easily by alkali with short time; the number of the filter cloth can be 1600-1800 meshes, and the filter cloth has the advantages of high temperature resistance, no deformation, no contraction, long service life and the like. The filter method shortens period, obviously improves yield and has good economic benefit.

Owner:温县中原科技有限公司

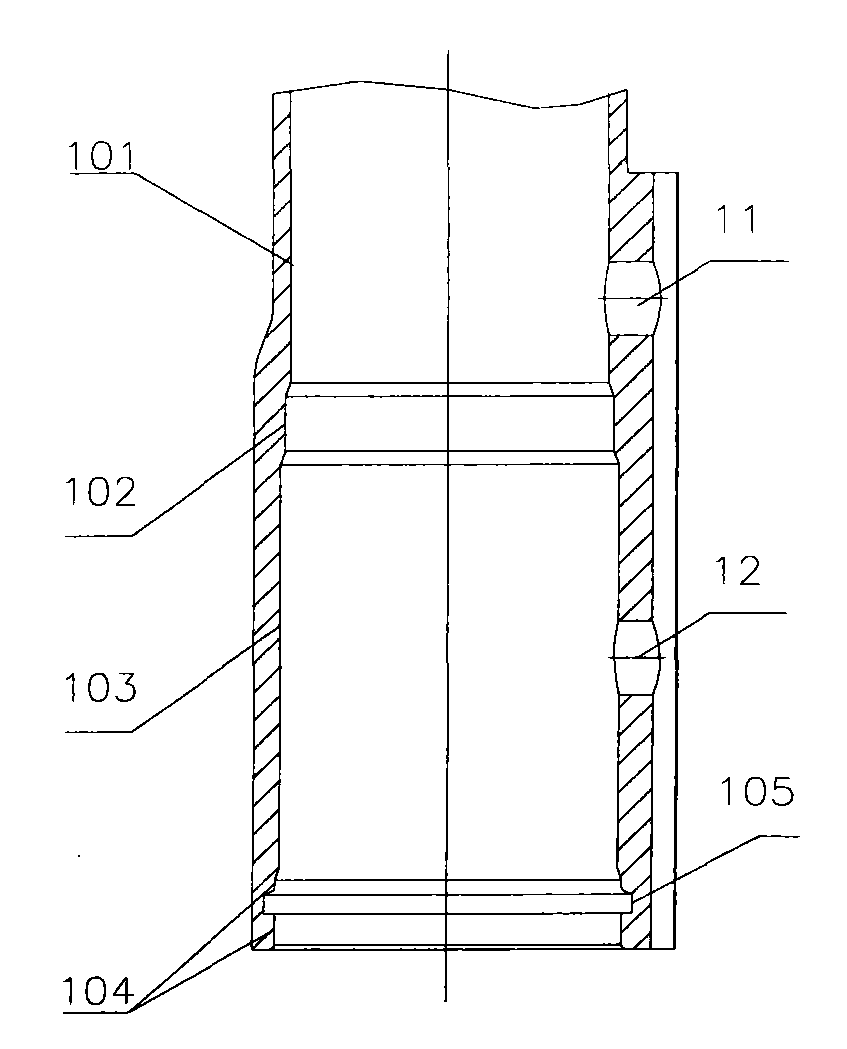

Liquid receiver and manufacturing method thereof

ActiveCN103968624AGuaranteed filtration accuracySolve the disadvantages of large flow resistanceRefrigeration componentsNormal filterControl theory

A liquid receiver comprises a shell with an opening at one end, a filter cap and a drying bag. The filter cap is arranged the open end of the shell, the drying bag is arranged in a cavity formed by the filter cap and the shell, the shell is provided with a first connection port and a second connection port, the filter cap comprises a filter portion and a seal cap portion close to the open end of the shell, the seal cap portion is in seal fit with the inner wall of the shell, the filter portion is of a cylindrical surface structure, the second connection port is communicated with space between the inner wall portion of the shell and the filter portion, the first connection port is communicated with internal space of the filter portion, the filter cap is provided with a matched seal structure close to one end of the drying bag and the inner wall portion of the shell, and refrigerant is filtered via the filter portion in the process of flowing between the first connection port and the second connection port. The liquid receiver further comprises a limiting structure for preventing the drying bag from falling into the filter cap, so that normal filter capacity of the filter cap is guaranteed.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

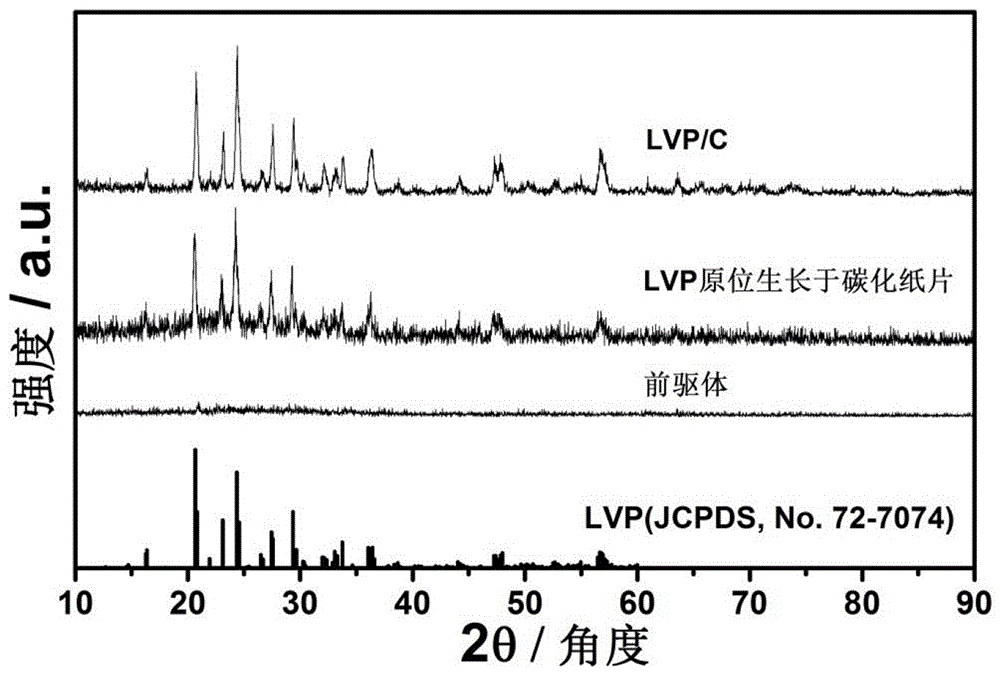

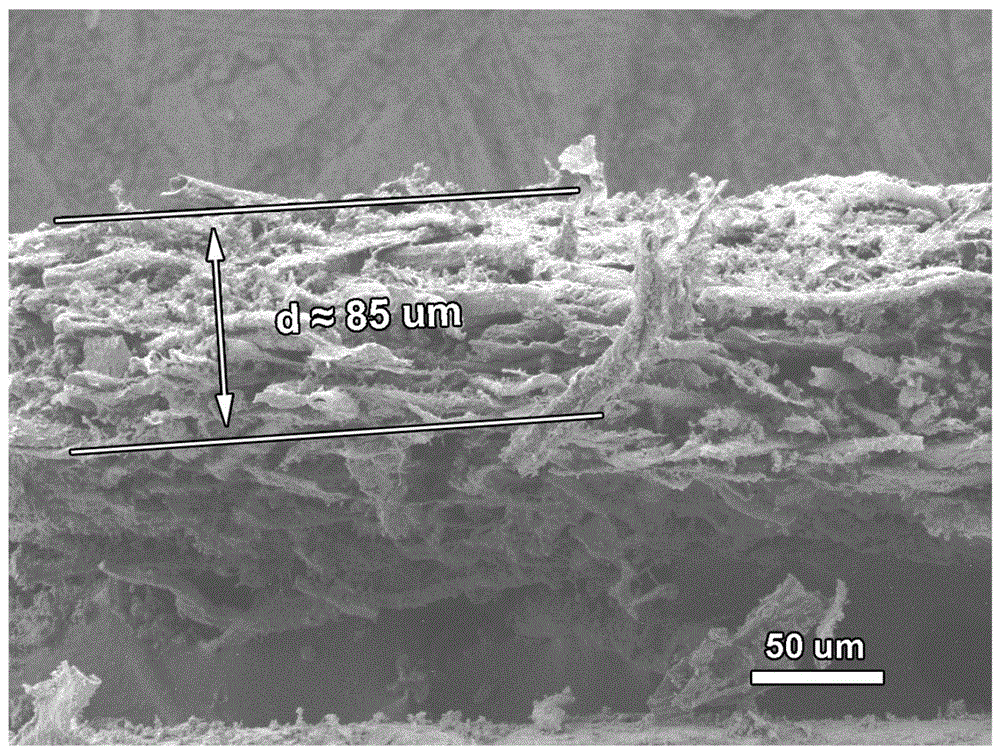

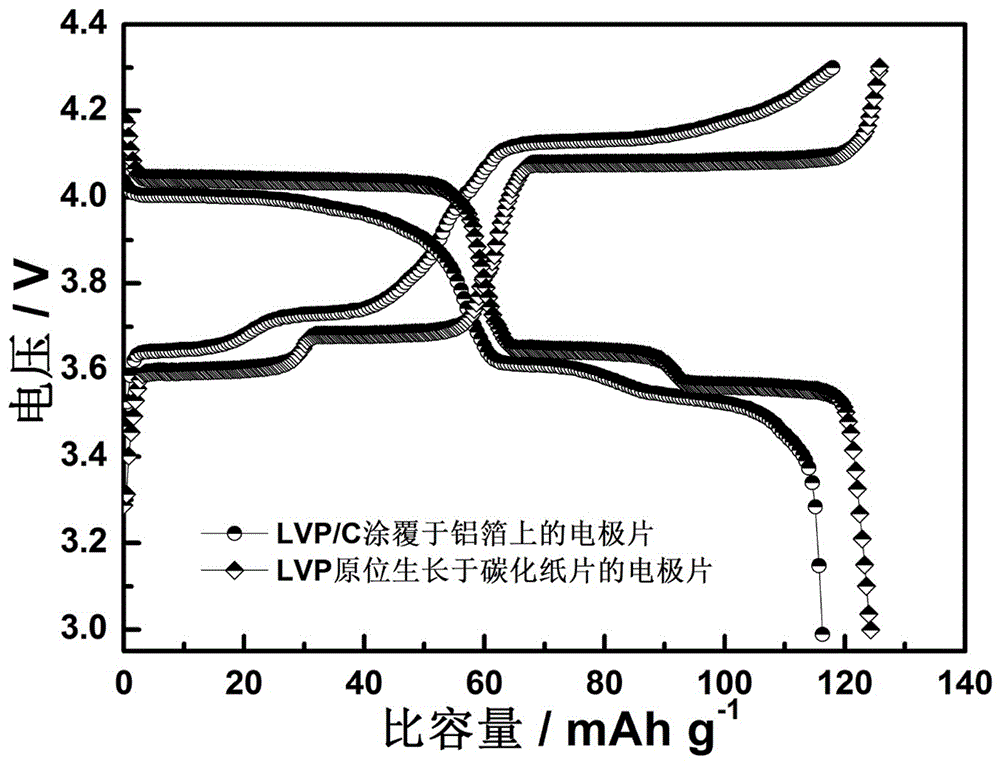

In-situ grown electrode plate made from active substances and manufacturing method thereof

InactiveCN106159204AReduce weightGood chemical stabilityElectrode carriers/collectorsFiberCarbon fibers

The invention provides an in-situ grown electrode plate made from active substances. An active material precursor uniformly coats normal filter paper in a soaking way; active materials formed by calcining grow in situ on carbon fibers which are obtained by carbonization of the filter paper and serve as a current collector; and an obtained composite material of the active materials and the carbon fibers is the in-situ grown electrode plate made from the active substances. The method comprises the following steps: transferring precursor powder into N-methyl pyrrolidone (NMP) serving as a medium, and stirring to obtain a sizing agent; soaking filter paper in the sizing agent, and performing ultrasonic treatment, drying and stamping to obtain a wafer; and sintering the wafer in a tubular furnace under an inert atmosphere at the temperature of 500-800 DEG C for 5-24 hours to obtain the electrode plate of which a positive electrode material grows in situ on the carbon fibers, namely, the in-situ grown electrode plate made from the active substances. Compared with a general electrode plate manufacturing method, the manufacturing method has the advantages that the carbon fibers obtained by carbonization of the filter paper are taken as the current collector, and the manufacturing of the electrode plate is directly finished by a sintering process of the active materials, so that the battery manufacturing process is simplified greatly, and the battery manufacturing cost is lowered.

Owner:CHINA THREE GORGES UNIV

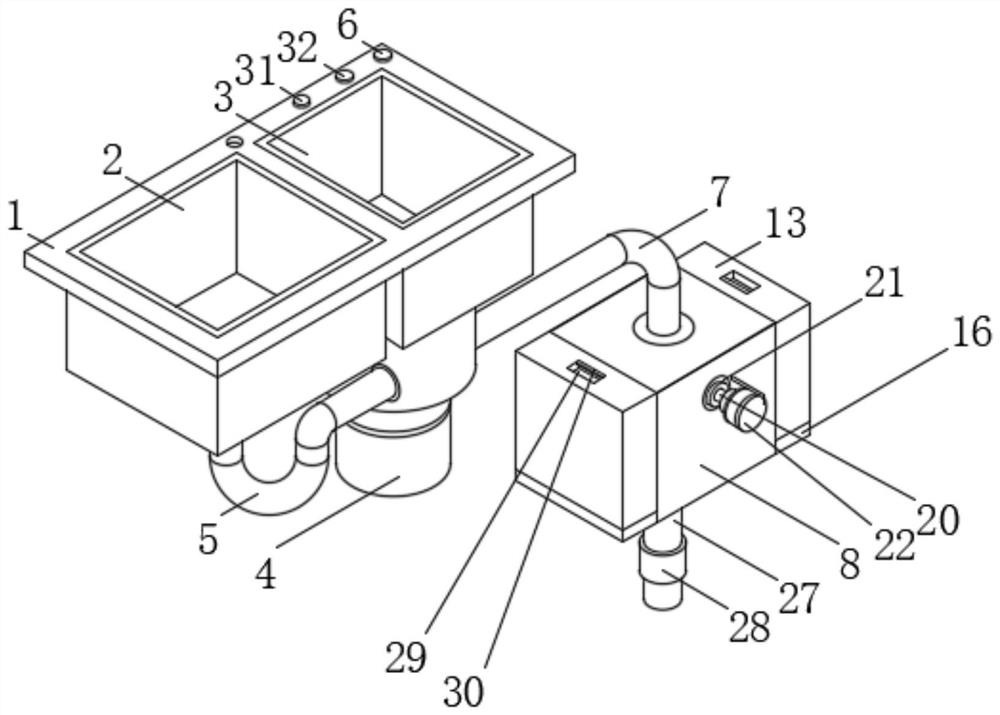

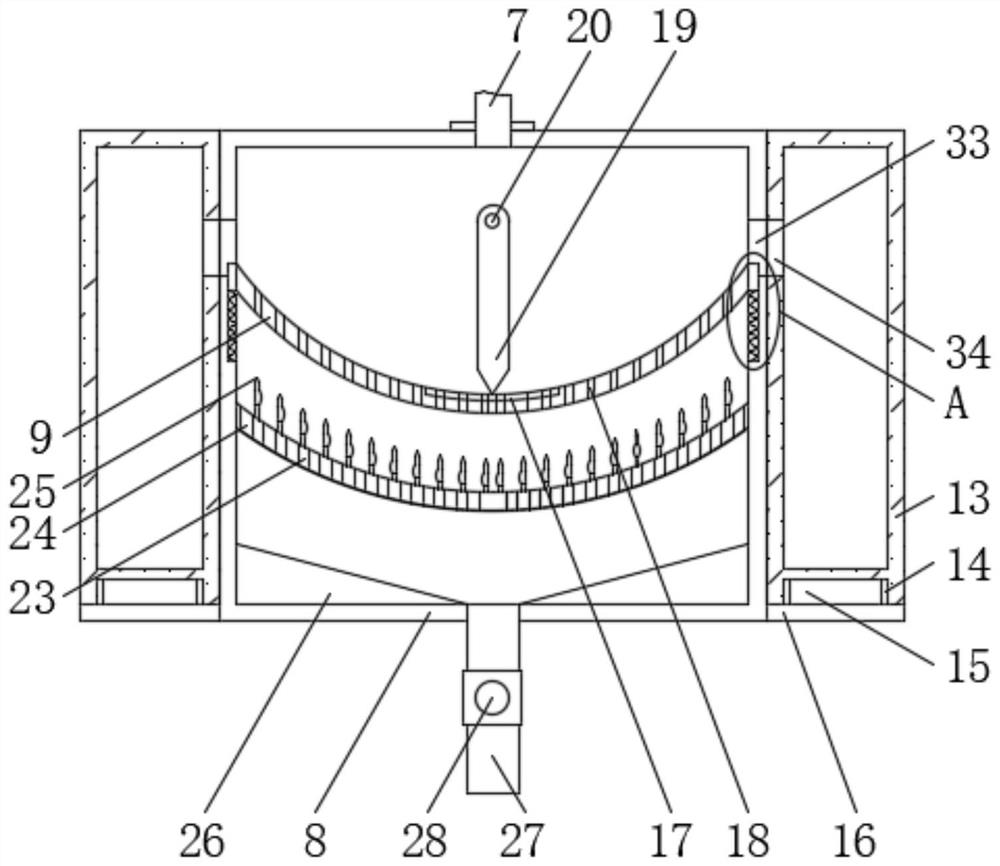

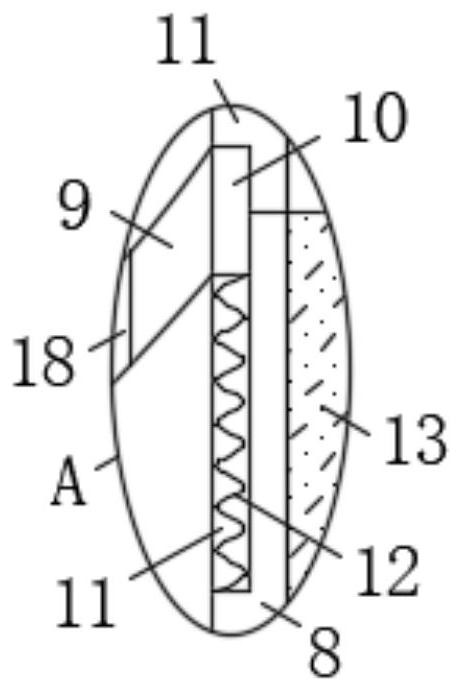

Slag-water anti-blocking device for garbage treatment

InactiveCN111701302AAvoid siltingReduce wasteDomestic plumbingStationary filtering element filtersNormal filterElectric machinery

The invention discloses a slag-water anti-blocking device for garbage treatment and belongs to the technical field of garbage treatment. The device includes a panel; the inner side of the panel is connected with a large cleaning cavity and a small cleaning cavity in an embedded mode; a garbage processor is arranged at an output port in the bottom of the small cleaning cavity; one side face of thegarbage processor is communicated with an output port in the bottom of the large cleaning cavity through a drainage pipe; and the other side face of the garbage processor is communicated with the topof a filtering chamber through a blow-off pipe. In the invention, a garbage processor, a motor, a scraper blade, a first sieve plate, first filter holes, a dredging device, a spring and a household garbage storage box are designed to be matched with one another; according to the device, domestic garbage is recycled, waste of food can be reduced to a certain extent, the domestic garbage is prevented from being deposited in a sewer line, the sewage discharge capacity of the sewer line is guaranteed, and the first sieve plate and the first filter holes can still keep the normal filter capacity after being used for a long time.

