Patents

Literature

32results about How to "Avoid floor space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

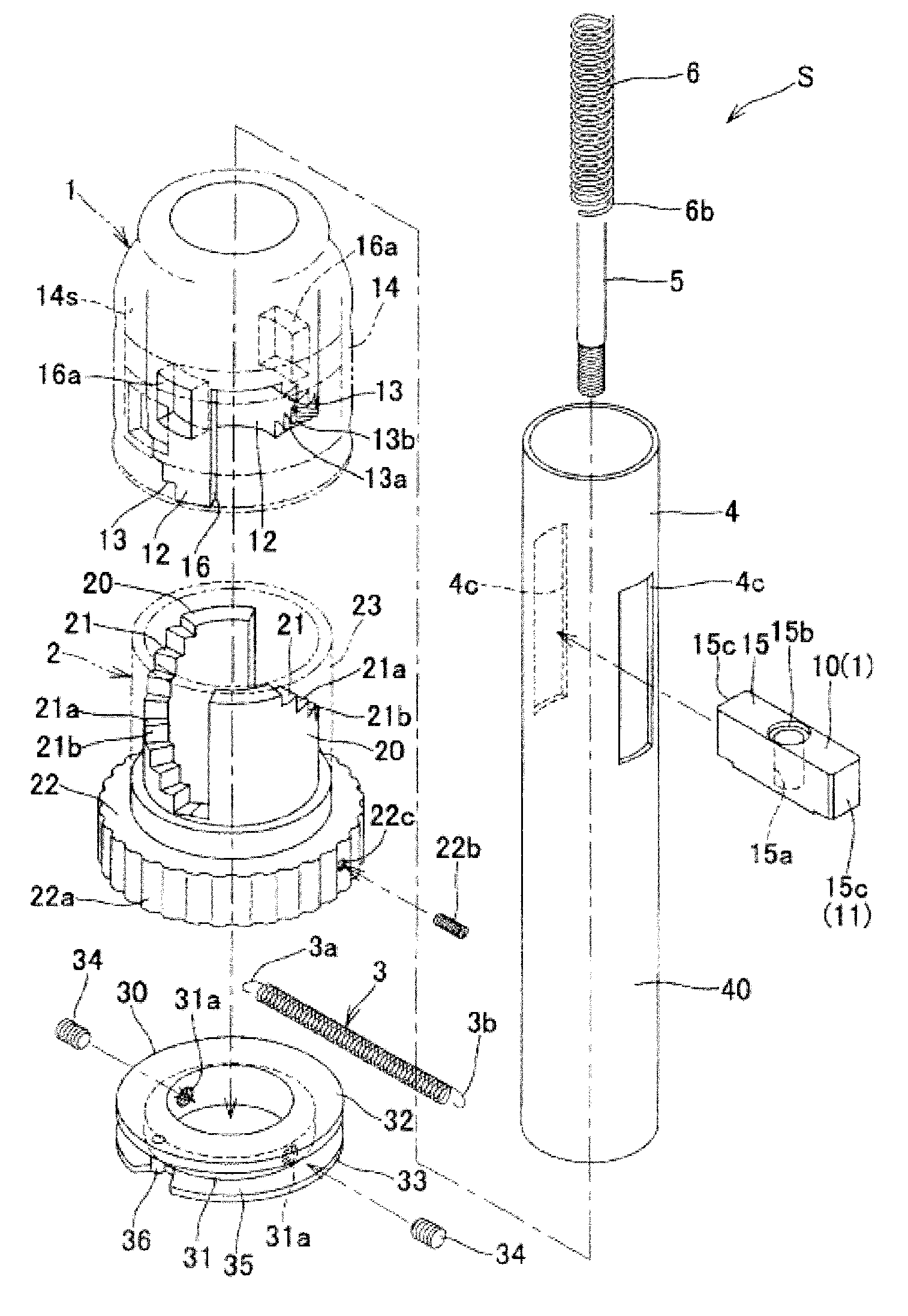

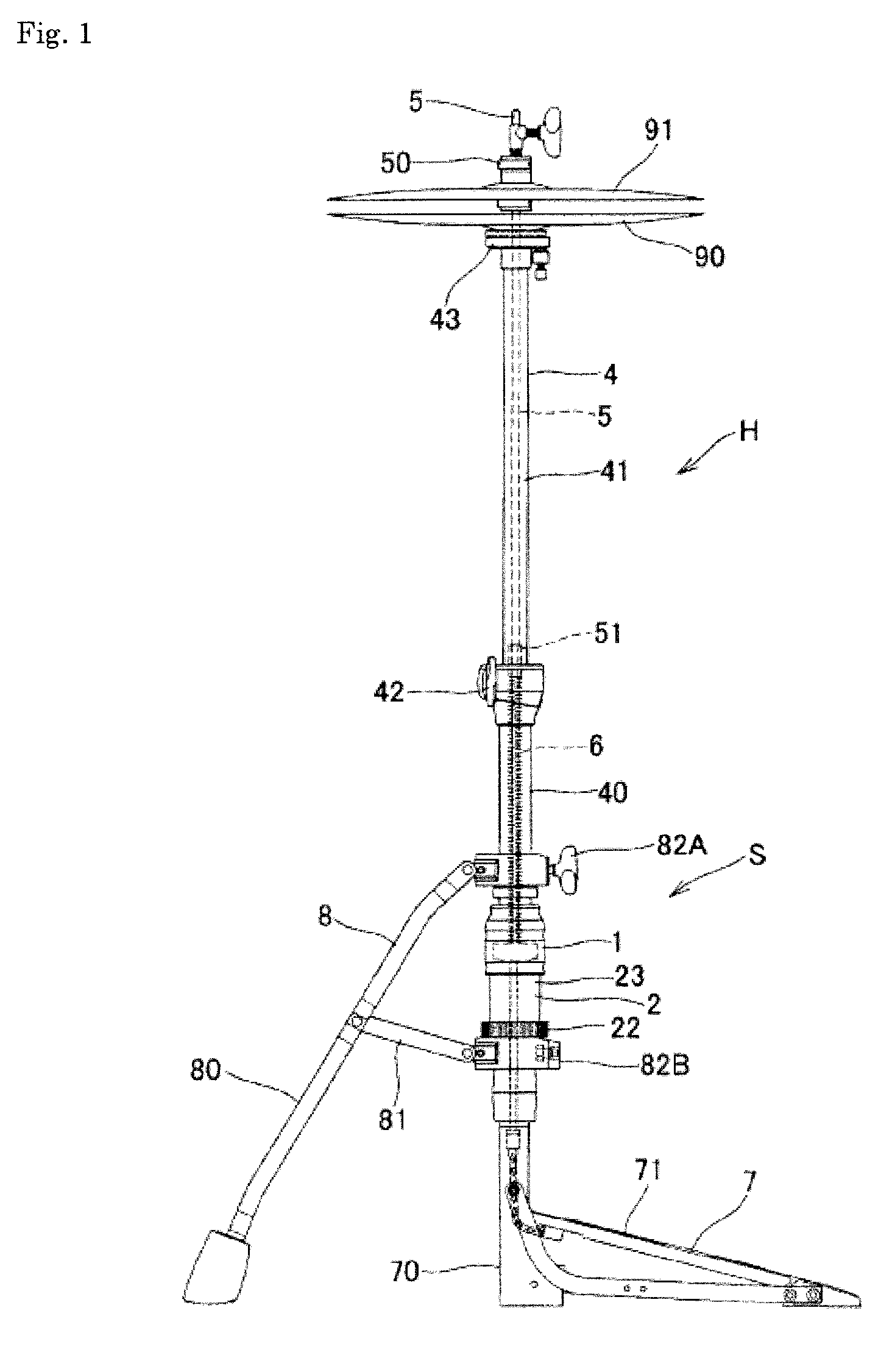

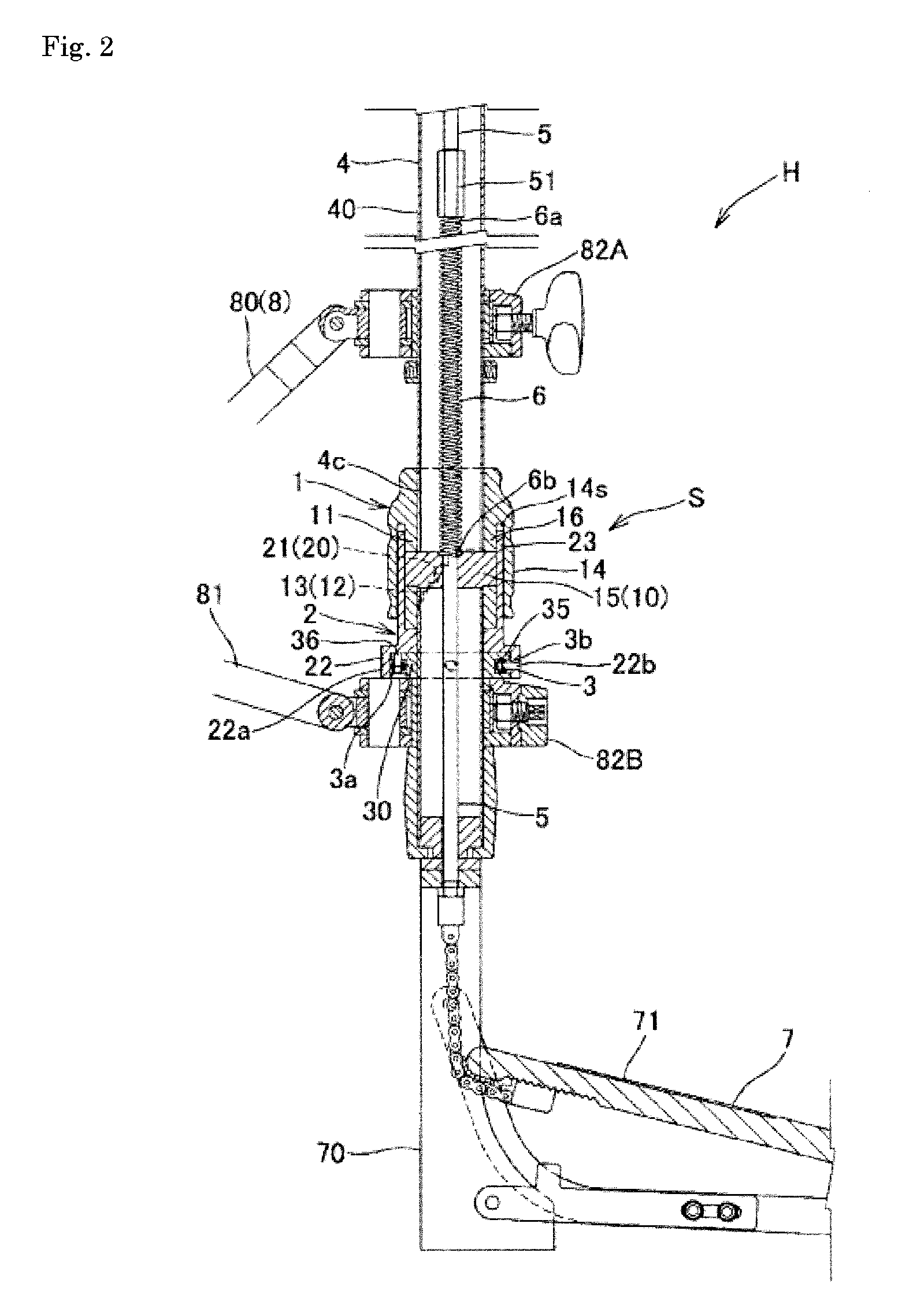

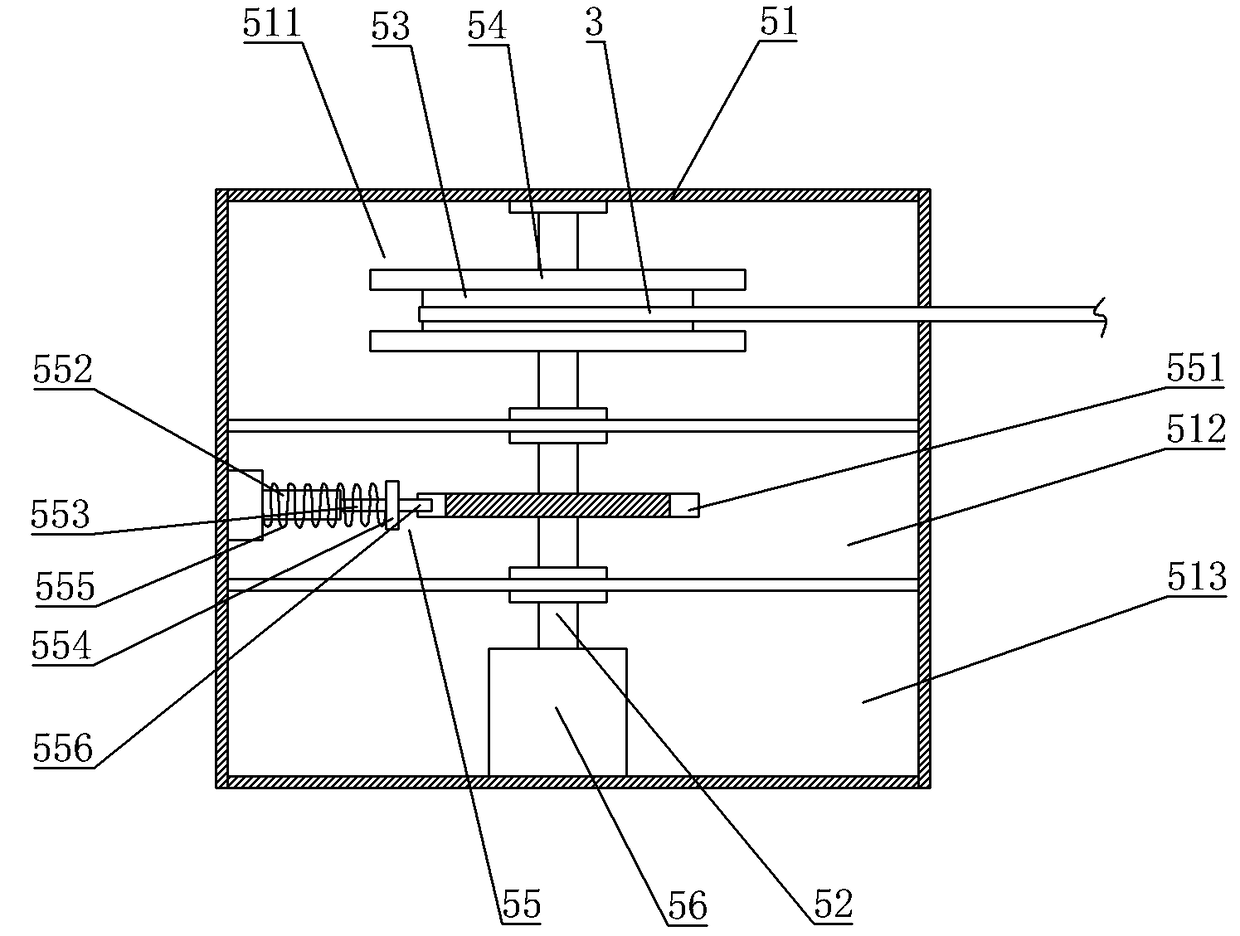

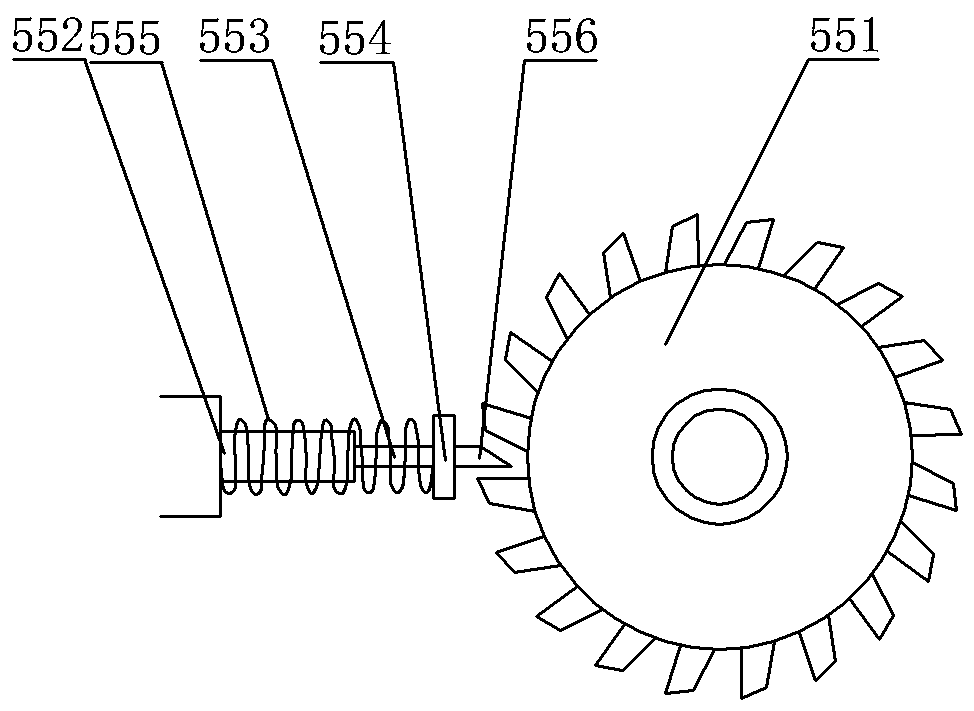

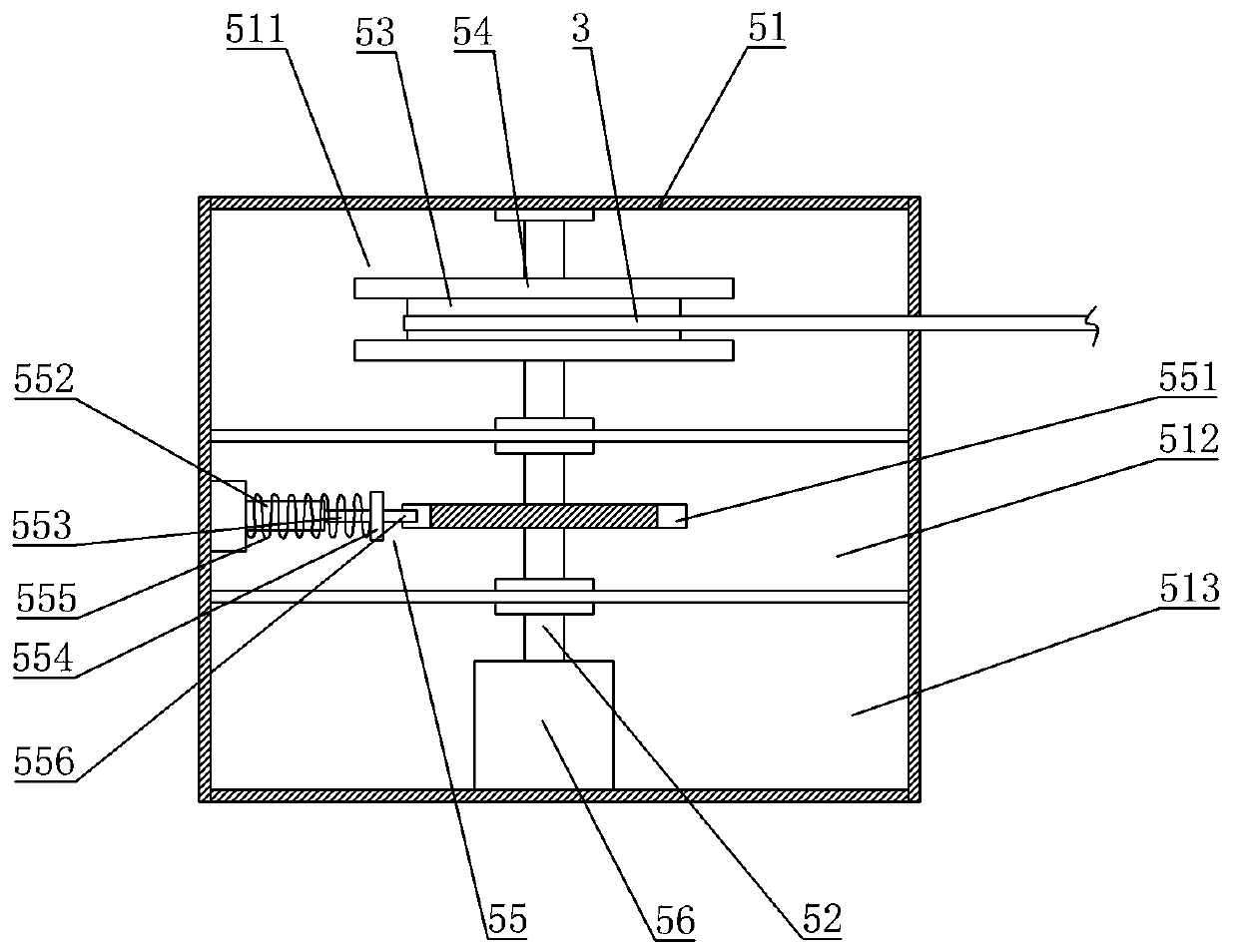

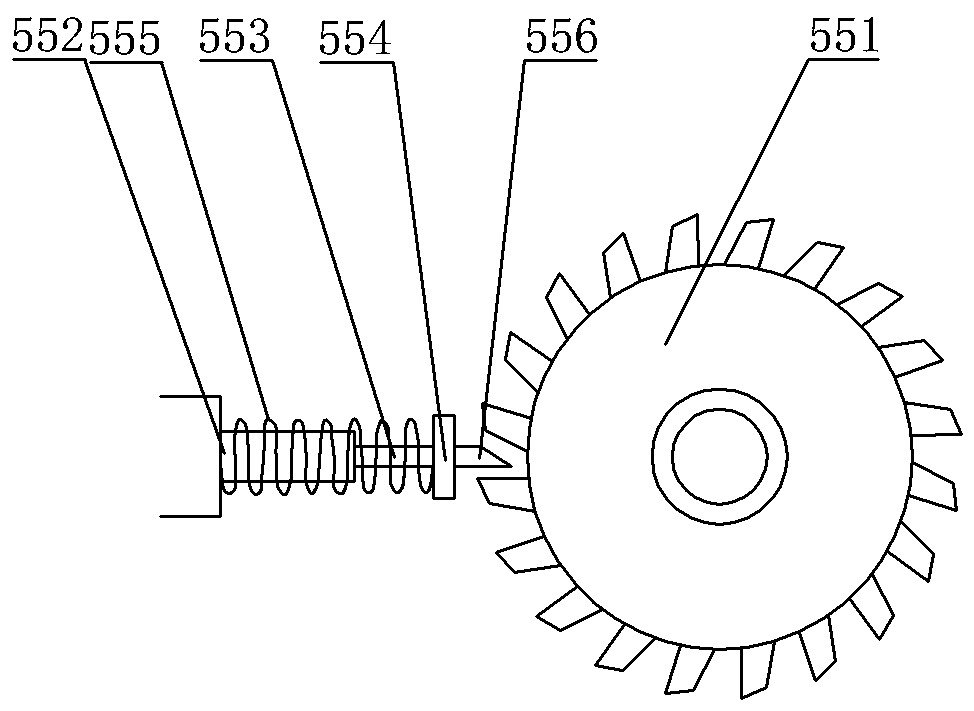

Spring force adjustment structure in high-hat stand and high-hat stand including the spring force adjustment structure

InactiveUS8946531B2Avoid floor spaceEasy for users to understandPercussion musical instrumentsWound springsSpring forceEngineering

To provide a spring force adjustment structure in a high-hat stand that allows a user to easily adjust a spring force with one hand without reducing a floor space, easily understand the amounts of adjustments made, easily estimate the amount of adjustment to be made when making a fine-tuning afterward, and easily return the spring force to the state before the adjustment.

