In-situ grown electrode plate made from active substances and manufacturing method thereof

An in-situ growth, active material technology, applied in battery electrodes, electrode carriers/current collectors, circuits, etc., can solve the problems of complex process and slurry coating process, impact on the performance of electrode materials, etc., to simplify the battery manufacturing process, specific capacity And the effect of improving cycle performance and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

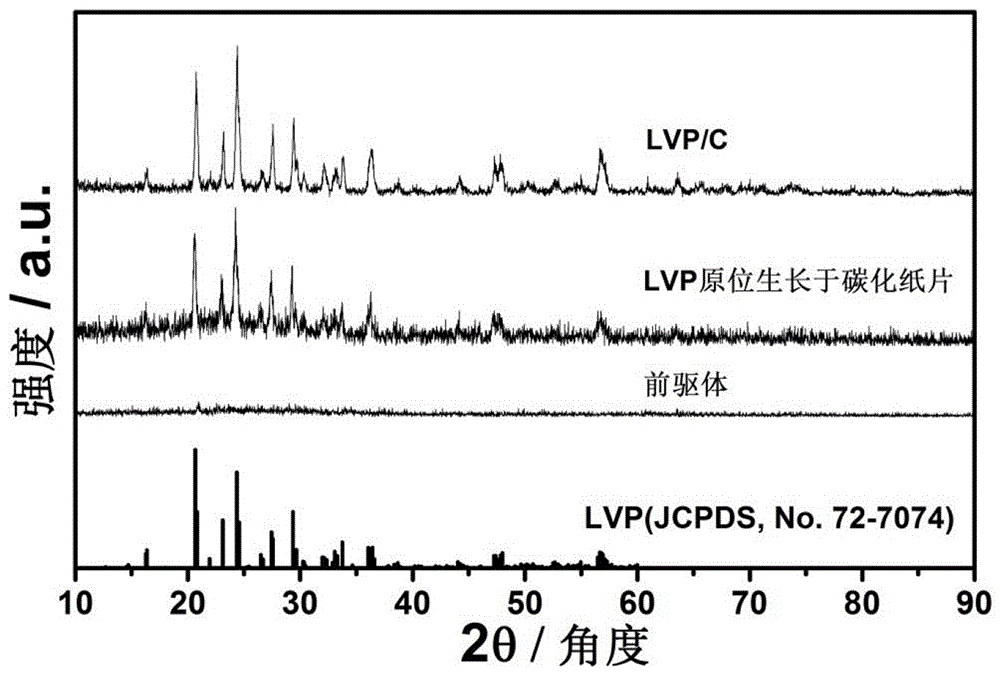

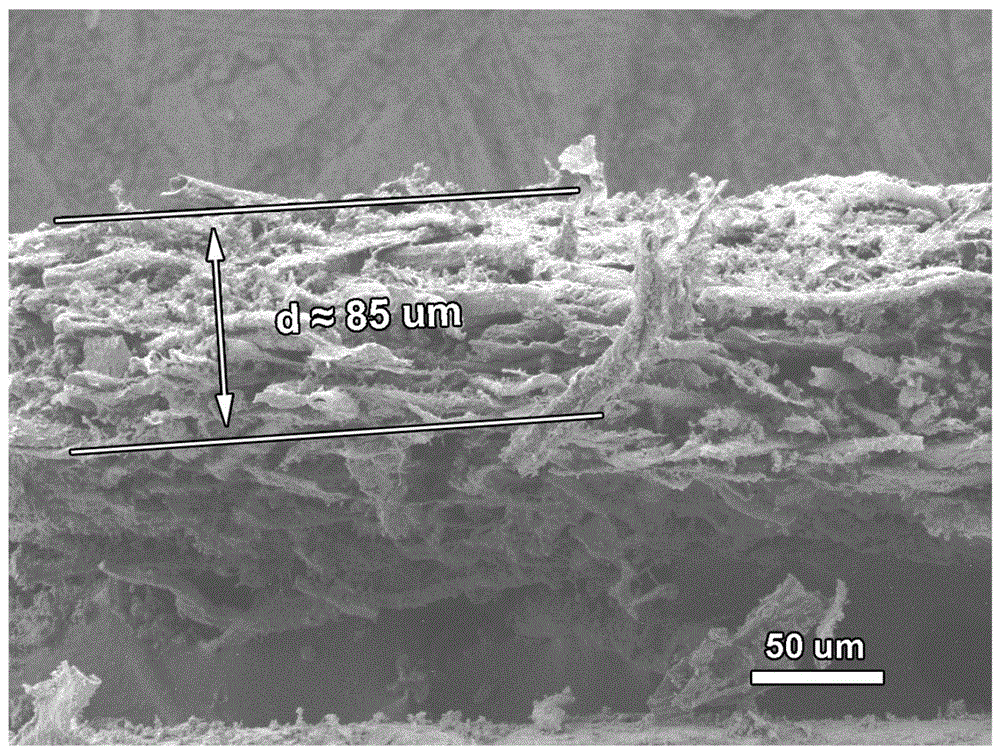

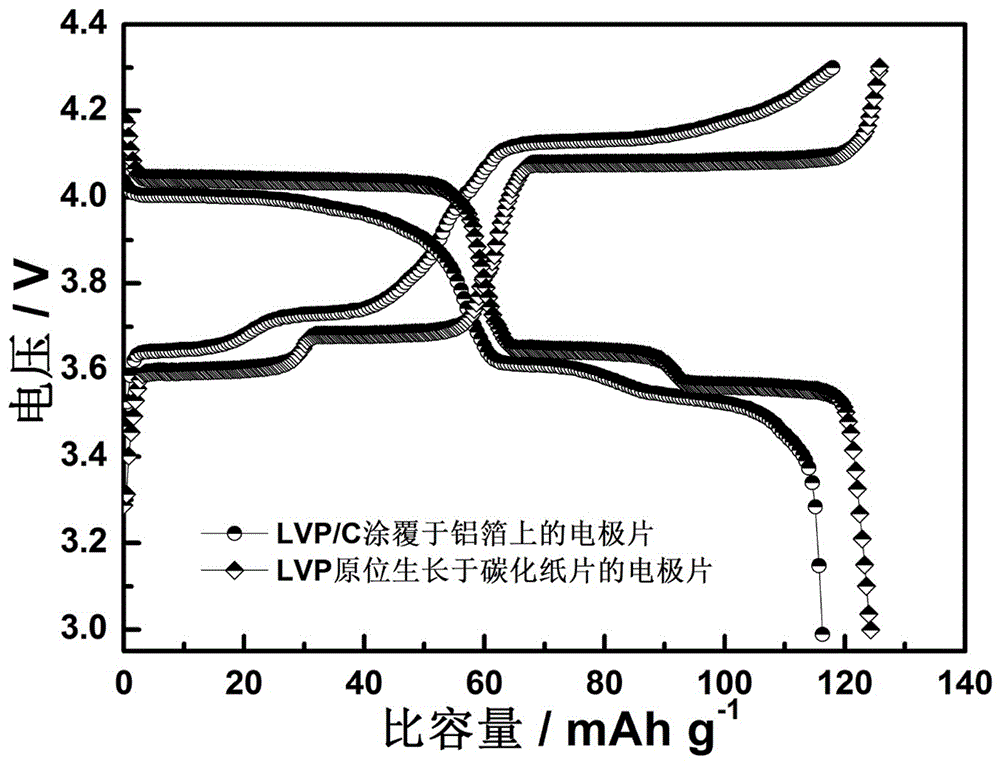

[0033] The normal filter paper is decontaminated with hydrochloric acid reagent, and the treatment time is 12 hours, after which the filter paper is rinsed clean. Will Li 2 CO 3 , NH 4 VO 3 , NH 4 h 2 PO 4 With a molar ratio of 1.5:2:3, ball mill in absolute ethanol medium for 10 h and mix evenly, then transfer to an oven at 50 °C and keep it warm for about 12 h. h, to obtain a pre-calcined product, adding 10% glucose as an organic carbon source to the pre-calcined product, ball milling with absolute ethanol as a medium for 6 h, and drying at 50°C to obtain a precursor powder. Transfer the precursor powder to N-methylpyrrolidone (NMP) medium and stir to form a slurry, then impregnate the filter paper in the slurry for ultrasonication, dry at 80°C, and punch the disc. The disc is placed in an inert atmosphere (nitrogen atmosphere) in a tube furnace ) at 700°C for 10 h, and cooled naturally to room temperature to obtain an electrode sheet in which the positive electrode m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com