A kind of adsorbent for removing cadmium, its preparation method and use

A technology of adsorbent and leaching agent, which is applied in the field of cadmium pollution control, can solve the problems of complex process, high cost, poor cadmium removal adsorption performance of adsorbent materials, etc., and achieve simple preparation process, high adsorption capacity, and good cadmium removal effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

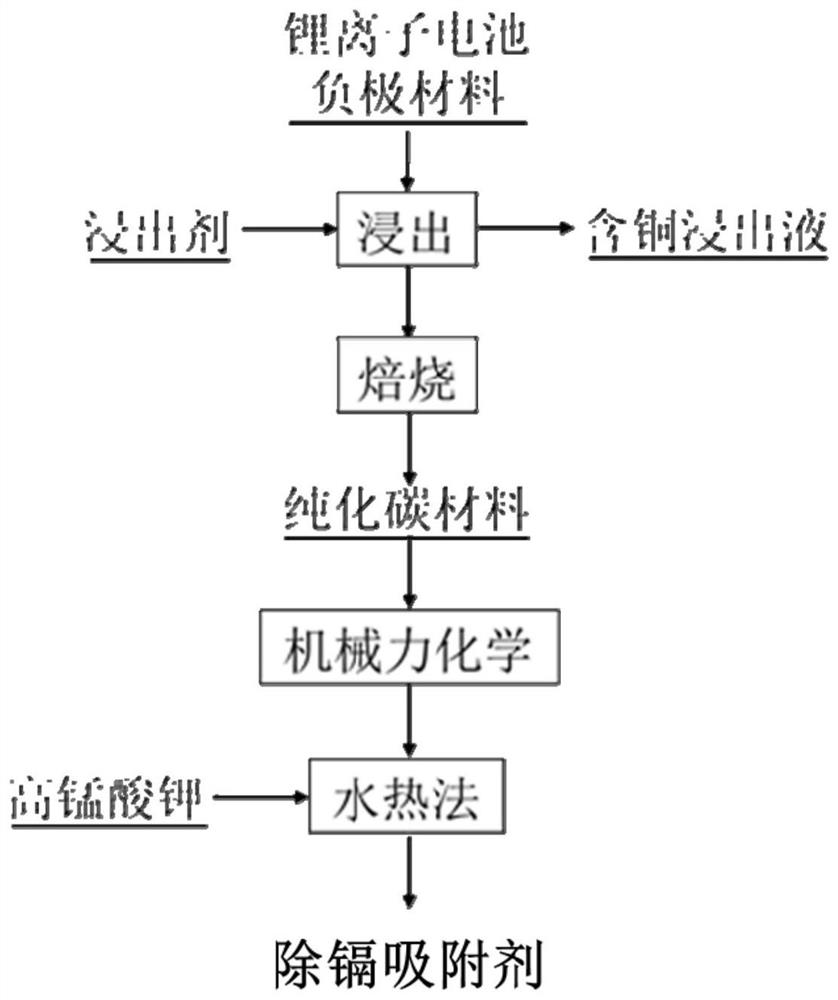

Method used

Image

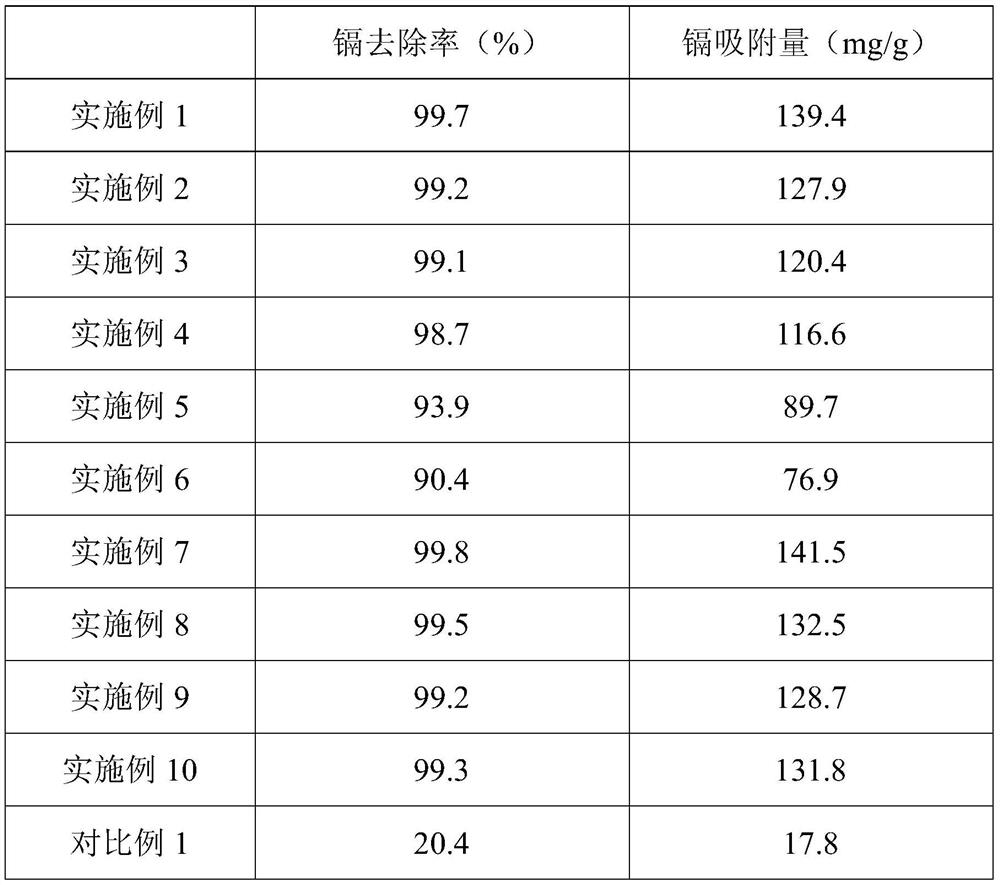

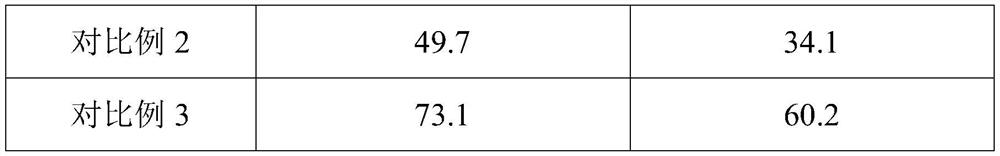

Examples

Embodiment 1

[0074] A preparation method for removing cadmium adsorbent comprises the steps:

[0075] (1) Obtain graphite negative electrode pole piece from waste lithium ion battery, cut described graphite negative pole pole piece into 2cm * 2cm pole piece, get 50 pole pieces after cutting and immerse in 1000mL water ultrasonic stripping, then sieve and Separate the suspension of the carbon material, mix the suspension with the leaching agent at a volume ratio of 10:1 for 2 h, the leaching agent is 80 mL of concentrated hydrochloric acid and 20 mL of hydrogen peroxide, separate the solid from the liquid, dry at 80°C for 8 h, 500 Calcined at ℃ for 2h to obtain purified carbon material;

[0076] (2) Mechanochemically activate the purified carbon material by using a ball mill, the ball-to-material ratio is 10:1, the activation speed is 800rpm, and the activation time is 10h, to obtain the carbon material;

[0077] (3) The carbon material is mixed with the acidic potassium permanganate solut...

Embodiment 2

[0080] The difference from Example 1 is that the purified carbon material in step (2) is graphite.

Embodiment 3

[0082] The difference from Example 1 is that the mass ratio of carbon material to acidic potassium permanganate in the mixed solution is 0.1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com