Owner:SAKAE RHYTHM MUSICAL INSTR

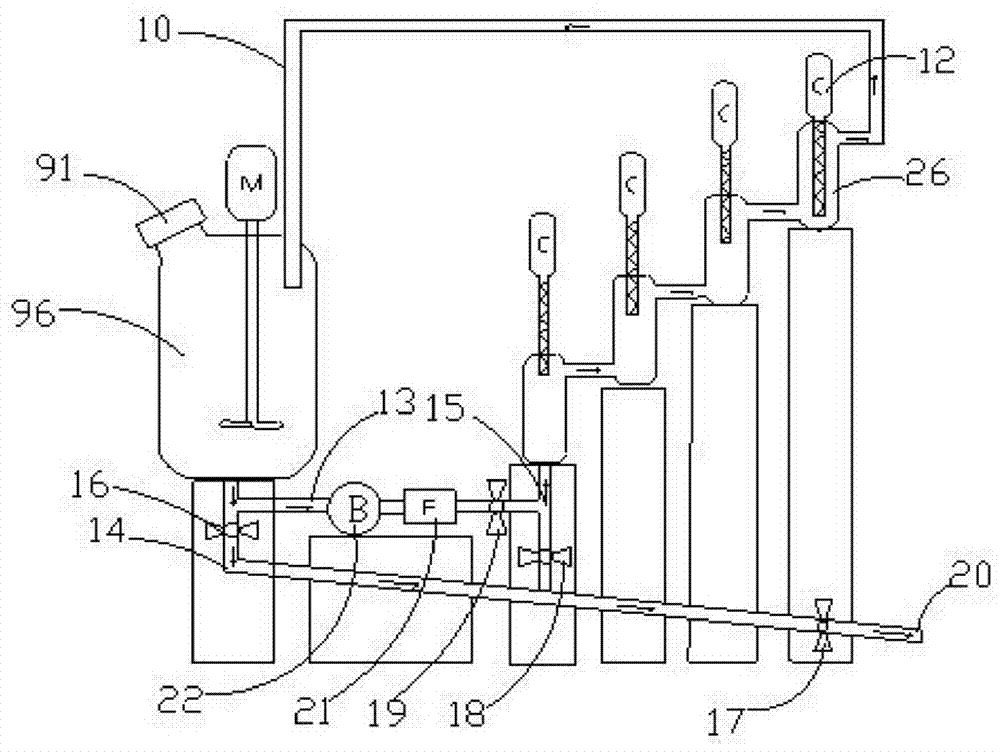

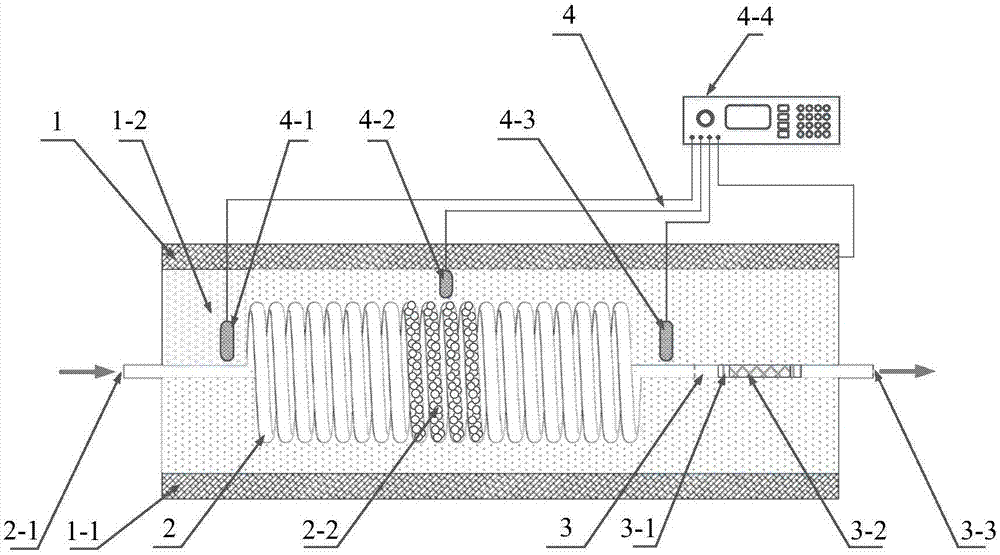

Continuous nylon polymerization process

ActiveCN112062950AIncrease productivityOvercome the disadvantages of intermittent productionPlastic recyclingPolymer sciencePolyamide

The invention provides a continuous nylon polymerization process, which comprises the following polymerization raw materials in parts by mass: 5-60 parts of polymerization monomer dibasic acid and / ordibasic acid ester, 3-50 parts of diamine and 10-90 parts of reactive dispersion medium polyamide. According to the process, the raw materials are continuously added into a screw extrusion device in aweight metering or volume metering mode, so that the polymerization monomers react in the molten dispersion medium and are uniformly mixed; and then the mixture enters a subsequent polymerization device to be continuously polymerized until the nylon resin reaches the required molecular weight. According to the invention, melting reaction mixing of the raw materials is completed in the screw extrusion device, the bottleneck of melt polymerization production efficiency can be solved by utilizing the advantages of high heat dissipation and mixing efficiency of the screw extrusion device, and thenylon polymerization process is efficient, green and environmentally friendly.

Owner:CHENGDU 401 TECH CO LTD

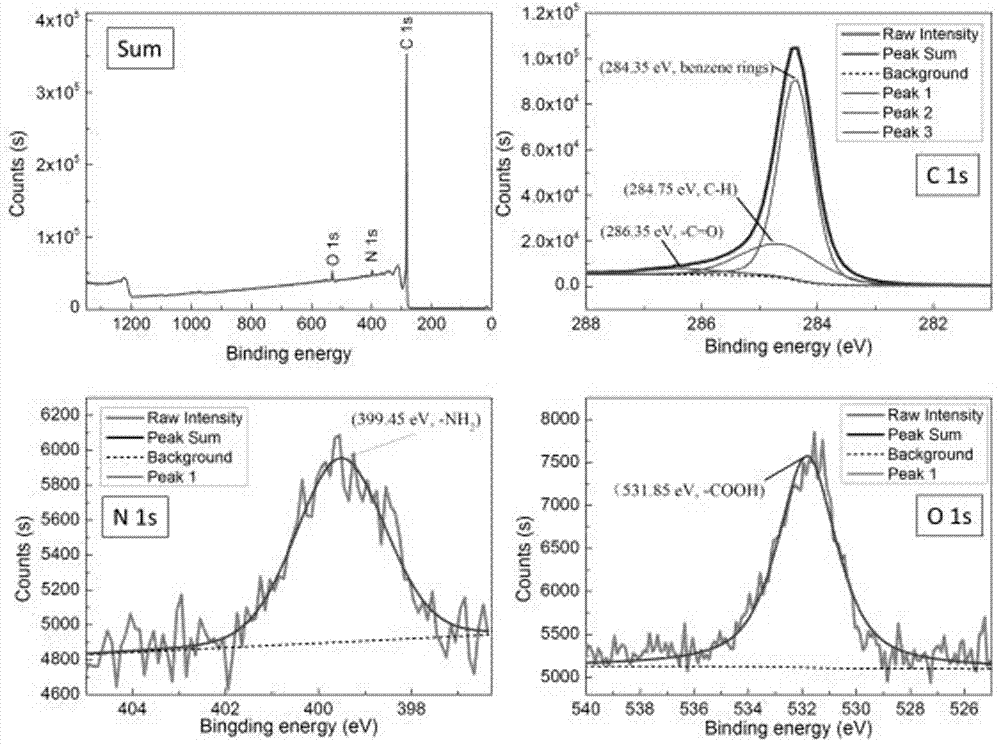

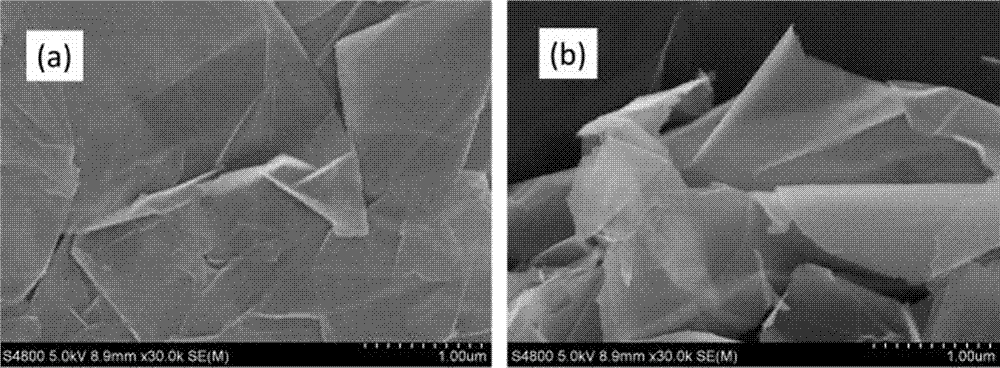

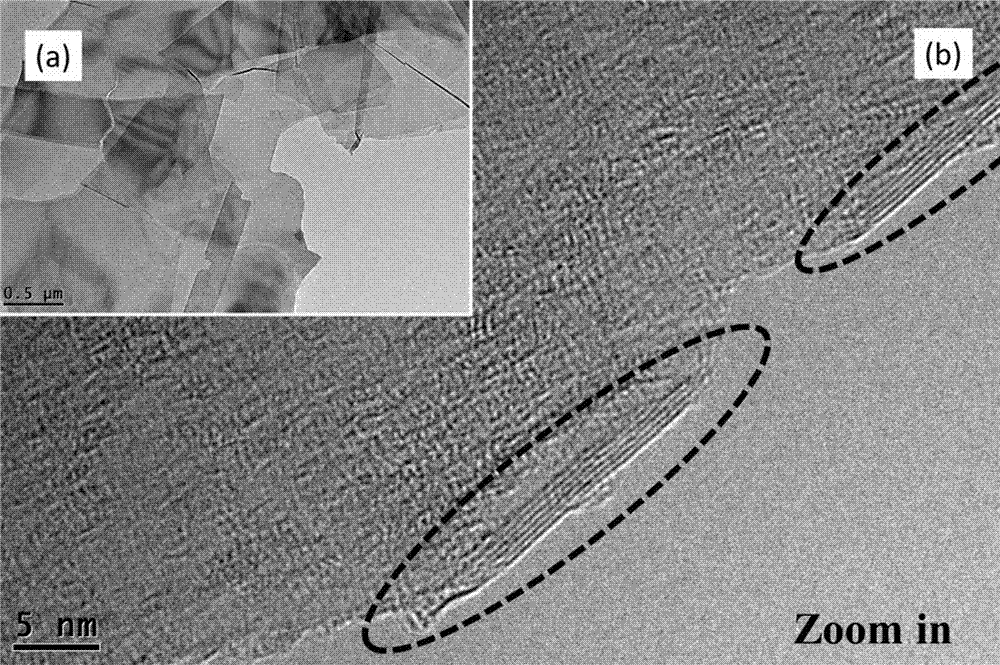

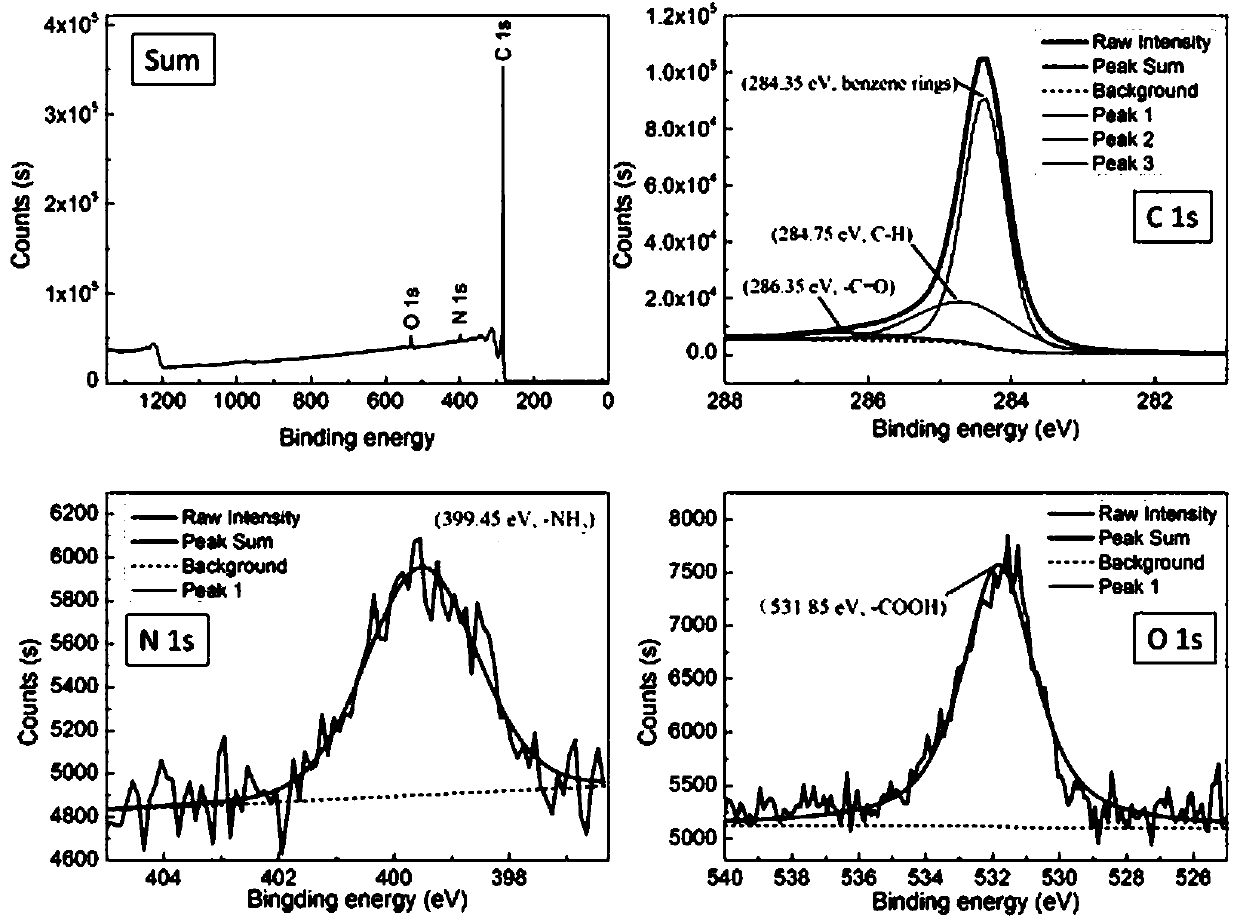

Method for preparing graphene from microcrystalline graphite

The invention belongs to the technical field of preparation of materials and particularly relates to a method for preparing graphene from expanded graphite. Microcrystalline graphite serving as a raw material is subjected to first chemical intercalation treatment, first high-temperature expansion treatment, second intercalation treatment and second high-temperature expansion treatment sequentially, second expanded microcrystalline graphite is obtained and subjected to ultrasonic treatment twice, and a peeling material is obtained and subjected to press filtering, separation and washing, and graphene is obtained. According to the method, the microcrystalline graphite is taken as the raw material, the production technology process is short, and the method is low in cost, produces no sulfur and can be used for mass production of graphene materials.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

Polymerization process for polyesteramide

ActiveCN111363144AIncrease productivityTo overcome the disadvantage that the efficiency of the reaction is slowed down by the esterification reactionPolyesterPolymer science

The invention provides a polymerization process for polyesteramide. The polymerization process is characterized by comprising the following polymerization raw materials by mass: 5-60 parts of a polymerization monomer, namely dibasic acid / dibasic acid ester, 3-50 parts of diamine, and 10-90 parts of a reactive dispersion medium, namely polyester / polyesteramide. The polymerization process comprisesthe following steps: uniformly dispersing the polymerization monomer into a molten reactive dispersion medium, and carrying out a polymerization reaction so as to obtain the polyesteramide with a proper molecular weight. The production efficiency of the polyesteramide can be significantly improved.

Owner:CHENGDU 401 TECH CO LTD

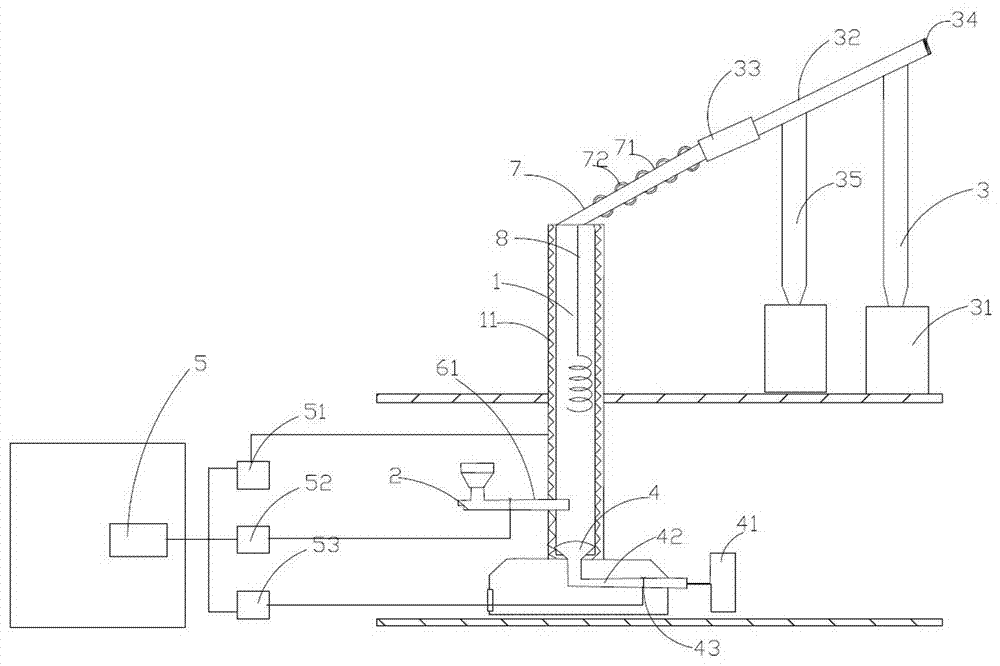

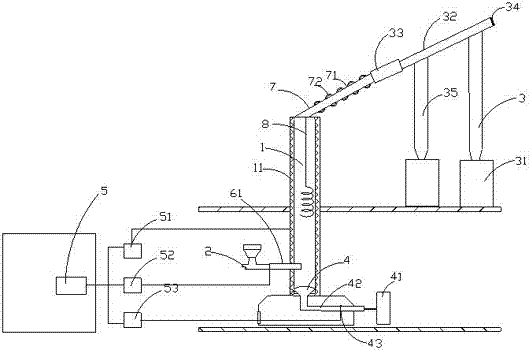

Batch preparation method of graphene and production system therefor

InactiveCN107500279AImprove stripping rateImprove stabilitySingle layer grapheneGraphiteCvd graphene

The invention relates to the field of graphene materials, and discloses a batch preparation method of graphene and a production system therefor. In the invention, a conventional high temperature expansion method is combined with a graphite expansion furnace, and by means of optimum expansion temperature, stability of a product is effectively improved by means of control on raw materials and process parameters on the basis of the expansion temperature, thereby producing expanded graphite with controllable expansion times, namely, distribution ratio with expansion times being 200-300 is highest. With the expanded graphite as a raw material for producing graphene through a mechanical stripping method, stripping rate of graphene is greatly increased. On the basis of the conventional mechanical stripping method for preparing graphene, the graphene is produced in batches with the expandable graphite as raw material and graphene quantum dots as a stripping liquid, wherein a pre-stripping process is added on the basis of the prior art, and secondary ultrasonic treatment is employed with process parameters in the ultrasonic treatment being optimized.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

