Patents

Literature

64results about How to "Quick Nest" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dissociation and recleaning technology for coking fine grain middling coal

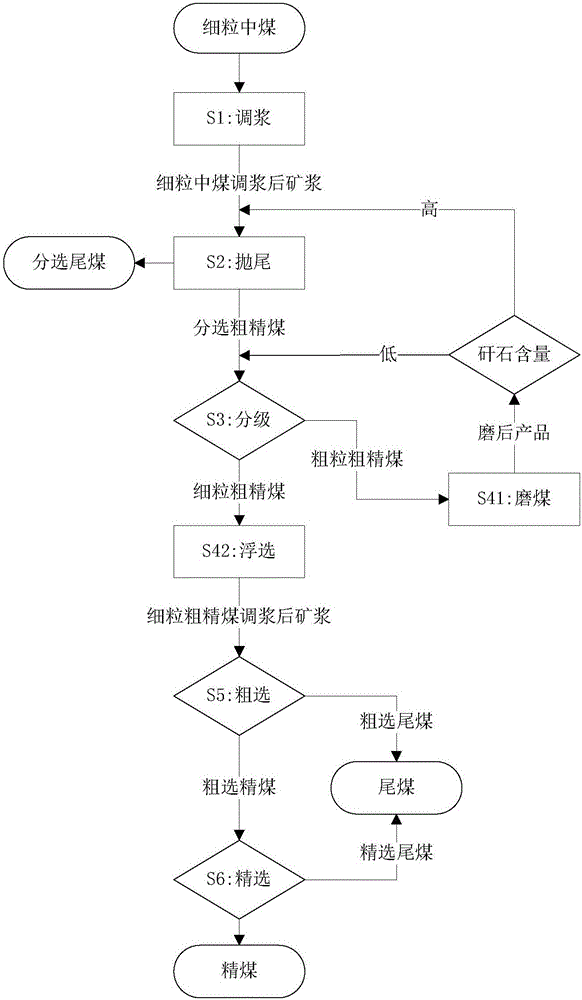

The invention relates to a dissociation and recleaning technology for coking fine grain middling coal. The technology comprises the processes that the size mixing operation is conducted on the fine grain middling coal; the operation of pretreating ore to remove tailings is conducted through coarse slime separation equipment; classification is conducted through classification equipment, and fine grain coarse clean coal and coarse grain coarse clean coal are produced; dissociation is conducted on the coarse grain coarse clean coal through coal grinding equipment; the flotation operation is conducted on fine grain coarse clean coal through size mixing equipment; after size mixing is conducted on the fine grain coarse clean goal through rough separation equipment, rough separation clean coal is produced; and concentrate is conducted on the rough separation clean coal through cleaning equipment, and the clean coal is produced. The dissociation and recleaning technology has the beneficial effects that the process is simple, the technology is mature, the investment is small, the operating cost is low, and the economic benefits are remarkable; the ash content of the tailings is guaranteed, and meanwhile the materials with the medium ash content and the low ash content are fully dissociated; and it is avoided that gangue enters a grinding machine, the load of the grinding machine is reduced greatly, the energy consumption is lowered, and the recovery rate of the tailings and the clean coal is increased.

Owner:CHINA UNIV OF MINING & TECH

Device for measuring reaction rateof flash magnetized calcination for refractory iron oxide ore

InactiveCN1776421AFast feedingQuick unloadingMaterial heat developmentPreparing sample for investigationEngineeringReaction speed

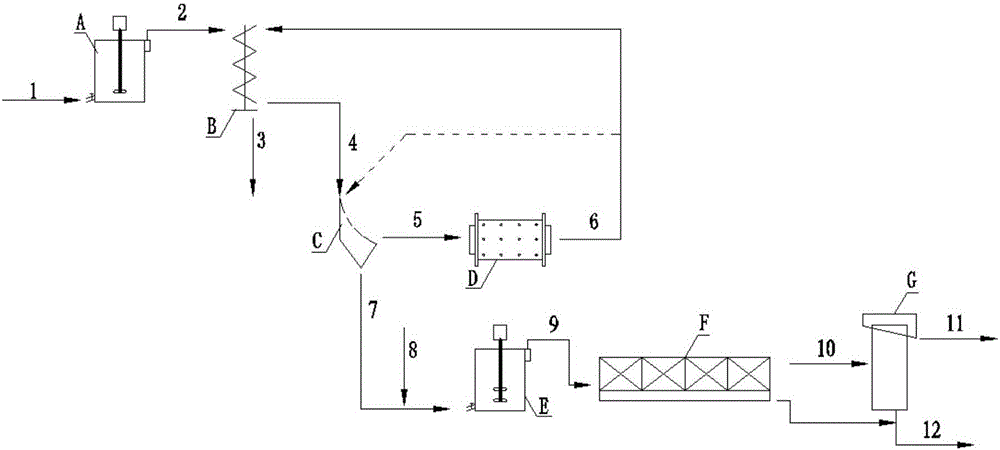

Structure of the testing device is as following: blower fan, gas generator, separator and reaction furnace are connected to each other through pipe; adjustable valve and switch valve are setup at pipe connected between the gas generator and the separator; material receiver is at lower part of the separator; the gas generator and reaction furnace are connected through pipe with switch valve; being setup at upper, middle, and lower part of the reaction furnace, the test points are in use for thermocouple to measure reduction gas in the furnace, temperature in furnace chamber and temperature of tail gas; through pipe with control valve, the bottom part of the reaction furnace is connected to the blower fan, and test points are in use for measuring flux of coal gas and component. Features are: low energy consumption; the testing device can be added to furnace and demount from furnace quickly, measuring reaction change velocity from weak magnetism to strong magnetism, etc.

Owner:HUAZHONG UNIV OF SCI & TECH +1

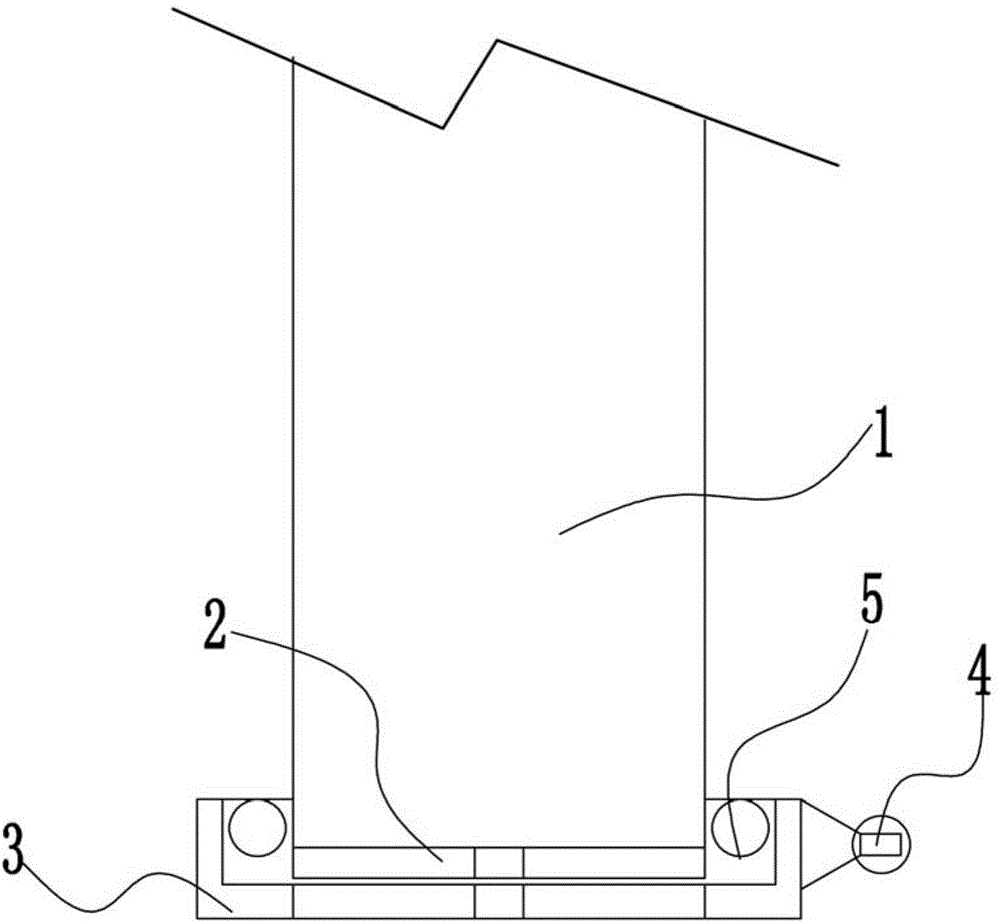

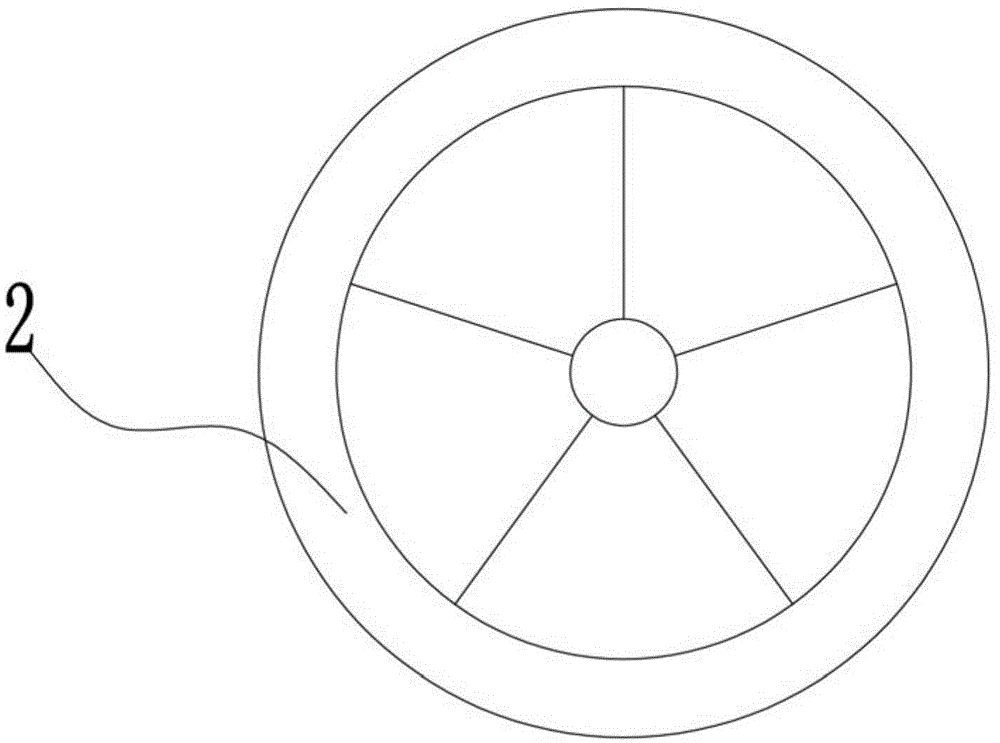

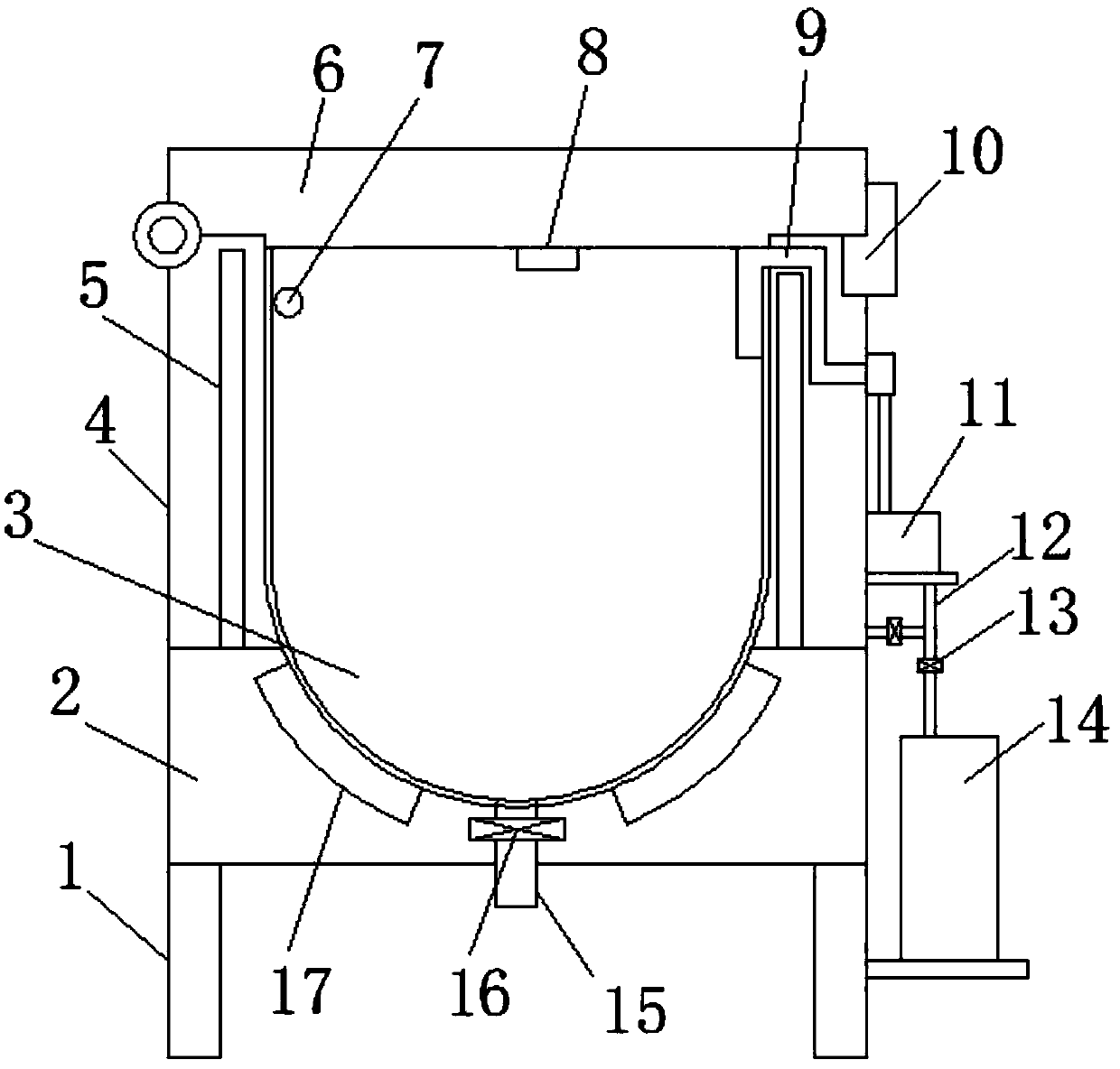

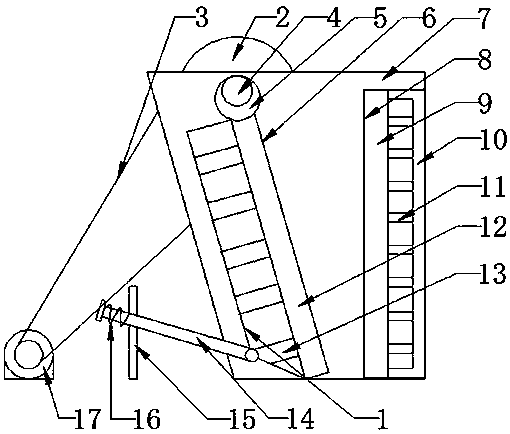

Bidirectional discharge circular vibrating screen

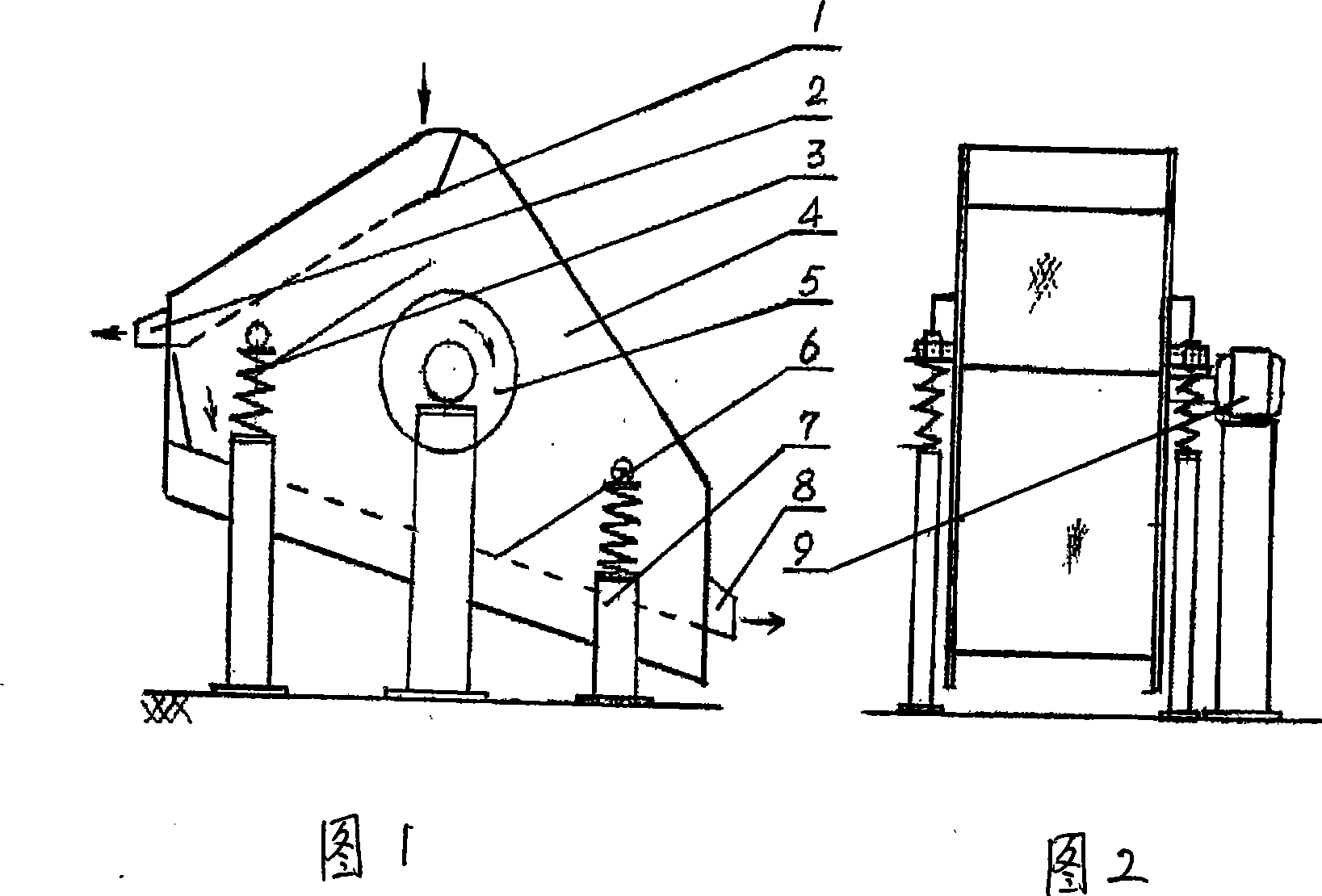

InactiveCN101462110AMultiple screening specificationsQuick NestSievingScreeningChemical industryBuilding material

The invention discloses a bidirectional discharge circular vibrating screen, which consists of a screen body, a vibration generator, springs, a support and a transmission device, and is characterized in that the screen body consists of a screen frame, an upper screen mesh and a lower screen mesh; the upper screen mesh is provided with a discharge opening I, and the lower screen mesh is provided with a discharge opening II; the support is arranged on the lower part of the screen body which is fixedly connected with the support through four groups of springs; and the vibration generator is arranged on the upper part of the gravity center of the screen body. The bidirectional discharge circular vibrating screen has the advantages that the material circular vibrating screen adopts a simple eccentric shaft block to adjust the amplitude, has the characteristics of long slip screen line, multiple screening specifications, quick discharge and high classification efficiency, also has the characteristics of reliable structure, strong excitation force, high screening efficiency, small vibrating noise, firmness and durability, convenient maintenance, safe use and the like, and can be widely applied to classification and separation of materials in the industries such as mining, building material, traffic, energy and the chemical industry.

