Patents

Literature

175 results about "Silicone foam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

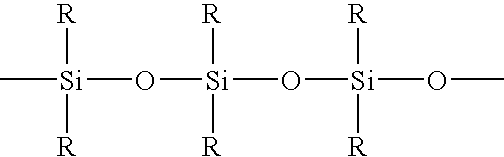

Silicone foam is a synthetic rubber product used in gasketing, sheets and firestops. It is available in solid, cured form as well as in individual liquid components for field installations.

High resilient silicone foam and process for preparing same

A method for producing a novel silicone foam by reaction of a polyisocyanate with a silicone oligomer having a plurality of functional end groups with active hydrogens, optionally in the presence of fire-retardants, under foam forming conditions which creates a new silicone foam for use in items such as residential upholstered furniture industry, seat cushions and bedding etc., and specifically for use in applications that require, high resilience and fire-retardant properties such as aircraft and surface transportation seat cushioning, military and shipboard mattresses etc.

Owner:CHESTNUT RIDGE FOAM

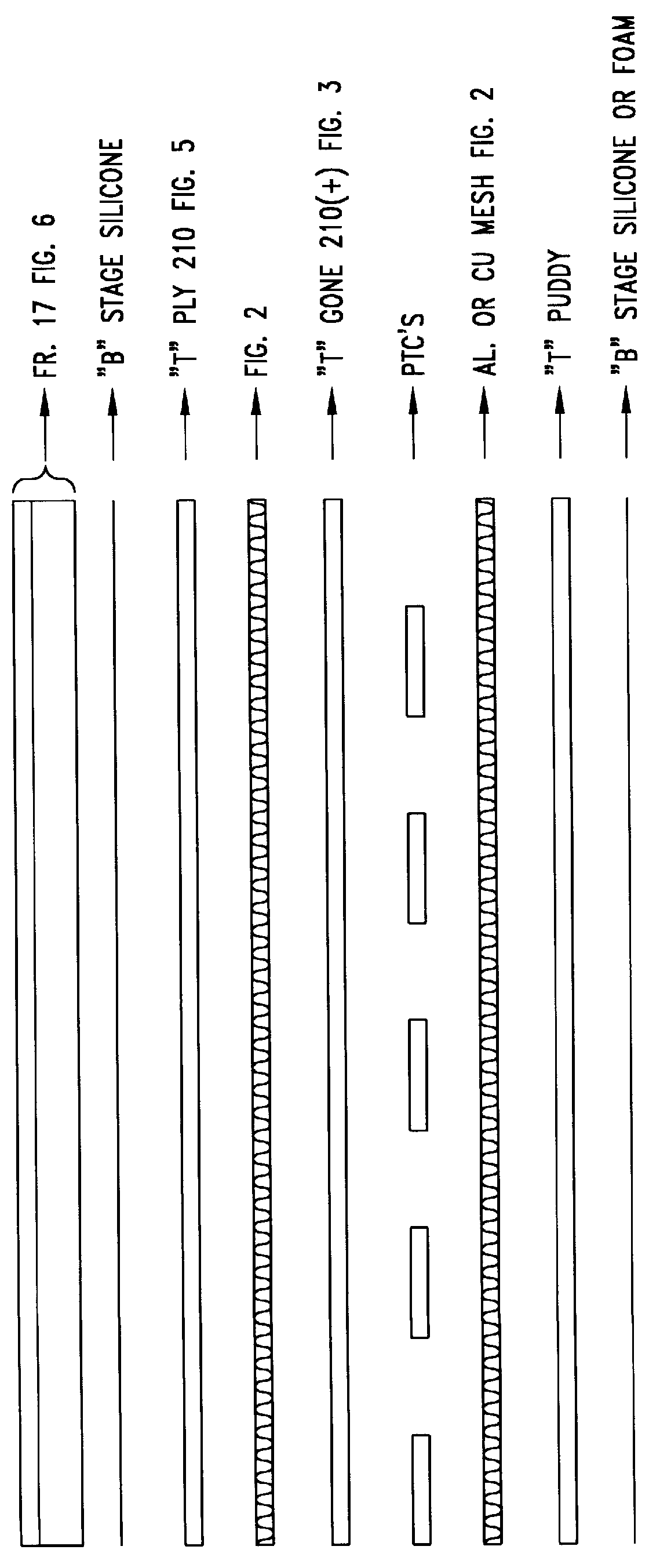

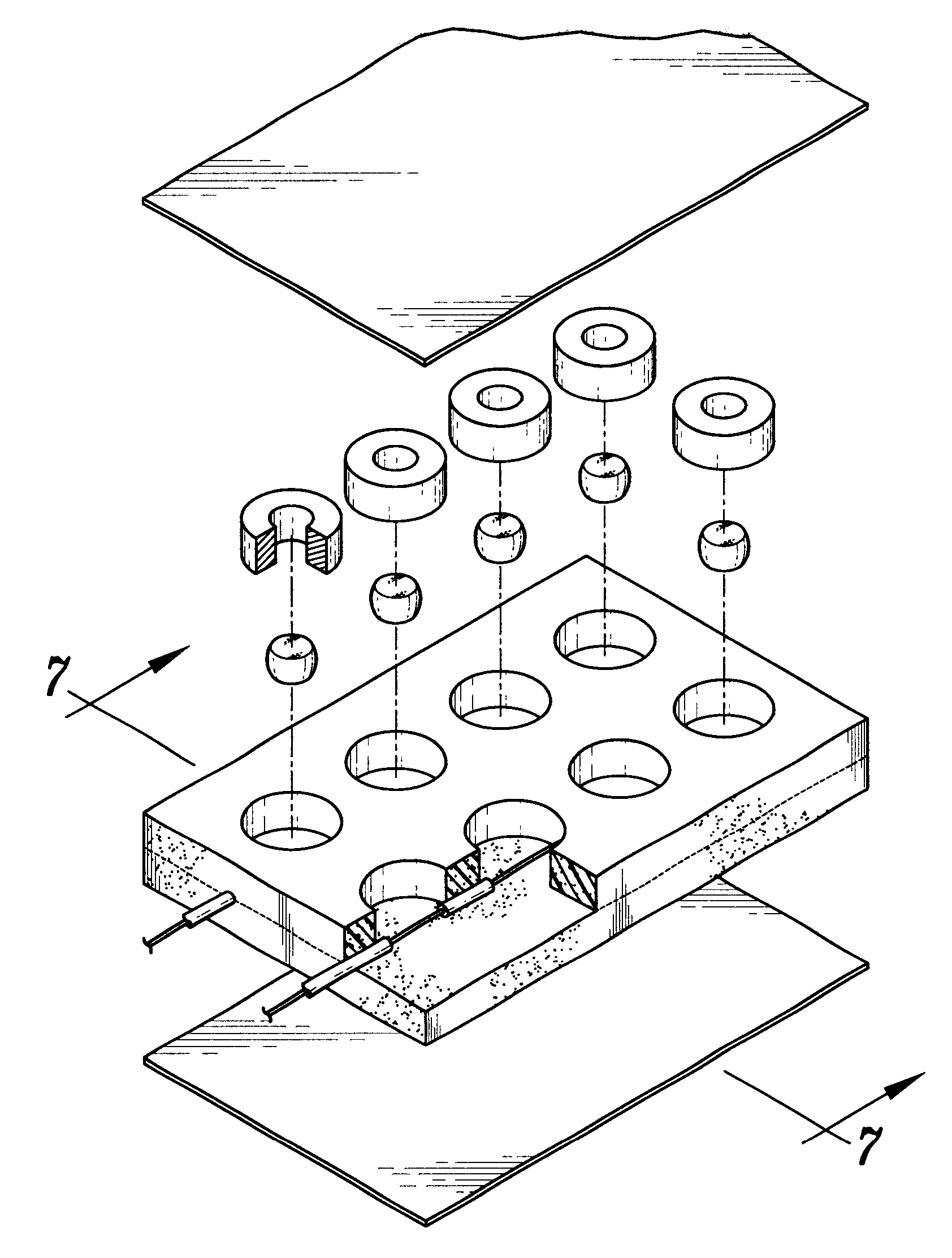

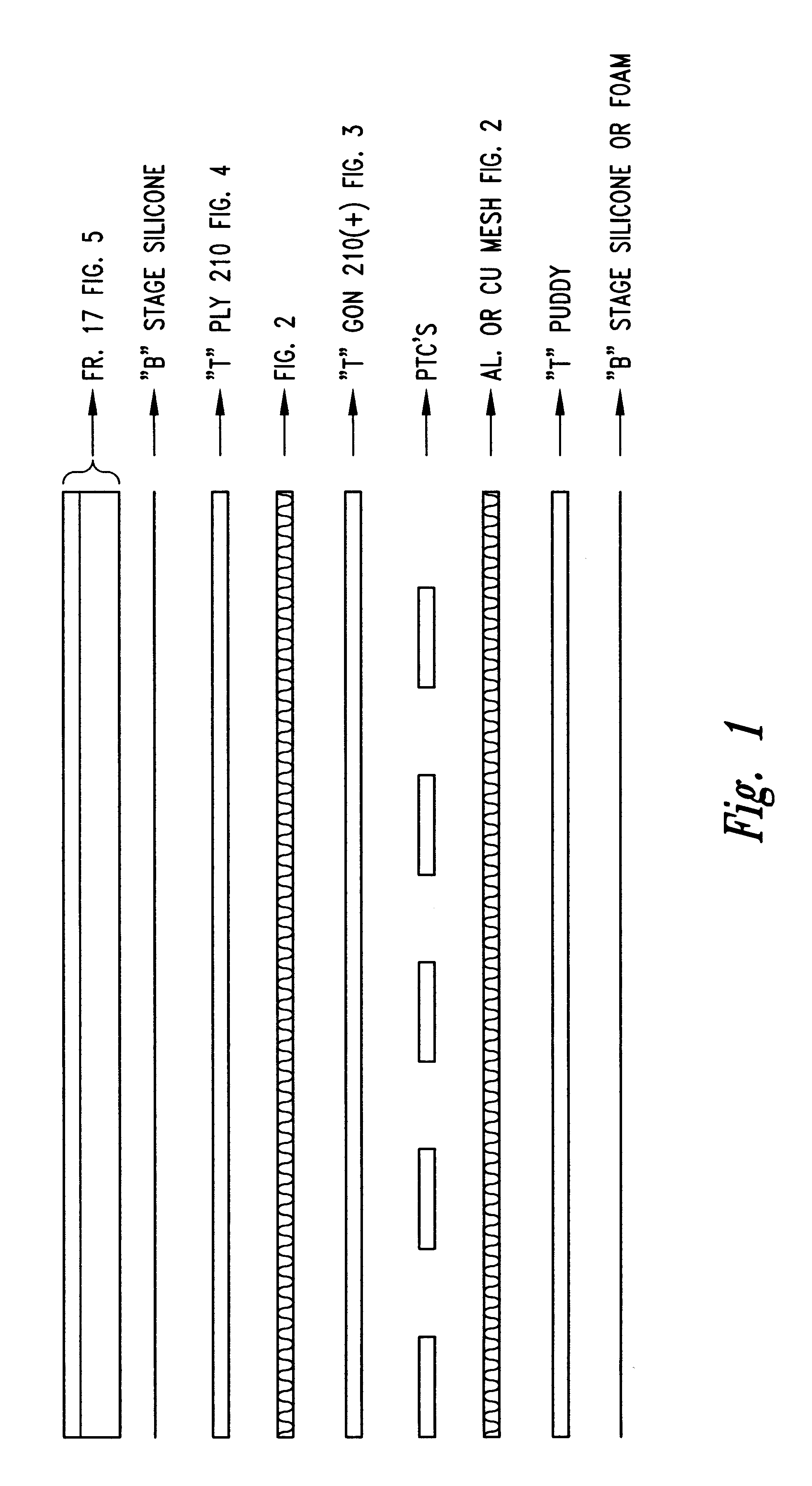

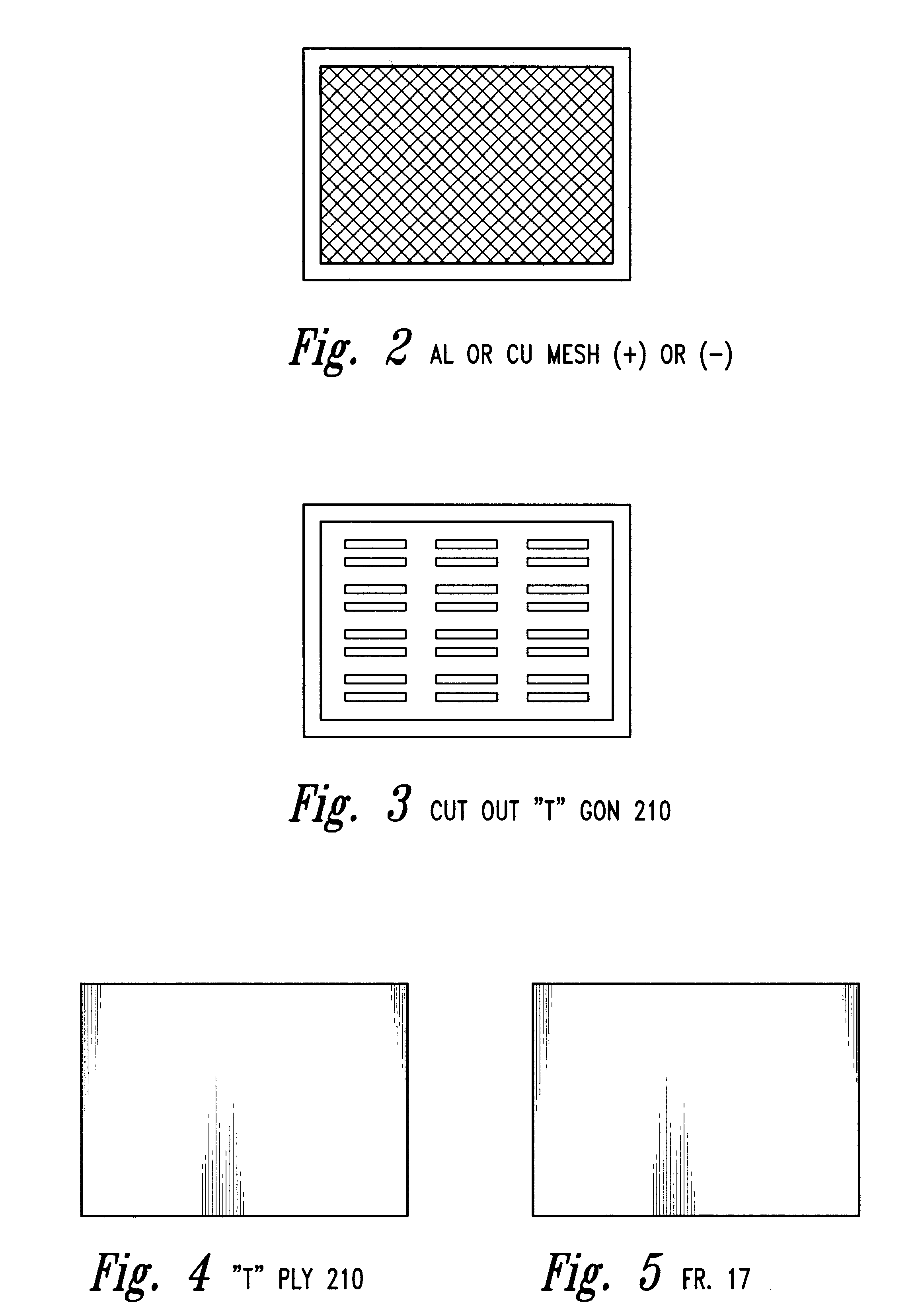

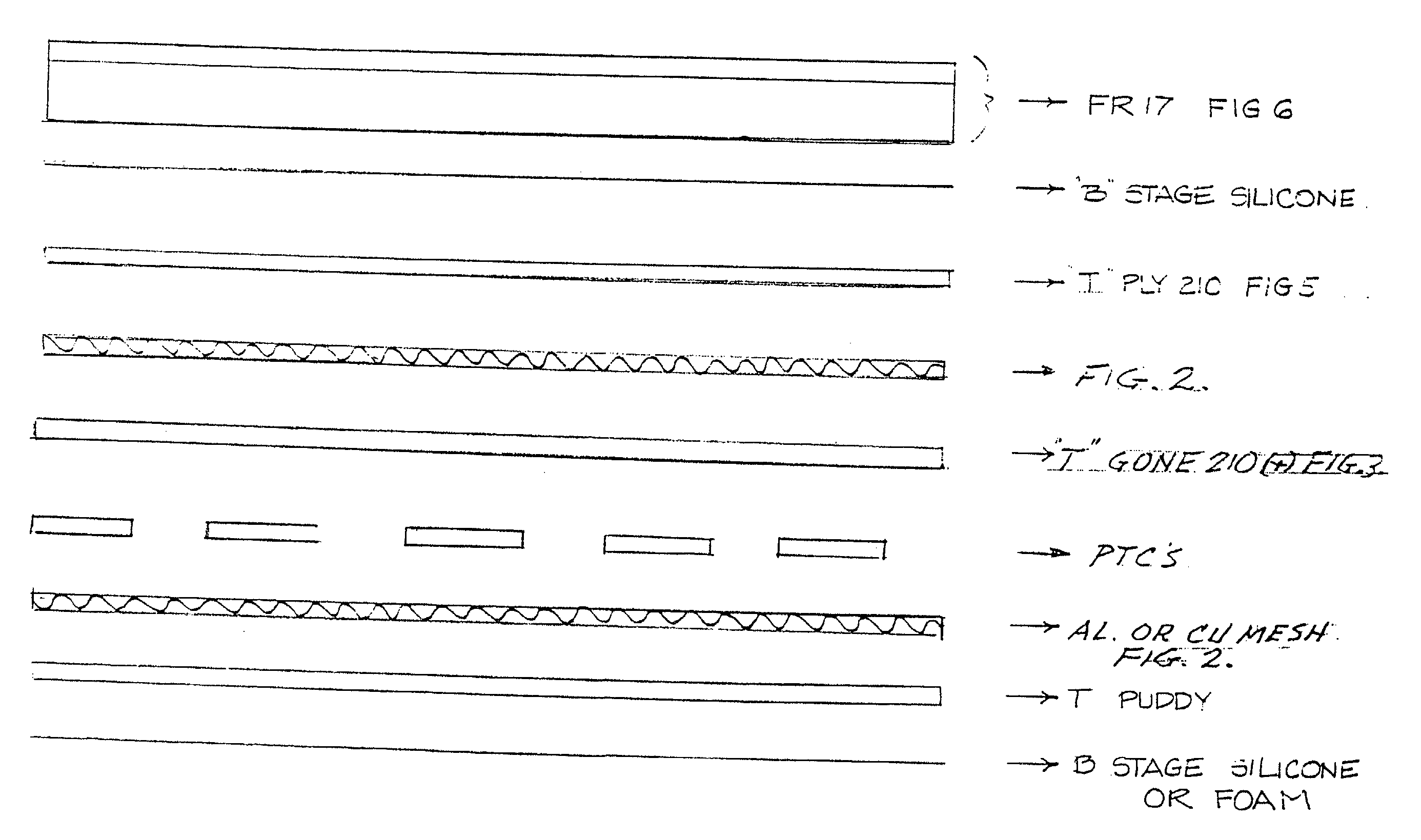

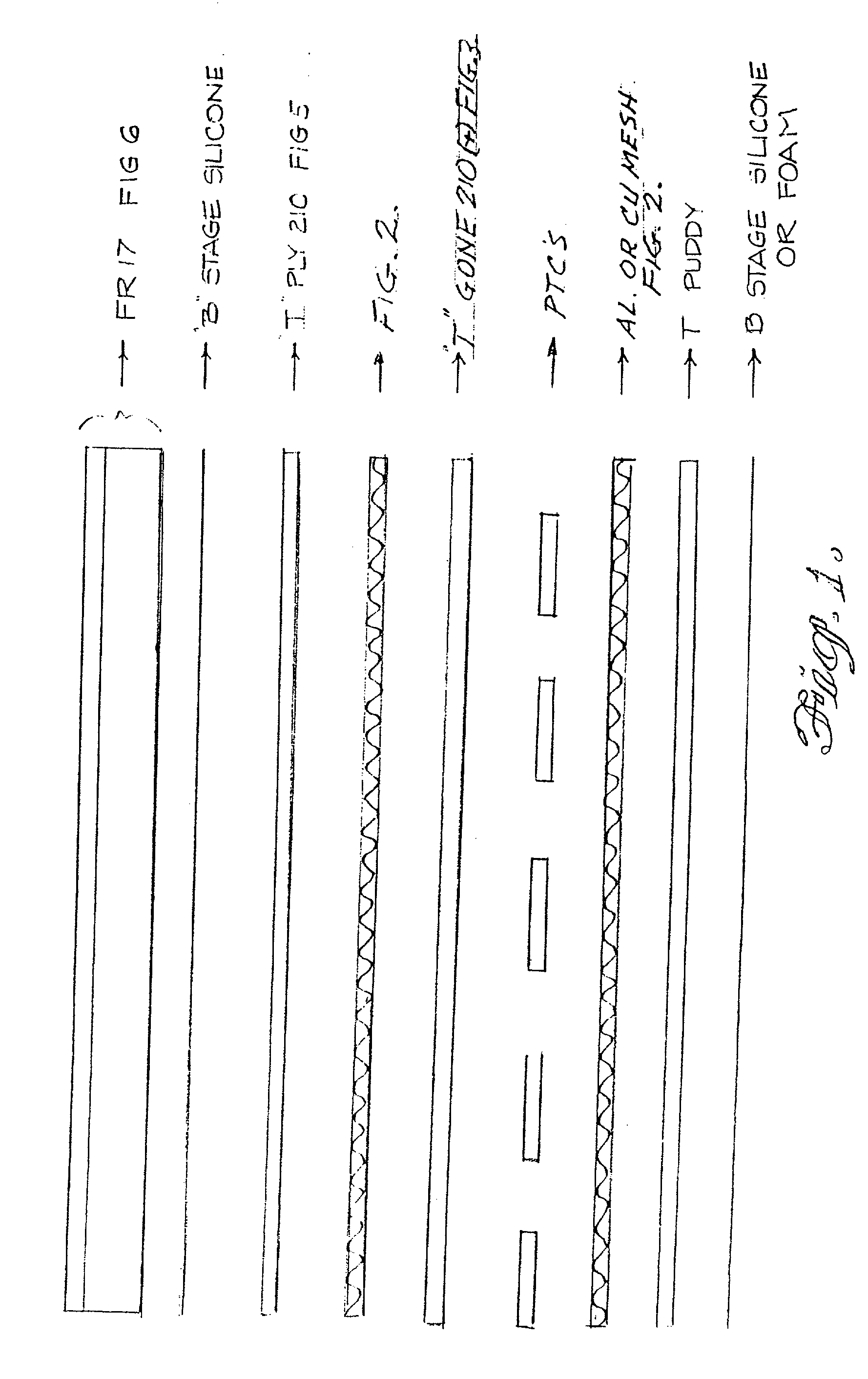

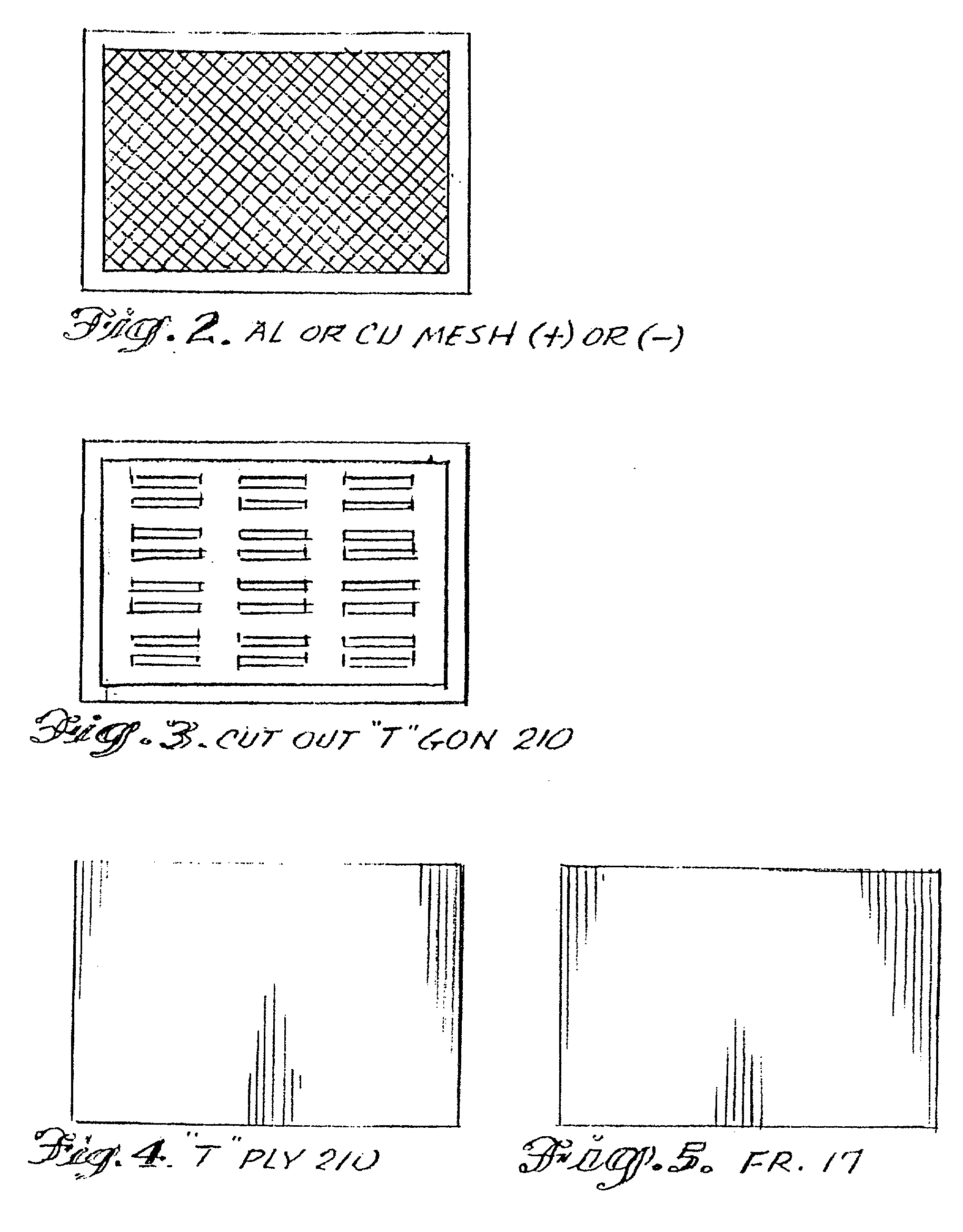

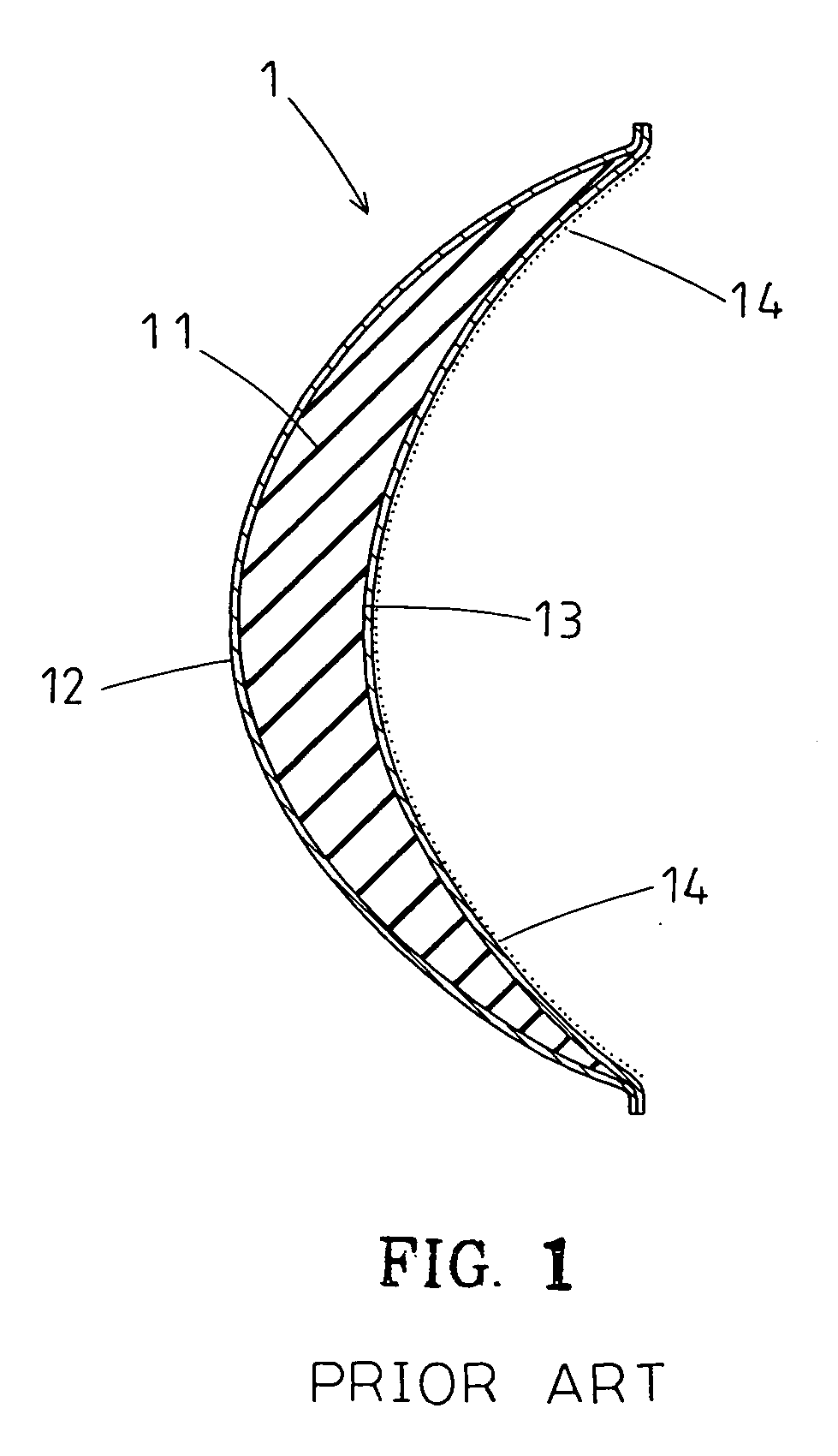