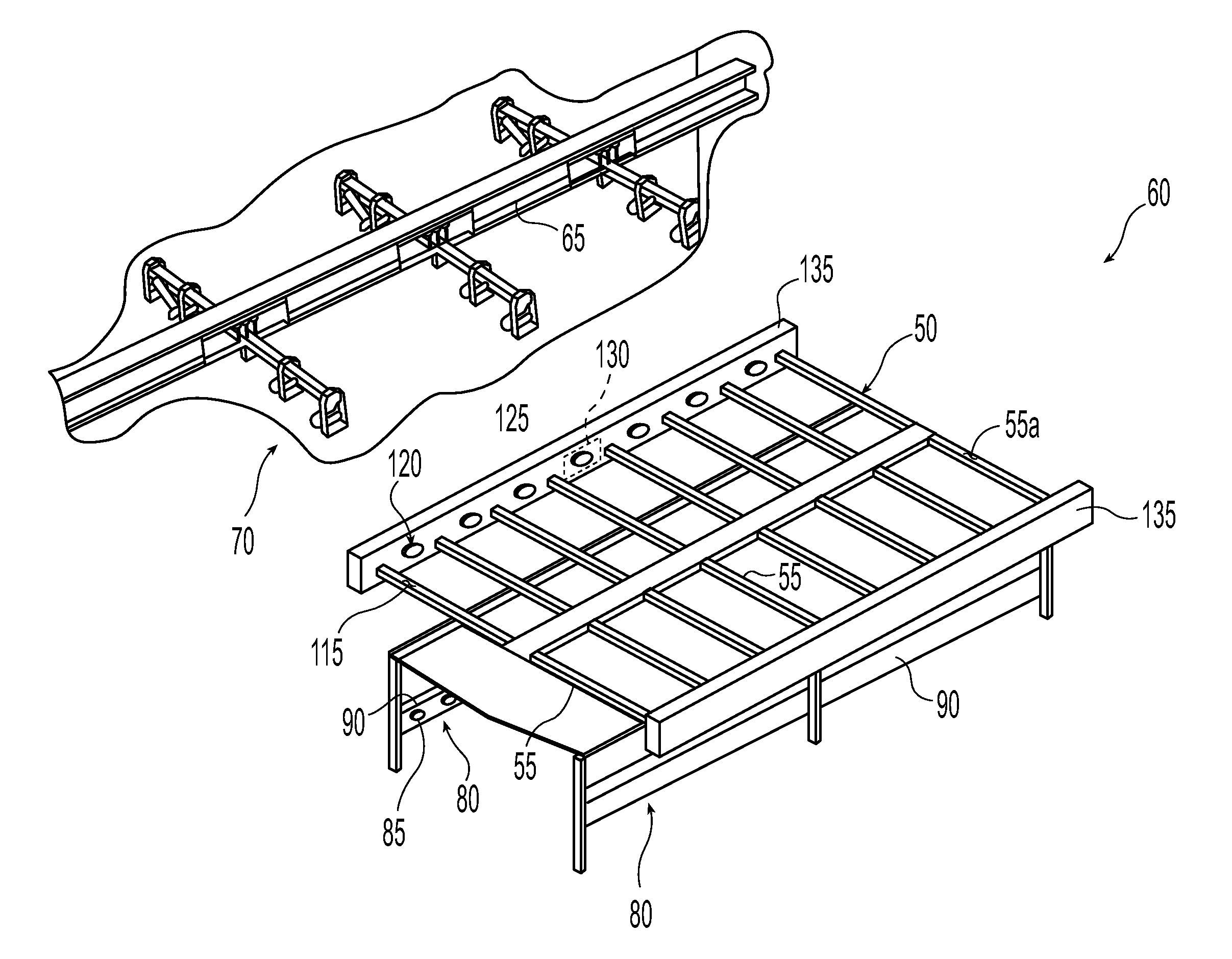

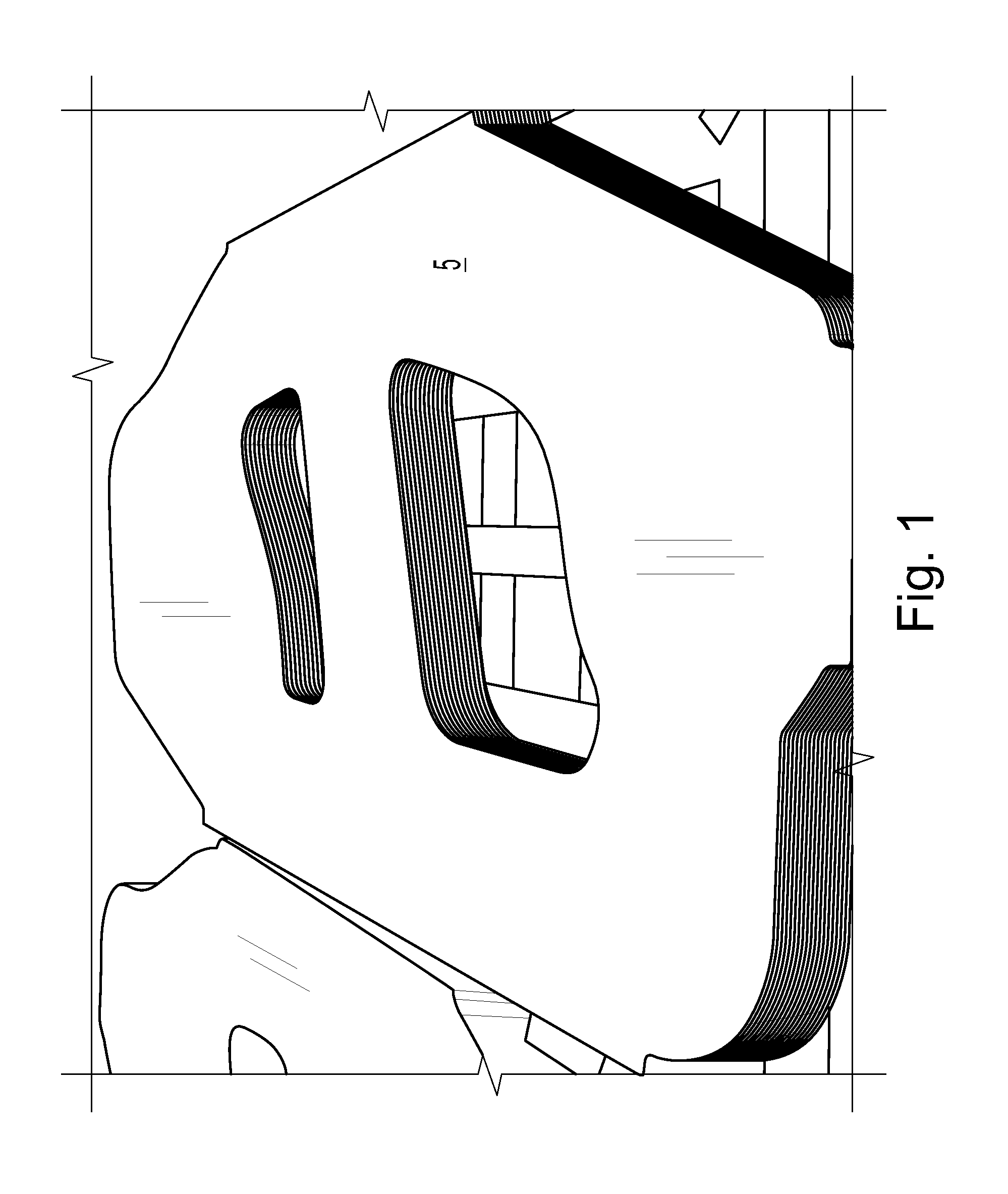

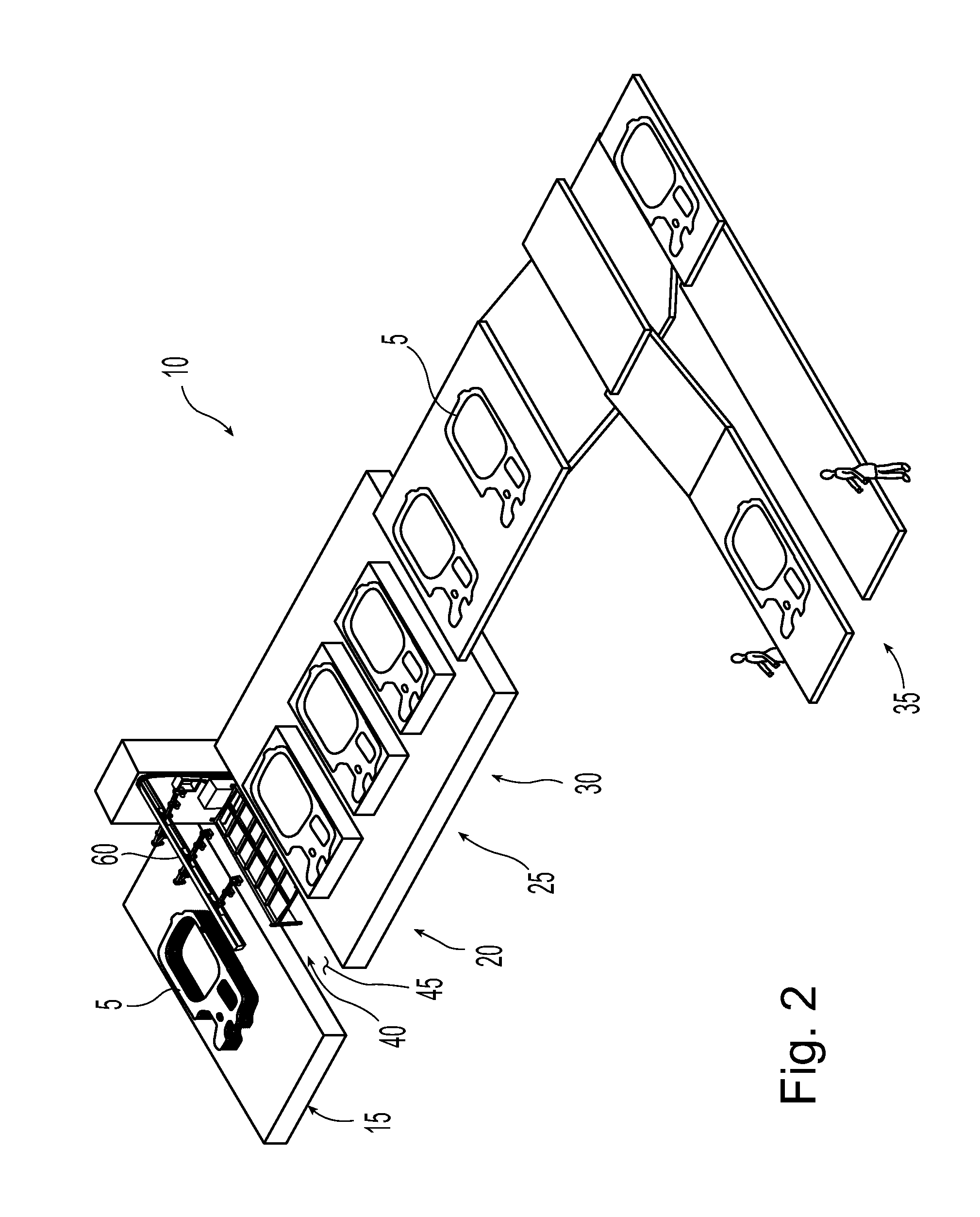

Stamping in-line crack detection system and method

InactiveUS7764823B1Effective blockingExtension of timeMaterial analysis by optical meansCharacter and pattern recognitionStamping processComputer science

A system and method for automatically detecting cracks in components produced by a stamping process. A substantially uniform backlighting of the component can be produced, even when direct backlighting is partially blocked by structure used to support the component during inspection. One or more image detectors simultaneously image the component from a top side while it is backlit. One or more images of the current component are then compared to a master image of the component. Light passing through or visible through cracks in the component will cause the system to see a difference between the current image(s) of the component and the master image(s), thereby indicating a crack(s). A user is automatically notified upon detection of a crack.

Owner:HONDA MOTOR CO LTD

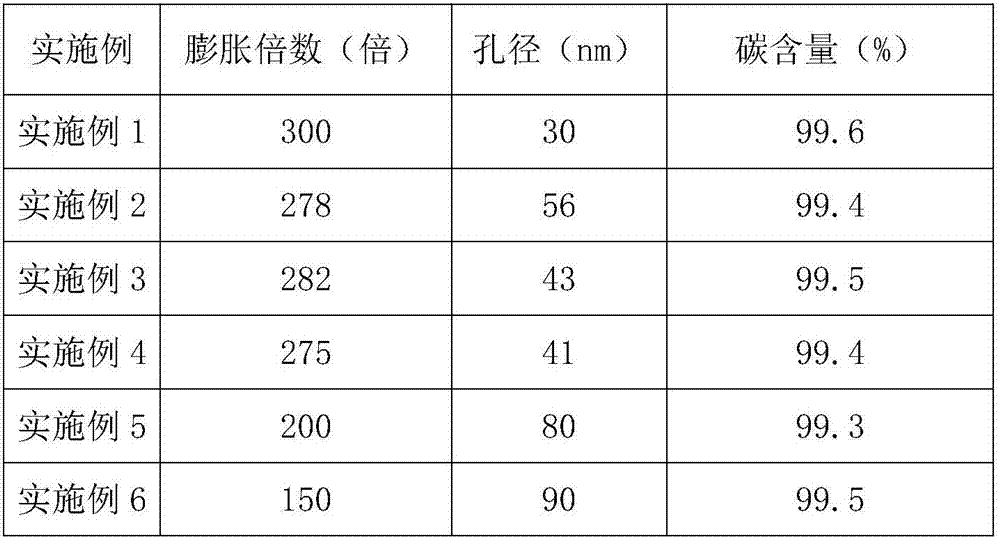

Expanded graphite and preparation method thereof

InactiveCN107311169AImprove stabilityControllable expansion ratioCarbon compoundsGas protectionWind speed

The invention relates to an expanded graphite material, and discloses expanded graphite and a preparation method thereof. The traditional high-temperature expansion method is combined with a graphite expansion furnace; the optimal expansion temperature is used; the product stability can be effectively improved through controlling the raw materials and the process parameters at the expansion temperature, so that the large-scale preparation of stable expanded graphite with controllable expansion times is realized; the expansion times is 200 to 300; the bore diameter is 30 to 100nm; the carbon content is stable. The temperature region is formed by defining the temperature of a feeding opening and a discharging opening; the expansion time is controlled by setting the feeding speed and the wind speed; then, the separation and collection are realized through wind speed; the large-scale preparation is realized; the inert gas protection is not needed; the graphite high-temperature oxidation caused by too high expansion temperature can be prevented, so that the expansion volume of the graphite is reduced.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

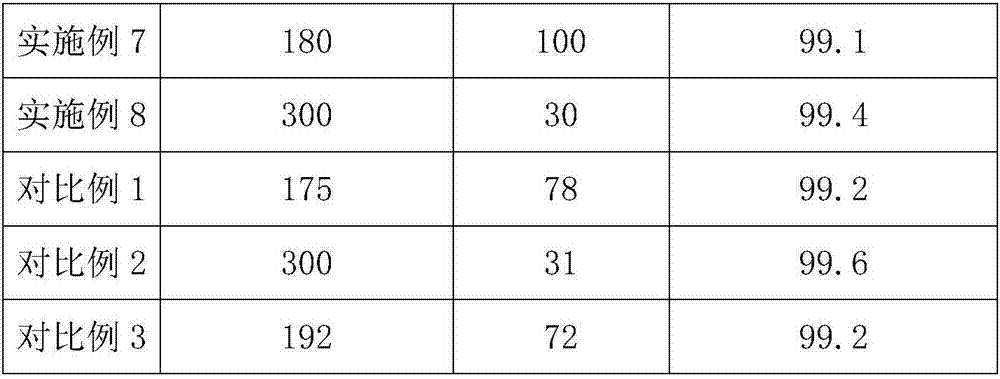

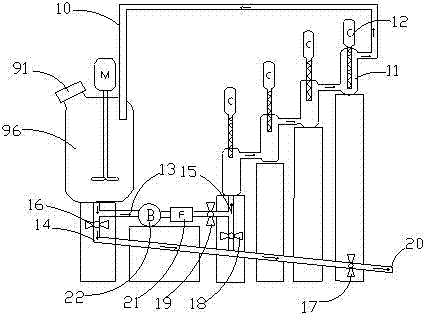

High-temperature pyrolyzing type gaseous mercury form conversion device and method

InactiveCN107238527AAvoid the problem of poison inactivationShort conversion timePreparing sample for investigationFurnace typesHeat fluxTime efficient

The invention discloses a high-temperature pyrolyzing type gaseous mercury form conversion device and a method. The device adopts a high temperature cracking furnace for heating the incoming flue gas on the basis of the high-temperature pyrolyzing characteristic of mercury under oxidation state, the in-furnace pipeline adopts the spiral arrangement for increasing the staying time of the flue gas in the cracking furnace and the heat exchange area of the gas flow in the pipe is expanded; and meanwhile, a granular inertial ceramic heat storage material is filled in a central area of a spiral pipe, the heat flux in the core area is increased, the heating uniformity of the gas flow in the pipe is promoted and the cracking time of the mercury under oxidation state is shortened; and an acidic gas absorbent is filled in a straight pipe on an outlet section of the cracking furnace, so that the secondary oxidation of the mercury under element state is eliminated and the measuring deviation of the mercury concentration is avoided. The device disclosed by the invention can completely realize the conversion of the mercury under oxidation state to the mercury under element state in the gas phase and can realize the real-time efficient conversion and online accurate measurement for the mercury form concentration in the gas phase under a practical flue gas condition.