Owner:谭丽

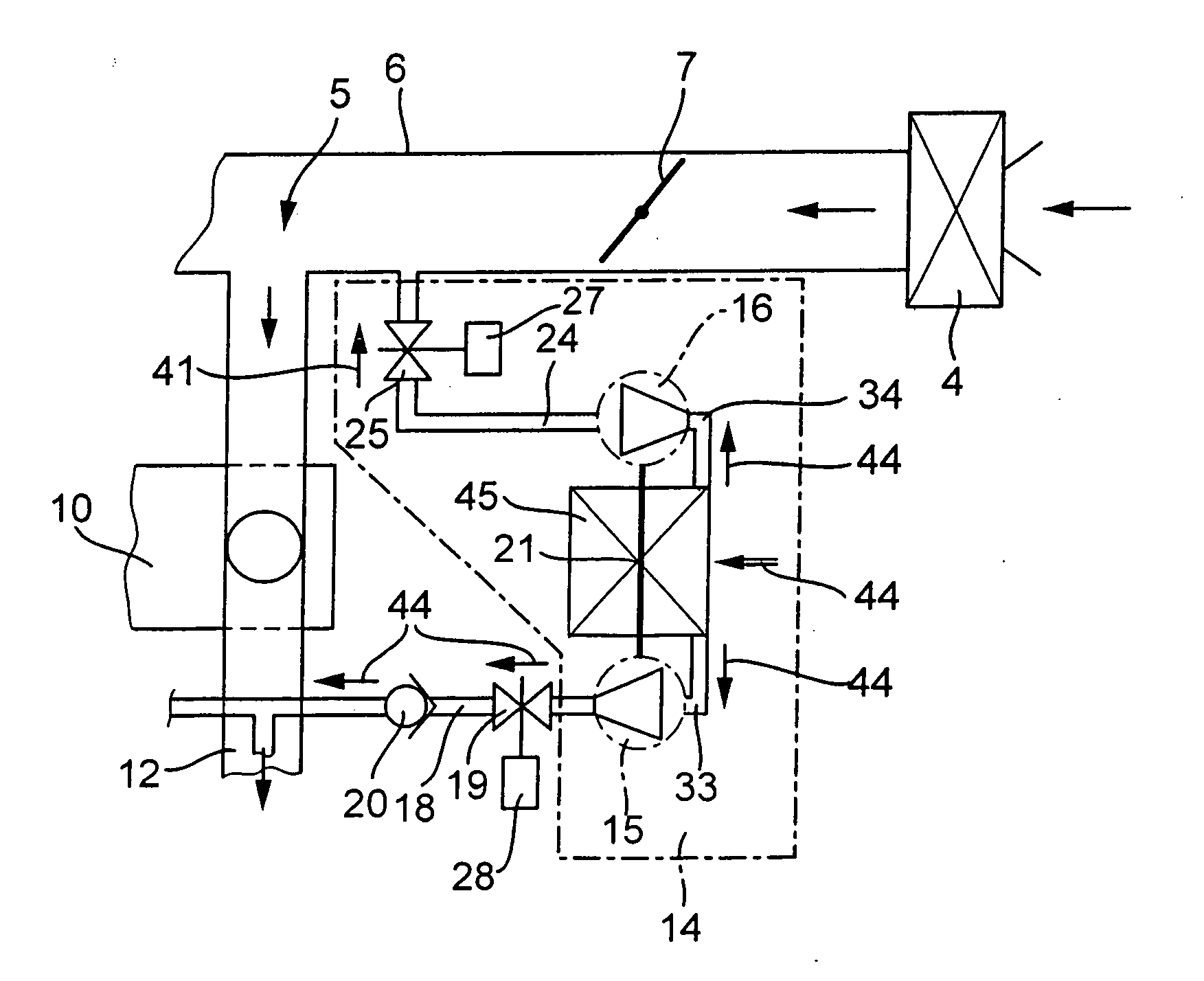

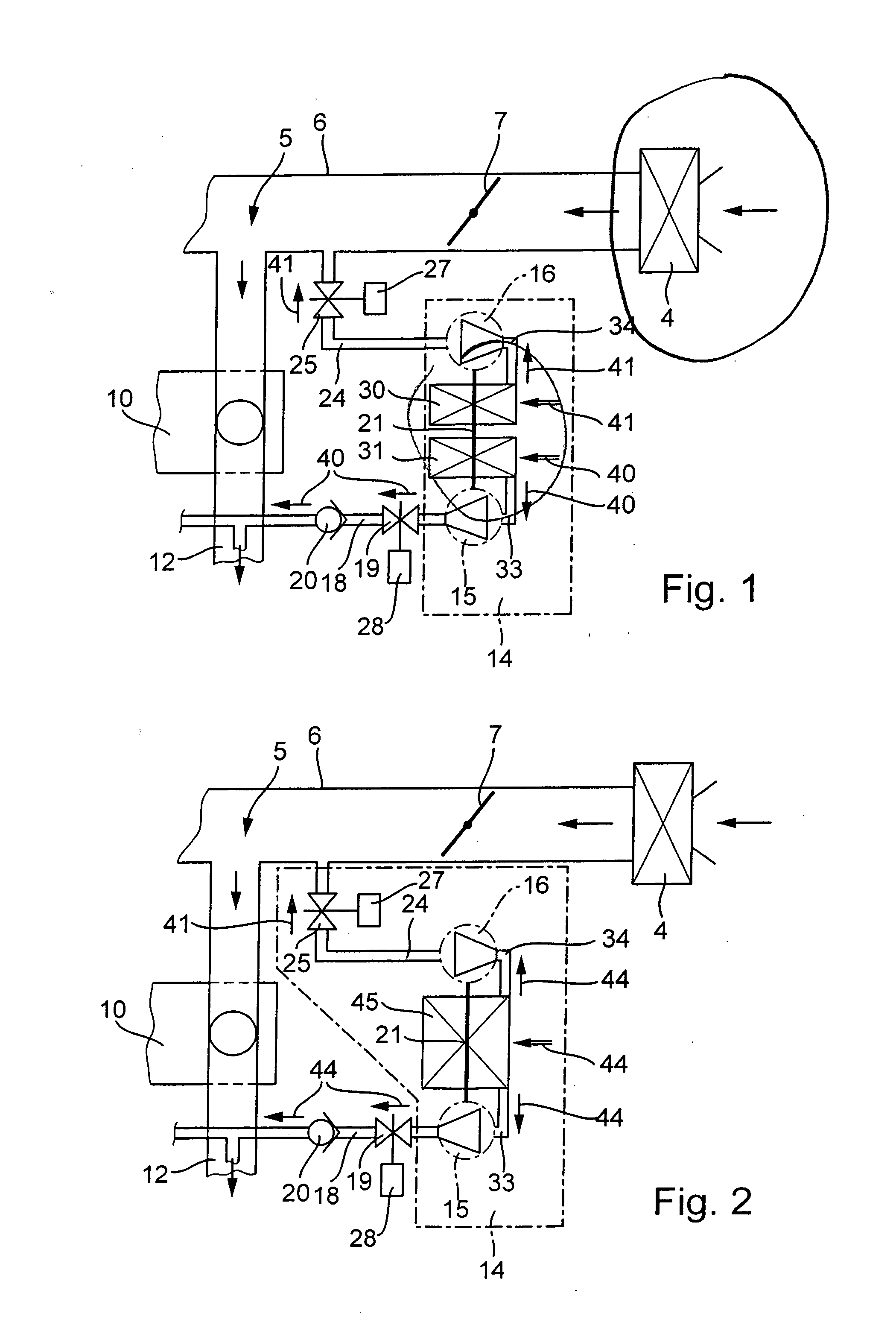

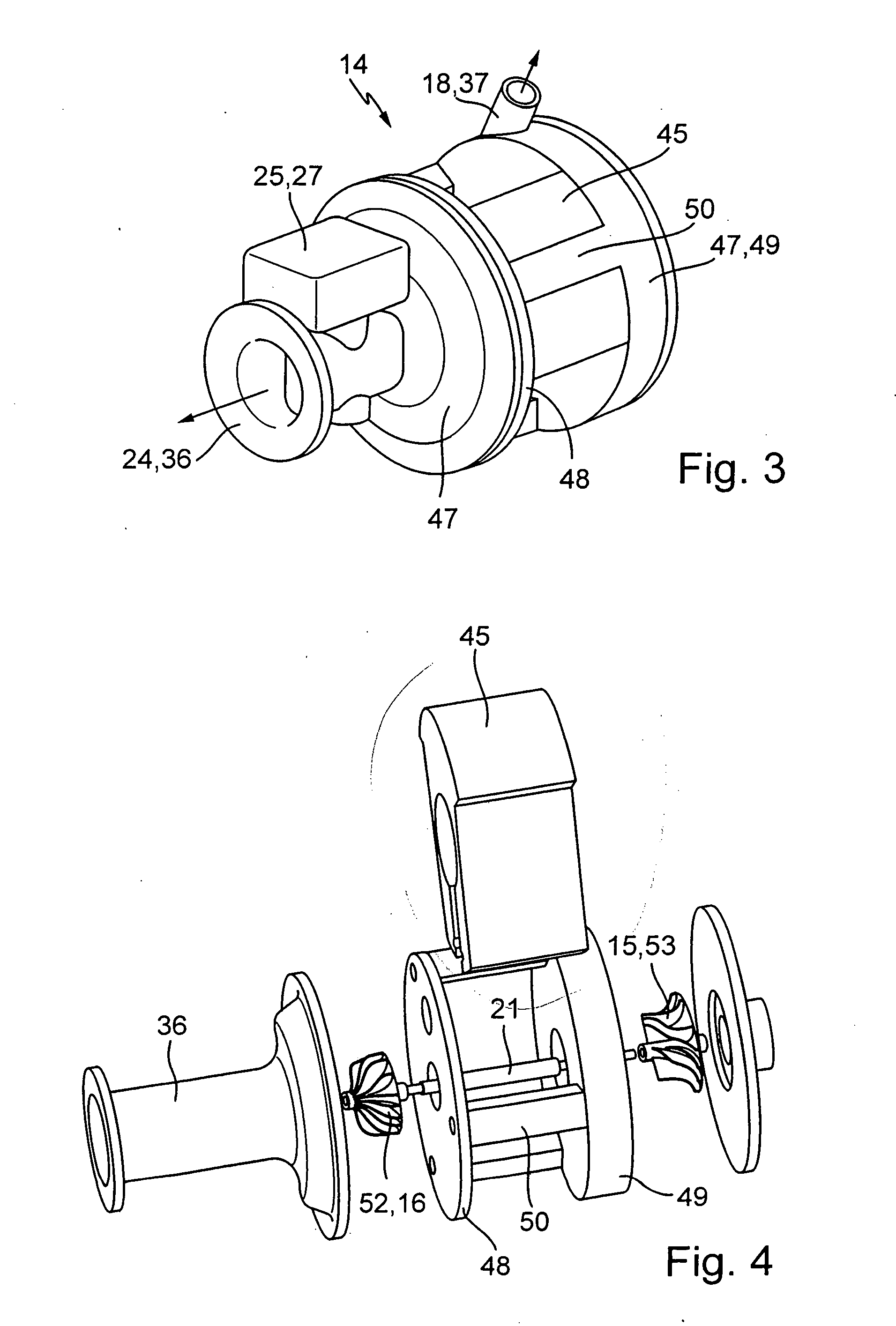

Air supply device for an internal combustion engine

ActiveUS7513107B2Simple inexpensive sealing arrangementEasy to manufactureInternal combustion piston enginesPump componentsImpellerTurbine wheel

In a secondary air supply device comprising a turbine and a compressor with turbine and compressor wheels having blades which are covered by wheel covers and an air filter structure disposed between the turbine and compressor wheels, so that air is supplied to the compressor and to the turbine from a common filter structure disposed between the compressor and the turbine wheels.

Owner:CHEMTRON RES

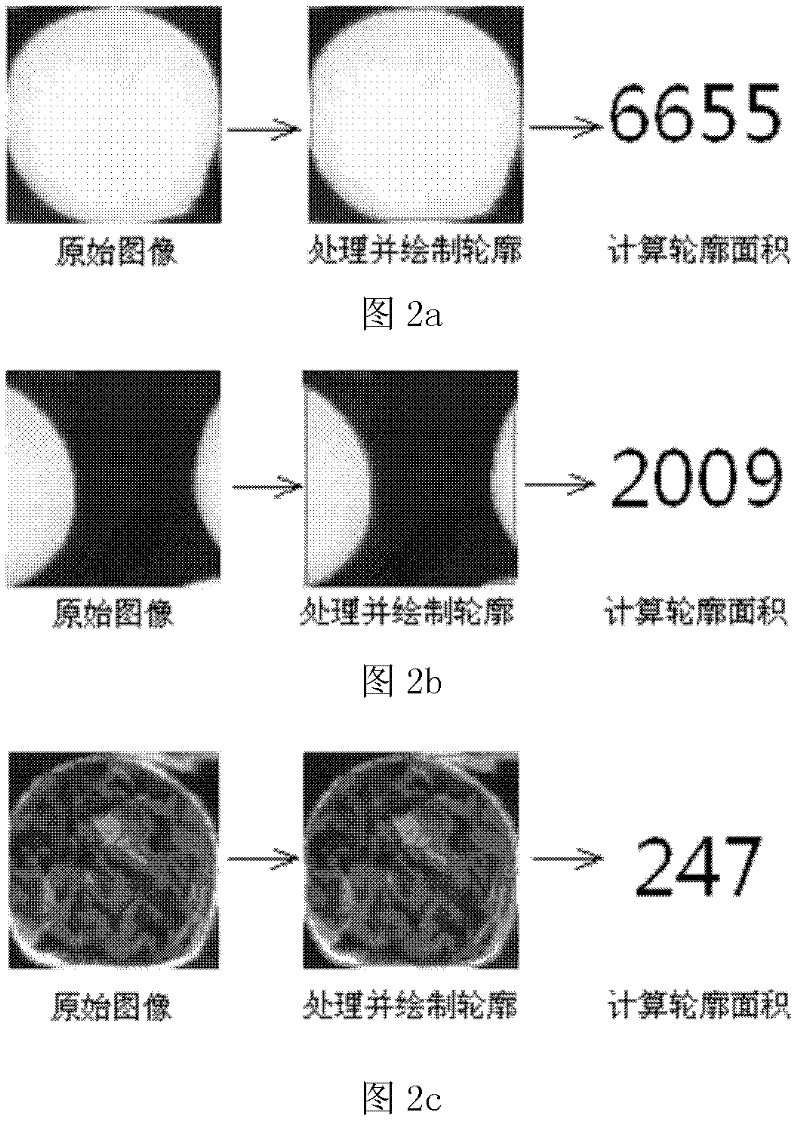

Method for detecting lack and upending of cigarettes in cigarette packet on basis of machine vision technology

ActiveCN102502000ABroad application spacePackaging cigarettePackaging cigarsMachine visionNormal filter

The invention discloses a method for detecting lack and upending of cigarettes in a cigarette packet on the basis of the machine vision technology. The method comprises the following steps: an image sensor is adopted for shooting the filter-tip end surface of the cigarette packet, and a forward image of the filter-tip end surface is shot by the image sensor; when the cigarette packet is lack of cigarettes, areas with the brightness becoming low obviously can occur in the image shot by the image sensor, the image is obviously different from a white image of the normal filter-tip end surface by contrast, and a computer can judge that the cigarette packet is lack of the cigarettes; if upended cigarettes exist in the cigarette packet, an image of a cigarette-tobacco end surface is shot by the image sensor and is obviously different from the white image of the normal filter-tip end surface by contrast, and the computer can judge that the upended cigarettes exist in the cigarette packet.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP +1