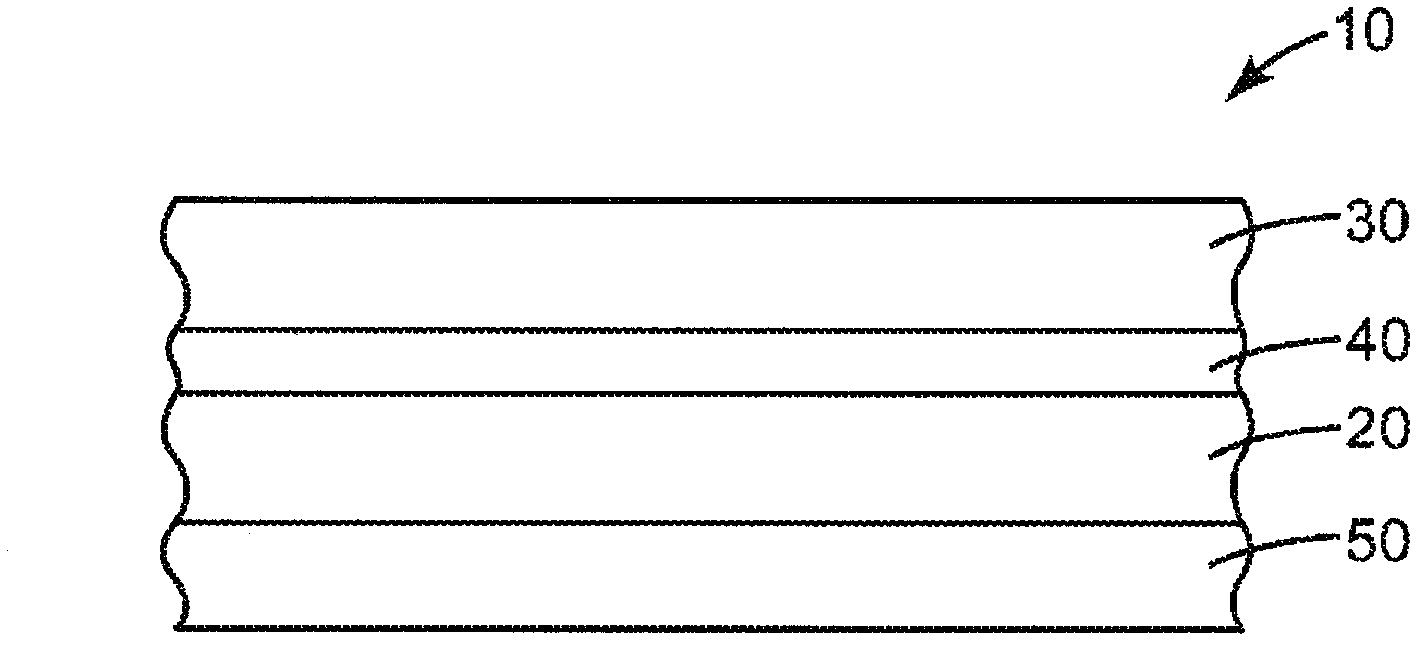

Internally temperature controlled heat blanket

An internally temperature controlled heat blanket. The heat blanket includes an outer layer of protecting foam fiberglass that affords operator safety, a layer of closed cell silicone foam which provides thermal and electrical insulation, a layer of thermally conductive mesh, another layer of thermally conductive silicone with holes cut into it, the holes containing positive temperature coefficient (PTC) heating elements, another layer of conductive mesh, a layer of thermally conductive silicone, and an inner layer of moderately conductive cured silicone or foam.

Owner:THE BOEING CO

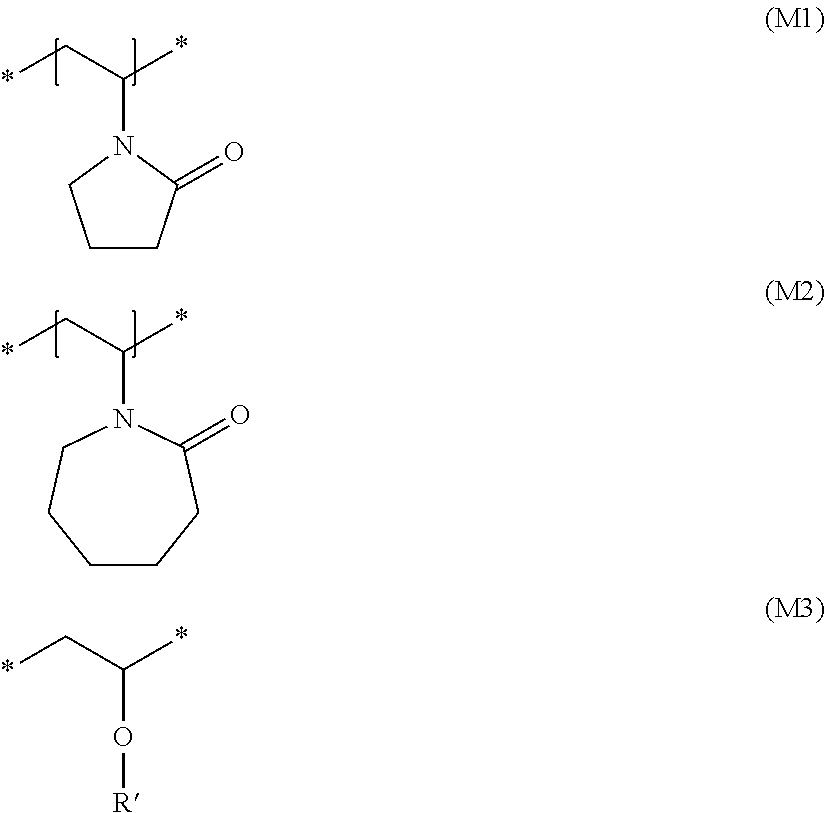

Hair care agents with selected non-ionic polymers and cationic silicones

Foaming hair treatment agents including selected non-ionic polymers and cationic silicones. In modern hair care agents the aim increasingly is to apply the product to the keratinic fibers in the form of a foam. The foam should be creamy and fine-pored, and at the same time should have a certain volume and be stable enough to remain stable while it is worked into the keratinic fibers.

Owner:HENKEL KGAA

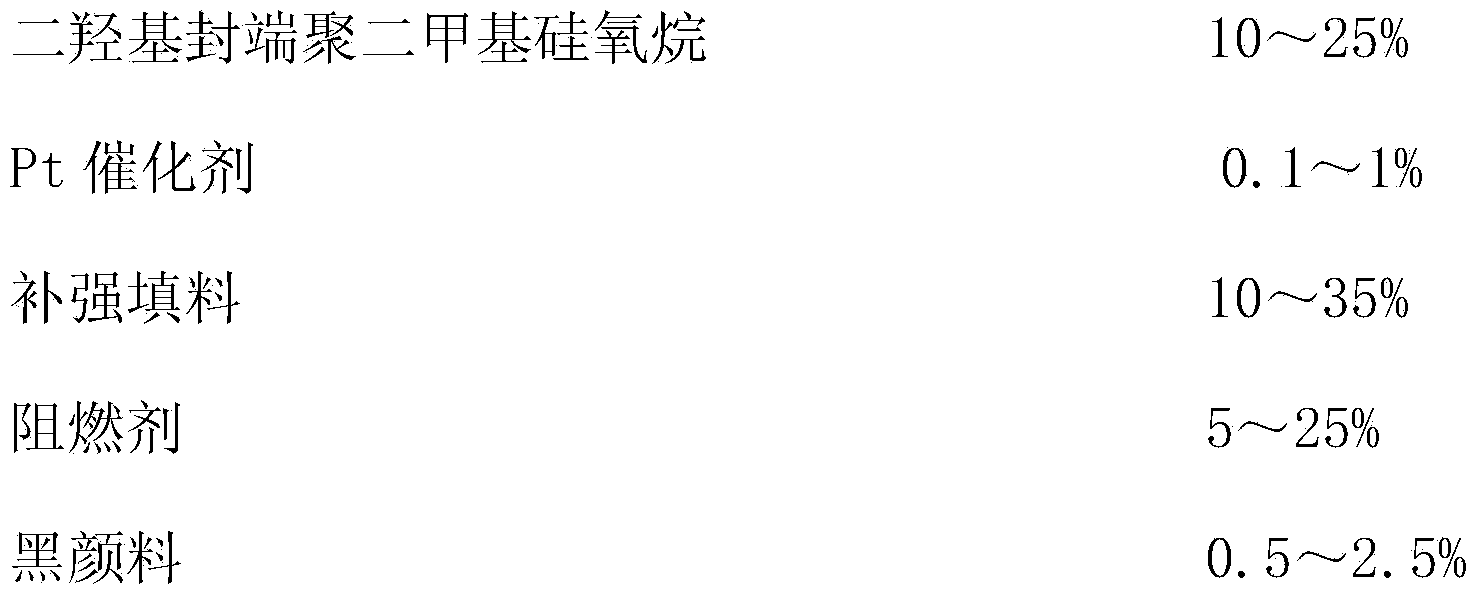

Double-component fireproof silicone foamed material with ultra-low density and preparation technology thereof

The invention discloses a double-component fireproof silicone foamed material with ultra-low density and a preparation method thereof. The double-component fireproof silicone foamed material with ultra-low density comprises a component A and a component B and is prepared by adopting the steps of mixing the component A and the component B according to a mass ratio being 1:1, and then curing the mixture at the temperature of 10-45 DEG C to generate a foaming body, wherein the component A is prepared from vinyl terminated polydimethylsiloxane, dyhydroxyl terminated polydimethylsiloxane, a Pt catalyst, black pigment, a reinforcing filler and a flame retardant, and the component B is prepared from vinyl terminated polydimethylsiloxane, an emulsifying agent, deionized water, hydrogen containing silicon oil, a reinforcing filler and an auxiliary foaming agent. The density of the prepared fireproof silicone foamed material with ultra-low density is 0.13-0.18g / cm<3>, thus materials can be saved, and the cost is reduced. The fireproof silicone foamed material with ultra-low density has the advantages of good flame retardance, simple preparation technology and the like, does not generate poisonous gases after catching fire, and can be widely applied to blocking structures with relatively high fireproof requirements, such as mechanical pipelines, cables and the like.

