Multi-stage fluidization tower

A technology of fluidized towers and tower tubes, which is applied in the field of feed processing equipment, and can solve problems such as uneven moisture content and quality, increased fault points, and large mixing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

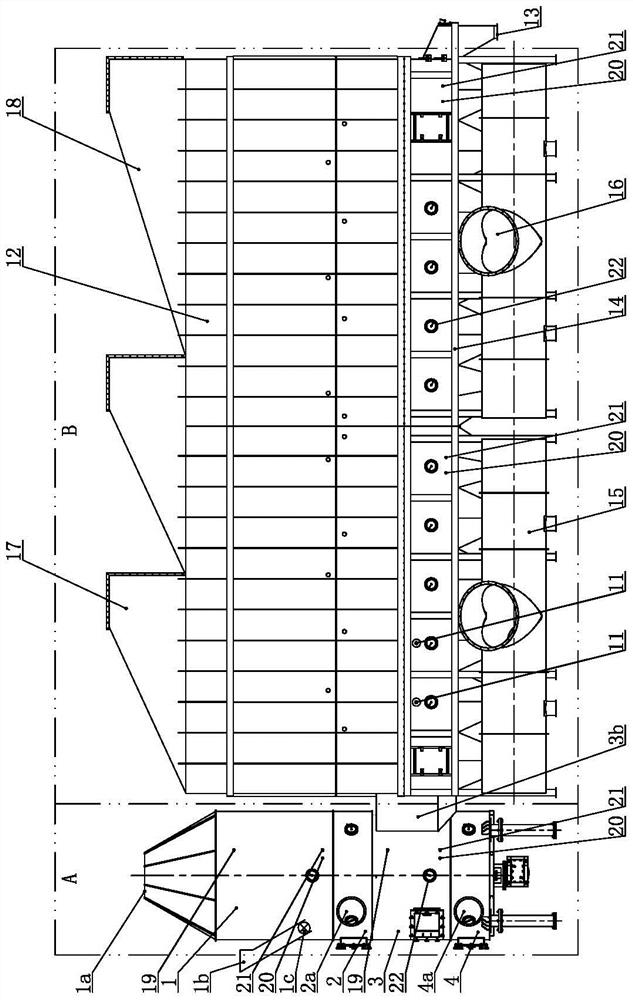

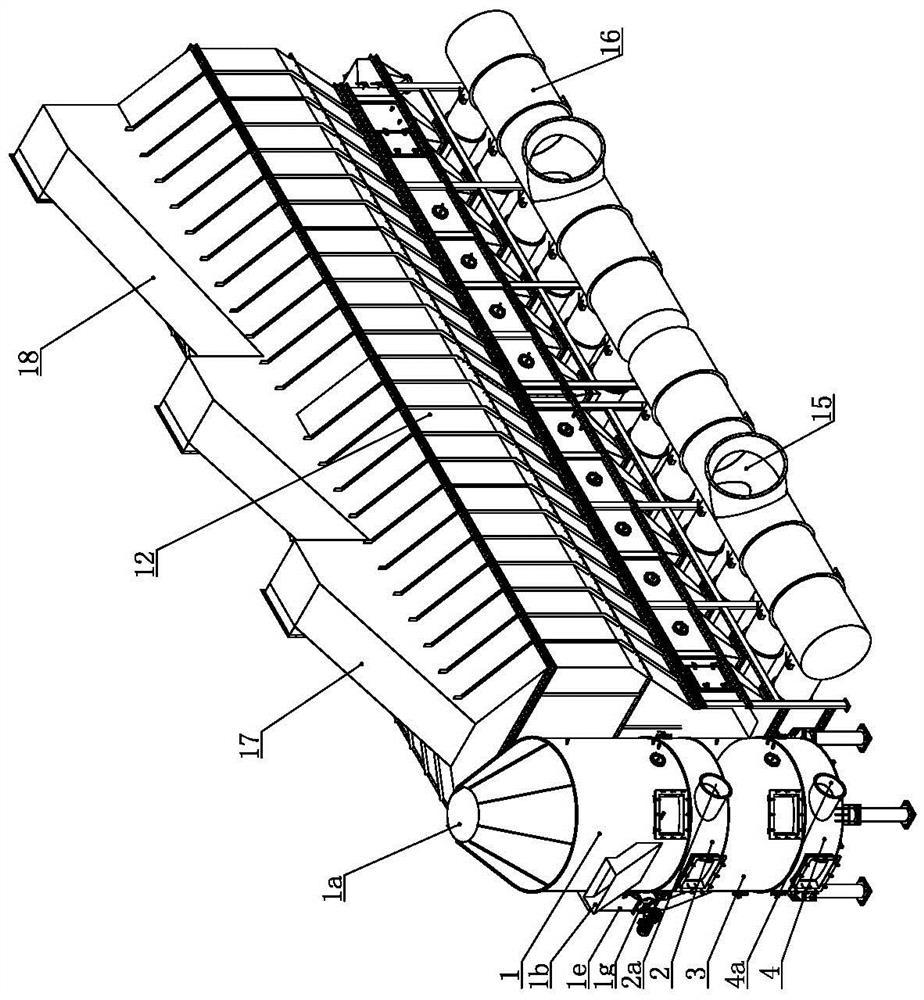

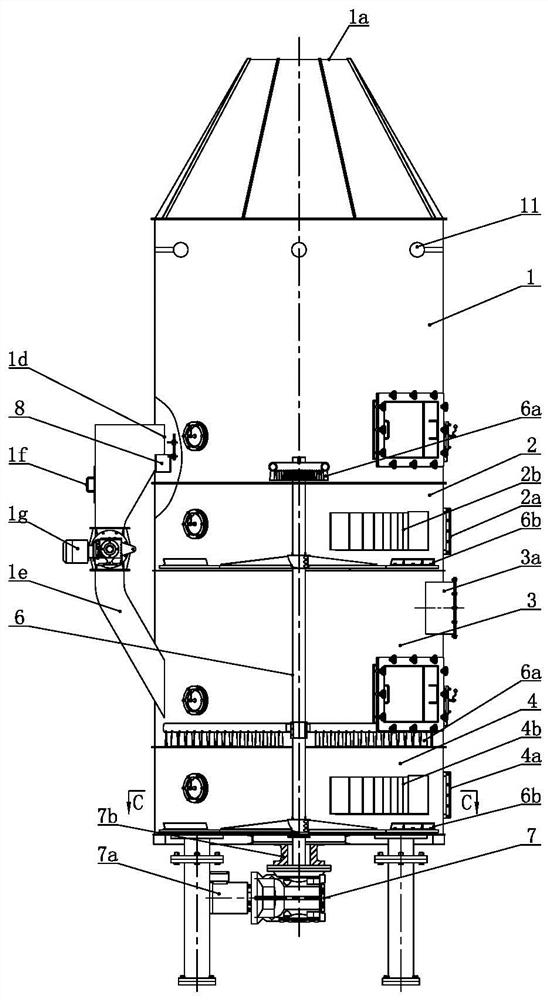

[0034] Such as Figure 1 to Figure 5 As shown, the multistage fluidized tower of the present invention includes a predrying tower A and a horizontal multistage fluidized bed B, and a main shaft 6 is arranged along the axis of the predrying tower A, and the inner cavity of the predrying tower cylinder is from top to bottom The first pre-drying layer 1, the first interlayer air chamber 2, the second pre-drying layer 3 and the second interlayer air chamber 4 are provided in sequence, and the tops of the first interlayer air chamber 2 and the second interlayer air chamber 4 are respectively provided with round Shaped sieve plate 5, above the circular sieve plates of the first pre-drying layer 1 and the second pre-drying layer 3 are respectively provided with rake type stirring fins 6a, and the material rake type stirring fins 6a are fixed on the main shaft 6; the first interlayer air chamber The side wall of 2 is provided with the first pre-drying air inlet 2a, and the top center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com