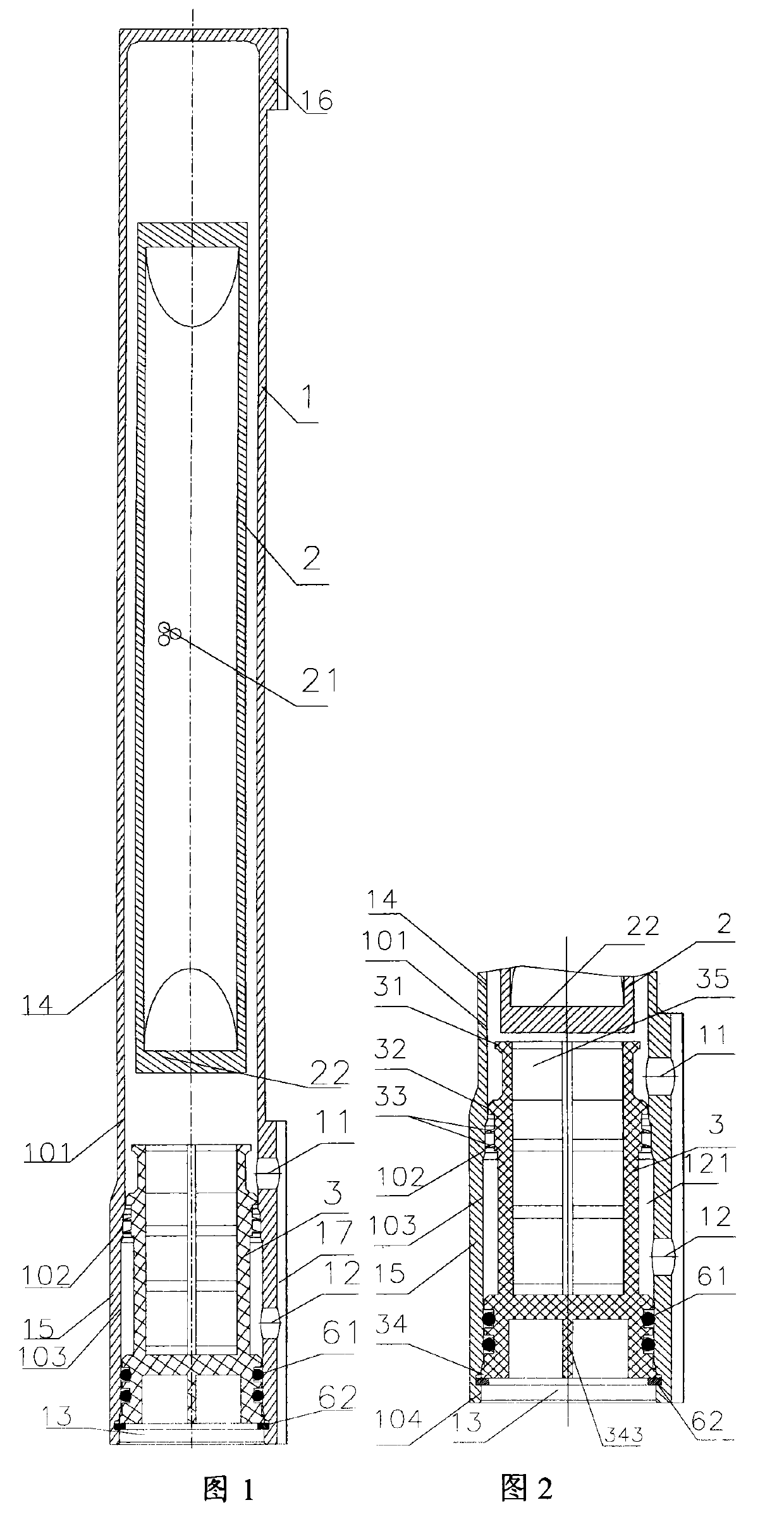

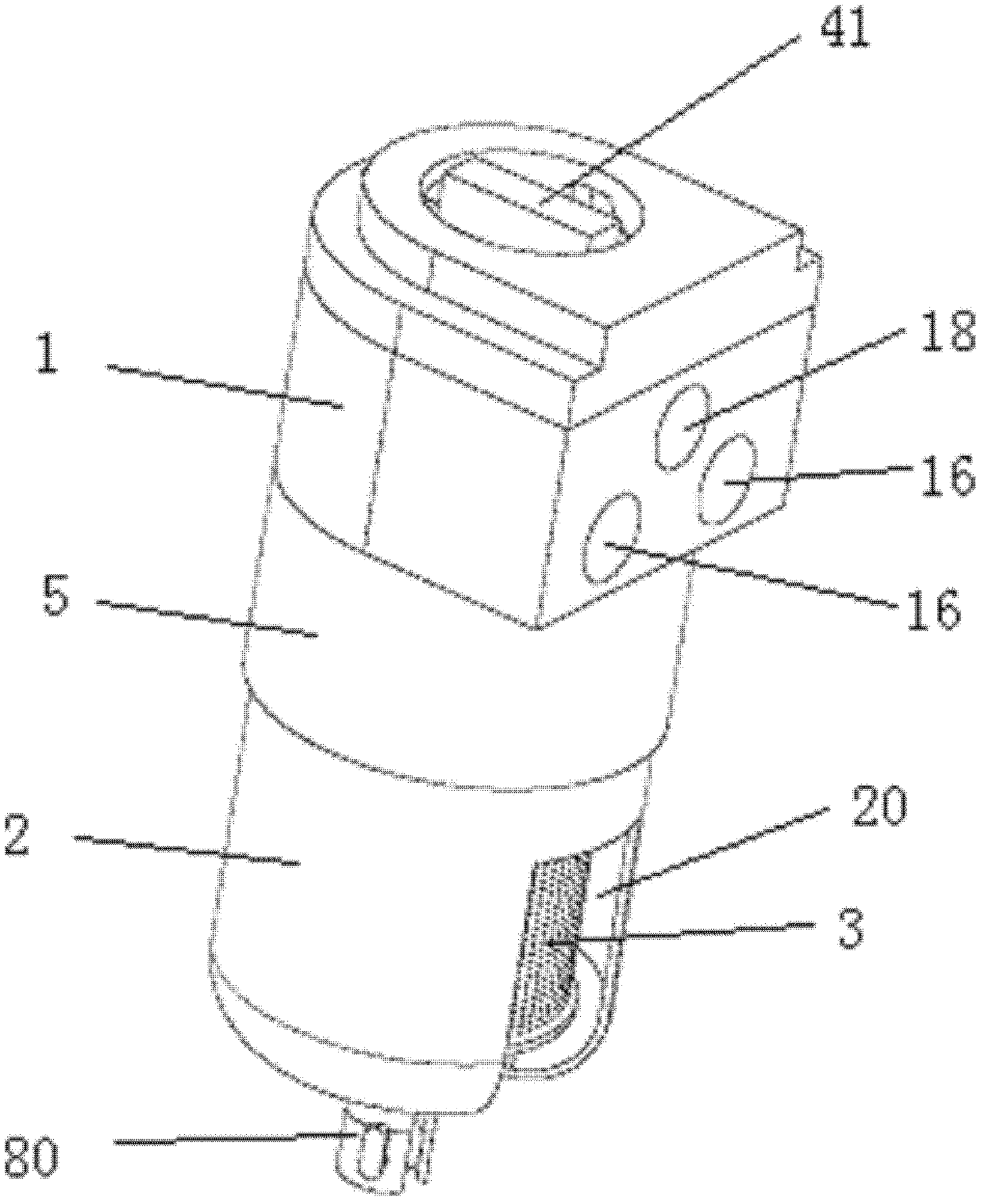

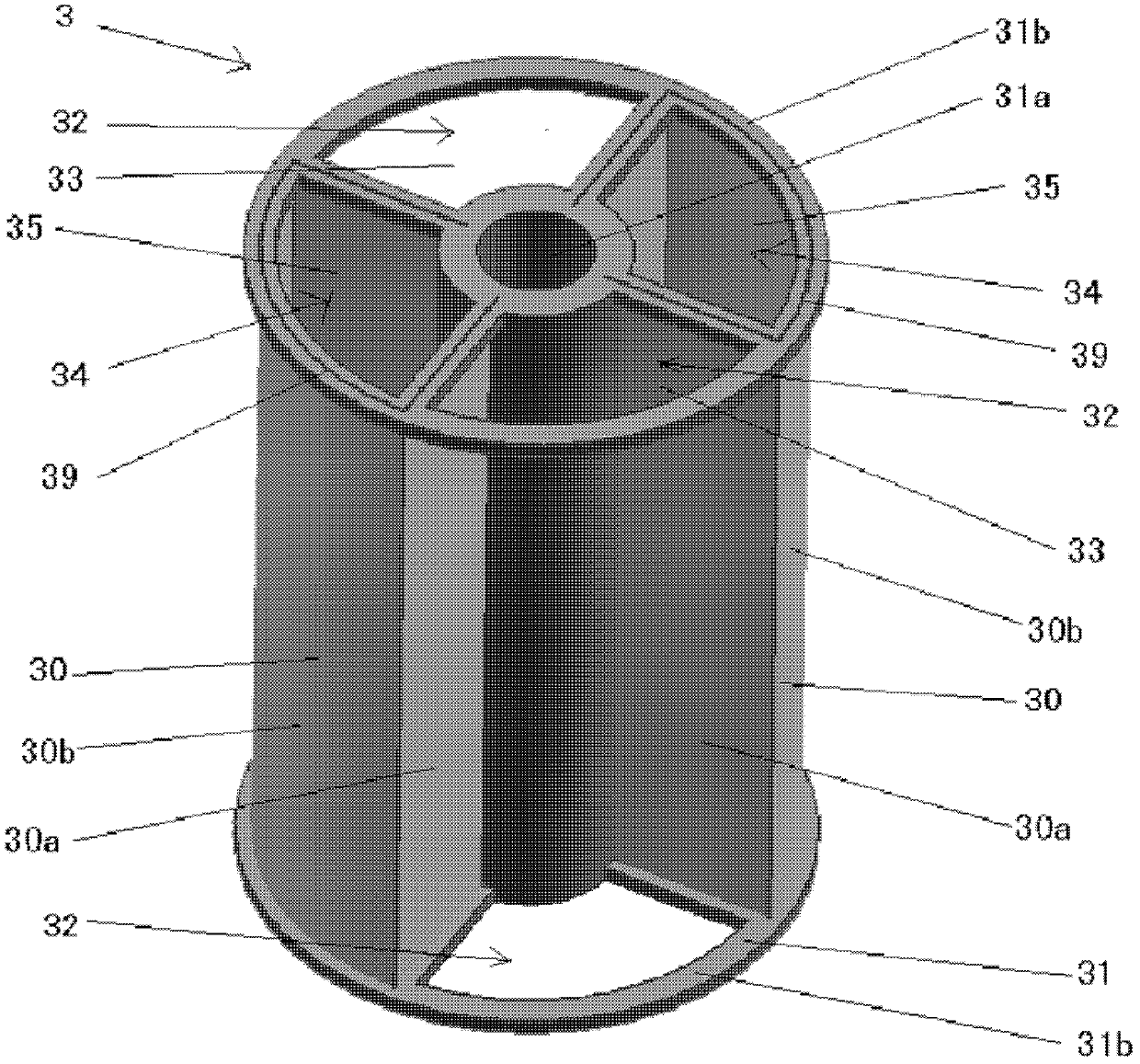

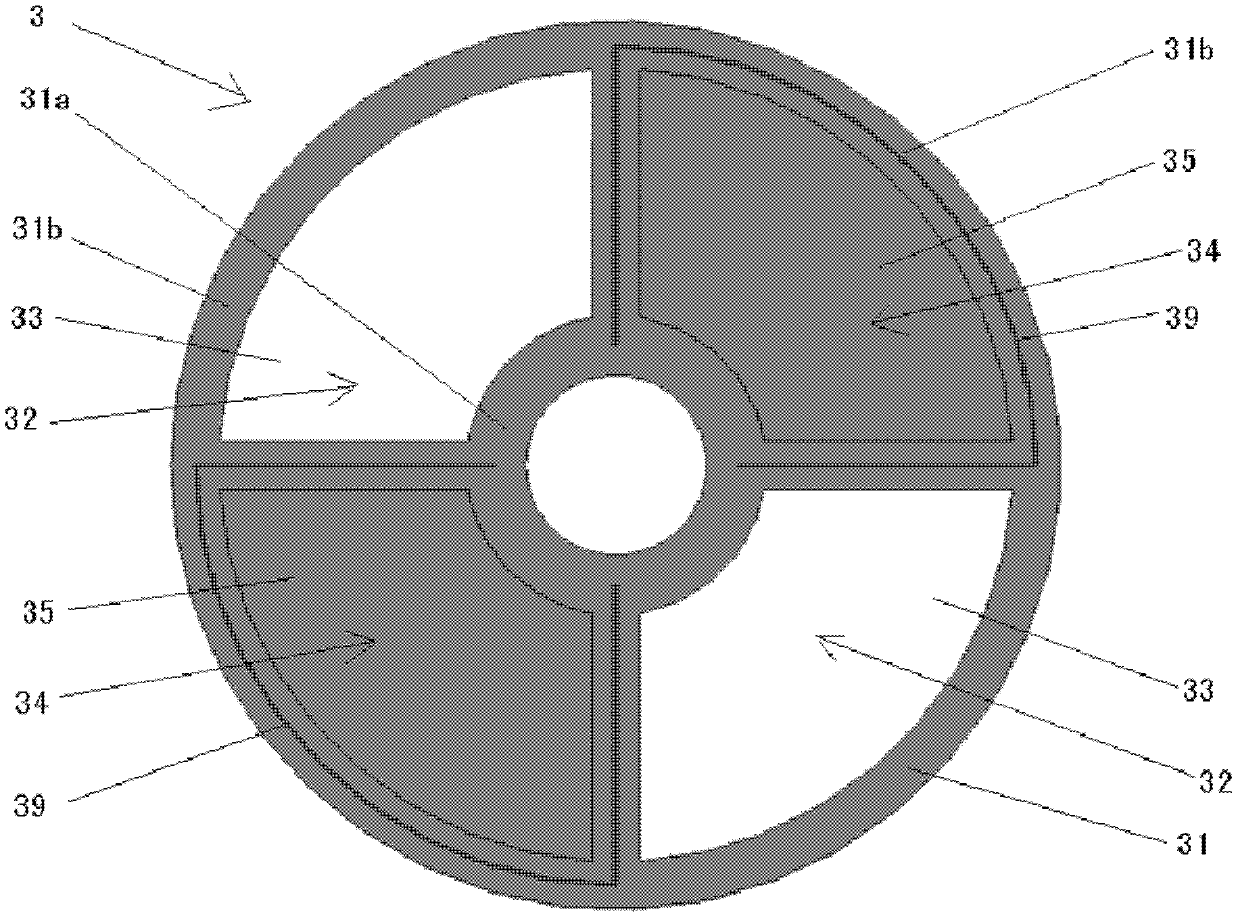

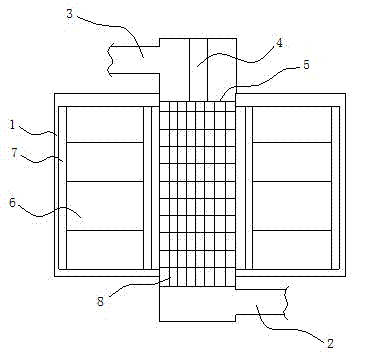

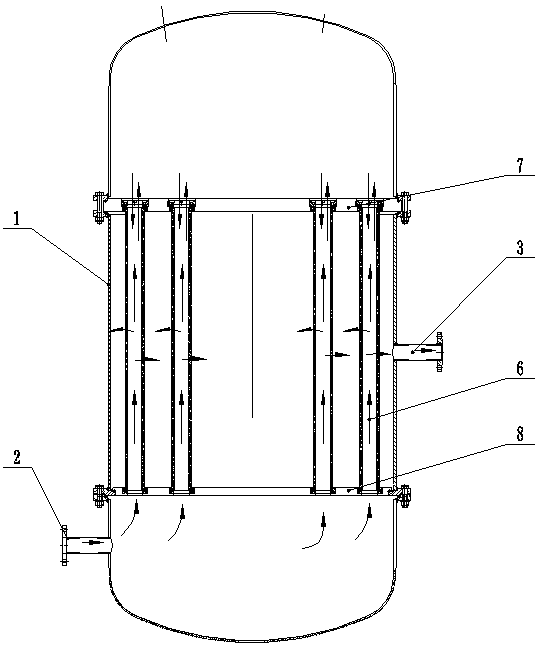

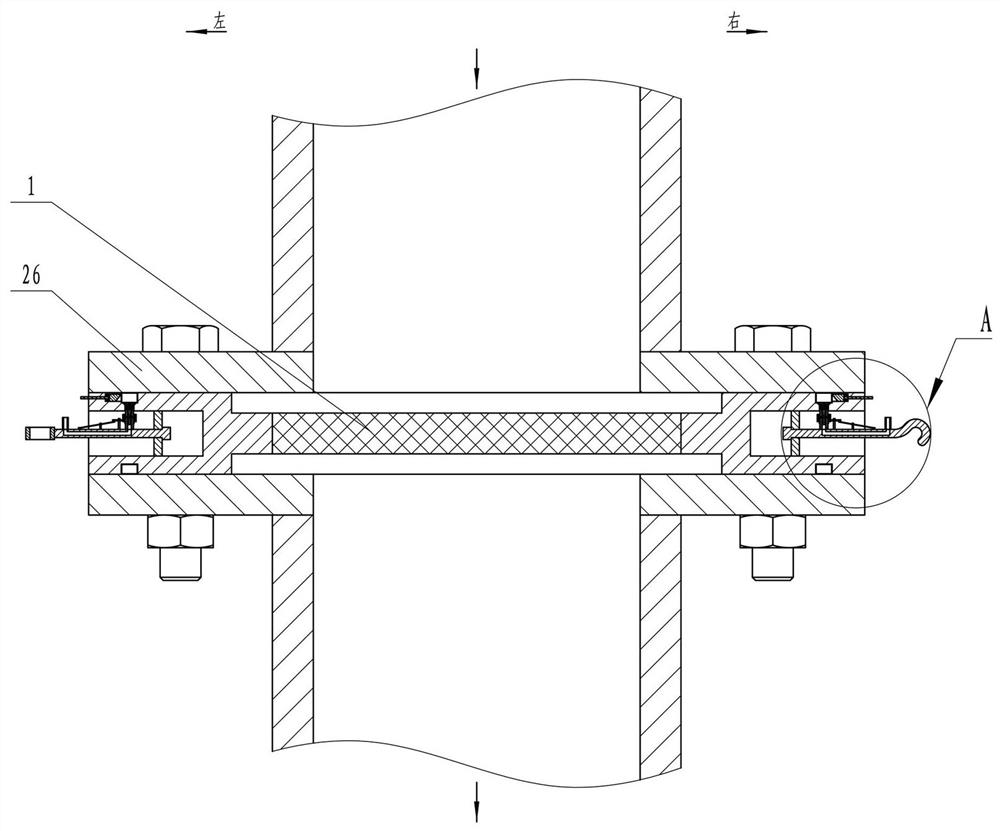

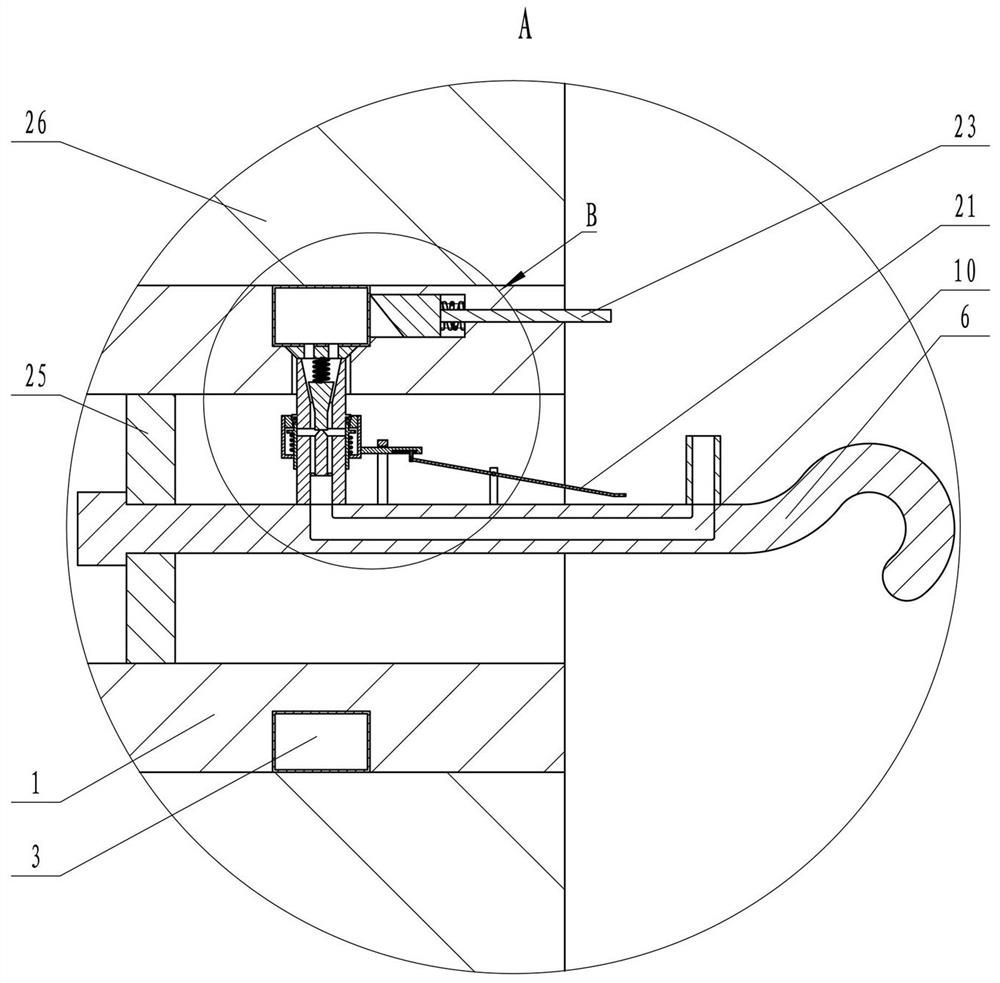

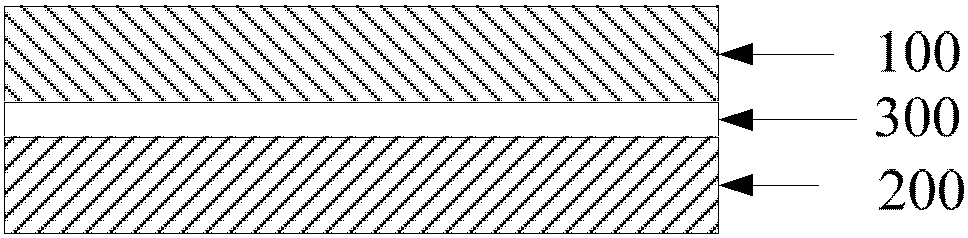

Back-flush-type water filter

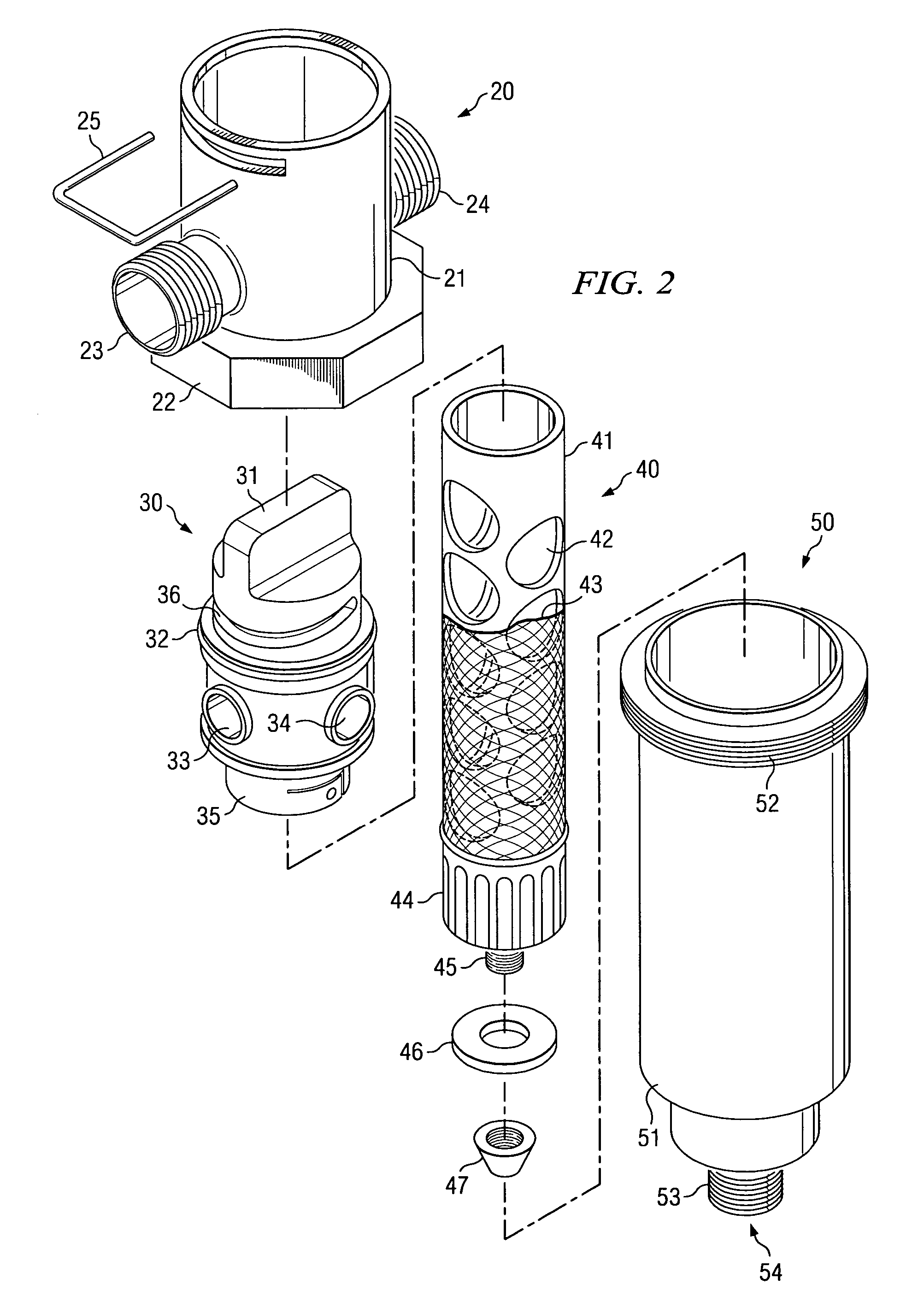

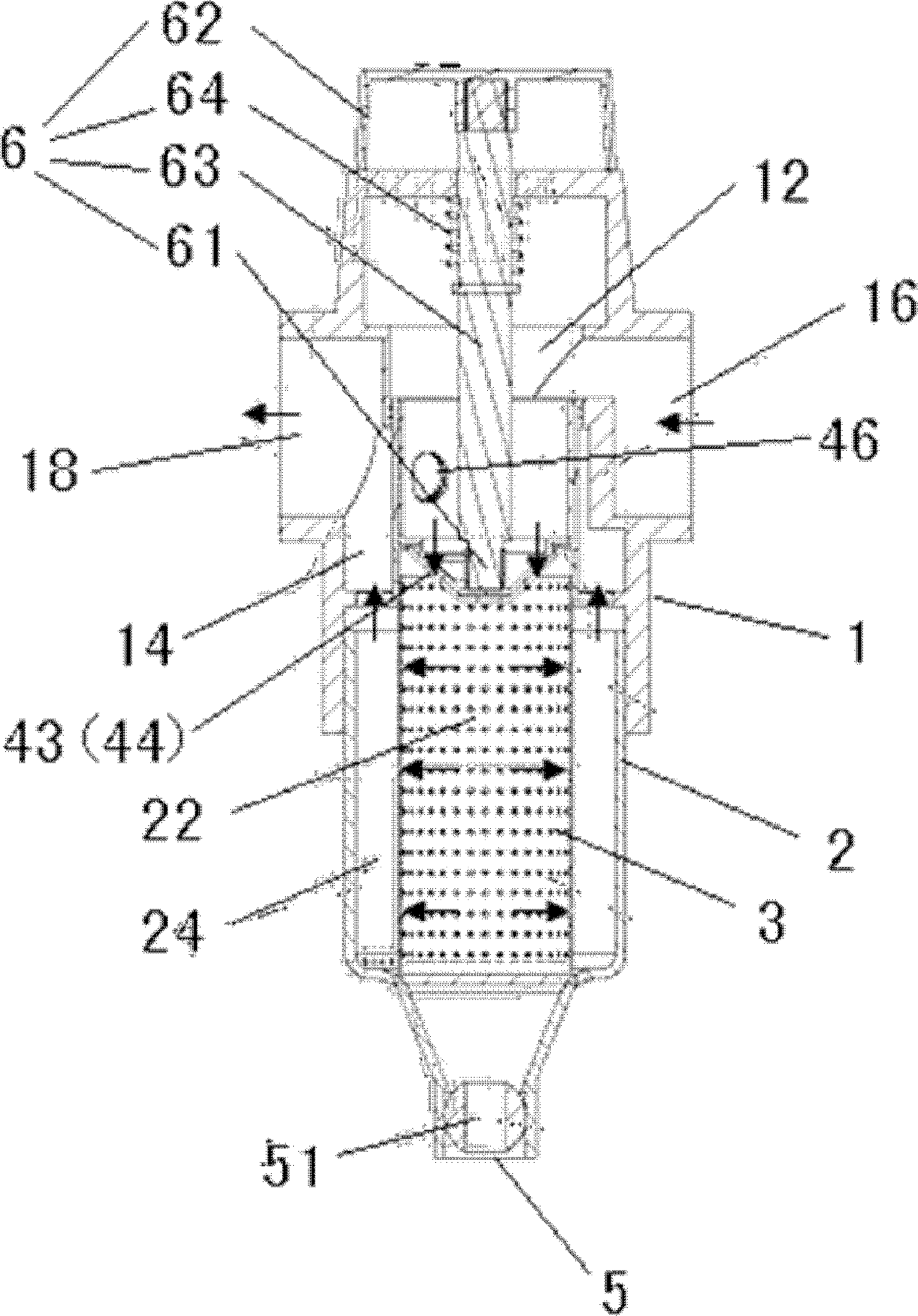

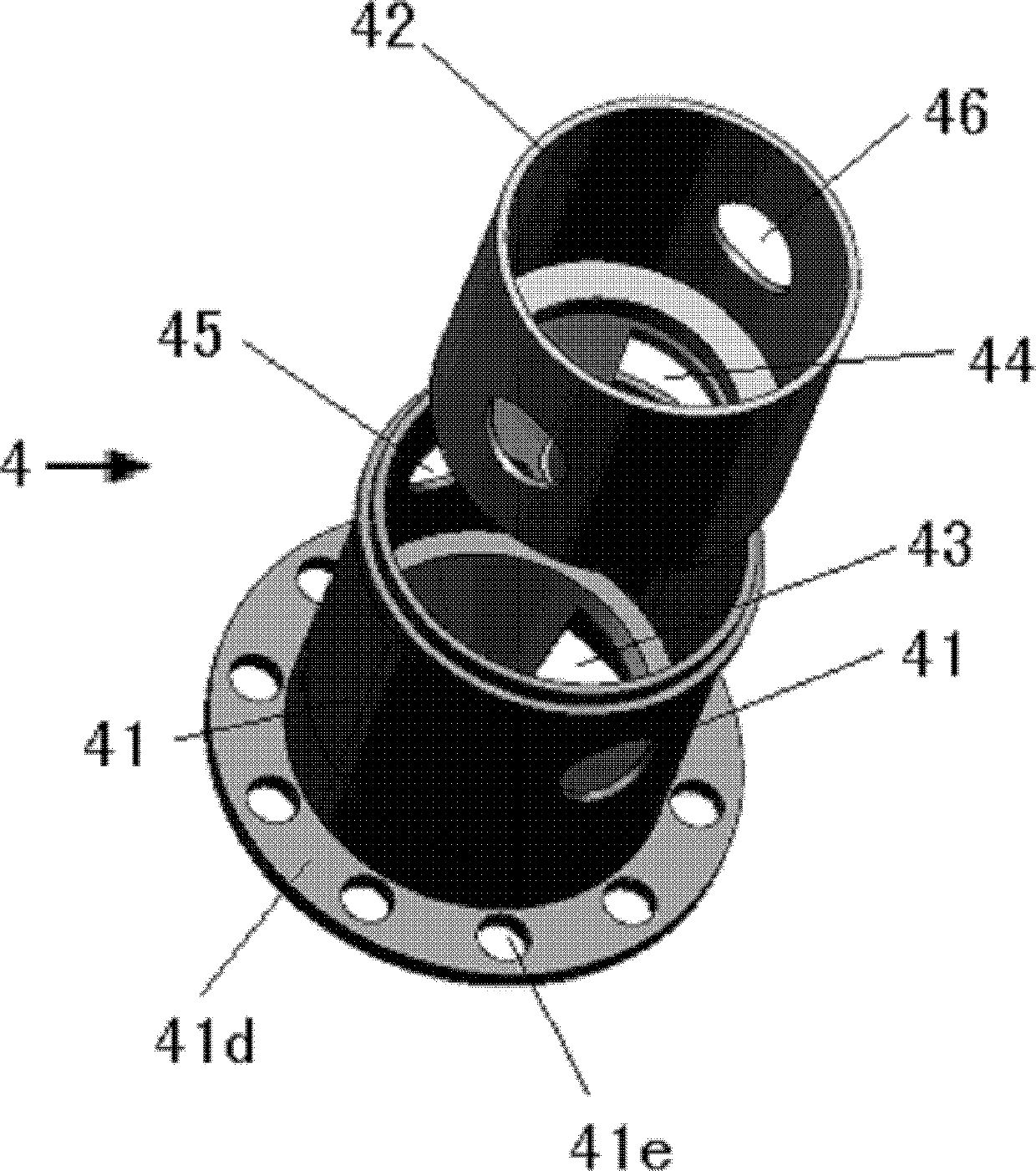

ActiveCN103372340ARealize self-cleaningLarge filter areaStationary filtering element filtersWater filterFiltration

The invention discloses a back-flush-type water filter. The back-flush-type water filter comprises a water inlet (16), a water outlet (18), a shell, a filtering unit (3) and a water flow direction conversion mechanism (4), wherein a cavity body (20) is defined by the shell (2), and water flowing from the water inlet flows through the cavity body, and then flows out of the water outlet; the filtering unit (3) is arranged in the cavity body, and comprises at least one first part (32) open toward the cavity body and at least one second part (34) with a filter screen (30); the water flow direction conversion mechanism (4) enables water flow to be converted between normal filter operation and back flush operation; when the water flow direction conversion mechanism is converted to the normal filter operation, water flows to the at least one second part with the filter screen through the filter screen from the at least one first part open toward the cavity body, thereby achieving water filtration; when the water flow direction conversion mechanism is converted to the back flush operation, water flows to the at least one first part open toward the cavity body through the filter screen from the least one second part with the filter screen, thereby flushing impurities deposited on the filter screen.

Owner:3M INNOVATIVE PROPERTIES CO

Stabilization and regeneration method of aluminum and aluminum alloy chemical milling solution

The invention provides a stabilization and regeneration method of aluminum and aluminum alloy chemical milling solution, which can realize the cycle use of the aluminum alloy chemical milling solution, improve service life, lower cost and reduce pollution of the aluminum alloy chemical milling solution. The method comprises the following five steps: (1) introducing part of the chemical milling solution into a storage tank, and then removing suspended matters with a common filer; (2) introducing the obtained filtrate into a reactor, adding deionized water and aluminum hydroxide seed crystals to the filtrate, and then evenly mixing to crystallize and precipitate aluminum hydroxide, wherein the volume of the deionized water is 0.5-2 times of that of the filtrate; (3) leading the obtained mixed liquid into a crystallization tank, adding a proper amount of aluminum hydroxide seed crystals to the mixed liquid for crystal growth for 24-48h to separate out aluminum hydroxide crystals, and then leading the obtained supernate into an adjusting tank; (4) adding a proper amount of sodium hydroxide and other components to the adjusting tank to recover chemical milling efficacy of the chemical milling solution; and (5) washing and then drying the aluminum hydroxide crystals to finally obtain the aluminum hydroxide solid product.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