Owner:HAILONG EMERSON ZHENJIANG ENERGY TECH

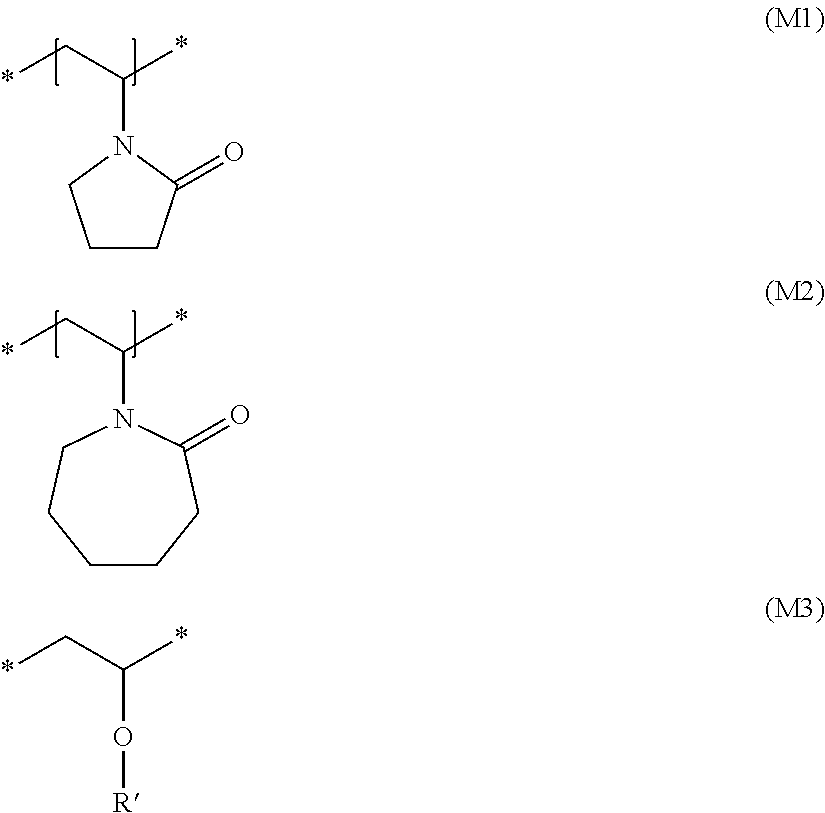

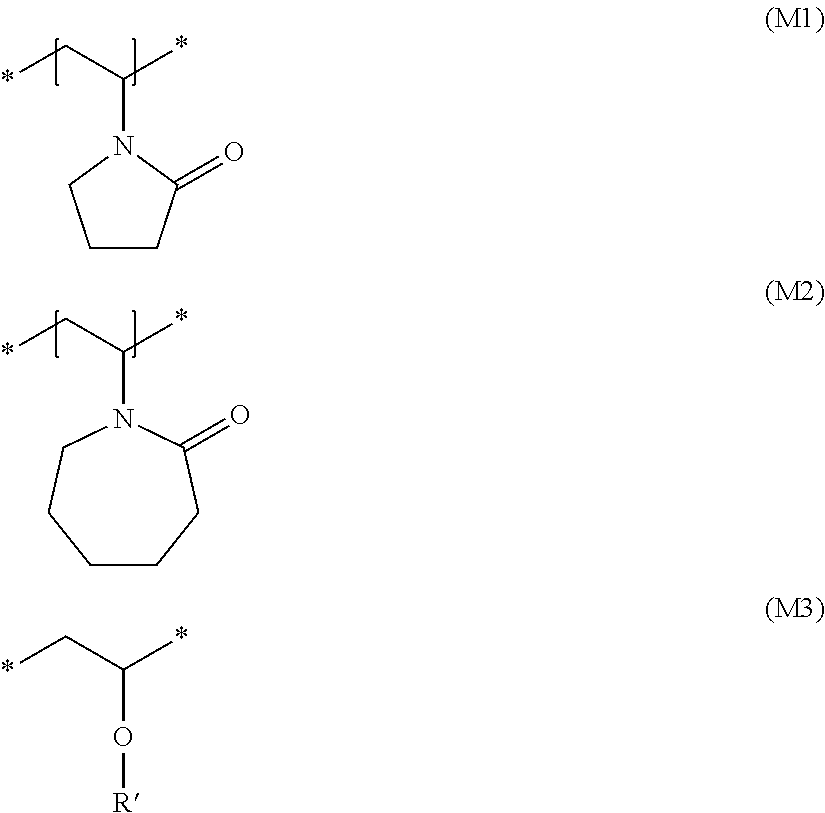

Low density polyurethane micropore elastomer added with thermal foamable microsphere and preparation thereof

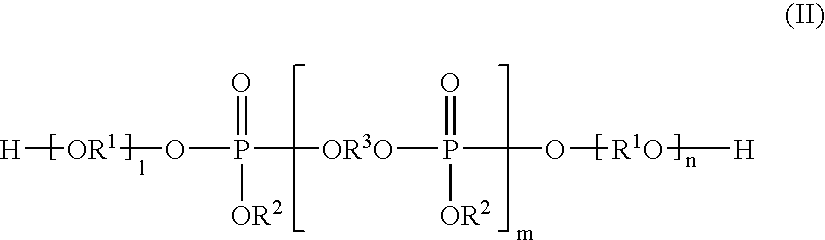

The invention discloses a low-density microporous polyurethane elastomer added with a thermal foaming microsphere and a preparation method thereof. In accordance with the preparation ratio of 1:1 for the molar number of the active hydrogen in A composition and the molar number of the -NCO in B composition, the A composition and the B composition are completely mixed and reacted for preparing the microporous polyurethane elastomer, wherein, the A composition is prepared by heating and mixing polyester polyol A1, polyester polyol A2, chain extender, cross-linking agent, tertiary amine or organic metal catalyst, organic silicone foam homogenizing agent, a thermal foaming microsphere, water and physical foaming agent in a reactor; and the B composition is a prepolymer which is prepared by mixing diisocyanate, polyester polyol B1, polyether polyol and a side effect inhibitor in the reactor, controlling the free-NCO content to be 18-22 weight%, and reacting. By adding the thermal foaming microsphere, the invention prepares a low-density (0.28-0.32g / cm) microporous polyurethane elastomer which is applied to the sole material; the obtained material has excellent additive mechanical property; the prepared sole is light and comfortable and has low cost, so the competitiveness of traditional sole materials such as microporous polyurethane elastomer and EVA, and the like is improved.

Owner:ZHEJIANG HUAFON NEW MATERIALS CO LTD

Process for producing flexible polyurethane foam

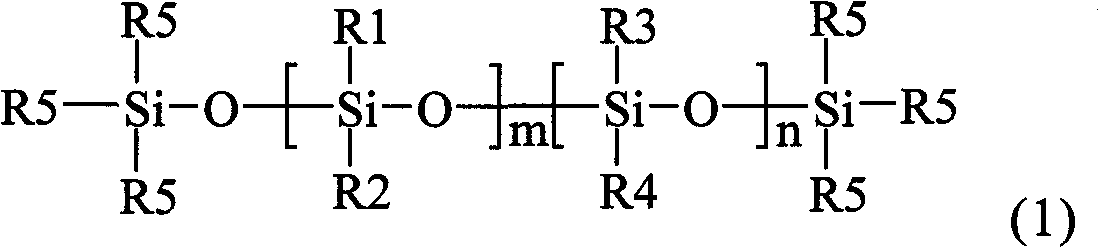

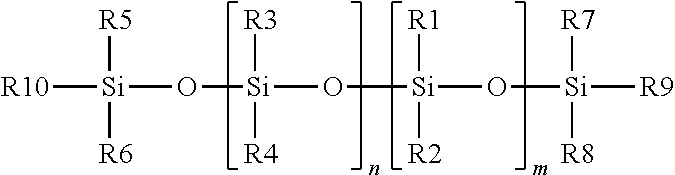

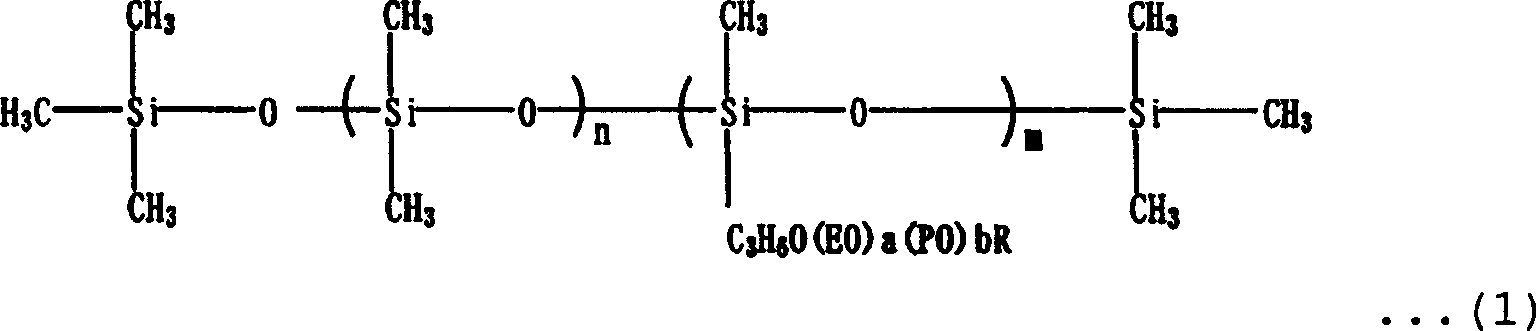

To produce a flexible polyurethane foam molded product having good air flow and cushioning characteristic and having cell roughening at the skin portion suppressed by using a raw material derived from a natural fat / oil.A release agent (X) containing a first polysiloxane compound (S1) having a number average molecular weight of at least 1,200 and at most 40,000, in which an organic group having an alkylene oxide chain is bonded to some of silicon atoms constituting the polysiloxane chain, is adhered to the inner surface of a mold, and in the mold, a reactive mixture (Y) containing a polyol (A) containing a polyol (A1) derived from a vegetable fat / oil, a polyisocyanate compound (B) and a silicone foam stabilizer (S) which is a second polysiloxane compound (S2) having a number average molecular weight of at least 150 and less than 1,200 is subjected to mold-foaming.

Owner:ASAHI GLASS CO LTD

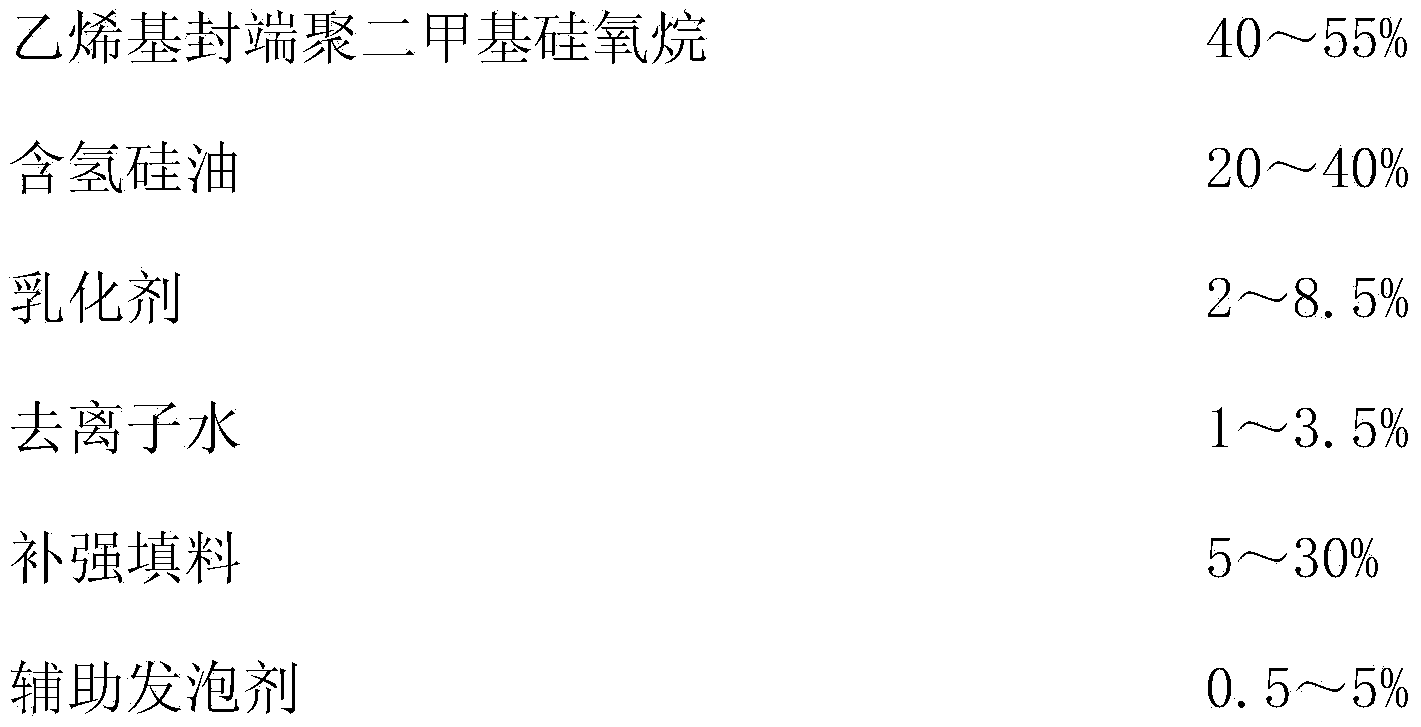

Fireproof and irradiation-resisting room temperature vulcanization two-component silicone foam sealant used in nuclear power station and preparation process thereof

ActiveCN103122146AImprove radiation resistanceEasy to makeOther chemical processesVulcanizationNuclear power