Owner:陆信

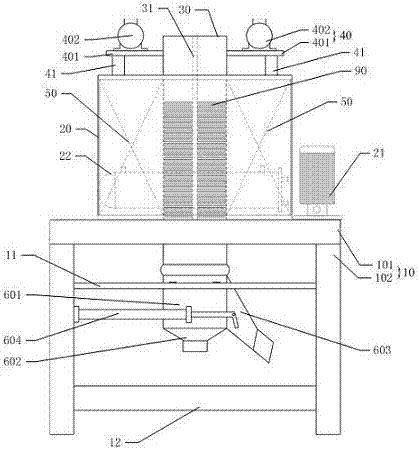

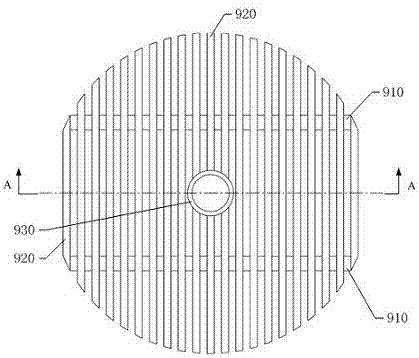

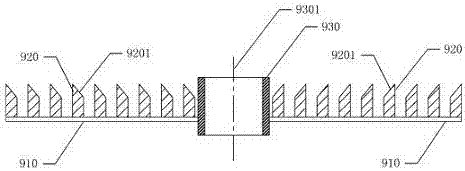

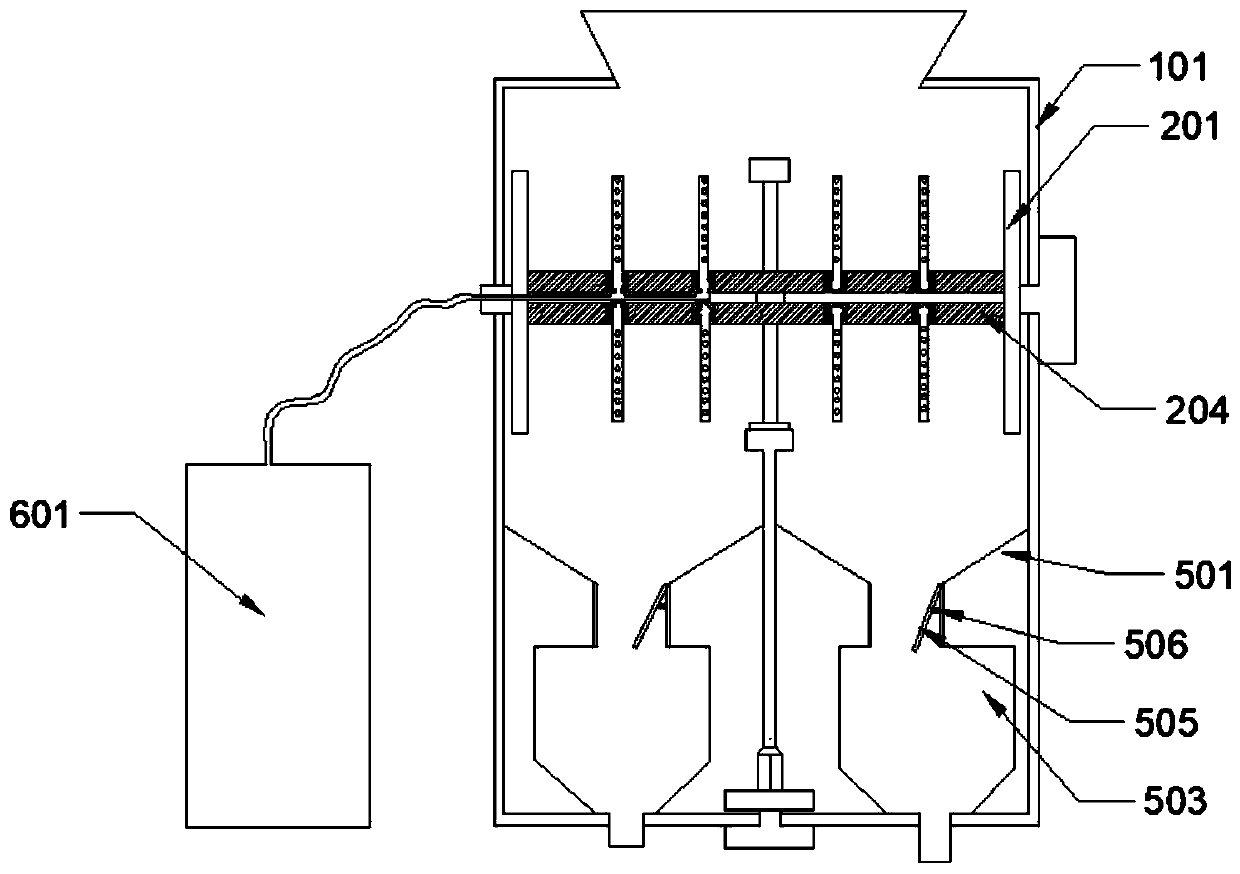

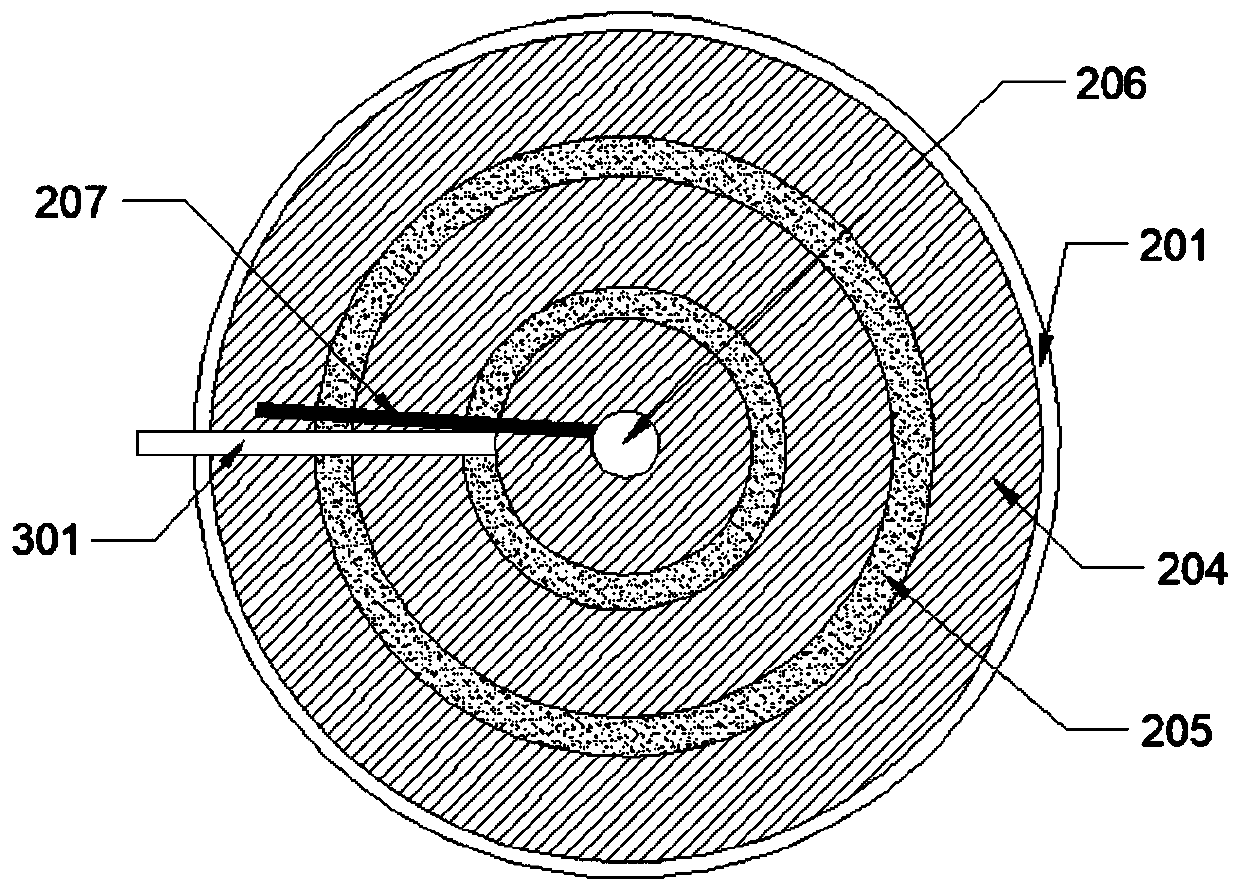

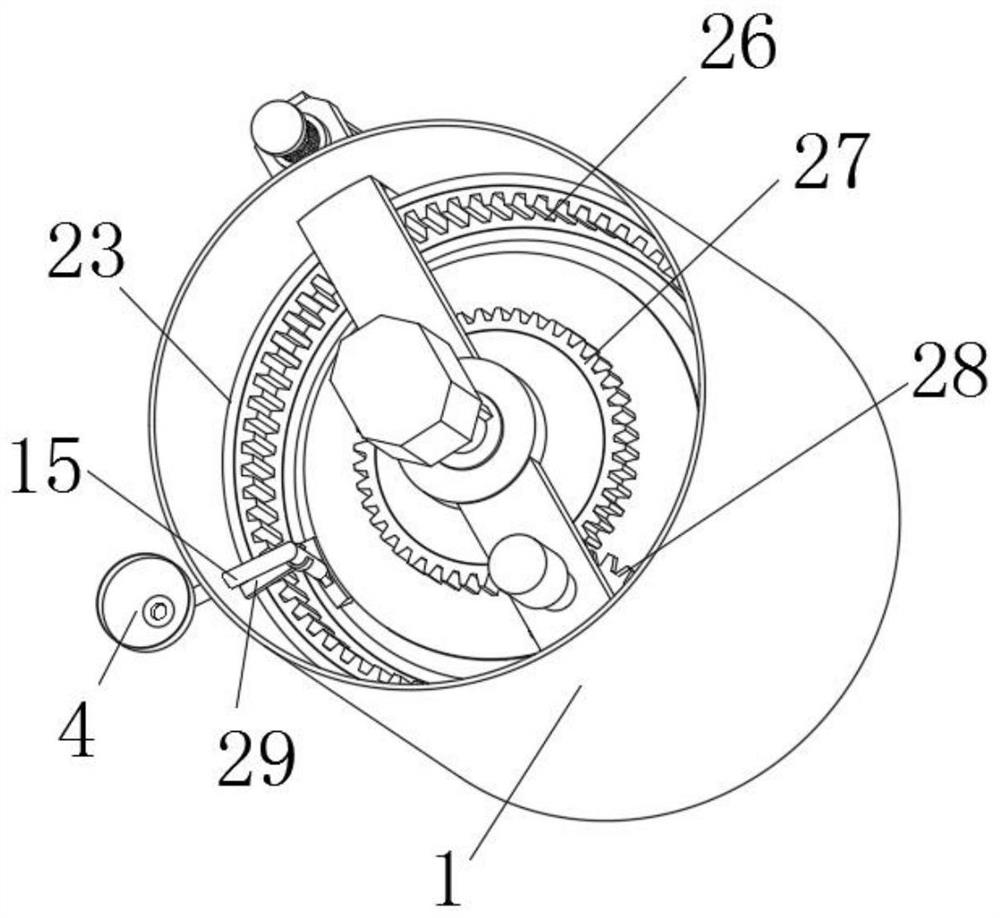

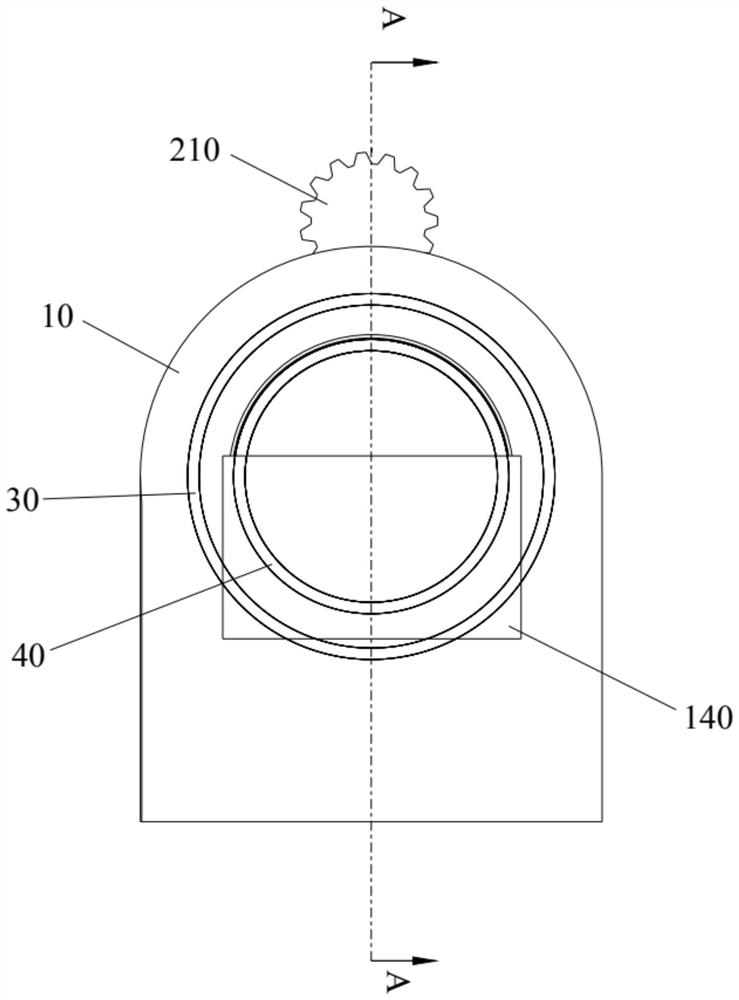

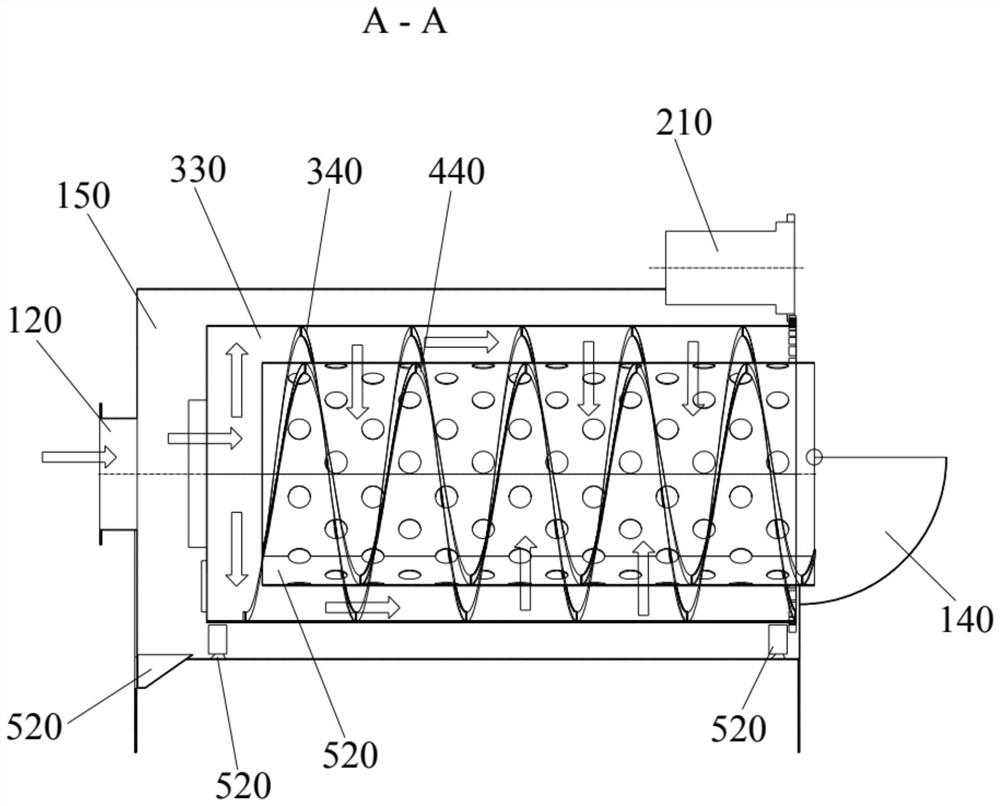

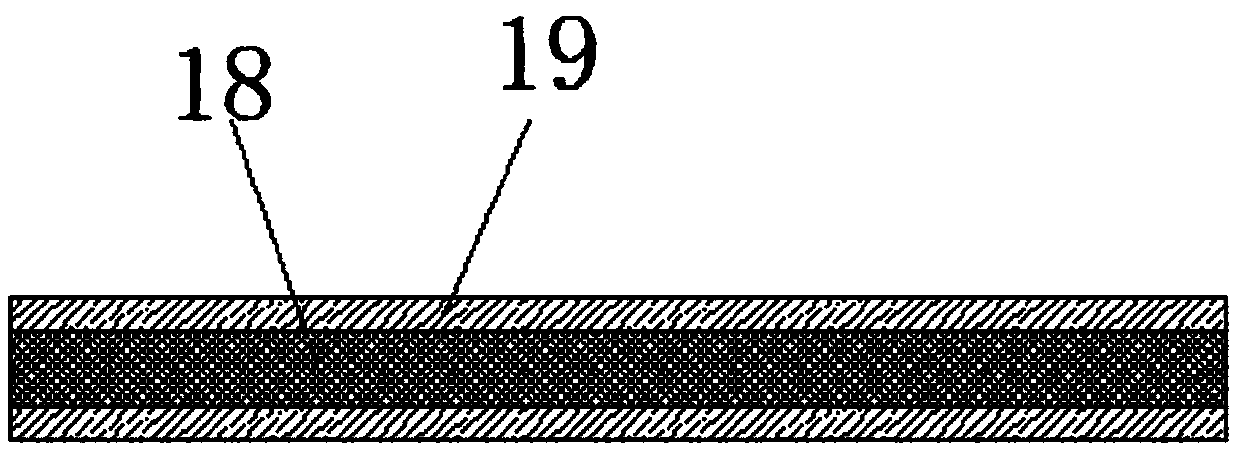

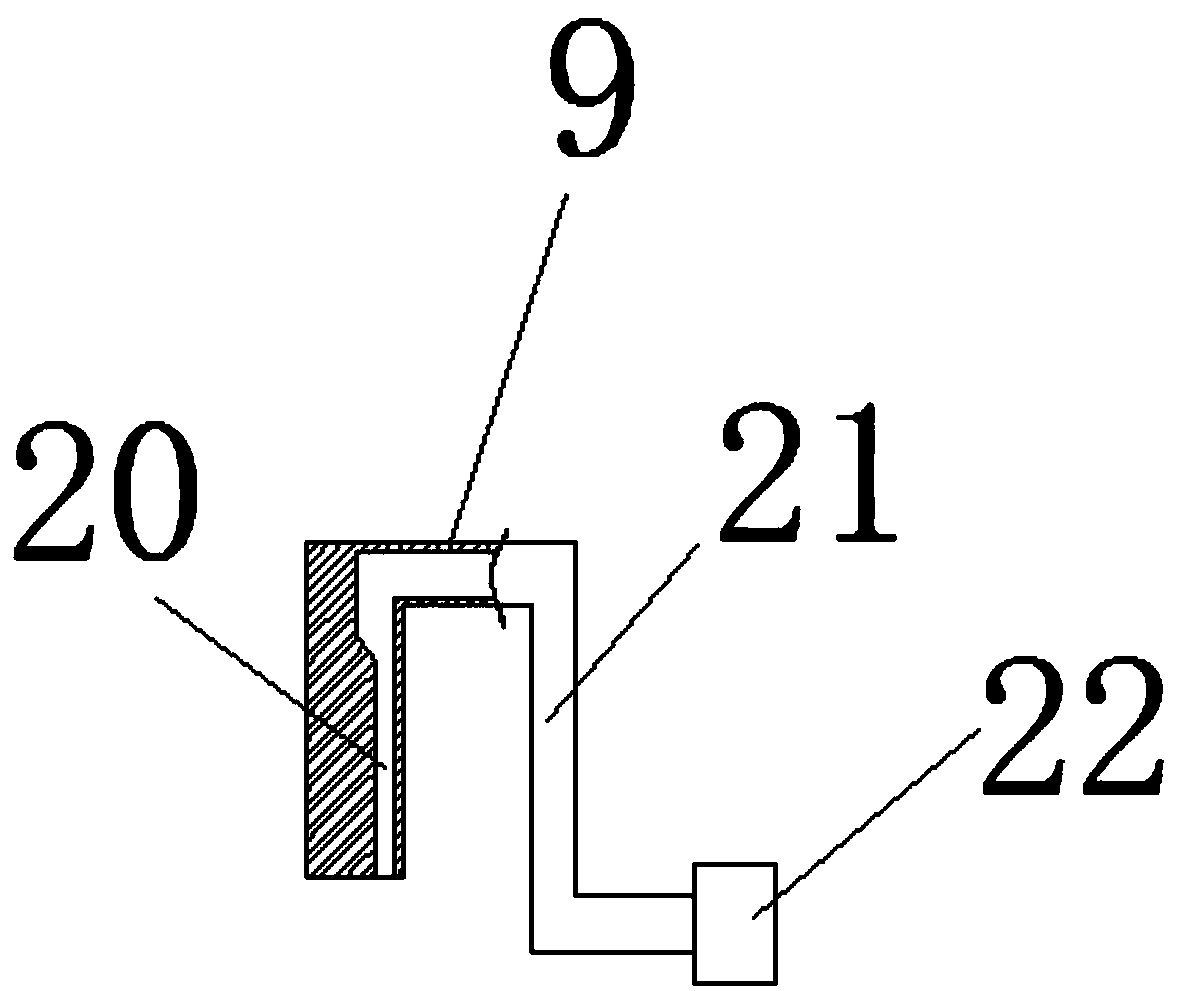

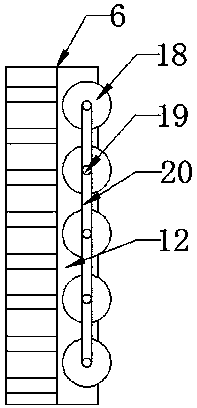

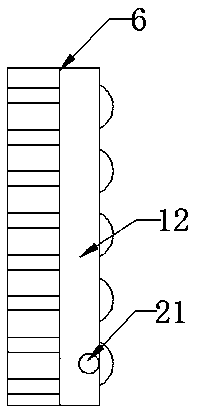

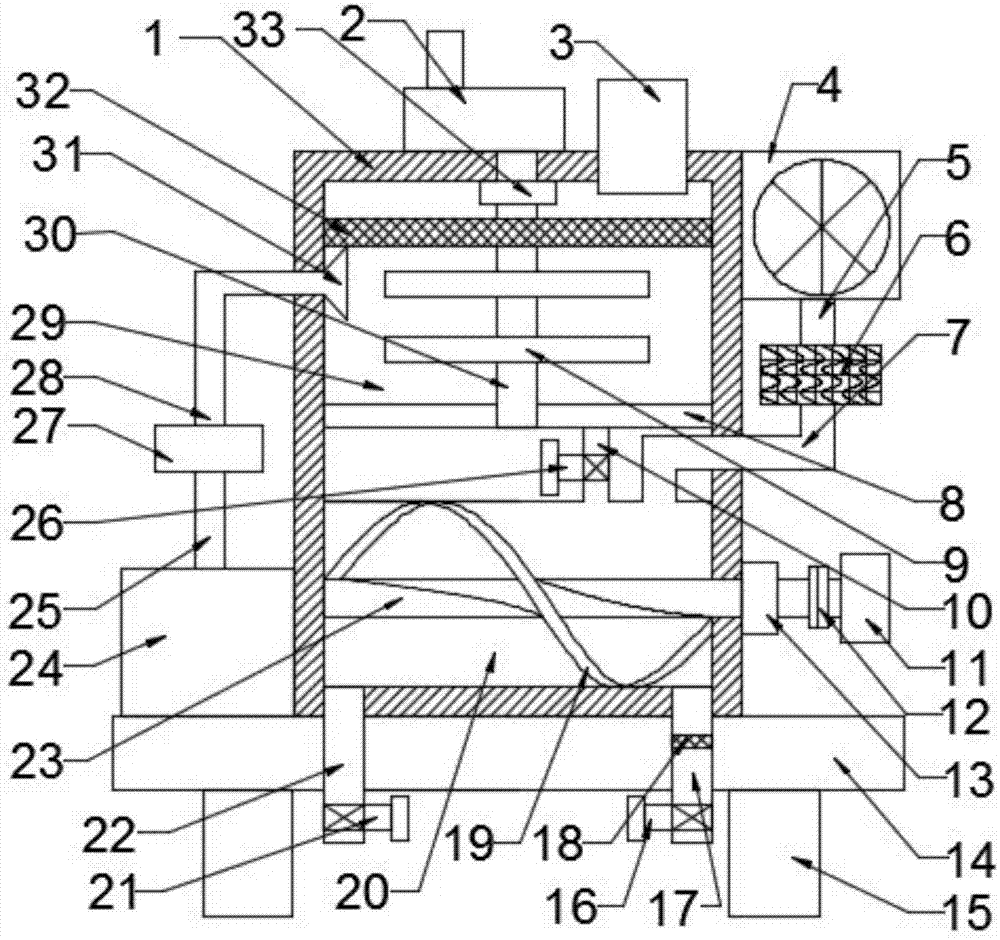

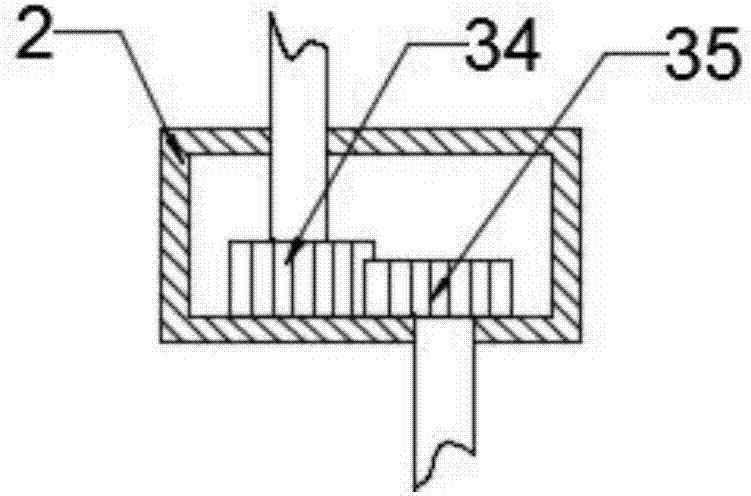

Powder electromagnetic separator

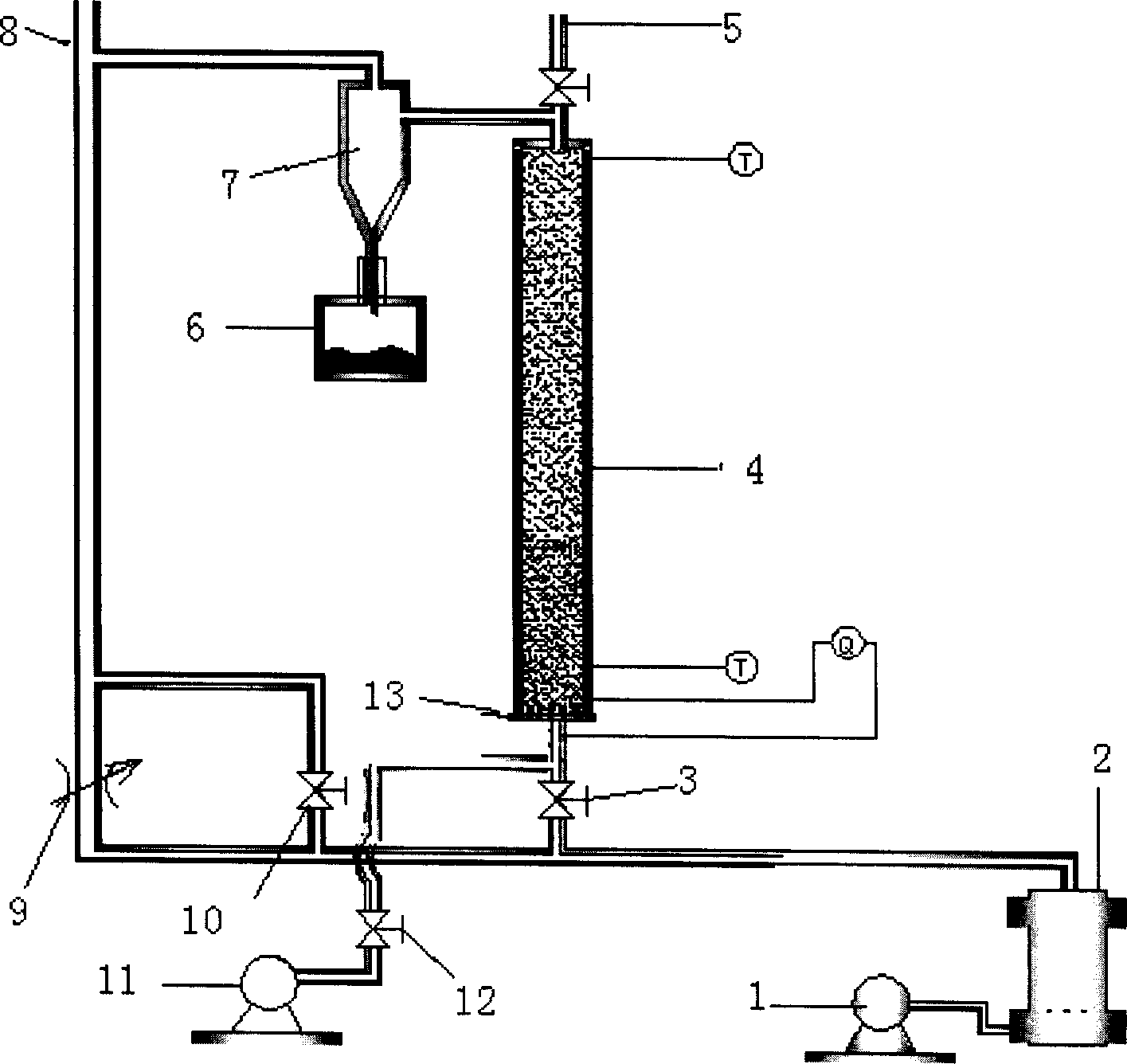

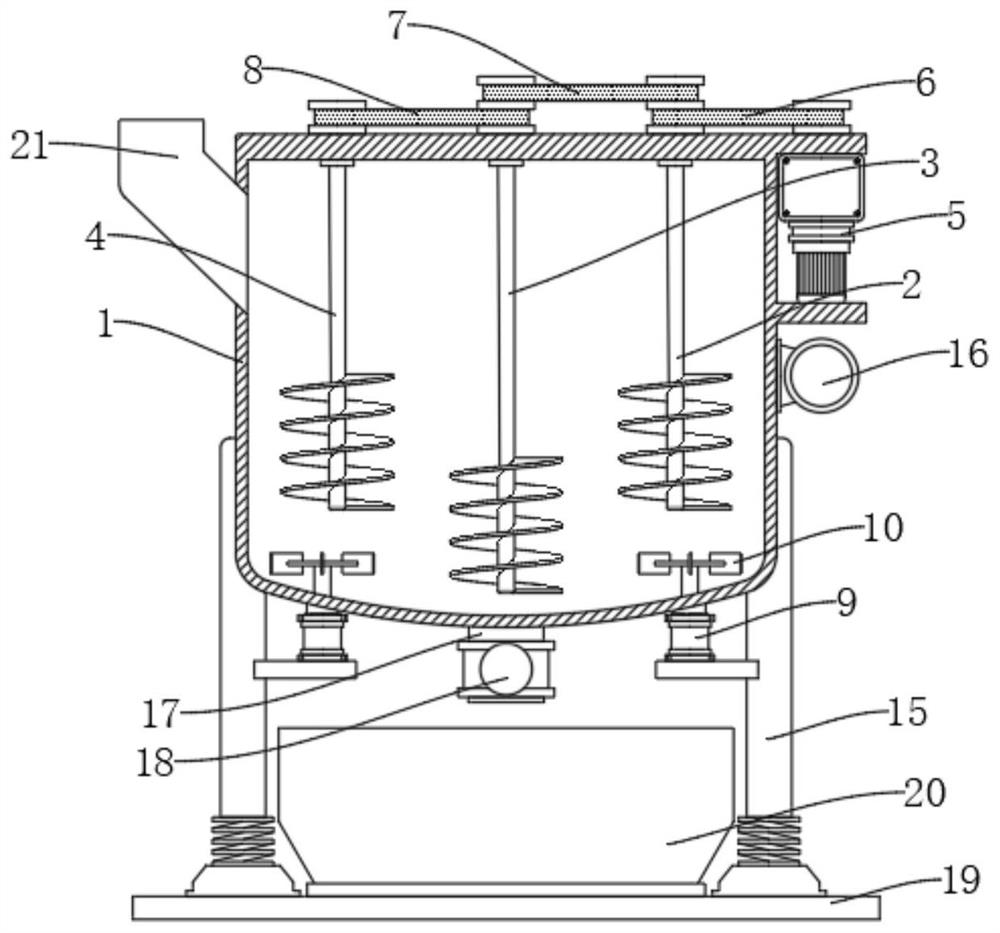

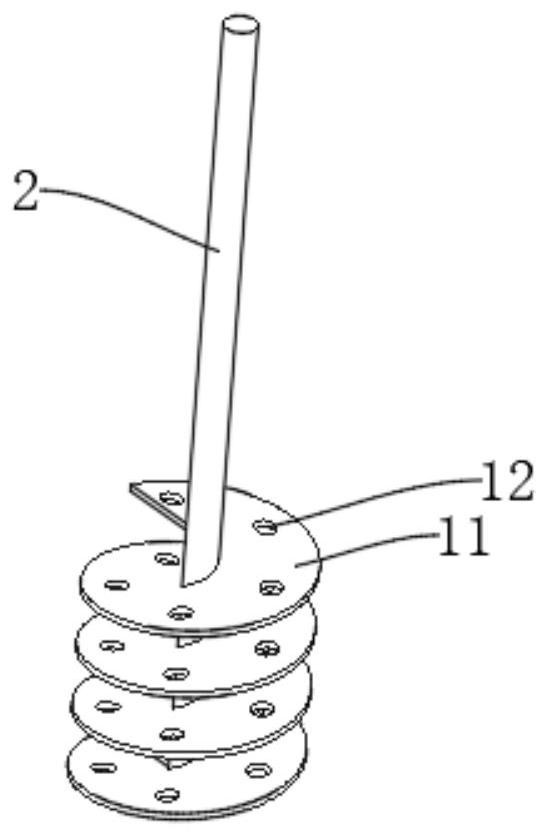

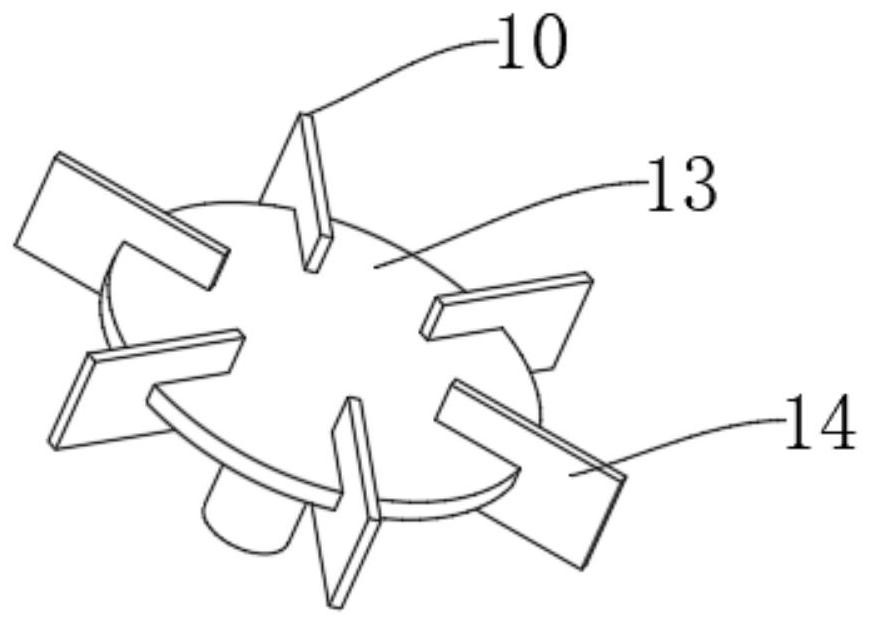

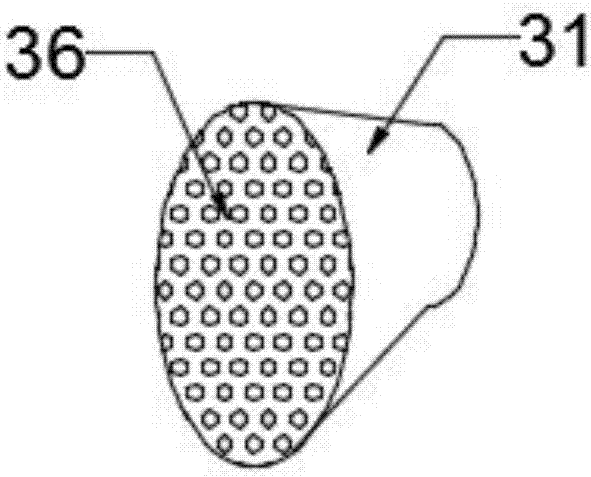

InactiveCN107234001AQuick NestImprove processing efficiencyMagnetic separationIron powderMagnetic media

The invention discloses a powder electromagnetic separator, which comprises a bottom frame, an oil tank, a heat exchanger and an oil pump arranged on the bottom frame, an electromagnetic coil arranged in the oil tank, an iron removal cylinder vertically penetrating the oil tank, and an iron removal cylinder arranged in the oil removal tank. The vibration device on the side wall of the iron cylinder, and the unloading device arranged at the bottom of the iron removal cylinder; several pieces of magnetic nets are stacked in the inner cavity of the iron removal cylinder; the oil tank, oil pump and heat exchanger pass through the oil pipe Loop connections. The powder electromagnetic separator provided by the invention improves the iron removal efficiency and quality of the powder, and can effectively remove the heat generated by the electromagnetic coil during operation.