Owner:SOUTHEAST UNIV

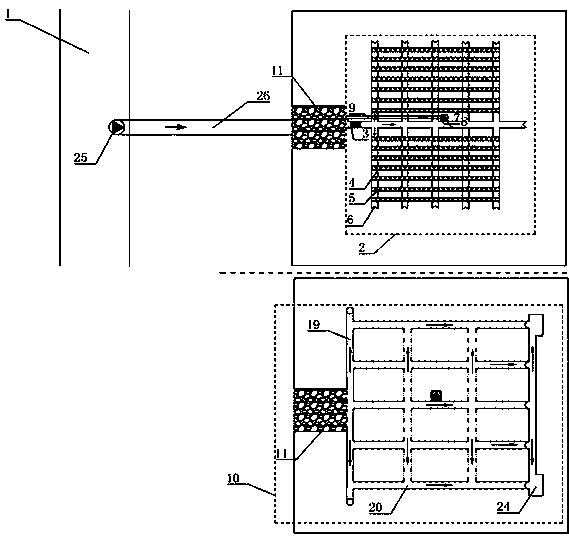

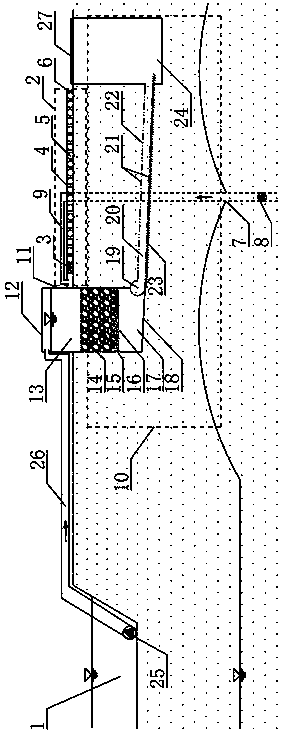

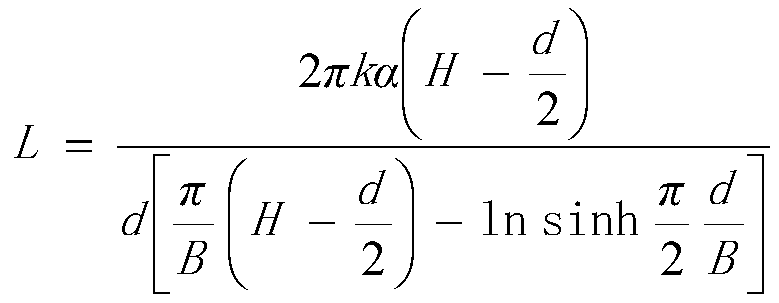

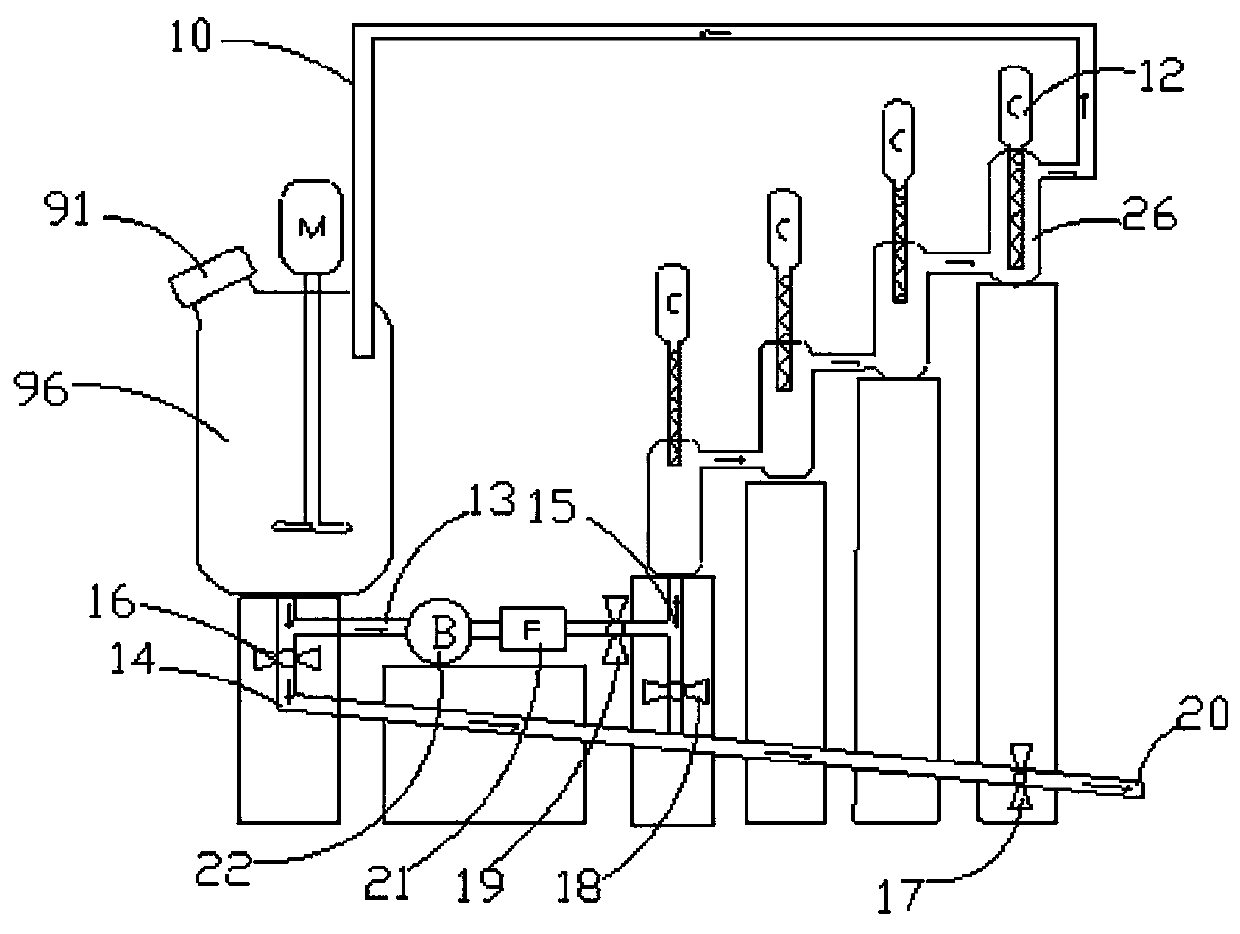

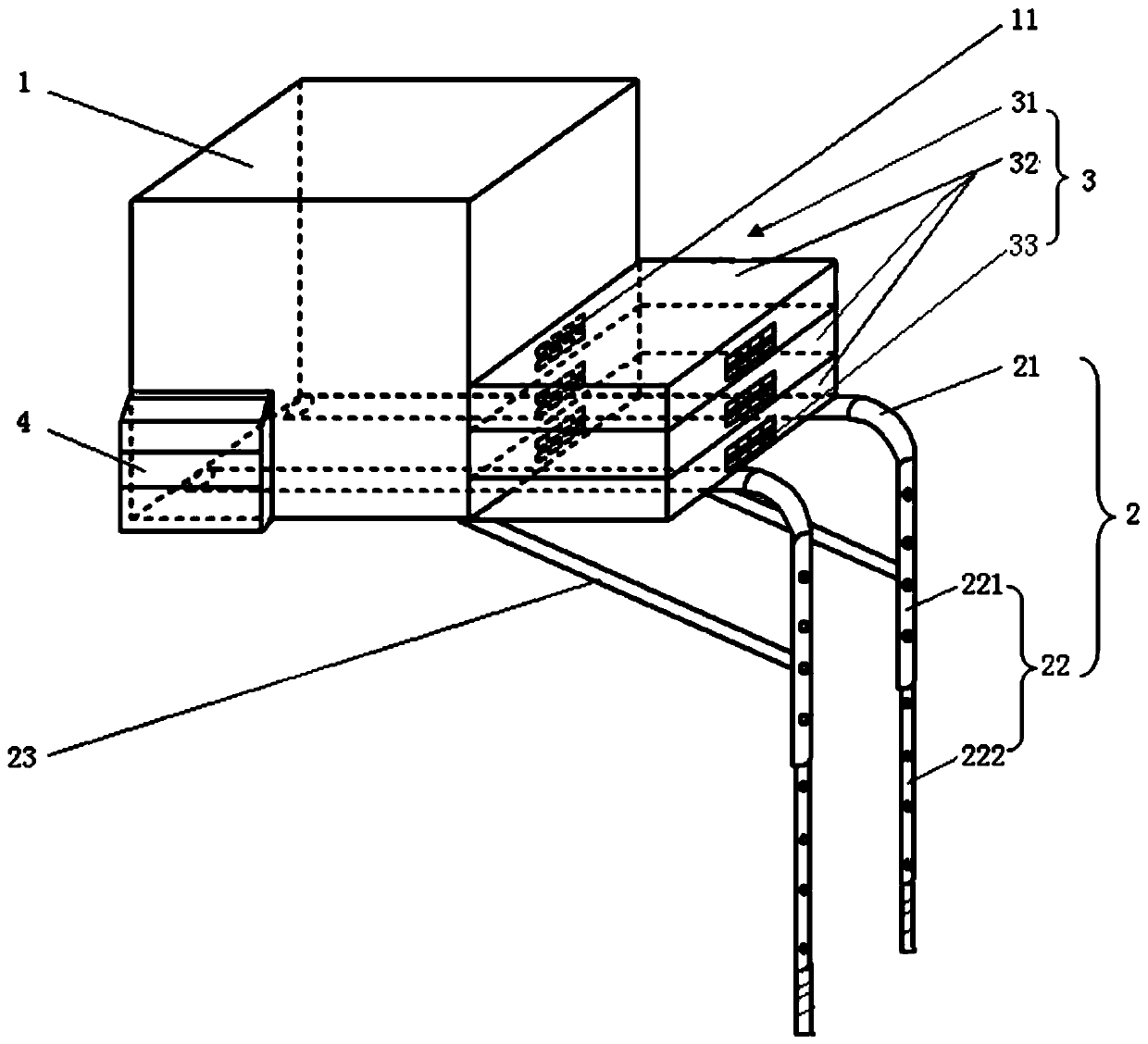

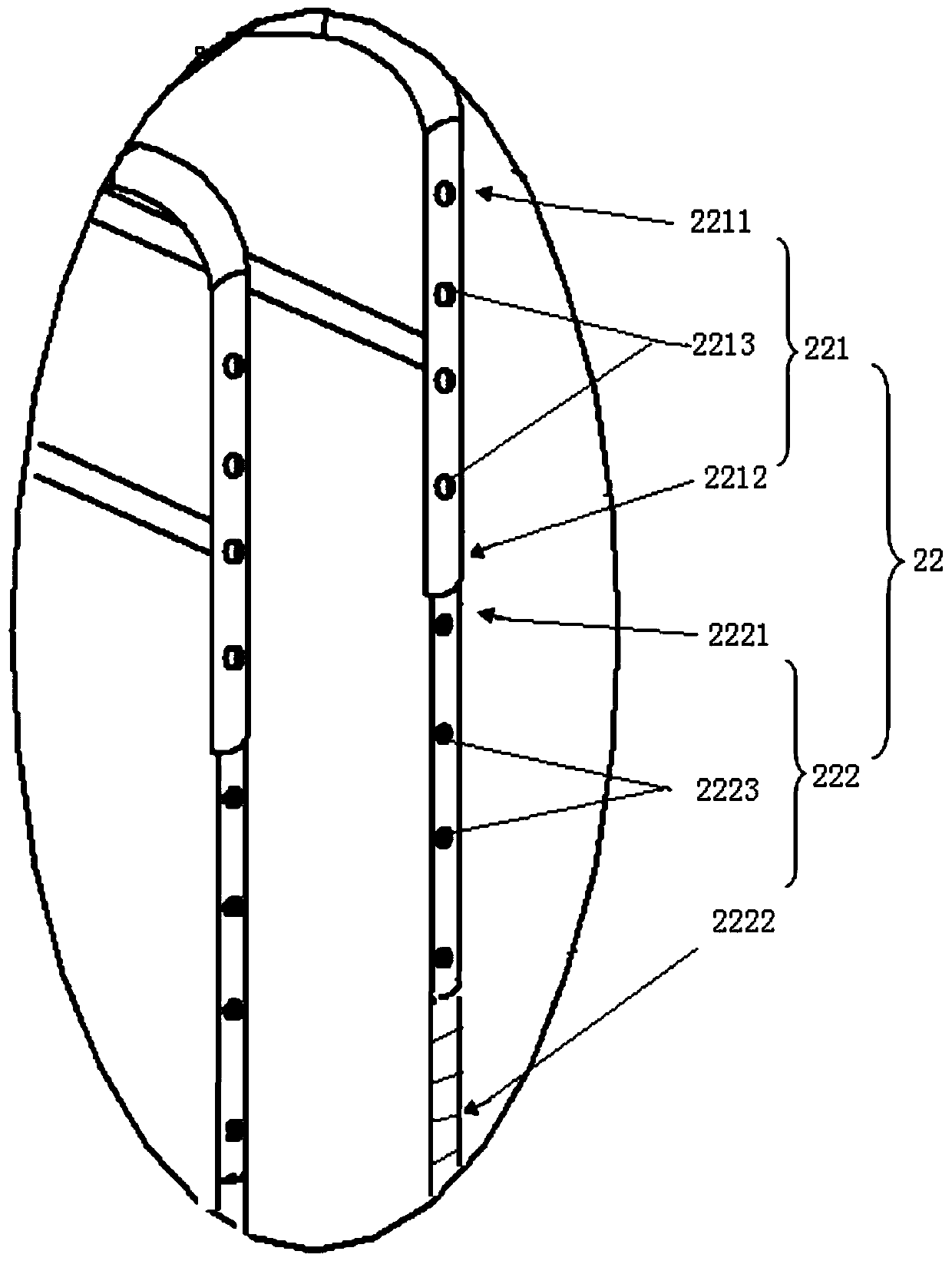

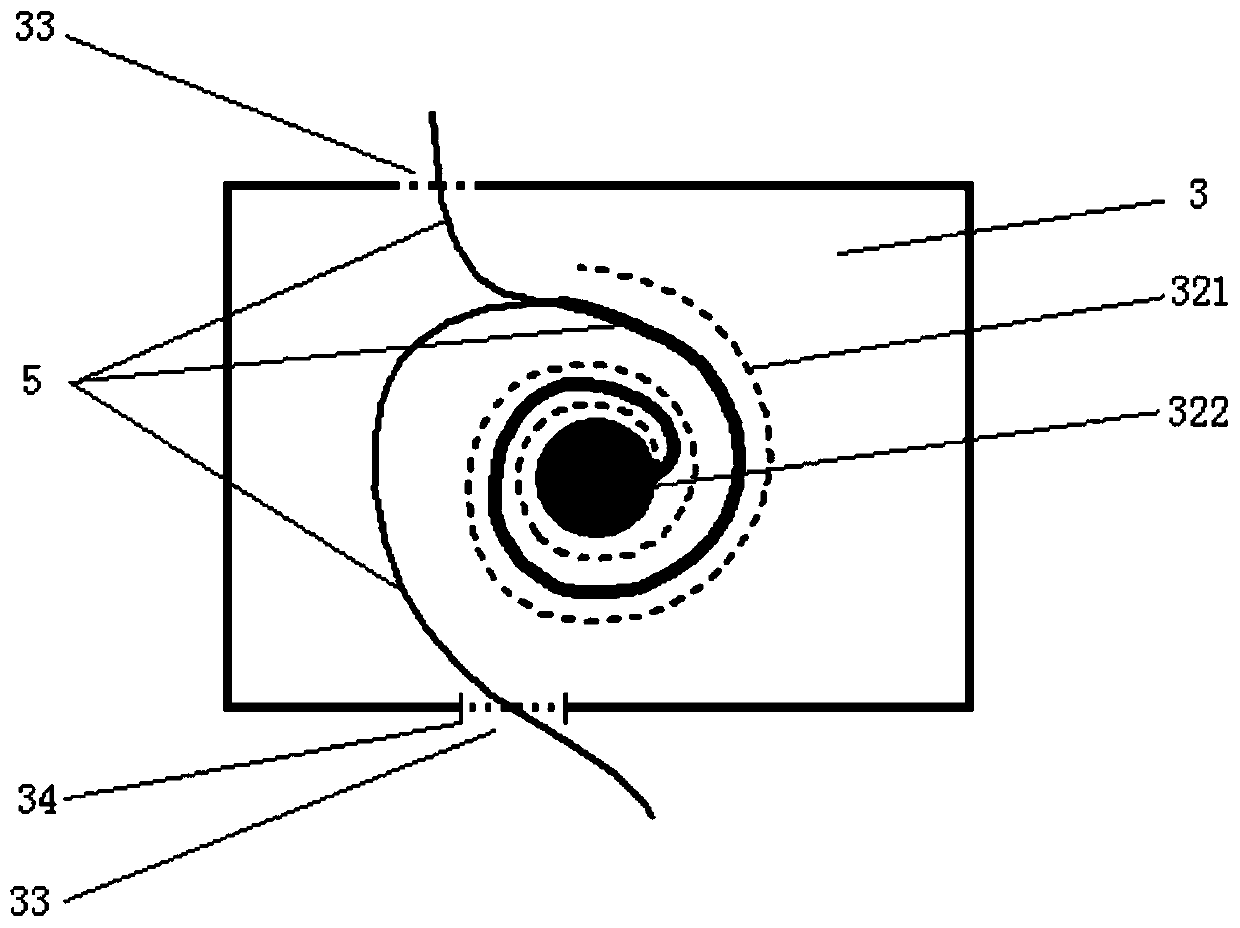

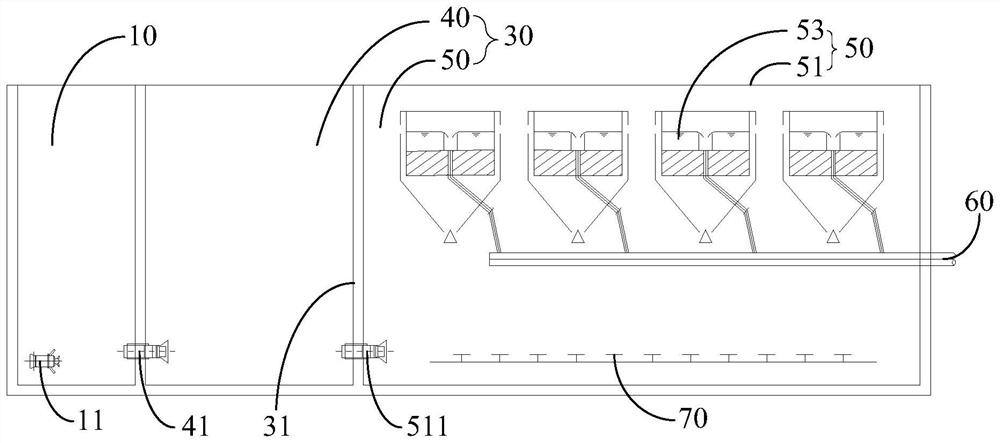

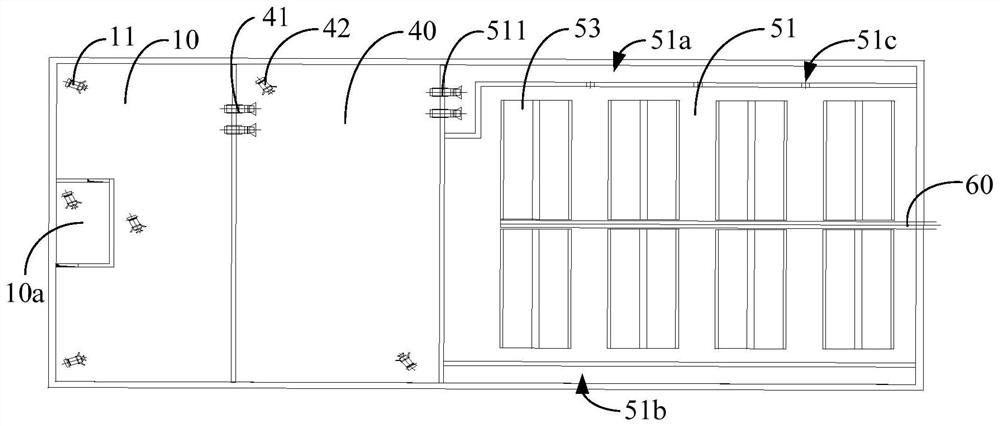

Overexploitation area surface water-saving irrigation and low-pressure underground pipe network recharge exploitation supplement coupled system

ActiveCN110663512AAvoid cloggingIncrease moisture contentWatering devicesCultivating equipmentsWater sourceWater filter

The invention provides an overexploitation area surface water-saving irrigation and low-pressure underground pipe network recharge exploitation supplement coupled system which comprises a water source, a filter tank, an underground pipe network, a surface drip irrigation device and an underground water recharge device. The water inlet end of the filter tank is communicated with the water source through a first centrifugal pump and a first conveying pipeline, the underground pipe network comprises a plurality of underground water filter pipes which are vertically and horizontally staggered andmutually communicated, one end of each underground water filter pipe is connected with the filter tank through a water collecting pipe, the other end of each underground water filter pipe is connectedwith a settling tank, the surface drip irrigation device comprises a pivot head, a drip irrigation belt and a drip irrigation head, one end of the pivot head is connected with the water outlet end ofthe filter tank, the other end of the pivot head is connected with multi-row main pipes, multi-line branch main pipes are connected with the main pipes, the drip irrigation belt is connected with thebranch main pipes, the drip irrigation head is arranged on the drip irrigation belt, the underground water recharge device comprises an exploited well, and underground water is conveyed into the irrigation belt through a second centrifugal pump and a water conveying pipeline.

Owner:UNIV OF JINAN

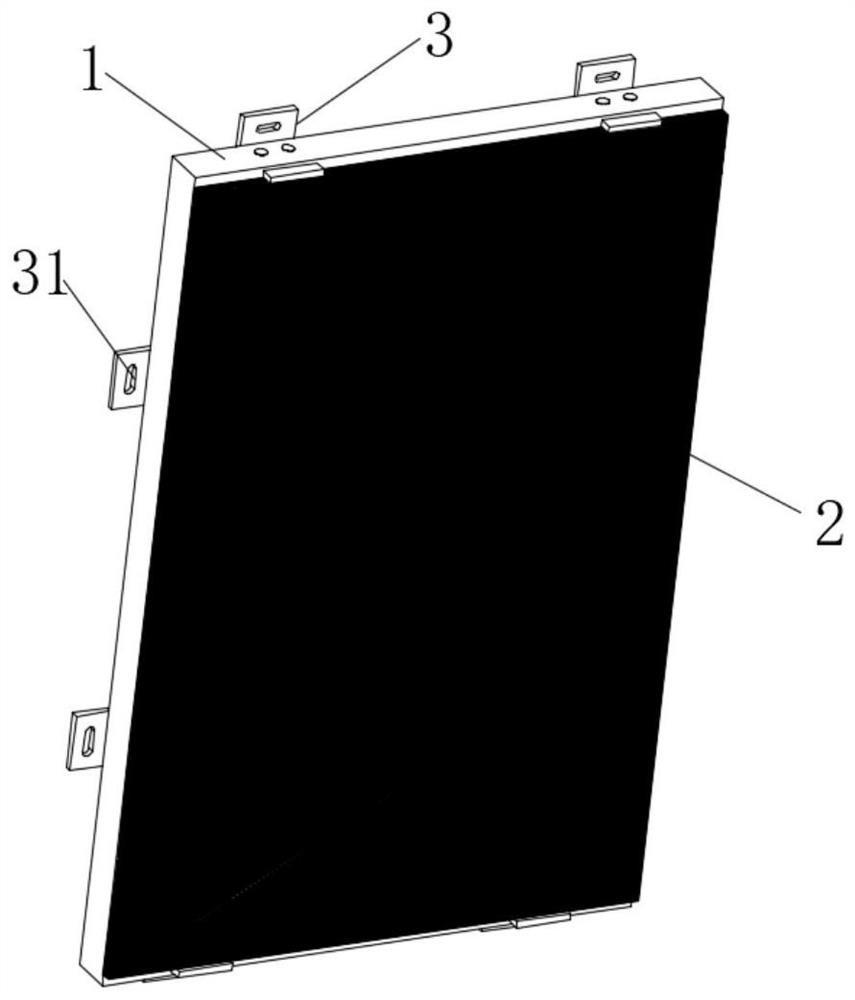

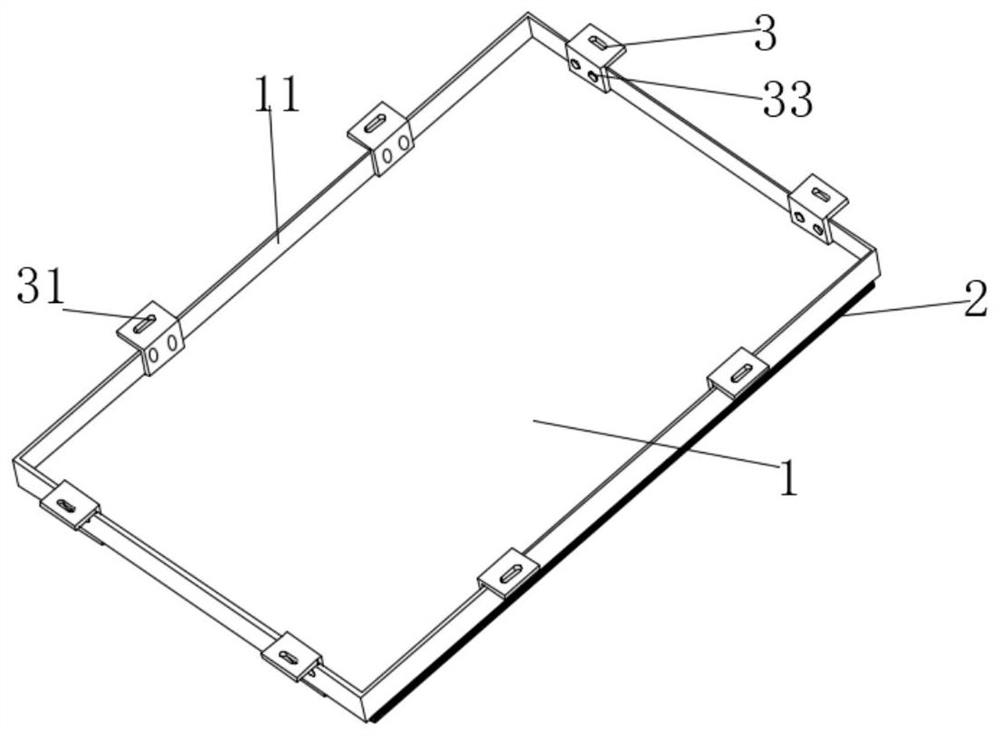

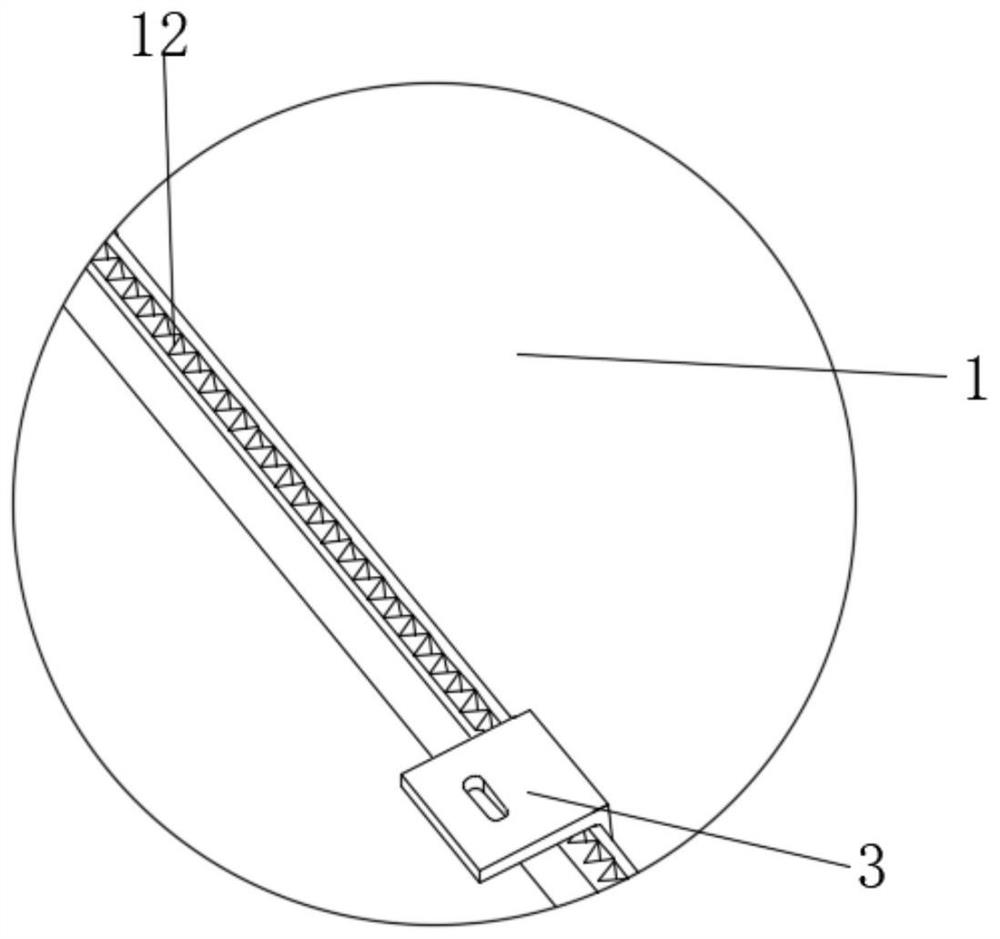

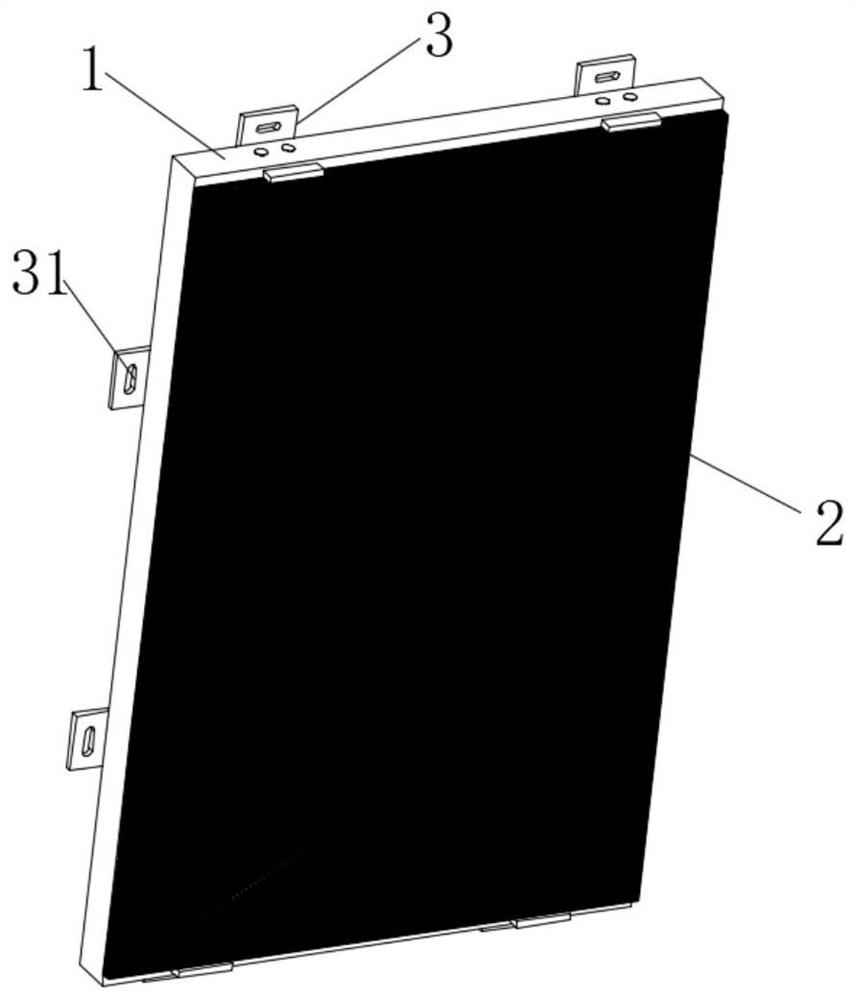

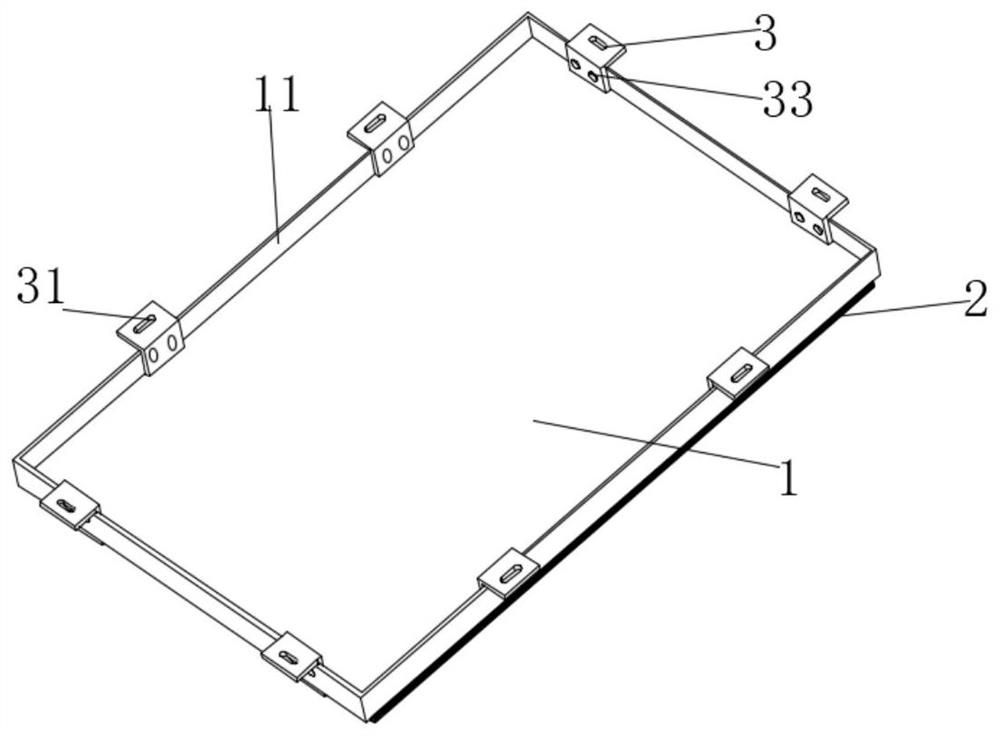

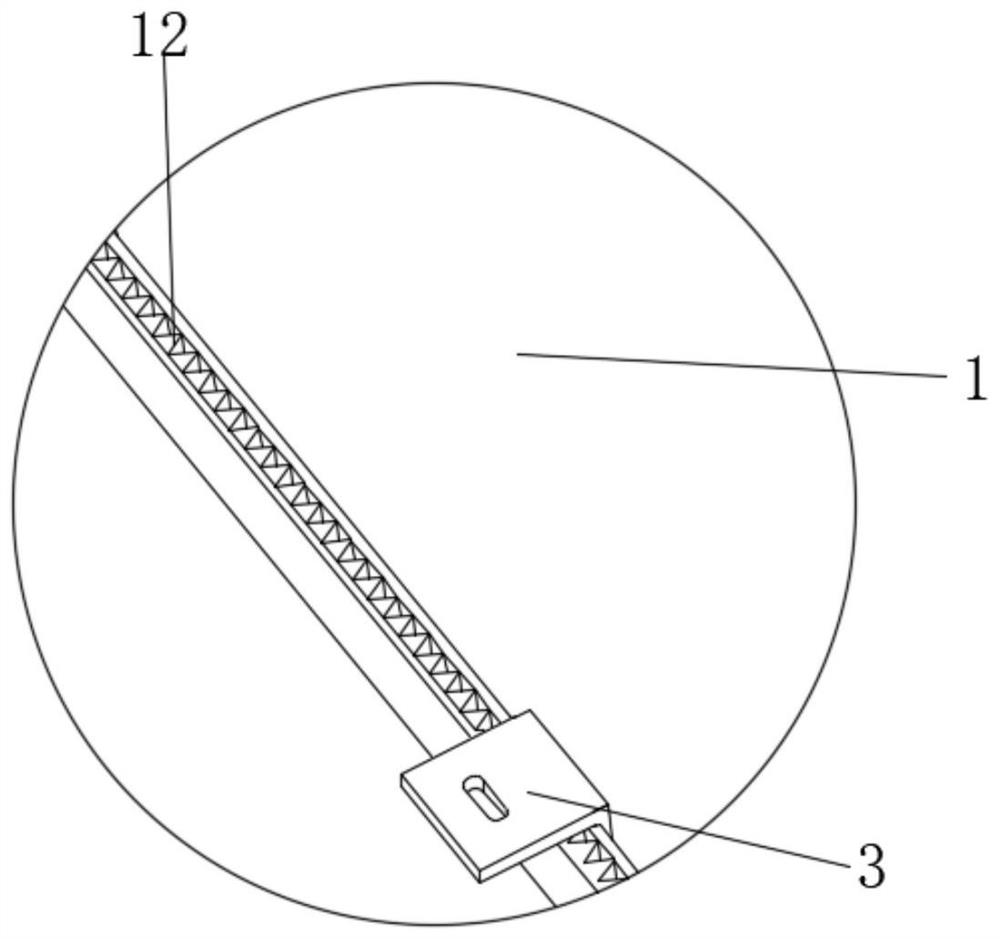

Rock-aluminum composite board unit type curtain wall and production process thereof

The invention discloses a rock-aluminum composite board unit type curtain wall which comprises an aluminum board; a rock board is fixed on the upper surface of the aluminum board; internal and external corner connector connecting pieces connected in series are fixed to the periphery of the aluminum board; and the rock-aluminum composite board unit type curtain wall has high strength, good rigidity and light weight, can be installed on an outer wall through keels for decoration in a way of being hidden at the inside, cannot fall off and has extremely high safety. The technical problem that exterior wall decoration cannot be performed in a tiling mode after a certain height is reached on an existing building is solved. The production process comprises the steps of material preparation, angle opening, hole punching, hole carving, bending forming, welding, acid pickling, chromizing, rock plate pasting and assembling to form the unit type curtain wall. According to the rock plate pasting process, automatic pasting is performed through pasting equipment, time and labor are saved, the automation degree is high, meanwhile, the precision is high, the yield is high, and the technical problem that manual pressing is needed in an existing pasting process is solved.