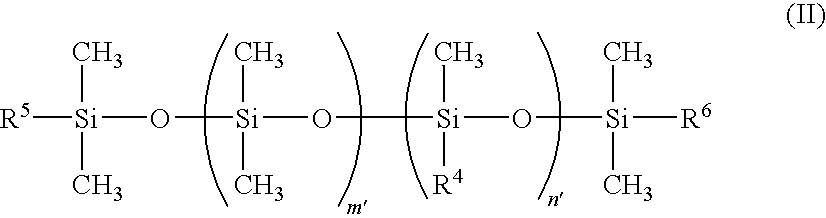

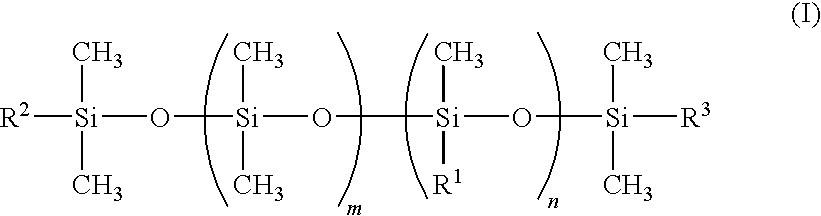

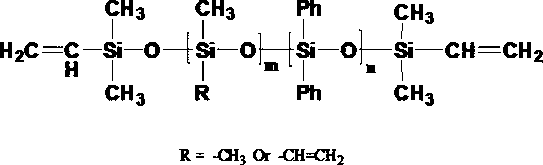

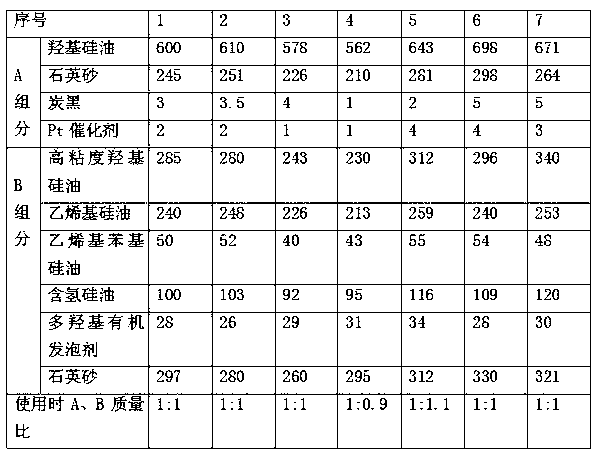

The invention discloses a fireproof and irradiation-resisting room temperature vulcanization two-component silicone foam sealant used in a nuclear power station and a preparation process thereof. The two-component silicone foam sealant comprises a component A and a component B, wherein the component A comprises 560 to 700 weight parts of hydroxyl silicone oil with the viscosity of 1,000 to 10,000mPa.s, 210 to 300 weight parts of 300 to 2,000-mesh quartz sand, 1 to 50 weight parts of carbon black and 1 to 4 weight parts of Pt catalyst; the component B comprises 230 to 340 weight parts of high-viscosity hydroxyl silicone oil with the viscosity of 5,000 to 15,000mPa.s, 210 to 260 weight parts of vinyl silicone oil with the viscosity of 1,000 to 10,000mPa.s, 40 to 55 weight parts of vinyl phenyl silicone oil with the viscosity of 200 to 2,000mPa.s, 90 to 120 weight parts of hydrogen-containing silicone oil containing 1.0 to 2.5 percent hydrogen, 0 to 34 weight parts of auxiliary foaming agent, 260 to 330 weight parts of 300 to 2,000-mesh quartz sand; and during use, the mass ratio of the component A to the component B is 1:0.9-1.1. The preparation process is relatively simple; and tests prove that various kinds of performance such as fireproof performance and irradiation-resisting performance of the two-component silicone foam sealant meets using standards of the nuclear power station.

Owner:HAILONG EMERSON ZHENJIANG ENERGY TECH

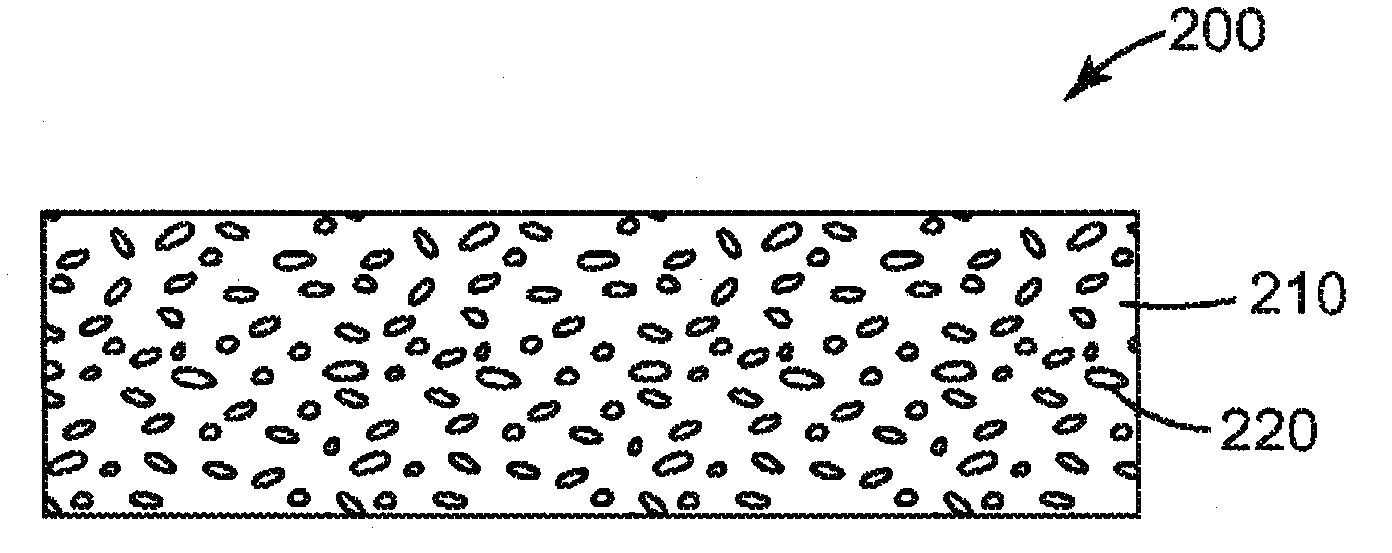

Silicone rubber foaming material and preparation method thereof

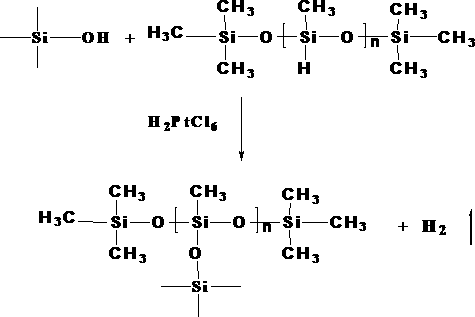

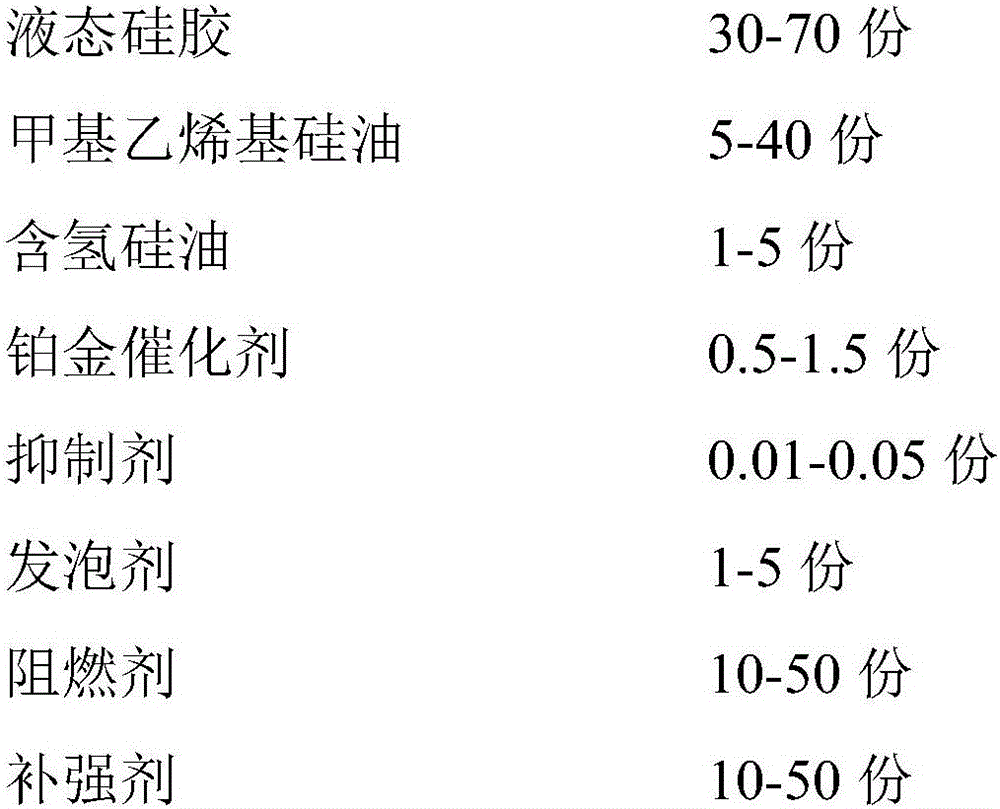

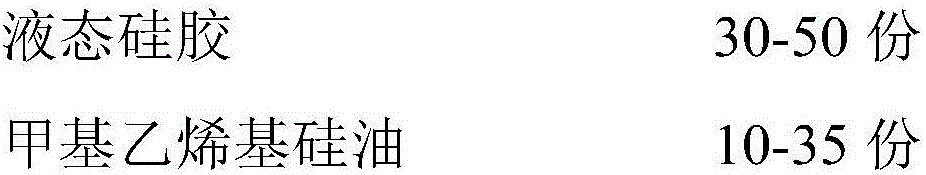

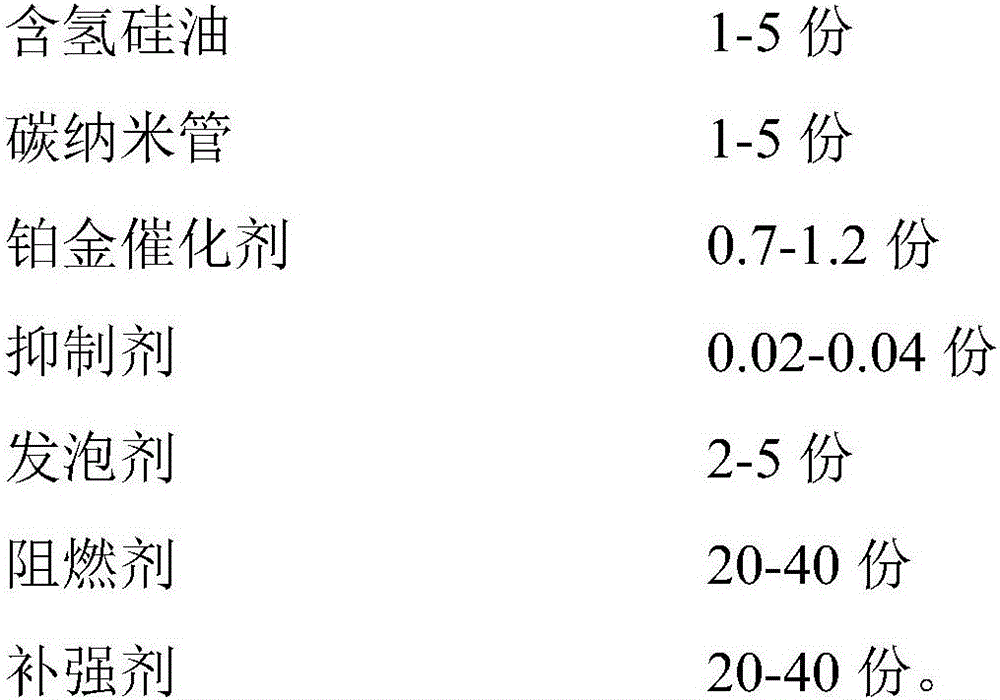

The invention relates to the technical field of silicone rubber, in particular to a silicone rubber foaming material and a preparation method thereof. The silicone rubber foaming material is prepared from the following components in parts by mass: 30 to 70 parts of liquid silicone rubber, 5 to 40 parts of methyl vinyl silicone oil, 1 to 5 parts of hydrogen-containing silicone oil, 0.5 to 1.5 parts of platinum catalyst, 0.01 to 0.05 part of inhibitor, 1 to 5 parts of foaming agent, 10 to 50 parts of flame retardant and 10 to 50 parts of reinforcing agent. The silicone rubber foaming material provided by the invention is characterized in that an Si-H bond of the hydrogen-containing silicone oil is activated by the platinum catalyst to generate a silicon hydrogenation addition reaction, so as to form an elastomer with a three-dimensional net structure, so that the silicone rubber foaming material provided by the invention has good flexibility; by adding the foaming agent, dense and uniform pores are formed inside the silicone rubber foaming material, the silicone rubber foaming material has better elasticity and smaller stress relaxation property, a sealing effect of communication equipment is guaranteed, and the maintenance cost is reduced.