Owner:佛山市高明星诺机械设备有限公司

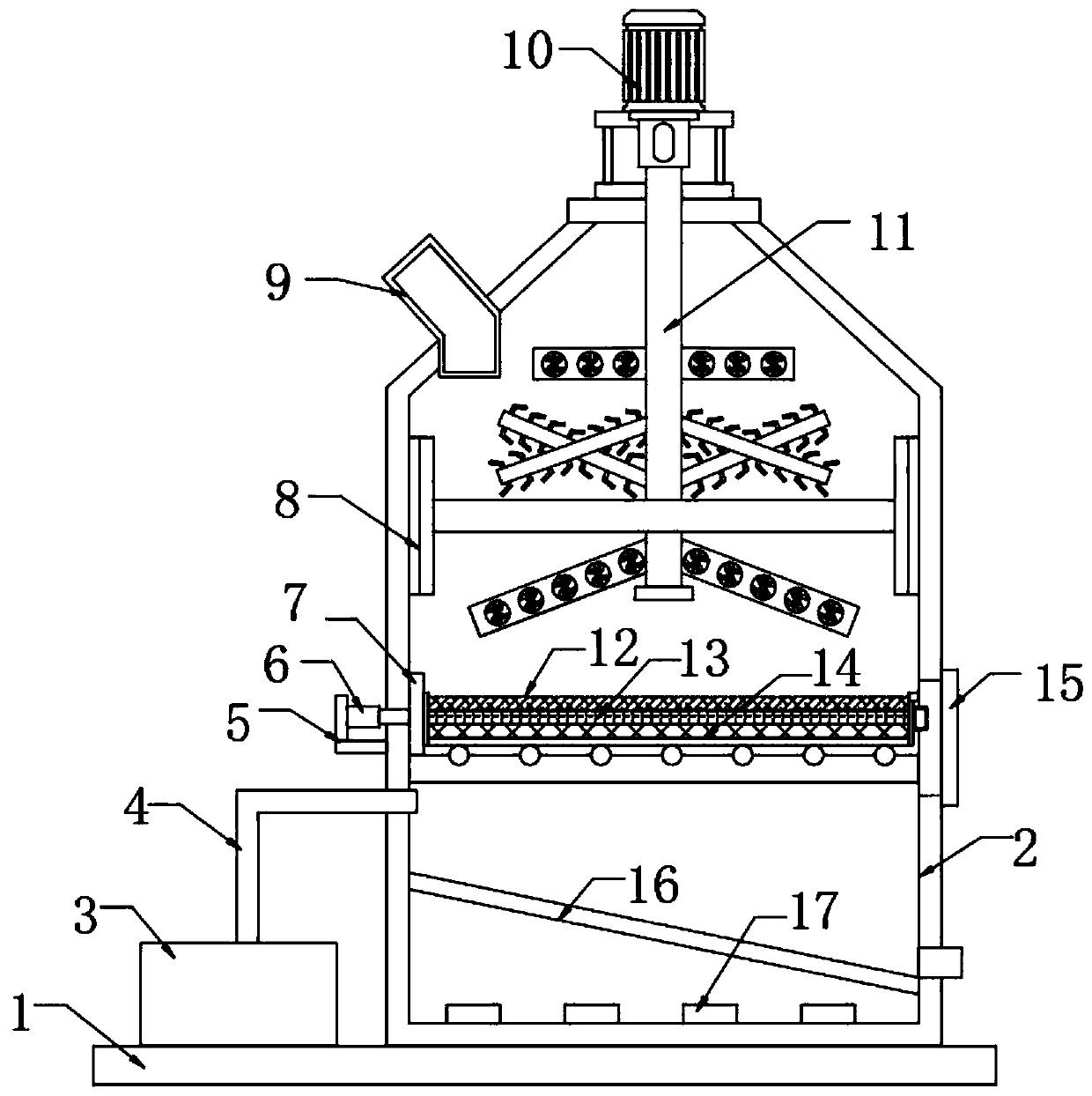

Liquid cosmetic semi-finished product filtering device

InactiveCN110917920AImprove mixing efficiencyReduce filter qualityDispersed particle filtrationRotary stirring mixersElectric machineryChemistry

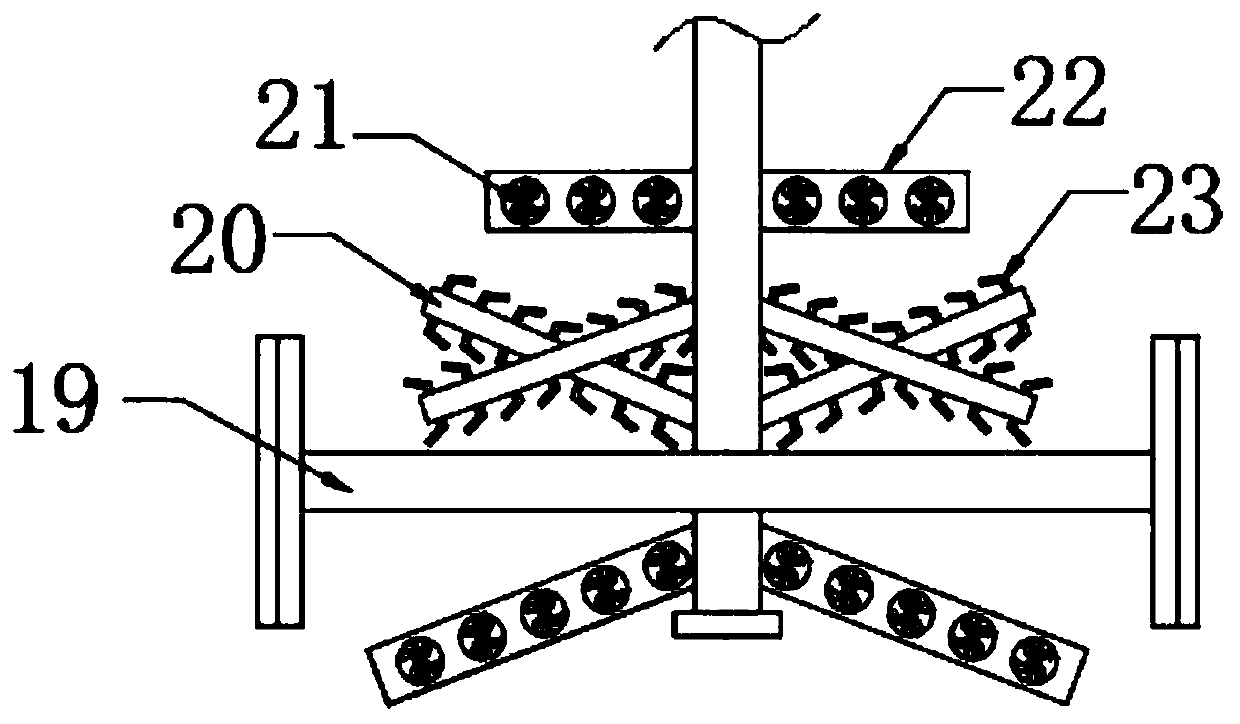

The invention belongs to the technical field of filtering devices, particularly relates to a liquid cosmetic semi-finished product filtering device, and provides the liquid cosmetic semi-finished product filtering device for solving the problem of poor stirring effect, the liquid cosmetic semi-finished product filtering device comprises a bottom plate, a filtering box is arranged on the outer wallof the top of the bottom plate, an L-shaped fixing plate is arranged on the outer wall of one side of the filtering box, and a motor is arranged on the outer wall of the top of the filtering box; andan output shaft of the motor is connected with a rotating rod through a coupler, a stirring frame is arranged on the outer wall of one side of the rotating rod, and stirring blades distributed at equal intervals are connected to the inner wall of the stirring frame through bearings. According to the liquid cosmetic semi-finished product filtering device, an X-shaped stirring rod, crushing cutters, the stirring frame and the stirring blades are arranged, the crushing cutters distributed at equal intervals are installed on the outer wall of the X-shaped stirring rod, the X-shaped stirring rod can stir layers with different water levels during stirring, the stirring effect is good, the crushing cutters can crush caked cosmetics, and the stirring effect is good. In addition, the stirring blades can rotate under the flowing of liquid during stirring, so that the mixing efficiency of cosmetics is improved.

Owner:周晶晶

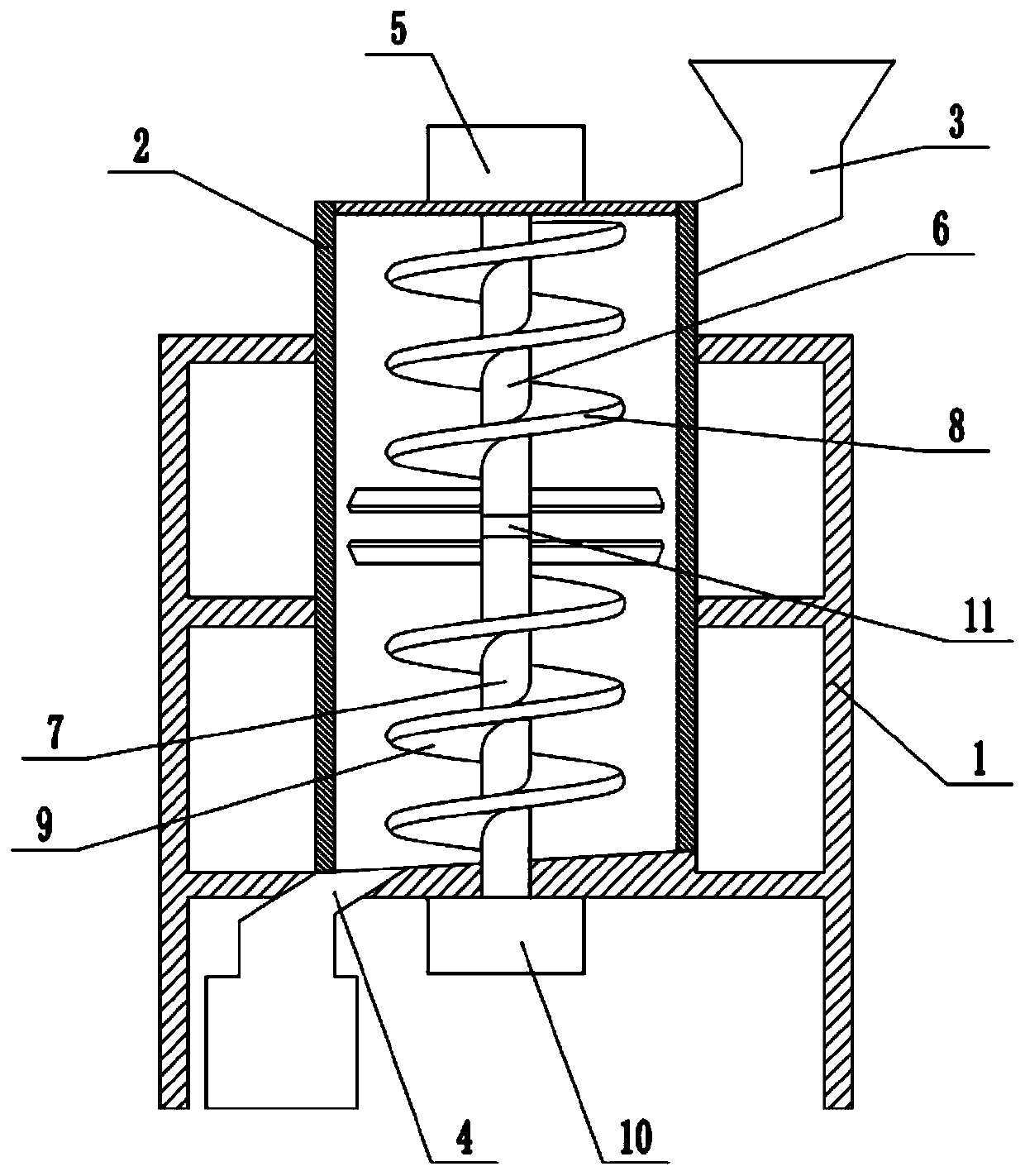

Building material processing device

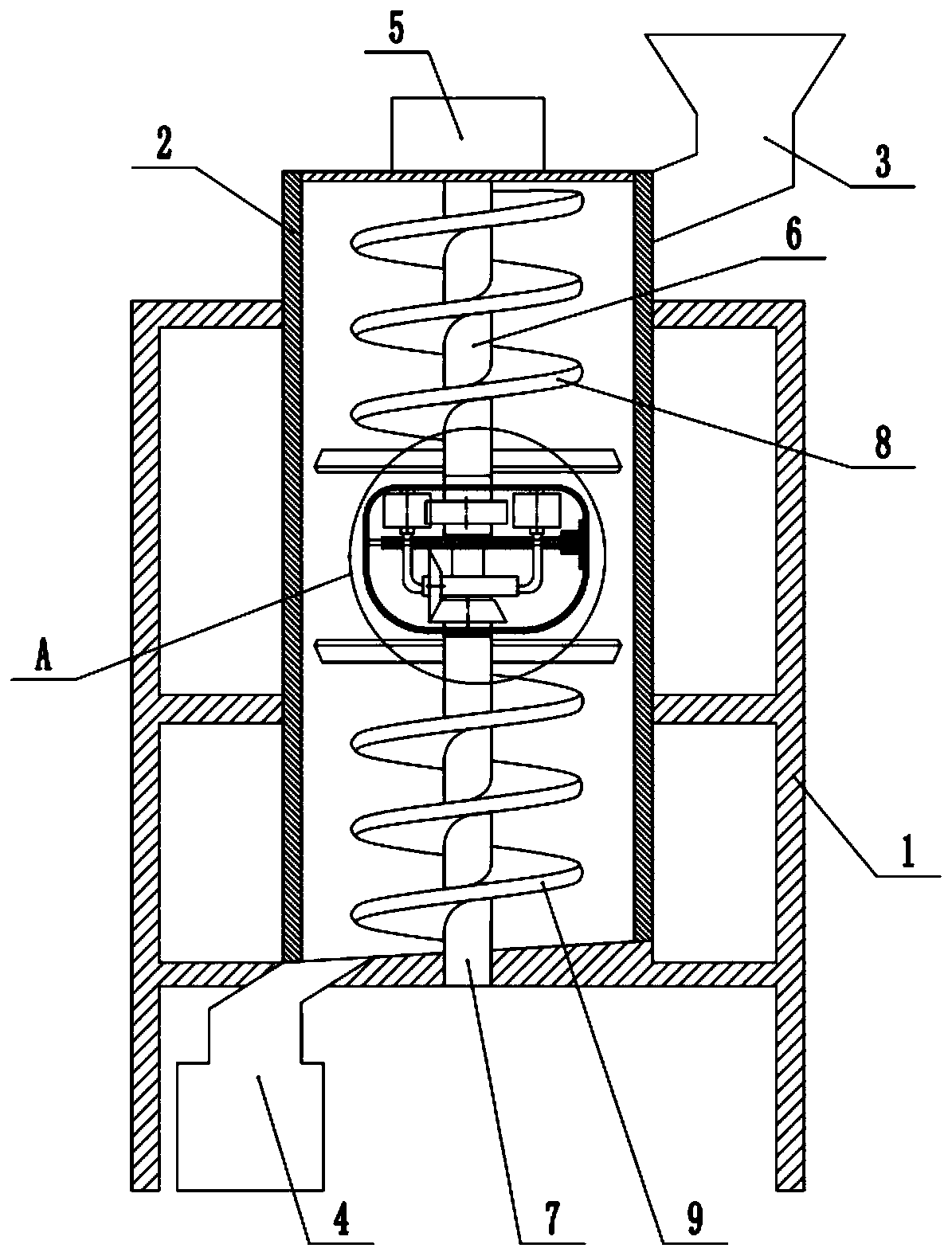

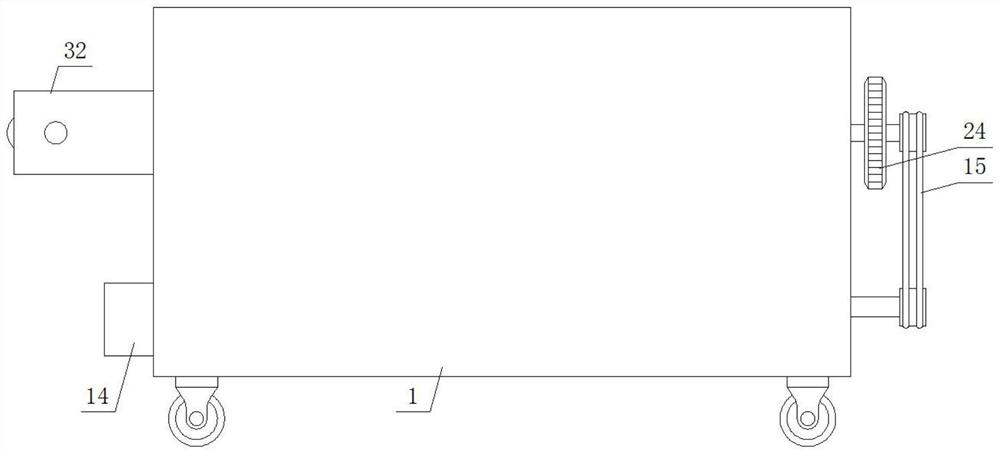

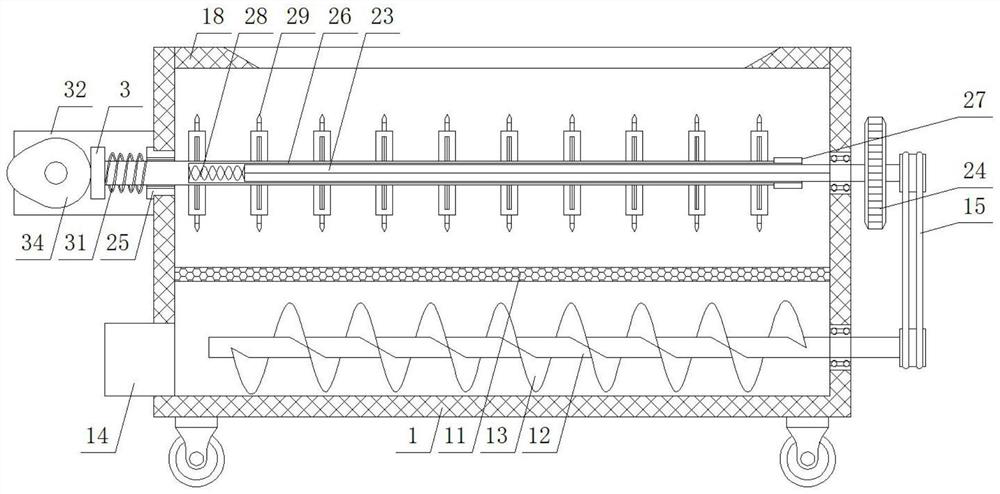

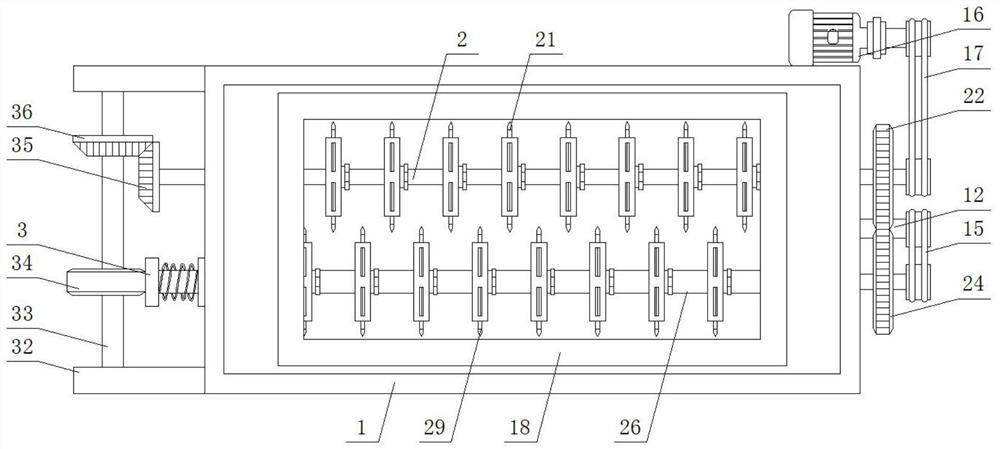

ActiveCN110281387AQuick NestFast pushDischarging apparatusMixing operation control apparatusMaterials processingMechanical engineering

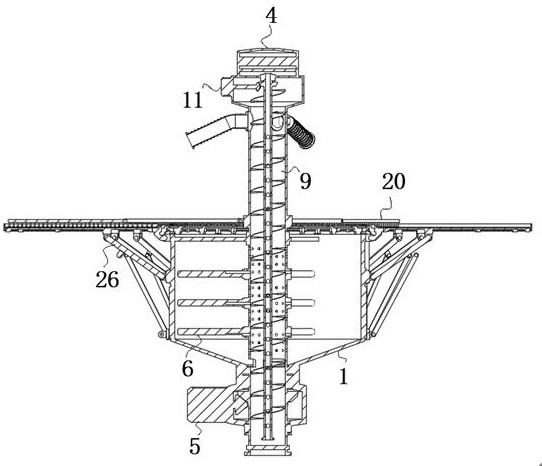

The invention relates to the technical field of building material equipment, in particular to a building material processing device. The building material processing device comprises a supporting frame; the supporting frame is fixedly connected with a stirring cylinder; a material discharging port is formed at the bottom of the stirring cylinder; a rotating shaft is coaxially arranged in the stirring cylinder; a driving unit for driving the rotating shaft to rotate is arranged on the stirring cylinder; the rotating shaft comprises an upper rotating shaft and a lower rotating shaft which are mutually linked; the upper rotating shaft is fixedly connected with an upper spiral sheet; the lower rotating shaft is fixedly connected with a lower spiral sheet; a reversing mechanism for changing the relative rotation direction of the upper rotating shaft and the lower rotating shaft is arranged between the upper rotating shaft and the lower rotating shaft; and the lower rotating shaft is close to the material discharging port. The rotation direction of the lower spiral sheet is changed sequentially through a switching mechanism, and the upper spiral sheet and the lower spiral sheet cooperate with each other to sequentially complete stirring operation and material discharging operation, so that the problems in the prior art that the stirring efficiency is low and the material discharging speed is low are solved.