Owner:吉祥铝业(长兴)有限公司

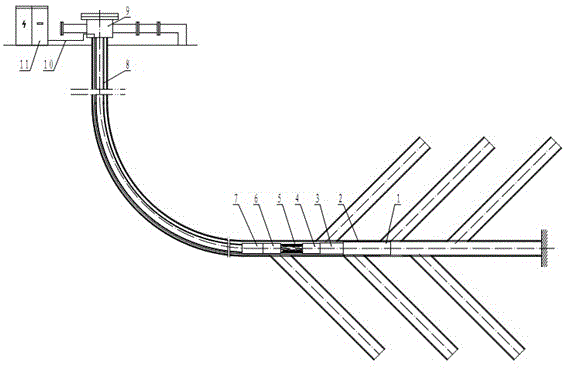

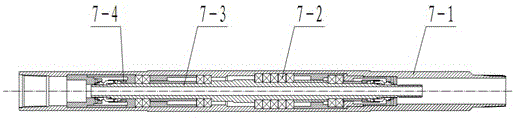

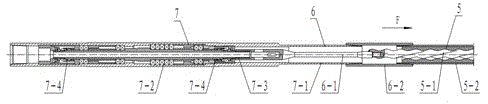

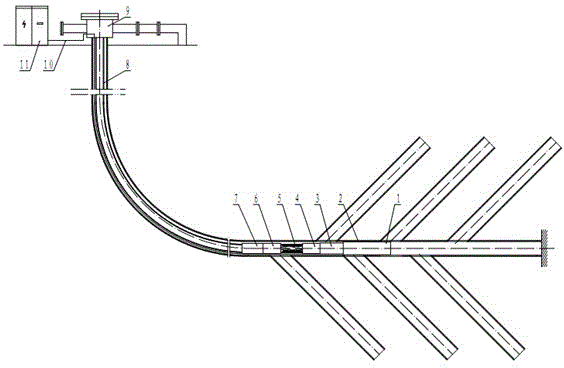

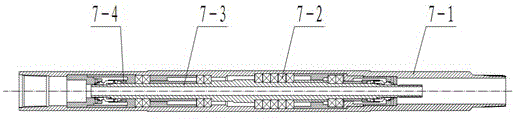

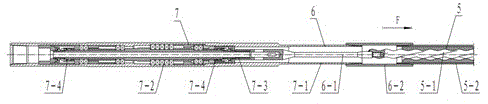

Special underground direct-driven discharging and extracting equipment for coal bed gas

The invention provides special underground direct-driven discharging and extracting equipment for coal bed gas, and belongs to the technical field of mining. The equipment comprises a sleeve, a motor, a motor protector, a righting bearing component, a screw pump, a special connector, a special axial force supporting mechanism and an oil pipe, wherein the motor is arranged on the bottom part of a pitshaft; a motor output shaft is connected with an input end of a rotor of the screw pump through the motor protector and the righting bearing component; an output end of the rotor of the screw pump is connected with the special axial force supporting mechanism; the special connector consists of an internal shaft and an outer casing; a stator of the screw pump and the special axial force supporting mechanism are connected by the special connector; the oil pipe is connected between a special pithead and the special axial force supporting mechanism; the sleeve is embedded on the inner wall of the pitshaft; all constitutive elements are sheathed in the sleeve. By applying the equipment, a gap at the aspect of discharging and extracting techniques for coal bed gas highly-deviated wells and multi-branch horizontal wells is filled; compared with a traditional discharging and extracting way, the equipment realizes the multiplied increase of gas production; meanwhile, the floor area of the discharging and extracting equipment is decreased.

Owner:TANGSHAN YULIAN ELECTROMECHANICAL

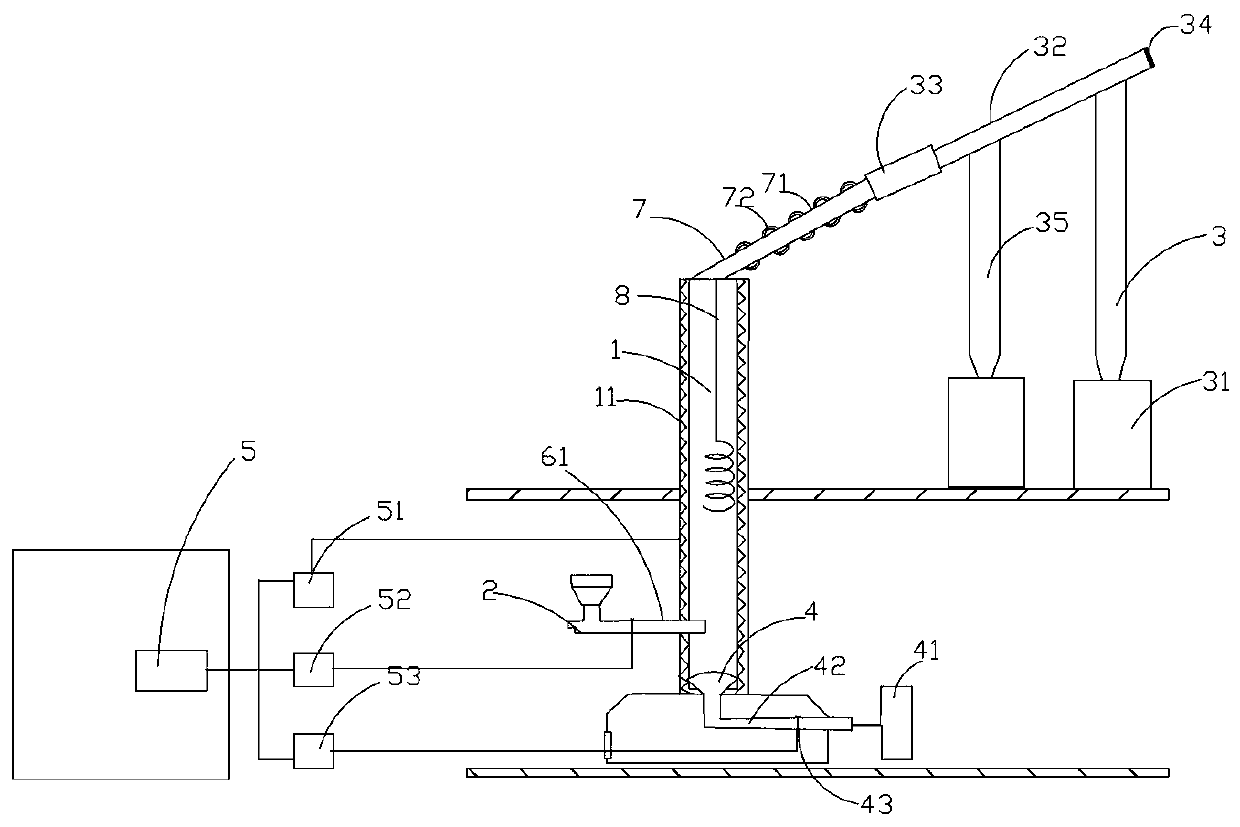

Graphene production system

The invention relates to the field of graphene production and discloses a graphene production system which comprises a graphite exfoliating furnace, a secondary ultrasonic device and a filtering device, wherein the graphite exfoliating furnace is connected with the secondary ultrasonic device; the secondary ultrasonic device is connected with the filtering device; intercalation graphite is adopted as a raw material; the intercalation graphite is exfoliated in sequence by using the graphite exfoliating furnace to prepare exfoliated graphite, the exfoliated graphite is further conveyed through the secondary ultrasonic device and the filtering device, and thus graphene is finally prepared. With the combination of the exfoliating furnace and the secondary ultrasonic device, high-multiplied exfoliated graphite is prepared by using the exfoliating furnace, the exfoliated graphite as the raw material is subjected to pre-exfoliation and ultrasonic exfoliation, circulation reaction is implemented, and together with secondary ultrasonic exfoliation, the exfoliation efficiency can be greatly improved, and thus large-scale, high-efficiency and low-cost production of graphene is achieved.

Owner:郴州国盛新材科技有限公司

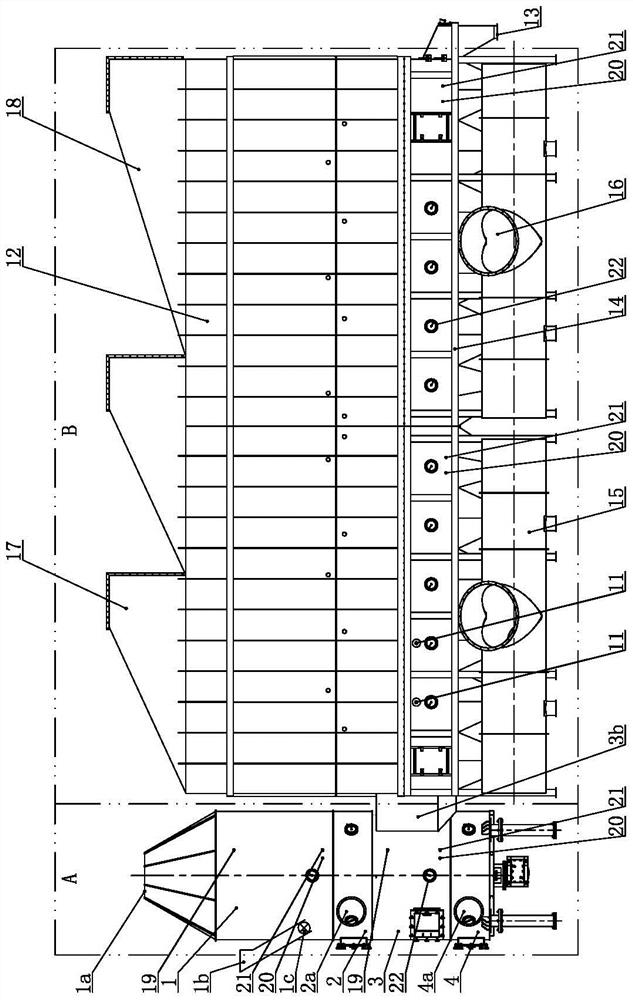

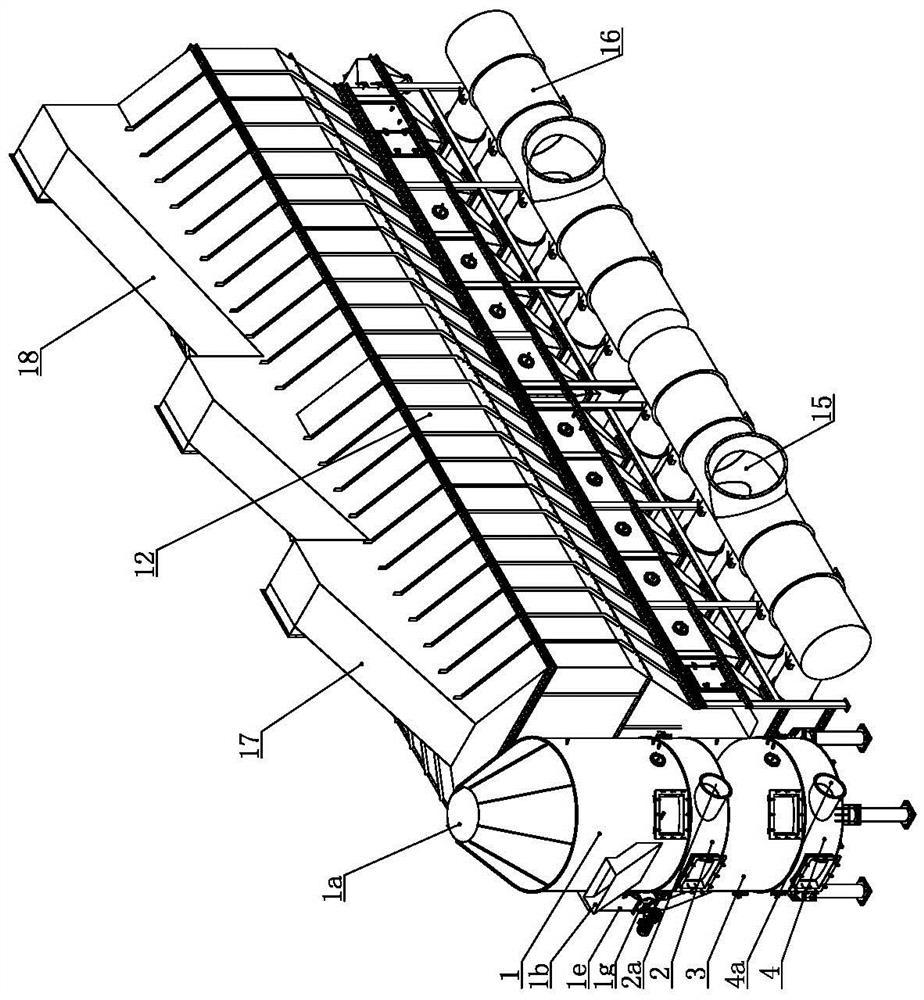

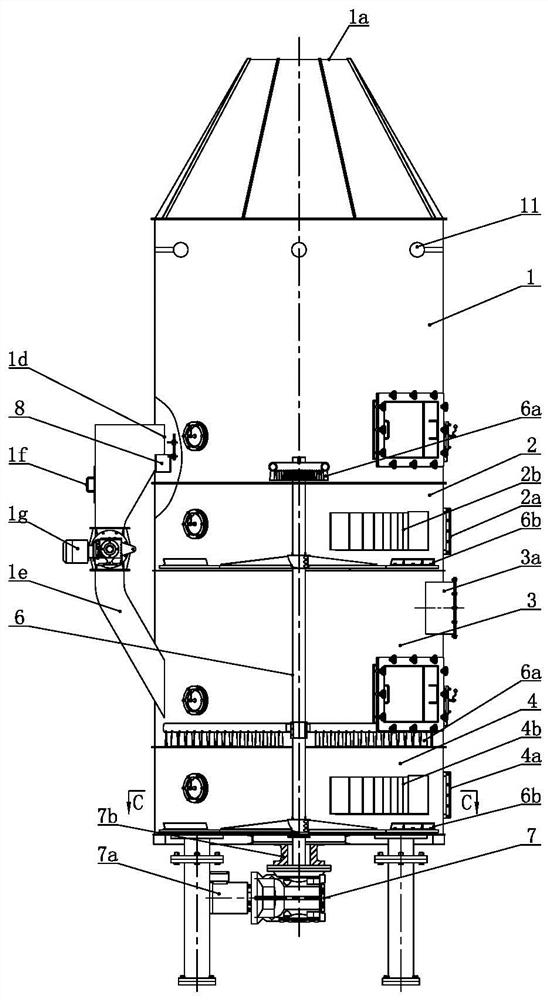

Multi-stage fluidization tower

PendingCN111637687AReduce pollutionAvoid repeated dryingDrying solid materials with heatFeeding-stuffStructural engineeringIndustrial engineering

The invention relates to a multi-stage fluidization tower. A main shaft is arranged along the axis of a pre-drying tower, a first pre-drying layer, a first interlayer air chamber, a second pre-dryinglayer and a second interlayer air chamber are sequentially arranged in an inner cavity of a cylinder body of the pre-drying tower from top to bottom, rake type stirring fins are arranged above circular sieve plates of the first pre-drying layer and the second pre-drying layer, and the rake type stirring fins are fixed on the main shaft; air inlets are formed in the side walls of the first interlayer air chamber and the second interlayer air chamber, and air outlets are formed in the top center of the first pre-drying layer and an upper cylinder wall of the second pre-drying layer; a feeding chute and a first pre-drying overflow port are connected to the side wall of the first pre-drying layer, a scattering device is arranged at an outlet of the feeding chute, and the first pre-drying overflow port is connected with a feeding port in the cylinder wall of the second pre-drying layer through a pre-drying chute; and a second pre-drying overflow port is further formed in the cylinder wall of the second pre-drying layer and is in butt joint with a feeding port of the horizontal multi-stage fluidized bed. The drying machine does not need material returning, first-in first-out of materialsis achieved, and the discharging quality is high.

Owner:MYANDE GRP CO LTD

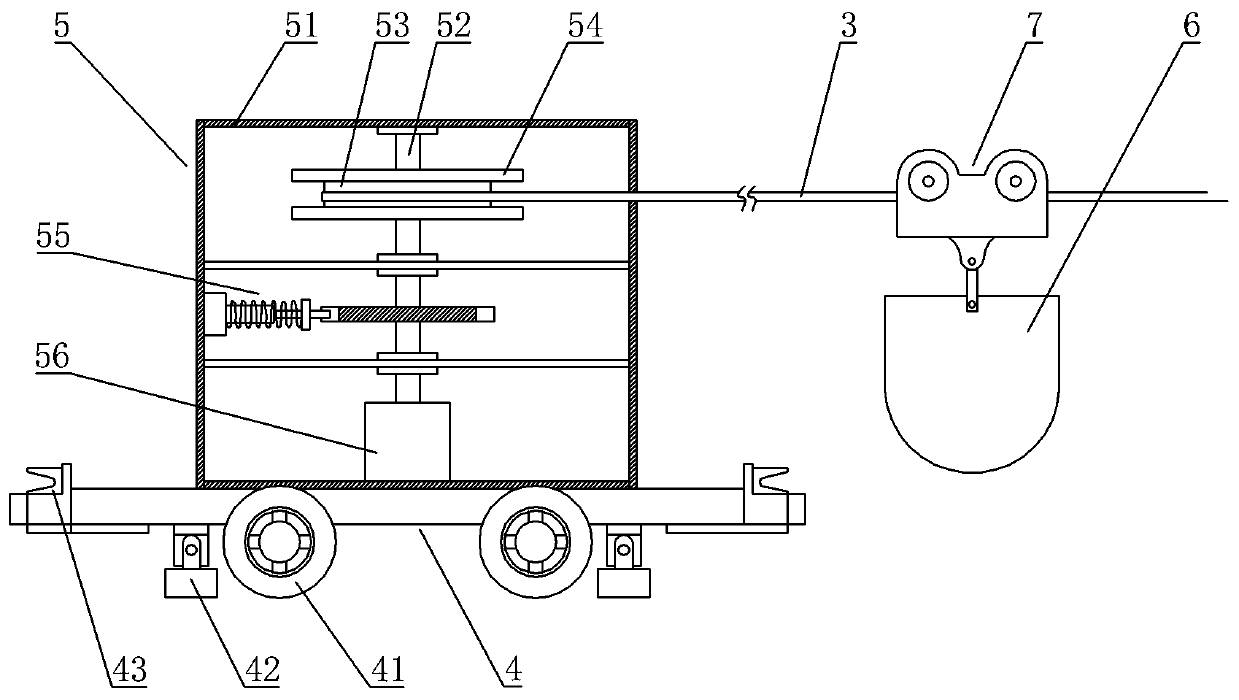

Aerial track capable of being used in mine

InactiveCN108438006AExtended service lifeImprove stabilityRope railwaysMine carsPower modeDerailment

The invention provides an aerial track capable of being used in a mine. The aerial track comprises a mine frame arranged in the mine and a tramcar chassis, and a plurality of track frames are arrangedin the mine frame. The track frames comprise horizontal rods, vertical rods are arranged at two ends of the horizontal rods, the horizontal rods are further provided with a connecting rod connected with the mine frame, and a track is arranged above the horizontal rods in a penetrating mode. The tramcar chassis is provided with a track transmission device, and the track transmission device is connected with the track in a power mode. When the aerial track is in use, the track can be directly placed on the track frames, so that a tramcar can be suspended and transported on the track, and the problem that a previous tramcar track occupies ground space is solved; the bottom of the tramcar is kept away from the wet ground, the problems of easy corrosion, corrosion and sticky bottom are prevented, and the service life of the tramcar is prolonged; and a gravity ball is arranged in a carriage to keep the carriage balanced to increase the stability of the track, and the problem of easy derailment of a track connection device is solved.