Owner:昆山市硕鸿电子科技有限公司

Silicone foam and production method thereof

The invention relates to a silicone foam and a production method thereof, belonging to the field of fireproofing materials. The silicone foam comprises hydrogenpolysiloxane, monohydric polysiloxane, vinylpolysiloxane, alkylpolysiloxane and platinum group metal catalysts, and a reinforced filler, flame retardant components, a black paint and a yellow paint can be added to prepare a dual-component silicone foam glue material. When in use, the materials are mixed in a proportion of 1:1 on site, and foamed and vulcanized on site at a normal temperature to form a high-density elastic fireproof foam. The silicone foam does not contain toxic or harmful components, and has fireproof performance, ray penetration protection, tensibility and pressure elasticity. The silicone foam can compensate displacement caused by vibration of mechanical pipelines and subsidence of a building, and is favorable to fire proof blockage for pipeline maintenance or cable maintenance.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Preparation method of interface heat conduction material silicone rubber pad

The invention discloses a preparation method of an interface heat conduction material silicone rubber pad. The method comprises steps as follows: (1) adding 10-300 parts of inorganic heat conduction powder by weight, 1-10 parts of a catalyst by weight and 1-10 parts of a mixture of dimethicone and hydrogen-containing silicone oil by weight to 100 parts of silicone rubber by weight, and evenly kneading the mixture to obtain a rubber compound; (2) taking 10-90 parts of a carbon material adopting a 3D network structure by weight, and filling the carbon material with the rubber compound obtained in step (1) to obtain a composite material; (3) vulcanizing the composite material to obtain a finished product, namely, the silicone rubber pad. With the adoption of the method, the carbon material with the ultrahigh heat-conducting property can be arranged directionally in the silicone rubber to form the regular directional heat conduction network structure, so that the product with the ultrahigh heat conductivity is obtained.

Owner:DEYANG CARBONENE TECH

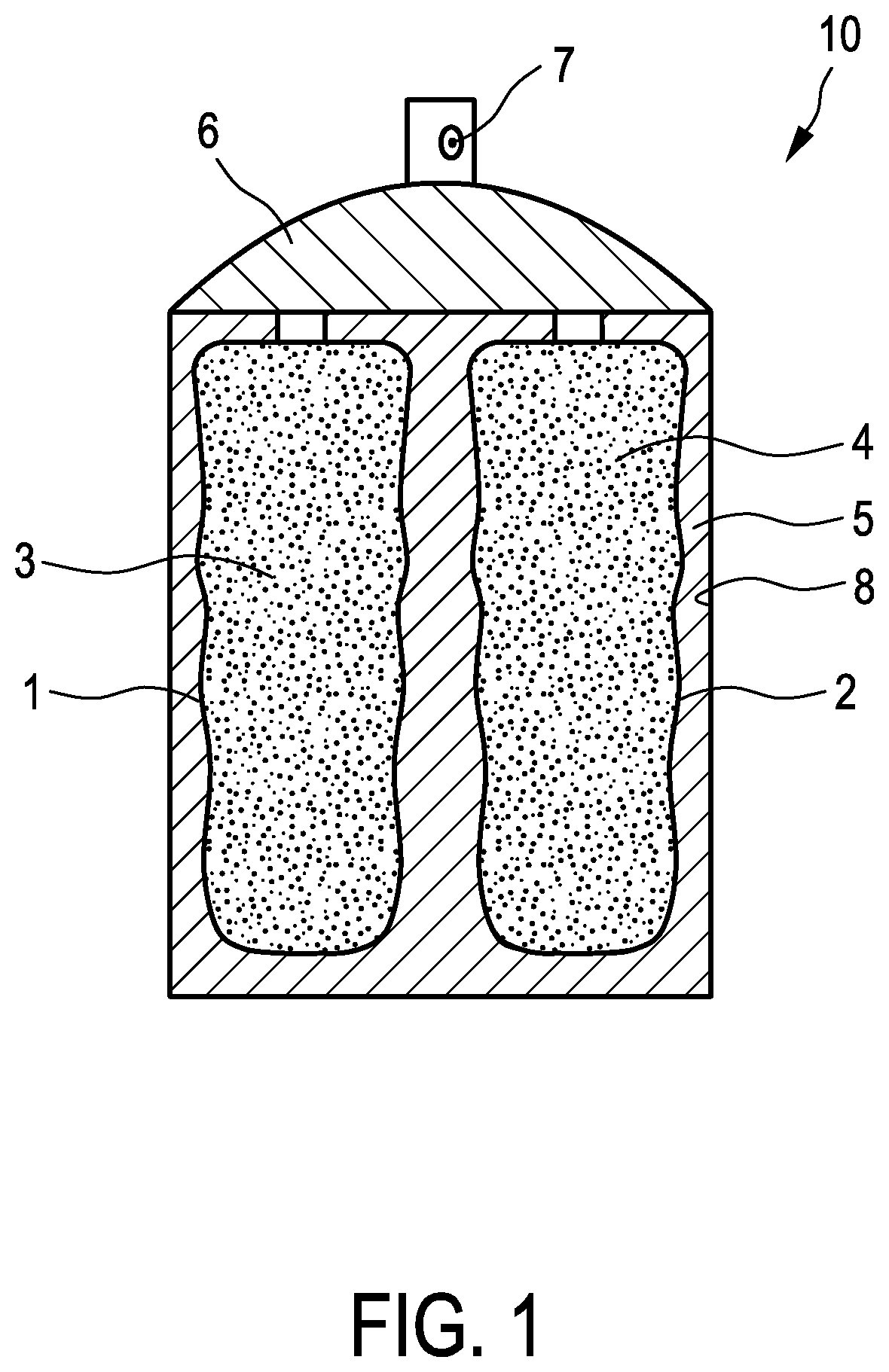

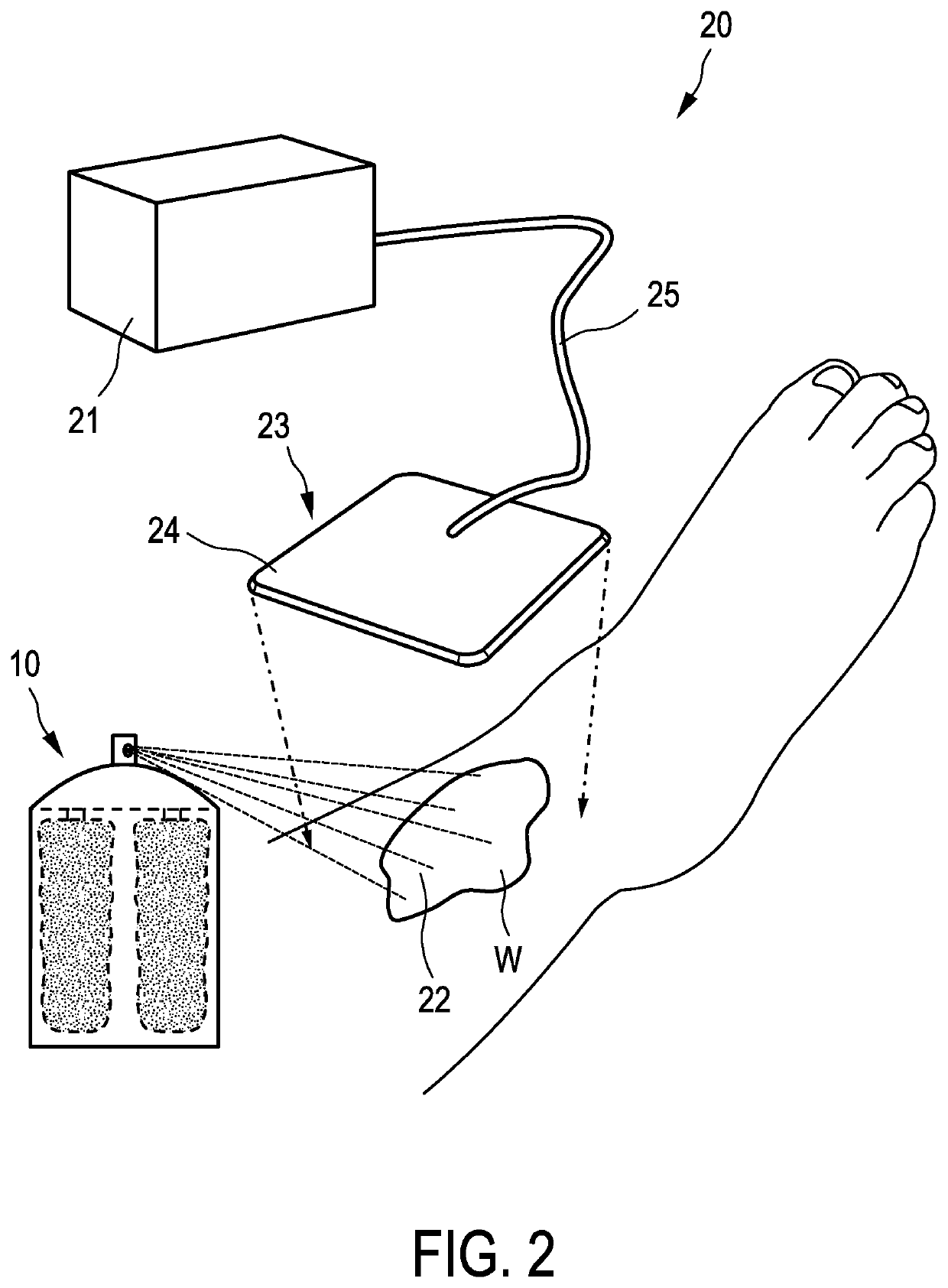

Foamed silicone in wound care

ActiveUS10744225B2Adapt quicklyEasy to controlNon-adhesive dressingsIntravenous devicesFoaming agentMedicine

