Special underground direct-driven discharging and extracting equipment for coal bed gas

A coalbed methane, direct drive technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve problems such as large drainage, wear and well inclination, difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

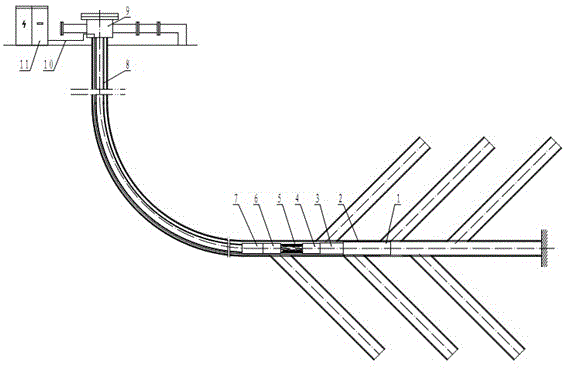

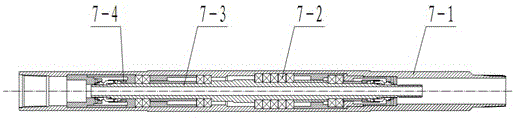

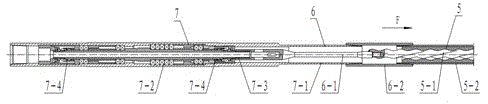

[0020] see figure 1 , image 3 , the present invention cooperates with the ground control system 11 and the special wellhead 9 to complete the drainage operation of coalbed methane, which includes the casing 2, the motor 1, the motor protector 3, the righting bearing assembly 4, the screw pump 5, the special connector 6, the special Axial force bearing mechanism 7 and tubing 8, the motor 1 is arranged at the bottom of the wellbore, the motor 1 is connected to the ground control system 11 through the cable 10, the output shaft of the motor passes through the motor protector 3, the centering bearing assembly 4 and the rotor of the screw pump 5 5-1 is connected to the input end, the output end of the rotor 5-1 is connected to the special axial force bearing mechanism 7, and the special connector 6 is composed of the inner shaft 6-1 and the outer shell 6-2, which connects the screw pump The stator 5-2 is connected with the special axial force bearing mechanism 7, the oil pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com