Regenerated powder-based inorganic gelling material toughening and cracking foaming agent and its application

A technology of inorganic cementitious material and foaming agent, which is applied in the field of inorganic cementitious material toughening and crack reduction foaming agent, can solve the problems of high energy consumption of incineration method, gas environment pollution, etc., and achieves good foam stabilization effect and simple preparation. , easy-to-mix effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

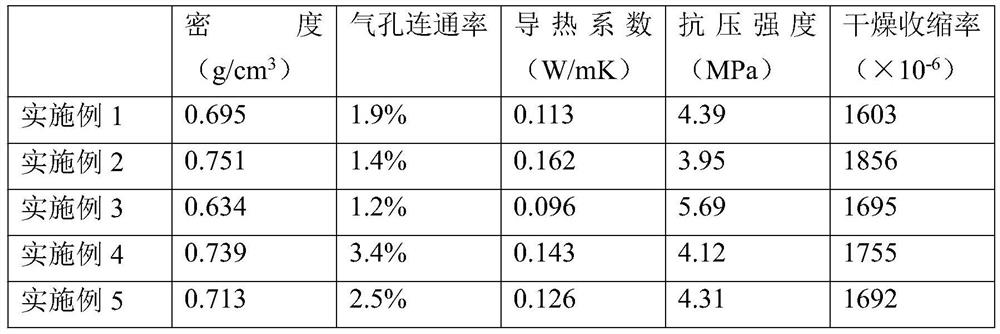

Examples

Embodiment 1

[0031] The present embodiment provides a novel blowing agent, the parts by weight of its components are as follows:

[0032] Component A: 90 parts of recycled FRP powder

[0033] B component: 10 parts of sodium hydroxide

[0034] Component C: 4 parts of sodium polyacrylate

[0035] Component D: 8 parts of sodium dodecylsulfonate

[0036] Component E: 3 parts of hydroxypropyl methylcellulose

[0037] The A component and the B component are foaming components;

[0038] The components C, D and E are foam stabilizing components.

[0039]During the preparation process of the regenerated FRP powder, the cutting size of the regenerated FRP cutting step is a cube with a side length of 80 mm. In the preparation process of recycled FRP powder, VI-9000 vertical shaft crusher is used in the raw FRP crushing process, and the crushing condition is 950-1050r / min. First crush for 3 minutes to complete the preliminary crushing. After the preliminary crushing is completed, the glass fibe...

Embodiment 2

[0046] The present embodiment provides a novel blowing agent, the parts by weight of its components are as follows:

[0047] Component A: 85 parts of recycled FRP powder

[0048] Component B: 8 parts of sodium hydroxide

[0049] C component: 3 parts of sodium polyacrylate

[0050] Component D: 9 parts of sodium dodecylsulfonate

[0051] E component: 4 parts of hydroxypropyl methylcellulose

[0052] The A component and the B component are foaming components;

[0053] The components C, D and E are foam stabilizing components.

[0054] Its component characteristics are identical with embodiment 1

Embodiment 3

[0056] The invention provides a novel blowing agent, the parts by weight of its components are as follows:

[0057] Component A: 94 parts of recycled FRP powder

[0058] B component: 13 parts of sodium hydroxide

[0059] C component: 4.5 parts of sodium polyacrylate

[0060] Component D: 8.5 parts of sodium dodecylsulfonate

[0061] Component E: 4.5 parts of hydroxypropyl methylcellulose

[0062] The A component and the B component are foaming components;

[0063] The components C, D and E are foam stabilizing components.

[0064] Its component characteristics are identical with embodiment 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com