Patents

Literature

33results about How to "Controllable expansion ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foaming synthetic leather manufacturing technology based on waterborne polyurethane (WPU)

ActiveCN102409554AFeel plumpSoft touchSynthetic resin layered productsTextiles and paperManufacturing technologyMicrosphere

The invention provides a foaming synthetic leather manufacturing technology based on waterborne polyurethane (WPU). In the manufacturing technology, the WPU is taken as a main raw material, and a hollow microsphere foaming agent is taken as a foaming material; and the technology can be widely used for manufacturing synthetic leathers such as clothing leathers, luggage leathers, shoe upper leathers, sofa leathers, home interior trim leathers and the like. The content of volatile organic compounds (VOC) in the finished leather is lower than 2mg / kg (leather), and the air permeability and moisture penetrability are good, thus meeting the EU (European Union) requirements for the ecological synthetic leather; and in addition, the foaming synthetic leather has the advantages of moderate foaming multiplying power, uniform and compact foaming holes, bulky and firm hand feel as well as good comprehensive performance which is equivalent to or superior to that of a solvent-borne product. The foaming synthetic leather manufacturing technology based on the WPU provided by the invention has the beneficial effects that by adopting the WPU instead of the traditional solvent-borne PU, organic pollution is eliminated from a source, organic solvent resources are saved, the comprehensive energy consumption is lowered, the employment environment of laborers is improved, and the ecological grade of the synthetic leather and the international market competitiveness of the product are enhanced, thus achieving obvious innovativeness and remarkable social and economic benefits.

Owner:DONGTAI FUAN SYNTHETIC MATERIAL CO LTD

Method for modifying water encounter swelling rubber by using hydrophobic monomer

InactiveCN101407601AGood compatibilityGood dispersionOther chemical processesCross-linkPolymer science

The invention belongs to the sealing material field and provides a method for carrying out modification to water-swelling rubber by using hydrophobicity monomer. The method is characterized by comprising the following steps: according to average particle size, the mass ratio of nano-level polyacrylic high-water absorption resin powder, acrylic acid, hydrophobic monomer, a cross-linking agent and an initiator is 100: 5 to 30: 20 to 60: 0.01 to 10: 0.01 to 0.5; according to the mass ratio, the materials are selected, uniformly mixed, placed for 30 to 60 minutes, carries out with swelling, and carries out with polyreaction for 20 to 60 minutes after being heated to 40 DEG C to 70 DEG C; the resin is taken out and dried at the temperature of 60 DEG C to 80 DEG C so as to obtain modified water absorption resin; and 2) according to the mass ratio of 100: 10 to 60: 0 to 15: 0.5 to 3: 2 to 6: 0.5 to 5: 0 to 3: 30 to 60: 0.5 to 3, rubber, modified water absorption resin, plasticizer, stearic acid, zinc oxide, a vulcanizing agent, an aging resister, a reinforcing agent and an accelerating agent are selected, mixed on a double roll mixing mill uniformly, formed, and vulcanized so as to obtain the water-swelling rubber. The method can avoid the gather of nano particles of water absorption resin, also can improve the compatibility of the water absorption resin in the rubber and leads the water absorption resin to be dispersed in the rubber.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

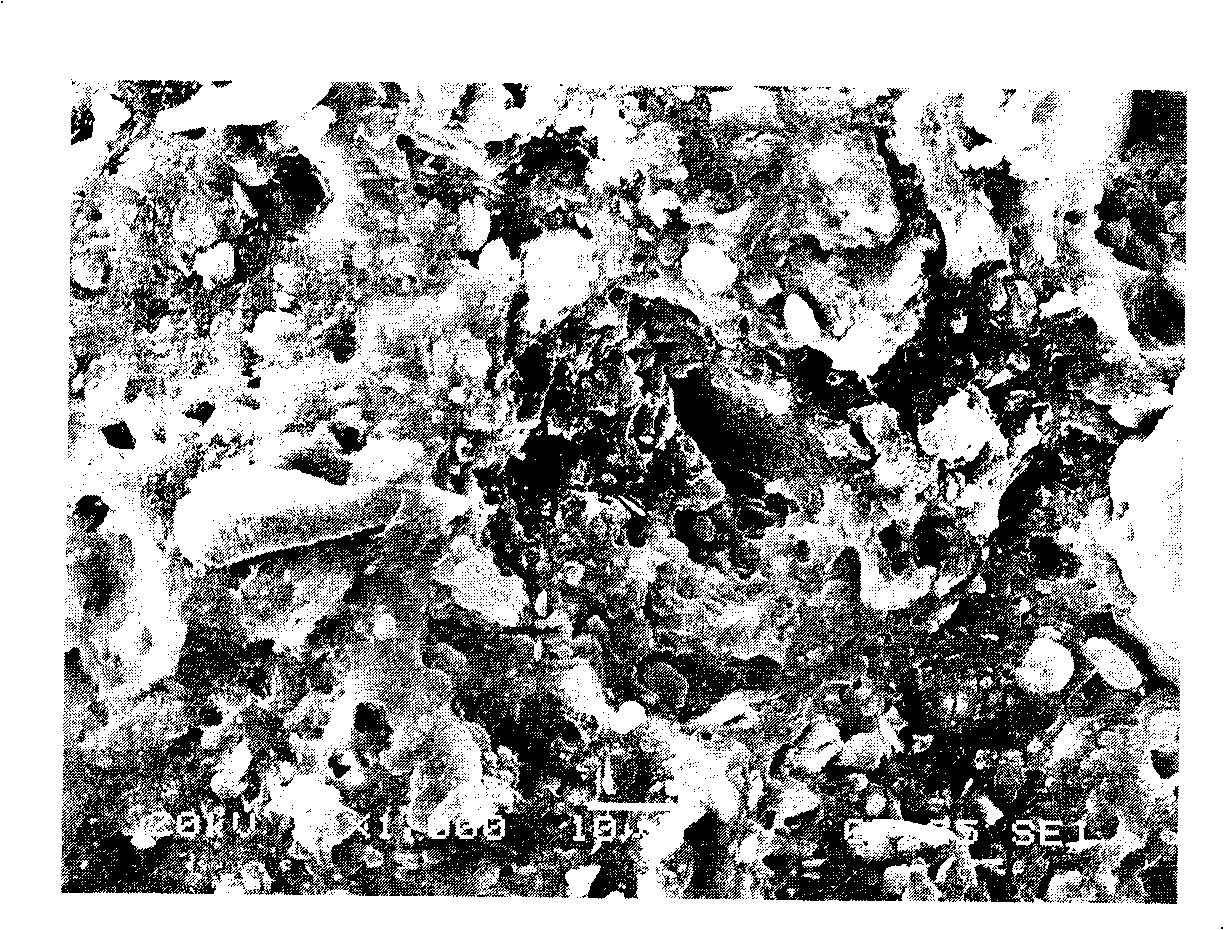

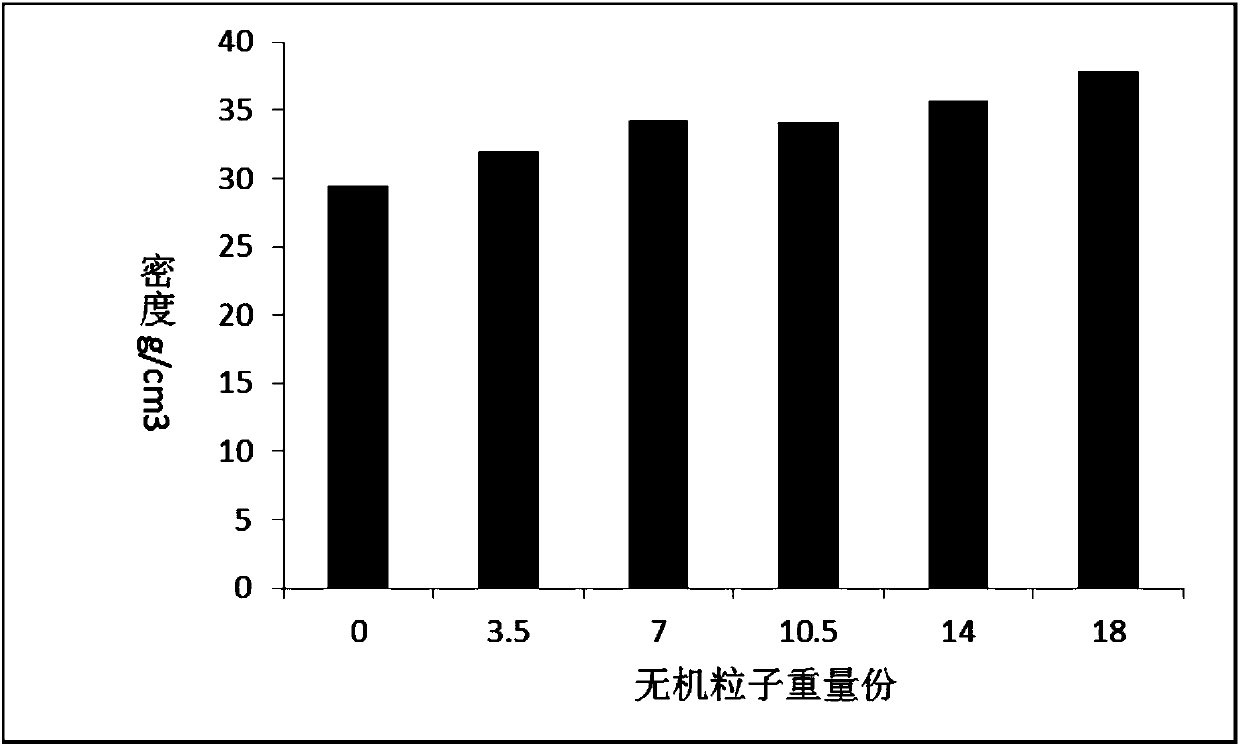

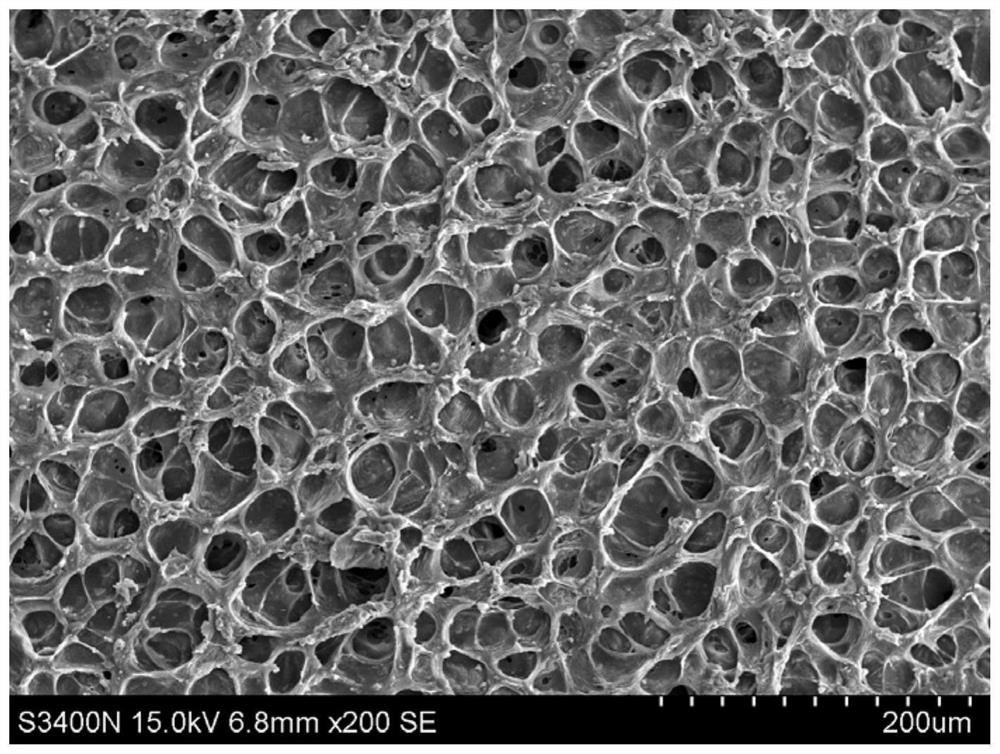

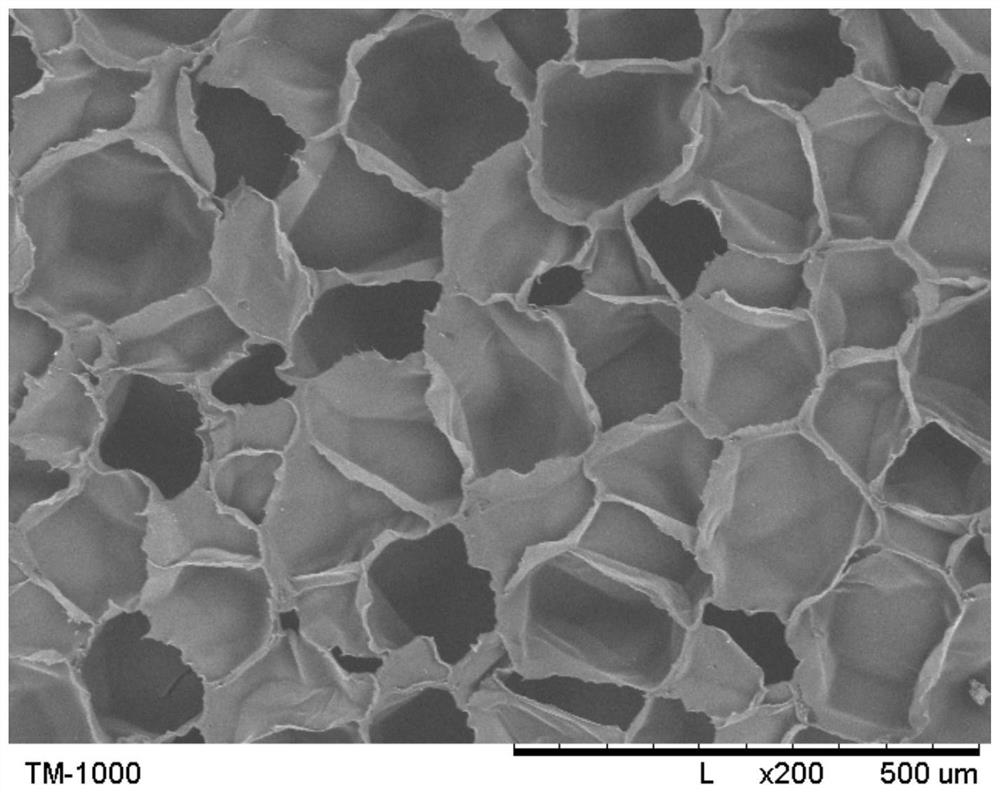

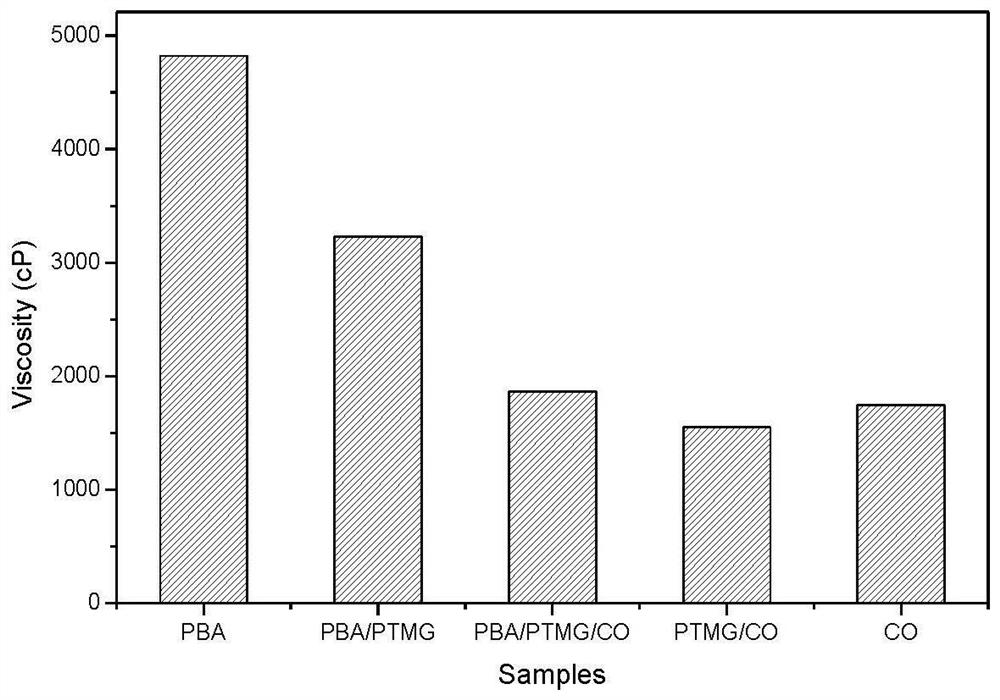

Inorganic filler modified polyurethane foam material and preparation method thereof