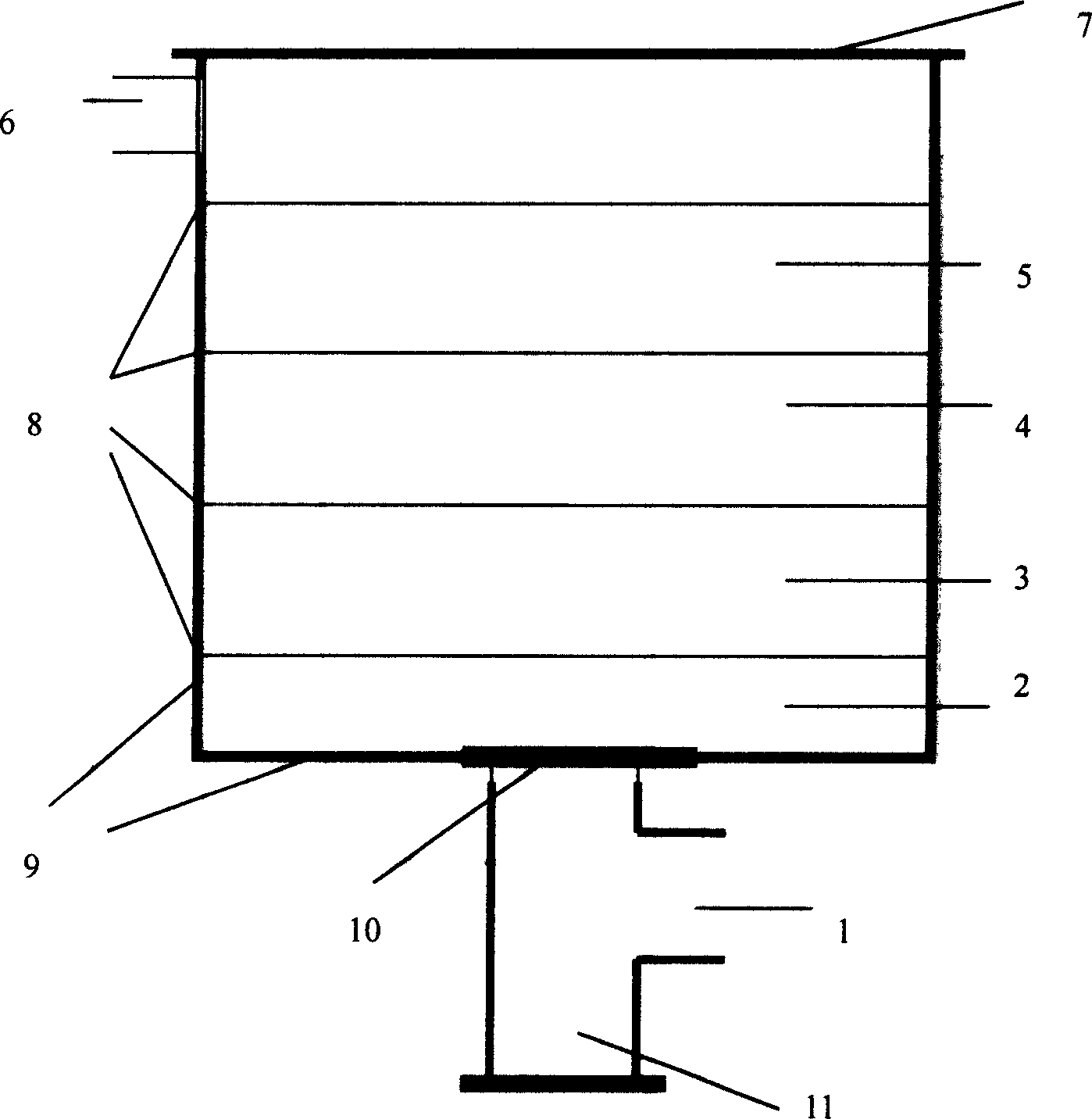

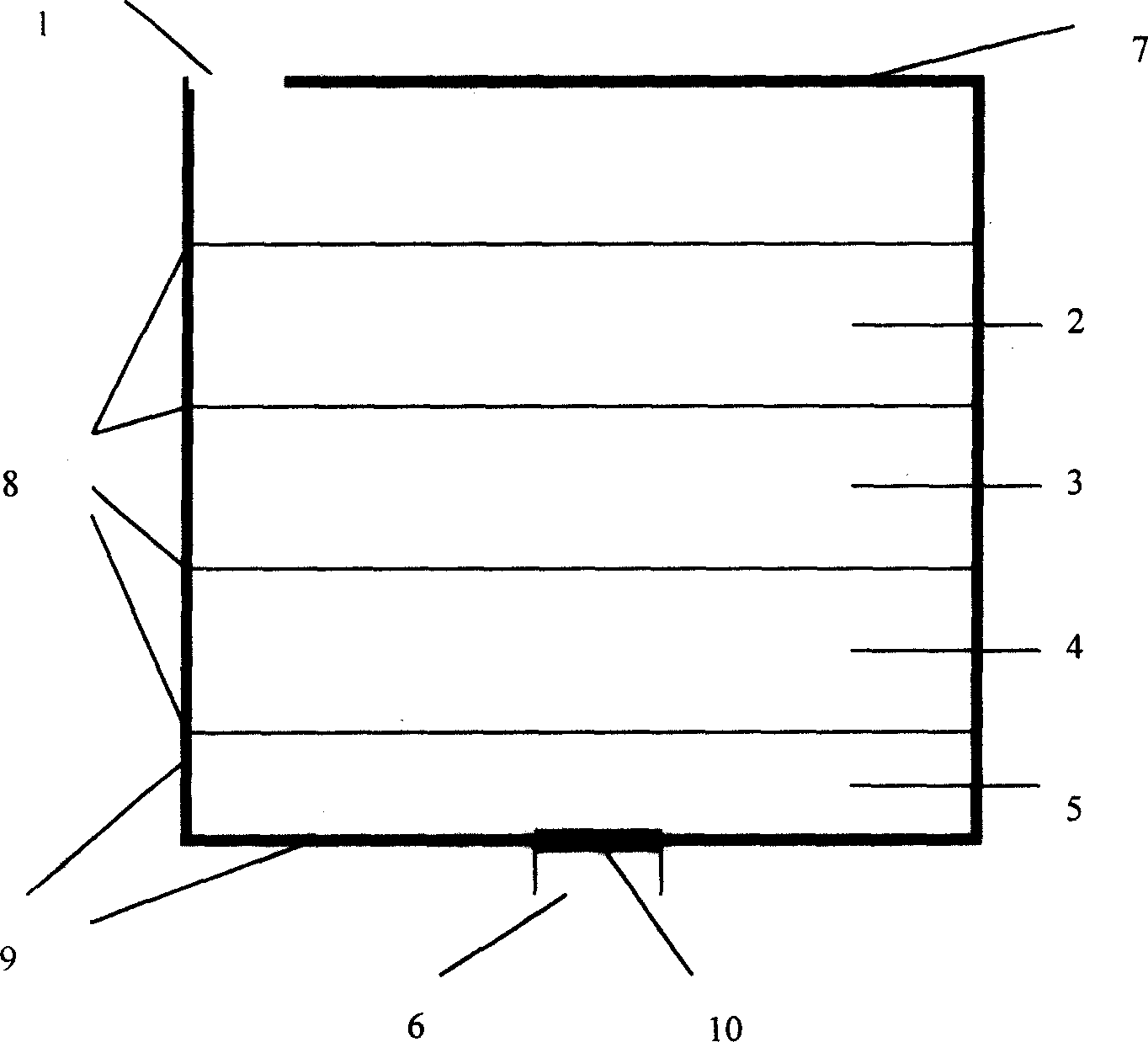

Deep sand filter

InactiveCN1528489ALarge dirt holding capacityAct as a coarse sand filterLoose filtering material filtersGravity filtersNormal filterEngineering

The invention is a depth-type sand filter, the size of sand gradually diminishing with the flow direction of the normal filtering fluid. It leads the fluid to the inlet of the sand filter through the pipeline, firstly holds back big suspension through big sand area, then holds back medium suspension through medium sand area, finally eliminates most fine suspension through fine sand area, and then makes the fluid flow out from the outlet. It is composed of wall body, filtering sand and ground leak; the wall body is set with inlet and outlet, the ground leak is set under the wall body, the filtering sand is spread in the liquid flow direction in turn according to the size. It can adopt upflow and downflow modes. It can stably and economically run in a wide range. It is applied to economical sand filtering field, especially the field where the sand filter is used infrequently or discontinuously.

Owner:安逢龙

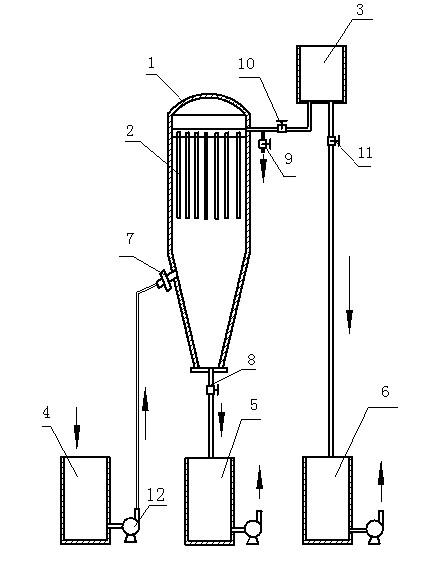

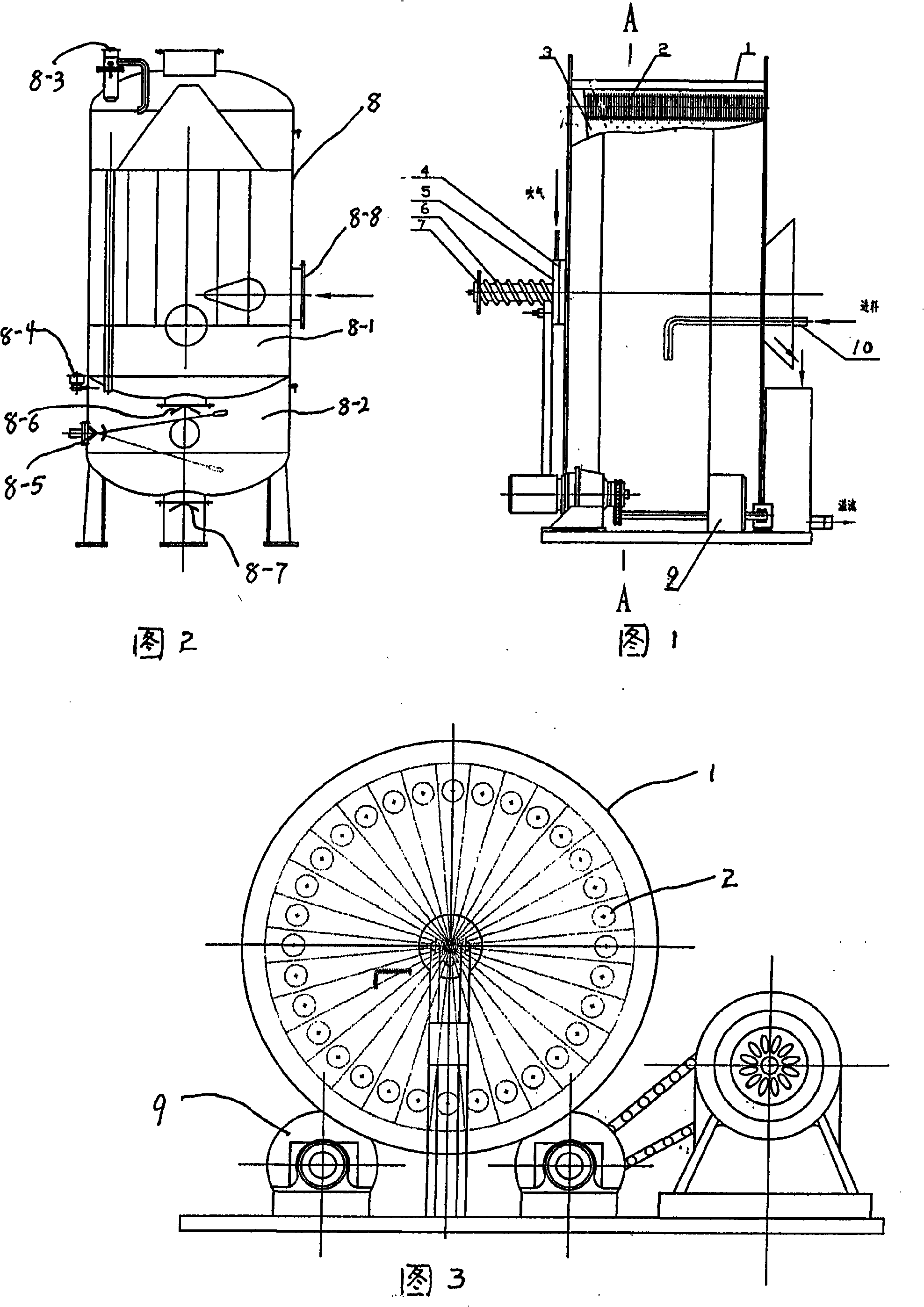

Special type separation filter

InactiveCN101352626AImprove separation efficiencySolve the problem of solid-liquid separationMoving filtering element filtersFilter mediaNormal filter

The invention provides a special filter machine which is characterized in that the special separation machine comprises a solid / liquid separation device which comprises a cylinder body and a filter core which is arranged by surrounding the internal chamber of the cylinder body; the internal side of the left end of the cylinder body seals the left end of the chamber to be filtrated by a plurality of sector plates and separating plates and forms a plurality of sector filter chambers together with the left end plate of the cylinder body; a distributing head which is communicated with a liquid drainage tank is arranged at the central position of the left end plate of the cylinder body and communicated with the sector filter chamber; the distributing head consists of a disc-shaped movable distributing head and a disc-shaped fixed distributing head which are matched with each other; the movable distributing head and the fixed distributing head are correspondingly provided with a hole; the two holes are communicated with each other. The separation filter is applicable to the separation and filtration of normal liquid, can carry out the separation and filtration of viscous material which is difficult to be processed and liquid which has strong thixotropy, effectively improves the solid / liquid separation efficiency and gas / liquid separation efficiency; the filter medium is not easy to be polluted; compared with the normal filter equipment, the special separation filter machine improves the filtration effect, realizes the full automation, reduces the running expense, and achieves the object of improving the production efficiency.