Owner:CHONGQING VOCATIONAL INST OF ENG

Rice impurity removing device for processing rice flour

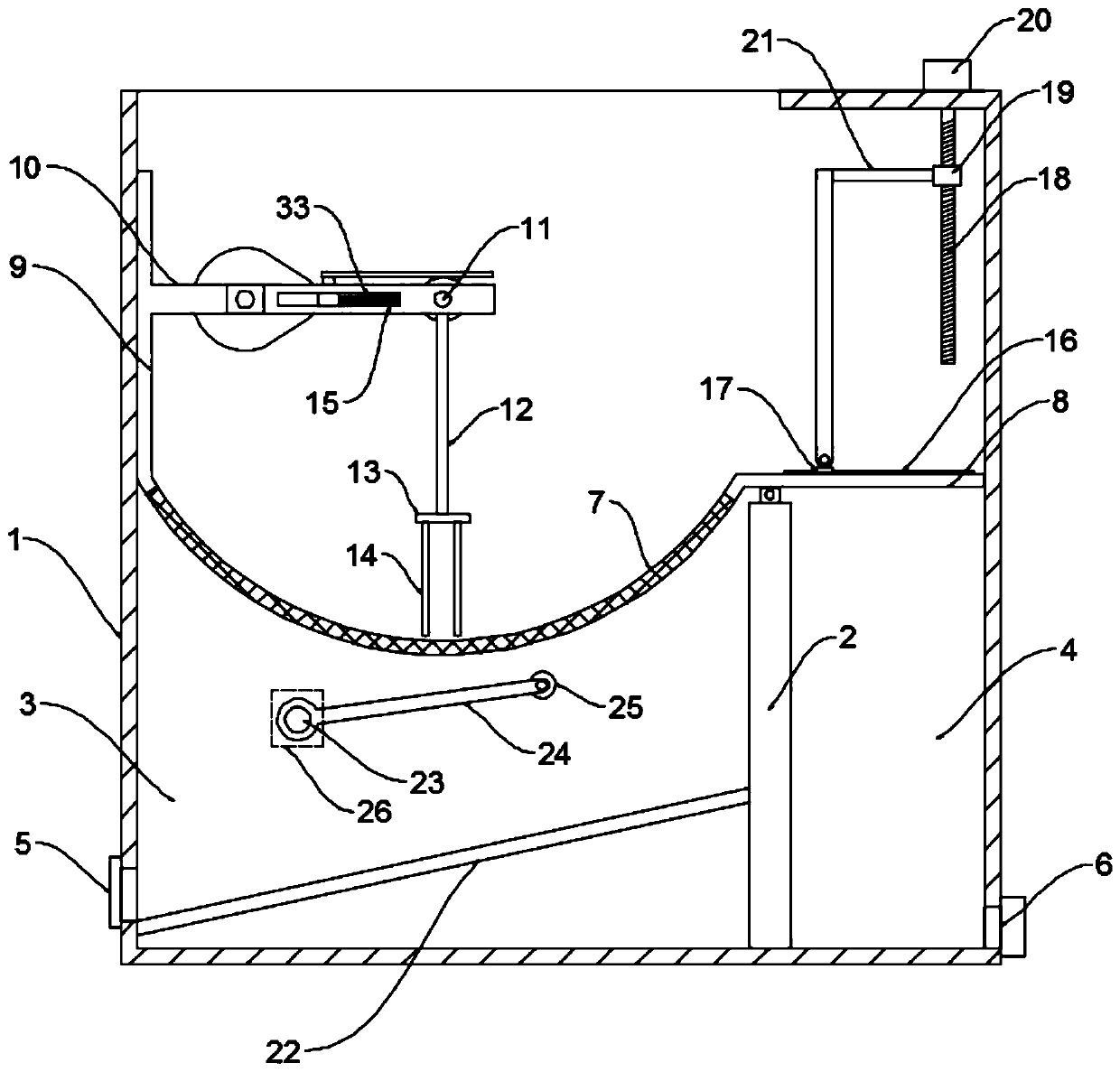

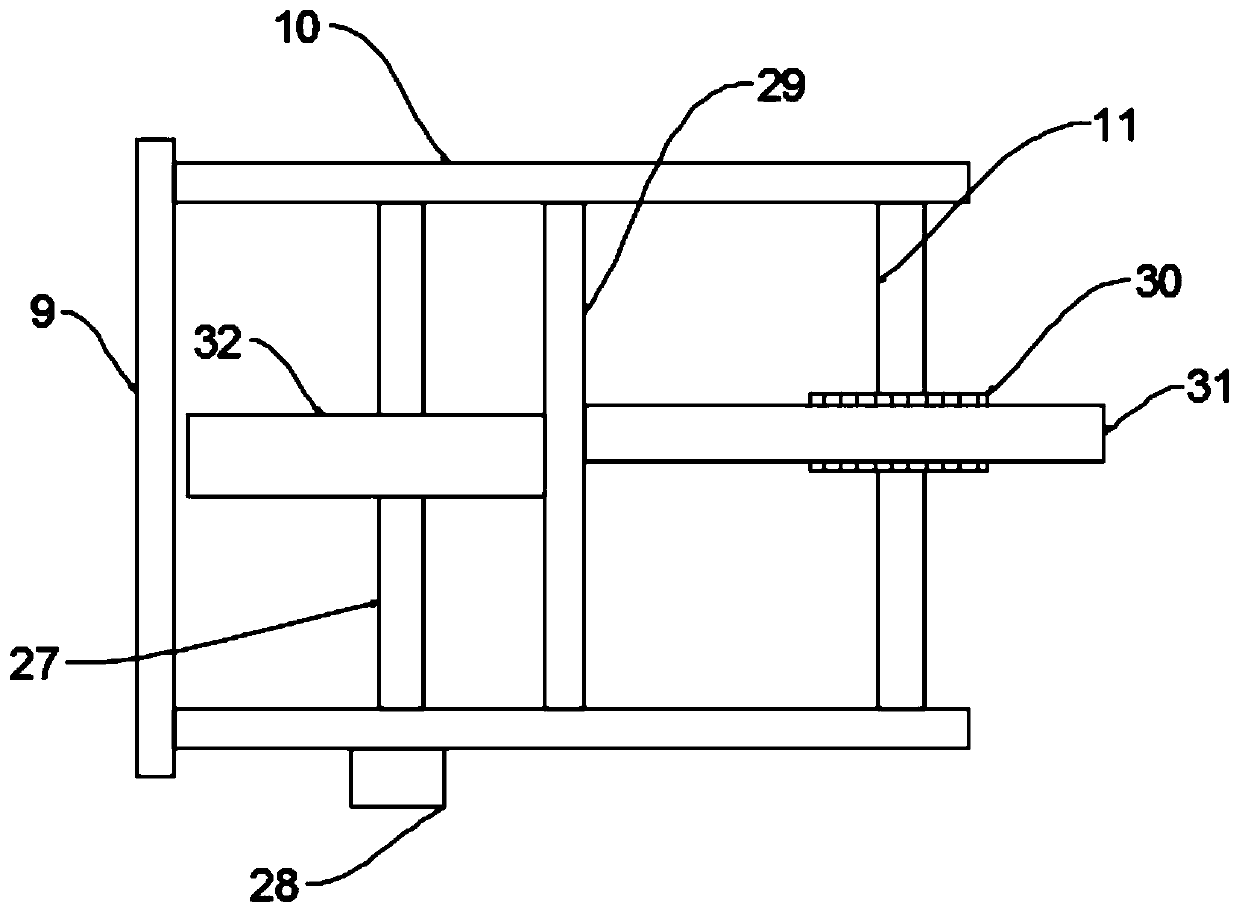

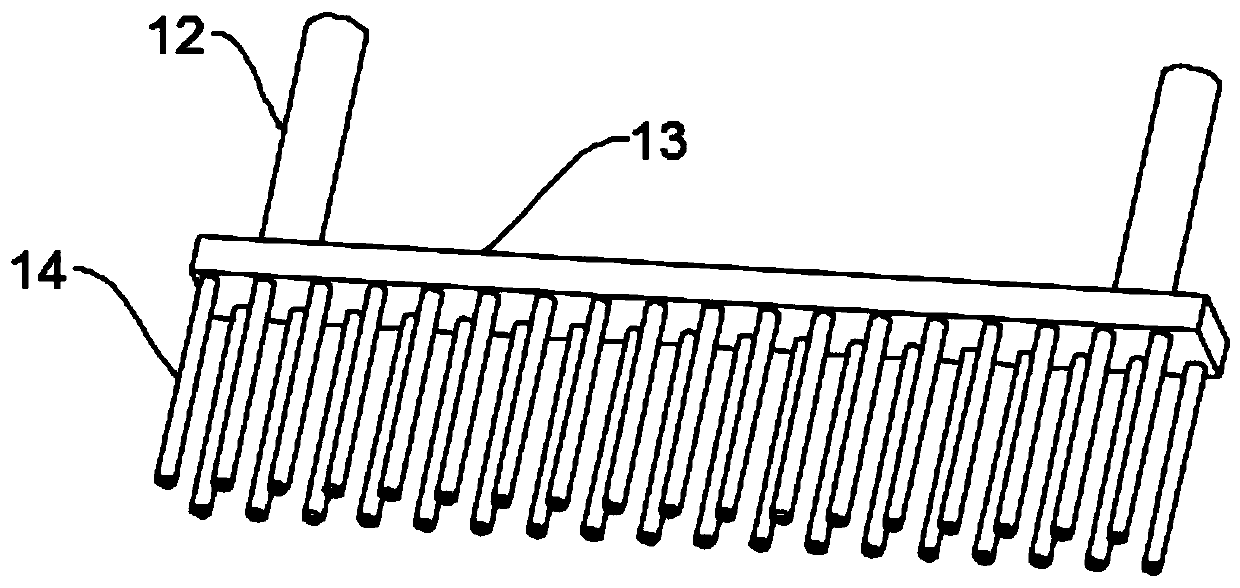

InactiveCN111389699AAvoid cloggingDischarge in timeSievingScreeningAgricultural engineeringStructural engineering

The invention discloses a rice impurity removing device for processing rice flour. The device comprises an impurity removing box body, wherein a baffle is arranged in the impurity removing box body, the baffle divides the interior of the impurity removing box body into a material collecting groove and an impurity collecting groove, a screening arc-shaped mesh plate is arranged in the material collecting groove, and a side plate and a cover plate are respectively arranged at two end parts of the screening arc-shaped mesh plate; and the cover plate covers an opening at the top end of the impurity collecting groove, the end part, close to the screening arc-shaped mesh plate, of the impurity collecting groove is hinged to the top of the baffle, the top of the side plate is provided with a toggle frame, the toggle frame is provided with a toggle rod shaft coaxial with the screening arc-shaped mesh plate, a dispersing assembly for stirring rice in the screening arc-shaped mesh plate is fixedon the toggle rod shaft, and a push-pull mechanism for pushing the cover plate to rotate around the end part of the cover plate is arranged on the upper part of the cover plate. According to the riceimpurity removing device, the structure is simple, materials are conveniently dispersed to improve the screening effect, impurities are timely discharged to avoid blockage, the operation is convenient, and the practicability is strong.

Owner:汕头市双捷金雀食品有限公司

Automatic vacuum spraying process method

InactiveCN110917938AFor quick cleanupEasy to cleanFeeding-stuffRotary stirring mixersProcess engineeringSlurry

The invention discloses an automatic vacuum spraying process method in the field of food, pet food and aquatic feed processing. The automatic vacuum spraying process method comprises the following steps: self-inspection: carrying out self-inspection resetting on a weighing sensor of material adding equipment; feeding: adding material particles into a mixing cavity through a feeding port; vacuumizing: opening a butterfly valve connected with a vacuumizing pipe, starting a vacuum pump, and vacuumizing the interior of the mixing cavity; spraying: spraying grease to the material particles in the mixing cavity through a first nozzle assembly; vacuum release: enabling air to enter the mixing cavity by adjusting the opening degree of a pressure release valve; normal-pressure slurry spray / powderspraying: spraying a pasty phagostimulant on the surfaces of the material particles in the mixing cavity through a second nozzle assembly, or adding a powdery phagostimulant into the mixing cavity through the feeding port; discharging: continuously rotating the stirring shaft, opening a discharge door, and discharging; and continuing self-inspection and feeding, and starting the next cycle. Vacuumspraying can be completed quickly and efficiently, and the spraying efficiency is higher.

Owner:远腾自动化设备(扬州)有限公司

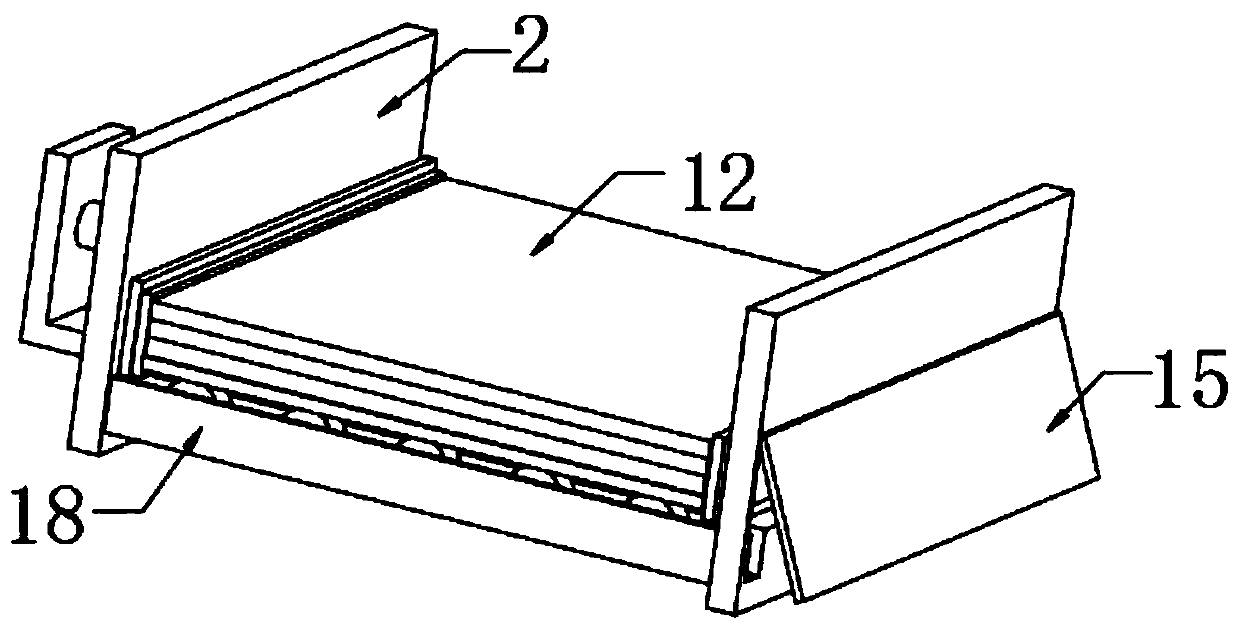

Airing device with material reversing function for agricultural and sideline product processing

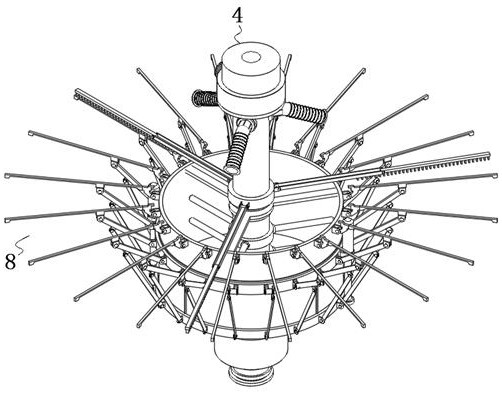

InactiveCN112212665ADrying in all directionsQuick storageDrying gas arrangementsDrying chambers/containersAgricultural scienceAgricultural engineering

The invention discloses an airing device with a material reversing function for agricultural and sideline product processing, and relates to the technical field of agricultural and sideline product processing. The airing device comprises a carrying platform; a storage tank is fixedly mounted on the surface of the carrying platform; the inner wall of the storage tank is rotationally connected witha material reversing mechanism through a bearing; the peripheral side face of the material reversing mechanism fixedly communicates with a group of material discharging assemblies which are distributed in a circumferential array; a hot air generation mechanism fixedly communicates with the top of the material reversing mechanism; a main driving motor is fixedly connected to the peripheral side face of the storage tank; one end of an output shaft of the main driving motor is matched with the material reversing mechanism; and a group of material stirring assemblies distributed in a linear arraymode and a material stirring mechanism are fixedly connected to the peripheral side face of the material reversing mechanism. By arranging an airing mechanism, the airing device is provided with a telescopic folding mechanism, and through the telescopic folding mechanism, on the one hand, the airing device is convenient to rapidly store and unfold; and on the other hand, rapid grain collecting anddischarging can be achieved, and then the automation degree and practicability of the device can be improved.

Owner:蓝健健

Chinese herbal medicine crushing and screening equipment and using method thereof

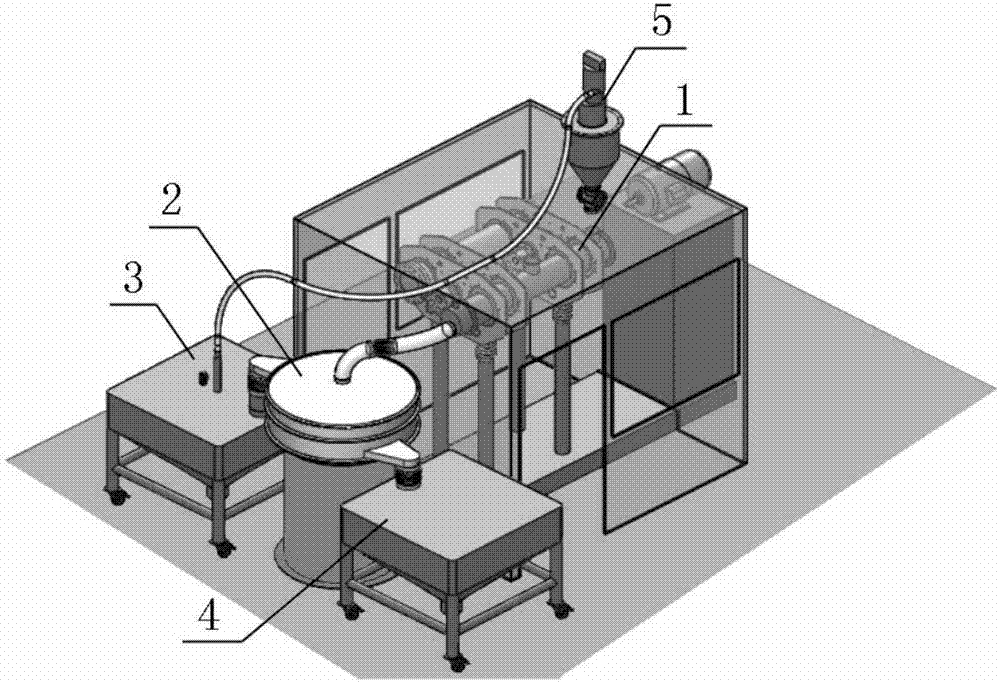

PendingCN107262223AImprove crushing efficiencyIncrease profitSievingScreeningProcess engineeringMechanical engineering

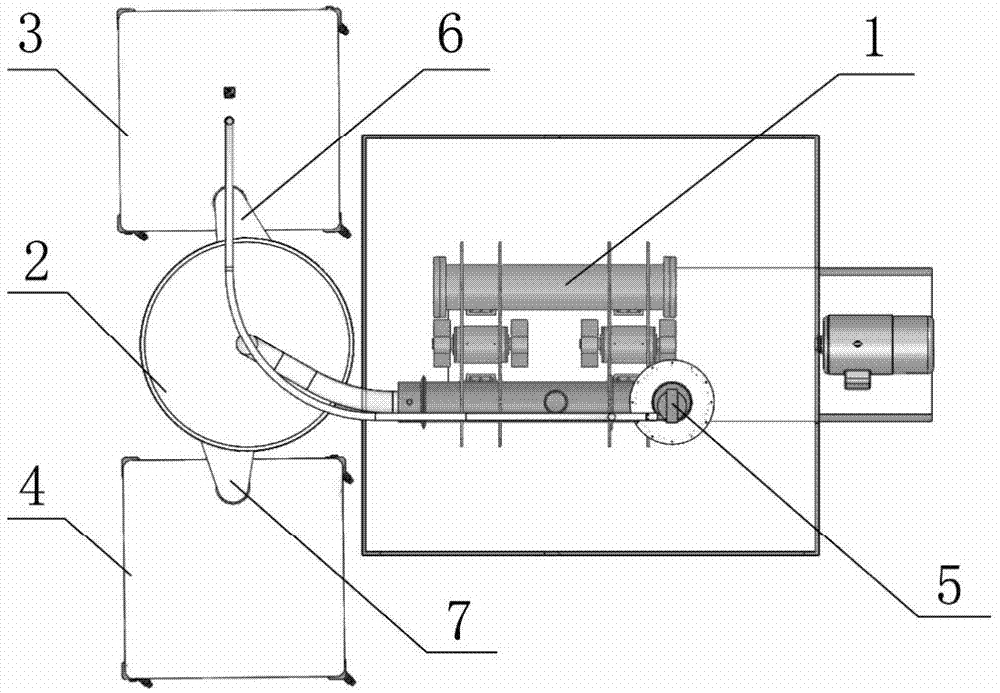

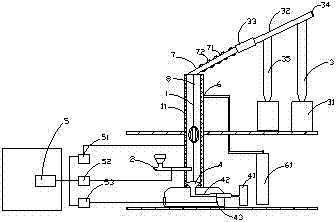

The invention discloses Chinese herbal medicine crushing and screening equipment and a using method thereof. The Chinese herbal medicine crushing and screening equipment is mainly composed of a vibrating mill 1, an ultrasonic vibrating screen 2, a coarse material circulating stock bin 3, a fine material circulating stock bin 4 and a vacuum feeder 5. The Chinese herbal medicine crushing and screening equipment is characterized in that an upper discharging outlet 6 of the ultrasonic vibrating screen 2 keeps closed soft connection with the coarse material circulating stock bin 3, a lower discharging outlet 7 of the ultrasonic vibrating screen 2 keeps closed soft connection with the fine material circulating stock bin 4, and the coarse material circulating stock bin 3 keeps closed connection with the vacuum feeder 5 through a vacuum feeding pipe 8. According to the Chinese herbal medicine crushing and screening equipment, design is novel, the structure is scientific, operation is convenient, the defects that Chinese herbal medicines are high in crushing rate, low in screening efficiency, large in dust amount, high in noise and the like can be overcome, full-closed automated continuous operation can be achieved while labor is saved, the pharmaceutical production GMP requirements are met, and a wide application and popularization prospect is achieved.

Owner:LUNAN PHARMA GROUP CORPORATION

Multi-stage stirring device for producing powder coating

PendingCN112588181AAchieve hybridImprove mixing uniformityShaking/oscillating/vibrating mixersTransportation and packagingElectric machineEngineering

The invention discloses a multi-stage stirring device for producing a powder coating, relates to the technical field of powder coatings, and aims to solve the problems of non-uniform mixing and relatively low stirring quality of existing stirring devices. A first stirring rod, a second stirring rod and a third stirring rod are arranged in a multi-stage stirring tank, a first motor is installed onone side of the exterior of the multi-stage stirring tank, the first motor is connected with the first stirring rod through a first belt wheel, the first stirring rod is connected with the second stirring rod through a second belt wheel, the second stirring rod is connected with the third stirring rod through a third belt wheel, second motors are installed on the two sides of the lower end of themulti-stage stirring tank correspondingly, auxiliary stirring mechanisms are installed at one ends of the second motors, and the two auxiliary stirring mechanisms are located on the two sides of the lower end in the multi-stage stirring tank correspondingly.

Owner:ANHUI SUNROAD ENVIRONMENT PROTECTIVE NEW MATERIALS

Discharge gate structure

The invention discloses a discharge gate structure comprising a discharge gate structure main body; the outlet of the discharge gate structure main body is successively provided with an inner grid and an outer grid in the axial direction; the outer grid is connected with the discharge gate structure main body through a bearing so that the outer grid can rotate oppositely with the discharge gate structure main body; the discharge gate structure also comprises an air cylinder which drives the outer grid to rotate so that the lattice bars of the outer grid and the inner grid stagger or overlap to change discharge amount. By means of the discharge gate structure, the uniformity of discharging can be refined and improved.

Owner:LIAONING GREEN AUTOMATION EQUIP

Degerming equipment for rhodiola rosea processing

ActiveCN111481683AAchieve stirring effectImprove sterilization effectLavatory sanitoryHeatRHODIOLA ROSEA ROOTStructural engineering

The invention discloses degerming equipment for rhodiola rosea processing. The degerming equipment comprises a bracket, a degerming tank, a material containing mechanism, a spraying mechanism, a driving mechanism and a steam generator, wherein the material containing mechanism comprises a material containing frame and two material containing assemblies, the material containing frame is arranged inthe degerming tank and rotationally connected with the sterilization tank, the two material containing assemblies are arranged in the material containing frame, and each material containing assemblycomprises a material containing disc rotationally connected with the inner side wall of the material containing frame; the spraying mechanism comprises a steam inlet pipe and an annular steam exhaustpipe, the end of the steam inlet pipe sequentially penetrates through a location hole and the material containing frame and is located between the two material containing discs, the annular steam exhaust pipe is arranged in the positioning block, and the end of the steam inlet pipe is communicated with a plurality of adjusting assemblies; the driving mechanism comprises a connecting shaft and a driving assembly which are coaxially arranged on the material containing disc; and one end, located outside the degerming tank, of the steam inlet pipe is communicated with the steam generator through asteam hose. By arranging the material containing mechanism and the spraying mechanism, steam can be sprayed to materials while the materials are stirred, and the degerming effect is effectively improved.

