Special type separation filter

A filter, a special technology, applied in the direction of filtration separation, separation method, mobile filter element filter, etc., can solve the problems of troublesome production automation operation, difficult to achieve solid-liquid separation, increased operating costs, etc., to improve the filtering effect and reduce Operating costs and efficiency improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further described below in conjunction with accompanying drawing:

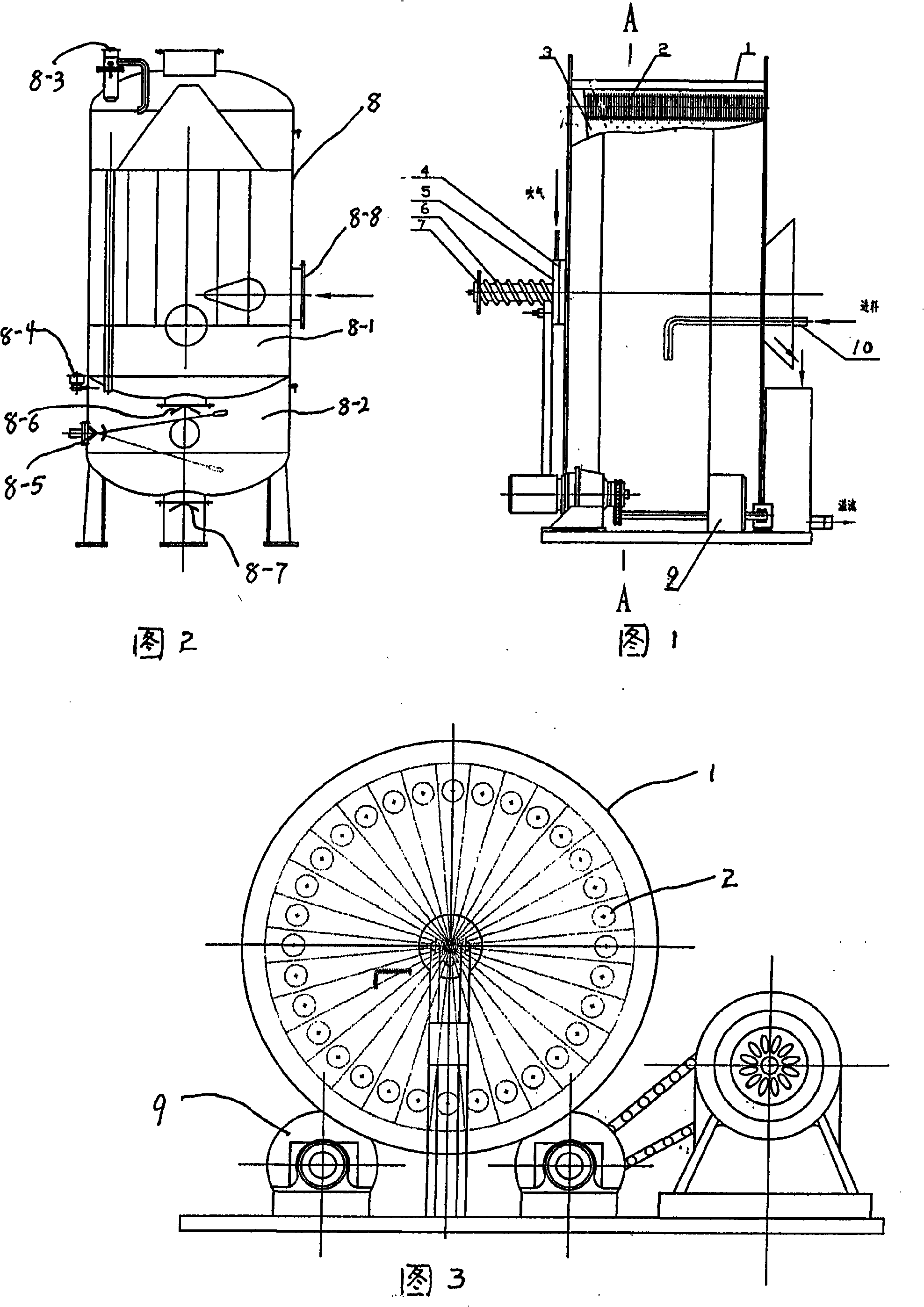

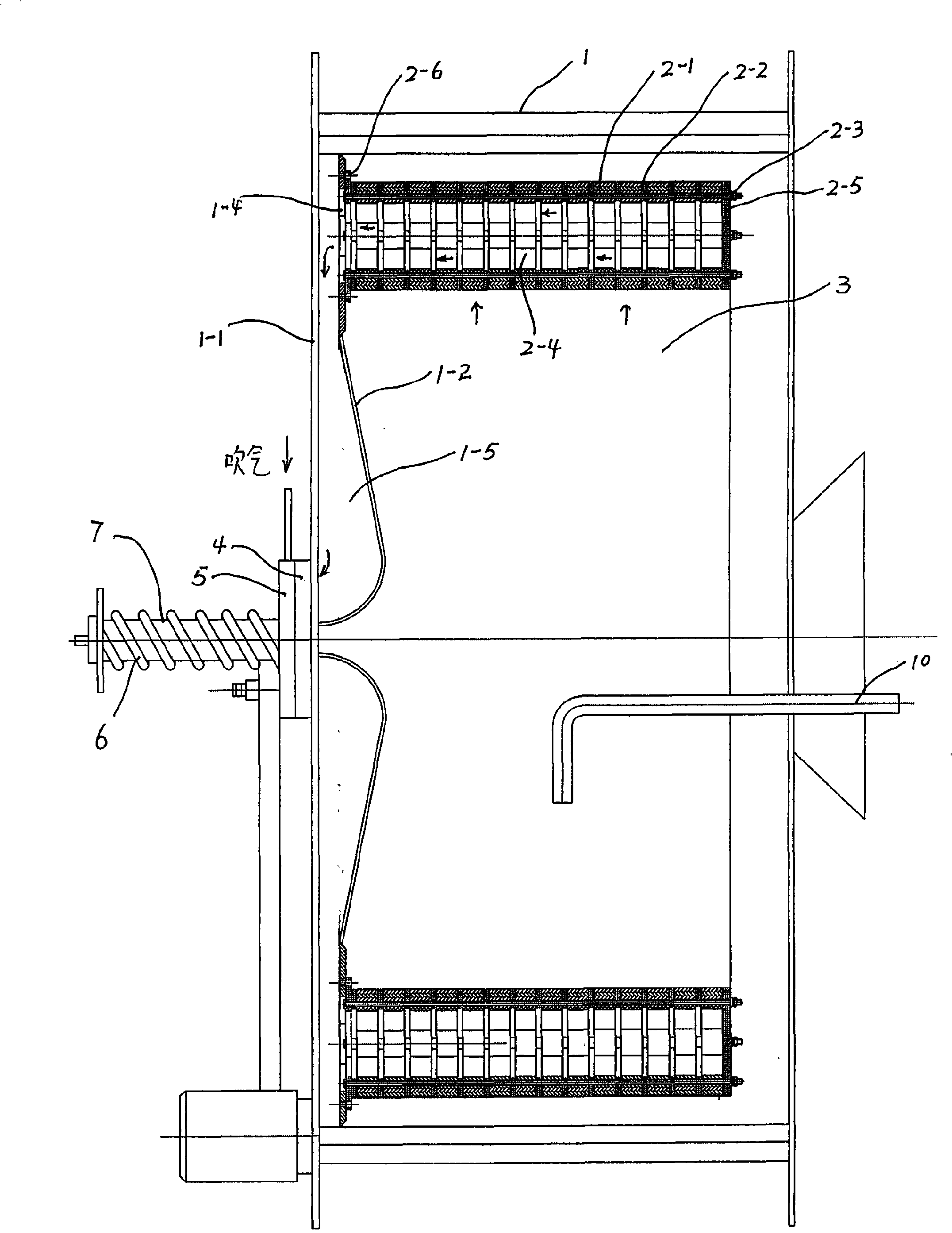

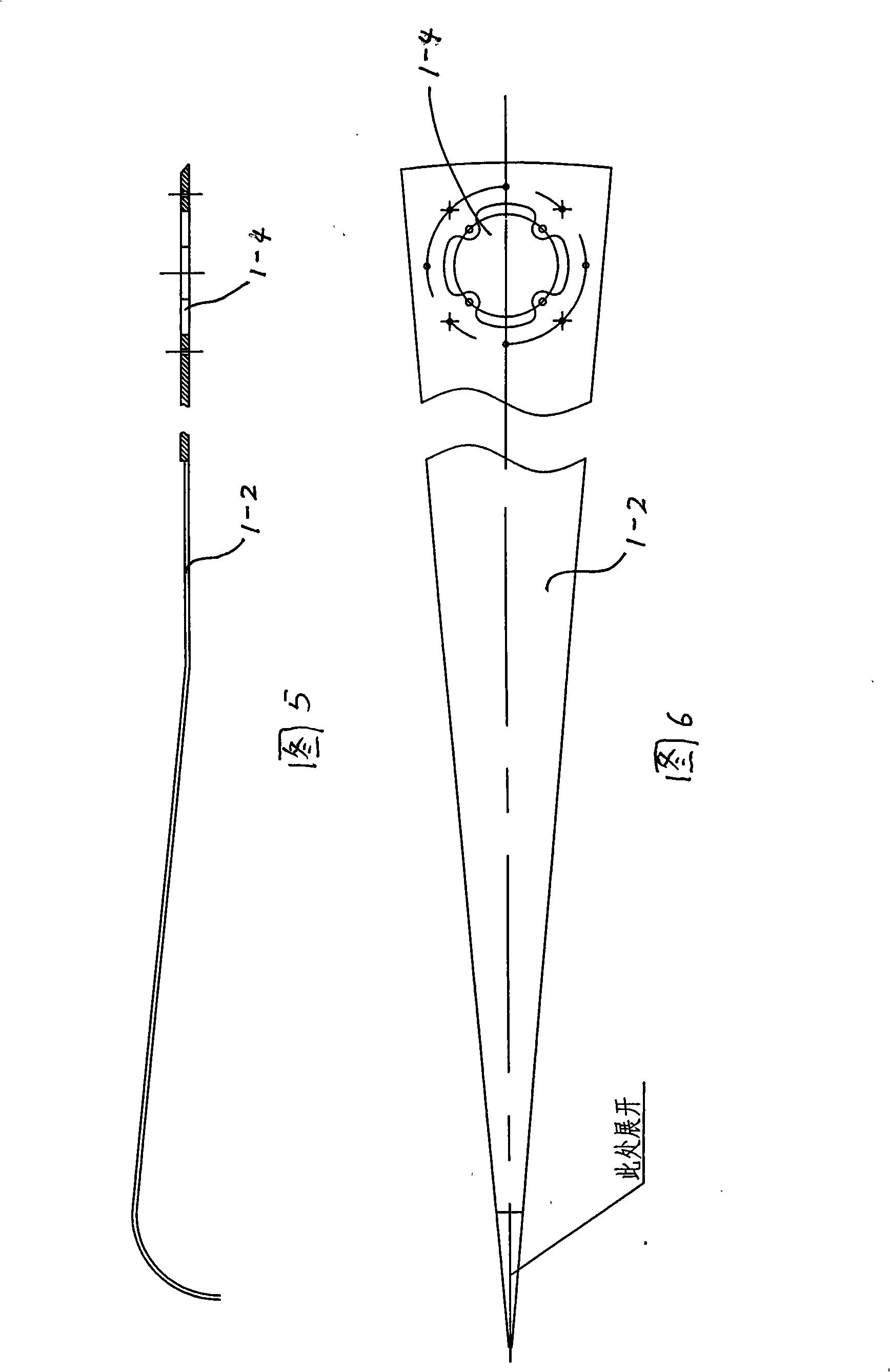

[0028] As shown in Figures 1 to 13: the separation filter for solid-liquid separation of the present invention includes a horizontal solid-liquid separation device, which includes a cylinder (1) driven by external power to rotate and a cylinder arranged around the inner cavity of the cylinder. The cylindrical filter element (2) seals the left end of the feed filter cavity (3) through a plurality of fan-shaped plates (1-2) and compartment plates (1-4) inside the left end of the cylinder, and is connected with the left end plate of the cylinder. (1-1) jointly form a plurality of fan-shaped filter chambers (1-5), the upper part of each fan-shaped plate (1-2) is directly connected with the base (2-6) of the corresponding cylindrical filter element, and each Each fan-shaped filter cavity (1-5) is communicated with the hollow cylinder chamber (2-4) of the cylindrical filter element (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com