Owner:姜光启

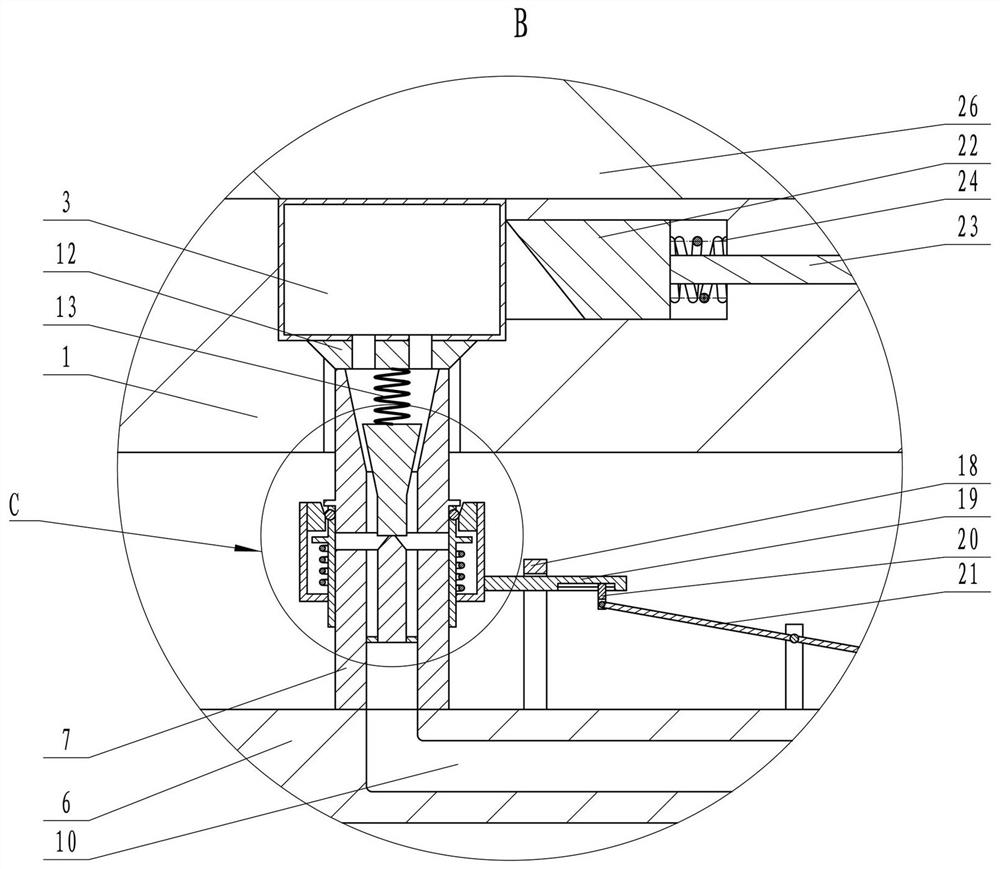

Self-driven sewage cleaning water filter

InactiveCN103055571ARealize the function of automatic sewage dischargeAdjust the speedStationary filtering element filtersImpellerWater filter

The invention relates to a self-driven sewage cleaning water filter, which comprises an upper casing, a lower casing, an impeller speed adjuster, a rotating speed annunciator, a balance shaft, a filter screen component, a sewage discharge branch pipe, a micro-impeller and a sewage discharge pipe. According to the self-driven sewage cleaning water filter, the self-driven sewage cleaning and discharging function is realized; during sewage discharging, a sewage discharge valve on a sewage discharge pipe 3 is opened, so that the water filter is in a sewage cleaning and discharging working condition; a sewage discharge branch pipe 15 is driven by the impeller 4 to rotate, so that pipe orifices on two arms of the sewage discharge branch pipe 15 are sequentially communicated with the washed filter screens of units, sewage attached to the filter screens are backwards washed by clean water, and effluent is discharged through the sewage discharge pipe 3, so that automatic sewage cleaning and discharging function is realized; and when the sewage valve is closed, the branch pipe is full of static pressure water, the sewage cleaning and discharging working condition is ended, and the water filter is recovered to the normal filtering working condition. According to the self-driven sewage cleaning water filter, redundant water energy in the water filter is fully utilized to drive the micro-impeller to realize self-driving, so that the technical effects of saving energy and simplifying structure are achieved.

Owner:苏九逵

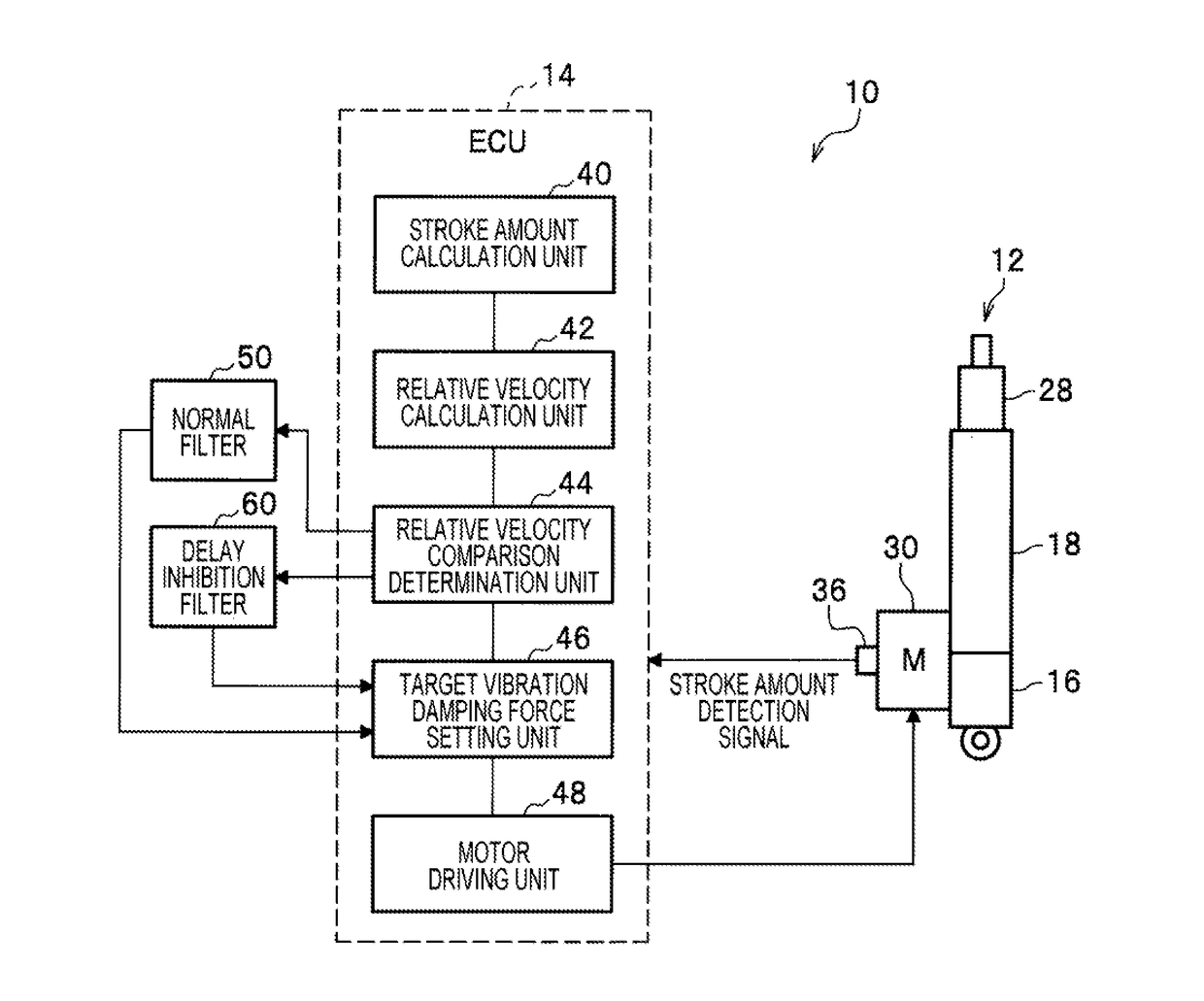

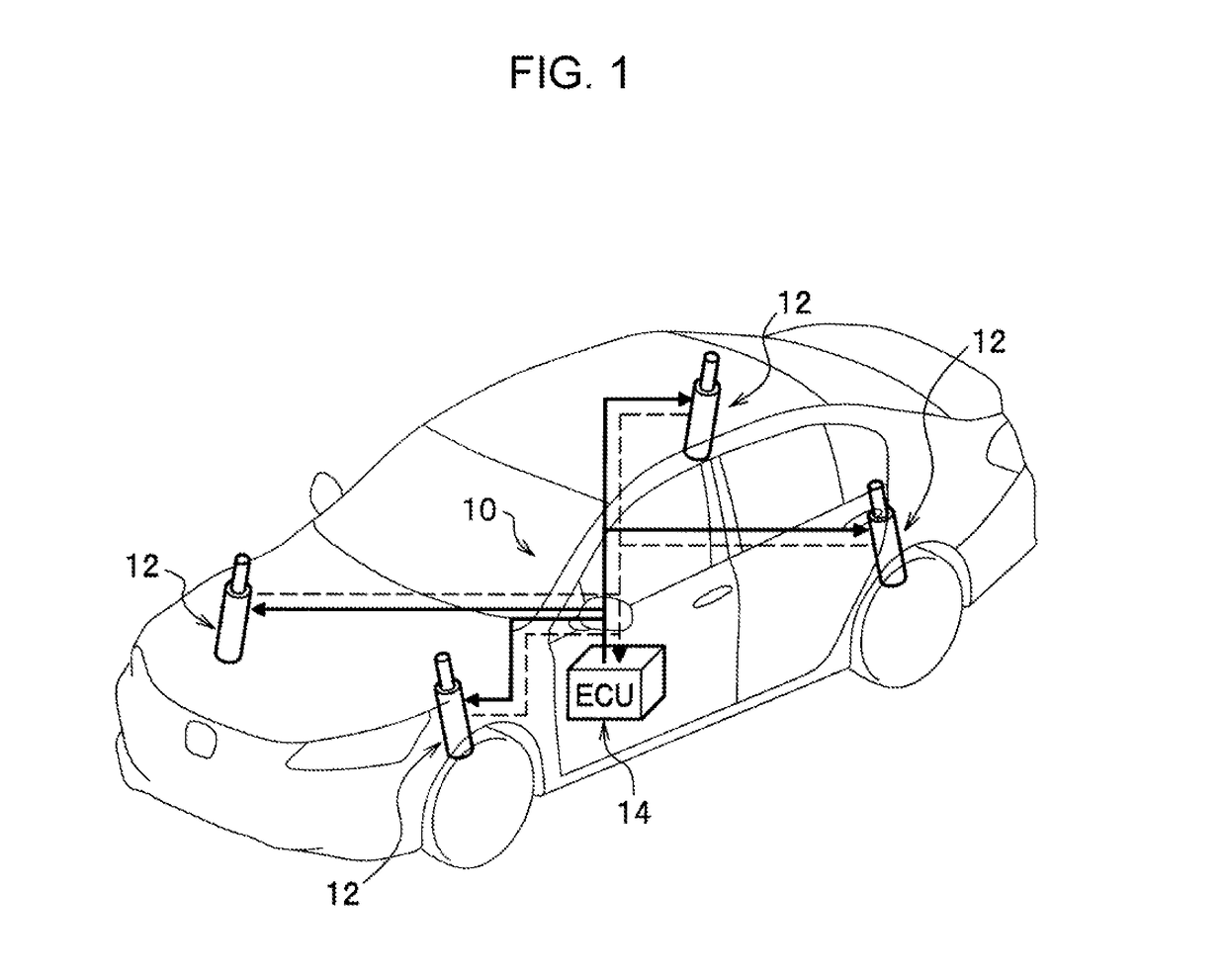

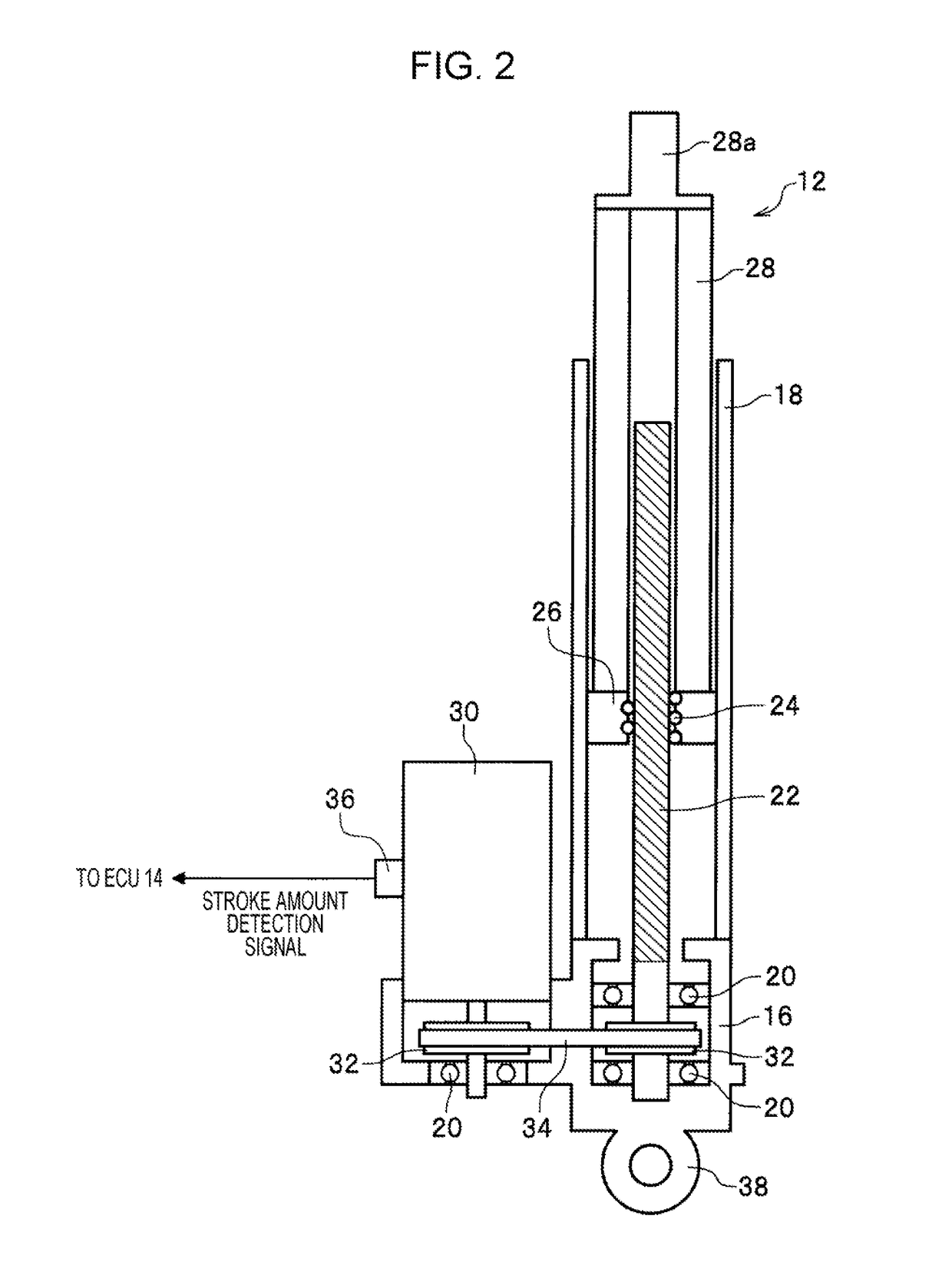

Electromagnetic damper system

A relative velocity between a sprung mass and an unsprung mass of a vehicle is calculated by differentiating a stroke amount of an electromagnetic damper with respect to time. The relative velocity is compared with a predetermined value that is set in advance, and a determination is made whether or not the relative velocity is the predetermined value or higher. In a case where the relative velocity is lower than the predetermined value (relative velocity<predetermined value), a normal filter is selected, and a gain G of only an unsprung resonance frequency range is increased. On the other hand, in a case where the relative velocity is the predetermined value or higher (relative velocity≧predetermined value), a delay inhibition filter is selected, and a gain of a high frequency range is increased compared to the normal filter.