InactiveCN107722230AImprove adsorption capacityImprove mechanical propertiesInorganic particleAlcohol

The invention provides an inorganic filler modified polyurethane foam material and a preparation method thereof, and belongs to the field of macromolecular foam materials. The inorganic filler modified polyurethane foam material is prepared from polyhydric alcohols, deionized water, catalysts, surface active agents, inorganic particles and isocyanate compounds. The preparation method comprises thefollowing steps that 1, polyhydric alcohols and isocyanate are preheated separately; 2, polyhydric alcohols, deionized water, catalysts, surface active agents and inorganic particles are mixed proportionally to be uniform; 3, the mixture is stirred with isocyanate compounds at high speed; 4, free foaming is performed, and the inorganic filler modified polyurethane foam material is obtained. The inorganic filler modified polyurethane foam material adopts deionized water as the foaming agent, is environmentally friendly, due to the high opening rate of polyurethane foams, a channel can be provided for sewage flowing, the adhesion property of microorganisms can be improved due to biocompatibility of filler, and the material has the advantages that the method is simple, the cost is low and the requirement for equipment is low.

Owner:BEIJING DRAINAGE TECH CO LTD

Method for preparing high-temperature-rusistance water-expansible rubber

InactiveCN1775849ASmall particle sizeSuitable for a wide temperature rangeOther chemical processesChemical synthesisCross-link

The invention relates to a method to manufacture functional rubber that could be expand when meet water between the temperature 25 degree centigrade and 150 degree centigrade. The process is: taking copolymerization by acrylic acid, sodium acrylate, acrylamide, heat endurable modification monomer and cross linking agent to gain heat endurable water absorbing resin powder, then, mixing and vulcanizing the mixture of the powder and rubber to gain high temperature endurable water expanding rubber. It has simple technology and low cost.

Owner:WUHAN CHEM COLLEGE

Double-component pouring silica gel, method for preparing same and pouring method

ActiveCN105623593AControllable expansion ratioAperture controllableNon-macromolecular adhesive additivesOther chemical processesHydrogenPore diameter

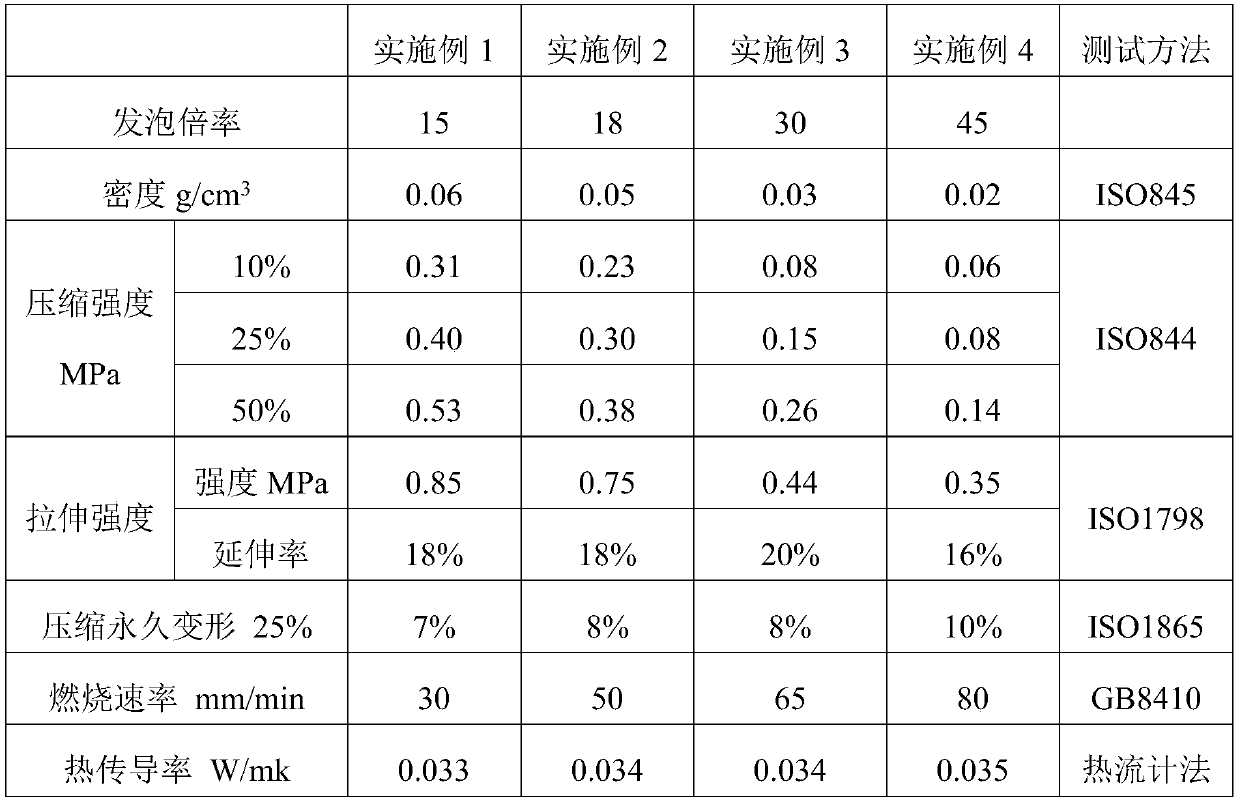

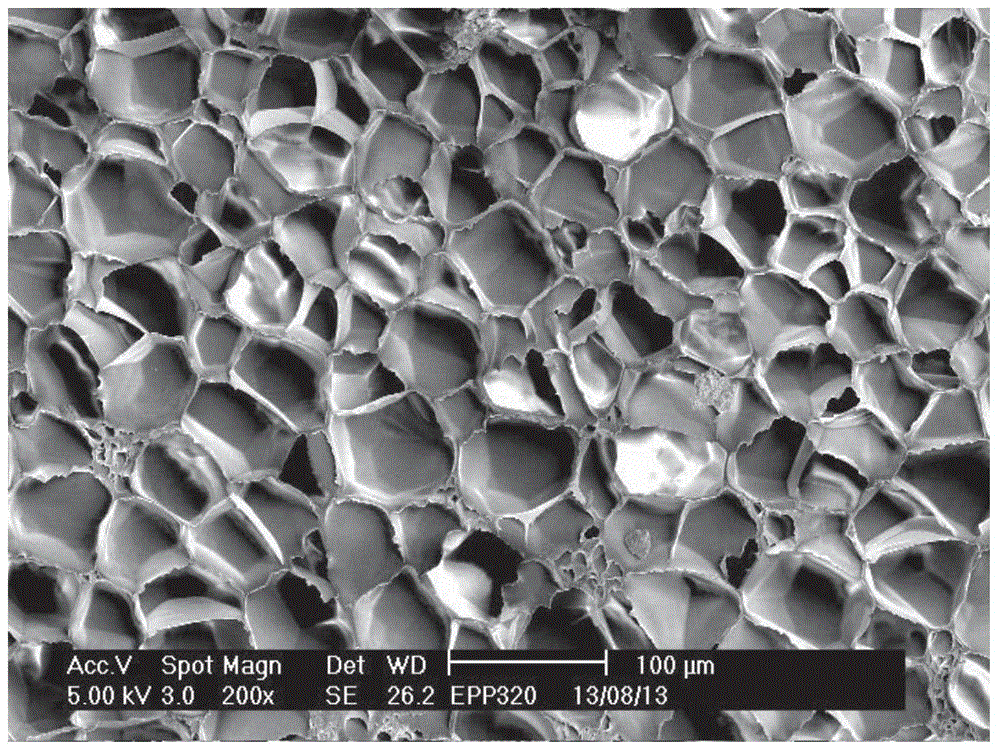

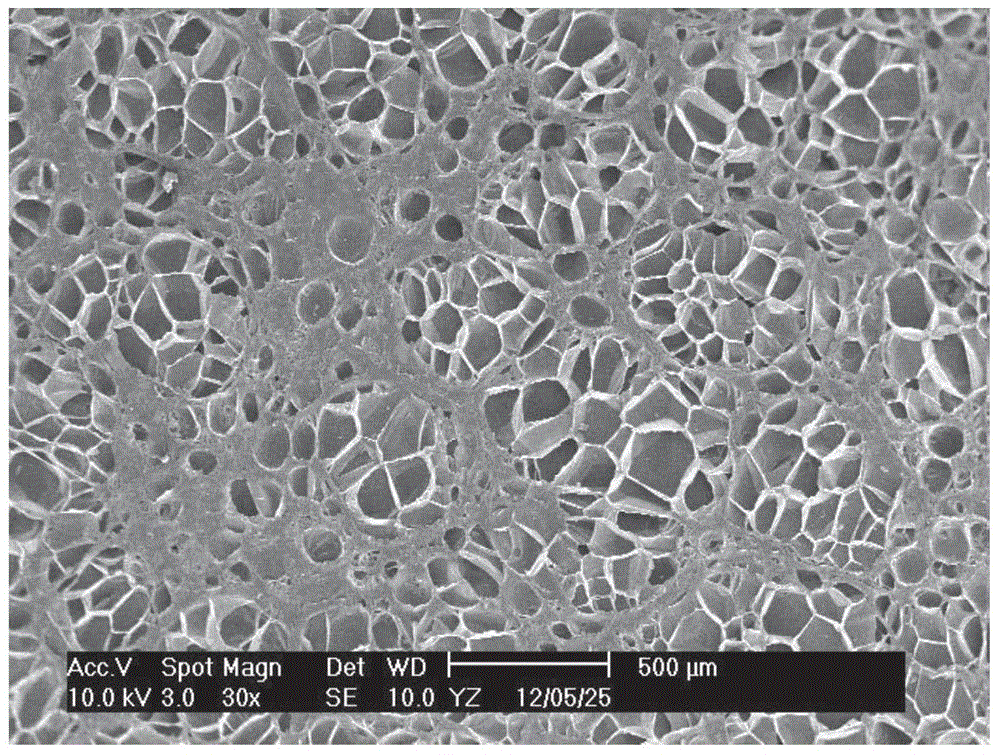

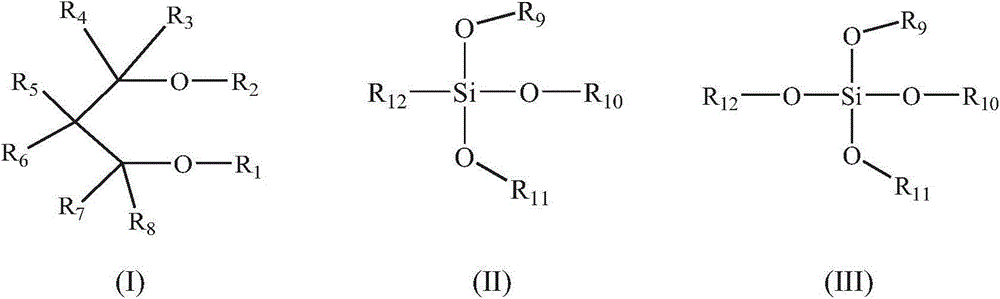

The invention discloses double-component pouring silica gel. The double-component pouring silica gel comprises a component A and a component B. The component A comprises, by weight, 100 parts of vinyl silicone oil, 0-100 parts of non-reactive silicone oil, 0.05-10 parts of hollow micro-powder, 0.01-1.5 parts of transition metal complex catalysts and 0-3 parts of white paste; the component B comprises, by weight, 100 parts of vinyl silicone oil, 0-100 parts of non-reactive silicone oil, 0.05-10 parts of hollow micro-powder, 0.01-1 part of alkynol inhibitors, 10-40 parts of hydrogen-containing silicone oil and 0-3 parts of black paste. The double-component pouring silica gel has the advantages that the hollow micro-powder is used as a pre-foam filler, so that stable foam is available in the component A and the component B before the double-component pouring silica gel is used, and the double-component pouring silica gel is low in density and small in pore diameter, and foam holes are uniform; the double-component pouring silica gel is used as a pore closing material and is excellent in impact resistance, rebounding performance, softness, sound insulation, waterproof performance and steam-proof performance, and the like.

Owner:GUANGZHOU RUIHE SILICONE RUBBER TECH CO LTD

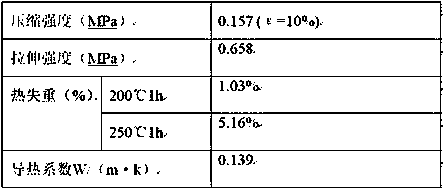

Lignin-based phenolic foam material and preparation method thereof

The invention discloses a lignin-based phenolic heat insulating material and a preparation method thereof. The preparation method comprises the following steps of: uniformly stirring expandable lignin basic phenolic resin with the conventional pH adjusting agent and a surfactant; adding a foaming agent and rapidly and uniformly stirring; adding a curing agent lastly; and uniformly stirring, and rapidly pouring into a specified enclosed container for foaming to the obtain lignin-based phenolic heat insulating material, wherein the used curing agent is a compound curing agent obtained by mixing toluenesulfonic acid and phosphoric acid in the mass ratio of 1.5:1. The foaming multiplying power of the lignin-based phenolic foam material is adjustable, the form hole fineness uniform density is 40-60 kg / m<3>, the compression strength is 0.07-0.45MPa, and the water absorbing rate is 7-15.5 percent.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Preparation method of foamed polypropylene beads

The invention discloses a preparation method of foamed polypropylene beads. The method comprises the following steps that 1, polypropylene resin, an active filler and auxiliaries are added into a high-speed mixing machine and mixed to be uniform at the temperature of 10-20 DEG C, and a polypropylene foaming material is obtained; 2, the polypropylene foaming material is added into a triple-screw extruder, plastification and mixing are conducted, a supercritical fluid is injected, the mouth mold pressure is controlled to be 5-25 MPa, the mouth mold temperature is 110-160 DEG C, instant pressure release is conducted through a mouth mold, foaming is conducted, and super-fine hole foamed polypropylene is obtained; 3, super-fine hole foamed polypropylene is subjected to mold surface water-ring hot-cutting granulation, drying and sieving, and the foamed polypropylene beads are obtained. The method is low in production cost, high in capacity, safe and environmentally friendly, no foaming agent decomposed residue exists in the prepared foamed polypropylene beads, secondary foaming can be conducted, the foaming ratio can be adjusted, the rebound resilience of a finished product is high, decomposing and recycling are easy, and the foamed polypropylene beads can be widely used in the fields of plastic packaging, transportation industry, military aerospace, office supplies and the like.

