Automatic vacuum spraying system

A vacuum spraying and nozzle technology, applied in chemical instruments and methods, chemical/physical processes, dissolution, etc., can solve problems such as failure to meet food hygiene requirements, single auger unable to fully stir materials, and unclean inside of the tank. , to achieve the effect of fast cleaning, good sealing performance and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

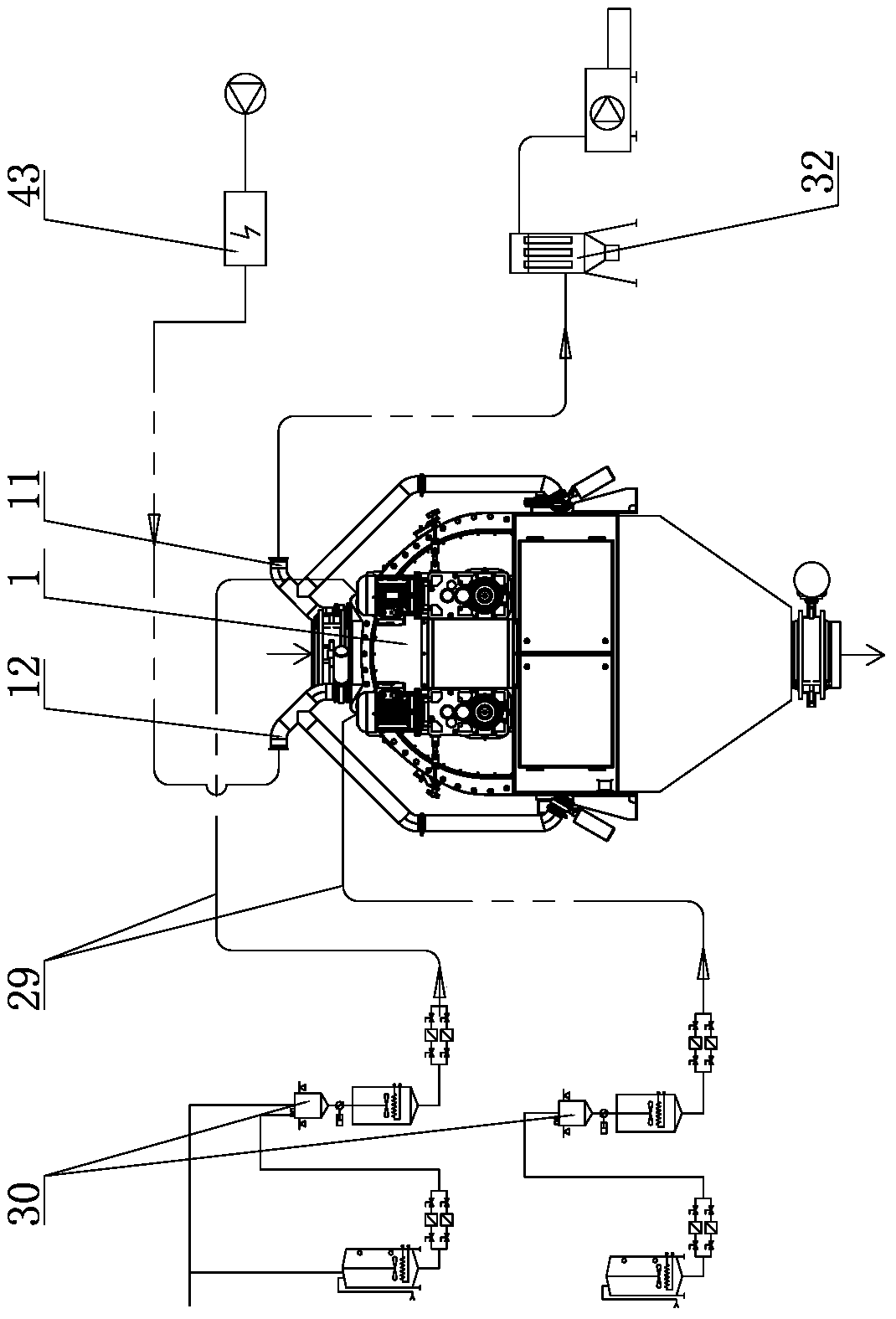

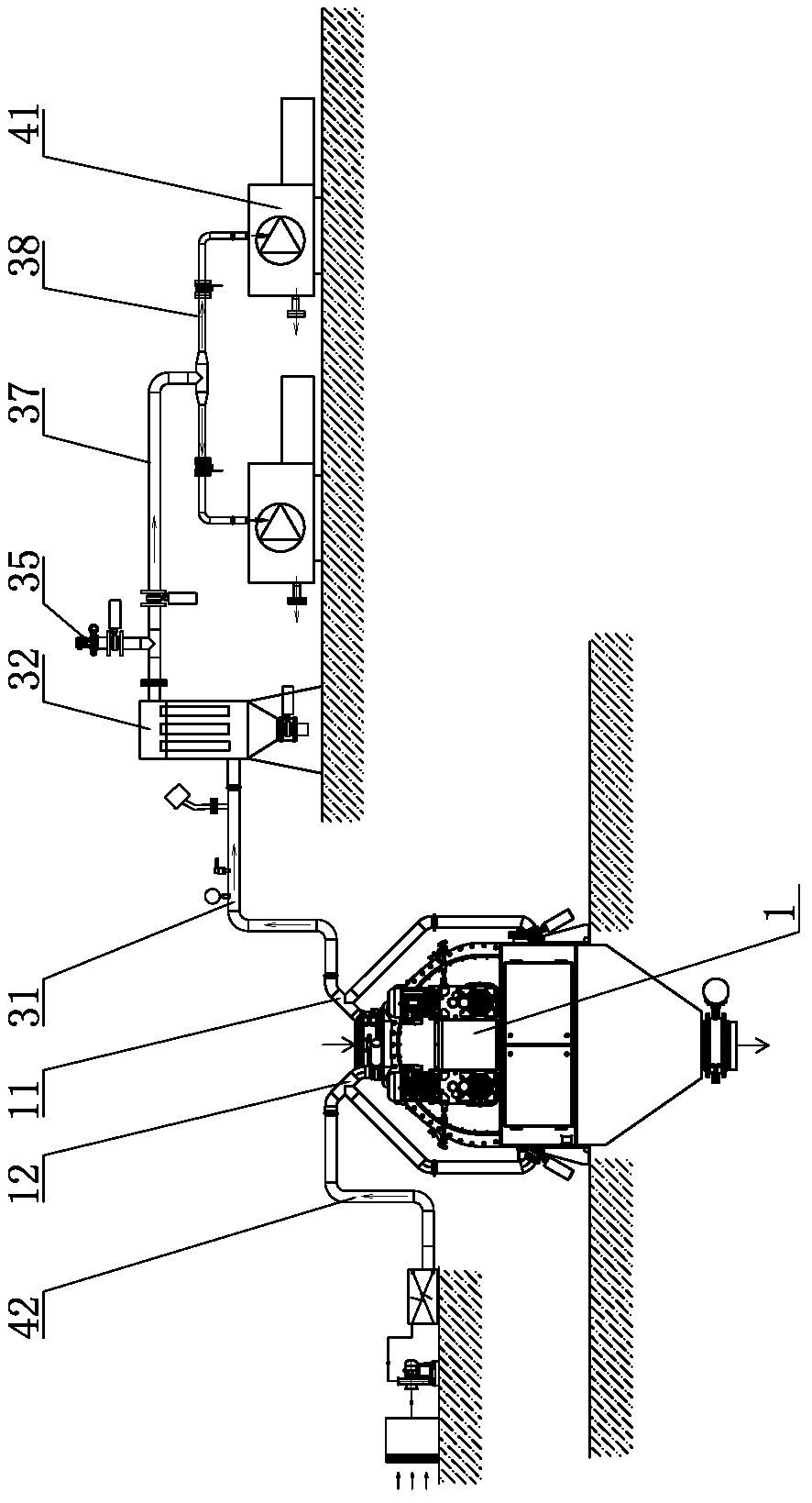

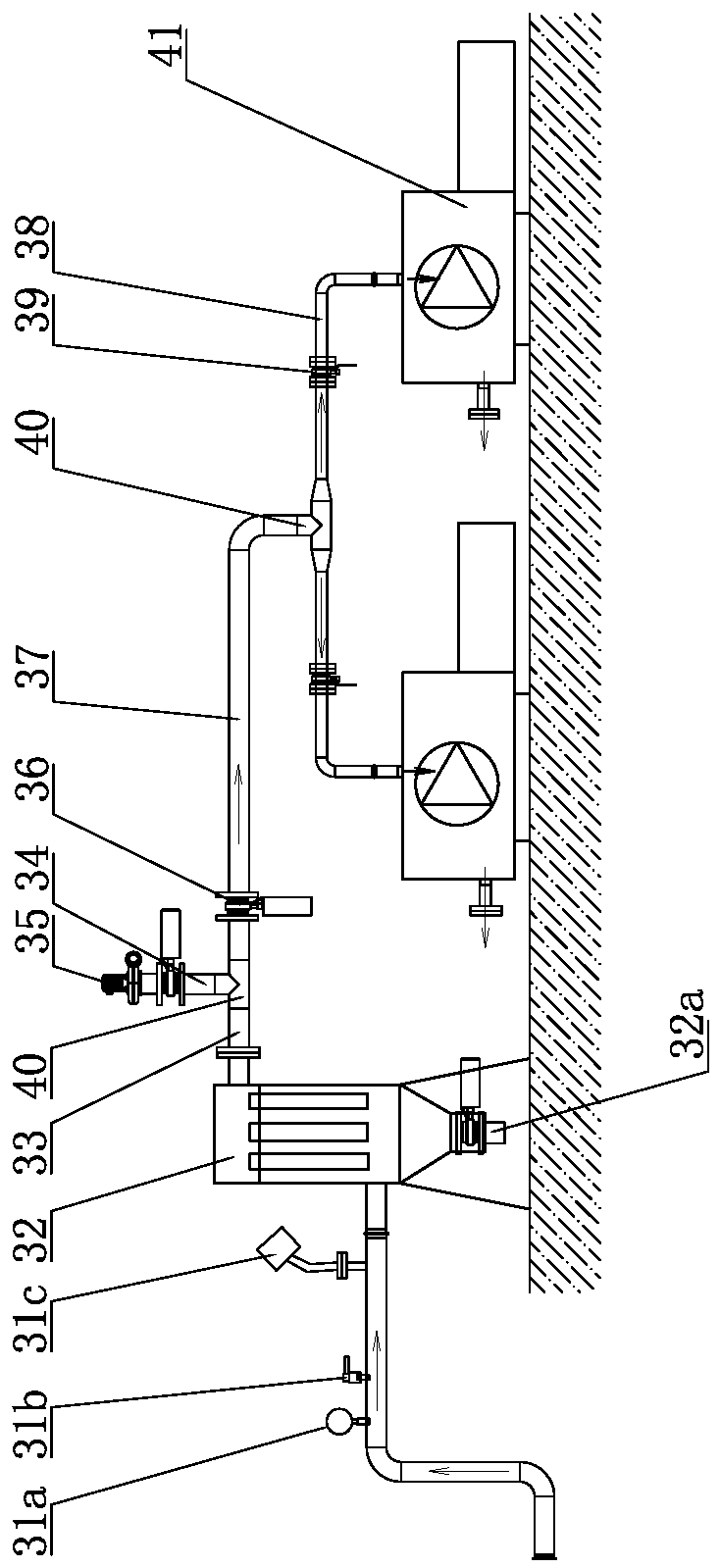

[0034] Such as Figure 1-13 As shown, it is an automatic vacuum spraying system, which includes a spraying host 1, a feeding port 2 is arranged on the top of the spraying host 1, a mixing chamber 101 is arranged inside the spraying host 1, a discharge port 9 is arranged at the bottom of the spraying host 