Highly Integrated Hollow Fiber Column Filter

A fiber column, highly integrated technology, applied in the field of filters, can solve the problems of large water consumption, inconvenient replacement, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings.

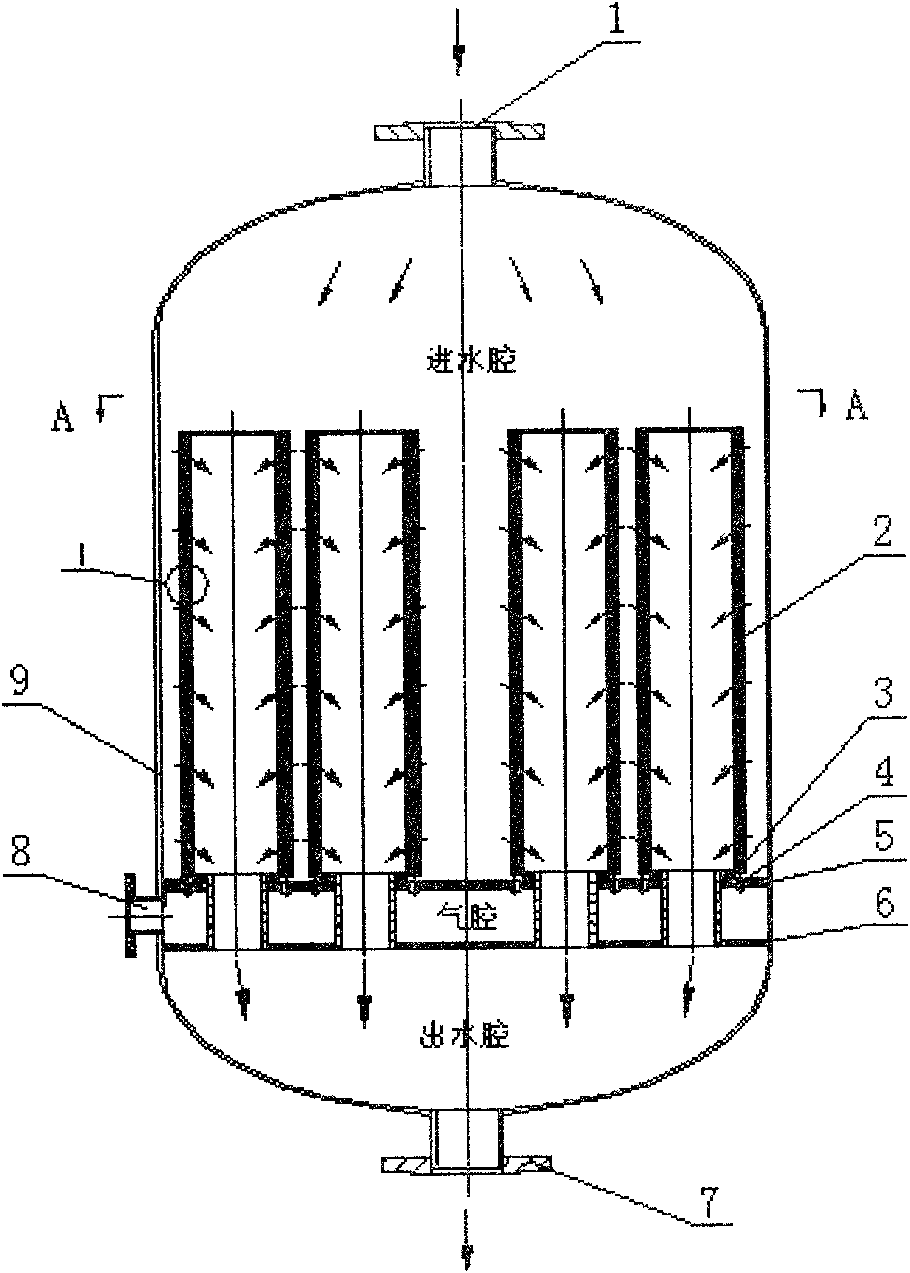

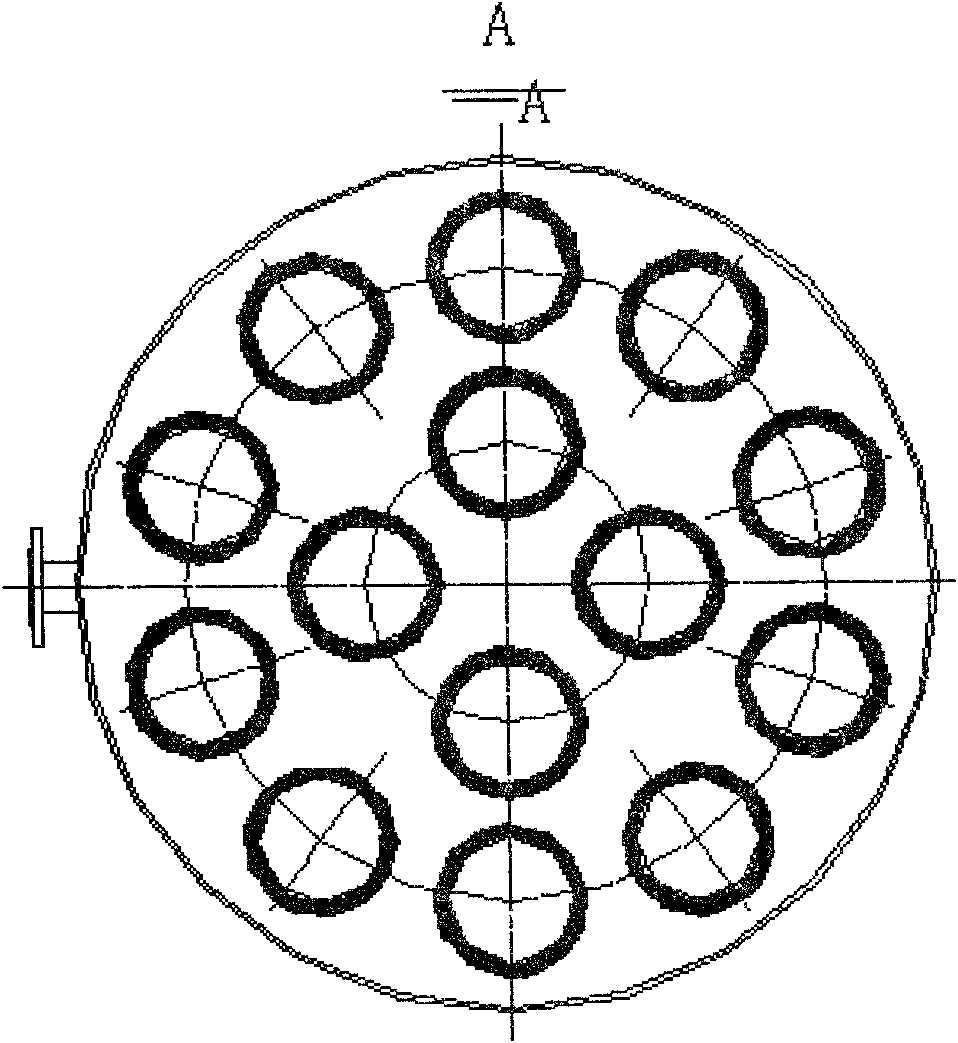

[0021] Such as Figure 1~6 As shown, the highly integrated hollow fiber column filter includes:

[0022] Water inlet 1, housing 9, several hollow fiber columns 2, water outlet 7, air inlet 8, partition 1 5, partition 2 6, gasket 3, air distribution pipe 4, of which hollow fiber column 2, partition One 5, clapboard two 6 divides filter into water inlet cavity, air cavity and water outlet cavity.