Owner:HONDA MOTOR CO LTD

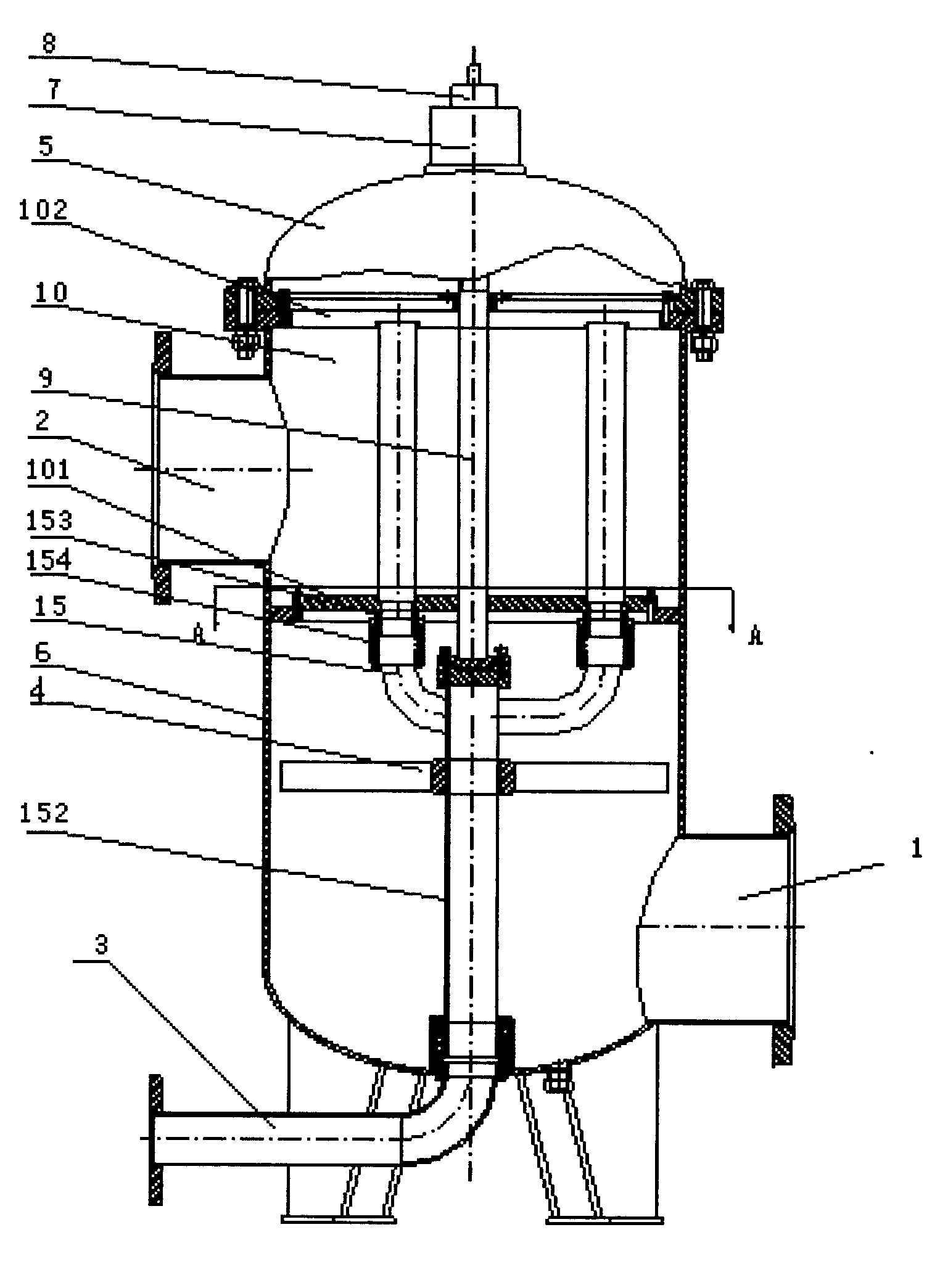

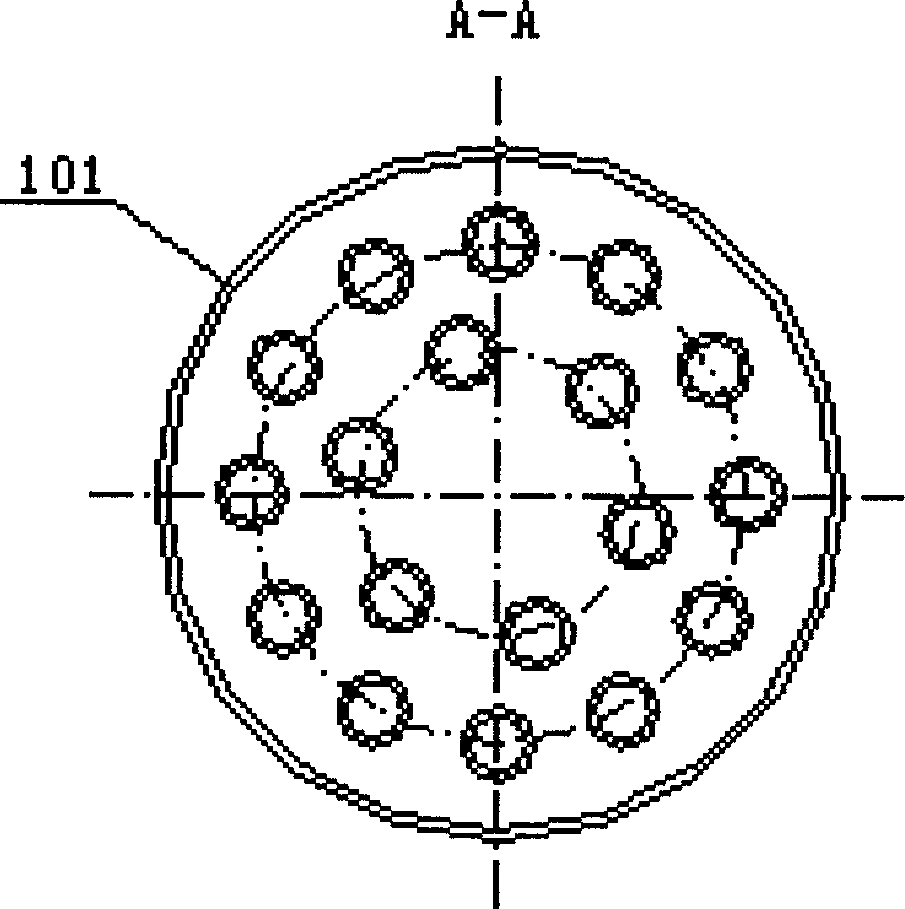

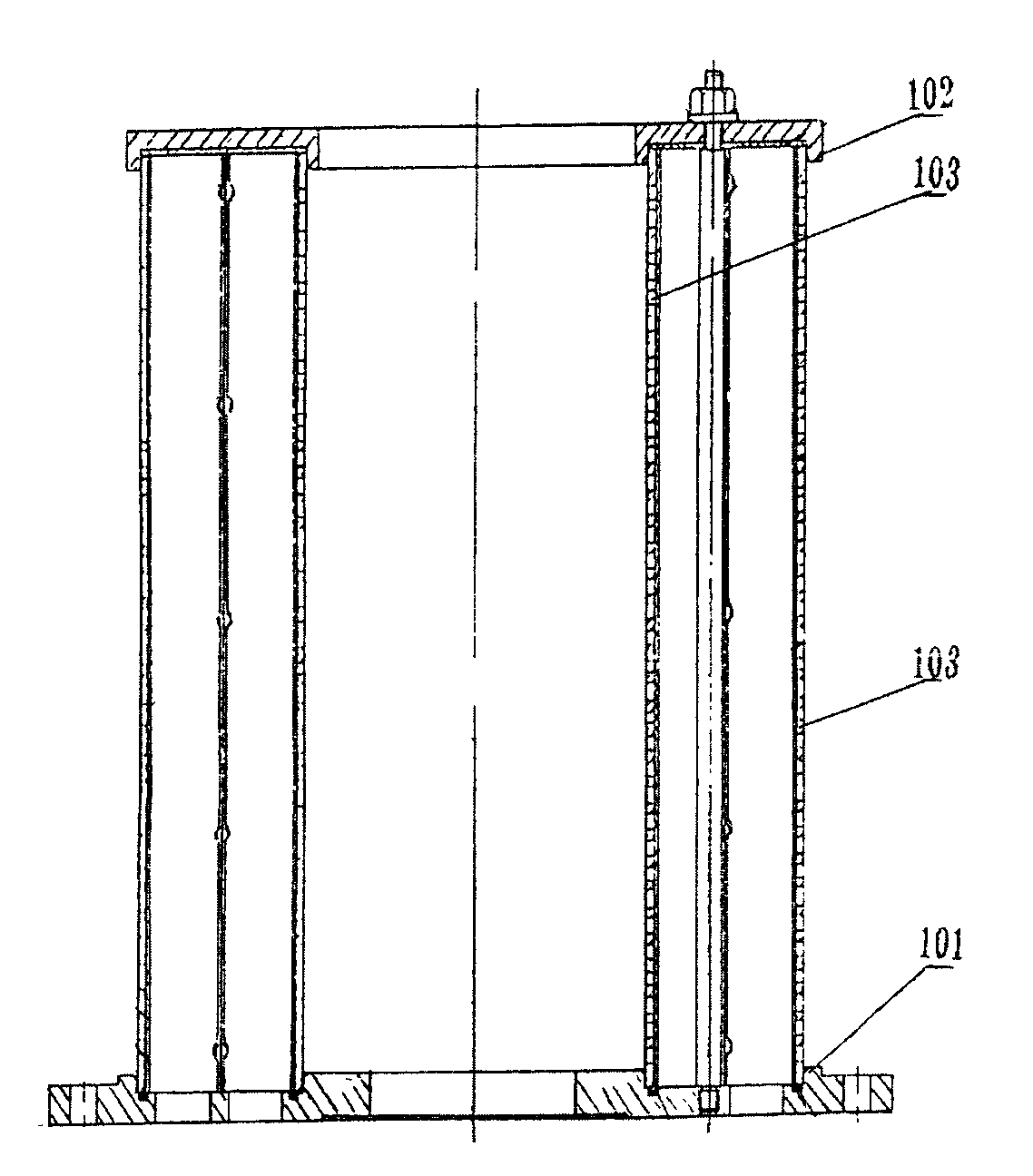

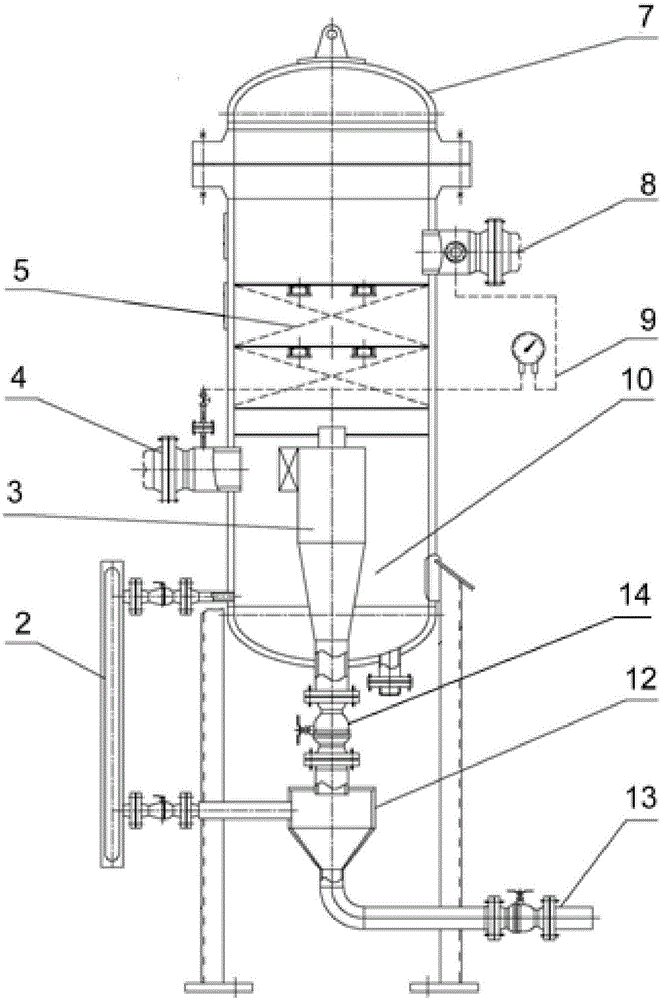

High-efficiency fine defoaming and desanding separator for natural gas

The invention discloses a high-efficiency fine deforming and desanding separator for natural gas. The high-efficiency fine deforming and desanding separator for the natural gas comprises a tank body, wherein a gravity settling chamber is formed at the bottom of the tank body, a cyclone separator is arranged at the center of the gravity settling chamber, a gas defoaming and desanding filter is arranged above an outlet of the cyclone separator, an air inlet of the high-efficiency fine defoaming and desanding separator for the natural gas is formed in the lower part of the tank body and is directly communicated with the gravity settling chamber, and a vent is formed in the upper part of the tank body and is arranged above the gas defoaming and desanding filter. The high-efficiency fine deforming and desanding separator for the natural gas has the advantages that the cyclone separator and a filtration tertiary treatment manner are well combined, especially the density gradient of a filter material in the filter can enable increasing rate of resistance of a filter layer to be greatly reduced, and a resistance formation time is increased by thousands of times compared with a common filter, so that the high-efficiency fine deforming and desanding separator for the natural gas has a broad application prospect.

Owner:陈志军 +6

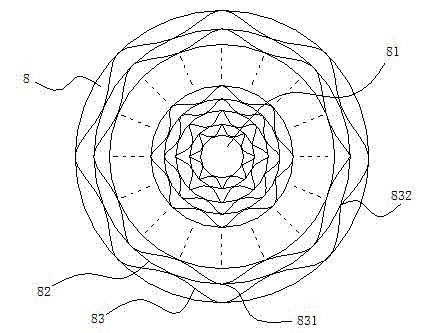

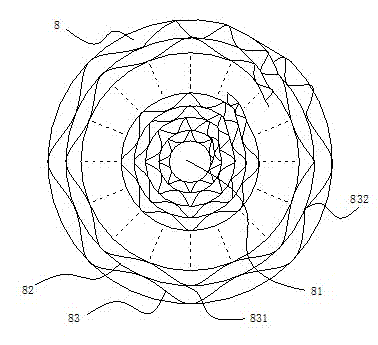

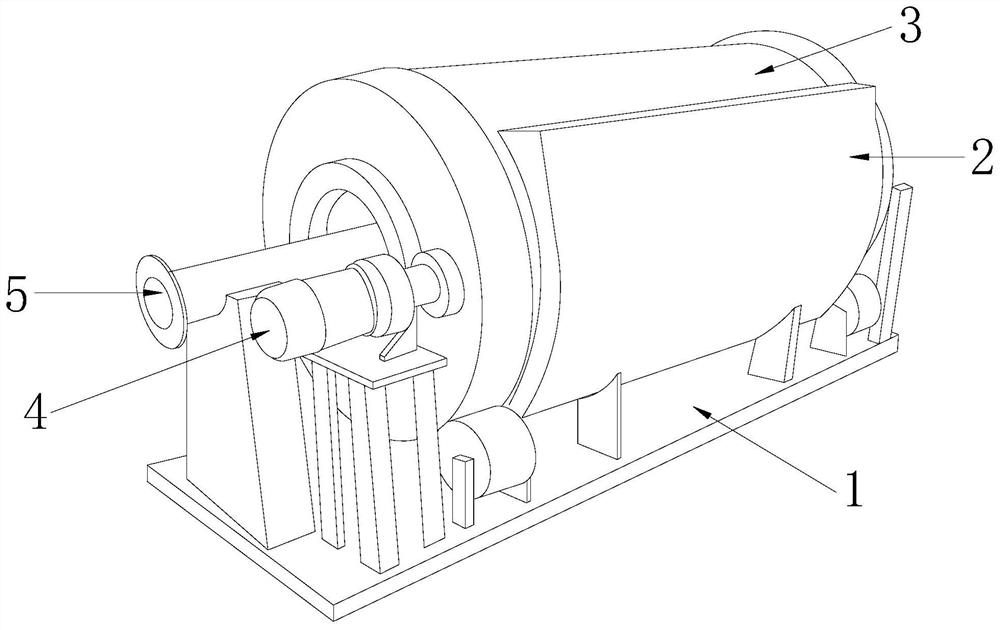

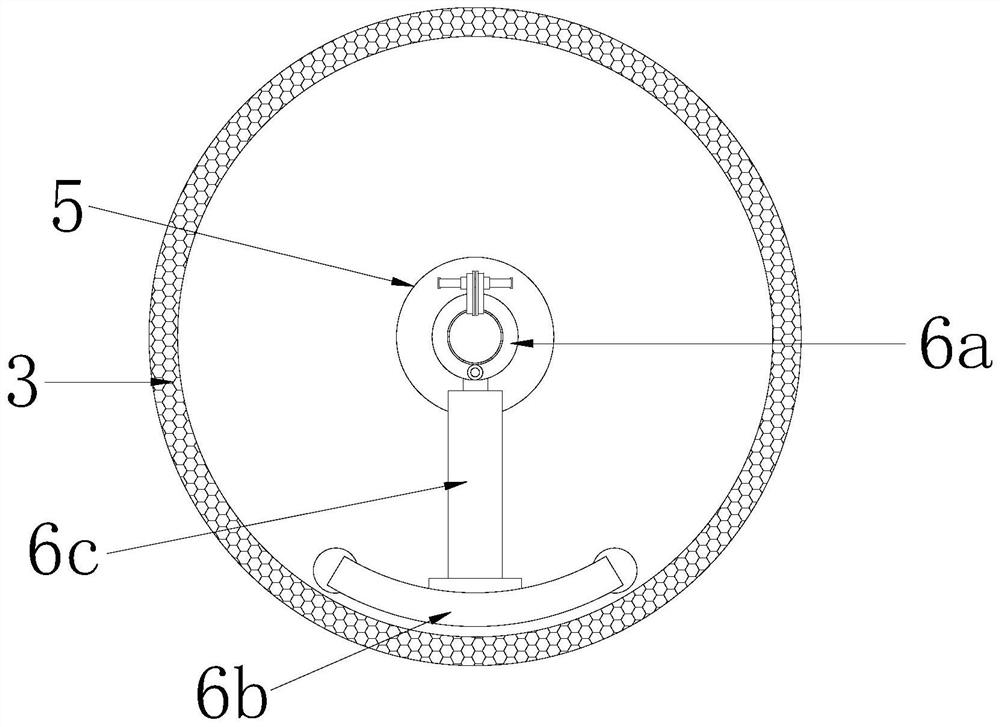

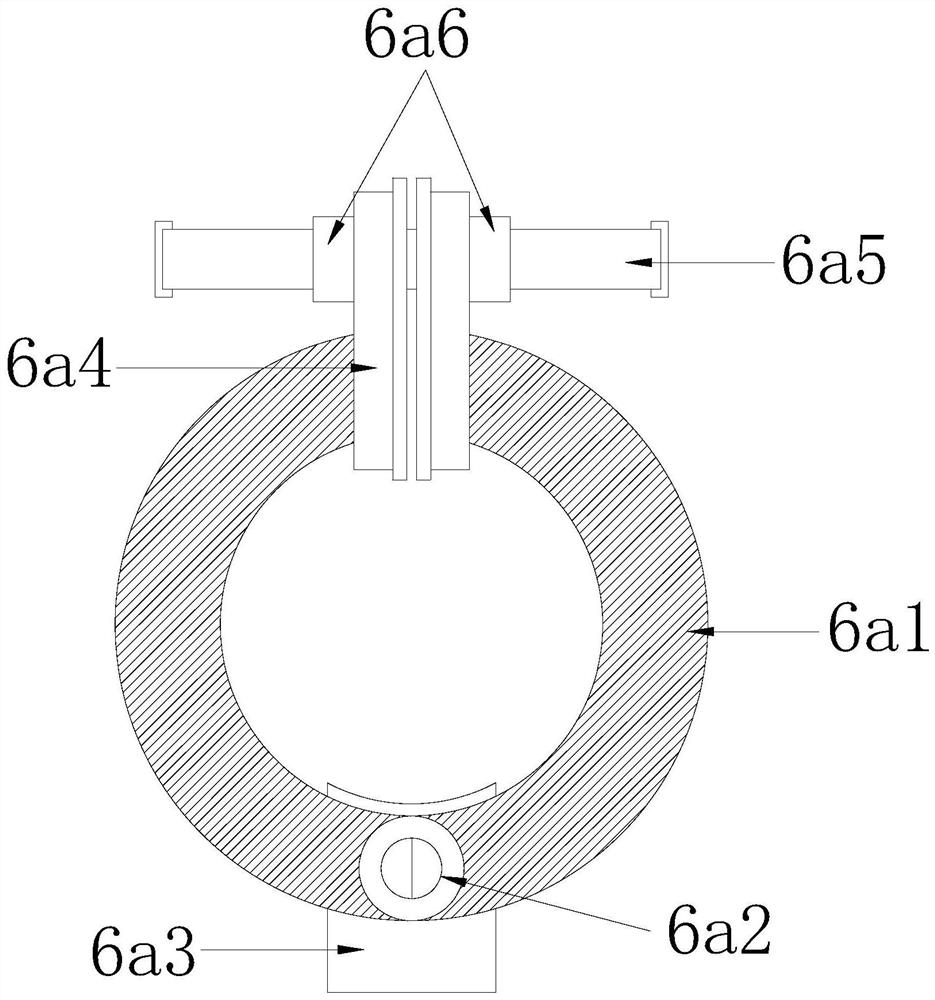

Electromagnetic iron removing machine for removing iron from kaolin

ActiveCN102962128AImprove the effect of iron removalCreate pollutionWire networkMagnetic separationIron removalNormal filter

The invention discloses an electromagnetic iron removing machine for removing iron from kaolin. The electromagnetic iron removing machine comprises a filter screen, wherein the filter screen is made of an iron cobalt magnetically soft alloy thus being different from the normal filter screen. The filter screen in the electromagnetic iron removing machine is made of the iron cobalt magnetically soft alloy, the effect of removing the iron from the kaolin as the electromagnetic iron removing machine is used can be improved, and in the process removing the iron from the kaolin, the pollution to the kaolin caused by brazing filler metal or residual welding rod components can be avoided.