Owner:湖北聚石新材料科技有限公司

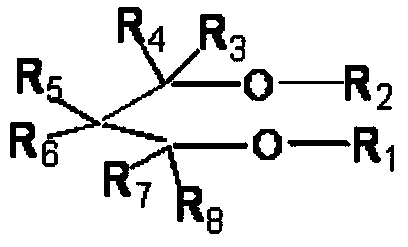

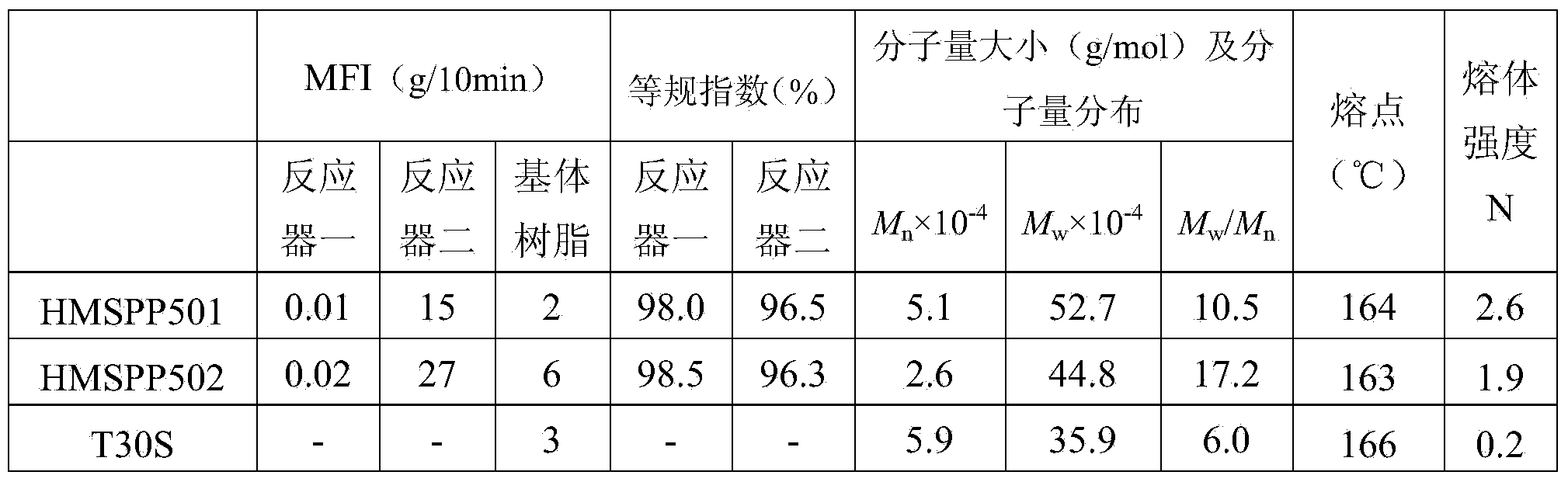

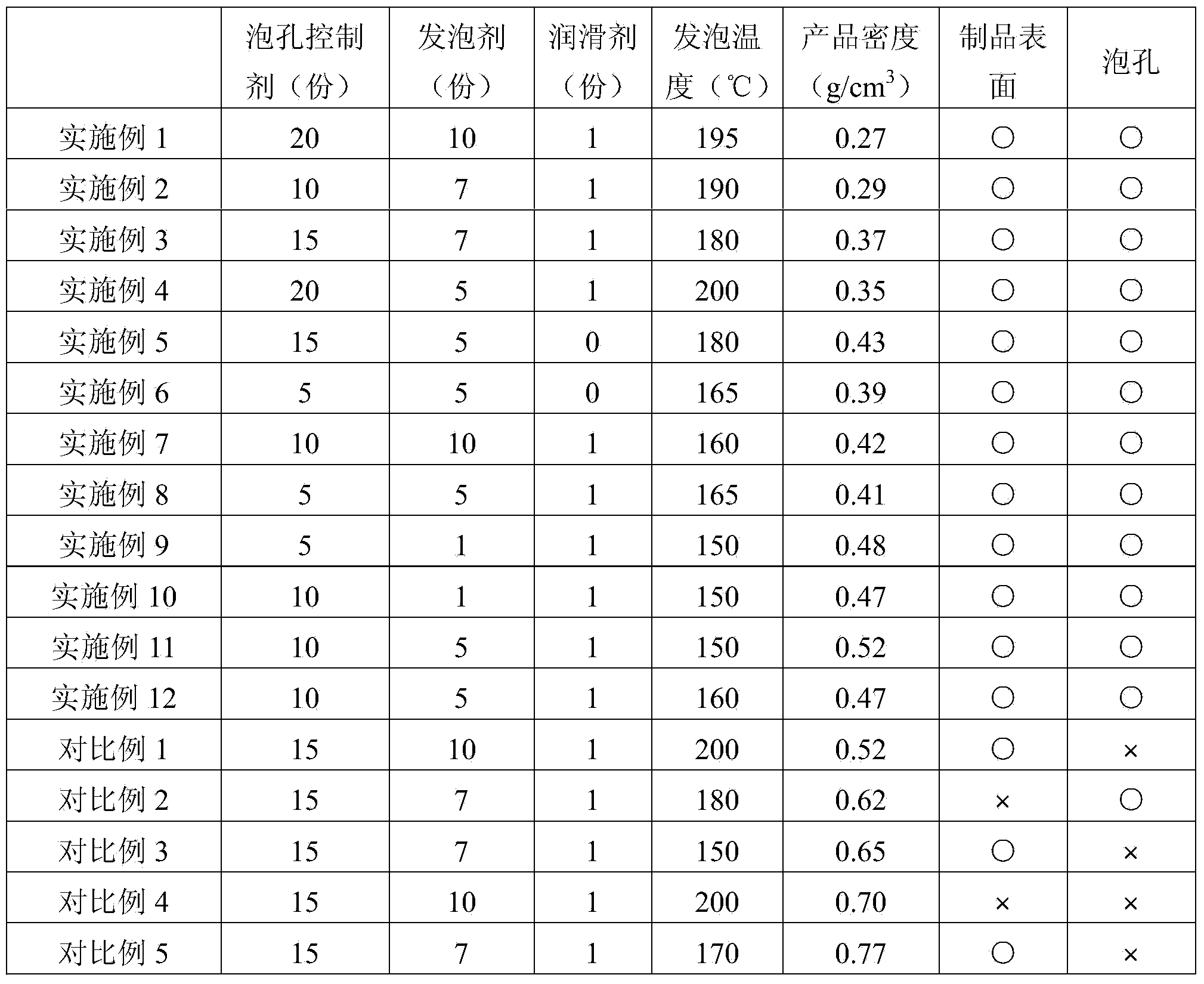

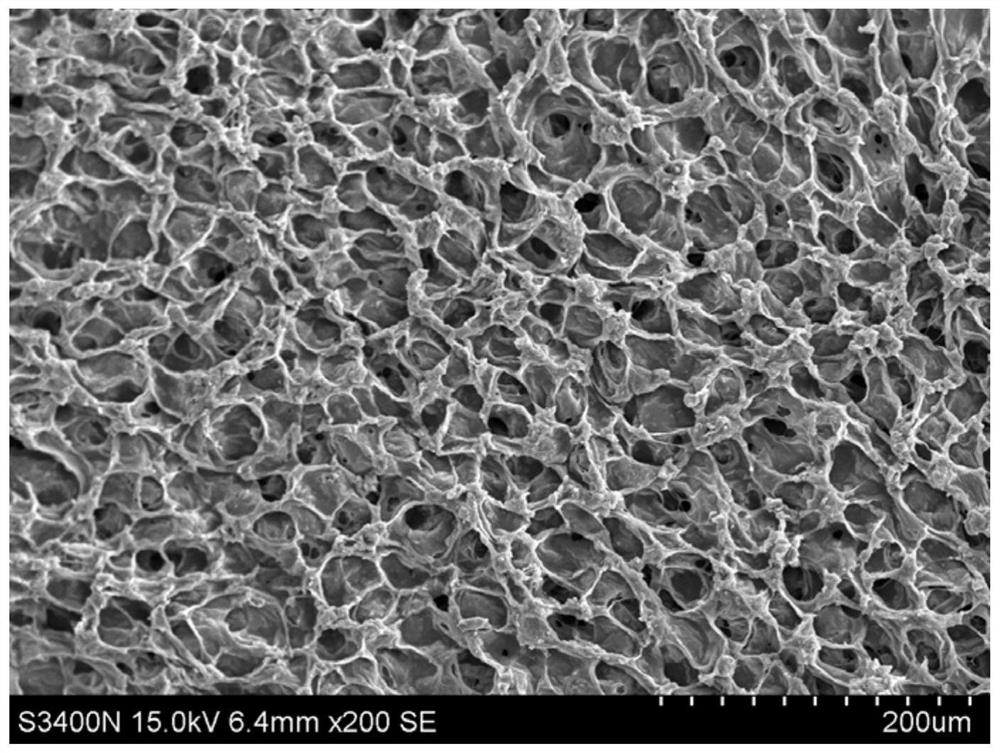

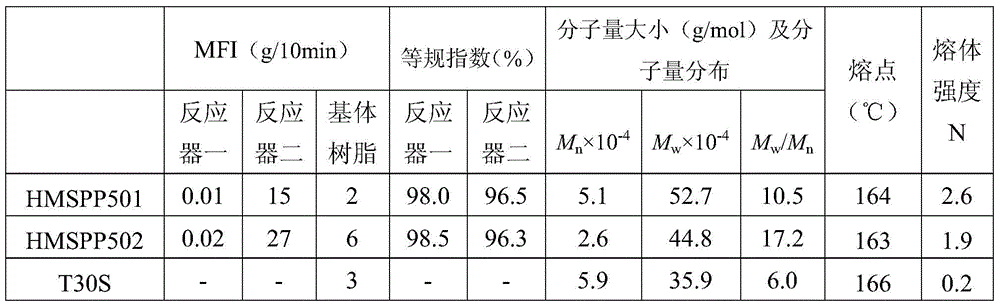

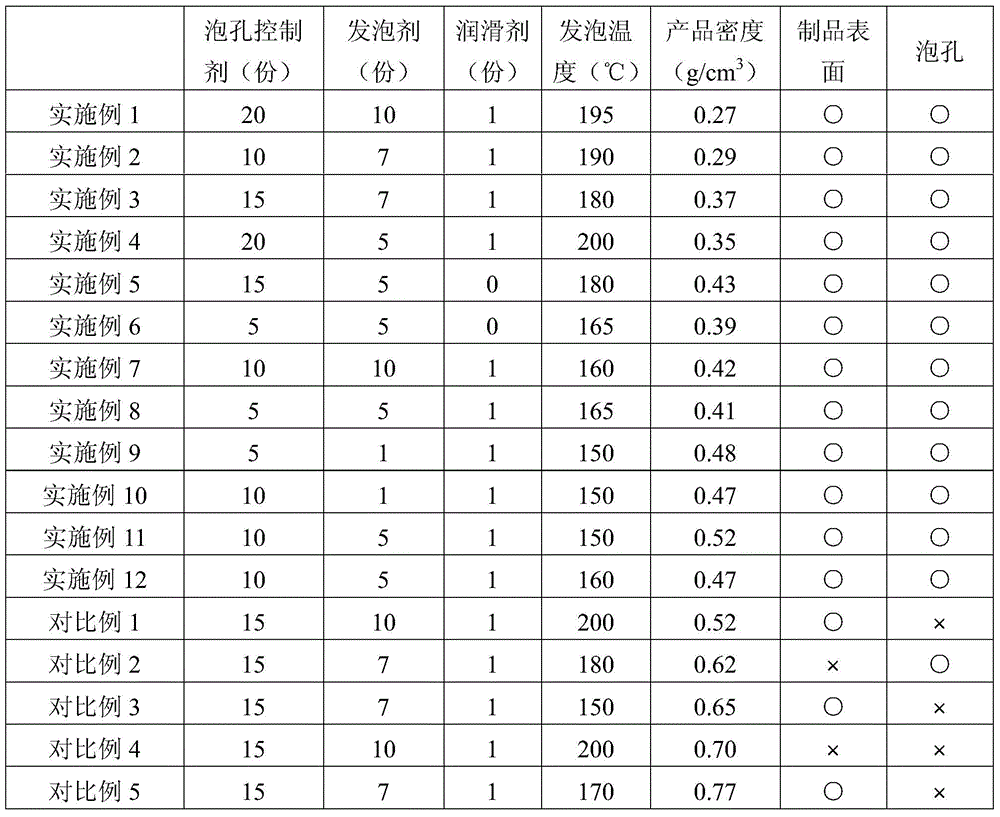

Preparation method of polypropylene foaming plate or sheet

The present invention provides a preparation method of a polypropylene foaming plate or sheet. According to the preparation method, high melt strength homopolymerization polypropylene is adopted as a matrix resin and a foaming agent is adopted to foam to prepare the polypropylene foaming plate or sheet, wherein the homopolymerization polypropylene preparation method comprises: in two or more than two reactors having the series connection operation, carrying out a two-stage or multi-stage propylene homopolymerization reaction, wherein the external electron donors used in the two-stage reaction are respectively a silane compound and a diether compound. According to the present invention, the high melt strength polypropylene having the wide molecular weight distribution is adopted as the raw material to achieve the stabilization of the polypropylene raw material, such that the foaming window is effectively expanded, the process is easy to adjust, the polypropylene foaming plate or sheet having the smooth self-skinning, the uniform foam hole diameter, the closed hole rigid structure, the density of 0.2-0.9 g / cm<3> and the thickness of 0.1-400 mm can be prepared, and the polypropylene foaming plate or sheet can be widely used in the fields of heat-insulation tableware, automotive interiors, building templates, camping supplies, decoration material sandwiches, product vibration reduction packaging and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polylactic acid foaming composite material as well as preparation method and application thereof

The invention belongs to the technical field of biodegradable foaming materials, and discloses a polylactic acid foaming composite material as well as a preparation method and application thereof. The polylactic acid foaming composite material comprises the following components in parts by weight: 100 parts of polylactic acid resin, 5-15 parts of other biodegradable materials, 0.5-3 parts of a bio-based nucleating agent, 0.5-4 parts of a chain extender and 0.1-1 part of a lubricant. The preparation method comprises the steps of mixing, extruding, drawing and pelletizing the components to prepare a polylactic acid foaming master batch; and putting the polylactic acid foaming master batch into a high-pressure reaction kettle, introducing a fluid serving as a foaming agent into the high-pressure reaction kettle, controlling the temperature of the high-pressure reaction kettle to be 40-200 DEG C and the pressure of the high-pressure reaction kettle to be 8-20 MPa, keeping the temperature and the pressure for 30-120 minutes, releasing gas in the reaction kettle, reducing the pressure to normal pressure, and taking out polylactic acid foaming particles from the reaction kettle, so as to obtain the particles, namely, the polylactic acid foaming composite material.