1, and a feeding port 9 is arranged on the bottom of the spraying host 1. Disc valves 36 are provided at the port 2 and the discharge port 9; the mixing chamber 101 includes two left-right symmetrical sub-chambers 101a, and a stirring shaft 3 is rotatably arranged in the two sub-chambers 101a, and the stirring shaft 3 Set in parallel with the length direction of the sub-chamber 101a of the spraying host 1, a number of paddles 5 are staggeredly arranged on the stirring shaft 3, and each paddle 5 on the two stirring shafts 3 is staggered and arranged along the circumferential direction, and the two stirring shafts 3 and The rotary drive mechanism is connected by transmission, an...

Embodiment 2

[0045] Such as Figure 14 and 15 , the difference from Embodiment 1 is that the first nozzle assembly 13 is connected to the pumping pipeline 1301 located above, and the first nozzle assembly 13 includes a left branch pipe one 1301a, a right branch pipe one 1301b and a right branch pipe two 1301c, six nozzles 26 are arranged on the left branch pipe 1301a, and four nozzles 26 are arranged on the right branch pipe one 1301b and the right branch pipe two 1301c; the second nozzle assembly 13 is connected with the pumping pipeline 1302 located below connection, the second nozzle assembly 13 includes a left branch pipe two 1302a and a right branch pipe three 1302b, four nozzles 26 are arranged on the left branch pipe two 1302a, two nozzles 26 are arranged on the right branch pipe three 1302b, and the left branch pipe two 1302a is set corresponding to the left branch pipe 1301a, and the right branch pipe 3 1302b is set corresponding to the right branch pipe 1 1301b and the right bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com