Method for removing cadmium and ferrum from crude antimony by using metaphosphoric acid

A technology of iron metaphosphate and cadmium metaphosphate, applied in the field of antimony pyrometallurgy, can solve the problems of difficulty in grasping the operation points, poor separation effect, inability to refine crude antimony, etc., and achieves good iron removal effect, good environmental protection benefits, and removal of Good effect of cadmium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

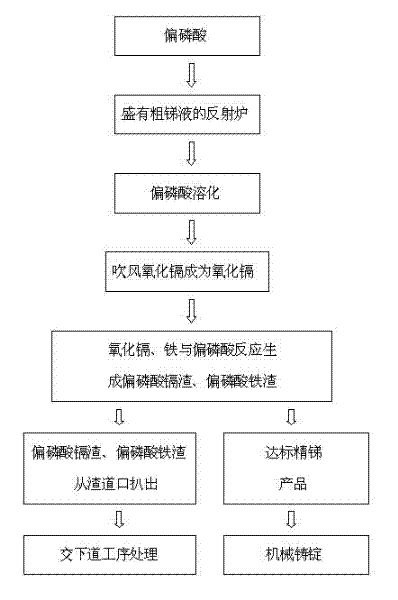

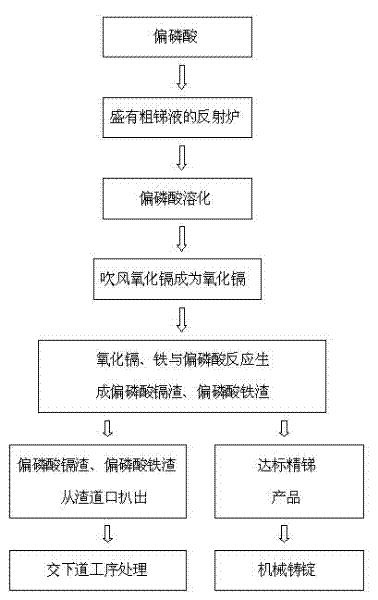

[0040] A method for removing cadmium and iron in thick antimony with metaphosphoric acid, it proceeds in the following steps:

[0041] 1. Add 400-500 kg of metaphosphoric acid to the reverberatory furnace containing the crude antimony liquid (the amount of metaphosphoric acid added is calculated as 30-40 kg per square meter of antimony liquid surface), and continue to increase the temperature of the furnace to melt the metaphosphoric acid to make it Cover the surface of the antimony solution.

[0042] 2. Turn on the air compressor, insert the pig iron blowpipe from the working door of the reverberatory furnace into the antimony liquid to blow air (the air volume blown in should be slightly foamed on the surface of the antimony liquid, if the air volume is too large, the antimony oxide will volatilize too much, Affect the direct yield of antimony), at the same time stir the antimony liquid to expand the contact surface with metaphosphoric acid, accelerate the process of removin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com