Owner:GUANGDONG UNIV OF TECH

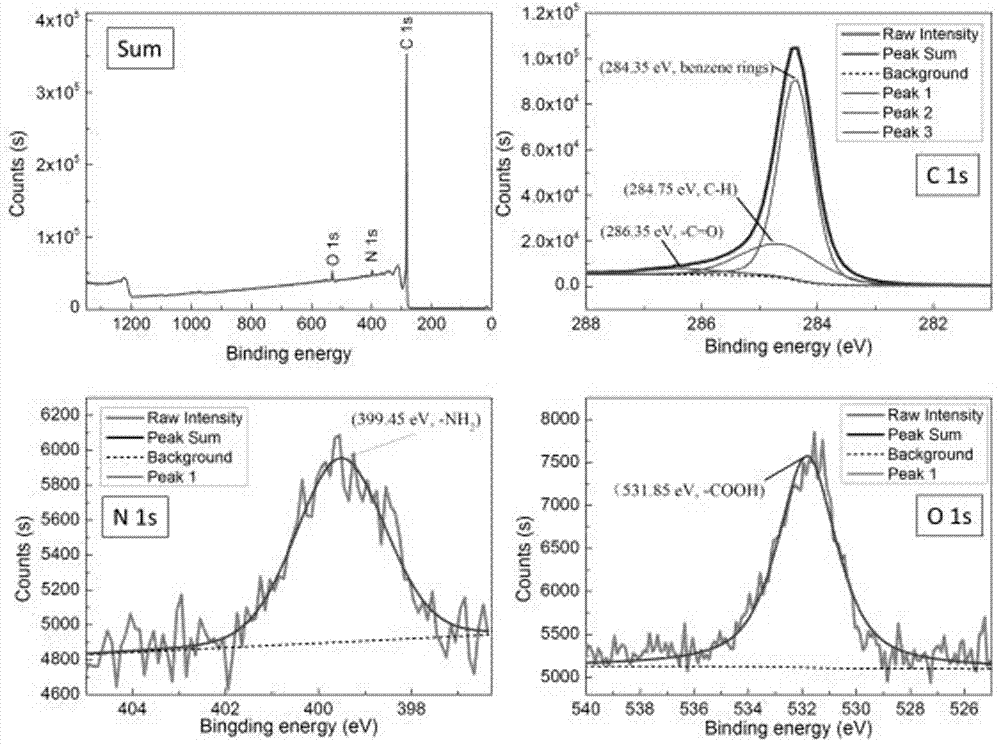

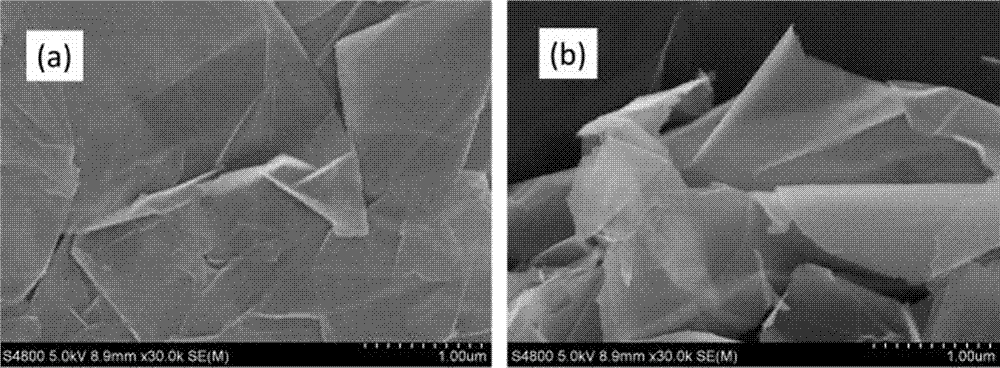

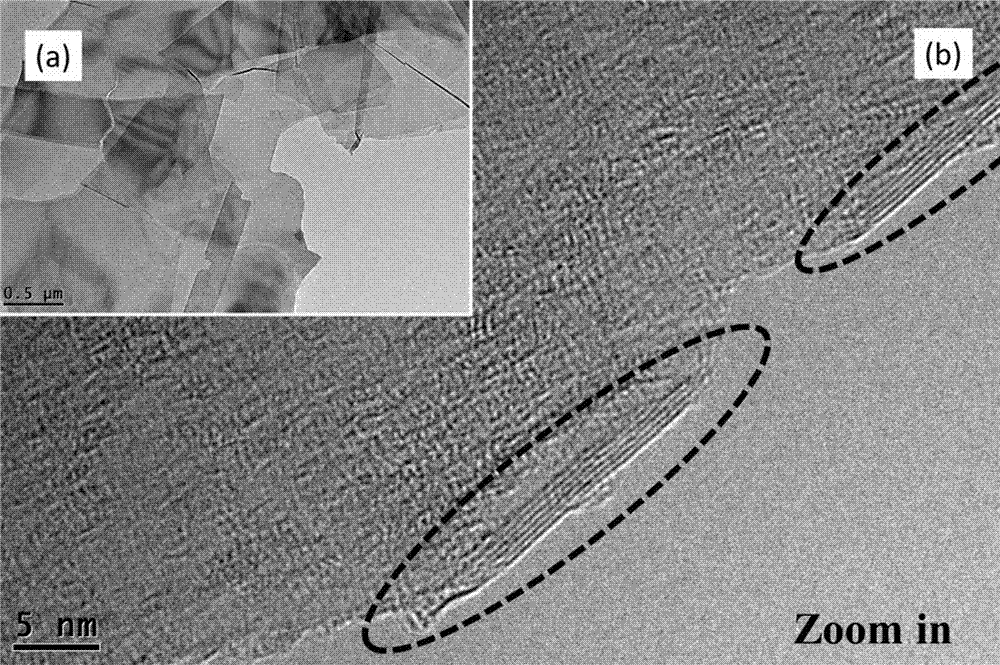

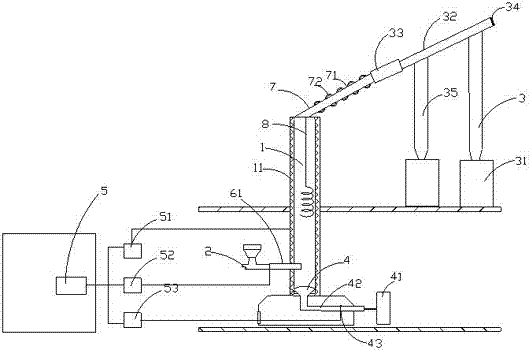

Batch preparation method of graphene and production system therefor

InactiveCN107500279AImprove stripping rateImprove stabilitySingle layer grapheneGraphiteCvd graphene

The invention relates to the field of graphene materials, and discloses a batch preparation method of graphene and a production system therefor. In the invention, a conventional high temperature expansion method is combined with a graphite expansion furnace, and by means of optimum expansion temperature, stability of a product is effectively improved by means of control on raw materials and process parameters on the basis of the expansion temperature, thereby producing expanded graphite with controllable expansion times, namely, distribution ratio with expansion times being 200-300 is highest. With the expanded graphite as a raw material for producing graphene through a mechanical stripping method, stripping rate of graphene is greatly increased. On the basis of the conventional mechanical stripping method for preparing graphene, the graphene is produced in batches with the expandable graphite as raw material and graphene quantum dots as a stripping liquid, wherein a pre-stripping process is added on the basis of the prior art, and secondary ultrasonic treatment is employed with process parameters in the ultrasonic treatment being optimized.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

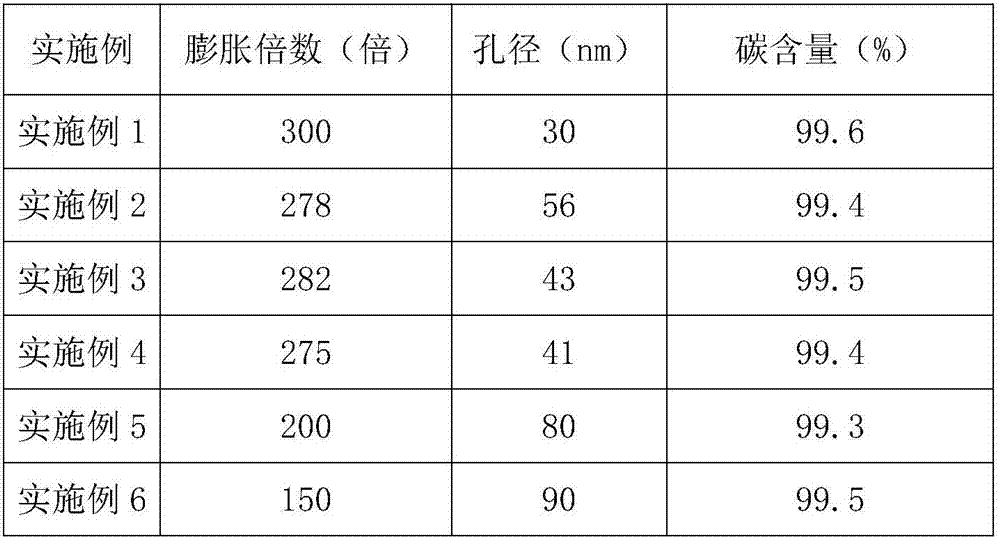

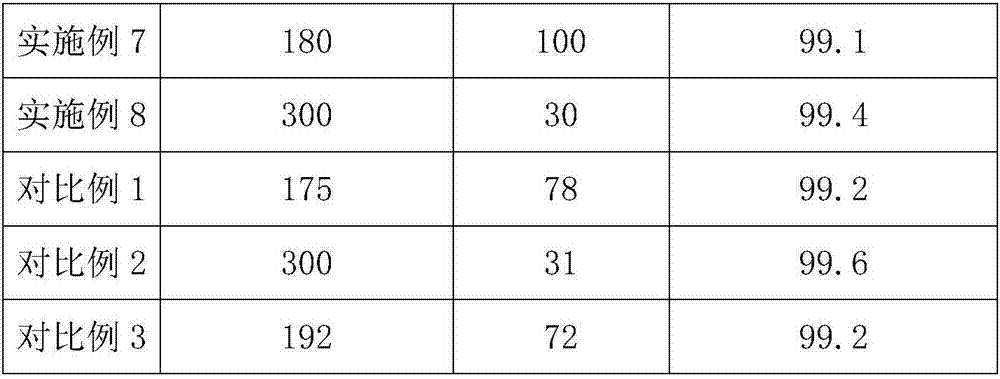

Expanded graphite and preparation method thereof

InactiveCN107311169AImprove stabilityControllable expansion ratioCarbon compoundsGas protectionWind speed

The invention relates to an expanded graphite material, and discloses expanded graphite and a preparation method thereof. The traditional high-temperature expansion method is combined with a graphite expansion furnace; the optimal expansion temperature is used; the product stability can be effectively improved through controlling the raw materials and the process parameters at the expansion temperature, so that the large-scale preparation of stable expanded graphite with controllable expansion times is realized; the expansion times is 200 to 300; the bore diameter is 30 to 100nm; the carbon content is stable. The temperature region is formed by defining the temperature of a feeding opening and a discharging opening; the expansion time is controlled by setting the feeding speed and the wind speed; then, the separation and collection are realized through wind speed; the large-scale preparation is realized; the inert gas protection is not needed; the graphite high-temperature oxidation caused by too high expansion temperature can be prevented, so that the expansion volume of the graphite is reduced.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

