High-temperature pyrolyzing type gaseous mercury form conversion device and method

A high-temperature cracking and conversion device technology, which is applied in the field of elemental mercury devices, can solve the problems of affecting the conversion efficiency of oxidized mercury, the low reduction efficiency of stannous chloride, and the need for regular replacement, so as to avoid poisoning and inactivation and increase retention Time and cost saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

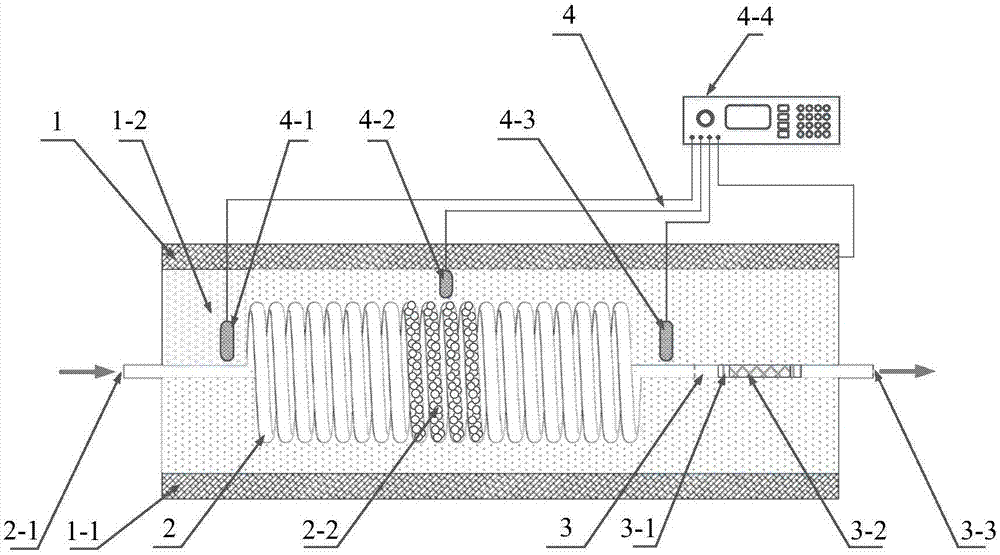

[0033] The high-temperature cracking gas-phase mercury form conversion device of the present invention includes four main parts of a high-temperature cracking furnace 1, a spiral tube 2, a straight tube at the outlet end 3 and an electronic temperature control device 4, and a heating tube bundle 1-1 is arranged on the inner wall of the high-temperature cracking furnace 1 , the heating tube bundle 1-1 is surrounded by refractory materials 1-2, one side of the spiral tube 2 is provided with a flue gas inlet 2-1, the central area is filled with heat storage ceramics 2-2, the other side of the spiral tube 2 is connected to the The straight pipe 3 at the outlet end is connected, the straight pipe 3 at the outlet end is filled with an acid gas scrubber 3-2, the glass fiber 3-1 is arranged before and after the acid gas scrubber 3-2, and the side of the straight pipe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com