Owner:西藏天虹科技股份有限责任公司

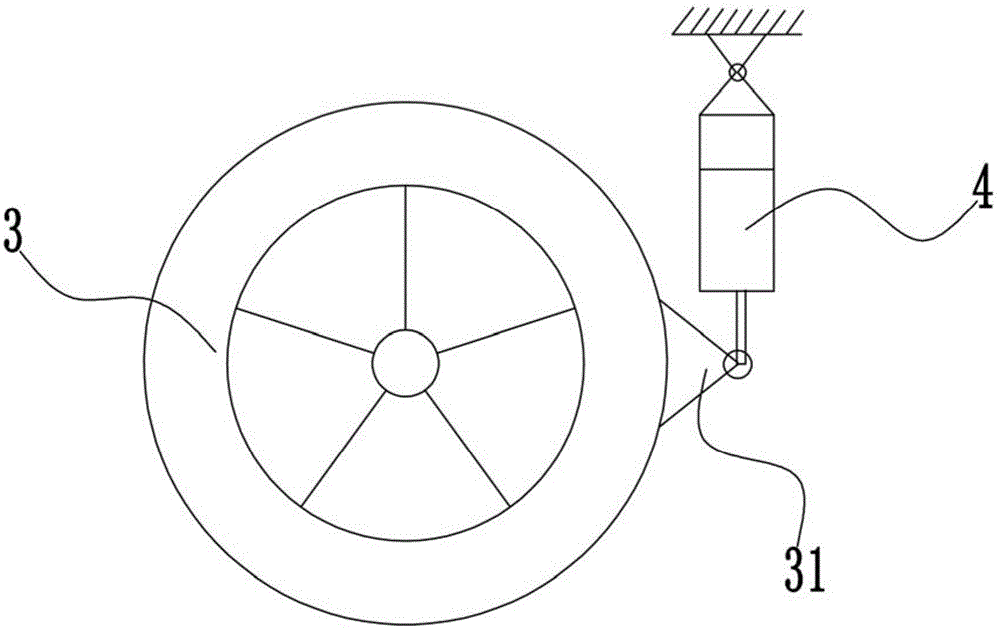

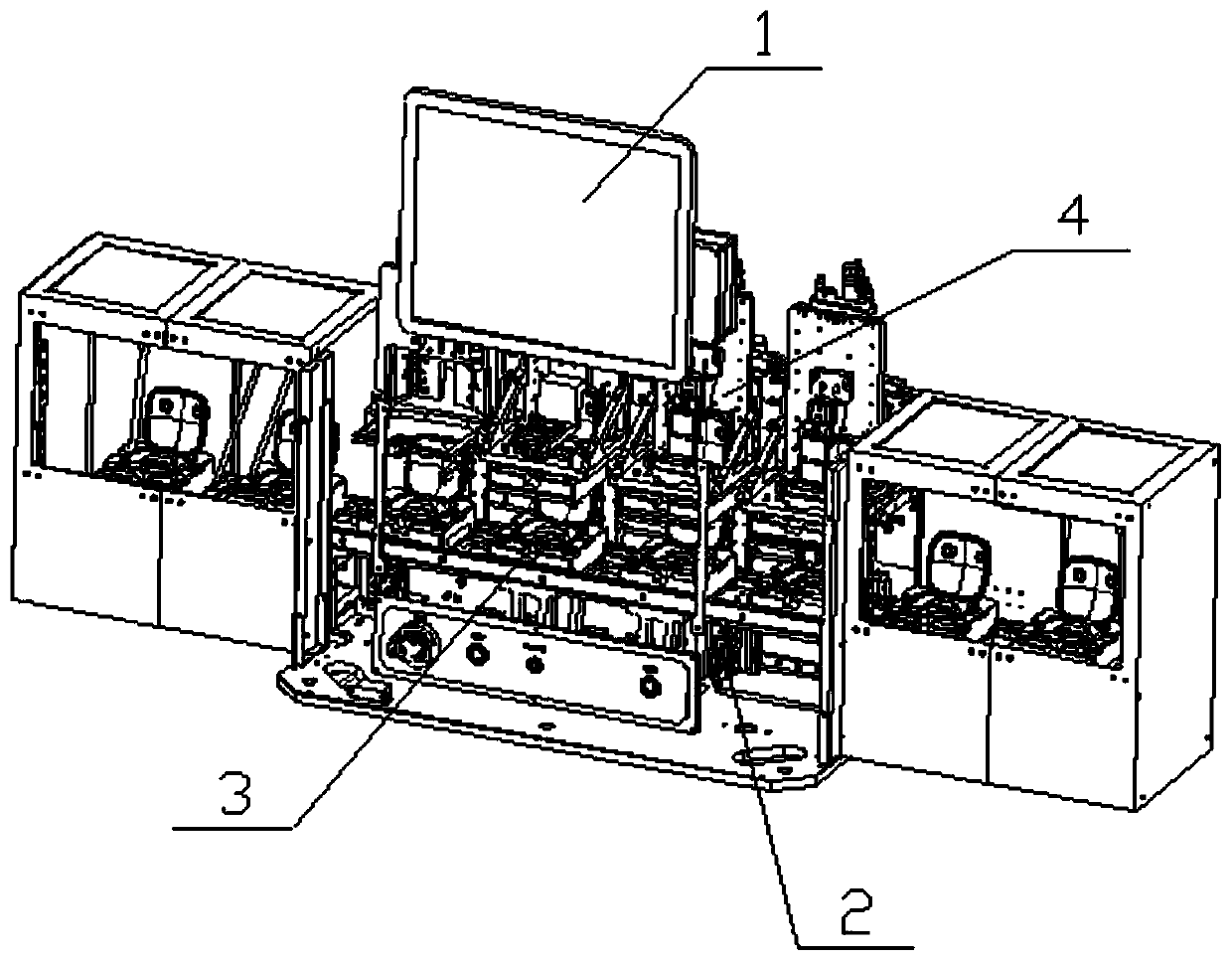

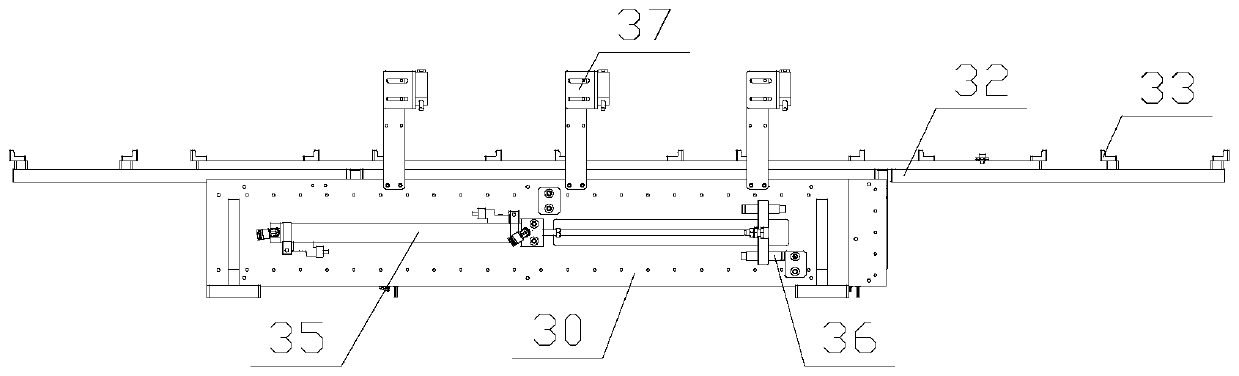

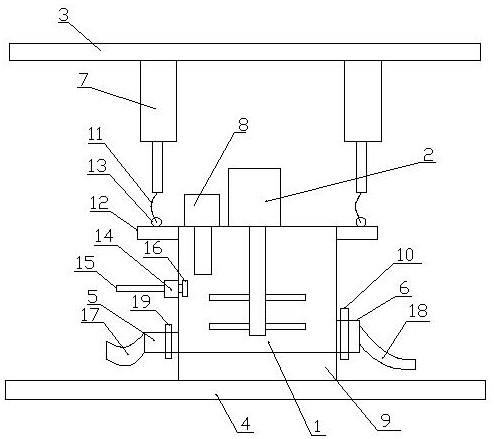

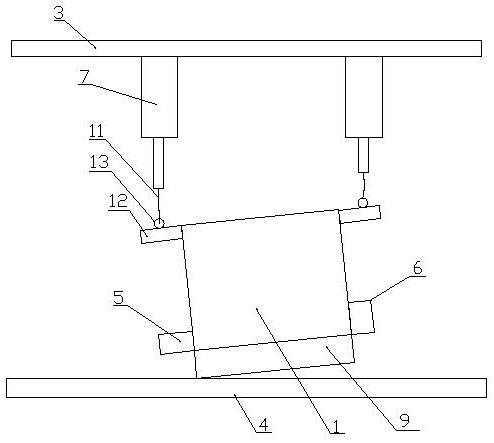

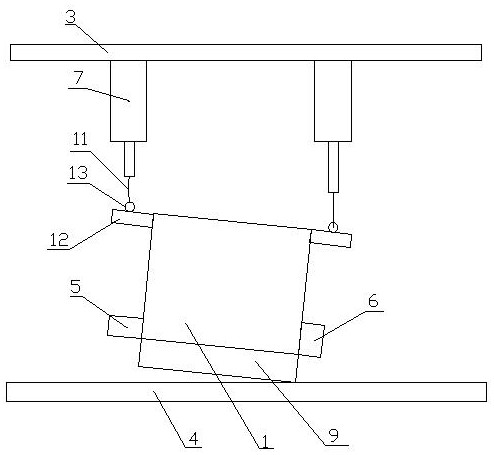

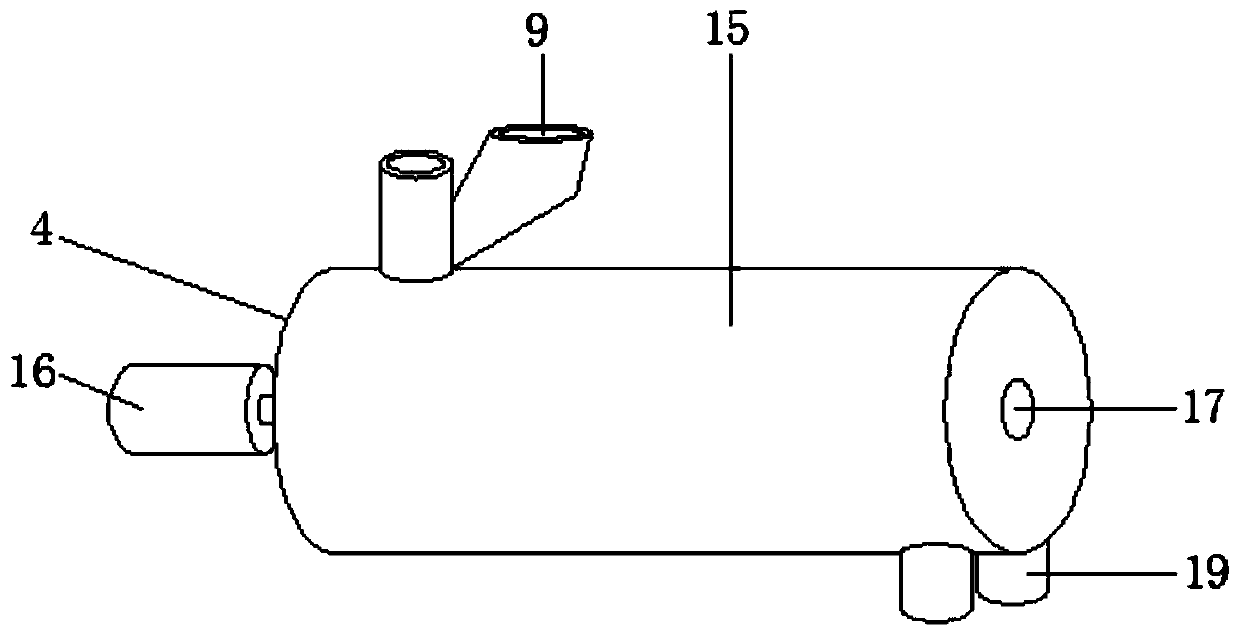

Testing equipment for wireless earphone box

The invention relates to testing equipment for a wireless earphone box. The equipment comprises an underframe, a runner, a carrying mechanism and a testing mechanism, the runner is fixed on the underframe; the carrying mechanism is arranged on the runner; the testing mechanism is arranged on the underframe. Rapid feeding and discharging of a wireless earphone box can be realized through the carrying mechanism, cover opening and closing of the wireless earphone box can be rapidly realized through the detection mechanism, impedance of an indicator light and a charging terminal of the wireless earphone box can be effectively detected, and the detection efficiency and the detection precision are high.

Owner:江苏帝浦拓普智能装备有限公司

Epoxy polyester powder coating production equipment and production process thereof

ActiveCN113321008AAdjustable distanceImprove production nesting effectChemical industryPowdery paintsEpoxyPolyester

The invention discloses epoxy polyester powder coating production equipment and a production process thereof, and relates to the technical field of epoxy polyester powder coating production equipment. The epoxy polyester powder coating production equipment comprises a machine box and a box cover installed on the top of the machine box, the bottom of the machine box is fixedly connected with a discharging pipe, a valve is arranged on the discharging pipe, discharging parts are installed in the machine box, and the discharging parts are connected with the box cover. The epoxy polyester powder coating production equipment is reasonable in structure, by arranging a discharging gap adjusting unit, the distance between the discharging parts is adjusted, the particle size of discharged epoxy polyester powder coating is conveniently adjusted, the production requirements of epoxy polyester powder coating with different requirements are met, and the production cost caused by machining of different equipment is reduced; and by arranging a power transmission unit, reverse simultaneous rotation of the discharging parts is achieved, the discharging effect of production of the epoxy polyester powder coating is improved, the discharging speed of production of the epoxy polyester powder coating is increased, and the practicability is good.

Owner:肇庆市大雄岭新材料有限公司

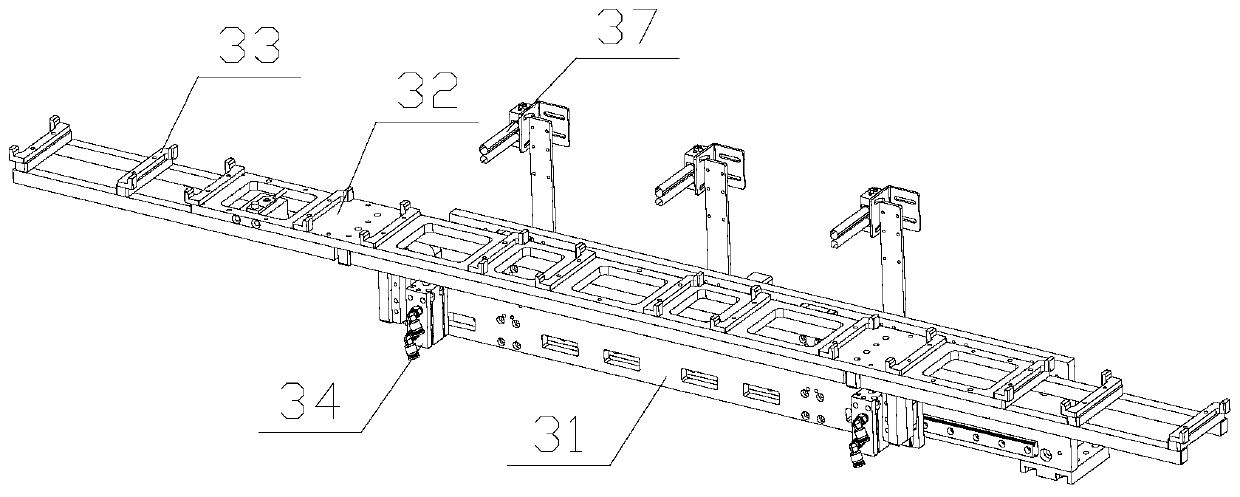

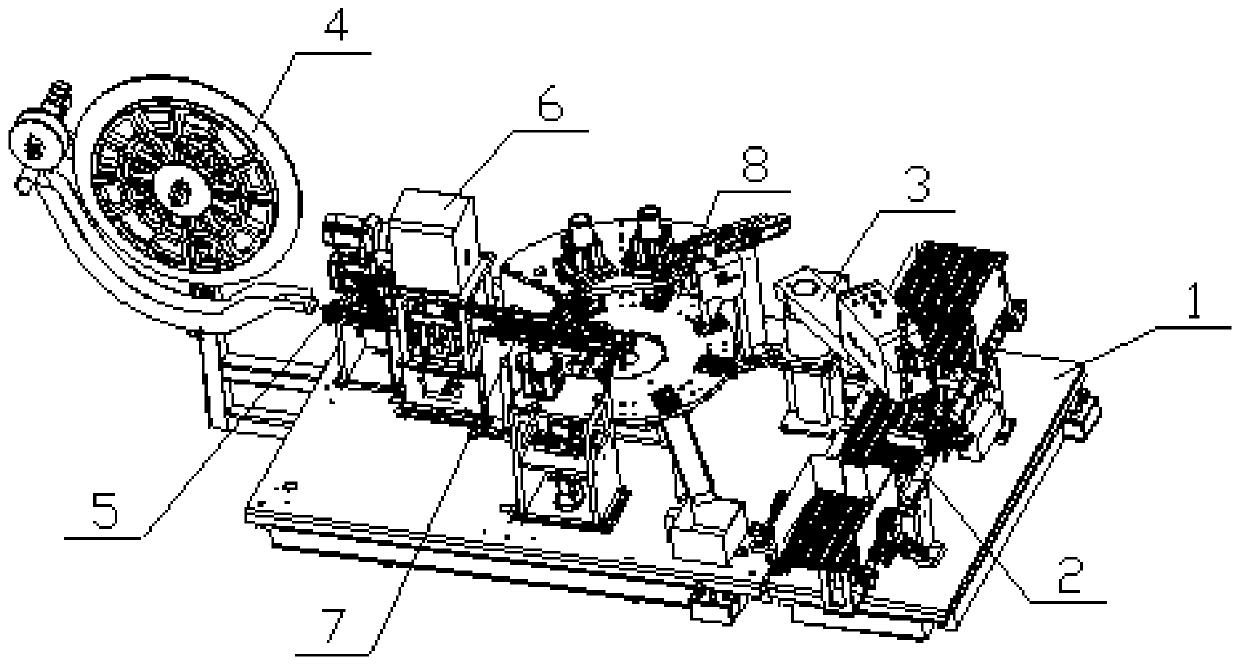

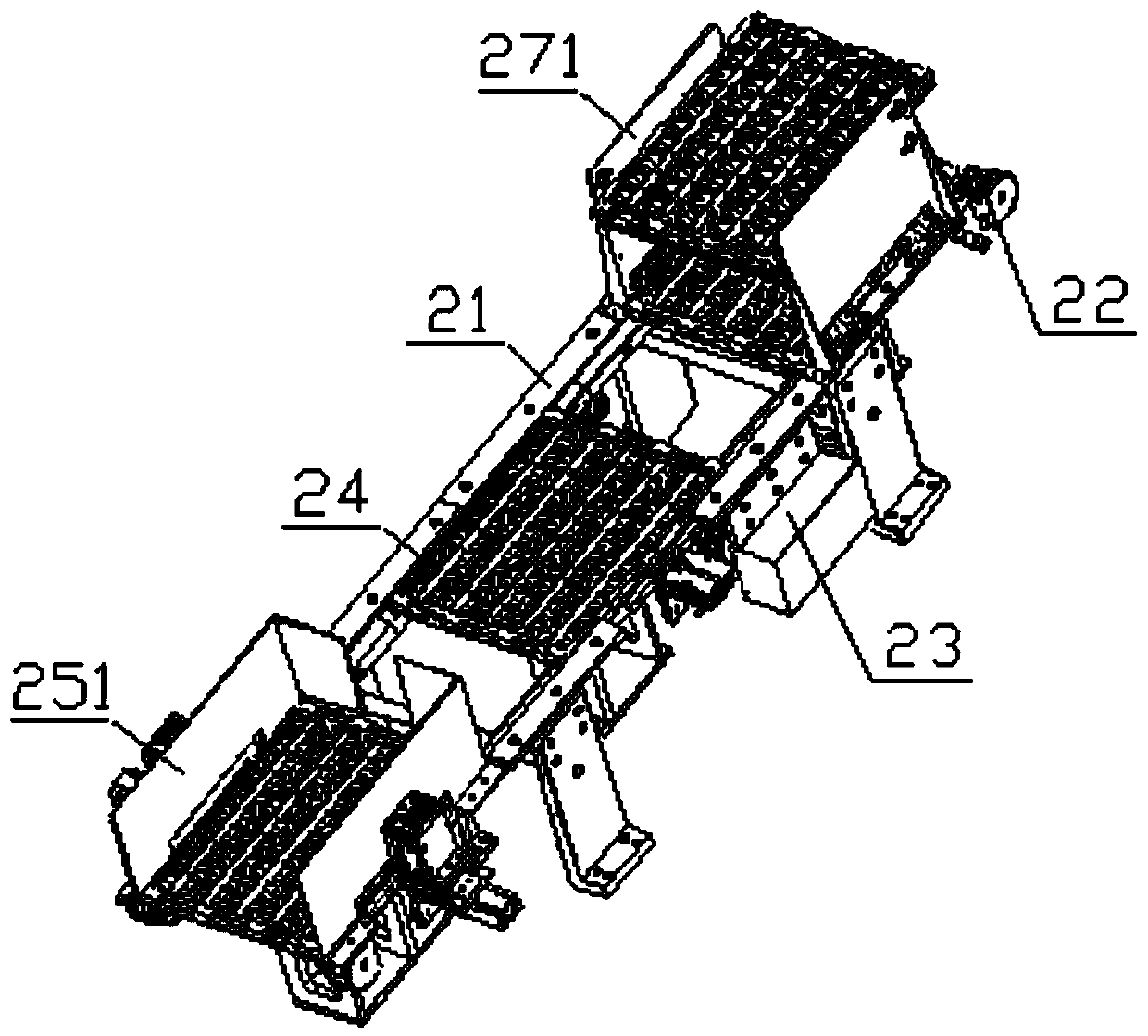

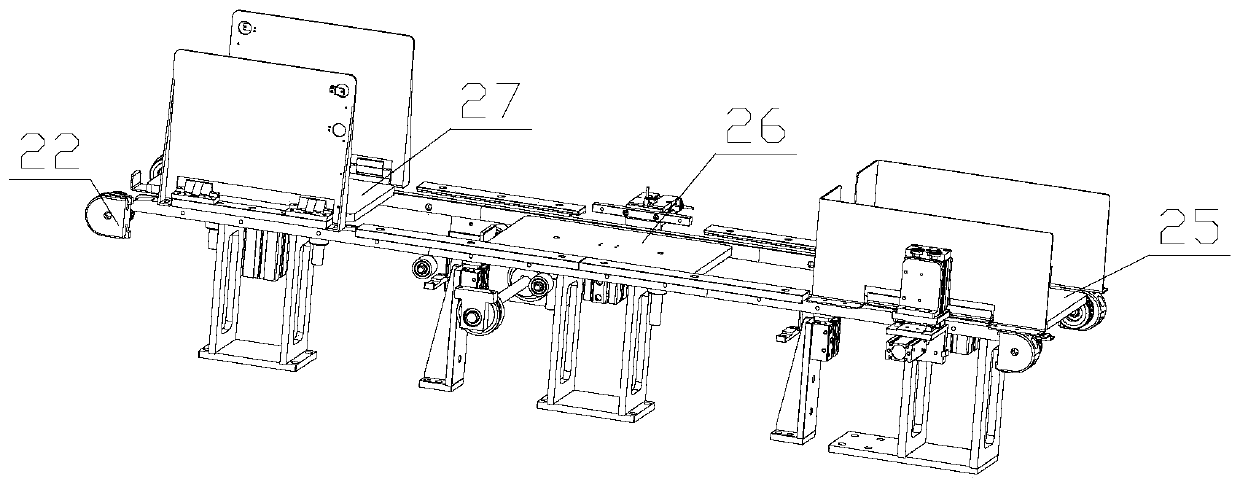

High-speed backboard connector backboard assembling equipment and assembling process

PendingCN110783795AFast loading and unloadingSmall footprintContact member assembly/disassemblyBackplaneStructural engineering

The invention relates to high-speed backboard connector backboard assembling equipment and an assembling process. The high-speed backboard connector backboard assembling equipment comprises a bottom plate, a feeding and discharging mechanism, a moving mechanism, a material roll, a feeding mechanism, a cutting mechanism, a carrying mechanism and an assembling mechanism. By using the high-speed backboard connector backboard assembling equipment and the assembling process, through cooperation of the feeding and discharging mechanism and the moving mechanism, rapid feeding and discharging of products can be achieved, and an occupied space is small; through cooperation of the feeding mechanism and the cutting mechanism, accurate feeding and rapid cutting of a material belt can be achieved, cutting precision is high, and quality of material sheets is good; through the carrying mechanism, accurate assembling of the material sheet and a plastic shell can be achieved, and the material sheet canbe prevented from being separated from the plastic shell through pre-pressing; and through the assembling mechanism, the material sheet and the plastic shell can be fixed together, two sides of thematerial sheet can be pressed downwards, and edge warping is prevented.

Owner:昆山三智达自动化设备科技有限公司

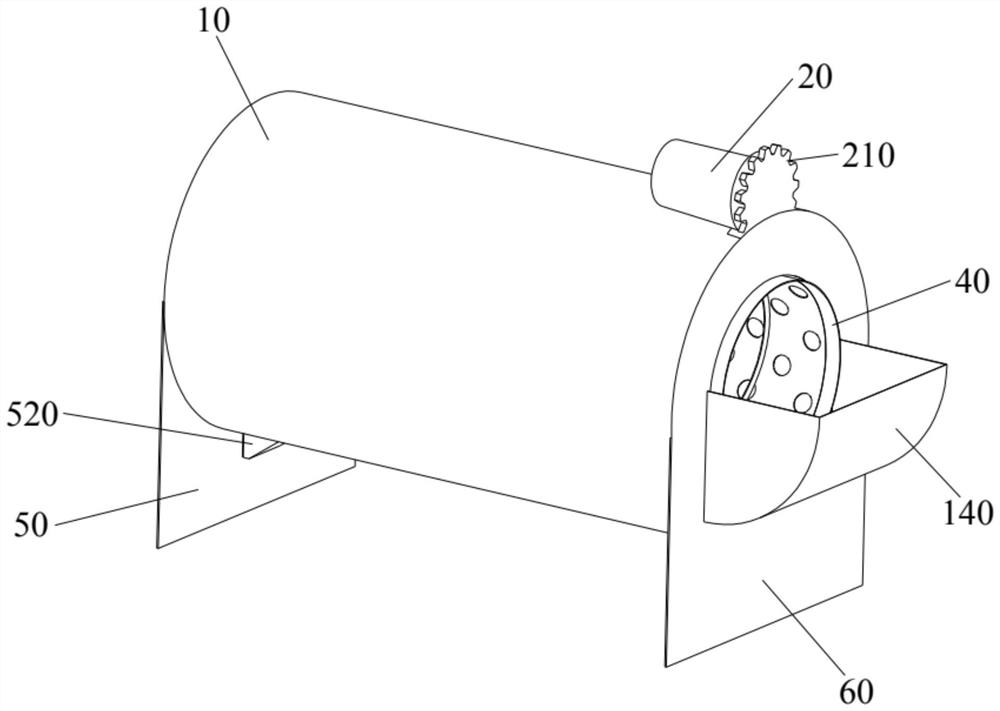

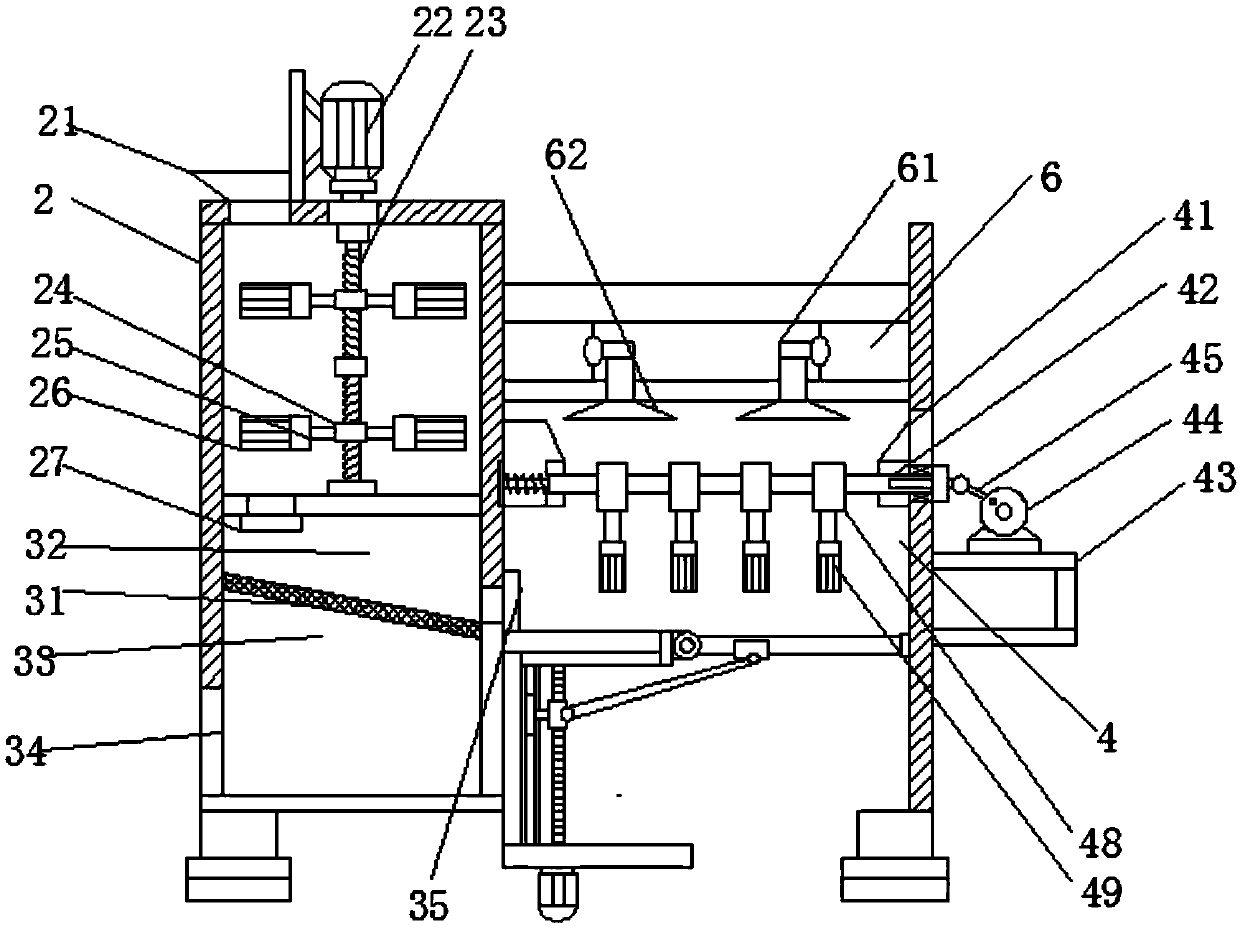

Camellia oleifera fruit drying and screening device

PendingCN114160404AAchieve dryingRealize overturn heatingSievingScreeningCamellia oleiferaSpiral blade

The invention provides a camellia oleifera fruit drying and screening device. The camellia oleifera fruit drying and screening device comprises a shell, a driving assembly, a first cylinder rotationally arranged in the shell and a second cylinder fixedly connected to the interior of the first cylinder. Wherein a first air inlet connector and a first discharging port are formed in the first air inlet end of the shell, a second air inlet connector is formed in the second air inlet end of the first barrel, a second feeding opening is formed in the second feeding end of the first barrel, a second discharging port is further formed in the bottom of the second air inlet end, and a first spiral blade is formed on the inner wall of the first barrel; the opening end of the second barrel is fixedly connected with the second feeding end of the first barrel, a third feeding opening is formed in the opening end of the second barrel, a plurality of screen holes are formed in the circumferential surface of the second barrel, and second spiral blades are formed on the inner wall of the second barrel. The first cylinder body and the second cylinder body are integrated in the shell, drying and screening integration of camellia oleifera fruits is achieved, the structure is compact, stability and reliability are achieved, and efficiency is high.

Owner:HUNAN NONGGUANG AGRI EQUIP CO LTD

Vacuum lead paste mixing machine

InactiveCN113368736ADoes not affect the stateAdaptive operationElectrode manufacturing processesRotary stirring mixersElectric machineryProcess engineering

The invention aims to provide a vacuum lead paste mixing machine, which comprises a paste mixing machine body, wherein a stirring mechanism and a vacuumizing mechanism are arranged on the paste mixing machine body, an upper platform and a lower platform are arranged on the upper side and the lower side of the paste mixing machine body respectively, the paste mixing machine body is placed on the lower platform through a supporting seat, a cleaning outlet and a discharge hole are respectively formed in the left side and the right side of the bottom of the paste mixing machine body, and lifting motors are movably connected to the left side and the right side of the top of the paste mixing machine body, one lifting motor lifts the paste mixing machine to enable the paste mixing machine to incline towards the other side. According to the invention, after paste mixing is completed, the paste mixing machine body can be inclined towards one side of the discharge hole, so that discharging is convenient; and when cleaning is needed after discharging is completed, the paste mixing machine body is inclined towards one side of the cleaning outlet, and the water spraying head sprays water for cleaning, so that water discharging is convenient.