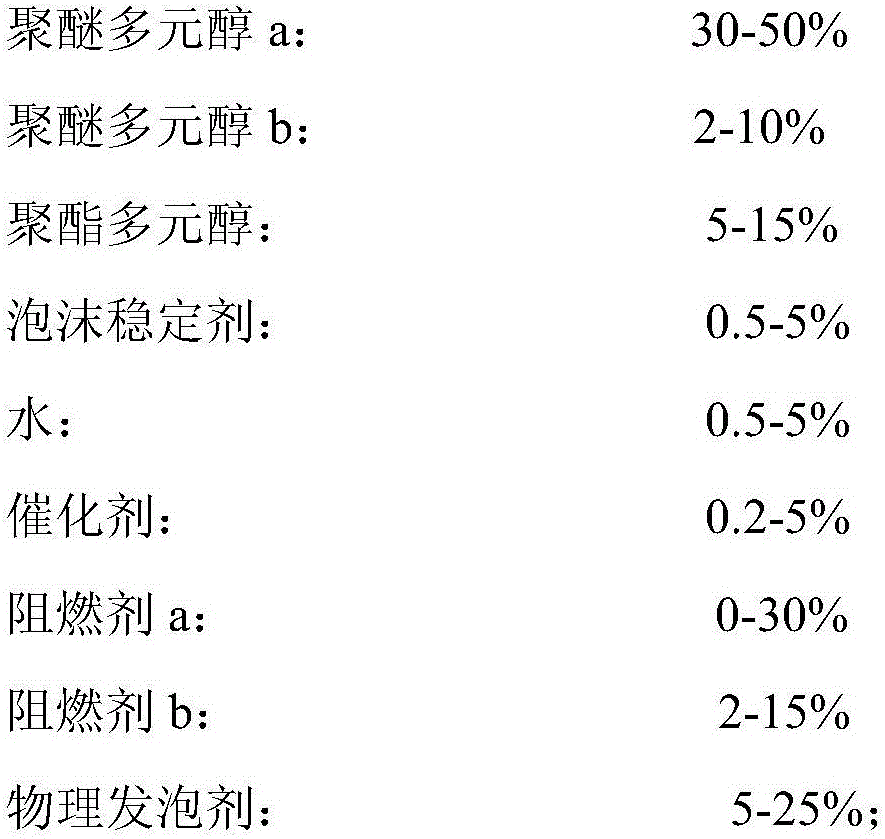

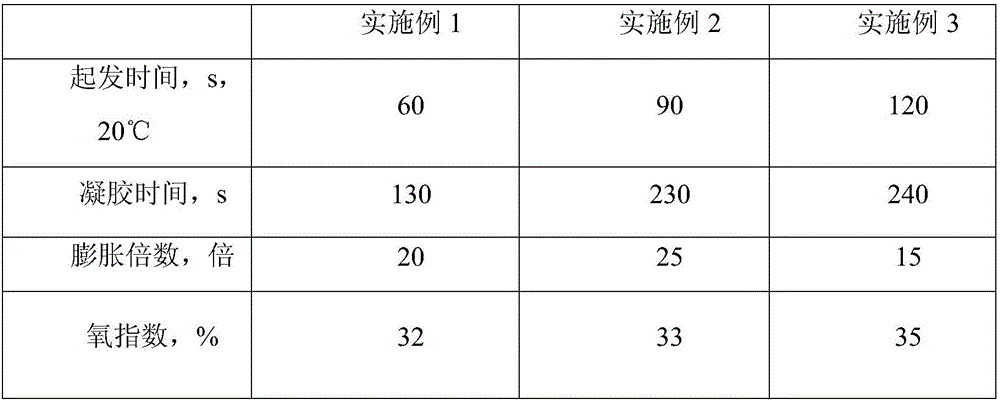

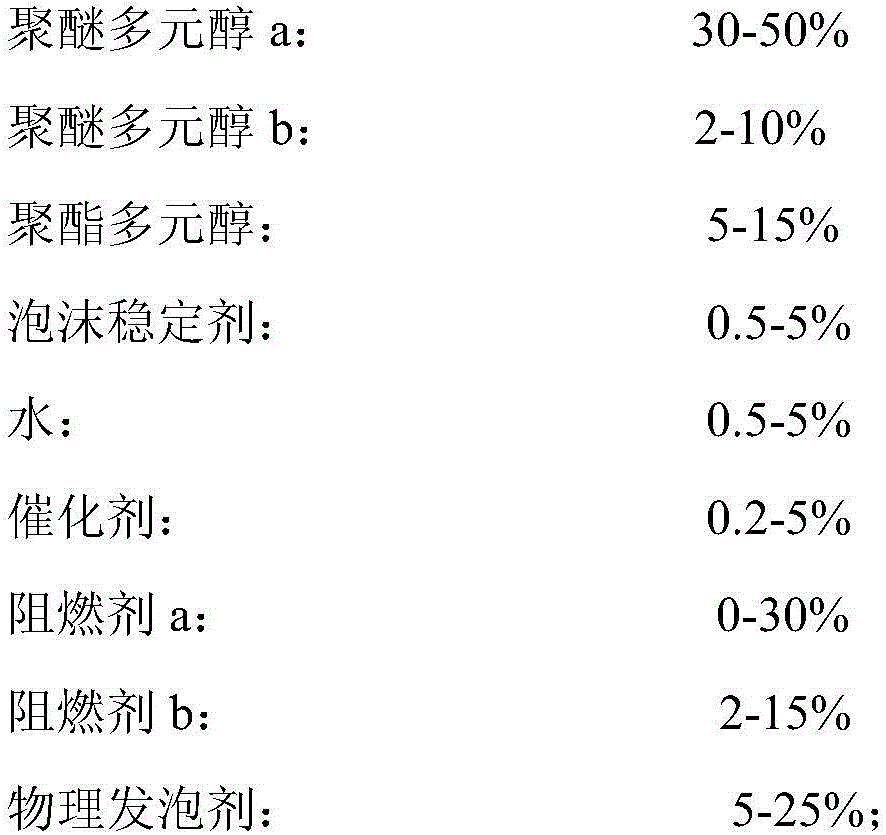

High-flame-retardancy polyurethane gas hole sealing material for coal mine and preparation method of high-flame-retardancy polyurethane gas hole sealing material

InactiveCN106832208AImprove flame retardant performanceImprove adhesionDrilling compositionFire retardantCoal

The invention relates to the technical field of polyurethane, in particular to a high-flame-retardancy polyurethane gas hole sealing material for a coal mine and a preparation method of the high-flame-retardancy polyurethane gas hole sealing material. The hole sealing material is prepared from a component A and a component B, wherein the component A comprises polyhydric alcohol, water, an adjuvant, a flame retardant and a physical foaming agent; the component B is polymethylene polyphenyl isocyanate. Due to the formula design, a high-flame-retardancy polyurethane material which is high in flame retardancy, stable in effect and applied to gas hole sealing is obtained by compounding the polyhydric alcohol, the adjuvant and the flame retardant, and has the advantages of normal temperature reaction, adjustable reaction speed, adjustable foaming rate and high flame retardancy; foam produced by the high-flame-retardancy polyurethane material is high in flame retardancy, high in bonding strength to a coal and rock mass, high in shear strength and toughness after being bonded and impact-resistant; relevant raw materials are low in odor and cannot generate any toxic gas, and the use and environmental protection requirements of the gas hole sealing material can be completely met.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

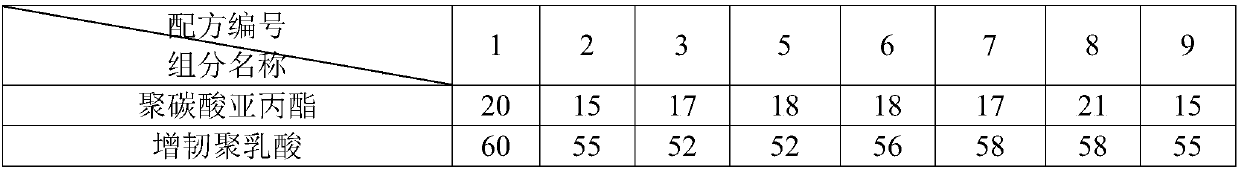

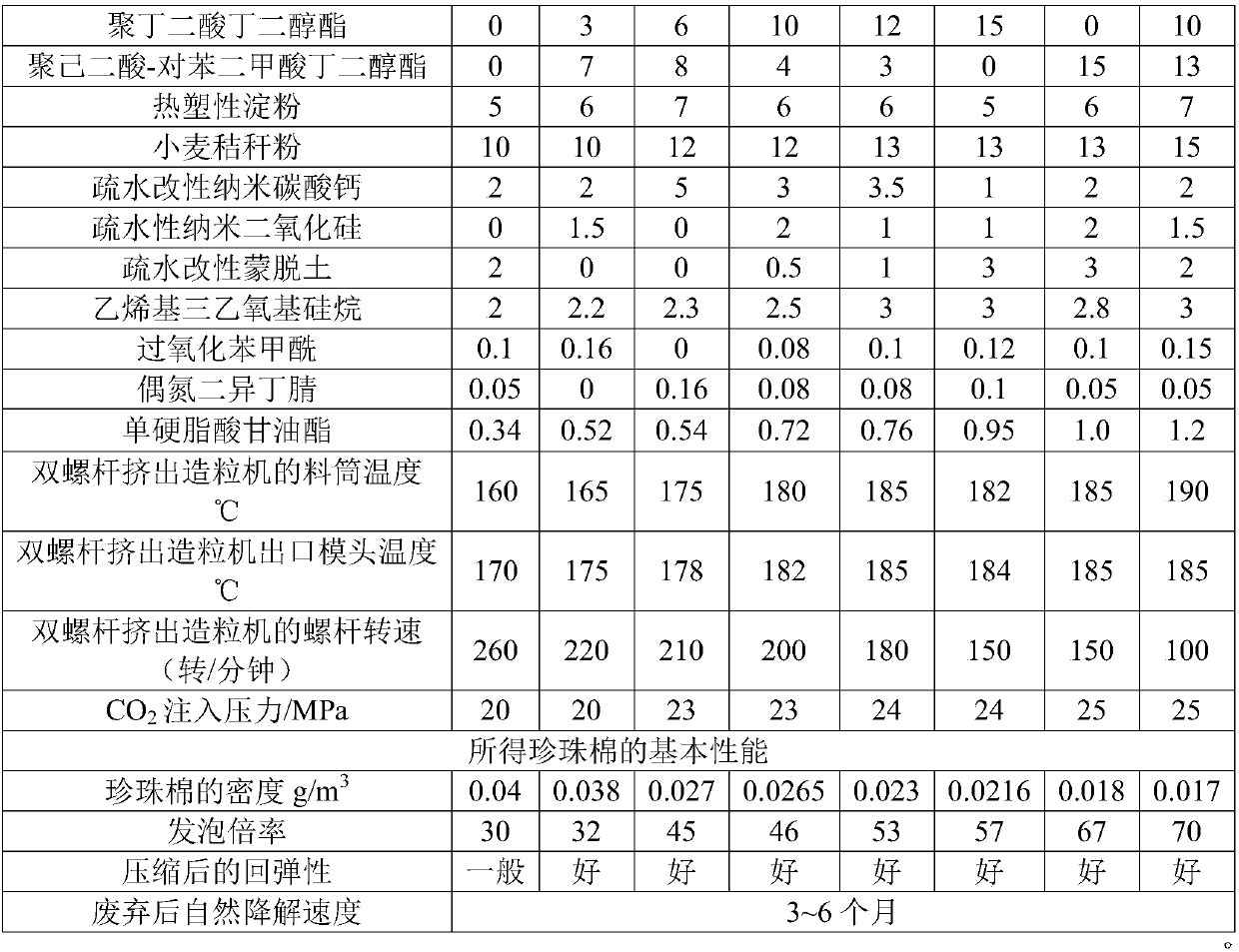

Biodegradable pearl cotton and preparation method thereof

The invention discloses biodegradable pearl cotton and a preparation method thereof. The preparation method of the pearl cotton comprises the steps of adding wheat straw powder and a nucleating agentto one or a mixture of polypropylene carbonate, toughened polylactic acid, polybutylene succinate and thermoplastic starch as a main material; mixing the mixture uniformly in a high-mixer; then mixingthe mixture through a double-screw mixer and extruding the mixture; air-cooling the extruded mixture, pulling the mixture into strips and pelletizing; further adding a cross-linking agent, an initiator and an anti-shrinking agent to be uniformly mixed; extruding and foaming the mixture through a dual-machine tandem type foaming sheet extrusion system by using supercritical carbon dioxide as a foaming agent to obtain a completely biodegradable environment-friendly pearl cotton sheet with a foaming ratio of 30-70 times. The pearl cotton can be used as a buffering package material or a package filler in place of the existing polyolefin pearl cotton.

Owner:泸州天浩新材料研究所(普通合伙)

