Graphene production system

A production system and graphene technology, applied in the direction of graphene, inorganic chemistry, non-metallic elements, etc., can solve the problems of high production cost of graphene, low reaction efficiency, low efficiency of production equipment, etc., to improve the peeling efficiency and improve the reaction efficiency. Efficiency, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

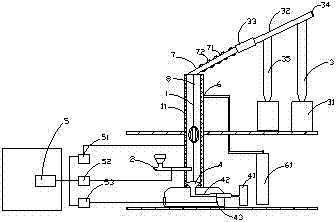

[0035] Such as Figure 1~4 As shown, the present embodiment provides a graphene production system, including graphite puffing furnace 101, secondary ultrasonic device and filtering device 104, graphite puffing furnace 101 is connected with secondary ultrasonic device, and secondary ultrasonic device is connected with filtering device 104;

[0036]The graphite puffing furnace 101 comprises a furnace body 1, a feeding device 2, a discharging device 3 and a control device. The raw material passes through the feeding device 2 to the furnace body 1, and then is collected by the discharging device 3; the discharging device 3 is arranged above the furnace body, and the feeding The device 2 is located below the furnace body; the furnace body 1 is provided with a heating device 11, which is heated by resistance wire in this embodiment, and the inner bottom of the furnace body 1 is also provided with an air flow nozzle 4, and the air flow nozzle 4 also includes an air source 41 and an ai...

Embodiment 2

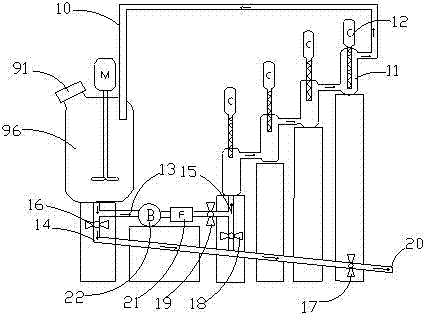

[0047] This embodiment is basically the same as Embodiment 1, the difference is that the stirrer 8 uses a centrifugal stirrer to rotate in the body of the furnace, such as Figure 7 As shown, the centrifugal stirrer includes a stirring rod 81 and a stirring part 82, the stirring part 82 is circular or oval, and a plurality of stirring parts 82 are arranged on the stirring rod 81 with the stirring rod 81 as the axis, and the upper and lower ends of the stirring rod 81 It is connected with the furnace body through the bearing and driven by the motor.

[0048] The agitator 5 in this embodiment drives the airflow through the centrifugal movement to make the intercalated graphite do the centrifugal movement, which avoids the problem of uneven heating caused by the difference in temperature between the inner wall and the middle part of the furnace, and greatly improves the reaction efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com