Owner:YONGCHENG VOCATIONAL COLLEGE

Method for preparing microcrystalline graphene nanosheet/silicon composite electrode material

InactiveCN107785556AImprove conductivityTake full advantage of high-capacity featuresMaterial nanotechnologyCell electrodesMaterials scienceRaw material

The invention belongs to the technical field of material preparation and in particular relates to a method for preparing a microcrystalline graphene nanosheet / silicon composite electrode material. Themethod disclosed by the invention comprises the following steps: by taking microcrystalline graphite as a raw material, sequentially performing primary chemical intercalation treatment, primary hightemperature puffing treatment, secondary intercalation treatment and secondary high temperature puffing treatment on the microcrystalline graphite so as to obtain secondary puffed microcrystalline graphite; performing ultrasonic treatment on the secondary puffed microcrystalline graphite twice so as to obtain a stripping material, performing filter pressing, separating, cleaning and drying on thestripping material to obtain graphene; and mixing and carrying out ball milling on graphene nanosheets and nanometer silicon in inert gases, thereby obtaining the microcrystalline graphene nanosheet / silicon composite electrode material. According to the method disclosed by the invention, the production process flow is simple, the cost is low and a sulfur-free effect is achieved, and the microcrystalline graphene nanosheet / silicon composite electrode material can be prepared in batches.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

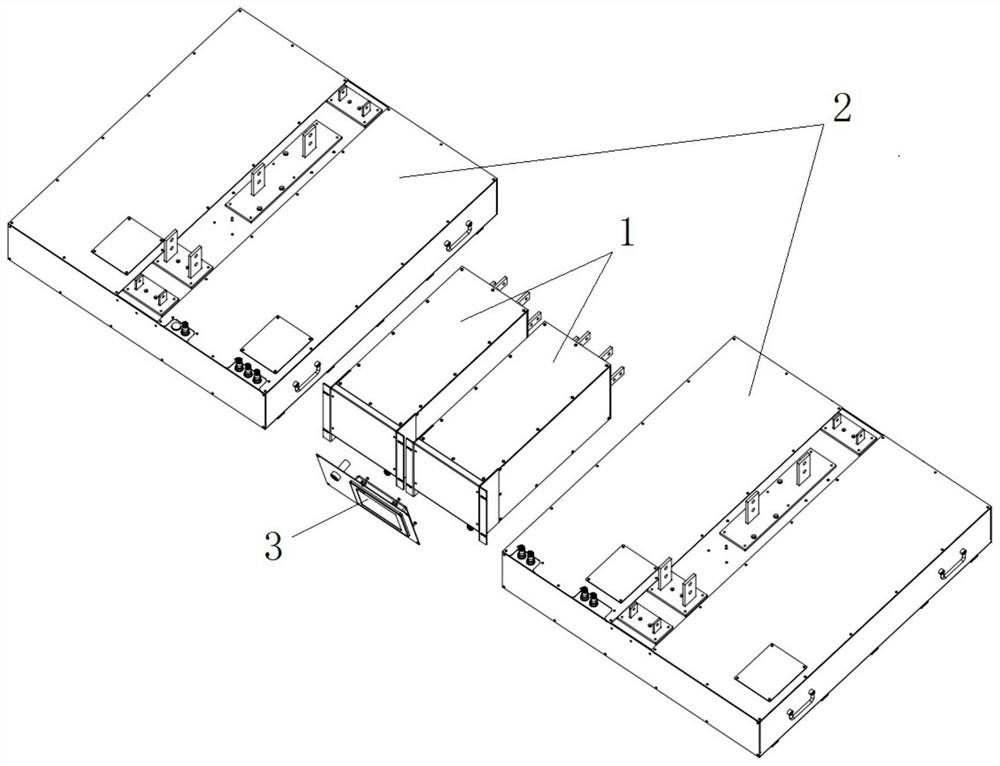

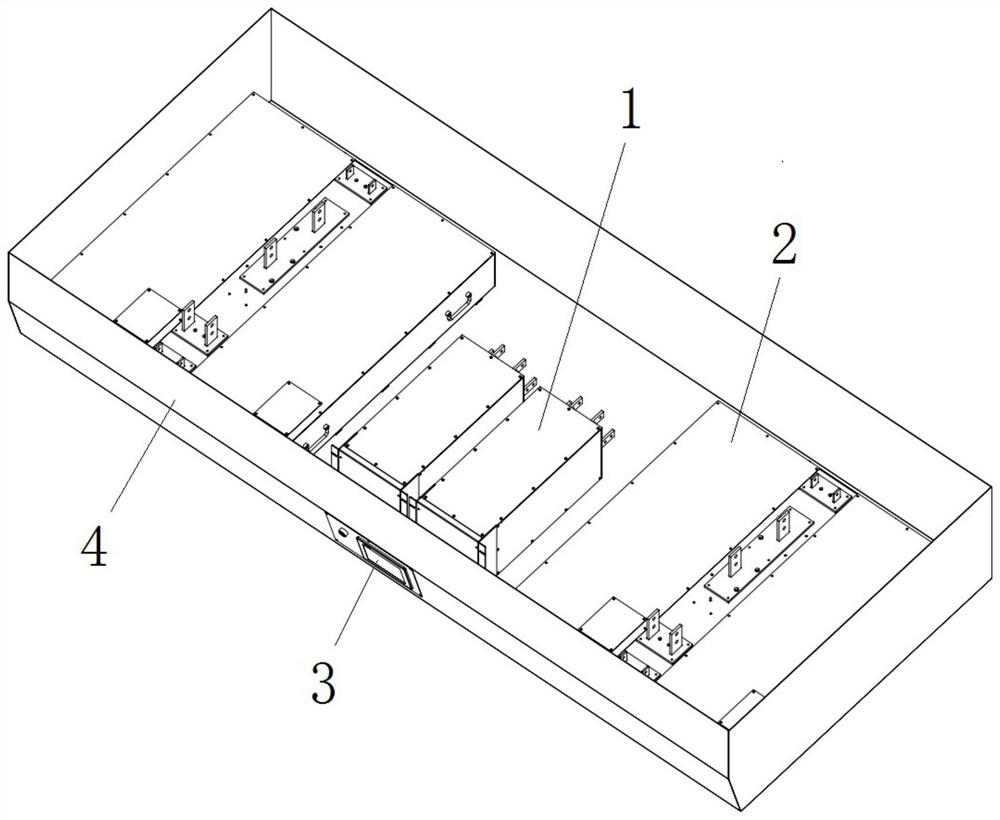

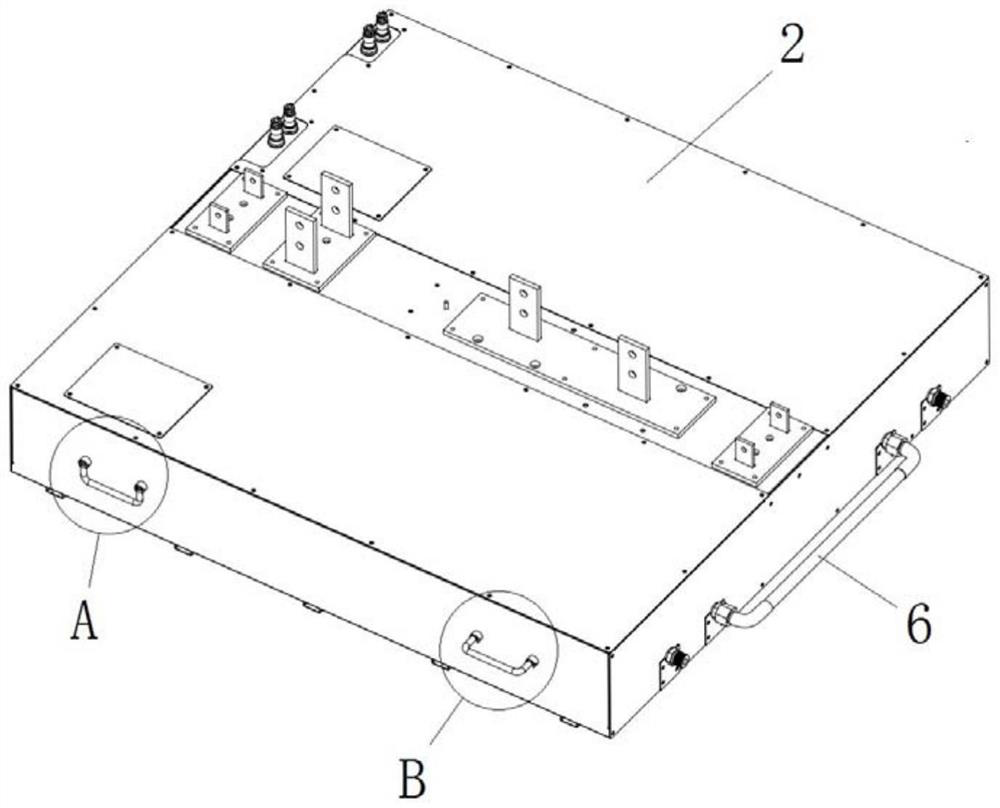

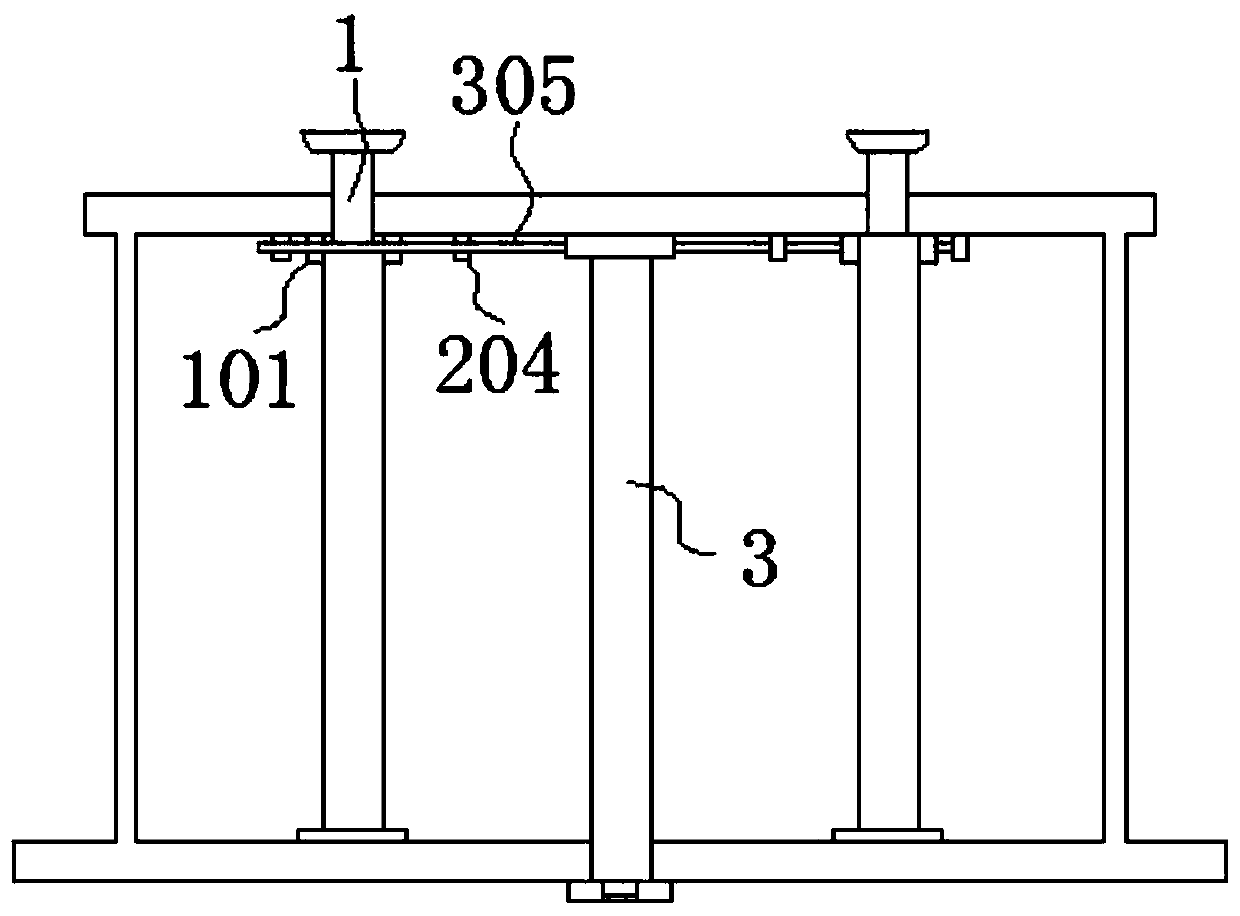

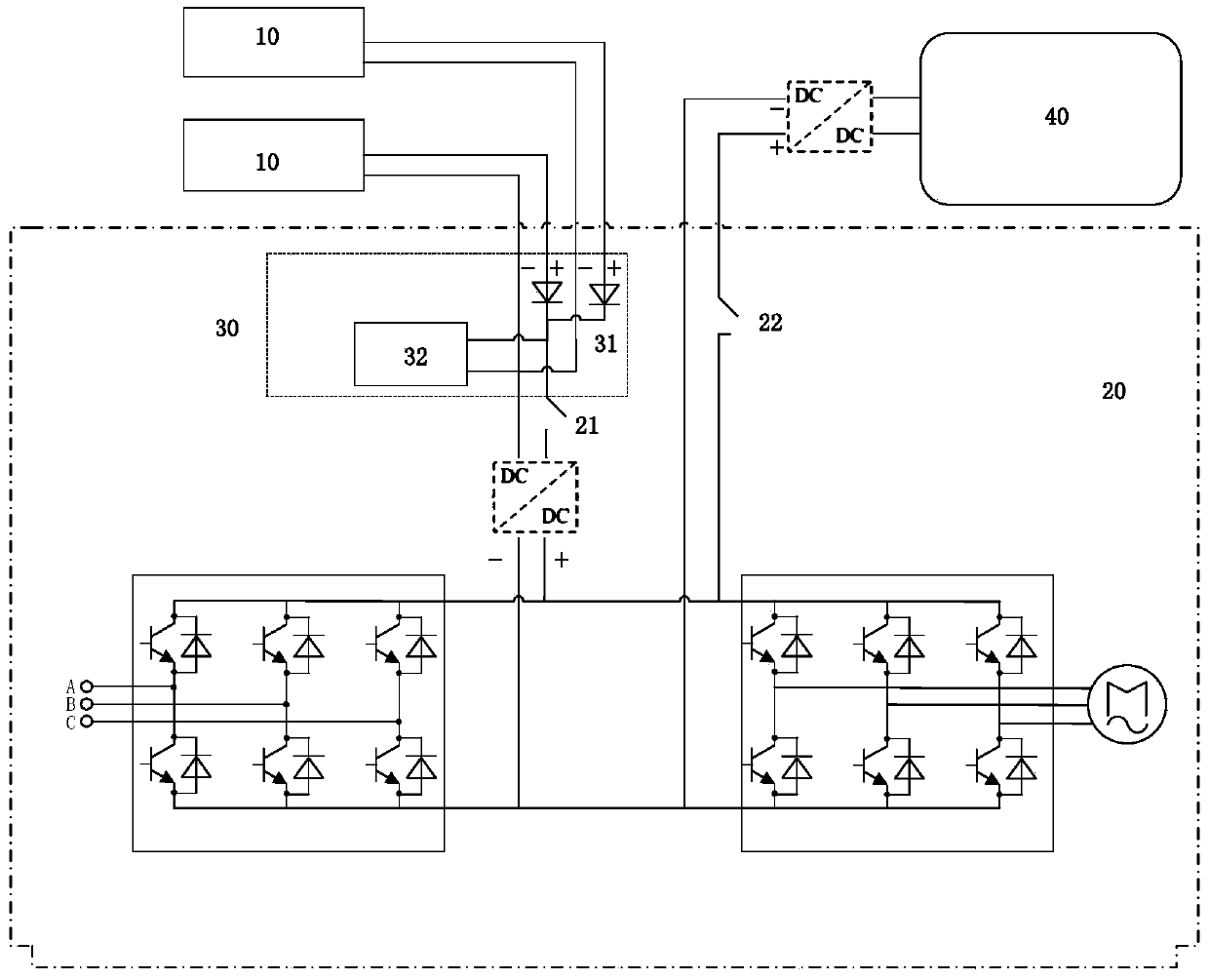

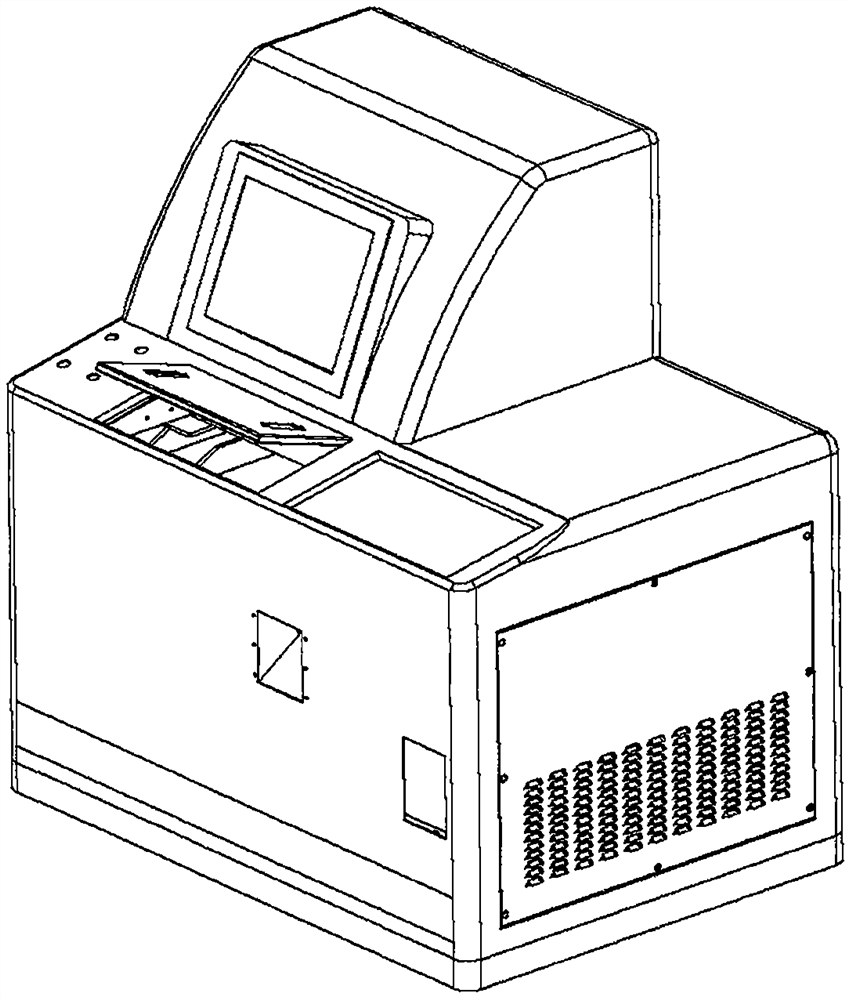

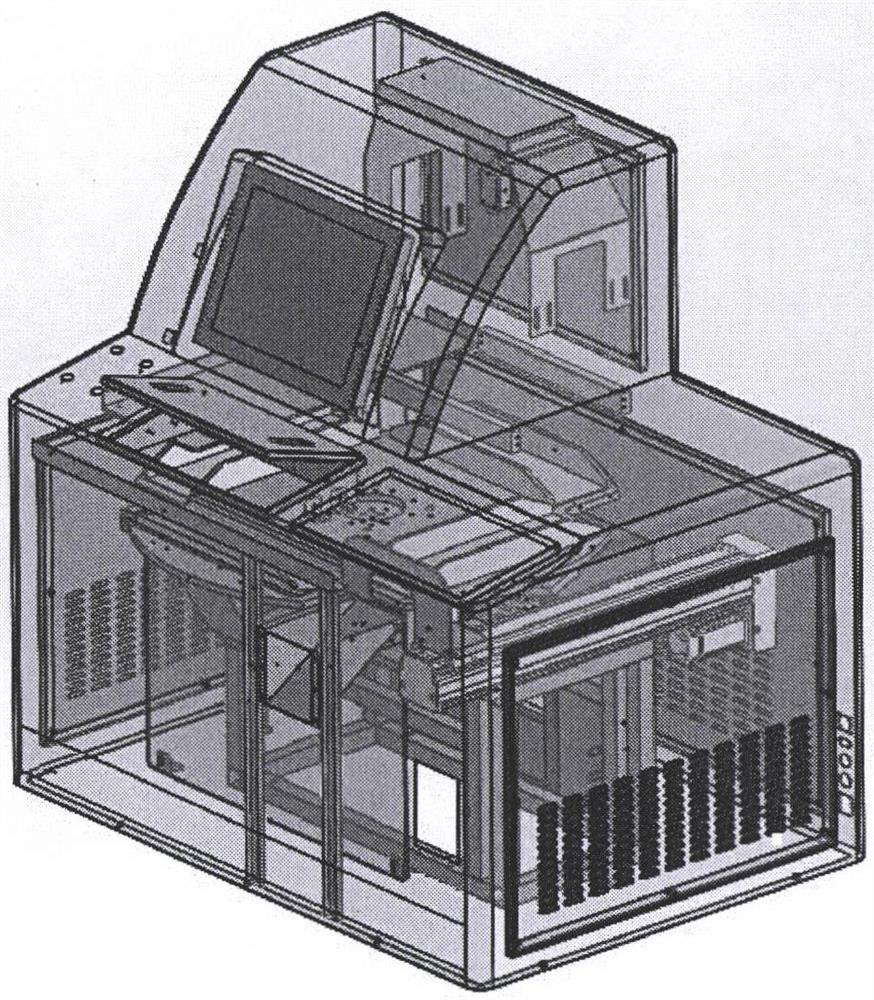

Pulse rectifier

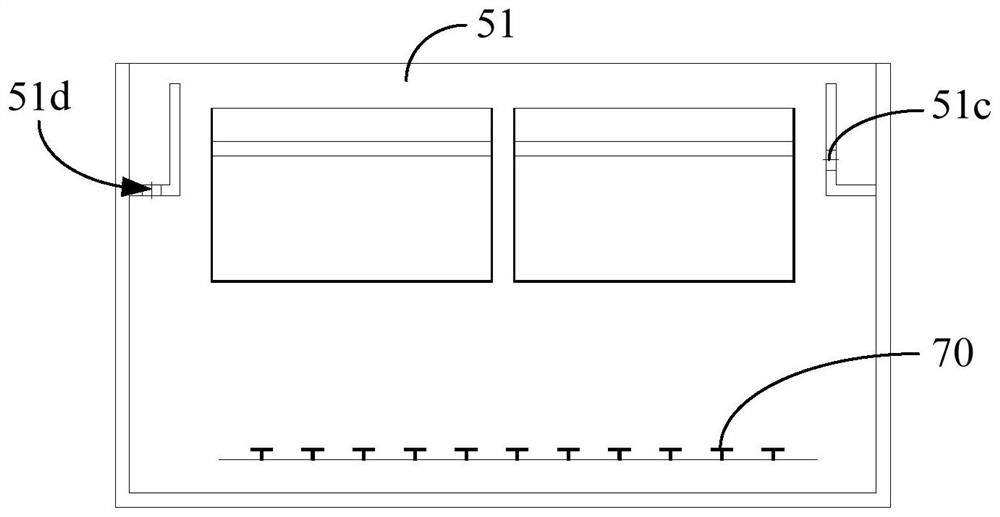

PendingCN111726013AReduce the overall heightAvoid floor spaceConversion constructional detailsPrinted circuit board receptaclesRectiformerMechanical engineering

The invention provides a pulse rectifier, which belongs to the technical field of pulse equipment, and comprises a preceding-stage power supply and a power module which are arranged in a split manner,the preceding-stage power supply and the power module are suitable for being arranged side by side in a frame, and the bottom end of the frame is suitable for being supported above electroplating orelectrolysis equipment; according to the pulse rectifier disclosed by the invention, the preceding-stage power supply and the power module are arranged in a split manner, so that the preceding-stage power supply and the power module can be arranged in the frame side by side, and the frame can be supported above electroplating or electrolysis equipment due to reduction of the overall height of thepower supply, thereby preventing the arrangement of the power supply from occupying the ground space and saving the factory land cost.

Owner:JIUJIANG LIYUAN RECTIFIER EQUIP

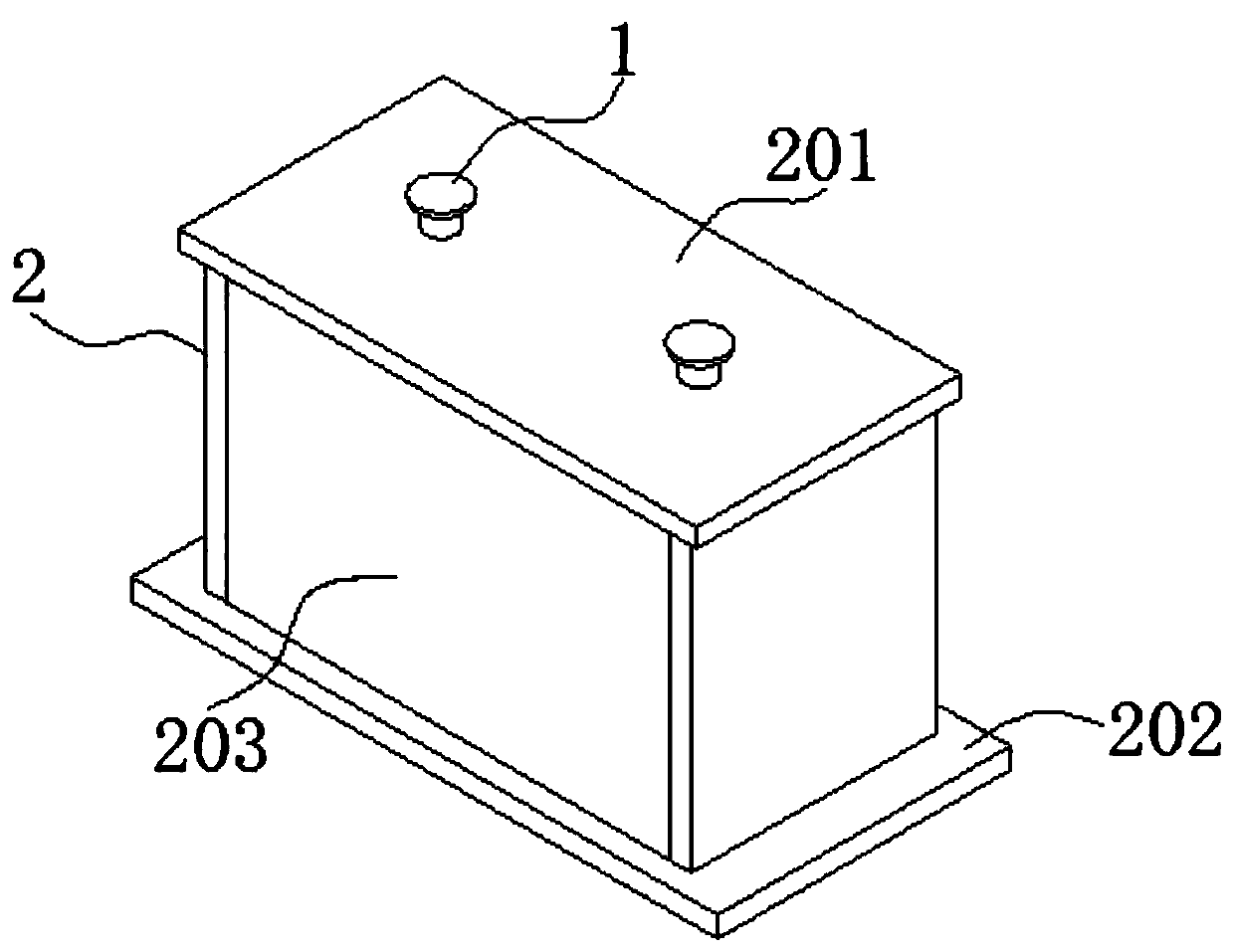

A flat-top cabinet for file storage

ActiveCN108378582BExtended service lifeAvoid breakingBook cabinetsFittingStructural engineeringMechanical engineering

The invention discloses a flat-top cabinet used for file storage, and belongs to the technical field of file cabinets. The flat-top cabinet comprises a cabinet body, wherein the cabinet body comprisesa substrate, a top plate and a side plate; a pair of mounting holes are formed in the top plate, and a suspension pull rod is fixedly arranged inside each mounting hole; one end of each of the suspension pull rods is fixed on the surface of the substrate, and the other ends of the suspension pull rods are fixedly connected with a roof; a mounting hole site is formed in the substrate, a control rotating rod is mounted inside the mounting hole site, one end of the control rotating rod is fixedly connected with the surface of the top plate, the other end of the control rotating rod is fixed in the mounting hole site; each suspension pull rod comprises a first connecting rod and a second connecting rod, each second connecting rod is a hollow rod, and each first connecting rod moves linearly inside a through hole in the corresponding second connecting rod. The cabinet body is mounted at the top of a house through the pull rods, the cabinet body is convenient to take and store, and the space of the house is saved.

