Electromagnetic iron removing machine for removing iron from kaolin

A technology of iron remover and kaolin, applied in the application, magnetic separation, household appliances and other directions, can solve the problems of easy contamination of solder or welding rod, poor iron removal effect of kaolin, and achieve the effect of improving iron removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

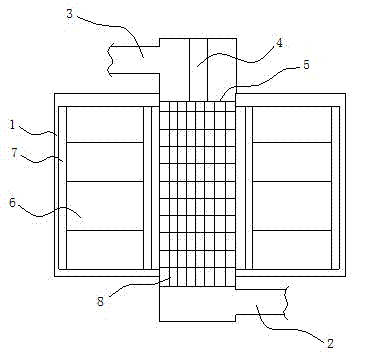

[0029] Embodiment 1: The present invention is used for the electromagnetic iron removal machine of kaolin clay removal

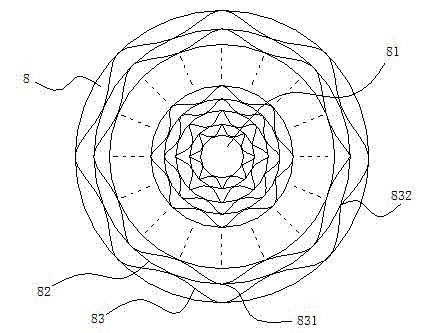

[0030] refer to Figure 1~2 , an electromagnetic iron remover for kaolin iron removal, including a filter screen 8, the filter screen 8 is an iron-cobalt soft magnetic alloy, and the iron-cobalt soft magnetic alloy is calculated by weight percentage, and its chemical composition is: C= 0.04%, Mn=0.30%, Si=0.30%, P=0.020%, S=0.020%, Cu=0.20%, Ni=0.50%, Co=49.0~51.0%, V= 0.80~1.80%, Fe=surplus quantity.

[0031] The filter screen 8 is galvanized.

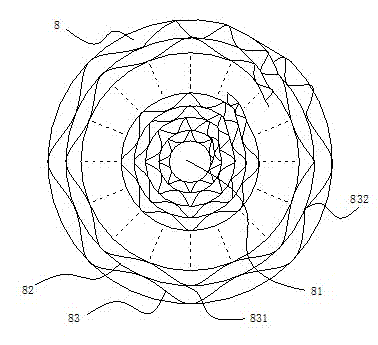

[0032] The filter screen 8 is disc-shaped, and a circular gap 81 is arranged in the middle of the filter screen 8, and the filter screen 8 is alternately surrounded by straight alloy sheets 82 and corrugated alloy sheets 83 It is coiled, and the straight alloy sheet 82 is fixedly connected to the crests 831 and troughs 832 of the corrugated alloy sheet 83 .

[0033] The circular notch 81 of the filter 8 is u...

Embodiment 2

[0043] Embodiment 2: The present invention is used for the electromagnetic iron removal machine of kaolin clay removal

[0044] refer to Figure 1~3 , an electromagnetic iron remover for kaolin iron removal, including a filter screen 8, the iron-cobalt soft magnetic alloy by weight percentage, its chemical composition is: C=0.04%, Mn=0.30%, Si=0.30% , P=0.020%, S=0.020%, Cu=0.20%, Ni=0.50%, Co=49.0~51.0%, V=0.80~1.80%, Fe=balance. The difference between the filter screen 8 described in this embodiment and the filter screen 8 described in Embodiment 1 is that the entire filter screen 8 only uses a straight alloy sheet 82 and a corrugated alloy sheet 83, so that the filter screen The structure of 8 is more solid, and it is not easy to deform or fall apart during use.

[0045] The difference between this embodiment and the preparation method of the filter screen 8 described in Example 1 is that in step d, the number of straight alloy sheets 82 used is 1, and the number of corru...

Embodiment 3

[0046] Embodiment 3 The present invention is used for the electromagnetic iron removal machine of kaolin clay

[0047] Mechanism reference of electromagnetic iron remover Figure 1~3 , the preparation method of the filter screen is the same as in Example 2, the difference is that the iron-cobalt soft magnetic alloy has a chemical composition of Co=49.0-51.0%, and the balance is iron.

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturation magnetic induction | aaaaa | aaaaa |

| saturation magnetic induction | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com