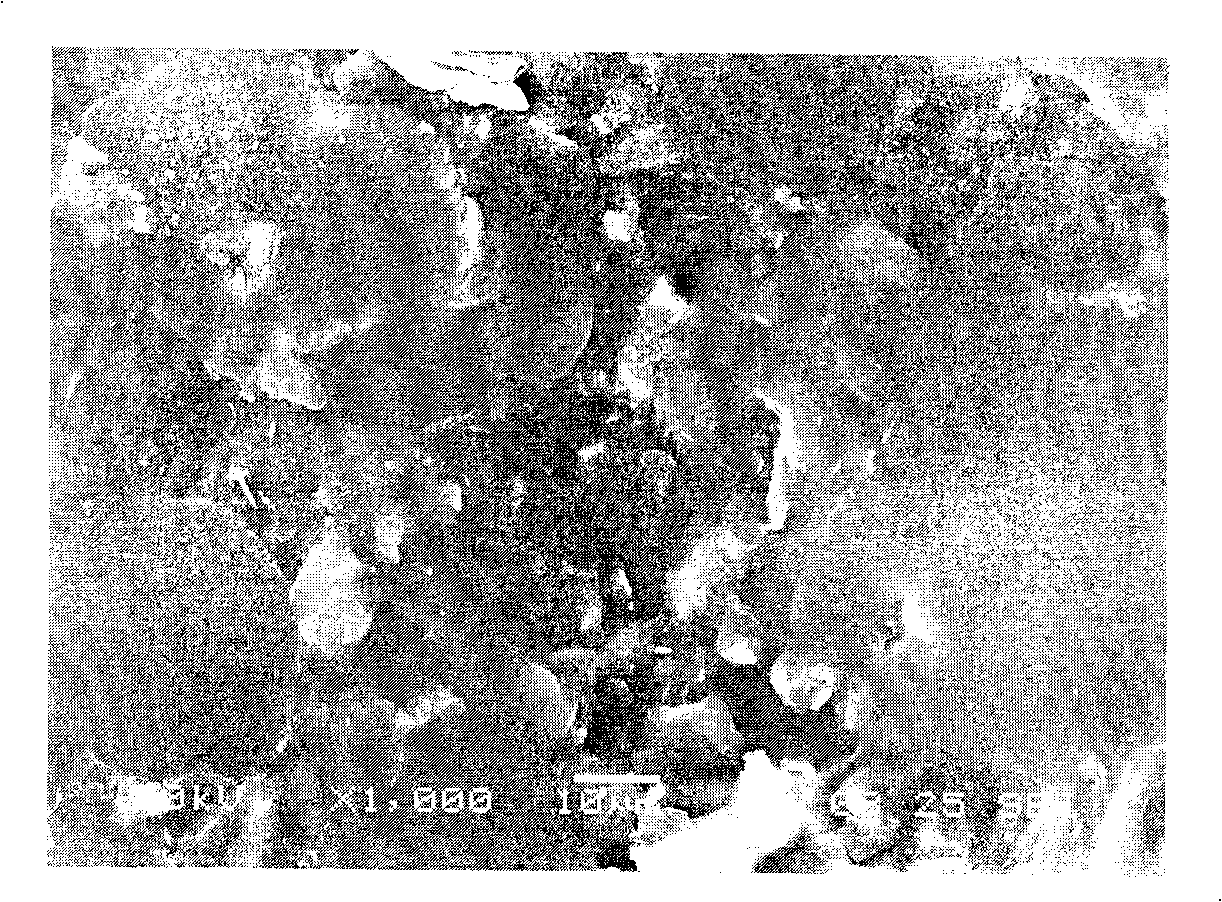

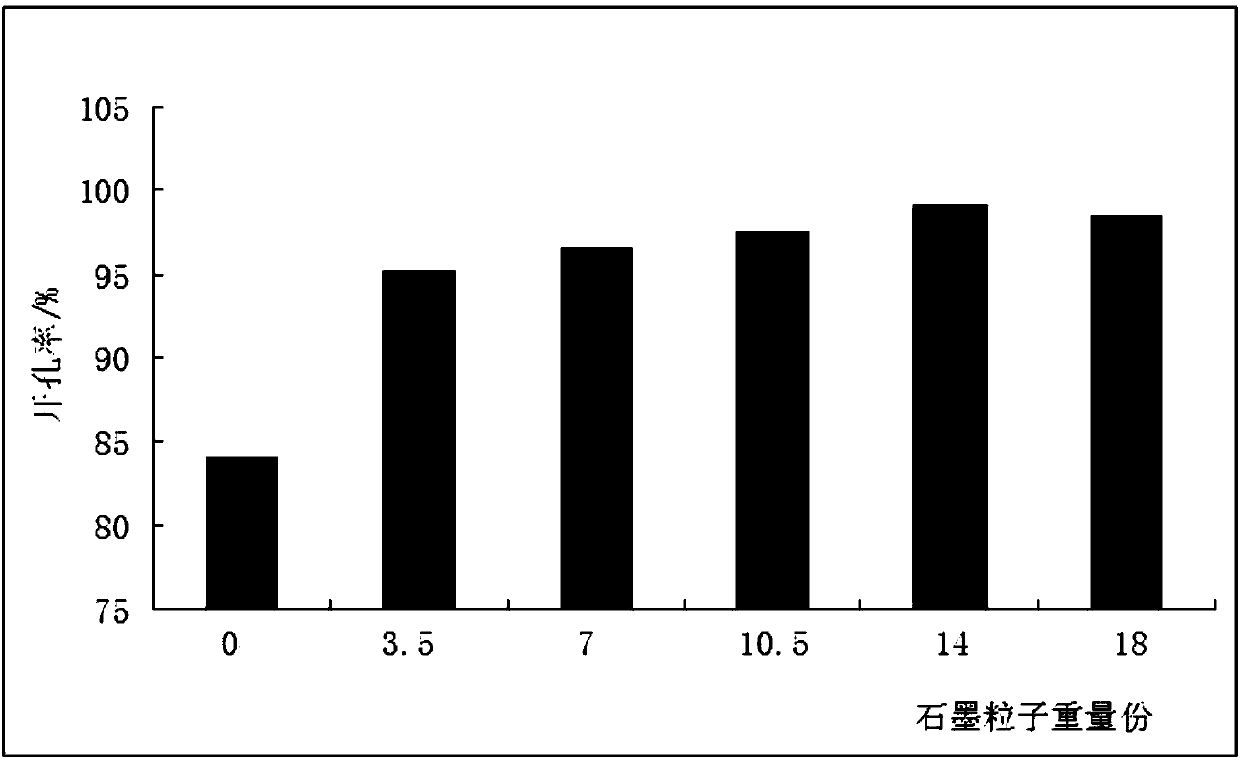

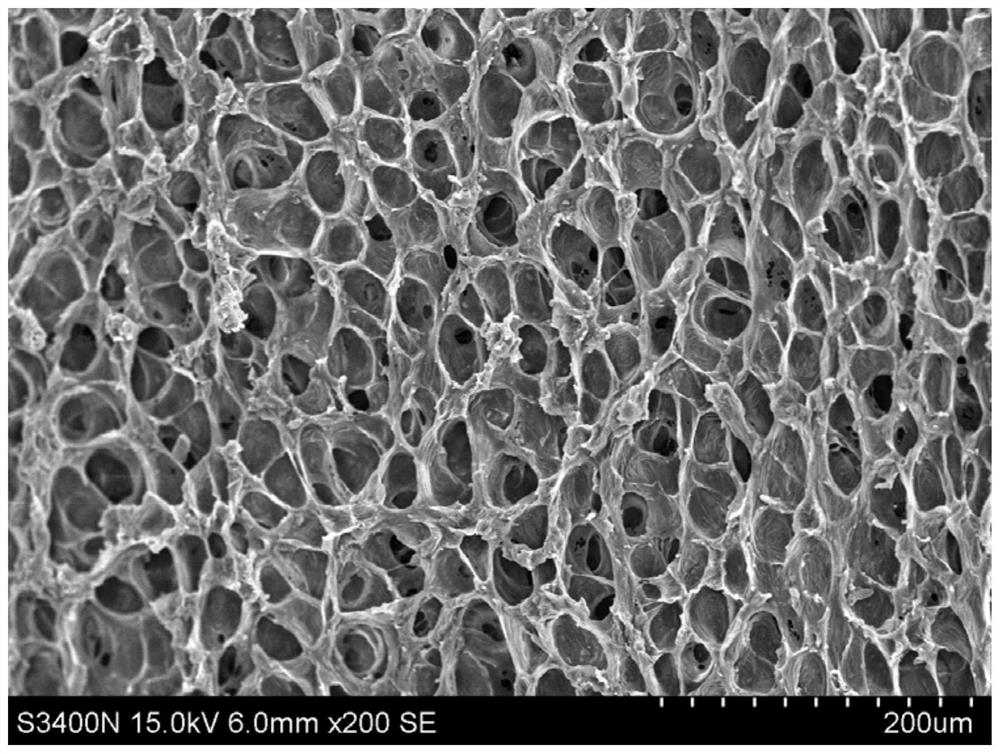

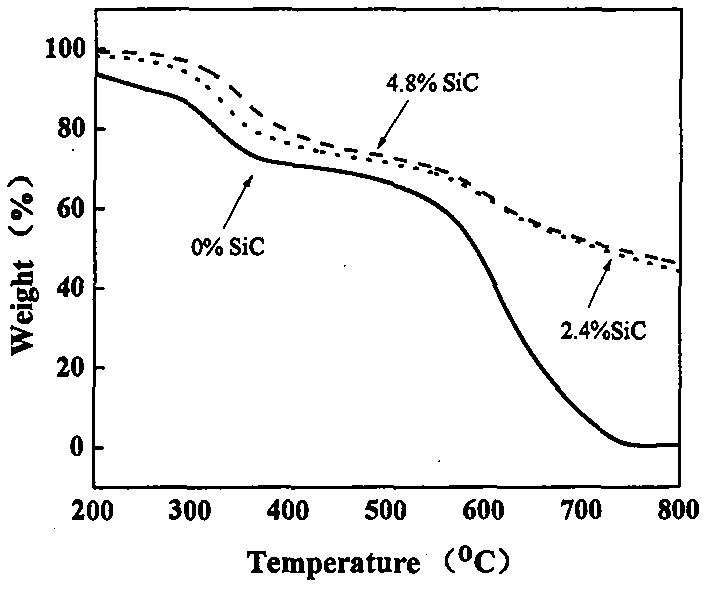

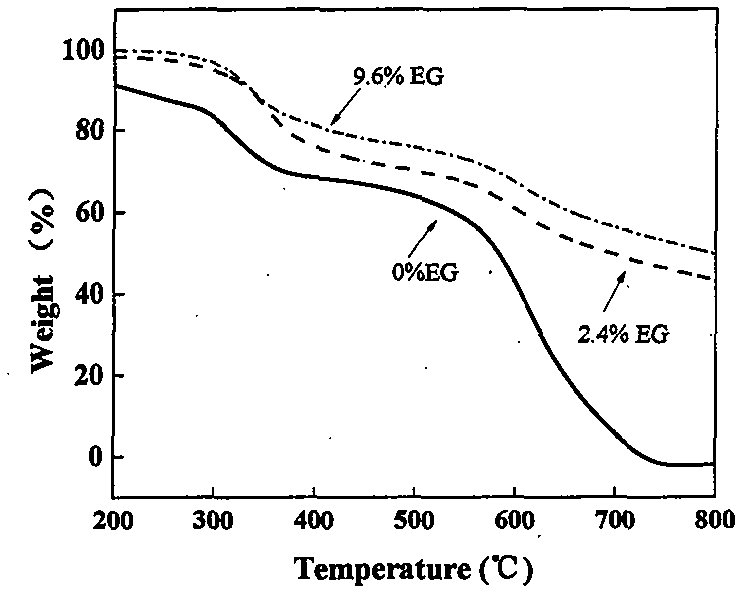

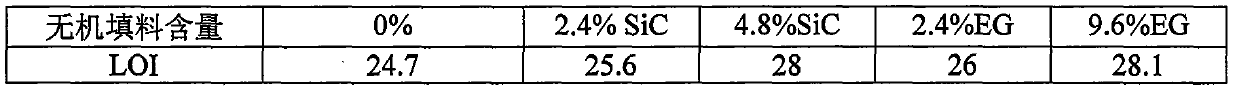

Inorganic-filler-filled high-temperature-resistant foam material and preparation method thereof

InactiveCN109553743AImprove flame retardant and high temperature resistanceOvercome the disadvantages of destroying the ozone layer of the atmosphereTemperature resistanceFire retardant

The invention provides an inorganic-filler-filled high-temperature-resistant foam material and a preparation method thereof, and relates to the field of high-molecular foam materials. The inorganic-filler-filled high-temperature-resistant foam material is prepared from dianhydride, polyol and isocyanate. The preparation method comprises mixing inorganic particles (silicon carbide, expandable graphite, vermiculite, graphene oxide and the like) with a prepolymer for polymerizing, and performing heat treatment at the later stage. According to the method, deionized water is adopted as a foaming agent, the inorganic particles are used as high-temperature-resistant and flame-retardant phases, the obtained foam has high thermal stability and flame retardancy, and the dimensional stability is alsoimproved. The high-temperature-resistant foam material is filled with an inorganic filler, a fluorine-containing foaming agent and a toxic flame retardant are not used, and the foaming process is environment-friendly. Compared with other high-temperature-resistant foam, the deionized water as a foaming agent is environment-friendly, and the inorganic particles are used as a flame retardant are free of harmful gas, and the inorganic-filler-filled high-temperature-resistant foam material good in high temperature resistance, simple in forming method and wide in application and development prospect.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Foaming method of polypropylene foamed microparticles

The invention discloses a foaming method of polypropylene foamed microparticles. The foaming method comprises the following steps: uniformly mixing polypropylene raw material particles with a first auxiliary agent, and extruding and granulating the mixture to obtain the polypropylene microparticles for foaming; adding the microparticles, a second auxiliary agent and water into a high pressure kettle to be stirred, heating the kettle by steam, injecting high pressure carbon dioxide into the polypropylene microparticles which are softened but not melted; keeping the temperature and the pressurefor a certain time to make sure that high pressure carbon dioxide fully impregnates the polypropylene microparticles, wherein the polypropylene microparticles are foamed; and after foaming, relievingthe pressure quickly to discharge to obtain the polypropylene foamed microparticles. The foaming method of the polypropylene foamed microparticles achieves continuous production and operation, and ishigh in efficiency, simple in process and suitable for industrial popularization and application. The foaming rate of the polypropylene foamed microparticles prepared by the invention is adjustable, the pores are uniform and fine, and the polypropylene foamed microparticles are excellent in mechanical property and has good compressive strength, tensile strength and buffer performance.

Owner:济南泰德包装科技有限公司

A kind of preparation method of expanded polypropylene beads

The invention discloses a preparation method of foamed polypropylene beads. The method comprises the following steps that 1, polypropylene resin, an active filler and auxiliaries are added into a high-speed mixing machine and mixed to be uniform at the temperature of 10-20 DEG C, and a polypropylene foaming material is obtained; 2, the polypropylene foaming material is added into a triple-screw extruder, plastification and mixing are conducted, a supercritical fluid is injected, the mouth mold pressure is controlled to be 5-25 MPa, the mouth mold temperature is 110-160 DEG C, instant pressure release is conducted through a mouth mold, foaming is conducted, and super-fine hole foamed polypropylene is obtained; 3, super-fine hole foamed polypropylene is subjected to mold surface water-ring hot-cutting granulation, drying and sieving, and the foamed polypropylene beads are obtained. The method is low in production cost, high in capacity, safe and environmentally friendly, no foaming agent decomposed residue exists in the prepared foamed polypropylene beads, secondary foaming can be conducted, the foaming ratio can be adjusted, the rebound resilience of a finished product is high, decomposing and recycling are easy, and the foamed polypropylene beads can be widely used in the fields of plastic packaging, transportation industry, military aerospace, office supplies and the like.

Owner:湖北聚石新材料科技有限公司

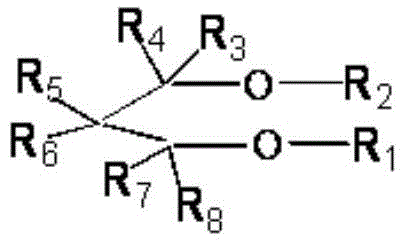

Impact-resistant polypropylene foaming material with high-melt strength and preparation method thereof

The invention discloses an impact-resistant polypropylene foaming material with high-melt strength. According to the invention, impact-resistant polypropylene with high-melt strength taken as matrix resin is obtained by foaming, The impact-resistant polypropylene with high-melt strength comprises a propylene homopolymer component and an ethylene / 1-butylene copolymer component; wherein the propylene homopolymer component comprises at least a first propylene homopolymer and a second propylene homopolymer; the ethylene content in the ethylene / 1-butylene copolymer is 20-45 wt%; the weight ratio of the ethylene / 1-butylene copolymer component to the propylene homopolymer component is 11-80: 100; and the ratio of room-temperature trichlorobenzene soluble Mw of the material to room-temperature trichlorobenzene insoluble Mw of the material is greater than 0.5 and is smaller than or equal to 1. The invention also relates to a preparation method of the foaming material. The foaming material has the characteristics of good shock resistance at high and low temperature, high physical heat resistance, high closed porosity, good insulation and sound insulation performances, controllable foaming multiplying power and foam structure, and easy recovery and utilization.