Owner:广东高瓷科技股份有限公司

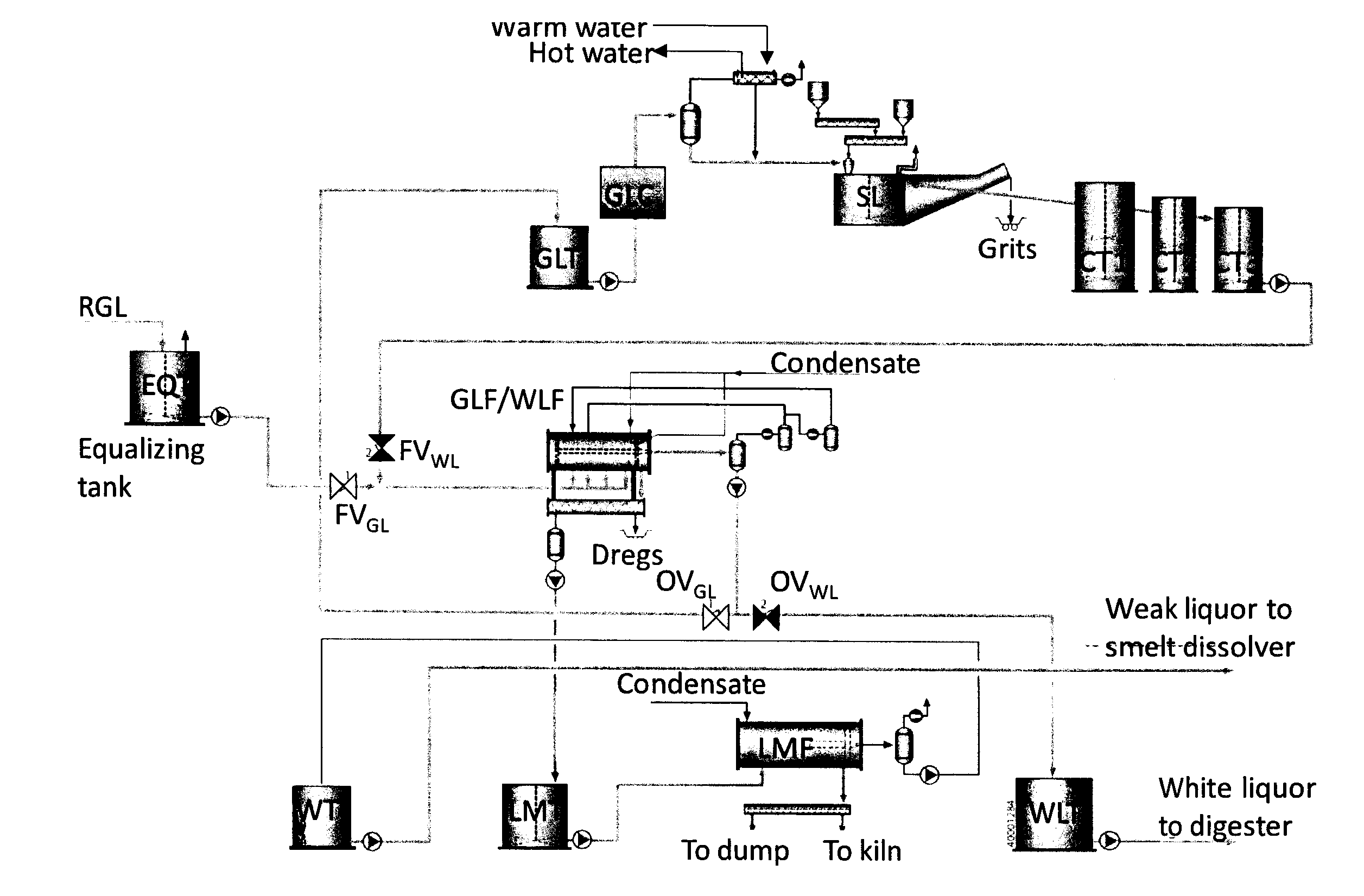

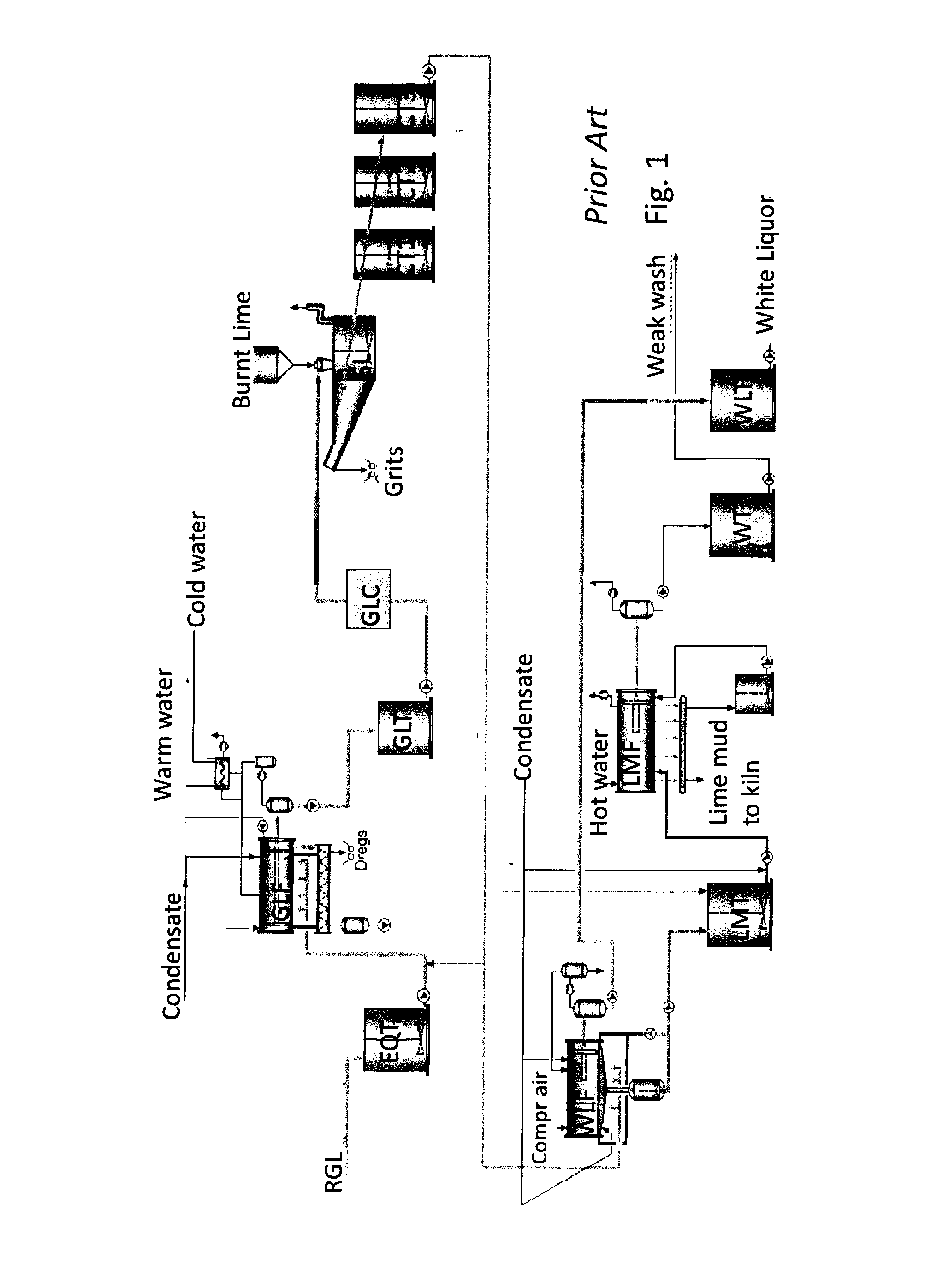

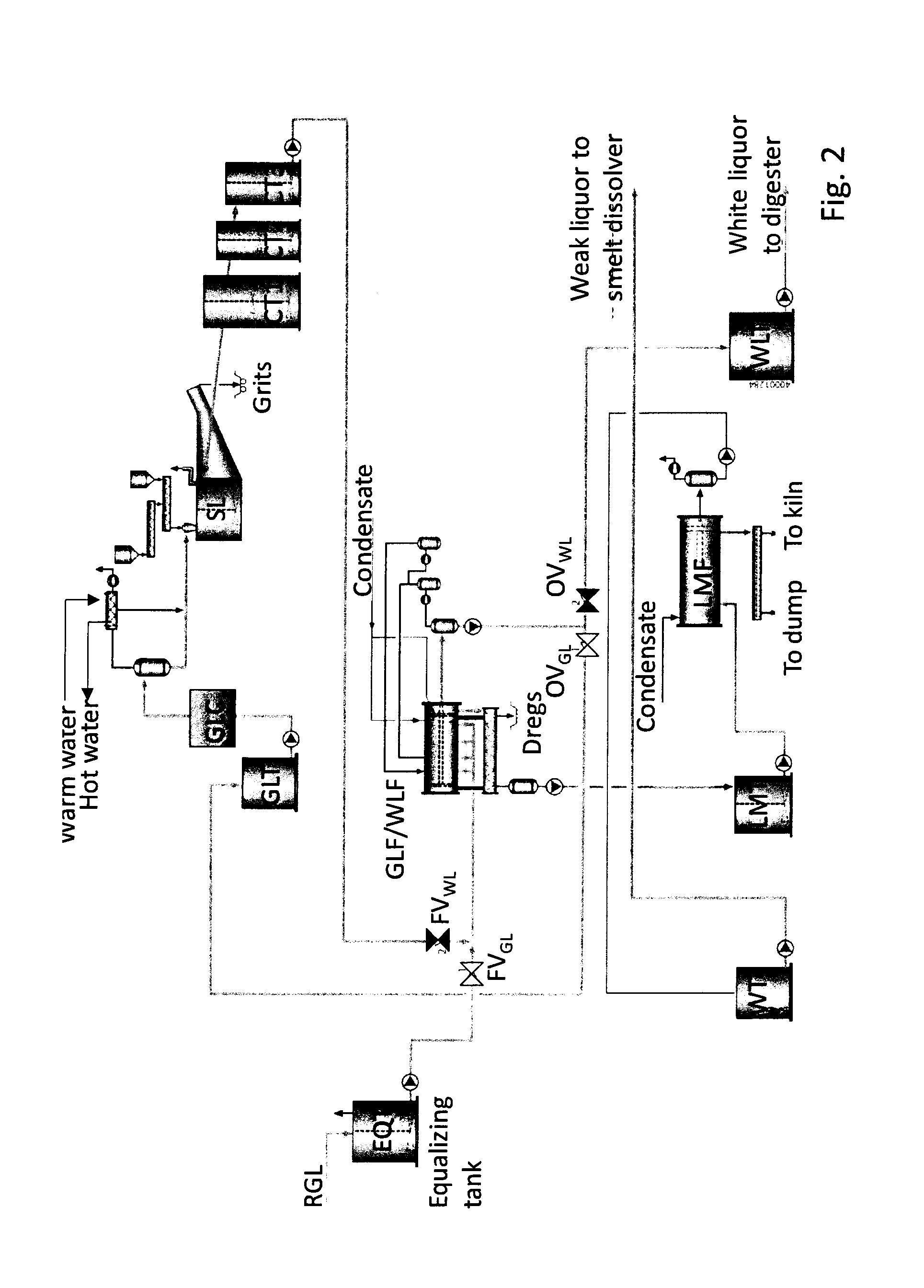

Method for the causticizing process for producing white liquor

ActiveUS20140374039A1Efficient processReduce contentPulp liquors combustionPulp by-products recoveryWhite liquorKraft process

The method is for preparation of white liquor in a chemical recovery process of the kraft process. The green liquor separation process and the white liquor separation process are taking place in the same common filter apparatus with no dedicated green liquor separation apparatus or any dedicated white liquor separation apparatus. The white liquor separation process and the green liquor separation process are conducted in sequence in the same filter apparatus. The white liquor separation process has a part of the cycle time in the range 20-50% of the total cycle time in the same filter apparatus.

Owner:VALMET AB

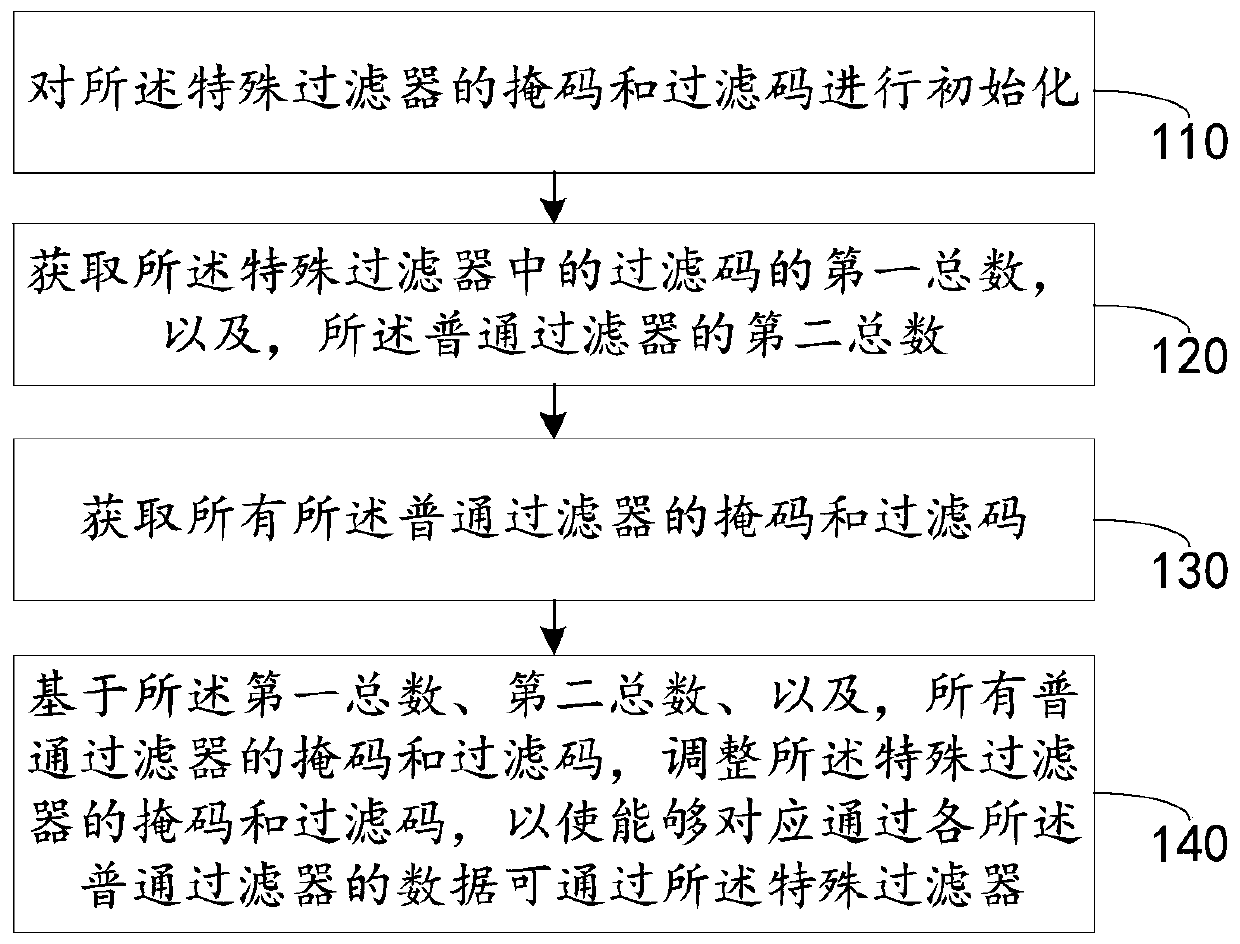

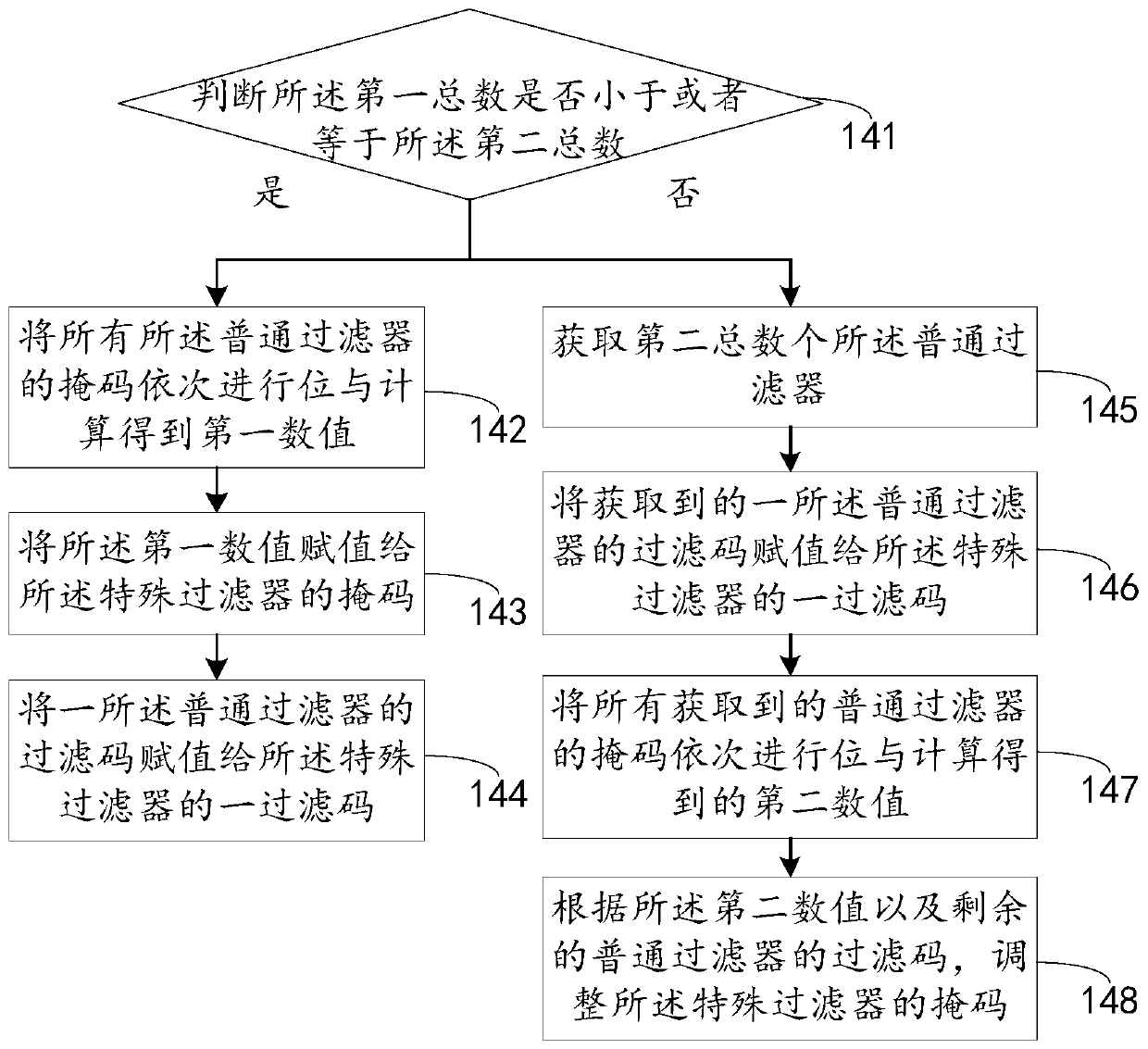

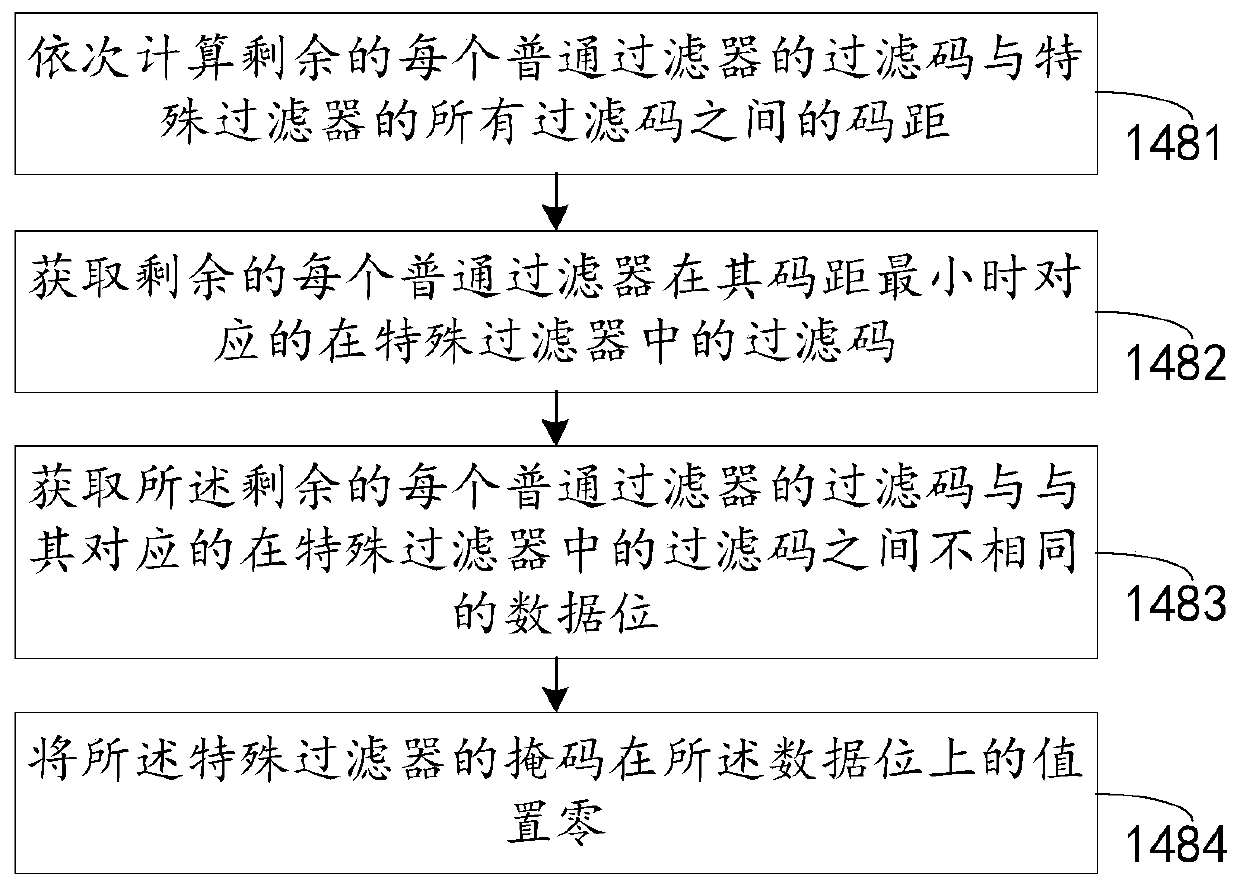

CAN filter merging method and device and CAN controller

ActiveCN110808891AReduce processingReduce the burden onComparison of digital valuesBus networksAlgorithmNormal filter

The embodiment of the invention relates to the technical field of electronic information. The invention discloses a CAN filter merging method. The CAN filter comprises a special filter and at least one common filter, the special filter comprises a mask and at least two filtering codes; the common filter comprises a mask and a filter code; the method comprises the following steps: firstly, initializing a mask and a filtering code of a special filter; obtaining a first total number of filtering codes in the special filter; and, a second total number of common filters, obtaining masks and filtering codes of all common filters; based on the first total number, the second total number; masks and filtering codes of all common filters are used; according to the method for merging the CAN filters,the masks and the filtering codes of the special filters are adjusted, so that data correspondingly passing through all the common filters can pass through the special filters, the burden of a processor can be reduced, the situation that a CAN controller processes a large amount of irrelevant data is avoided, and the communication speed is increased.