Owner:TIANNENG BATTERY WUHU

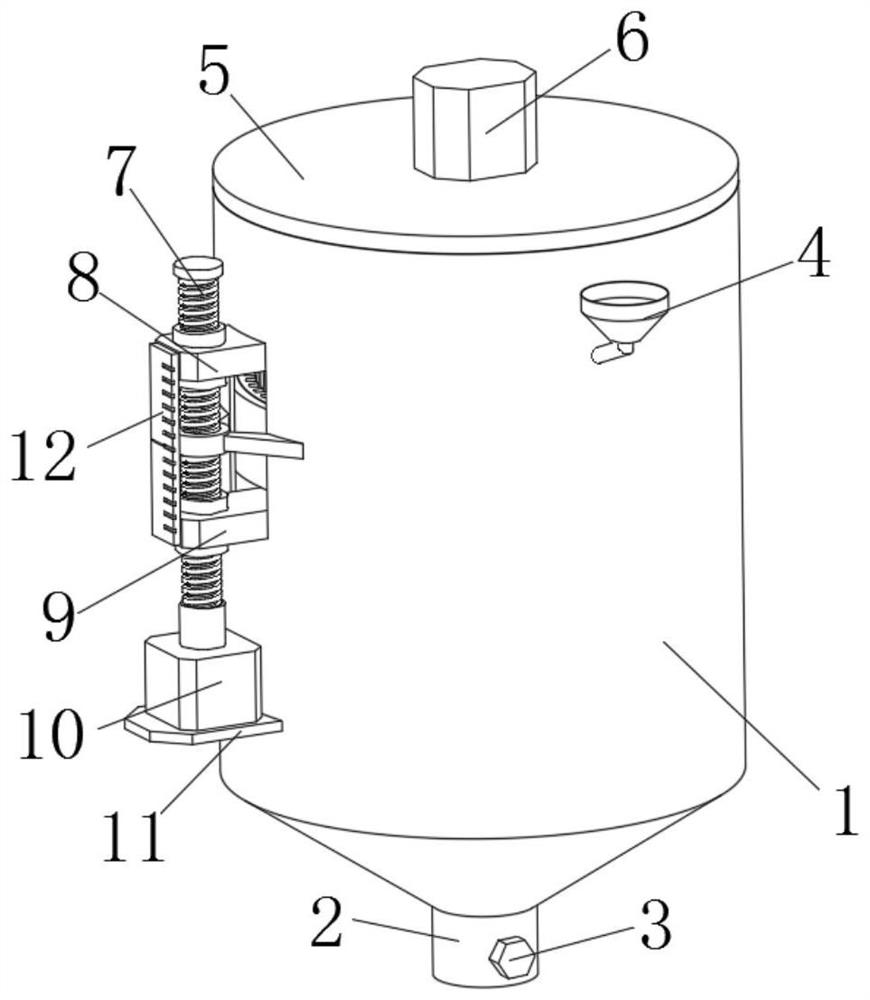

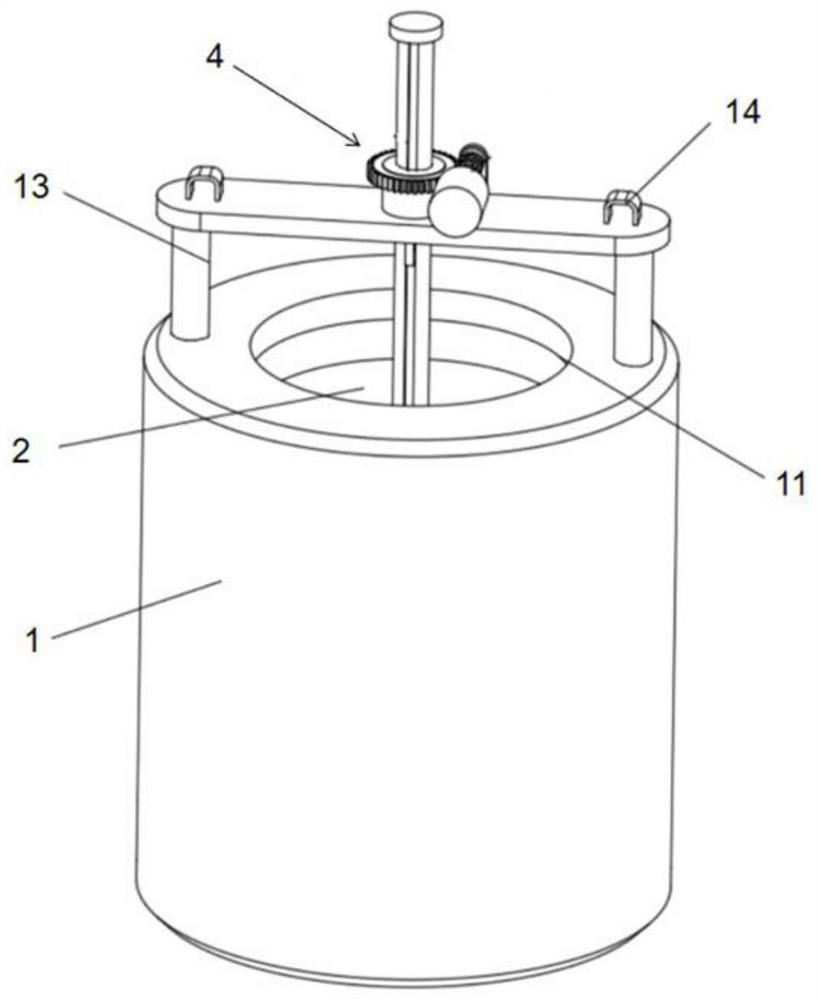

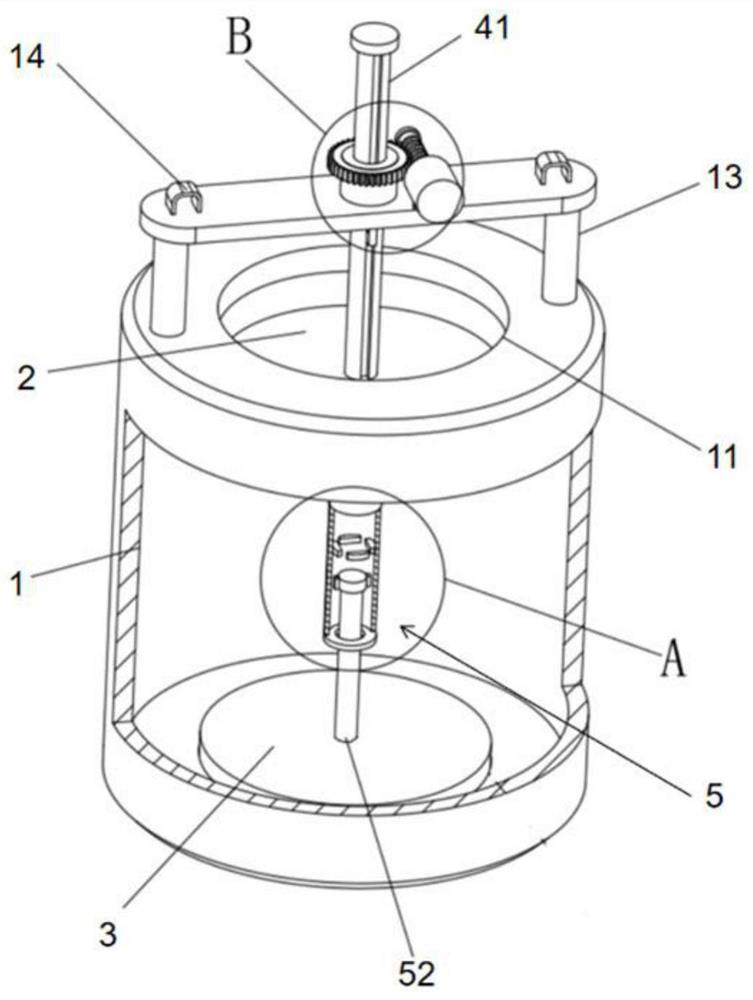

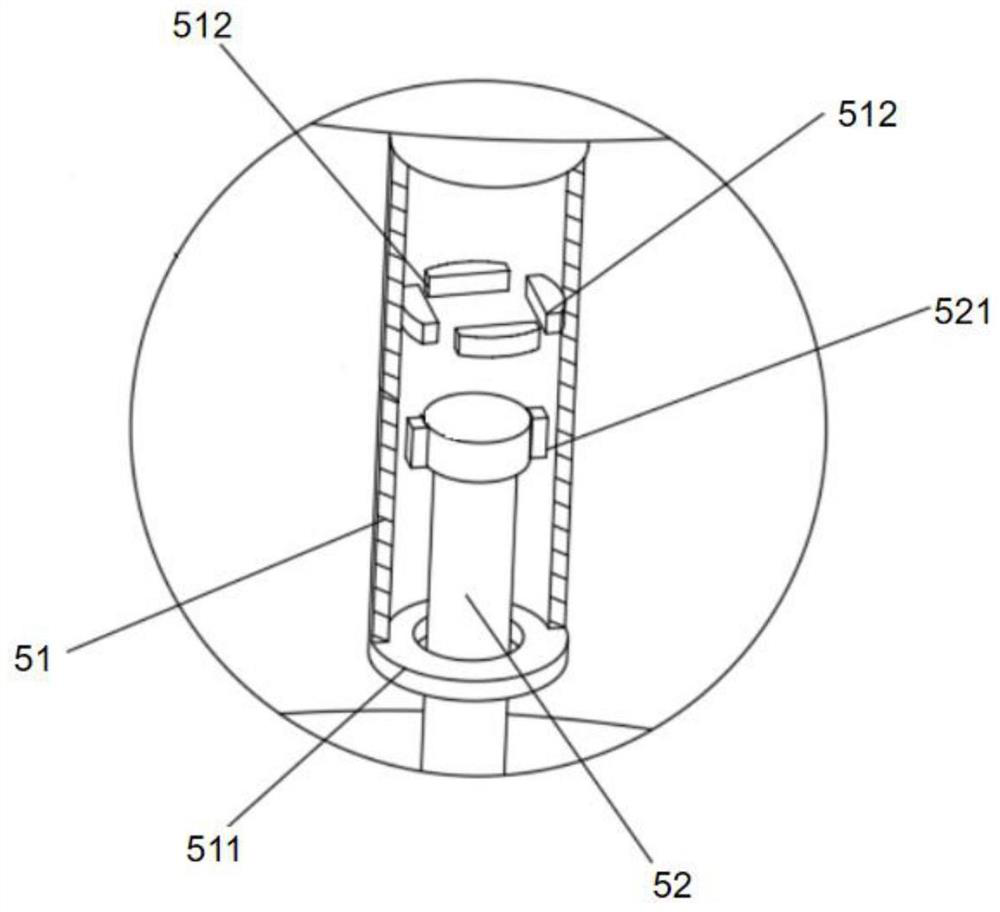

Sewage sampling device

The invention discloses a sewage sampling device which comprises a sampling barrel provided with a material taking opening and a material discharging opening, a first sealing plug used for closing thematerial taking opening, a second sealing plug used for closing the material discharging opening, a first linkage device and a second linkage device, and the first linkage device and the second linkage device are mounted on the sampling barrel; the sampling barrel is connected with the first sealing plug through the first linkage device; the first sealing plug is connected with the second sealingplug through the second linkage device. The device has three working states, wherein the first working state is that the first sealing plug is in sealed connection with the material taking opening and the second sealing plug is in sealed connection with the material discharging opening; the second working state is that the first sealing plug leaves the material taking opening, and the second sealing plug is in sealed connection with the material discharging opening; the third working state is that the first sealing plug leaves the material taking opening, and the second sealing plug leaves the material discharging opening. The sewage sampling device is simple in structure and convenient to operate, rapid sampling and rapid discharging can be achieved, meanwhile, sludge can be fully pouredout, dredging work of the dredging device is more convenient and efficient, and then the sampling efficiency can be effectively improved.

Owner:WUXI HUA YAN WATER

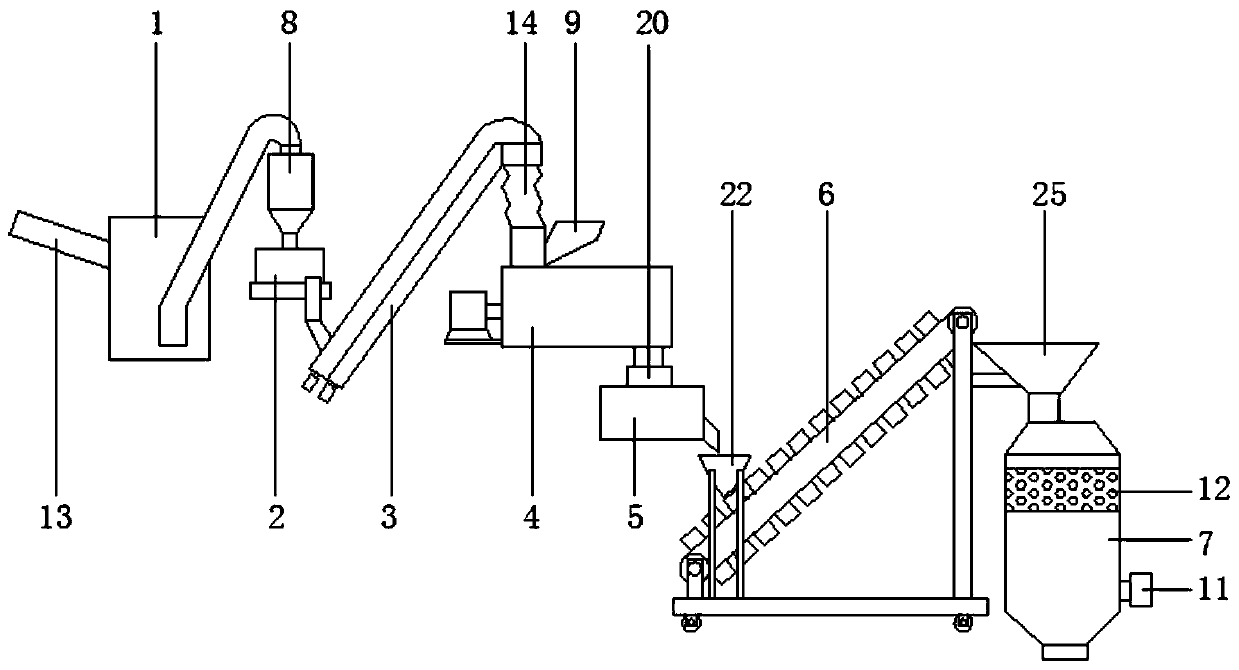

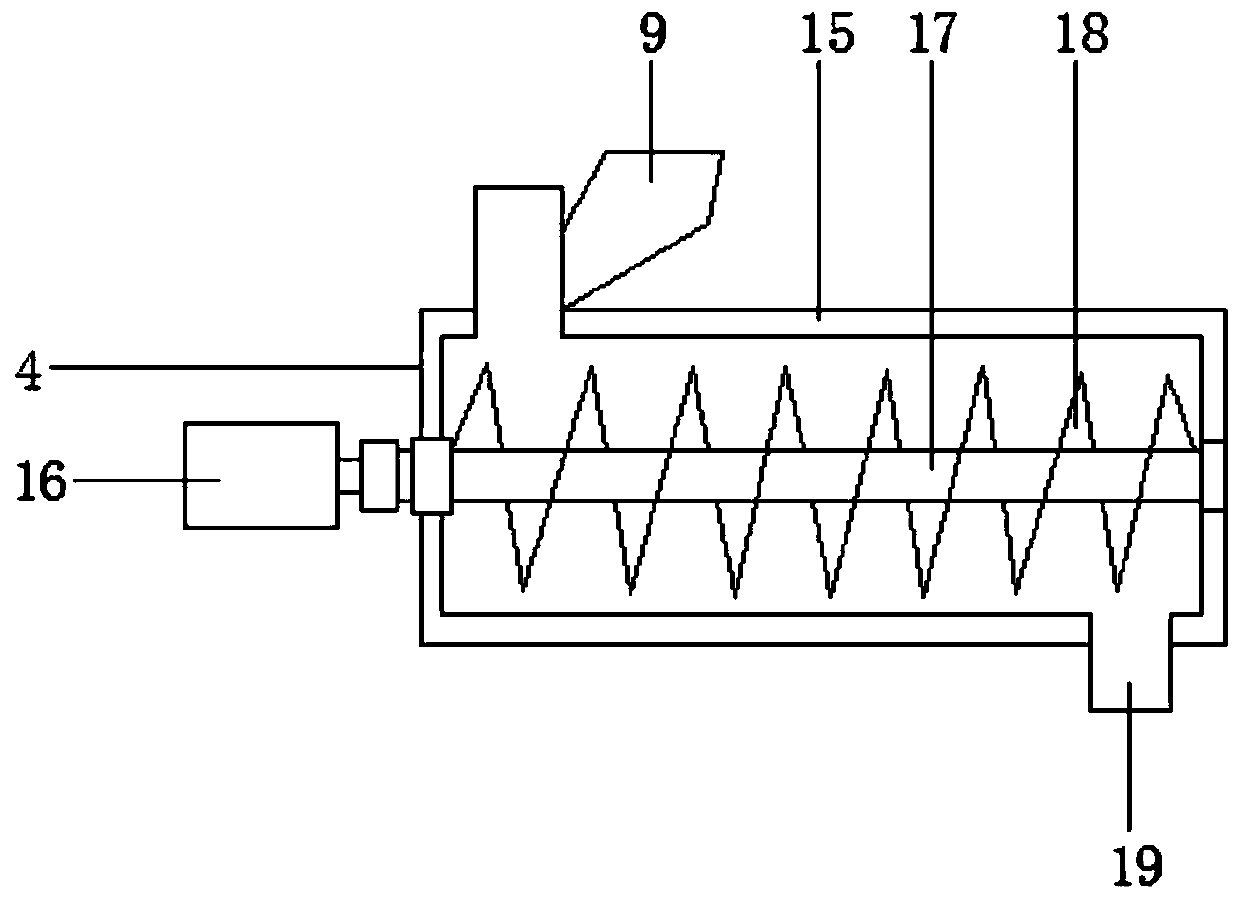

Straw material particle processing equipment

InactiveCN110355187AAvoid discharge blockageQuick NestSolid waste disposalPulverizerDischarge efficiency

The invention relates to straw material particle processing equipment. The straw material particle processing equipment comprises a pulverizer, a secondary crushing device, a conveyor, a stirring buffer cylinder, a granulator, a lifting machine and a cooling screening tower, wherein the pulverizer, the secondary crushing device, the conveyor, the stirring buffer cylinder, the granulator, the lifting machine and the cooling screening tower are sequentially arranged from left to right, the discharge port of the crusher is connected with a buffer hopper through a pipeline, and the bottom end of the buffer hopper communicates with the top end of the secondary crushing device. According to the straw material particle processing equipment, the discharging amount is large, the discharging efficiency can be improved, crushed material particles can be buffered, and meanwhile the dust-proof effect is achieved; due to the arrangement of the secondary crushing device, the crushing is more thorough, and the quality of subsequent granulation is improved; and through the arrangement of the cooling screening tower, countercurrent cooling is adopted, so that the cooling effect and efficiency are improved, screened powder can be recycled, the quality of the particles is guaranteed, straw materials are fully utilized, and the granulating efficiency and the yield are improved.

Owner:王彪

Cleaning and drying equipment for processing melon seeds

InactiveCN108669589ASpeed up the drying processIncrease impactFood treatmentWater filterEngineering

The invention discloses cleaning and drying equipment for processing melon seeds. The equipment comprises a machine compartment, a cleaning cavity, a water filtering cavity, a drying cavity and a discharging cavity are formed in the machine compartment, fixing grooves are formed in the front side wall and the back side wall of an inner cavity of the drying cavity respectively, movable rods are transversely installed in inner cavities of the fixing grooves, a rack is installed on the rear wall of the drying cavity, a driving disc is installed on the rack, a drive rod is connected to the outer disc edge of the driving disc, the rear end of the drive rod penetrates through the side wall of the drying cavity and is connected with the driving disc, a reset spring is installed at the front end of the movable rod, a limiting plate is installed in an inner cavity of the fixing groove in the front side, one end of the reset spring is connected with the movable rod, the other end of the reset spring is fixed to the limiting plate, multiple brushing rods are installed on the movable rod, and distributing brushes are installed at the bottom ends of the brushing rods respectively. According tothe cleaning and drying equipment, through crank connecting rod drive, the distributing brushes are driven to reciprocate in the horizontal direction in cooperation with the reset spring, and therefore the melon seeds are dried at much higher speed.

Owner:何彩萍

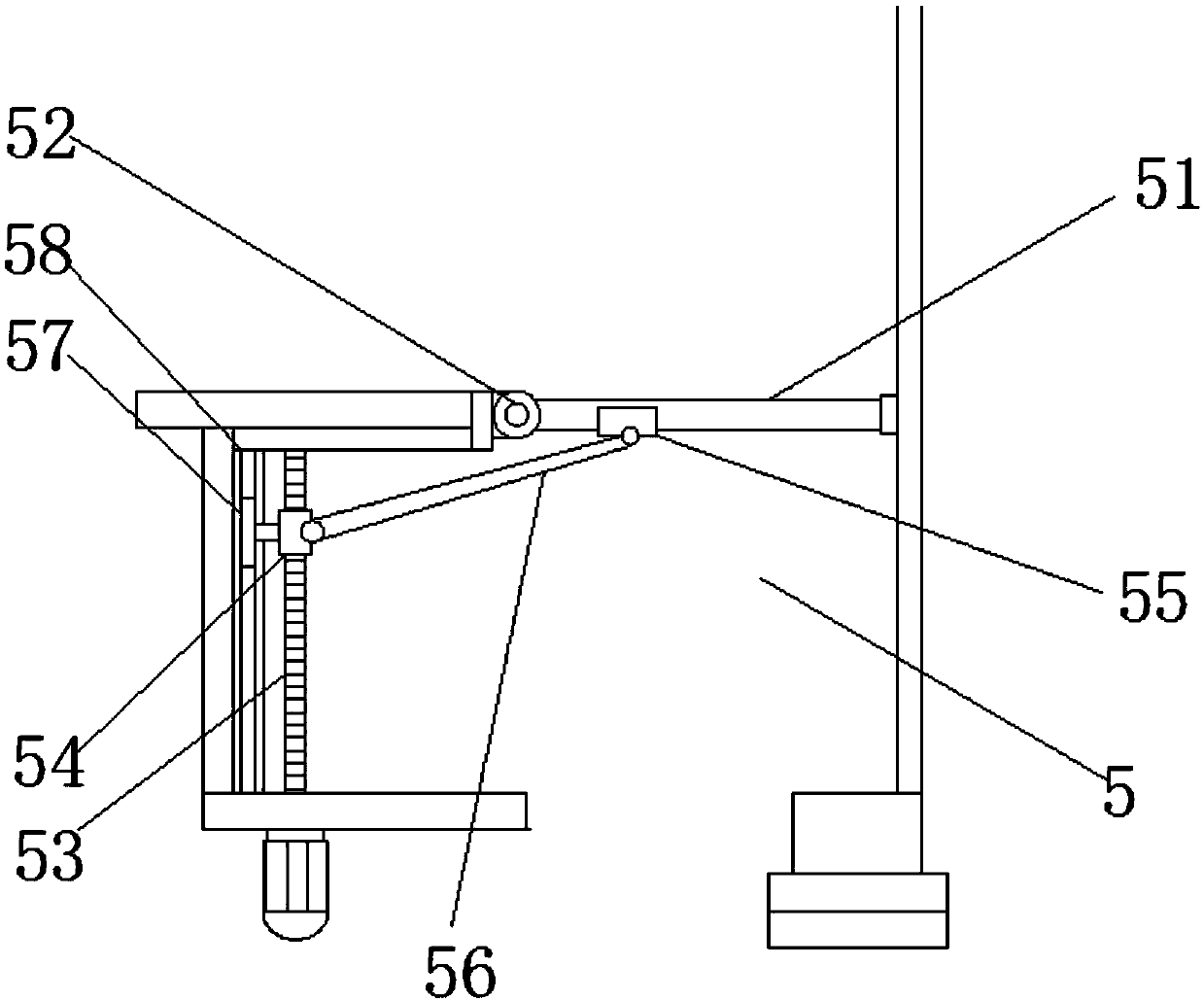

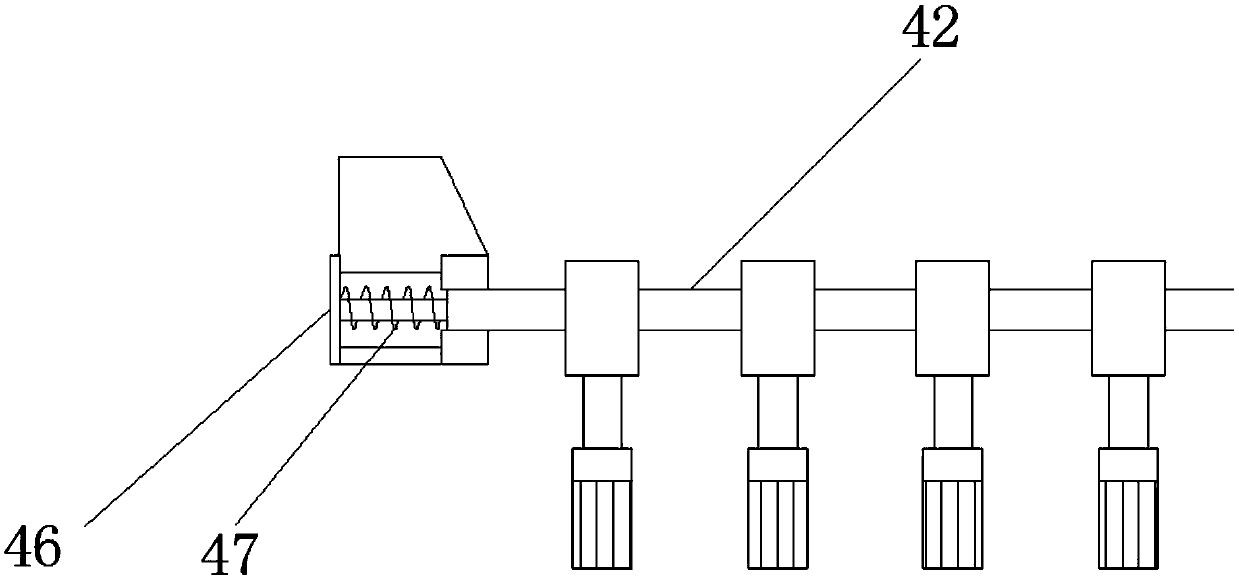

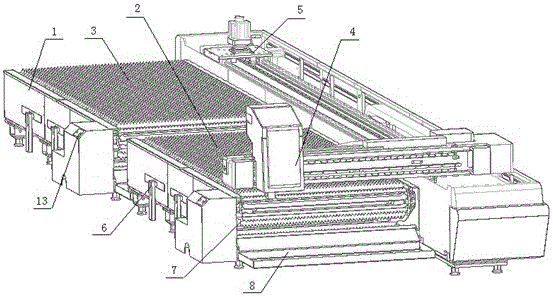

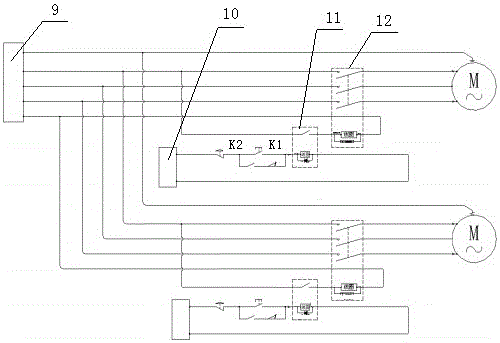

Rotary dual-workbench cantilever type laser cutting machine

InactiveCN105817772AImprove efficiencyFast switching speedLaser beam welding apparatusLaser cuttingEngineering

The invention provides a rotary double-table cantilever laser cutting machine, which includes a frame, a workbench 1, a workbench 2, a laser cutting assembly, a host for longitudinally moving the laser cutting assembly, and workbench 1 and workbench 2. The same and all adopt rotary workbenches. Workbench 1 includes motor, driving roller, driven roller and chain plate conveyor belt. The chain plate conveyor belt surrounds the driving roller and driven roller. The driving roller is connected to the rotating shaft of the motor. The limit switch is connected in series with the motor and power supply in sequence. Side storage boxes are respectively provided on the sides of workbench 1 and workbench 2, and end storage boxes are respectively provided at the ends of workbench 1 and workbench 2. Not only can materials be discharged to the side, It can also discharge to the end face, the discharge is fast and complete, saving time and effort, and flexible application.