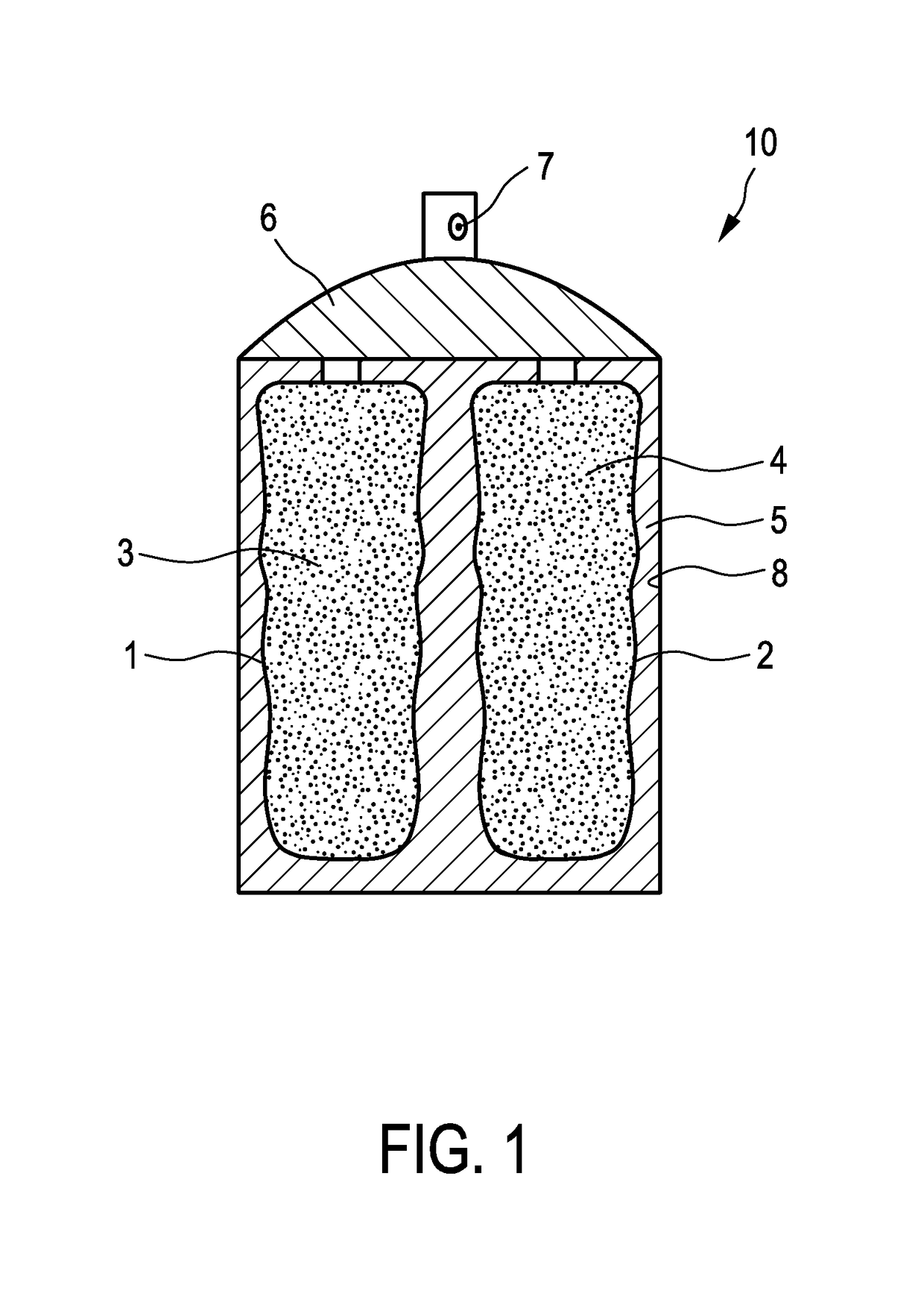

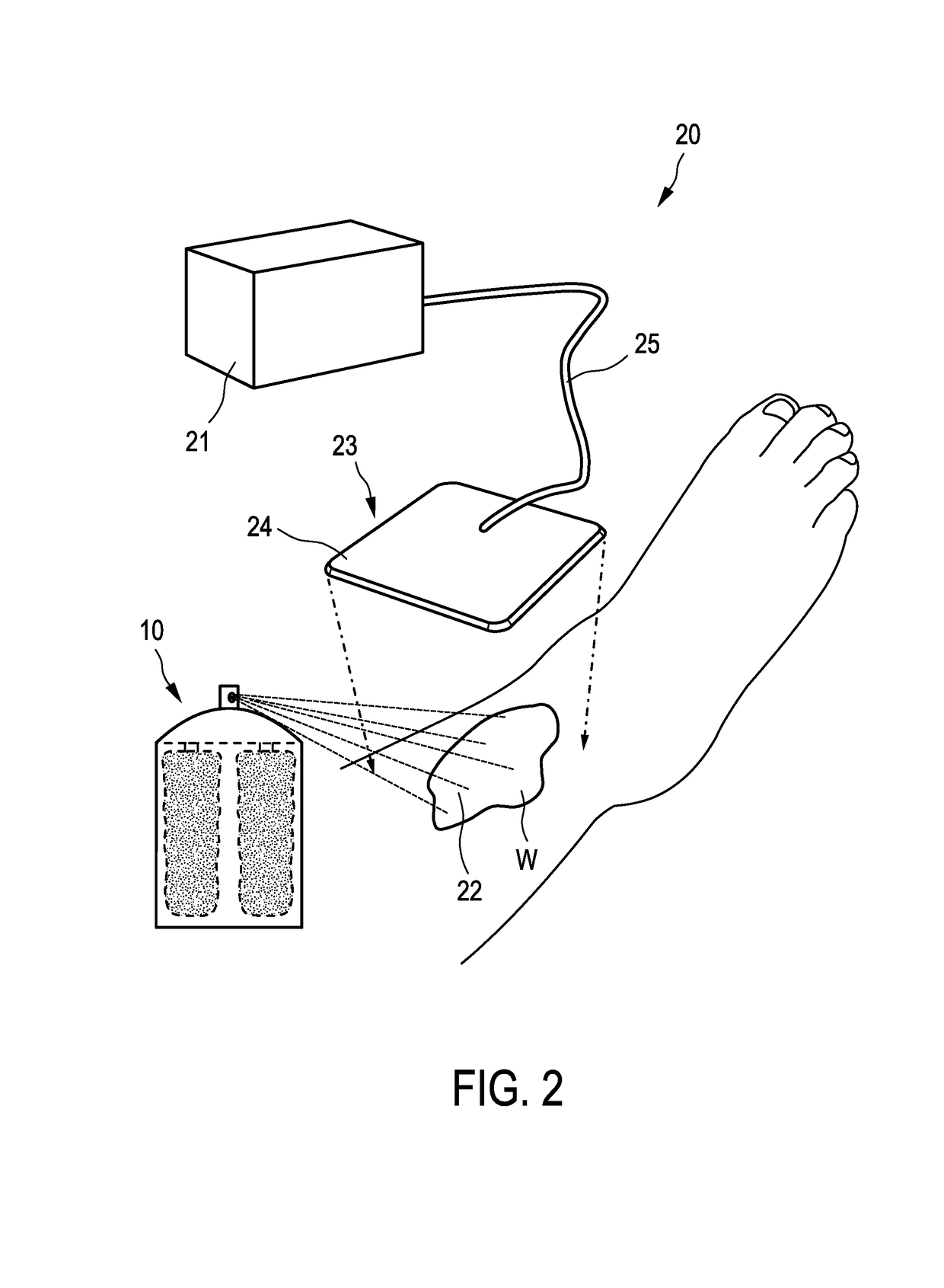

A silicone foam is described that is produced in-situ at a wound site, e.g. in a wound cavity, through a multi-component system, based on a physical foaming process, wherein the gas required to form the foam structure is provided through a blowing agent independently of the curing reaction of polyorganosiloxane components of the multi-component system. Therefore, the blowing agent is provided as a distinct entity of the multi-component system that is, in particular, not the result of any chemical reaction taking place in the multi-component system. A device for producing the foam and the corresponding negative pressure wound therapy kit are also described.

Owner:MOLNLYCKE HEALTH CARE AB

Silicone high-density elastomer and production method thereof

The invention relates to a silicone high-density elastomer and a production method thereof, which belongs to the field of fireproofing materials. The silicone high-density elastomer comprises hydrogenpolysiloxane, monohydric polysiloxane, vinylpolysiloxane, alkylpolysiloxane, metal powder and platinum group metal catalysts, and a reinforced filler, flame retardant components, a black paint and a yellow paint can be added to prepare a dual-component silicone foam glue material. When in use, the materials are mixed in a proportion of 1:1 on site, and foamed and vulcanized on site at a normal temperature to form a high-density elastic fireproof foam. The silicone high-density elastomer does not contain toxic or harmful components, and has fireproof performance, ray penetration protection, tensibility and pressure elasticity. The silicone high-density elastomer can compensate displacement caused by vibration of mechanical pipelines and subsidence of a building, and is favorable to fire proof blockage for pipeline maintenance or cable maintenance.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Internally temperature controlled heat blanket

An internally temperature controlled heat blanket. The heat blanket includes an outer layer of protecting foam fiberglass that affords operator safety, a layer of closed cell silicone foam which provides thermal and electrical insulation, a layer of thermally conductive mesh, another layer of thermally conductive silicone with holes cut into it, the holes containing positive temperature coefficient (PTC) heating elements, another layer of conductive mesh, a layer of thermally conductive silicone, and an inner layer of moderately conductive cured silicone or foam.

Owner:SAINT GOBAIN BAYFORM AMERICA

Process for producing flexible polyurethane foam

To provide a process for producing a flexible polyurethane foam, which comprises reacting a polyol compound and a polyisocyanate compound in an open system substantially without using a silicone foam stabilizer.A process for producing a flexible polyurethane foam, which comprises reacting a polyol composition (I) containing at least a polyol compound and containing at least one of a polyol compound (A) and a monool compound (X) obtained by ring-opening polymerization of an alkylene oxide with an initiator by using a double metal cyanide complex catalyst, and a polyisocyanate composition (II) in the presence of a urethane-forming catalyst made of a metal catalyst and an amine catalyst, and a blowing agent, in an open system substantially without using a silicone foam stabilizer.