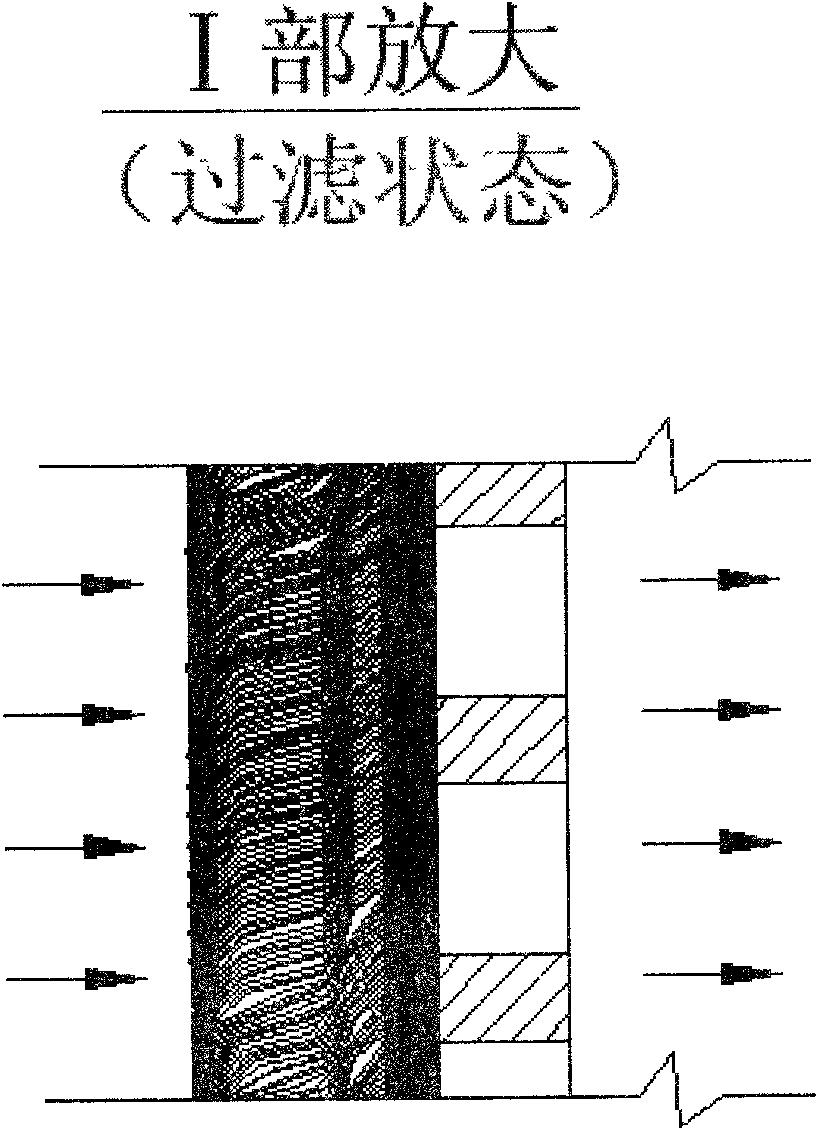

[0023] The above-mentioned partition one 5 and partition two 6 are welded or sealed and fixed on the lower part of the housing. In order to install and fix the hollow fiber column 2, the partition one 5 and partition two 6 are respectively provided with through holes and threaded holes. The gas in the air cavity does not leak, and a sealing gasket 3 is provided between the hollow fiber column 2 and the partition plate 1 . In order to improve the filtration efficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com