Owner:SUZHOU TIANHONG LASER

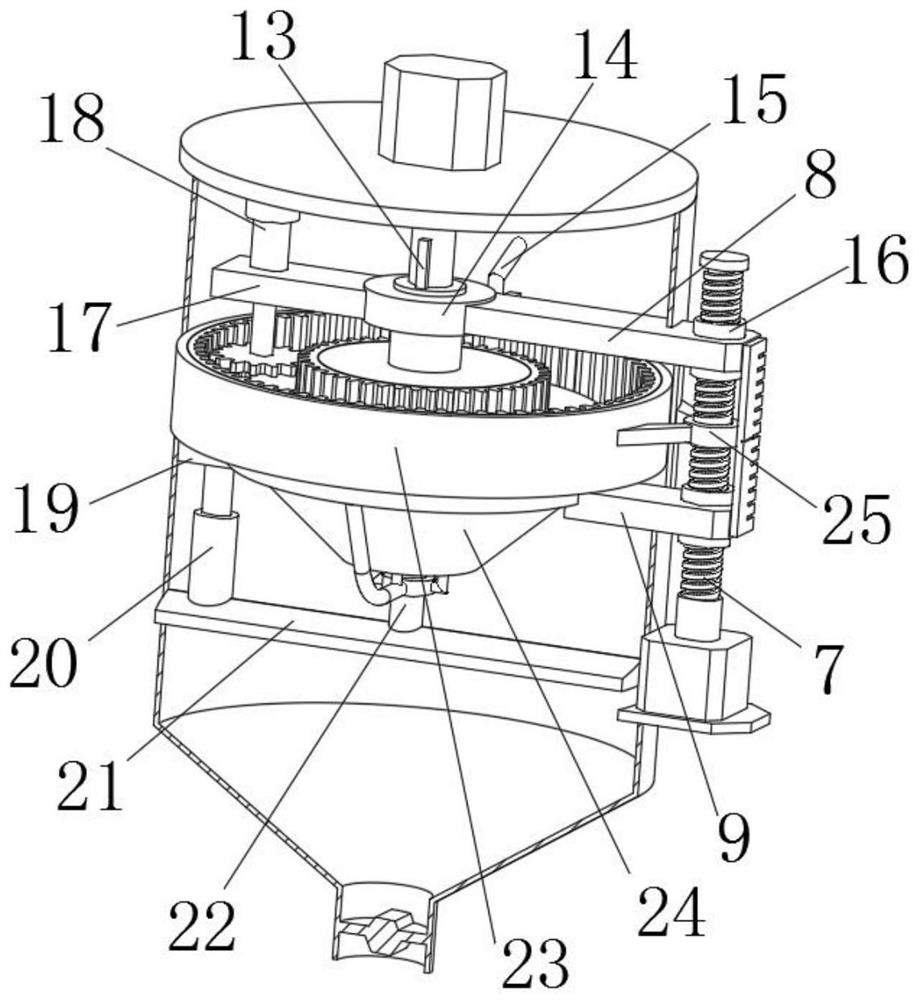

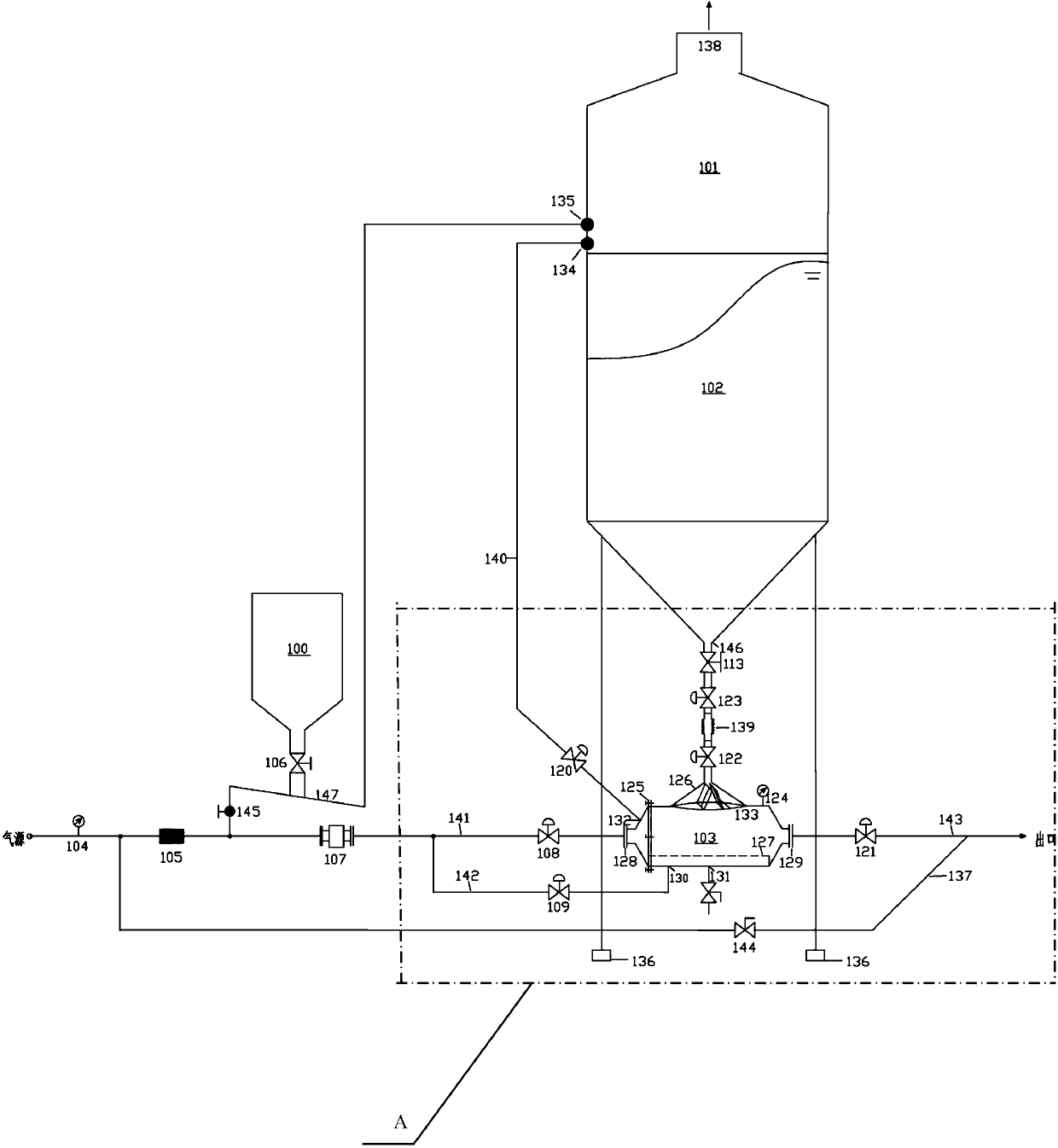

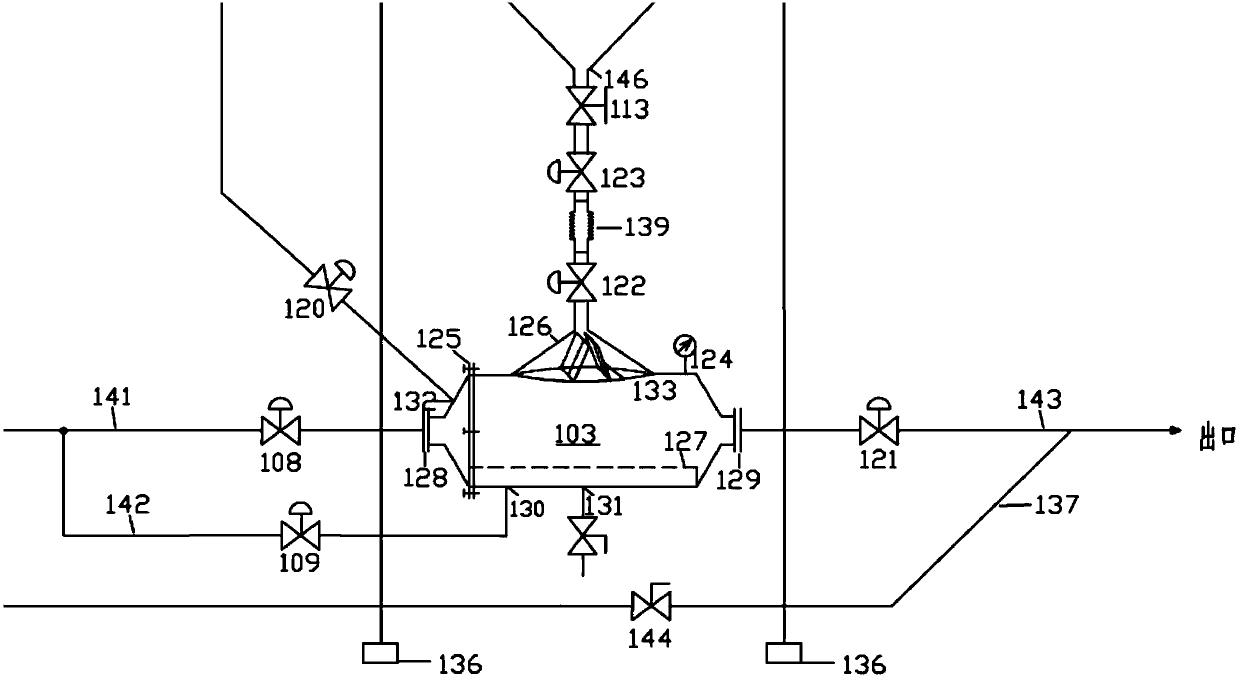

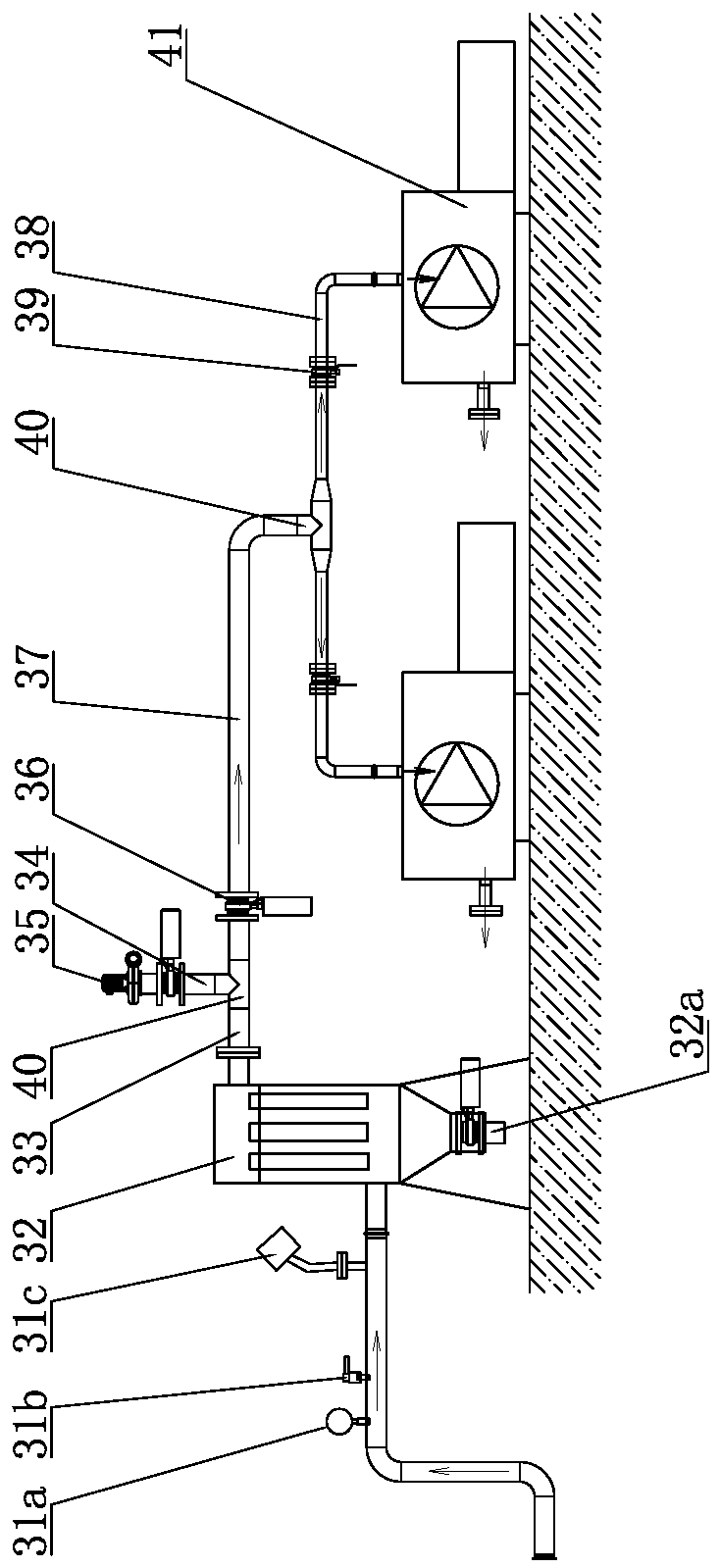

Automatic solid catalytic promoter adding system

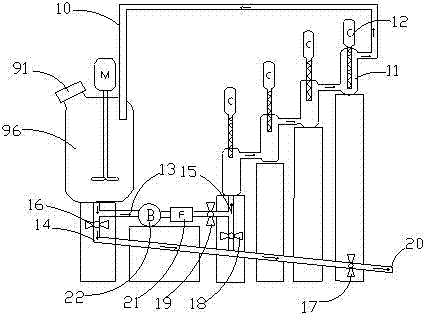

InactiveCN103623751AUniform effectWeight controlCatalytic crackingChemical/physical/physico-chemical processesEngineeringLoad cell

The application of the invention provides an automatic solid catalytic promoter adding system which comprises a catalyst storage tank, a feeding hopper and a fluidization tank, wherein the top of the catalyst storage tank is provided with a gas-solid separation device; an outlet of the gas-solid separation device runs through the top of the catalyst storage tank and extends outside; the top of the gas-solid separation device is provided with an air outlet; the side wall of the catalyst storage tank is provided with a supplementary feeding hole; one end of the supplementary feeding hole is connected with the gas-solid separation device, and the other end of the supplementary feeding hole is connected with an air source by a feed pipe; the feed pipe connected with the air source is provided with a branch pipe connected with the feeding hopper; the feeding hopper is provided with an inlet, and fresh catalysts can enter the feeding hopper through the inlet; the bottom of the catalyst storage tank is provided with a discharge hole which is connected with the fluidization tank by a pipeline; the catalyst storage tank is supported by a plurality of support legs; weighing sensors are arranged at the bottom parts of the support legs. The adding system is small in size, stable in running, safe, reliable and convenient to operate and needs less conveying air; particularly, due to the design of the fluidization tank, the automatic solid catalytic promoter adding system is high in fluidization efficiency and ensures complete and thorough emptying.