Owner:合肥泓泉档案信息科技有限公司

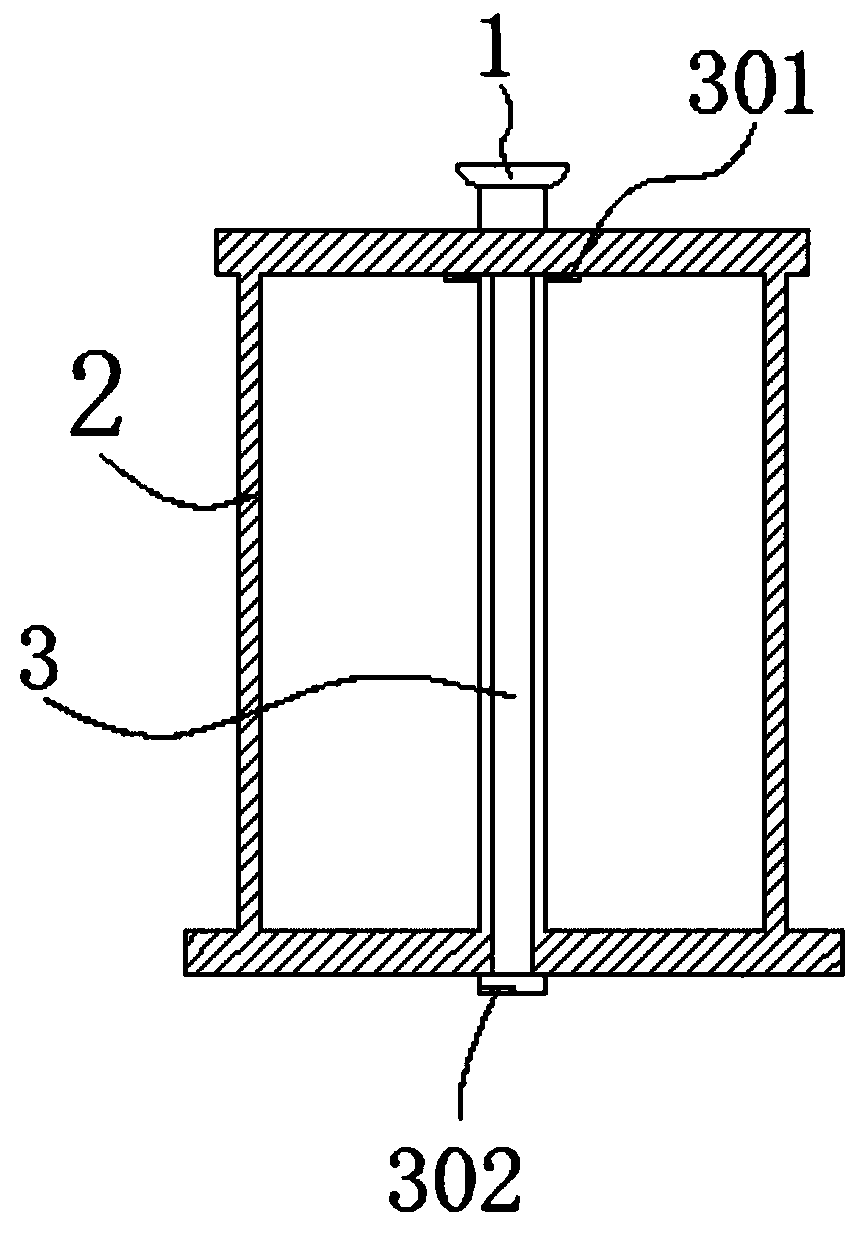

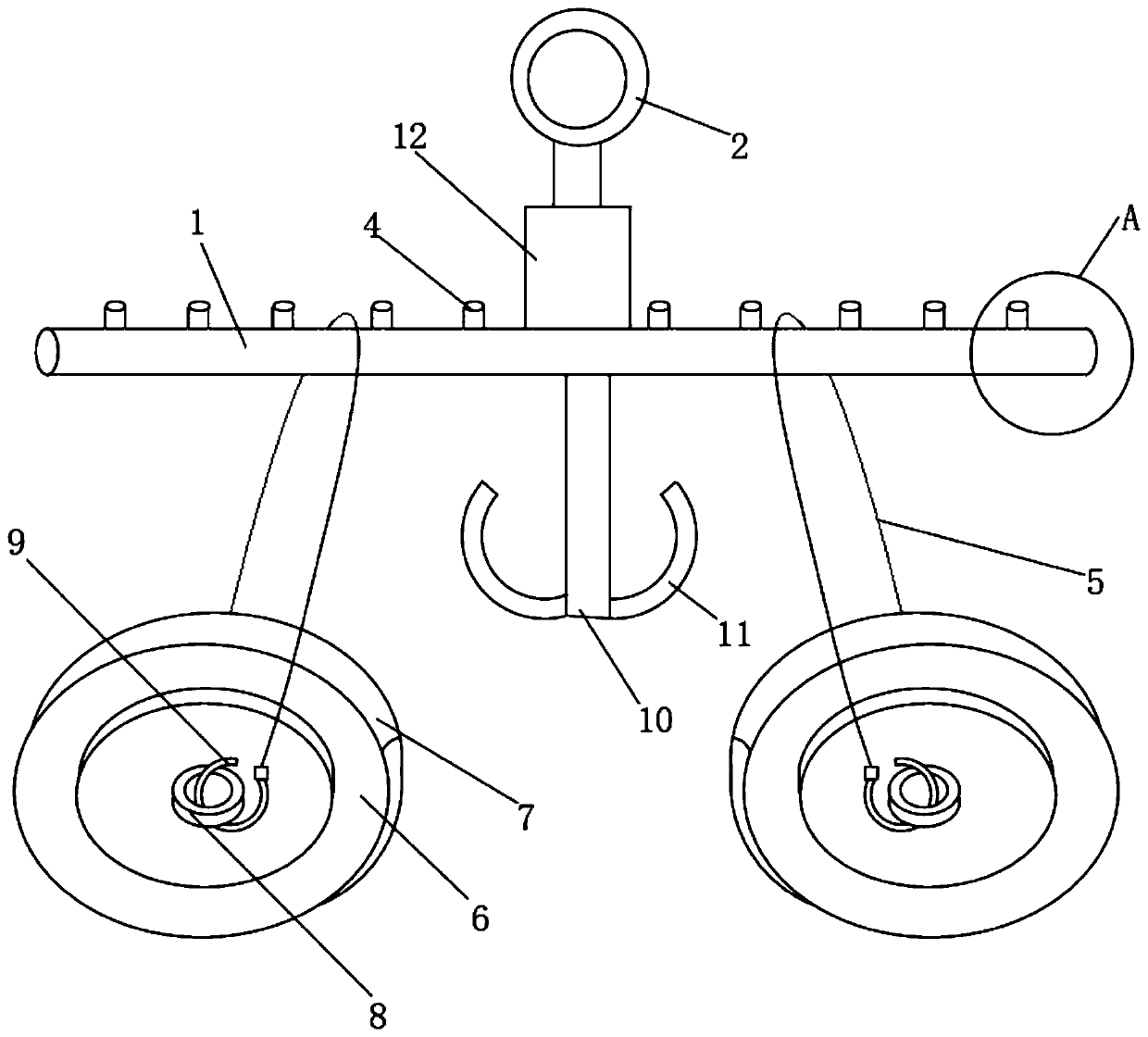

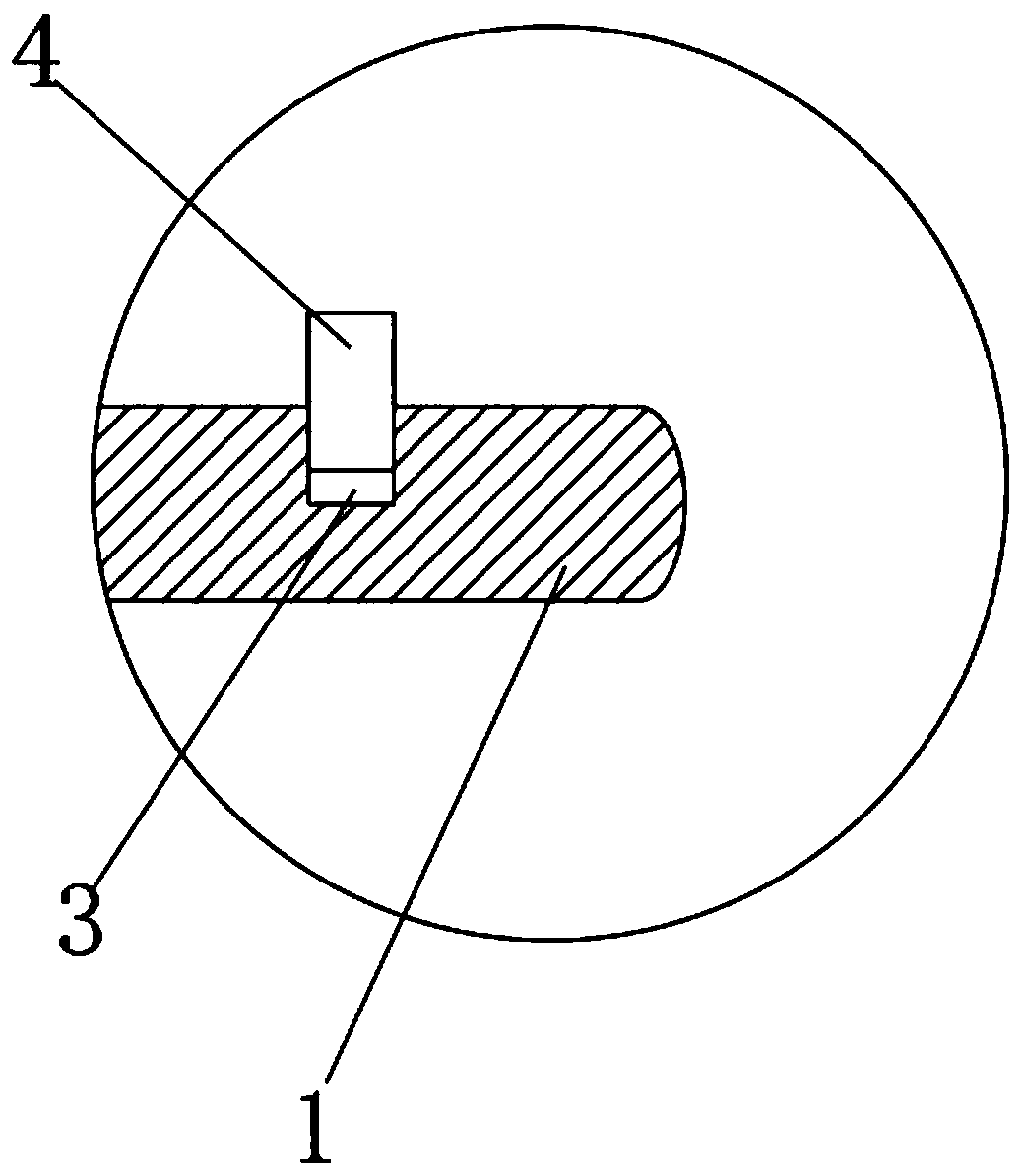

Hanging type umbrella dryer

InactiveCN107101468ASolve the wet problemAvoid floor spaceDrying gas arrangementsDrying solid materialsEngineeringLand occupation

The invention discloses a hanging type umbrella dryer, and belongs to the field of umbrella drying equipment. The hanging type umbrella dryer comprises a shell. A water collecting groove folded inwards is formed in the lower portion of the shell. A rotation part is arranged at the center of the top face in the shell. A plurality of vertical rods vertically downwards extending around the rotation part evenly are arranged at the middle portion of the top face of the shell. The lower end of each vertical rod is provided with an elastic rope, wherein one end of the elastic rope is connected with the vertical rod, and the other end of the elastic rope is connected with the inner wall of the water collecting groove. The elastic ropes are provided with a plurality of closely-arranged cylindrical water absorbing columns in a stringing manner. A plurality of drying parts distributed around a center shaft of the shell in a radial manner are arranged in the shell. The drying parts are connected with the top face of the shell through a first hanging column and a second hanging column which are perpendicular to the top face. The hanging type umbrella dryer can solve the problem that an umbrella is wet after being used. The hanging type umbrella dryer is arranged on a ceiling, and the problem of land occupation of the umbrella dryer is solved.

Owner:韦尧天

New energy air conditioner

ActiveCN105299800BAvoid floor spaceLow costLighting and heating apparatusPhotovoltaicsNew energyLightning

The invention discloses a new energy air conditioner which comprises photovoltaic cell components, an air conditioner and a photovoltaic lightning protection combiner component, wherein the air conditioner is connected with the photovoltaic cell components, and comprises an air conditioner shell; and the photovoltaic lightning protection combiner component is arranged inside the air conditioner shell, and is connected with the photovoltaic cell components. Through the adoption of the technical scheme provided by the invention, photovoltaic lightning protection combiner boxes in the prior art can be decreased, extra floor space of the photovoltaic lightning protection combiner boxes can be avoided, the cost is reduced, and the mounting and fixing manners of the photovoltaic lightning protection combiner boxes need no consideration, so that the purposes that the engineering period is shortened, and the maintenance cost after engineering is reduced are achieved.

Owner:GREE ELECTRIC APPLIANCES INC

An aerial track that can be used in mines

InactiveCN108438006BExtended service lifeImprove stabilityRope railwaysMine carsPower modeDerailment

The invention provides an aerial track capable of being used in a mine. The aerial track comprises a mine frame arranged in the mine and a tramcar chassis, and a plurality of track frames are arrangedin the mine frame. The track frames comprise horizontal rods, vertical rods are arranged at two ends of the horizontal rods, the horizontal rods are further provided with a connecting rod connected with the mine frame, and a track is arranged above the horizontal rods in a penetrating mode. The tramcar chassis is provided with a track transmission device, and the track transmission device is connected with the track in a power mode. When the aerial track is in use, the track can be directly placed on the track frames, so that a tramcar can be suspended and transported on the track, and the problem that a previous tramcar track occupies ground space is solved; the bottom of the tramcar is kept away from the wet ground, the problems of easy corrosion, corrosion and sticky bottom are prevented, and the service life of the tramcar is prolonged; and a gravity ball is arranged in a carriage to keep the carriage balanced to increase the stability of the track, and the problem of easy derailment of a track connection device is solved.

Owner:YONGCHENG VOCATIONAL COLLEGE

Special underground direct-driven discharging and extracting equipment for coal bed gas

ActiveCN103953315BAvoid floor spaceReduced floor footprintFluid removalElectric machineHorizontal wells

The invention provides special underground direct-driven discharging and extracting equipment for coal bed gas, and belongs to the technical field of mining. The equipment comprises a sleeve, a motor, a motor protector, a righting bearing component, a screw pump, a special connector, a special axial force supporting mechanism and an oil pipe, wherein the motor is arranged on the bottom part of a pitshaft; a motor output shaft is connected with an input end of a rotor of the screw pump through the motor protector and the righting bearing component; an output end of the rotor of the screw pump is connected with the special axial force supporting mechanism; the special connector consists of an internal shaft and an outer casing; a stator of the screw pump and the special axial force supporting mechanism are connected by the special connector; the oil pipe is connected between a special pithead and the special axial force supporting mechanism; the sleeve is embedded on the inner wall of the pitshaft; all constitutive elements are sheathed in the sleeve. By applying the equipment, a gap at the aspect of discharging and extracting techniques for coal bed gas highly-deviated wells and multi-branch horizontal wells is filled; compared with a traditional discharging and extracting way, the equipment realizes the multiplied increase of gas production; meanwhile, the floor area of the discharging and extracting equipment is decreased.

Owner:TANGSHAN YULIAN ELECTROMECHANICAL

A kind of polymerization process of polyester amide

ActiveCN111363144BIncrease productivityTo overcome the disadvantage that the efficiency of the reaction is slowed down by the esterification reactionPolyesterPolymer science

The invention provides a polyester amide polymerization process, which is characterized in that the polymerization raw materials include 5-60 parts of polymerized monomer dibasic acid / dibasic acid ester, 3-50 parts of diamine and reactive Dispersion medium: 10-90 parts of polyester / polyesteramide; uniformly disperse the polymerized monomers into the molten reactive dispersion medium, and undergo polymerization reaction to obtain polyesteramide with suitable molecular weight. It can significantly improve the production efficiency of polyester amide.

Owner:CHENGDU 401 TECH CO LTD

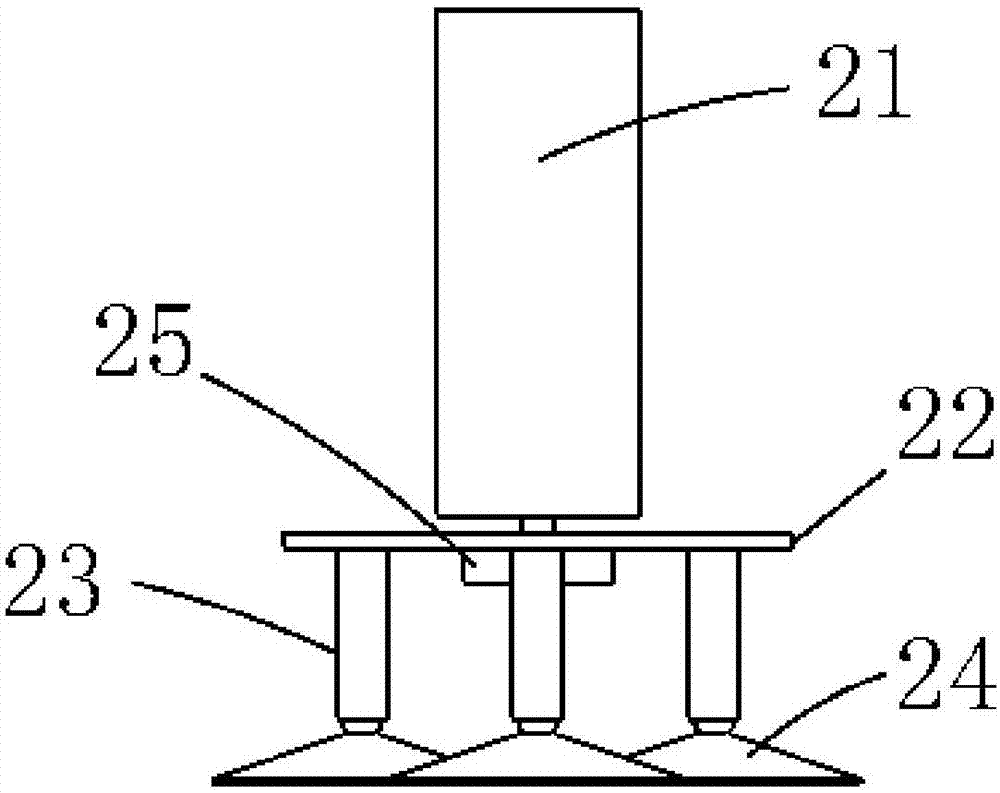

Repeater and repeater communication system

InactiveCN110611850AAvoid floor spaceAvoid desk spaceSelection arrangementsCommunications systemEngineering

The invention discloses a repeater. The repeater comprises a repeater body, a supporting device and a line concentration device, the supporting device comprises a fixing part and an extending part, and the extending part comprises a first telescopic piece and a second telescopic piece which are connected with each other; and the line concentration device is detachably connected with the repeater body and is arranged at one side, provided with the line interface, of the repeater body. Through arranging the supporting device on the repeater body, the repeater body can be installed and fixed at aposition far away from the ground, so that the problem that the repeater body occupies more ground or desktop space due to the fact that the repeater body is placed on the ground or a desktop is effectively prevented, and meanwhile, the problem that the repeater body is damaged when being collided due to the fact that the repeater body cannot be fixed is avoided. Besides, the length of the extension part is adjustable, so that the problem that the repeater cannot be used normally due to the fact that the repeater body is far away from other equipment or an interference source can be solved. And the wire collecting device can effectively store the wire bodies, and the situation that the wire bodies scatter at will is avoided. The invention also discloses a repeater communication system.