Owner:CHINA PETROLEUM & CHEM CORP +1

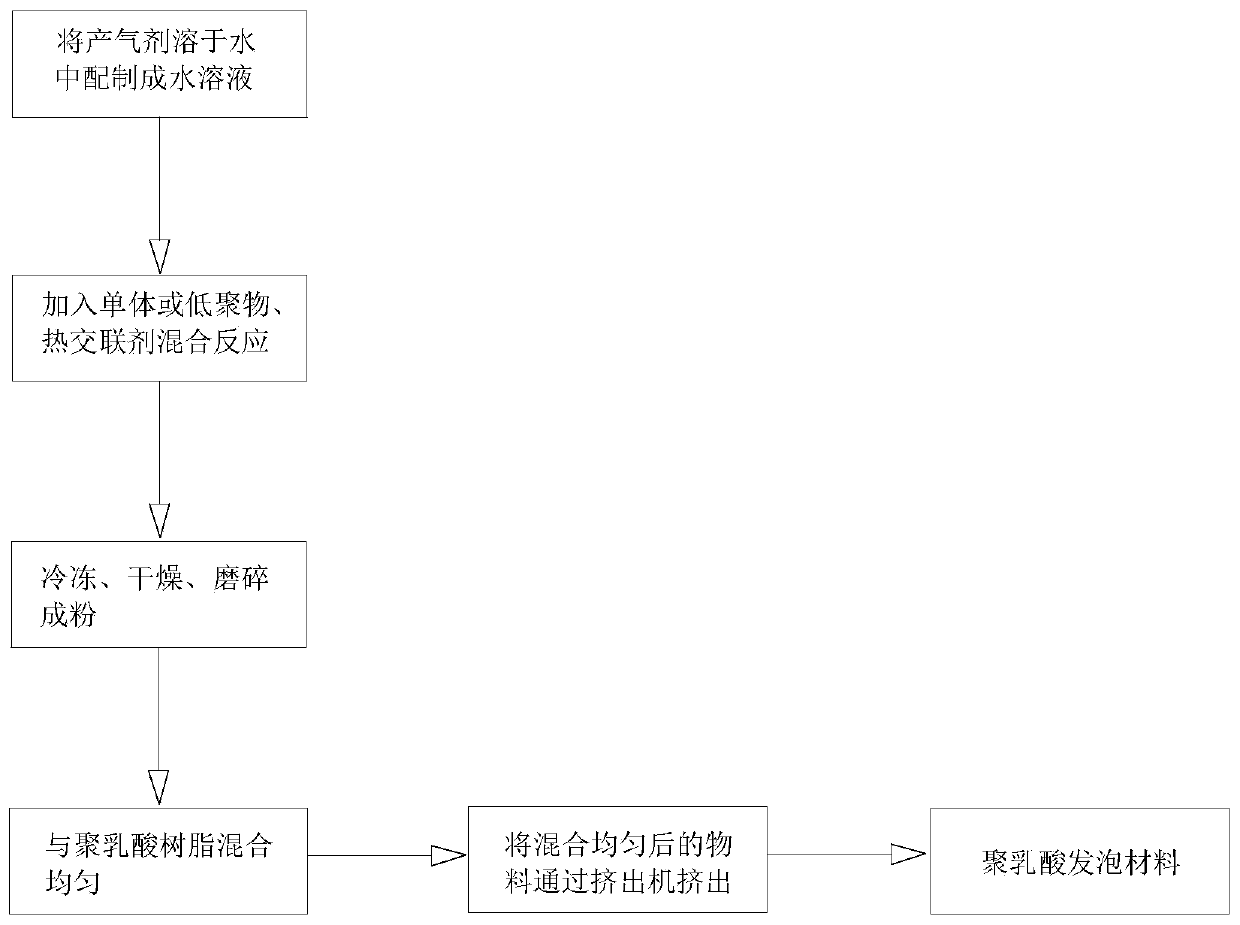

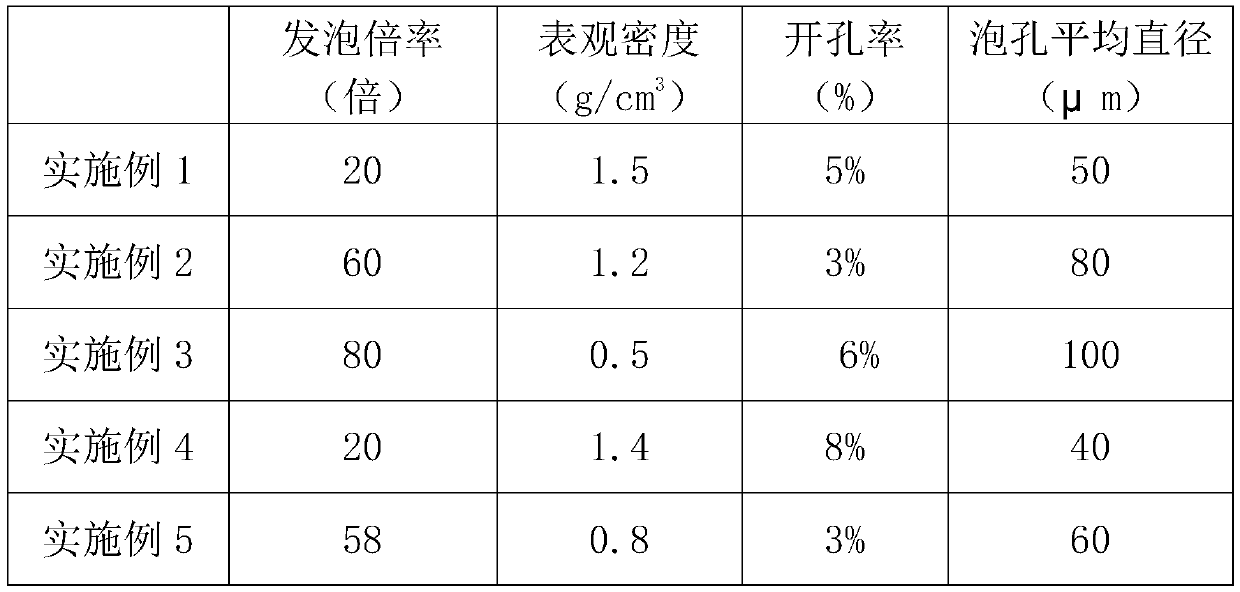

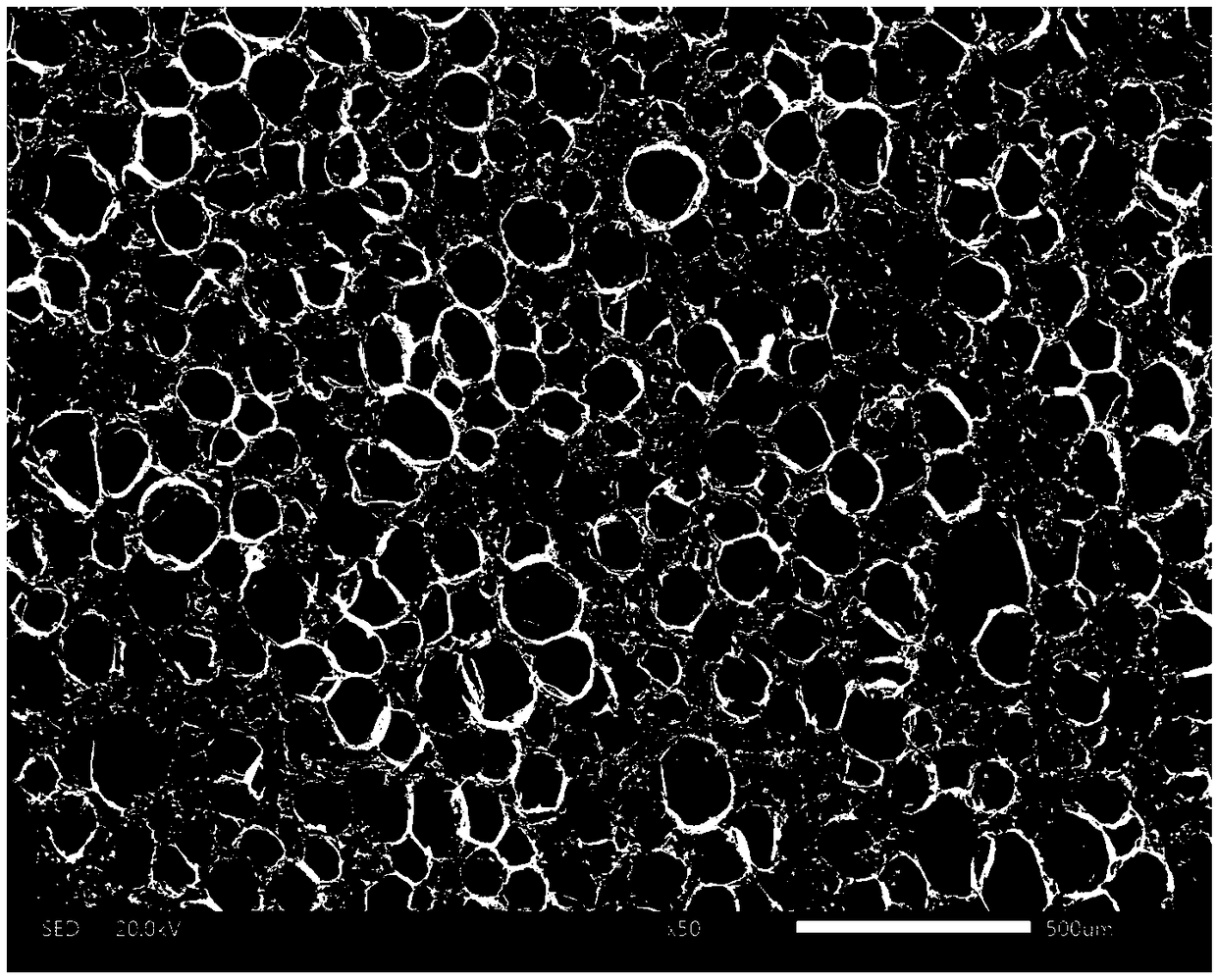

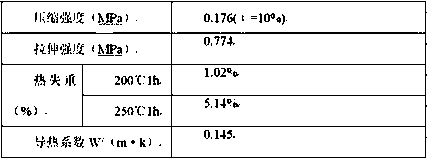

Polylactic acid foaming method

The invention discloses a polylactic acid foaming method. The polylactic acid foaming method comprises the following steps that A, a gas-generating agent is dissolved into water to prepare a solution;B, monomer or oligomer, a thermal crosslinking agent are mixed with the aqueous solution of the step A to obtain an initial reaction mixed solution, and after the initial reaction mixed solution is frozen and dried in a freeze drying device, grinding is conducted; C, polylactic acid resin and the ground initial reaction mixture powder obtained in the step B are uniformly mixed; D, the uniformly mixed material in the step C is added into an extruder, process parameters of the extruder are set for melt extrusion, the gas-generating agent is heated and generated expansion during the extrusion process, and a polylactic acid melt displays a foaming state; and E, the polylactic acid melt in the step D is extruded through the extruder and the polylactic acid foaming material is obtained after cooling and shaping. The foaming method is simple and efficient, no special equipment is needed, the cost is low, the operation is easy, the control is easy, and the obtained foaming material is stablein quality, uniform in the foam size, and high in the foaming rate.

Owner:佛山碧嘉高新材料科技有限公司

Preparation method with high yield, low cost and environmental protection for polypropylene beads

The invention provided a preparation method with high yield, low cost and environmental protection for polypropylene beads. The preparation method is characterized by comprising the following steps: adding polypropylene resin, an active filling material, caprolactam and an auxiliary agent into a high-speed mixer, and carrying out uniform mixing at 10 to 20 DEG C so as to obtain a polypropylene foamed material.

Owner:绵阳旺通科技有限公司

Expandable silicone rubber sheet and preparation method thereof

The invention discloses an expandable silicone rubber sheet and a preparation method thereof. The expandable silicone rubber sheet is prepared from the following components in parts by weight: 100 parts of silicone rubber, 10 to 30 parts of white carbon black, 100 to 150 parts of filler, 3 to 5 parts of vulcanizing agent, 6 to 10 parts of foaming agent and 3 to 8 parts of hydrogenated silicone oil. The preparation method of the expandable silicone rubber sheet comprises the following steps: putting and mixing the silicone rubber and the white carbon black in proportion in an open mill, then sequentially adding the filler, the vulcanizing agent, the foaming agent and the hydrogenated silicone oil, and mixing, thus preparing the expandable silicone rubber sheet. The expandable silicone rubber sheet disclosed by the invention can be used as a filling material for filling a gap of a structural member, and the gap of the structural member can be spontaneously filled during a temperature rising process through foaming; compared with a foamed silicone rubber filling material prepared by a traditional method, the preparation method has the advantages that advanced foaming is not required,the expandable silicone rubber sheet and the structural member are integrally formed, filling is compact, the foaming is uniform, and the like.

Owner:WUHAN UNIV OF TECH

Foaming synthetic leather manufacturing technology based on waterborne polyurethane (WPU)

ActiveCN102409554BSave resourcesImprove employment environmentSynthetic resin layered productsTextiles and paperManufacturing technologyMicrosphere

The invention provides a foaming synthetic leather manufacturing technology based on waterborne polyurethane (WPU). In the manufacturing technology, the WPU is taken as a main raw material, and a hollow microsphere foaming agent is taken as a foaming material; and the technology can be widely used for manufacturing synthetic leathers such as clothing leathers, luggage leathers, shoe upper leathers, sofa leathers, home interior trim leathers and the like. The content of volatile organic compounds (VOC) in the finished leather is lower than 2mg / kg (leather), and the air permeability and moisture penetrability are good, thus meeting the EU (European Union) requirements for the ecological synthetic leather; and in addition, the foaming synthetic leather has the advantages of moderate foaming multiplying power, uniform and compact foaming holes, bulky and firm hand feel as well as good comprehensive performance which is equivalent to or superior to that of a solvent-borne product. The foaming synthetic leather manufacturing technology based on the WPU provided by the invention has the beneficial effects that by adopting the WPU instead of the traditional solvent-borne PU, organic pollution is eliminated from a source, organic solvent resources are saved, the comprehensive energy consumption is lowered, the employment environment of laborers is improved, and the ecological grade of the synthetic leather and the international market competitiveness of the product are enhanced, thus achieving obvious innovativeness and remarkable social and economic benefits.

Owner:DONGTAI FUAN SYNTHETIC MATERIAL CO LTD

A kind of preparation method of polypropylene foam board or sheet

The present invention provides a preparation method of a polypropylene foaming plate or sheet. According to the preparation method, high melt strength homopolymerization polypropylene is adopted as a matrix resin and a foaming agent is adopted to foam to prepare the polypropylene foaming plate or sheet, wherein the homopolymerization polypropylene preparation method comprises: in two or more than two reactors having the series connection operation, carrying out a two-stage or multi-stage propylene homopolymerization reaction, wherein the external electron donors used in the two-stage reaction are respectively a silane compound and a diether compound. According to the present invention, the high melt strength polypropylene having the wide molecular weight distribution is adopted as the raw material to achieve the stabilization of the polypropylene raw material, such that the foaming window is effectively expanded, the process is easy to adjust, the polypropylene foaming plate or sheet having the smooth self-skinning, the uniform foam hole diameter, the closed hole rigid structure, the density of 0.2-0.9 g / cm<3> and the thickness of 0.1-400 mm can be prepared, and the polypropylene foaming plate or sheet can be widely used in the fields of heat-insulation tableware, automotive interiors, building templates, camping supplies, decoration material sandwiches, product vibration reduction packaging and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

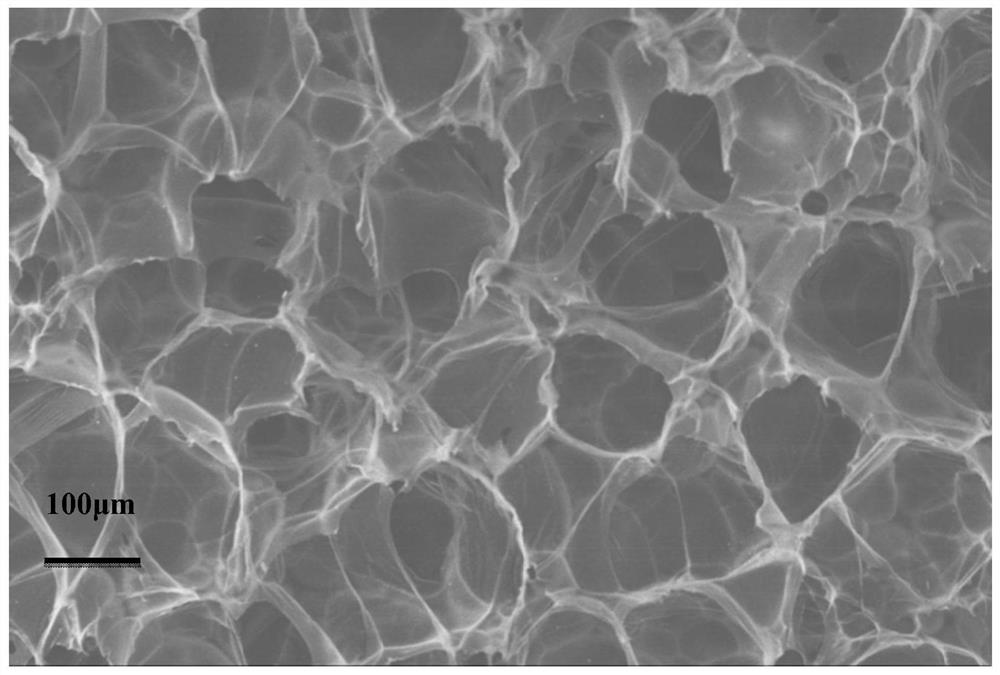

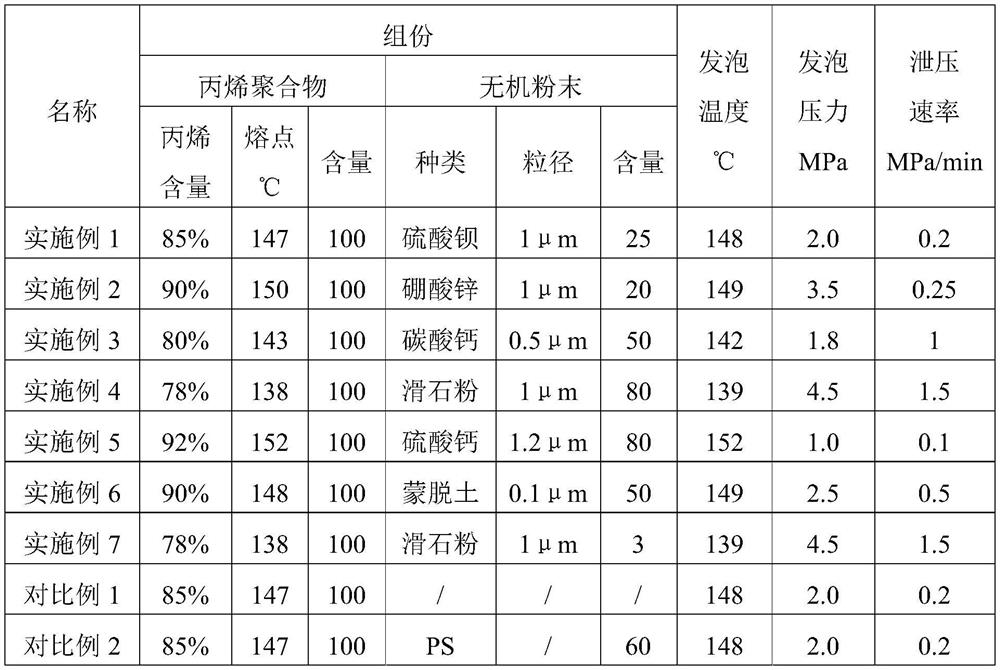

Preparation method of open-cell propylene polymer foamed beads

The invention discloses a preparation method of open-cell propylene polymer foamed beads, which at least comprises the following steps: (1) uniformly mixing a mixture containing a propylene polymer and inorganic powder to prepare blended propylene polymer particles; and (2) placing the blended propylene polymer particles in an environment containing carbon dioxide and water, heating to the melting point of the propylene polymer, swelling and permeating, and cooling after pressure relief to obtain the open-cell propylene polymer foamed beads. The preparation method has the characteristics of simple process, controllable process and controllable expansion rate. And the prepared open-cell propylene polymer foamed beads are uniform in cells, have the effects of oil absorption, filtration and the like, and have a very good industrial application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Single-component polyurethane foaming adhesive as well as preparation method and application thereof

PendingCN114045147AAdjustable foaming ratioAdjustable mechanical propertiesPolyureas/polyurethane adhesivesIsocyanatePolyester

The invention discloses a single-component polyurethane foaming adhesive as well as a preparation method and application thereof. The single-component polyurethane foaming adhesive is prepared from the following components in parts by mass: 31.1 to 55.3 parts of vegetable oil polyol, 15.0 to 53.4 parts of polyether polyol, 30 to 106 parts of polyester polyol, 100 parts of isocyanate and 0.176 to 1.570 parts of a catalyst. The single-component polyurethane foaming adhesive provided by the invention does not contain an organic solvent, has a good micro-bubble structure and cohesiveness after being cured, is simple in preparation process, adjustable in curing rate and foaming times, simple and convenient to use, and suitable for bonding of foaming ceramic tile gap base plane materials.