Owner:CESTOIL ENVIRO CO LTD

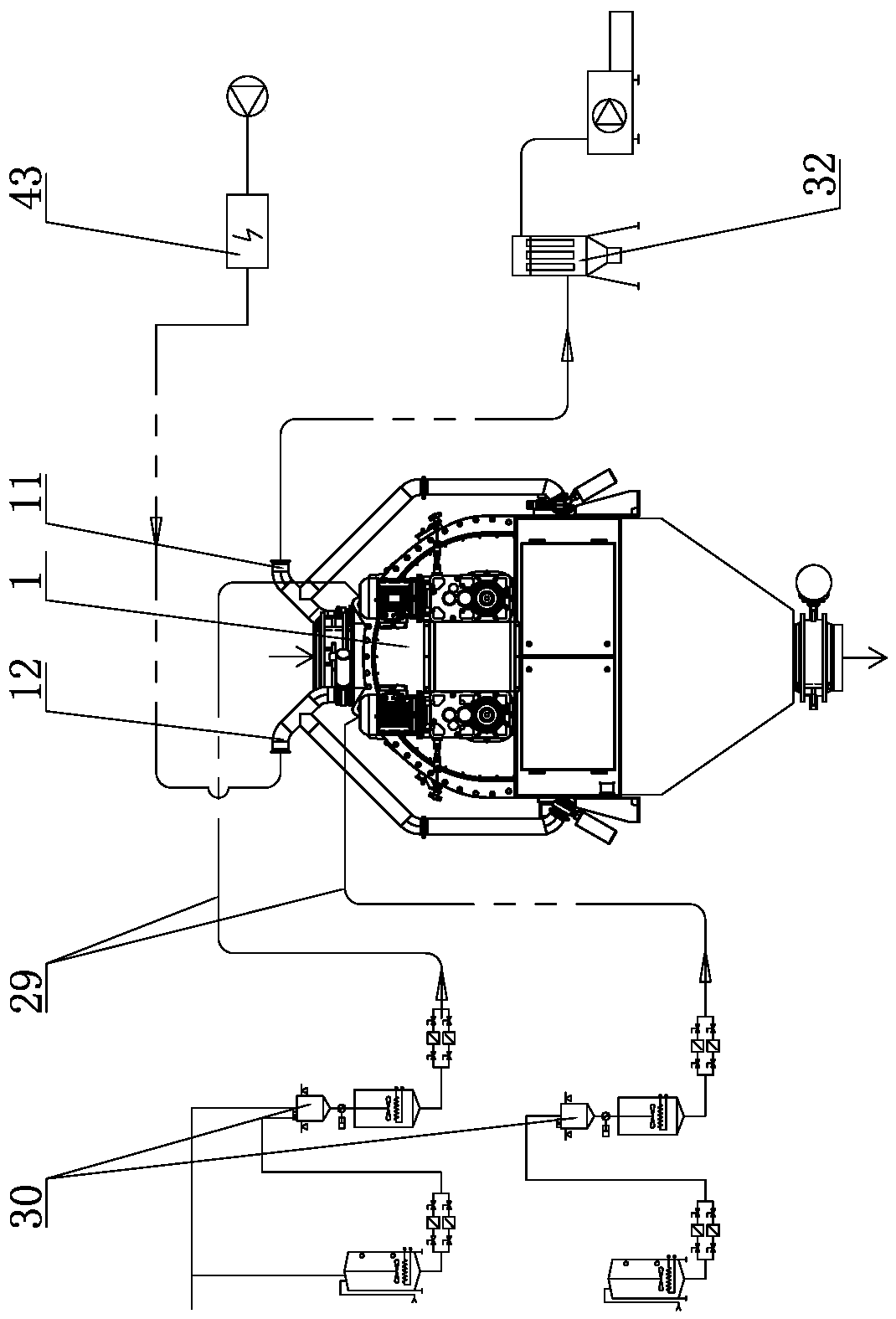

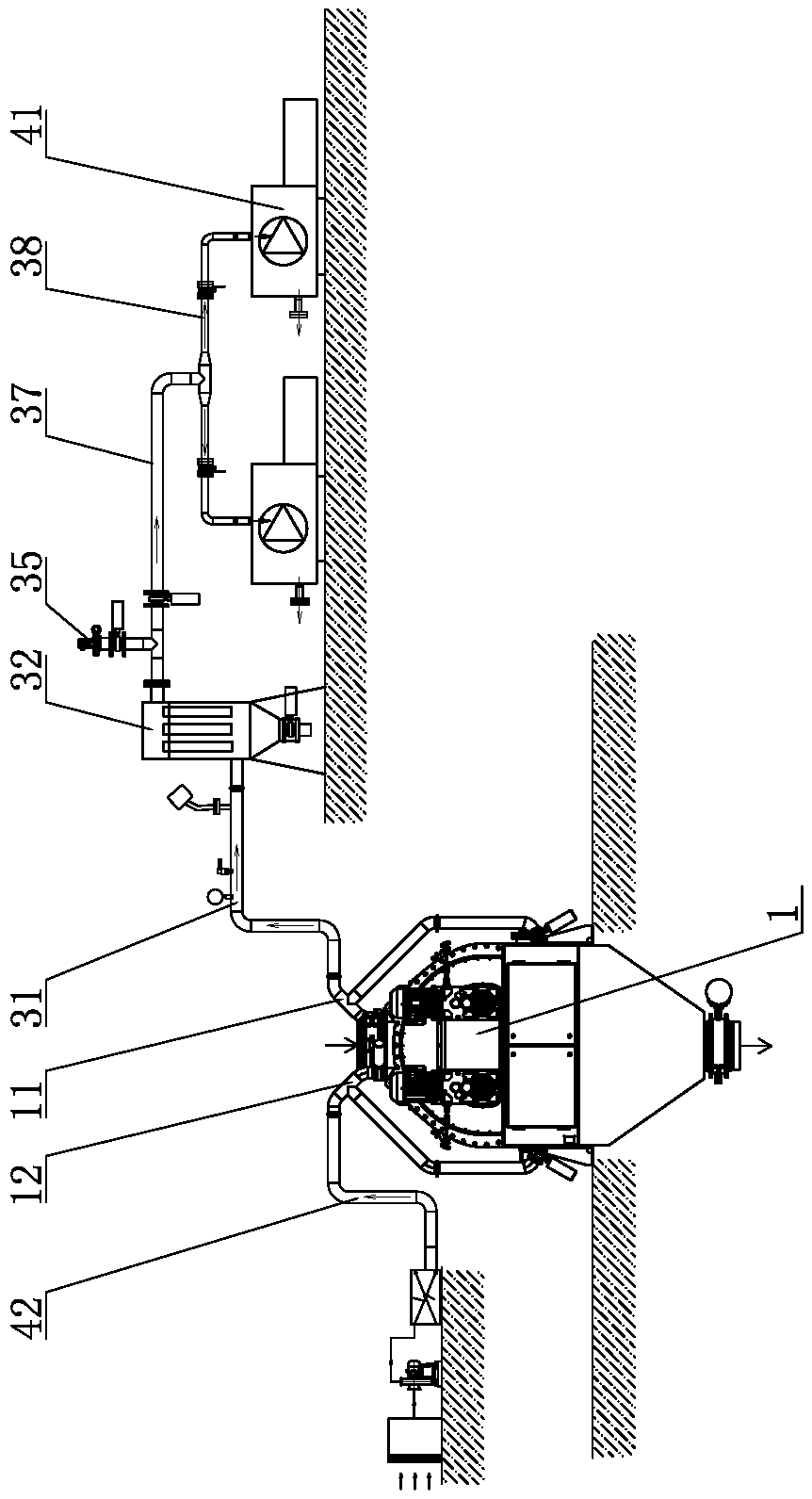

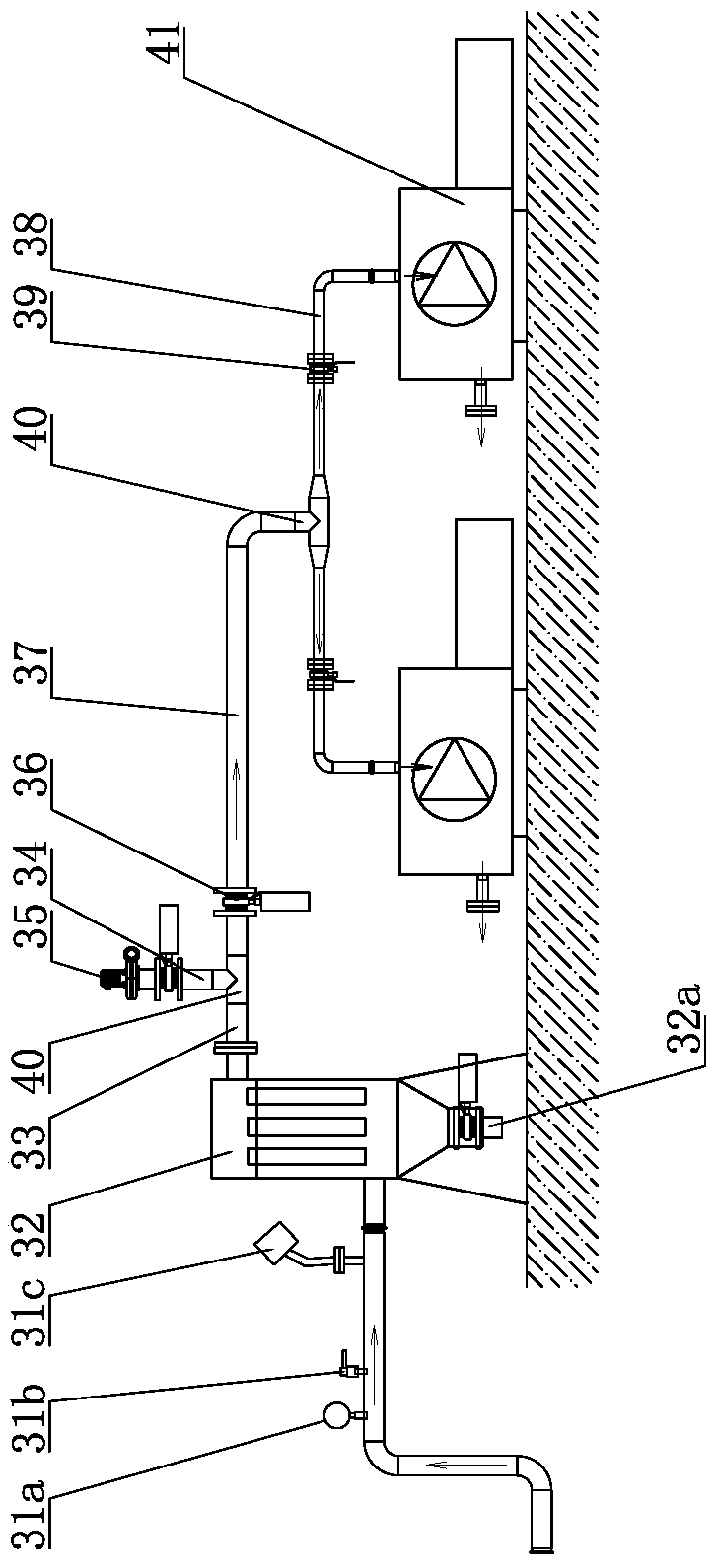

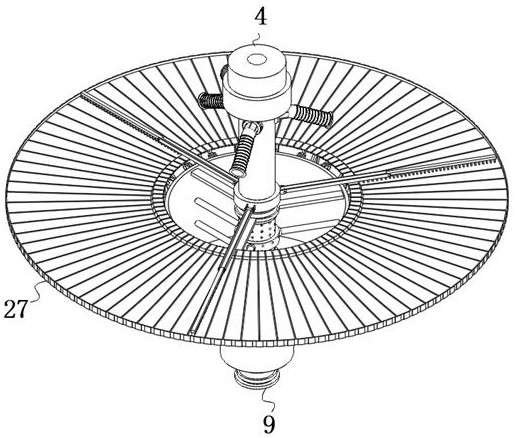

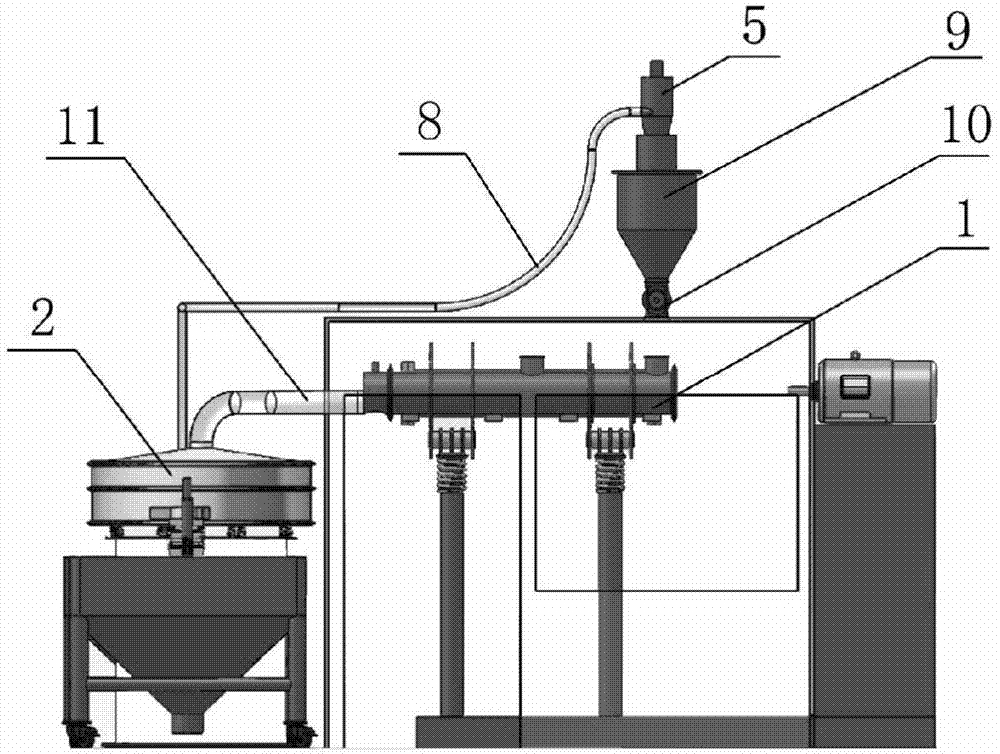

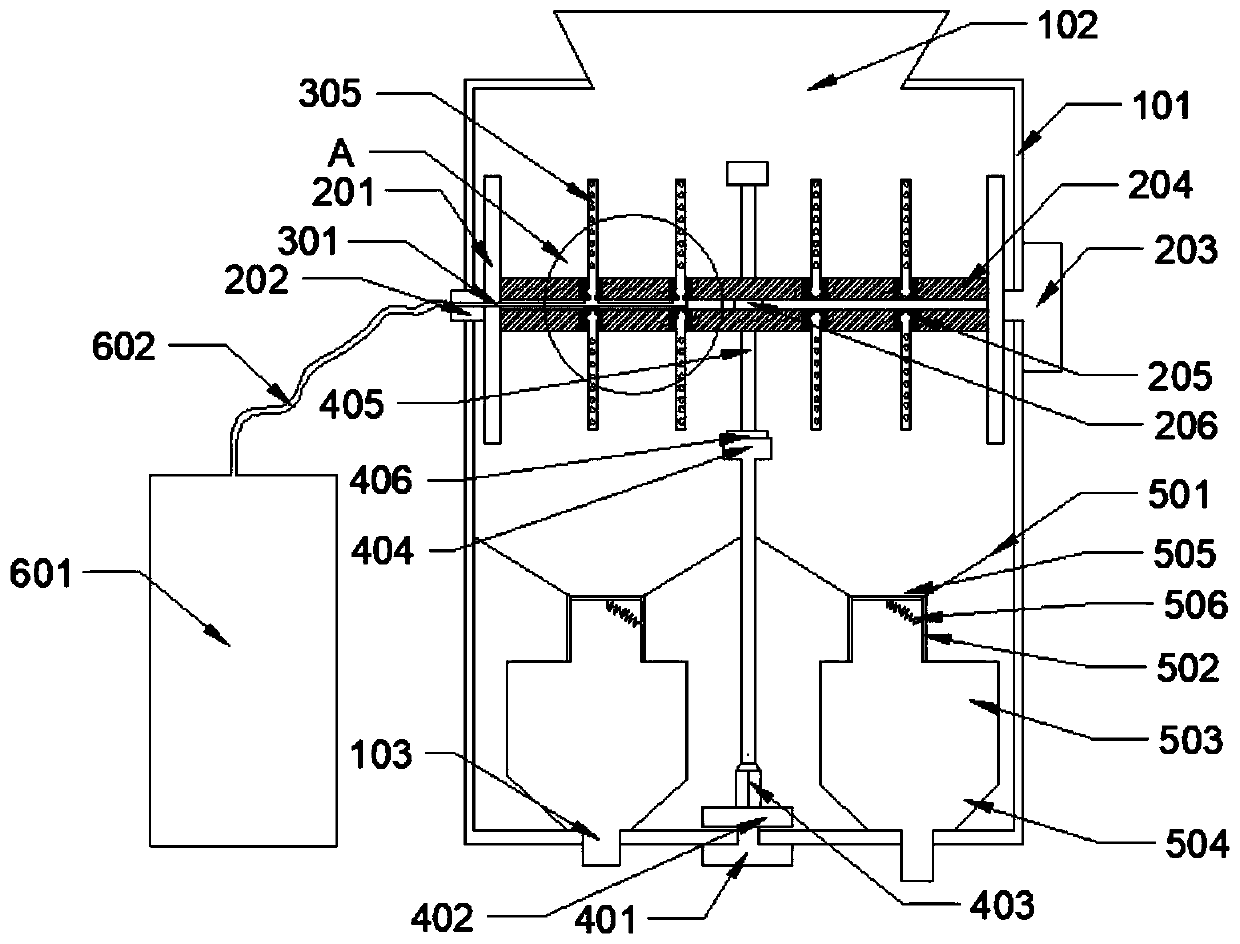

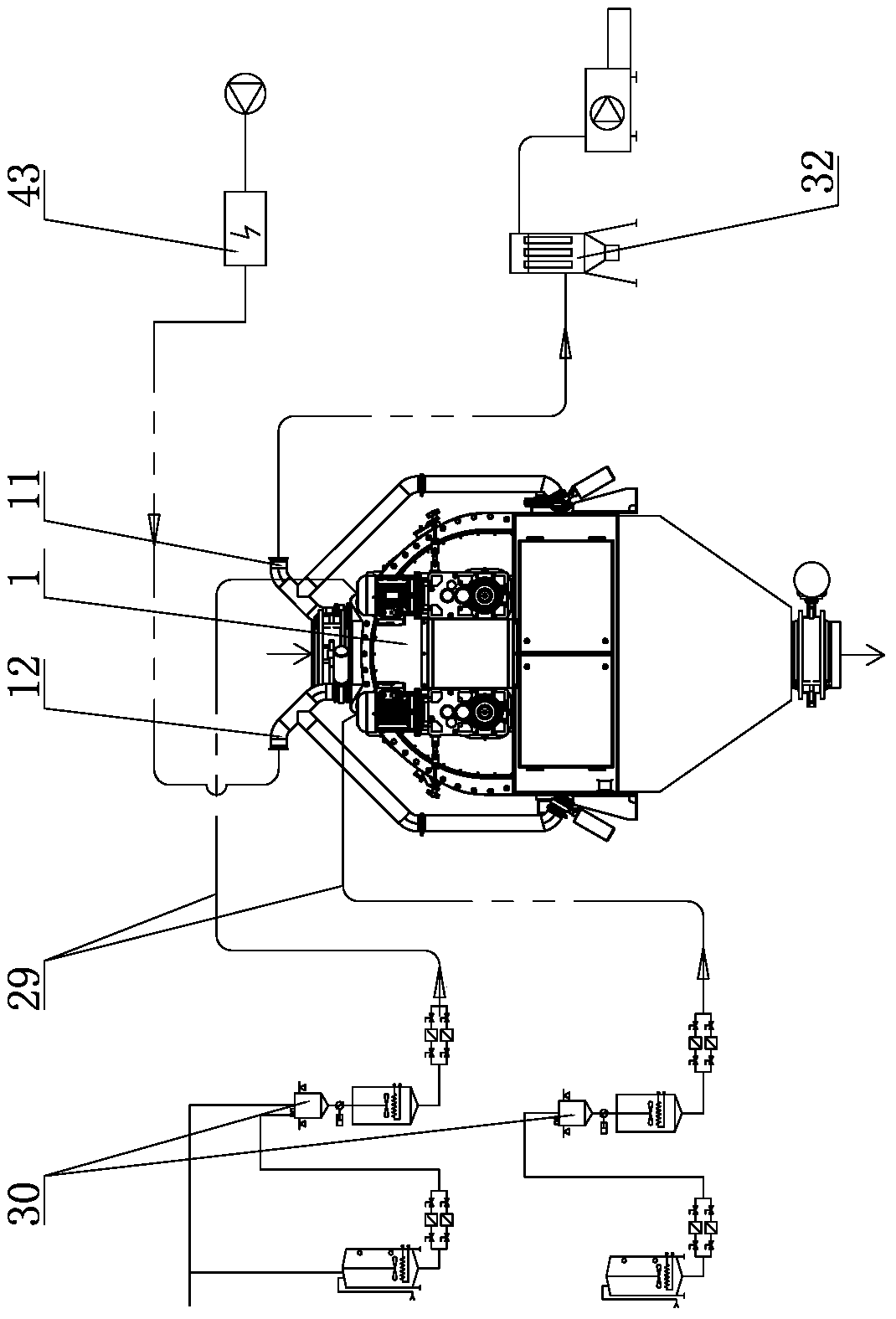

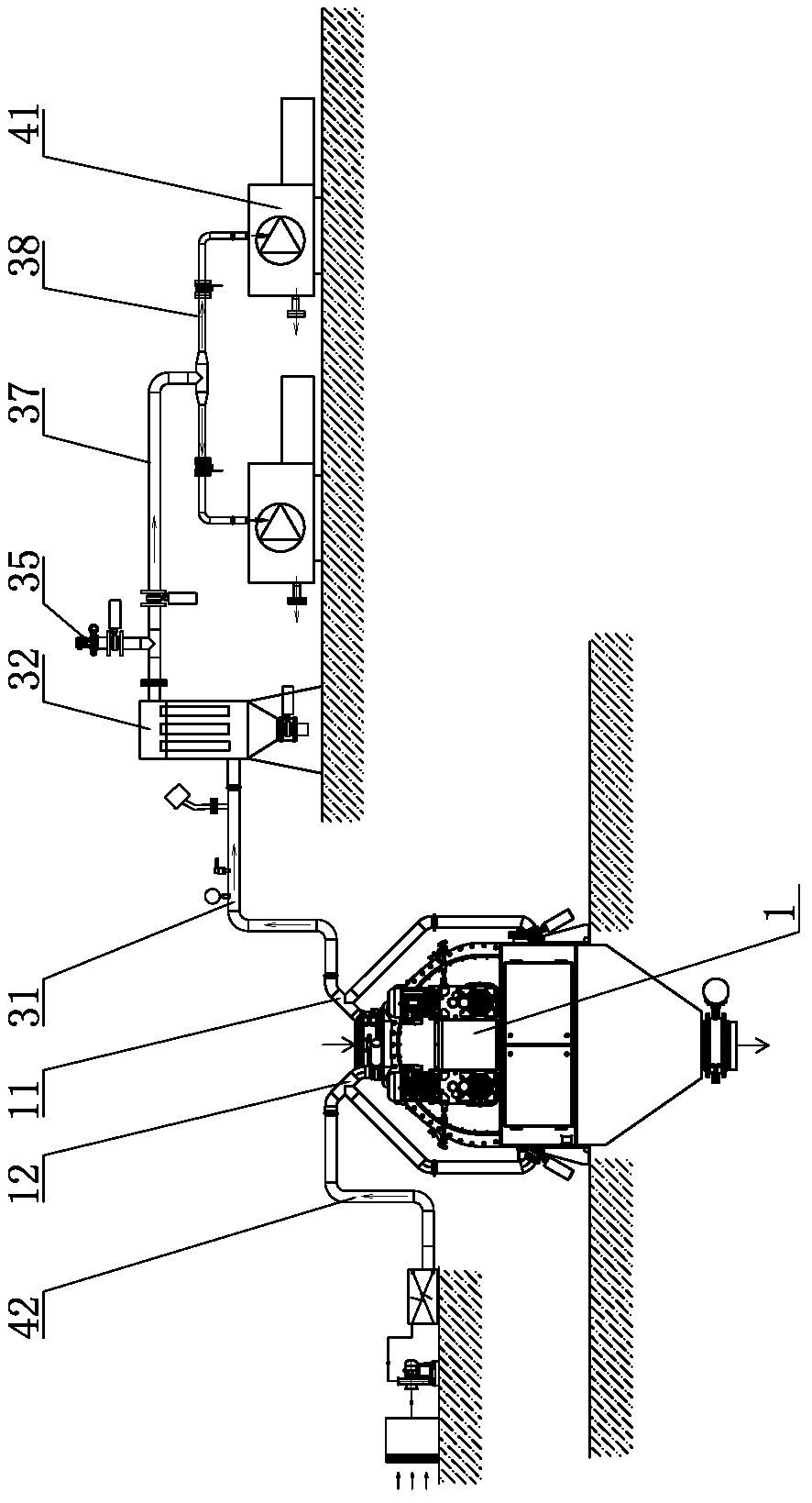

Automatic vacuum spraying system

PendingCN110893327AQuick NestNo residueRotary stirring mixersTransportation and packagingPhysicsFeed processing

The invention discloses an automatic vacuum spraying system used in the fields of food, pet food and aquatic feed processing. The automatic vacuum spraying system comprises a spraying host, wherein afeeding port is formed in the top of the spraying host; a mixing cavity is formed in the spraying host; a discharge hole is formed in the bottom of the spraying host; the mixing cavity comprises two sub-cavities which are symmetrical in a left-right direction; stirring shafts are respectively arranged in the two sub-cavities; a plurality of paddles are arranged on each stirring shaft in a staggered manner; the stirring shafts are in transmission connection with a rotary driving mechanism; a discharging port is formed in the bottom of each sub-cavity, and a discharging door is correspondingly arranged at each discharging port; a vacuumizing pipe and a hot air drying pipe are arranged on the upper side of the spraying host; a nozzle assembly is arranged at the top of the spraying host; liquid adding equipment is connected to the head end of a pumping pipeline of the nozzle assembly; and material adding equipment is correspondingly arranged above the feeding hole. According to the invention, the mixing cavity of the spraying host is convenient to clean, requirements of food hygiene can be met, and spraying efficiency is higher.

Owner:远腾自动化设备(扬州)有限公司

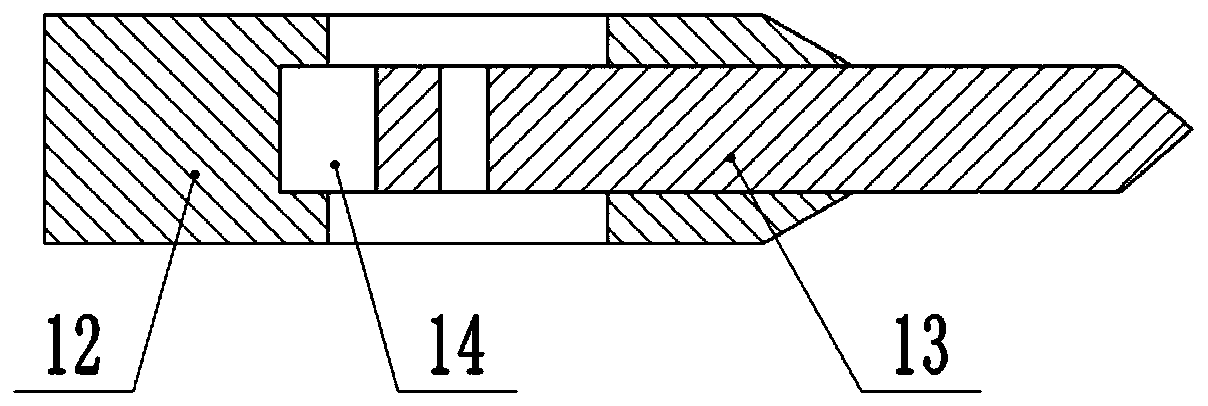

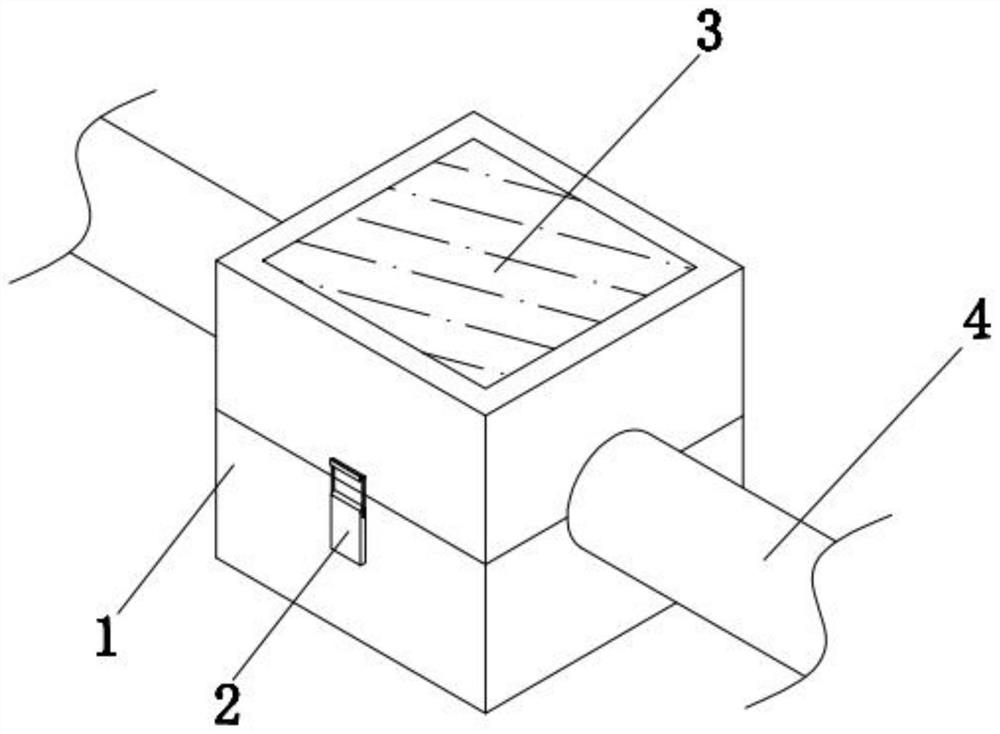

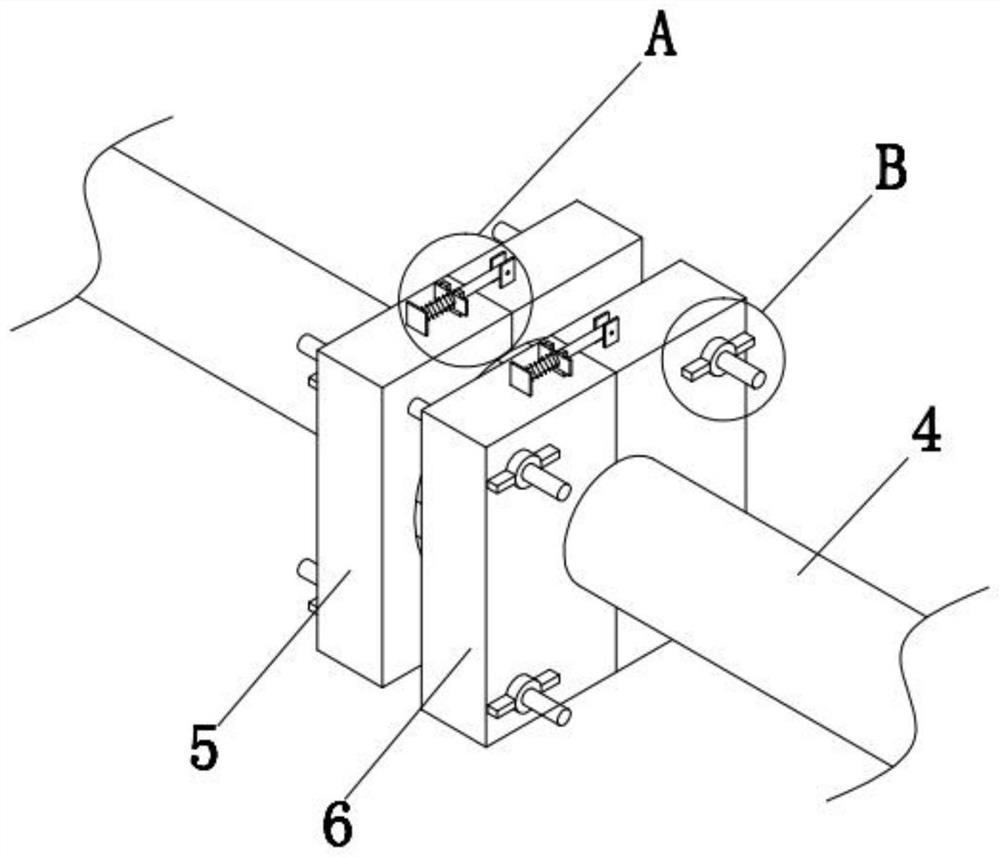

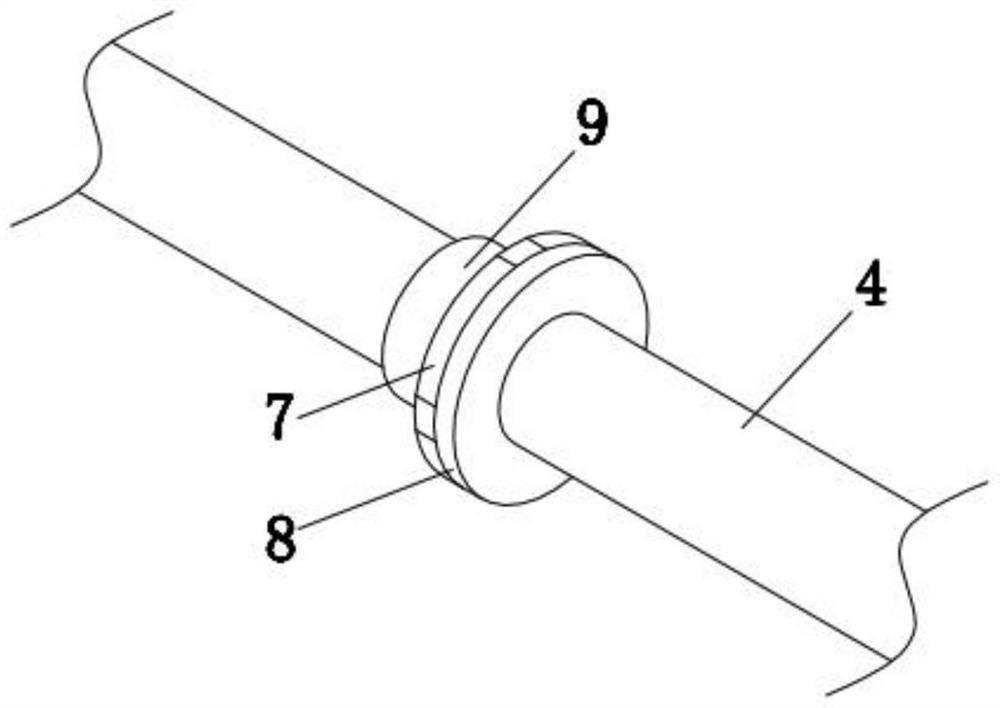

A kind of pipeline seal for construction machinery

ActiveCN112066105BImprove stabilityImprove sealingSleeve/socket jointsPipe protection against damage/wearStructural engineeringMechanical engineering

The invention discloses a pipeline sealing piece for construction machinery, comprising a first connecting piece and a second connecting piece, wherein the first connecting piece and the second connecting piece are respectively installed on two sets of butted pipes, and the first connecting piece The connector includes a sleeve, the sleeve is provided with a first plug-in tube, the first plug-in tube is connected to the pipeline, and there is a gap between the sleeve and the sleeve, and the second connector includes a second plug-in tube, so The second plug-in pipe is sealed and inserted into the gap between the first plug-in pipe and the sleeve, and the inner wall of the second plug-in pipe is recessed with a notch for the first plug-in pipe to be sealed and connected, and the first connector The connecting end with the second connecting piece is provided with an edge plate; the end of the sleeve away from the second connecting piece is vertically sleeved with a first fixing piece, and the pipe at the rear end of the second connecting piece is sleeved with a second fixing piece pieces. The pipeline seal for construction machinery has good sealing performance and protection performance, and is more stable, and is worthy of promotion.

Owner:HUNAN MASTER SEALING

Plastic hot melting device for plastic solidification

The invention discloses a plastic hot melting device for plastic solidification. The plastic hot melting device comprises a base and a thermal insulation box, wherein the thermal insulation box is arranged on the base; a hot melting kettle is arranged in the base and the thermal insulation box; the upper part of the hot melting kettle is of an open structure; the lower part of the hot melting kettle is of a semispherical structure; a semispherical placing slot matched with the lower part of the hot melting kettle is formed in the base; a heating device is arranged in the placing slot; the shape of the heating device is matched with that of the lower part of the hot melting kettle, and the heating device clings to the hot melting kettle; a gas ejection pipe is arranged on the inner wall ofthe upper end of the hot melting kettle and is connected with a gas pump; the gas pump is arranged on the outer side of the thermal insulation box; a circulating gas hole is formed in the upper end ofthe hot melting kettle and is connected with the gas pump through a gas pipe; a sealing cover is arranged at the upper end of the hot melting kettle and is articulated to the thermal insulation box;the sealing cover is a pressure-proof sealing cover. The plastic hot melting device disclosed by the invention has a stable structure, can realize quick melting of plastic for solidification and can carry out stirring after start and realize quick discharge so as to ensure plastic stability and meet current requirements of use.

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

Movable jaw assembly of jaw crusher

The invention provides a movable jaw assembly of a jaw crusher, and belongs to the technical field of crushers. The movable jaw assembly comprises protective plates, a movable jaw and a fixed jaw; theprotective plates are arranged in front of and behind the movable jaw and the fixed jaw; the top of the movable jaw is fixedly connected with a lantern ring; a first motor is arranged on the left side of the movable jaw; an eccentric shaft is arranged in the lantern ring and fixed to the eccentric position of a rotating wheel; the first motor and the rotating wheel are connected through a belt; the movable jaw comprises a movable jaw plate, a movable jaw plate bracket and a plurality of second reinforcing ribs; and the movable jaw plate bracket is welded to the left side of the movable jaw plate, and the multiple second reinforcing ribs are arranged between the movable jaw plate bracket and the movable jaw plate at equal intervals. Rotating rollers are utilized to act on the surface of amaterial, downward acting force is provided for the material, rebound of the material and continuous overturning of the material in a crushing area can be effectively prevented, thus quick material discharging is completed, and the crushing efficiency is improved.

Owner:ZAOZHUANG SNKSAN INTELLIGENT MACHINERY CO LTD

Self-cleaning feed mixing and drying device

InactiveCN107388730AImprove work efficiencyEasy to stir and mixHollow article cleaningDrying gas arrangementsFeed processingResistance wire

The invention provides a self-cleaning feed mixing and drying device, belonging to the technical field of feed processing, comprising a box body, a transmission device, a blower, a resistance wire mesh, a base, feet and a water storage tank; a transmission device is arranged above the box body; The first rotating shaft is fixedly connected under the transmission device; the first rotating shaft passes through the box body and the filter screen and is fixedly connected with the bearing on the top of the box body; the filter screen is fixed on the two side walls inside the box body; the second Stirring blades are embedded on a rotating shaft; the invention utilizes a high-pressure water pump to pressurize the clean water in the water storage tank, and the pressurized clean water is sprayed out through the high-pressure nozzle and flows through the whole device to achieve the purpose of cleaning and to speed up the working efficiency; The setting of the plate can scrape off the feed that adheres to the bottom of the mixing chamber, which is convenient for full mixing and mixing, and it is also conducive to complete discharge during discharge; the setting of resistance wire mesh can make the feed in the drying chamber dry quickly and facilitate storage.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

Straw crushing and feeding machine for agricultural livestock

PendingCN114342674AEfficient crushingQuick NestCuttersFood processingLivestockAgricultural engineering

The straw smashing and feeding machine comprises a bottom box, an arc-shaped sieve plate is arranged in the middle of the interior of the bottom box, an oval cavity is formed between the top face of the arc-shaped sieve plate and the inner top wall of the bottom box, and a transverse shaft is arranged in the oval cavity; a T-shaped ring is arranged at the top of the left side face of the bottom box, a sleeve is inserted into the T-shaped ring, smashing mechanisms are installed on the transverse shaft and the sleeve and located in the oval cavity, an eccentric vibration mechanism is arranged between the left end of the transverse shaft and the left end of the sleeve, and a square long shaft is arranged on the right side in the oval cavity. And the right end part of the transverse shaft is connected with the right end part of the square long shaft through a meshing mechanism. The problem that the straw smashing effect is poor is solved, through the staggered smashing design, the straw smashing effect is improved, and rapid discharging after smashing is facilitated.

Owner:合肥茗满天下茶叶有限公司

Graphene production system

The invention relates to the field of graphene production and discloses a graphene production system which comprises a graphite exfoliating furnace, a secondary ultrasonic device and a filtering device, wherein the graphite exfoliating furnace is connected with the secondary ultrasonic device; the secondary ultrasonic device is connected with the filtering device; intercalation graphite is adopted as a raw material; the intercalation graphite is exfoliated in sequence by using the graphite exfoliating furnace to prepare exfoliated graphite, the exfoliated graphite is further conveyed through the secondary ultrasonic device and the filtering device, and thus graphene is finally prepared. With the combination of the exfoliating furnace and the secondary ultrasonic device, high-multiplied exfoliated graphite is prepared by using the exfoliating furnace, the exfoliated graphite as the raw material is subjected to pre-exfoliation and ultrasonic exfoliation, circulation reaction is implemented, and together with secondary ultrasonic exfoliation, the exfoliation efficiency can be greatly improved, and thus large-scale, high-efficiency and low-cost production of graphene is achieved.

Owner:郴州国盛新材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com