Owner:兰州立云信息科技有限公司

A method for preparing graphene in batches and its production system

InactiveCN107500279BImprove stripping rateImprove stabilitySingle layer grapheneGraphiteMaterials science

The invention relates to the field of graphene materials, and discloses a batch preparation method of graphene and a production system therefor. In the invention, a conventional high temperature expansion method is combined with a graphite expansion furnace, and by means of optimum expansion temperature, stability of a product is effectively improved by means of control on raw materials and process parameters on the basis of the expansion temperature, thereby producing expanded graphite with controllable expansion times, namely, distribution ratio with expansion times being 200-300 is highest. With the expanded graphite as a raw material for producing graphene through a mechanical stripping method, stripping rate of graphene is greatly increased. On the basis of the conventional mechanical stripping method for preparing graphene, the graphene is produced in batches with the expandable graphite as raw material and graphene quantum dots as a stripping liquid, wherein a pre-stripping process is added on the basis of the prior art, and secondary ultrasonic treatment is employed with process parameters in the ultrasonic treatment being optimized.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

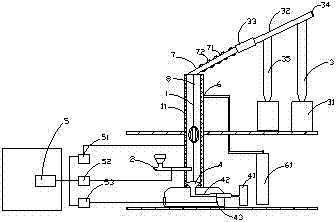

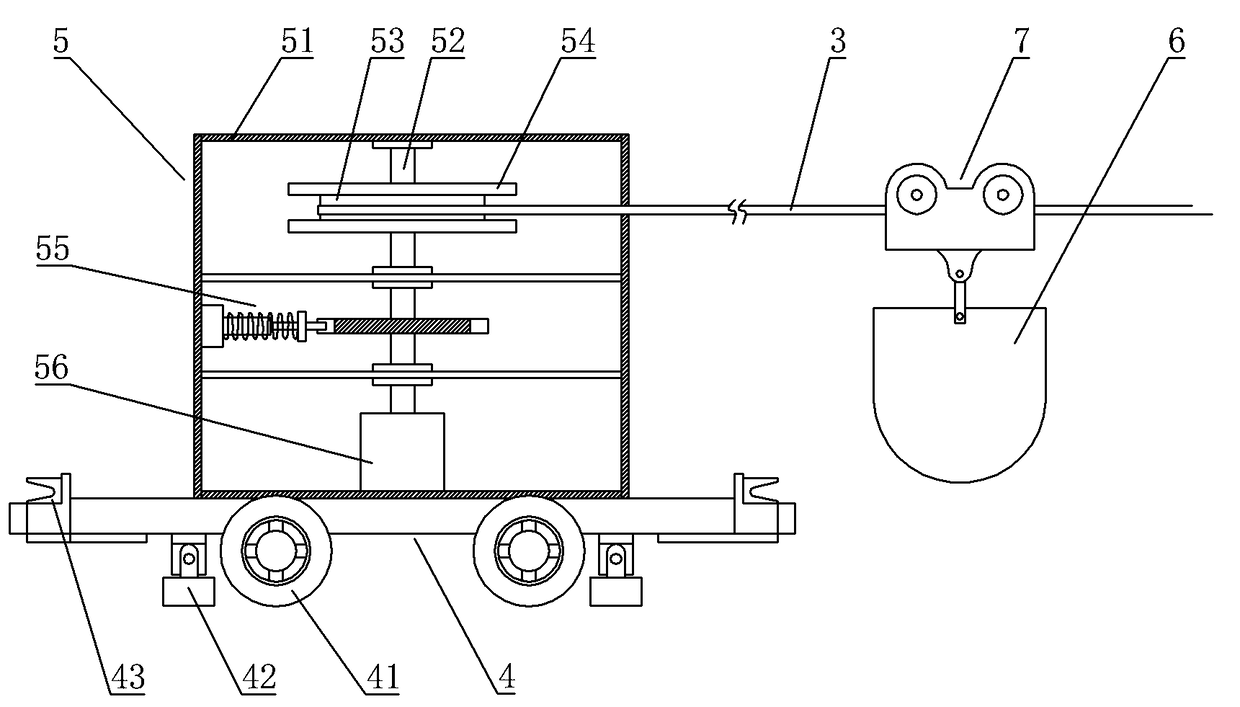

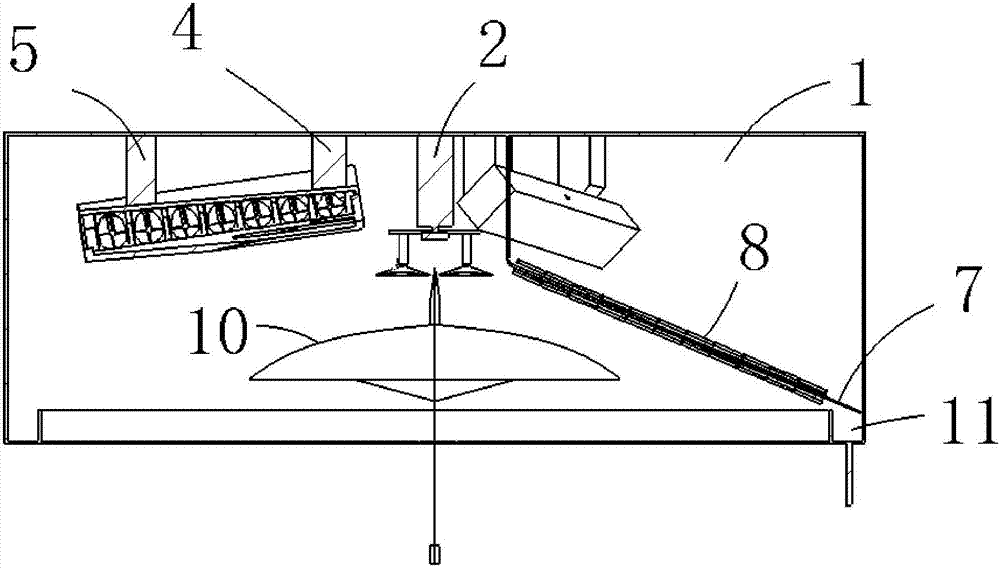

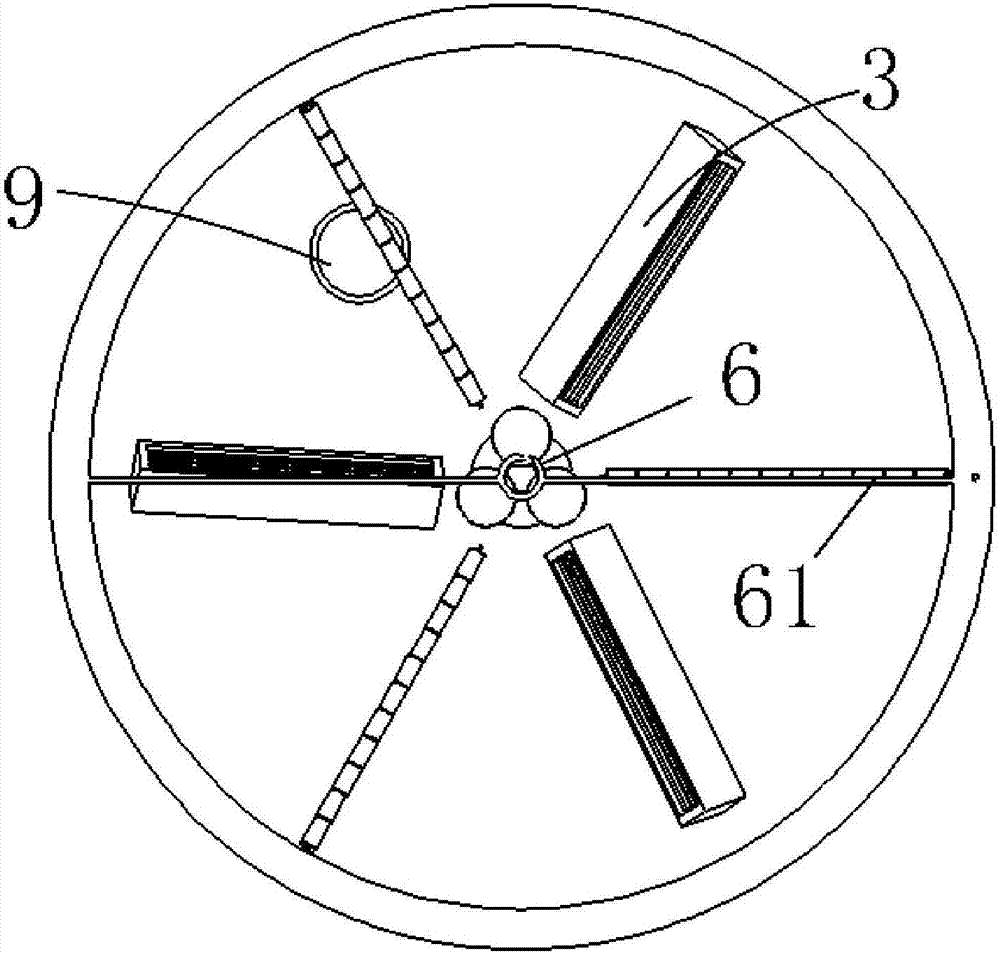

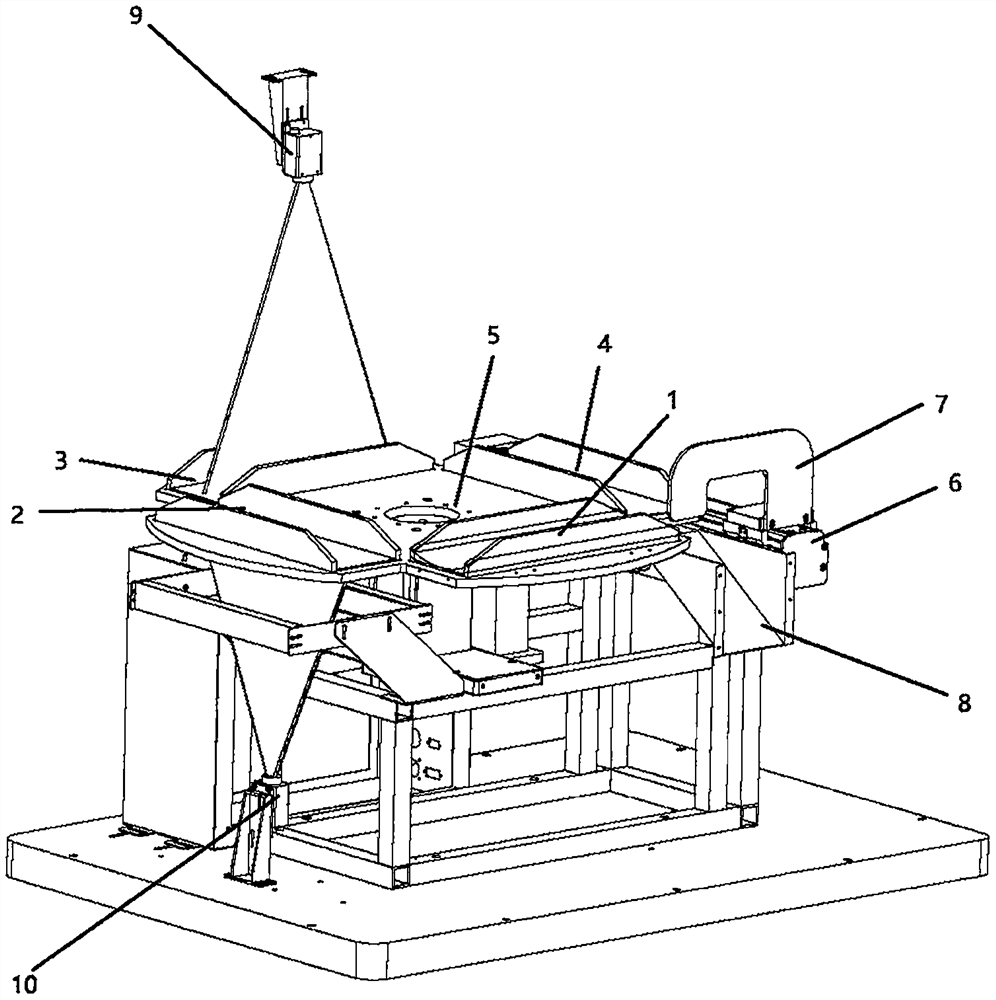

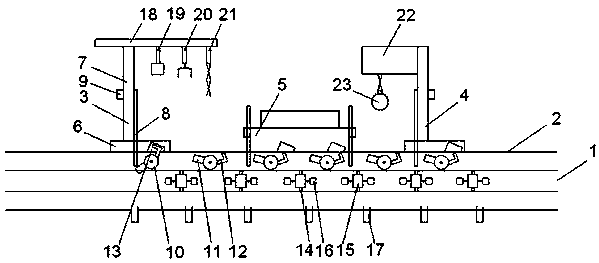

Full-automatic corn ear high-throughput seed test instrument

PendingCN112557394AAvoid operabilityAvoid mechanical propertiesInvestigation of vegetal materialMaterial weighingAgricultural scienceImaging processing

The invention discloses a full-automatic corn ear high-flux seed test instrument. According to the device, high-precision, high-flux and full-automatic corn ear phenotypic information acquisition anddigital integrated data storage are realized. The corn ears placed on a transparent tray are shot from the upper surface and the lower surface by utilizing an industrial camera, so that the phenotypiccharacters of the corn ears are obtained; the ear tray is rotated to a specific station by using the rotating mechanism to execute corresponding actions, so that the purpose of full-automatic corn ear test is achieved; and in combination with an image processing technology, fifteen character parameters related to corn ears and grains are extracted from ear pictures. The invention provides a high-throughput, full-automatic and high-precision corn ear test scheme, which effectively helps corn researchers to quickly and accurately obtain corn yield traits, so that corn test does not become the bottleneck of corn research any more.

Owner:武汉谷丰光电科技有限公司

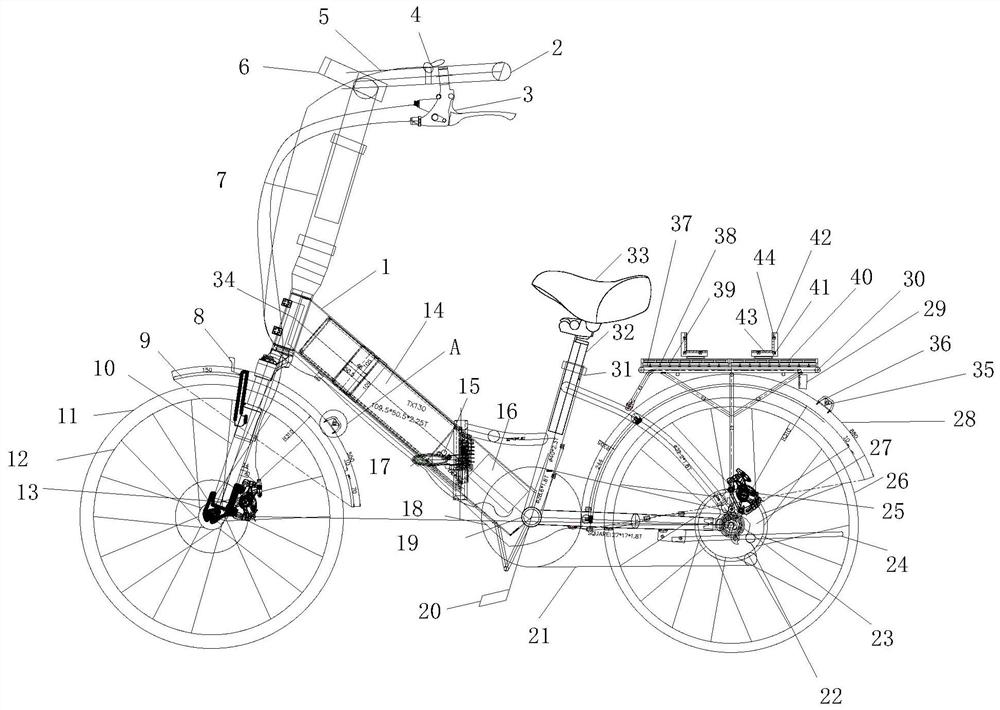

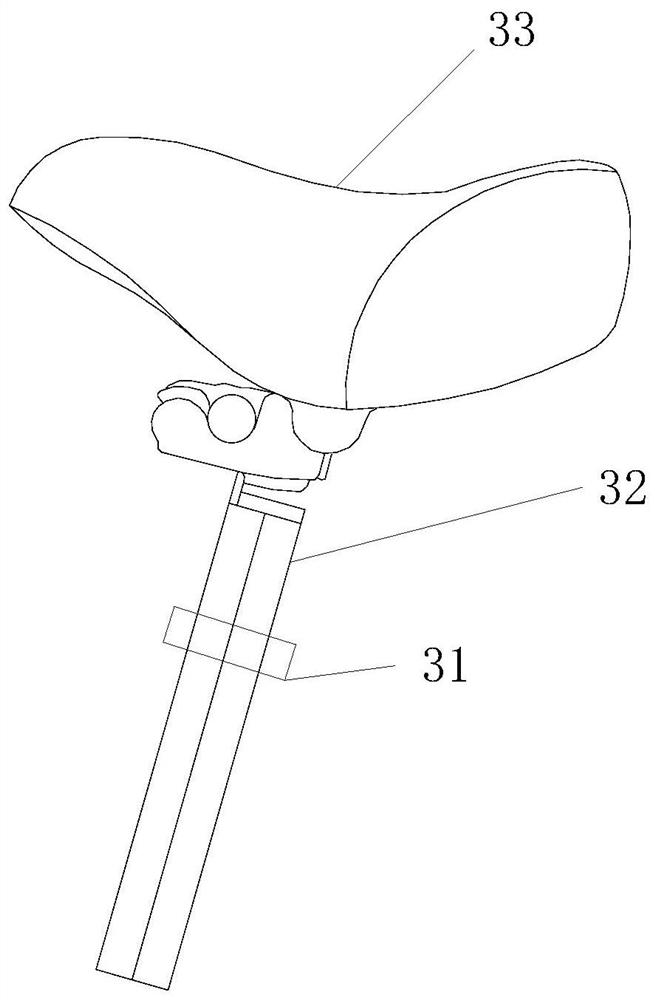

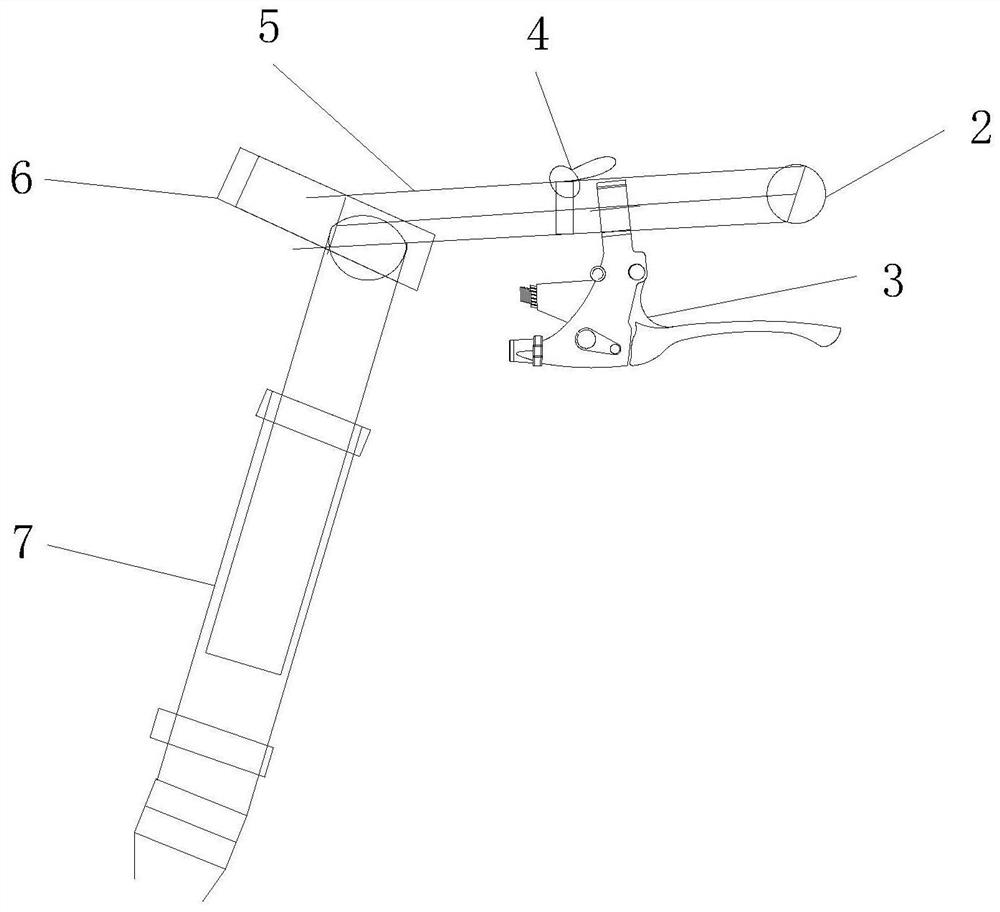

Electric bicycle with folding storage function

PendingCN113147979AWith folding storage functionAvoid floor spaceLuggage carriersOptical signalFenderVehicle frame

The invention relates to the technical field of bicycles, and discloses an electric bicycle with a folding storage function, the electric bicycle comprises a frame, a front lamp, a battery, a folder, a rear lamp, a saddle tube clamp and double welding beads, the upper end of the frame is provided with a handle sleeve, one side of the handle sleeve is provided with a power-off brake handle, one end of the power-off brake handle is provided with a speed changer, and the other end of the power-off brake handle is provided with a motor; one end of the transmission is provided with a handlebar, one end of the handlebar is provided with an instrument, the lower end of the instrument is connected with a folding vertical pipe, the front lamp is arranged at one end of the frame, one end of the frame is provided with a front fender, one side of the front fender is connected with a front fork, one end of the front fork is provided with a front wheel, and the other end of the front wheel is provided with a rear wheel. spoked wheels are arranged on the inner sides of the front wheels. According to the electric bicycle with the folding and storing functions, by arranging the folder, the electric bicycle can be folded and stored, so that the occupied space is better reduced, and convenience is provided for outdoor carrying.

Owner:七洲(广州)电动车有限公司

A rock-aluminum composite panel unit curtain wall and its production process

The invention discloses a rock-aluminum composite panel unit type curtain wall, which includes an aluminum plate, a rock plate is fixed on the upper surface of the aluminum plate, and internal and external series corner code connectors are fixed around the aluminum plate, with high strength and rigidity. Good, light weight, can be installed on the outer wall through the keel, used for decoration hidden inside, will not fall, high safety, solves the problem that the existing building can not be used for exterior decoration after reaching a certain height The technical problems of wall decoration, its production process is divided into: material preparation→angle opening→punching→hole carving→bending forming→welding→acid washing→chromizing→pasting slate→assembling to form a unitized curtain wall, the pasting slate The process is automatically pasted by pasting equipment, which not only saves time and labor, but also has a high degree of automation, and at the same time has high precision and a high yield rate, which solves the technical problem of manual pressing in the existing pasting process.

Owner:吉祥铝业(长兴)有限公司

Double-side clamp positioning machining device

InactiveCN108296778AEasy to useMeet diversityOther manufacturing equipments/toolsPositioning apparatusSmall footprintUpper floor

The invention discloses a double-side clamp positioning machining device comprising a three-layer rail. A table facet rail is arranged on the uppermost portion of the three-layer rail; a first machining device and a second machining device are arranged on the table facet rail; a bearing frame is arranged between the first machining device and the second machining device; the first machining deviceand the second machining device are each provided with a base and a vertical rod; and telescopic rods are arranged on the vertical rods. In the three-layer rail, a plurality of rotary position clamping devices are arranged in the upper-layer rail body; convex blocks and position-clamping blocks are arranged on the rotary position clamping devices; the position-clamping blocks and grooves in the bottoms of the bases are matched; and the rotary position clamping devices are arranged on rotating shafts and controlled by rotating motors to rotate. The middle-layer rail body is provided with elastic clamping devices; the elastic clamping devices comprise controllers, and the two sides of the controllers are connected with clamping blocks through springs; and storage grooves are formed in the bottom of the lower-layer rail body. The double-side clamp positioning machining device has the following advantages that remote unmanned control can be achieved, multiple procedures are integrated into a set of equipment, the occupied area is small, and the production efficiency is improved.

Owner:马鞍山纽盟知识产权管理服务有限公司

Special suspension bracket for rubber pipe

InactiveCN111217196AAvoid floor spaceIncrease occupancyFilament handlingStructural engineeringMechanical engineering

The invention discloses a special suspension bracket for a rubber pipe. The special suspension bracket comprises a suspension rod, the upper end of the suspension rod is connected with a lifting ring,more than two screw holes are linearly distributed on the suspension rod, studs are arranged in the screw holes, a suspension rope is hung between two adjacent studs on the suspension rod, a windingdisc assembly used for winding the rubber pipe is connected to the lower portion of the suspension rope and comprises two blocking discs and a winding barrel arranged between the two blocking discs, hanging rings are connected to the outer sides of the blocking discs, the hanging rings are connected with hooks, and the hooks are connected to the suspension rope. By means of the special suspensionbracket, the rubber pipe can be stored in order, and overlarge ground area is not occupied.

Owner:ANHUI WEIWEI RUBBER PARTS GRP

In-situ upgrading reconstruction method for CASS pool

PendingCN112047470AAvoid floor spaceAvoid increasingWater contaminantsTreatment with aerobic and anaerobic processesPre treatmentSewage

The invention discloses an in-situ upgrading reconstruction method for a CASS pool. The in-situ upgrading reconstruction method comprises the following steps: reconstructing a pretreatment pool of theCASS pool into an anaerobic pool; dismantling an original structure in a main reaction tank of the CASS pool, arranging a partition wall in the main reaction tank to make the main reaction tank isolated and reconstructed into a denitrification tank and a biochemical sedimentation tank through the partition wall, installing a circulation clarifier in the biochemical sedimentation tank, installingan aeration disc below a sewage return opening of the circulation clarifier, forming a backflow channel in one side in the biochemical sedimentation tank, mounting a first reflux pump at the position,close to the denitrification tank, of a reflux channel to make sludge in the reflux channel guided into a denitrification tank, and arranging a water distribution channel on the other side in the biochemical sedimentation tank. The water distribution channel and the reflux channel are oppositely arranged, so that the water distribution channel communicates with the denitrification tank and the biochemical sedimentation tank and is used for guiding denitrification sewage in the denitrification tank into the biochemical sedimentation tank. Namely, according to the technical scheme, on the premise that the occupied area is not additionally increased, it is guaranteed that the total nitrogen content of the effluent reaches the emission standard smaller than 15 mg / L.

Owner:SHENZHEN QINGYAN ENVIRONMENTAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com