Owner:广东省科学院生物与医学工程研究所

Method for modifying water encounter swelling rubber by using hydrophobic monomer

InactiveCN101407601BGood compatibilityGood dispersionOther chemical processesCross-linkPolymer science

The invention belongs to the sealing material field and provides a method for carrying out modification to water-swelling rubber by using hydrophobicity monomer. The method is characterized by comprising the following steps: according to average particle size, the mass ratio of nano-level polyacrylic high-water absorption resin powder, acrylic acid, hydrophobic monomer, a cross-linking agent and an initiator is 100: 5 to 30: 20 to 60: 0.01 to 10: 0.01 to 0.5; according to the mass ratio, the materials are selected, uniformly mixed, placed for 30 to 60 minutes, carries out with swelling, and carries out with polyreaction for 20 to 60 minutes after being heated to 40 DEG C to 70 DEG C; the resin is taken out and dried at the temperature of 60 DEG C to 80 DEG C so as to obtain modified waterabsorption resin; and 2) according to the mass ratio of 100: 10 to 60: 0 to 15: 0.5 to 3: 2 to 6: 0.5 to 5: 0 to 3: 30 to 60: 0.5 to 3, rubber, modified water absorption resin, plasticizer, stearic acid, zinc oxide, a vulcanizing agent, an aging resister, a reinforcing agent and an accelerating agent are selected, mixed on a double roll mixing mill uniformly, formed, and vulcanized so as to obtain the water-swelling rubber. The method can avoid the gather of nano particles of water absorption resin, also can improve the compatibility of the water absorption resin in the rubber and leads the water absorption resin to be dispersed in the rubber.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

A kind of two-component potting silica gel and its preparation method and potting method

ActiveCN105623593BControllable expansion ratioAperture controllableNon-macromolecular adhesive additivesOther chemical processesHydrogenPore diameter

The invention discloses double-component pouring silica gel. The double-component pouring silica gel comprises a component A and a component B. The component A comprises, by weight, 100 parts of vinyl silicone oil, 0-100 parts of non-reactive silicone oil, 0.05-10 parts of hollow micro-powder, 0.01-1.5 parts of transition metal complex catalysts and 0-3 parts of white paste; the component B comprises, by weight, 100 parts of vinyl silicone oil, 0-100 parts of non-reactive silicone oil, 0.05-10 parts of hollow micro-powder, 0.01-1 part of alkynol inhibitors, 10-40 parts of hydrogen-containing silicone oil and 0-3 parts of black paste. The double-component pouring silica gel has the advantages that the hollow micro-powder is used as a pre-foam filler, so that stable foam is available in the component A and the component B before the double-component pouring silica gel is used, and the double-component pouring silica gel is low in density and small in pore diameter, and foam holes are uniform; the double-component pouring silica gel is used as a pore closing material and is excellent in impact resistance, rebounding performance, softness, sound insulation, waterproof performance and steam-proof performance, and the like.

Owner:GUANGZHOU RUIHE SILICONE RUBBER TECH CO LTD

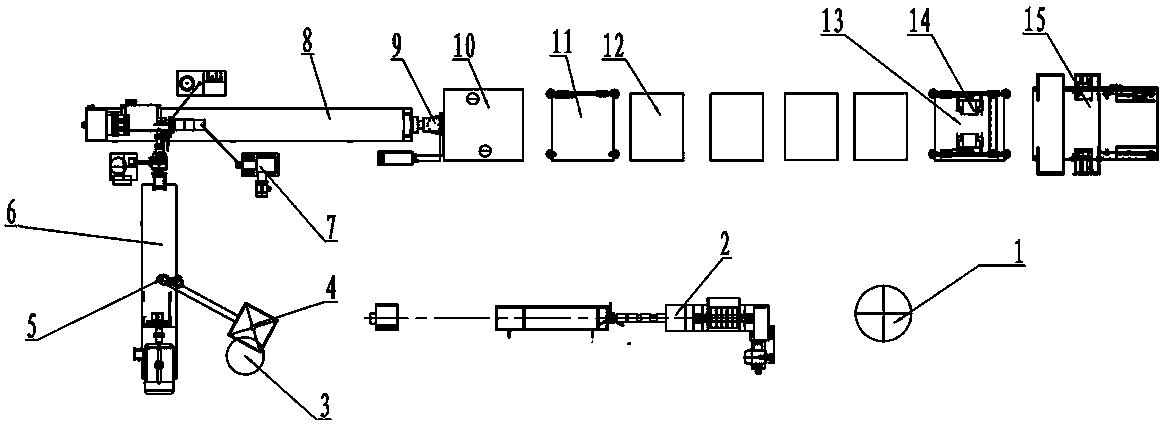

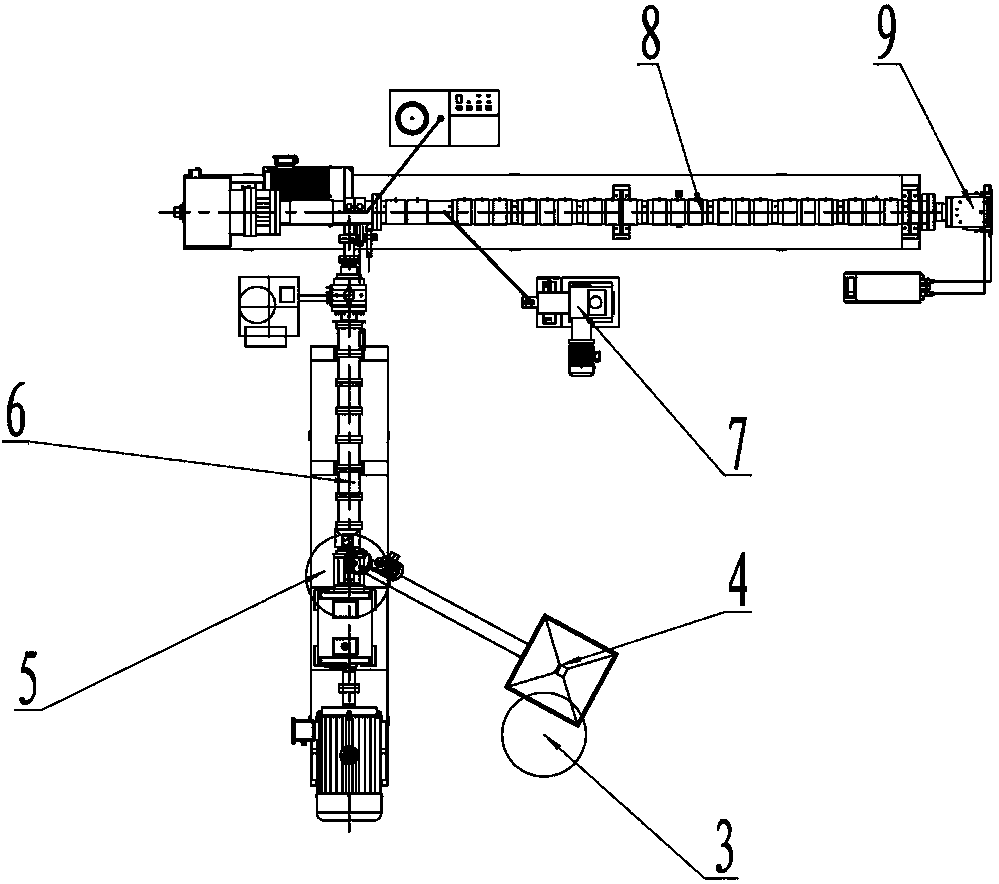

Forming method of polyvinyl chloride physical foam board

ActiveCN106363892BGuaranteed not to break downGuaranteed no pasteFlat articlesMasterbatchFoaming agent

The invention discloses a forming method for a polyvinyl chloride physical foam board. The forming method comprises the steps of granulation, first level extrusion, second level extrusion, pressure relief and foaming, cooling forming, first level traction, second level traction and cutting and is characterized in that a compatibilizer, a compound stabilizer, a nucleating agent, color masterbatch, a fire retardant and a foaming agent are added into polyvinyl chloride and polystyrene which serve as raw materials, and extrusion forming is achieved through a physical foaming method. The forming method has the beneficial effects that the physical foaming method is adopted for the polyvinyl chloride foam board, the production cycle is short, the production cost is low, and the product quality is stable; the compound stabilizer and the foaming agent are adopted, foam holes are fine, close and uniform, and the thermal insulation performance is excellent; the polystyrene is added into the polyvinyl chloride raw materials, so that the effect that decomposition and thickening do not occur to the raw materials during foaming is ensured; and the compatibilizer is adopted, so that the polar polyvinyl chloride and the nonpolar polystyrene are compatible very well, and the foaming ratio is easy to control.

Owner:SHANDONG TONGJIA MACHINERY

Method for preparing high-temperature-rusistance water-expansible rubber

InactiveCN1331936CSmall particle sizeSuitable for a wide temperature rangeOther chemical processesChemical synthesisCross-link

The invention relates to a method to manufacture functional rubber that could be expand when meet water between the temperature 25 degree centigrade and 150 degree centigrade. The process is: taking copolymerization by acrylic acid, sodium acrylate, acrylamide, heat endurable modification monomer and cross linking agent to gain heat endurable water absorbing resin powder, then, mixing and vulcanizing the mixture of the powder and rubber to gain high temperature endurable water expanding rubber. It has simple technology and low cost.

Owner:WUHAN CHEM COLLEGE

Foamable composite material composition, foamed composite material and preparation method and application thereof

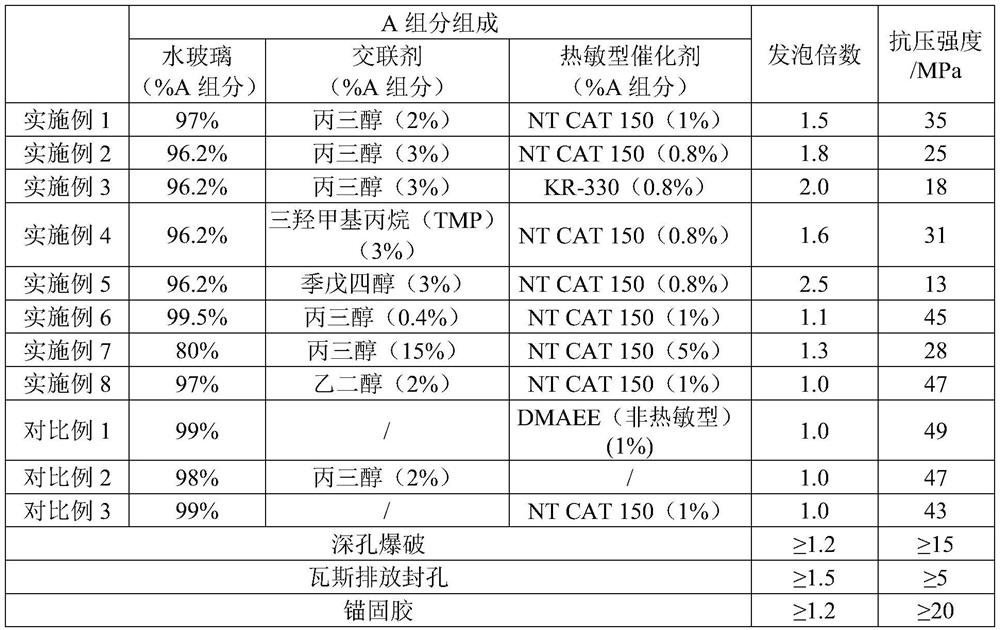

The invention relates to the field of composite materials, and discloses a foamable composite material composition, a foaming composite material and a preparation method and application thereof. The foaming composite material comprises a component A, a component B and a component C, the weight ratio of the component A to the component B to the component C is 1: (0.7-0.95): (0.01-0.4); the component A comprises the following components in percentage by weight: 80 to 99.5 percent of an alkaline solution, 0.3 to 10 percent of a cross-linking agent and 0.3 to 10 percent of a thermosensitive catalyst; the component B contains a polyisocyanate prepolymer and a solubilizer, the content of the polyisocyanate prepolymer is 80-99% by weight, and the content of the solubilizer is 1-20% by weight; and the component C contains a silicon-aluminum material. The foaming composite material has controllable foaming degree and excellent compressive strength, and can be applied to the fields of coal mine gas drainage hole sealing, deep hole blasting, anchoring glue and the like.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

A method for preparing graphene in batches and its production system

InactiveCN107500279BImprove stripping rateImprove stabilitySingle layer grapheneGraphiteMaterials science

The invention relates to the field of graphene materials, and discloses a batch preparation method of graphene and a production system therefor. In the invention, a conventional high temperature expansion method is combined with a graphite expansion furnace, and by means of optimum expansion temperature, stability of a product is effectively improved by means of control on raw materials and process parameters on the basis of the expansion temperature, thereby producing expanded graphite with controllable expansion times, namely, distribution ratio with expansion times being 200-300 is highest. With the expanded graphite as a raw material for producing graphene through a mechanical stripping method, stripping rate of graphene is greatly increased. On the basis of the conventional mechanical stripping method for preparing graphene, the graphene is produced in batches with the expandable graphite as raw material and graphene quantum dots as a stripping liquid, wherein a pre-stripping process is added on the basis of the prior art, and secondary ultrasonic treatment is employed with process parameters in the ultrasonic treatment being optimized.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com