Owner:深圳市道通合盛软件开发有限公司

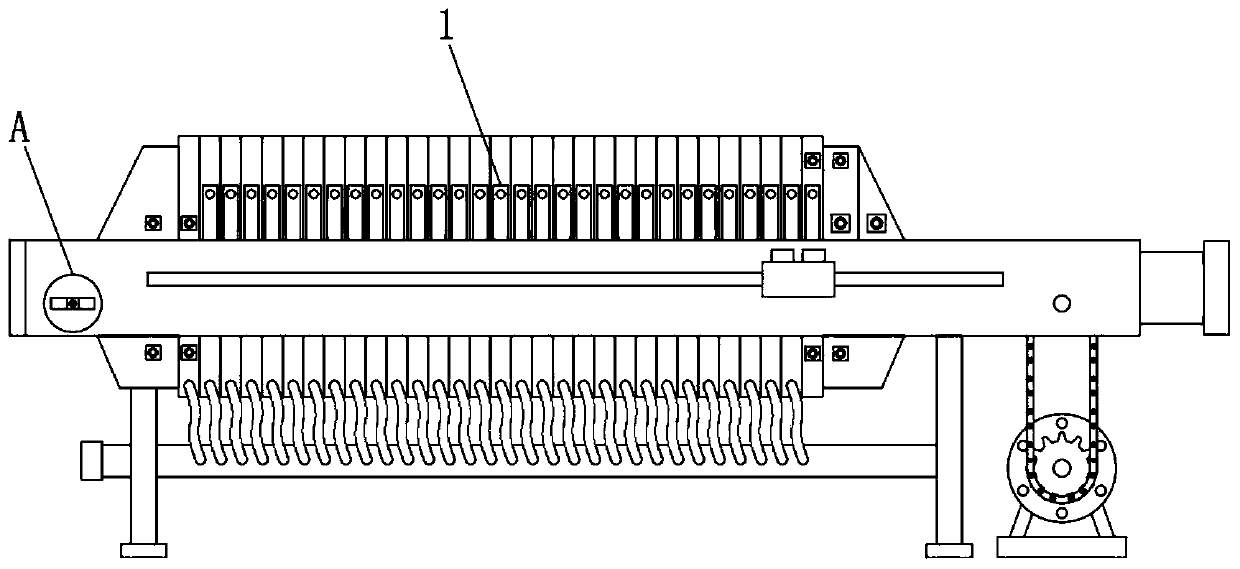

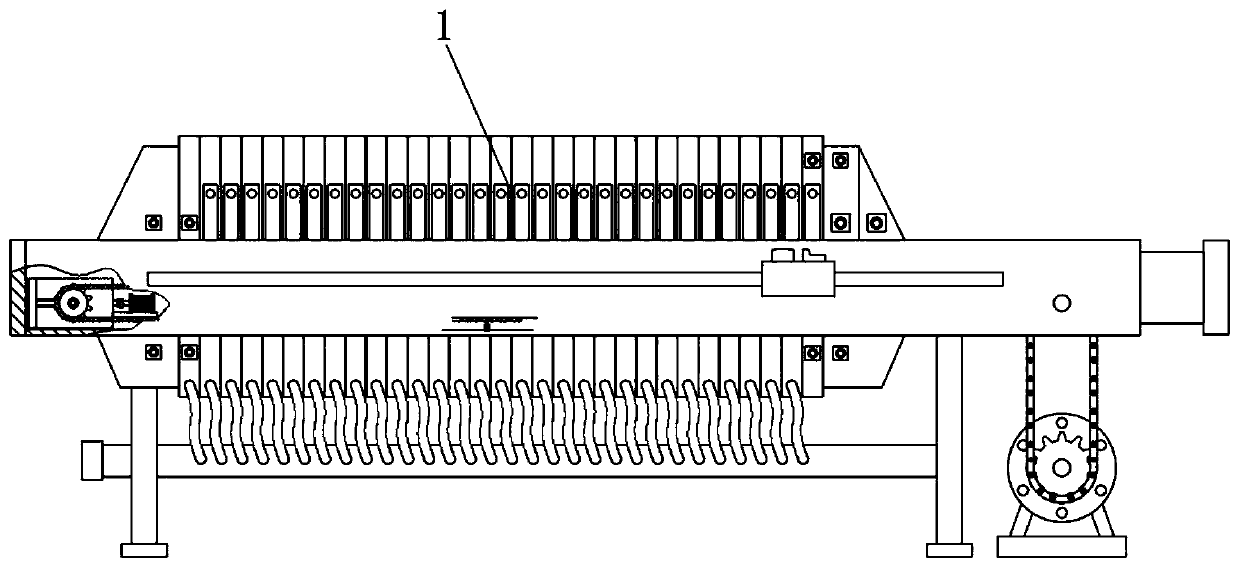

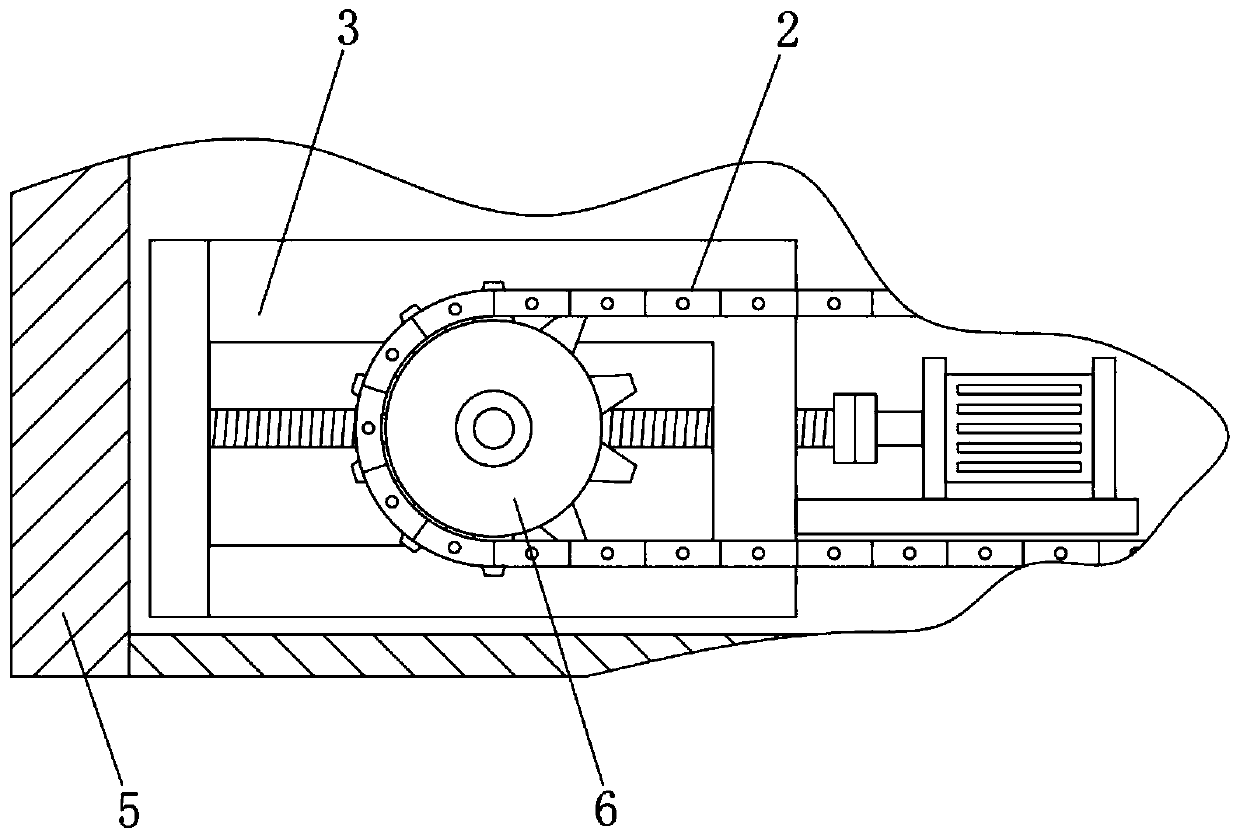

Chain driving mechanism for filter press

The invention discloses a chain driving mechanism for a filter press. The chain driving mechanism comprises a filter press main body, a driving chain for driving a pulling plate trolley is arranged inthe filter press main body, an automatic adjusting mechanism is arranged in the filter press main body, an overhauling port is arranged at one end, close to the automatic adjusting mechanism, of theouter side of the filter press main body, and a movable door is movably mounted at the overhauling port. The chain driving mechanism for the filter press is different from like products in the prior art. When a driving chain is loosened and affects the normal use of the pulling plate trolley in the long-time use process of the filter press, the tensioning of the driving chain can be conveniently and quickly adjusted to ensure the tensioning of the driving chain, so the stable operation of the pulling plate trolley is guaranteed, the abrasion caused by contact collision of the driving chain anda chain box is effectively avoided, and noise pollution and the influences on the service life of the above device are avoided, thereby the normal filter pressing of a material is guaranteed, and theproduction and processing efficiency of enterprises is effectively improved.

Owner:邵芮

Sewage filtering device for chemical industry

InactiveCN112791481AEasy to operateEasy to scrapeStationary filtering element filtersChemical industryFiber

The invention discloses a sewage filtering device for chemical industry. The sewage filtering device structurally comprises a mounting seat, a sheath, a filter cartridge, a driving motor, a stirring pipe and a separation and forward overflow system. The device has the beneficial effects that: a matched storage plate is connected with a scraping mechanism, so that a cavity plate synchronously rotates along with the stirring pipe under the action of a lock catch structure, and a scraping piece arranged on the surface of the scraping mechanism and a grid in the filter cartridge are compactly attached and stroked; under the cooperation of rotation, a shoveling strip plate and a hook are used for shoveling fiber impurities blocked on the surface of the grid, and normal filtering work of the grid is achieved through hooking and grabbing cooperation; meanwhile, the shoveled fiber impurities are intensively absorbed in the cavity plate through adsorption airflow in the cavity plate under the action of the storage plate; and meanwhile, with a grabbing plate arranged in the cavity plate, the absorbed fiber impurities can be prevented from being grabbed and falling back into the filter cartridge again.

Owner:陈娅雄

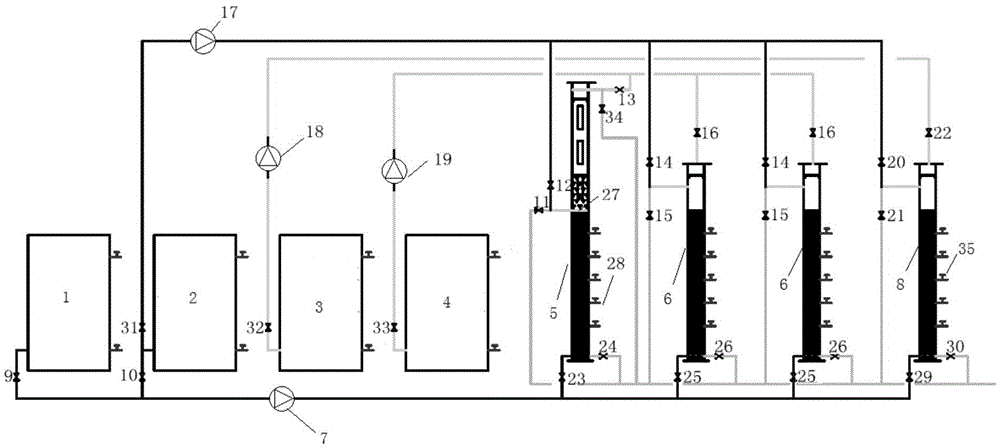

Simulation test device for testing filter material properties and test method

ActiveCN105628585ATest accurateReduce experimental errorPermeability/surface area analysisNormal filterComputer module

The invention relates to a simulation test device for testing filter material properties and a test method. The test device comprises a resin test module, wherein the resin test module comprises a resin filtering unit, a resin drug washing unit and a resin washing unit; the resin filtering unit is formed by connecting a resin raw water tank with a resin tank; the resin drug washing unit is formed by connecting a drug washing tank with the resin tank; and the resin washing unit is formed by connecting a flush water tank with the resin tank. In the test process, the simulation test device utilizes the resin filtering unit, the resin drug washing unit and the resin washing unit in turn to test the sample under the running working condition of each pipeline and compares and analyzes the processing results, so that normal filtering property parameters, regenerating property parameters and the like of the resin filter material can be acquired. Compared with the prior art, the simulation test device has the advantages of simple structure, comprehensive testing, complete function, and the like.

Owner:TONGJI UNIV +1

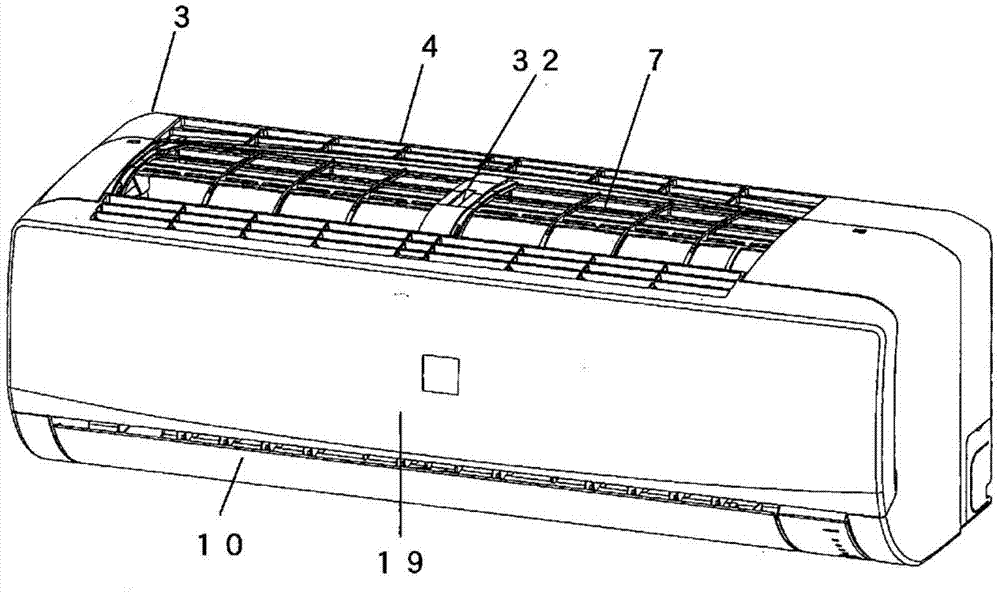

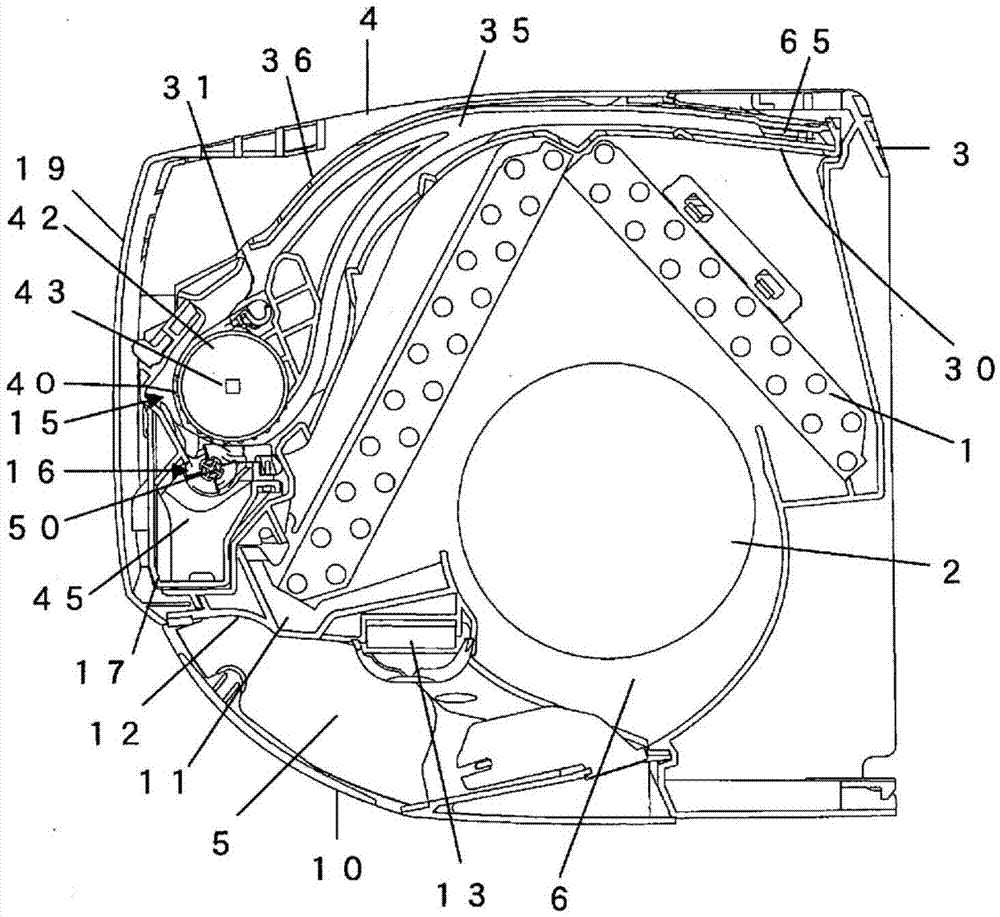

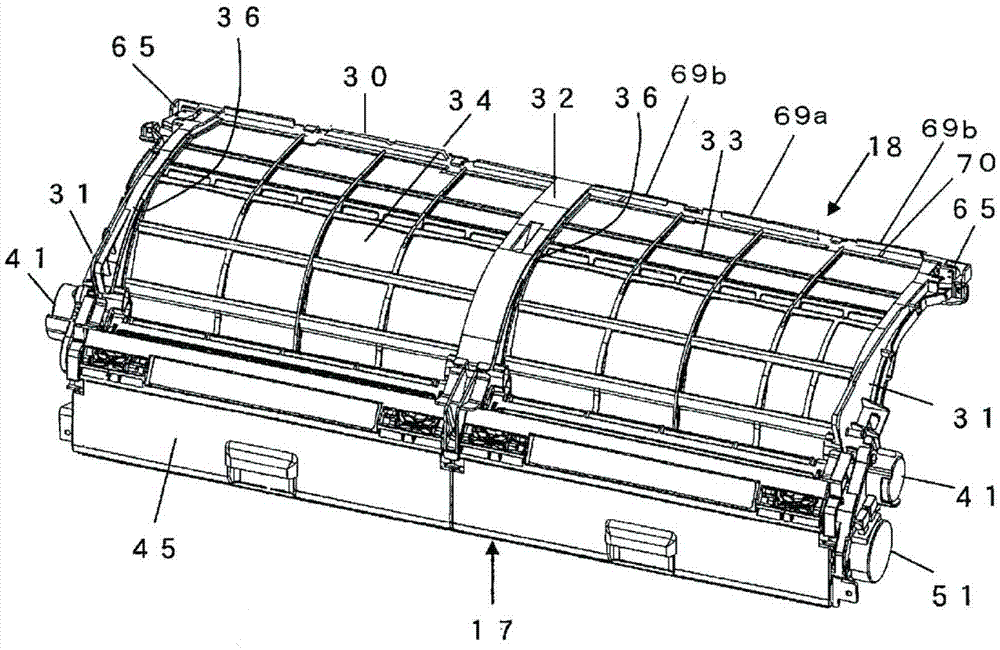

Filter holding device, filter cleaning device and air conditioner

ActiveCN105452780APrevent floatingNormal installation statusMechanical apparatusDispersed particle filtrationLimit switchNormal filter

Provided are a filter holding device for maintaining a normal filter installation state, and increasing the position detection precision of a limit switch, a filter cleaning device and an air conditioner. A frame is provided with a guide path through which a filter passes, a limit switch for detecting the presence or absence of the filter, a stopper wall that is formed on the end of the guide path and that restricts the movement of the filter, and an inclined wall that is inclined so as to prevent the filter from floating and to lead the filter to the stopper wall side. The inclined wall is formed across the whole area in the width direction of the guide path, and prevents the filter from floating even if the filter were to bend in the width direction of the guide path due to oscillation or operation of the limit switch.

Owner:SHARP KK

Fluid filter

ActiveCN107638726AWash evenlyEasy to break awayStationary filtering element filtersNormal filterFluid filtration

The invention belongs to the technical field of filter equipment, and provides a fluid filter. The fluid filter comprises a container shell, a feeding port, a discharge port, filter bodies, a rotary displacement back flushing mechanism and a rotary displacement pollutant discharge mechanism; the rotary displacement back flushing mechanism and the rotary displacement pollutant discharge mechanism are used for carrying out back flushing on a group of filter units and pollutant discharge; and the other filtering units are in a normal filtering state. Fluid treated by the fluid filter provided bythe invention, especially coal tar or crude oil, reach a specified filtering precision, and the filuid filter is reliable in operation, free of interruption, free of faults, free of maintenance, low in cost, long in cycle operation, less in emission of dust pollutant and extremely high in popularization value.

Owner:HENAN DRAGON INTO COAL TECH CO LTD +1

A rapidly replaceable filter screen for sewage treatment

ActiveCN109529435BSo as not to damageImprove sealingMembrane filtersStationary filtering element filtersNormal filterSewage treatment

The invention relates to a quick-replaceable filter screen for sewage treatment, which effectively solves the problems of difficulty in replacing common filter screens and poor sealing performance of quick-change filter screens or easy damage to seals; the technical solutions include: The filter is replaced by pulling. When the replaced filter is completely pulled out of the sewage treatment pipe, the clean filter is installed in place. The operation of changing the filter is convenient and quick, saving manpower and time. Sealing between them can not only achieve a good sealing effect, but also can deflate the inflatable sealing ring first when replacing the filter screen. The deflated inflatable sealing ring will not produce resistance when pulling the filter screen, and will When the filter screen is used, the inflatable sealing ring will not be worn out, so that the inflatable sealing ring can be reused and resources are saved.

Owner:广州市海珠羊城环保有限公司

band pass filter

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com