Simple removal method for cadmium in scallop processing waste

A waste and scallop technology, which is applied in the field of simple removal of cadmium in scallop processing waste, can solve the problems of no good treatment method for cadmium waste liquid and the inability to realize better utilization of waste raw materials, etc., and achieve good cadmium removal effect , easy to operate, to achieve the effect of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

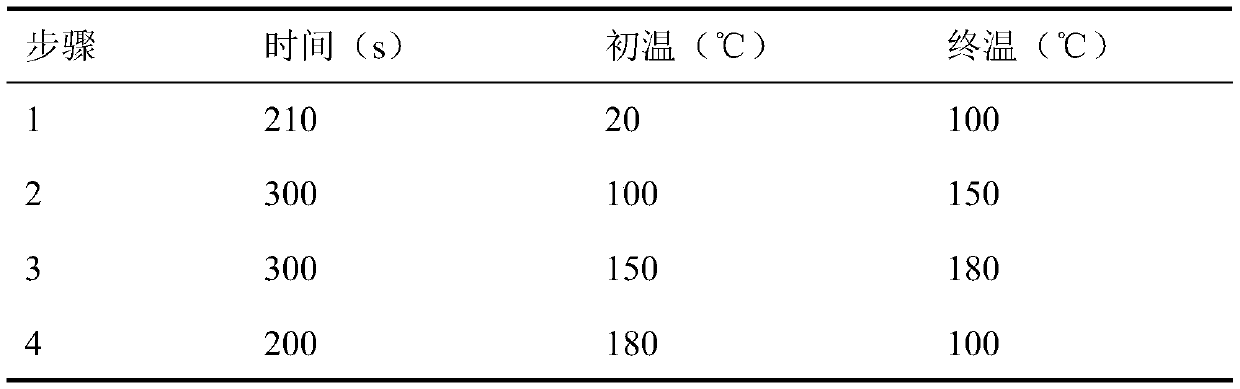

Embodiment 1

[0053] This example provides a simple method for removing cadmium from scallop processing waste, and the specific process is as follows.

[0054] (1) Get 100g scallop processing waste (including scallop skirt and viscera), add 4% citric acid and 10% distilled water by weight of the waste, carry out pickling at 55-60°C and filter, separate solid-liquid, and wash Dehydration 1. Add distilled water with twice the amount of solids for washing, and then perform solid-liquid separation again, then add distilled water with twice the amount of solids for washing with water for the second time. After solid-liquid separation, mix the eluents to obtain eluent 2. At this time, the cadmium removal rate is 94%, and the complete scallop skirt and viscera can be obtained, which is beneficial to further processing.

[0055] (2) Take 50mL of eluent 2, add raw eggshells in three times, the addition amount is 5%, 3% and 2% respectively (relative to the mass fraction of eluent), the shaking condi...

Embodiment 2

[0057] This example provides a simple method for removing cadmium from scallop processing waste, and the specific process is as follows.

[0058] (1) Get 100g of scallop processing waste (including scallop skirt and viscera), add 4% acetic acid of waste weight, then add 10% of waste weight distilled water, pickle at 55-60°C, filter, and separate solid and liquid , to obtain eluent 1; then add distilled water twice the amount of solids to wash and then separate, and then perform a second wash with water twice the weight of the solids. After solid-liquid separation, the eluents are mixed. At this time, the cadmium removal rate is 89%, and the complete scallop skirt and viscera can be obtained, which is beneficial for further processing.

[0059] (2) Take 50mL eluent 2 and add raw eggshells to the eluent three times, the addition amount is 3%, 2% and 1% respectively, the shaking condition is 30°C, the shaking speed is 139r / min, and the total shaking time is 3h (single shaking ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com