Expandable silicone rubber sheet and preparation method thereof

A silicone rubber sheet, expandable technology, applied in the field of rubber, to achieve the effect of adjustable foaming ratio, simple foaming process, and improved mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

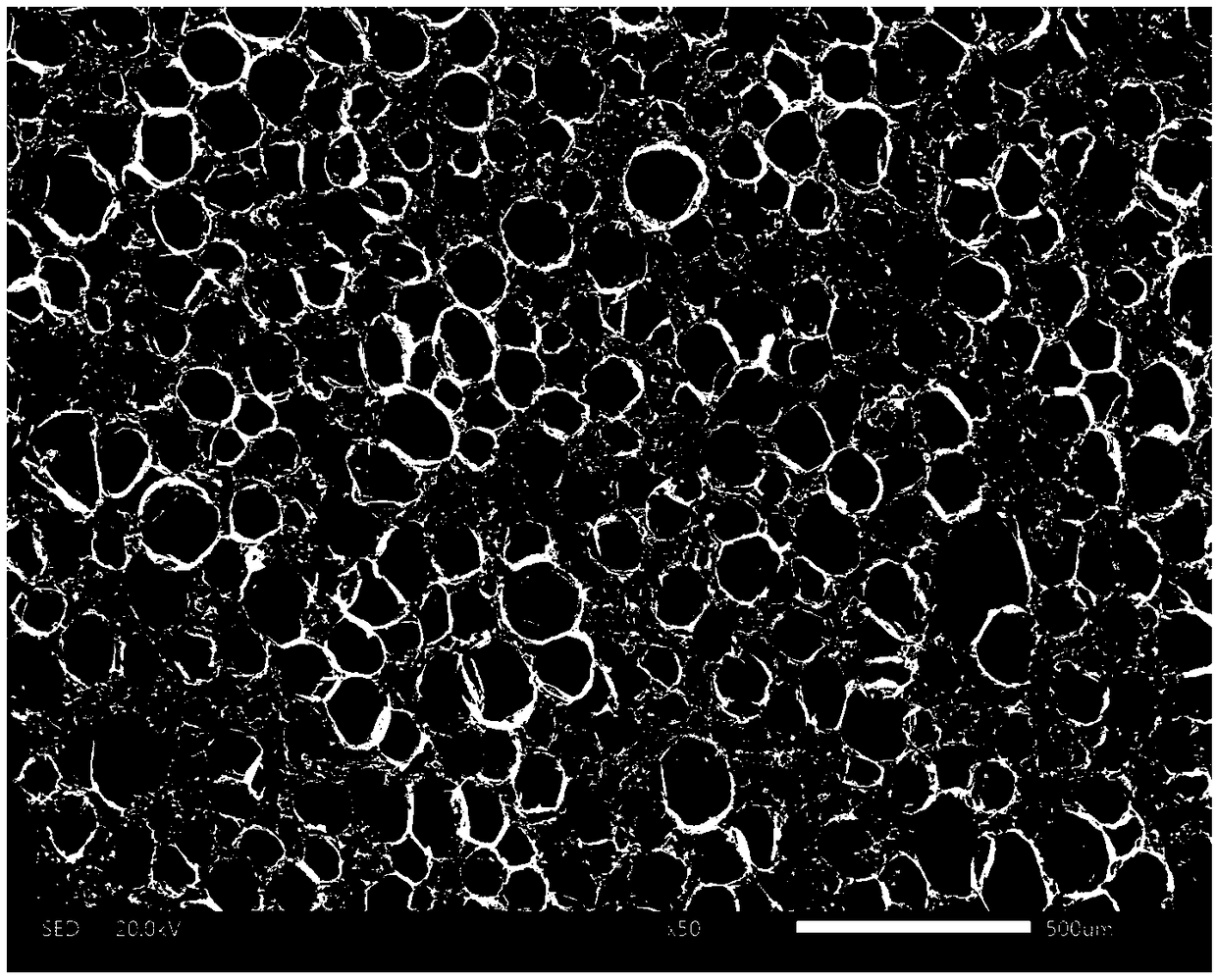

Image

Examples

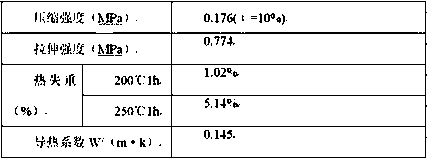

Embodiment 1

[0026] The expandable silicone rubber sheet disclosed in Example 1 comprises the following raw materials:

[0027] In parts by mass, 100 parts of silicone rubber, 15 parts of white carbon black, 40 parts of talcum powder, 100 parts of aluminum hydroxide, 3 parts of vulcanizing agent (DCP), 8 parts of foaming agent, and 4 parts of hydrogenated silicone oil.

[0028] Above-mentioned expandable silicone rubber sheet is made by following method steps:

[0029] Step 1, put the weighed silicone rubber and white carbon black into the open mixer for mastication, then add talcum powder, aluminum hydroxide, vulcanizing agent, and foaming agent in sequence, and finally add 4 parts of hydrogenated silicone oil to increase the hardness of the silicone rubber. Fluidity, the prepared rubber compound.

[0030] Step 2, put the compounded rubber obtained in step 1 into a calender to produce a sheet, adjust the roller distance according to the size of the mold cavity and the required foaming ra...

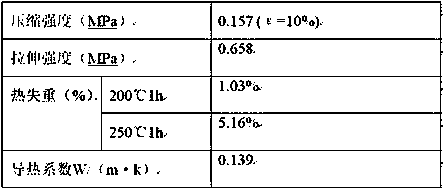

Embodiment 2

[0035] Compared with Example 1, the change of Example 2 lies in the change of the type of vulcanizing agent.

[0036] The expandable silicone rubber sheet disclosed in Example 2 includes the following raw materials measured in parts by mass:

[0037] In parts by mass, 100 parts of silicone rubber, 15 parts of white carbon black, 40 parts of talcum powder, 100 parts of aluminum hydroxide, 3 parts of vulcanizing agent (BPO), 8 parts of foaming agent, and 4 parts of hydrogenated silicone oil.

[0038] Above-mentioned expandable silicone rubber sheet is made by following method steps:

[0039] Step 1: Put the weighed silicone rubber and white carbon black into an open mill for mastication, then add aluminum hydroxide, vulcanizing agent, foaming agent in sequence, and finally add hydrogenated silicone oil to prepare a rubber compound.

[0040] Step 2, put the compounded rubber obtained in step 1 into a calender to produce a sheet, adjust the roller distance according to the size o...

Embodiment 3

[0045] Compared with Embodiment 1, Embodiment 3 is changed in that the type of vulcanizing agent is changed.

[0046]The expandable silicone rubber sheet disclosed in Example 3 includes the following raw materials measured in parts by mass:

[0047] In parts by mass, 100 parts of silicone rubber, 15 parts of white carbon black, 40 parts of talcum powder, 100 parts of aluminum hydroxide, 3 parts of vulcanizing agent (double two five), 8 parts of foaming agent, and 4 parts of hydrogenated silicone oil.

[0048] Above-mentioned expandable silicone rubber sheet is made by following method steps:

[0049] Step 1: Put the weighed silicone rubber and white carbon black into an open mill for mastication, then add aluminum hydroxide, vulcanizing agent, foaming agent in sequence, and finally add hydrogenated silicone oil to prepare a rubber compound.

[0050] Step 2, put the compounded rubber obtained in step 1 into a calender to produce a sheet, adjust the roller distance according to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com