Owner:ASAHI GLASS CO LTD

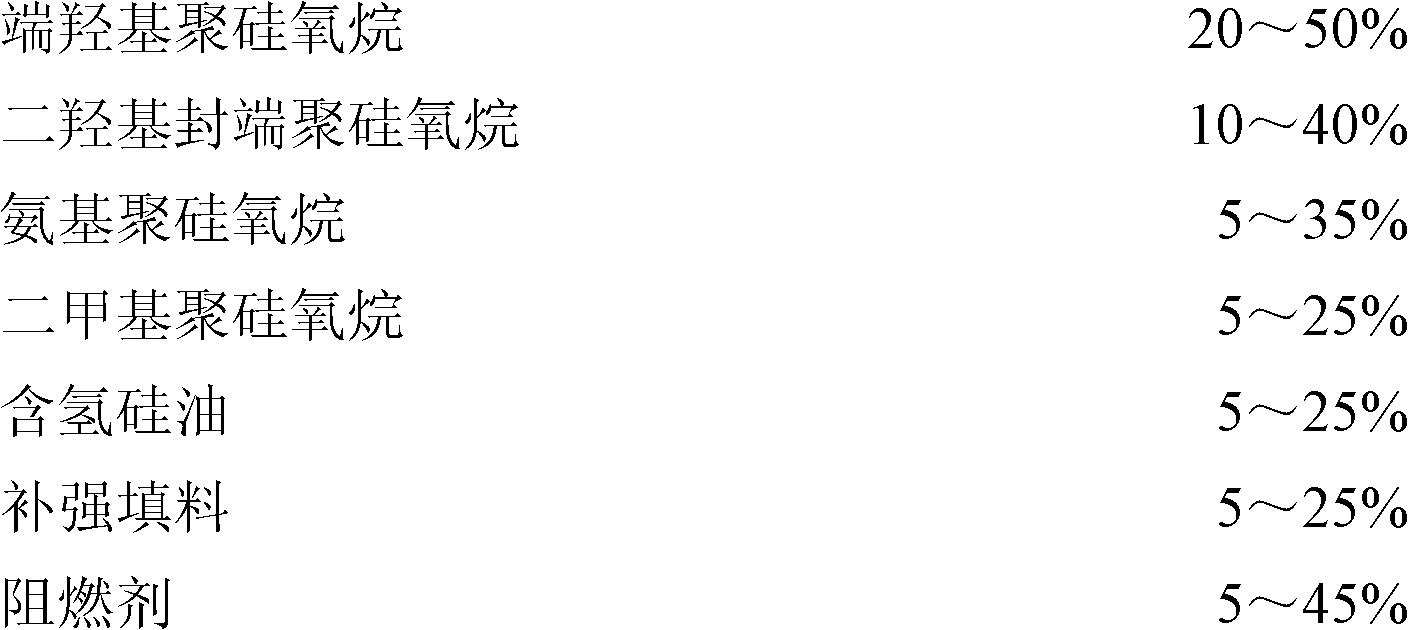

Fireproof silicone foam material and preparation method thereof

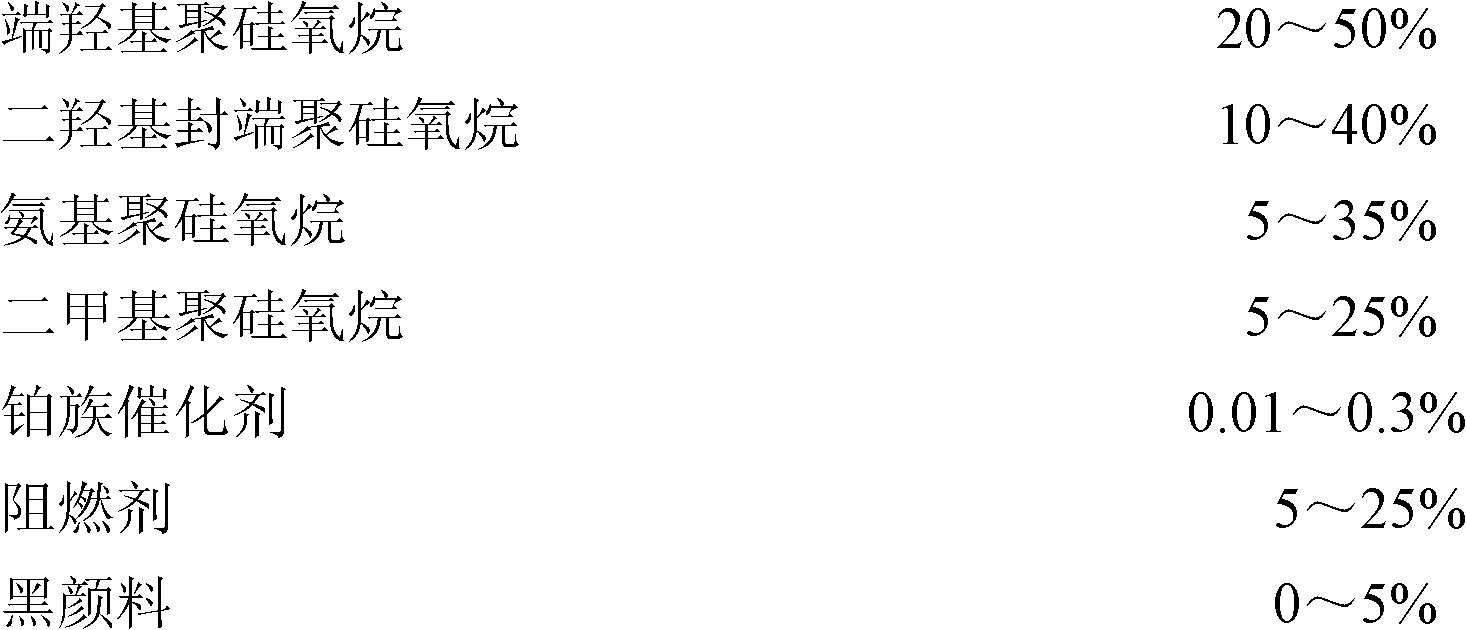

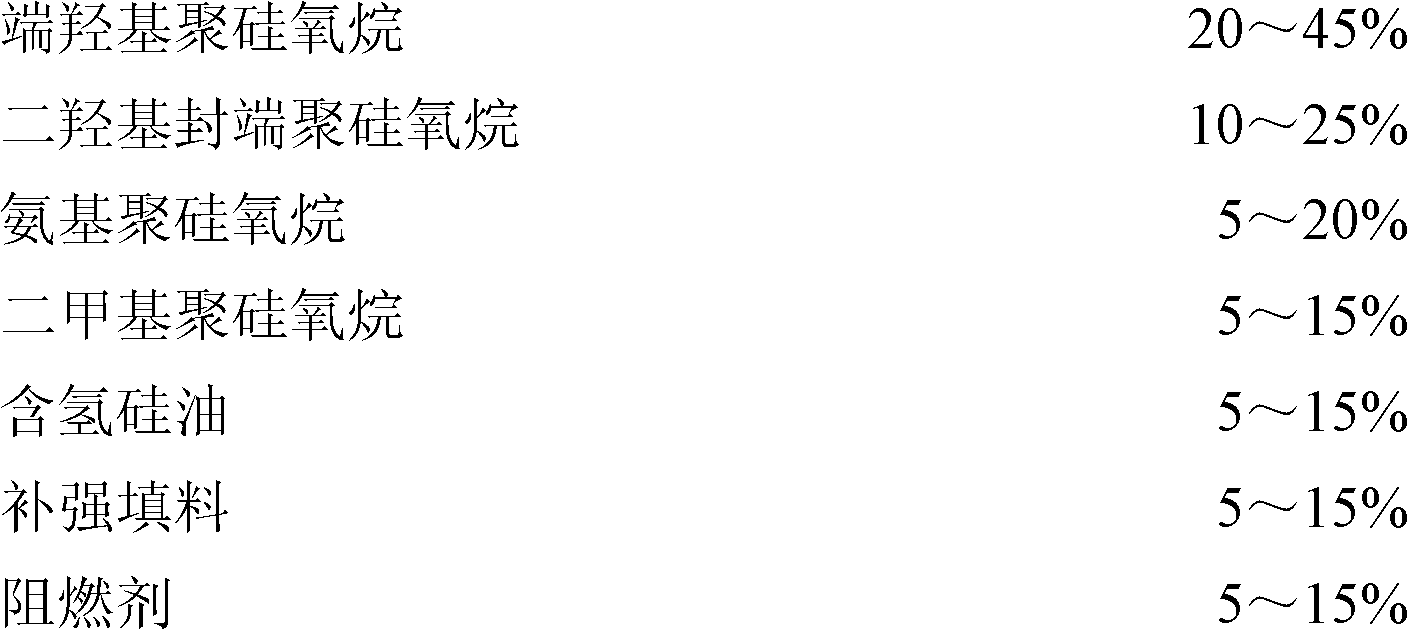

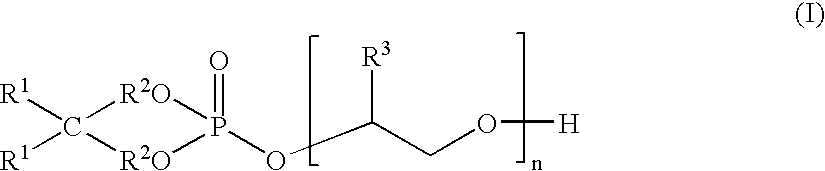

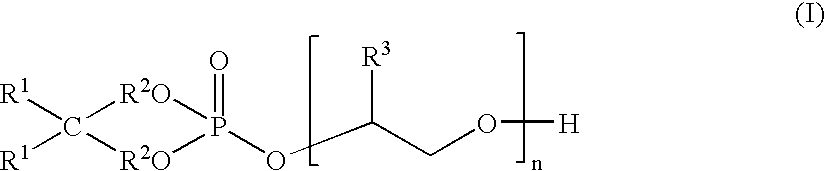

The invention discloses a fireproof silicone foam material and a preparation method of the fireproof silicone foam material. The fireproof silicone foam material is composed of a component A and a component B, wherein the component A and the component B are mixed according to volume ratio of 1: 1 to generate foams after being cured at 15-40 DEG C; the component A is composed of hydroxyl-terminated polysiloxane, dyhydroxyl-terminated polysiloxane, amino-polysiloxane, dimethyl polysiloxane, hydrosilicone oil, reinforcing filler and fire retardant according to a certain proportion; the component B is composed of hydroxyl-terminated polysiloxane, dyhydroxyl-terminated polysiloxane, amino-polysiloxane, dimethyl polysiloxane, platinum group catalyst, fire retardant and black pigment according to a certain proportion. The fireproof silicone foam material not only has good flame retardation, but also has good mechanical property such as tensibility and compression elasticity, does not produce toxic gas when meeting fire, can be widely applied to plugging structures with high fireproof requirements such as mechanical pipes, cables and the like.

Owner:HAILONG EMERSON ZHENJIANG ENERGY TECH

Composition for production of flame-retardant flexible polyurethane foams

Owner:DIAHACHI CHEMICAL INDUSTRY CO LTD

Preparation method for super macroporous polyurethane reticulated foam plastic

The present invention discloses a preparation method for a super macroporous polyurethane reticulated foam plastic. The method comprises the following steps: (1) preparing raw materials, wherein the raw materials comprise the following components: polyol, isocyanate, a silicone foam stabilizer, water, an auxiliary foaming agent, a cross-linking agent, a cell opening agent, a gel catalyst and a colorant; (2) storing the raw materials by a storage tank with a constant temperature freezing device; (3) concurrently adding the raw materials excluding the isocyanate to a mixing device, and uniformly stirring in 3 seconds to obtain a mixed material; (4) opening a isocyanate feeding valve, adding the isocyanate to the mixed material, carrying out high-speed stirring to obtain a mixture; (5) injecting the mixture into a foaming chamber to carry out foaming, closing the foaming chamber after 150-200 seconds, then opening a gas valve to carry out vacuum pumping; (6) removing the formed super macroporous polyurethane reticulated foam body with a reflection-like membrane from the foaming chamber, carrying out a reticulation treatment for the super macroporous polyurethane reticulated foam bodyto form the super macroporous polyurethane reticulated foam plastic. With the present invention, the super macroporous polyurethane reticulated foam plastic can be prepared.

Owner:深圳市国志汇富高分子材料股份有限公司

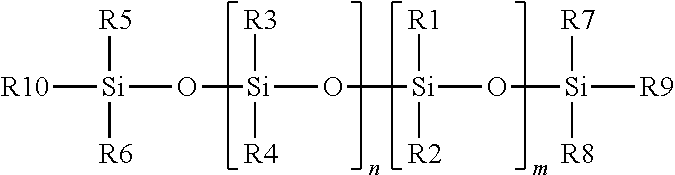

Thermoplastic polyurethane composite material composition, thermoplastic polyurethane composite material and manufacturing method thereof, shoe material and wearable apparatus

A thermoplastic polyurethane composite material composition includes a plastic base material and a curing agent, the plastic base material includes a thermoplastic polyurethane and a silicone gum including at least two alkenyl groups in each of molecules thereof, wherein the thermoplastic polyurethane and the silicone gum are uniformly mixed, and a weight ratio of the thermoplastic polyurethane and the silicone gum is ranging from 95.01:4.99 to 99.5:0.5. The curing agent is uniformly mixed with the plastic base material, wherein the curing agent has an adding amount enabling the silicone gum to crosslink to form a silicone rubber.

Owner:EVERMORE CHEM IND

Internally temperature controlled heat blanket

An internally temperature controlled heat blanket. The heat blanket includes an outer layer of protecting foam fiberglass that affords operator safety, a layer of closed cell silicone foam which provides thermal and electrical insulation, a layer of thermally conductive mesh, another layer of thermally conductive silicone with holes cut into it, the holes containing positive temperature coefficient (PTC) heating elements, another layer of conductive mesh, a layer of thermally conductive silicone, and an inner layer of moderately conductive cured silicone or foam.

Owner:SAINT GOBAIN BAYFORM AMERICA

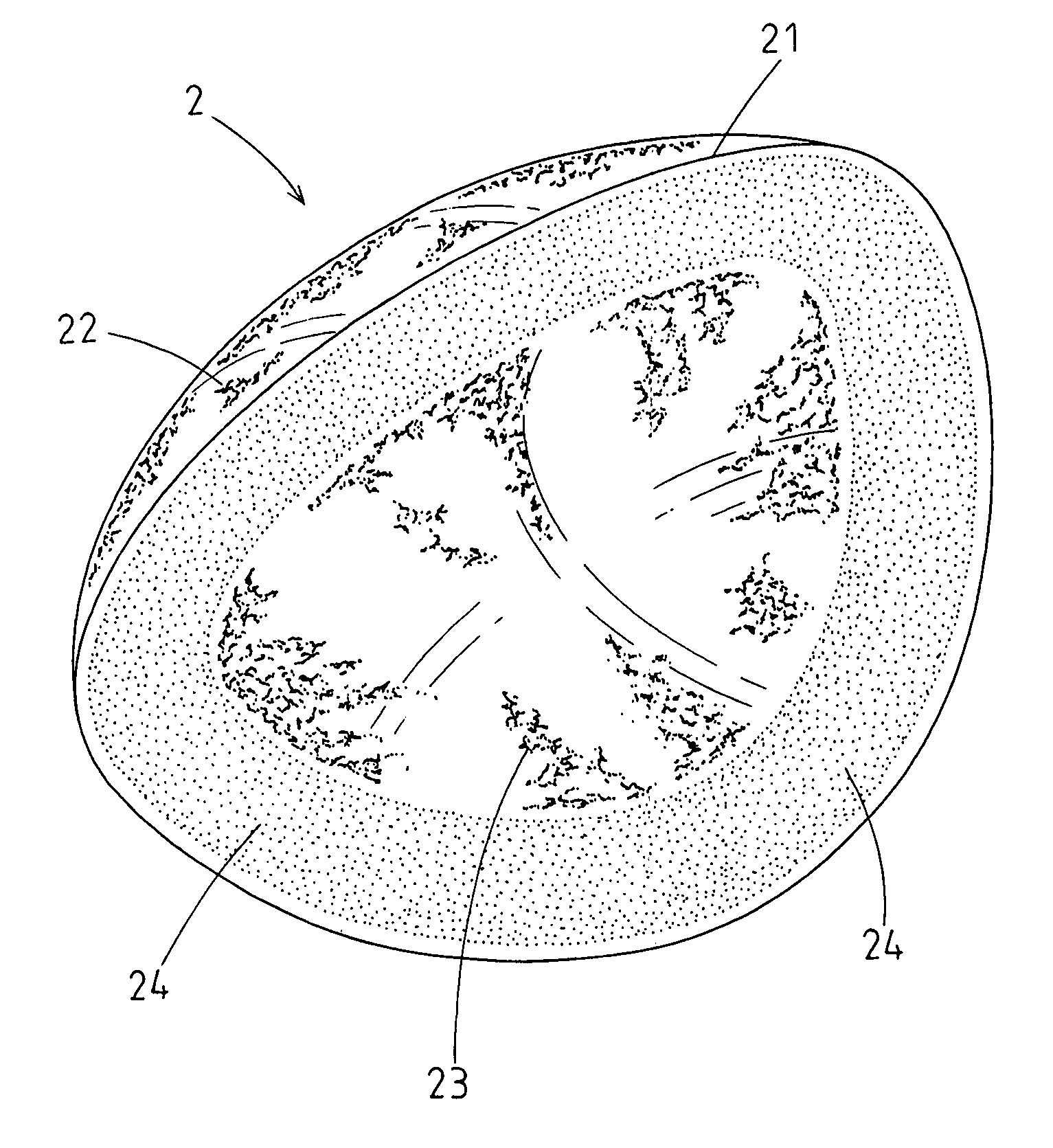

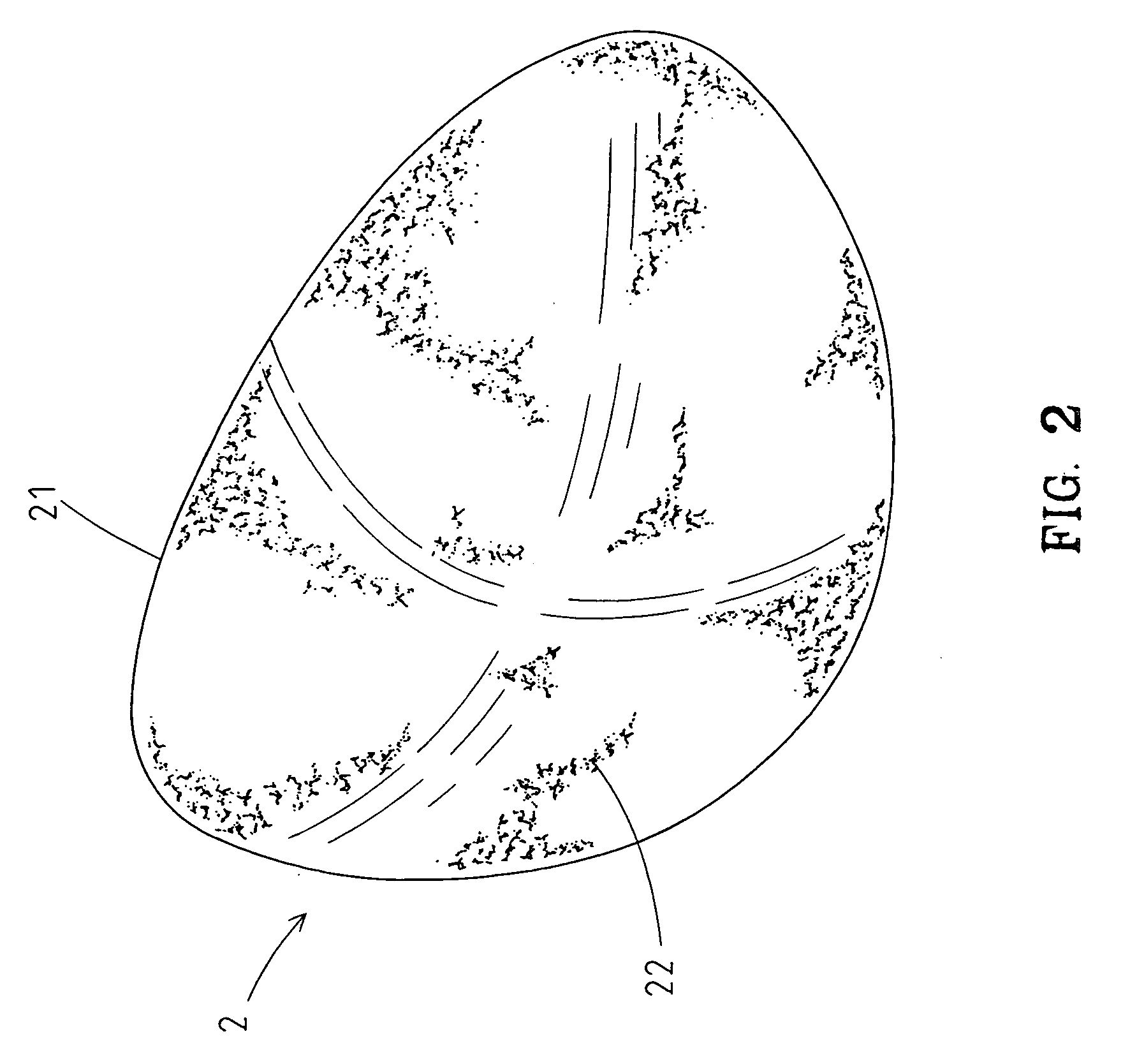

Air-permeable elastomeric bra cup

A bra cup includes a convexo-concave body having an inner face and an outer face. The body of the bra cup is a silicone foamed elastomer. Adhesive is applied to the inner face of the body. The body of the bra cup includes a plurality of holes in an interior and a surface of the body, providing a light, air-permeable, elastomeric structure.

Owner:JIAN JIN YI

Electron beam cured silicone materials

InactiveCN102232103AThin material handlingPressure sensitive film/foil adhesivesHot meltSilicone foam

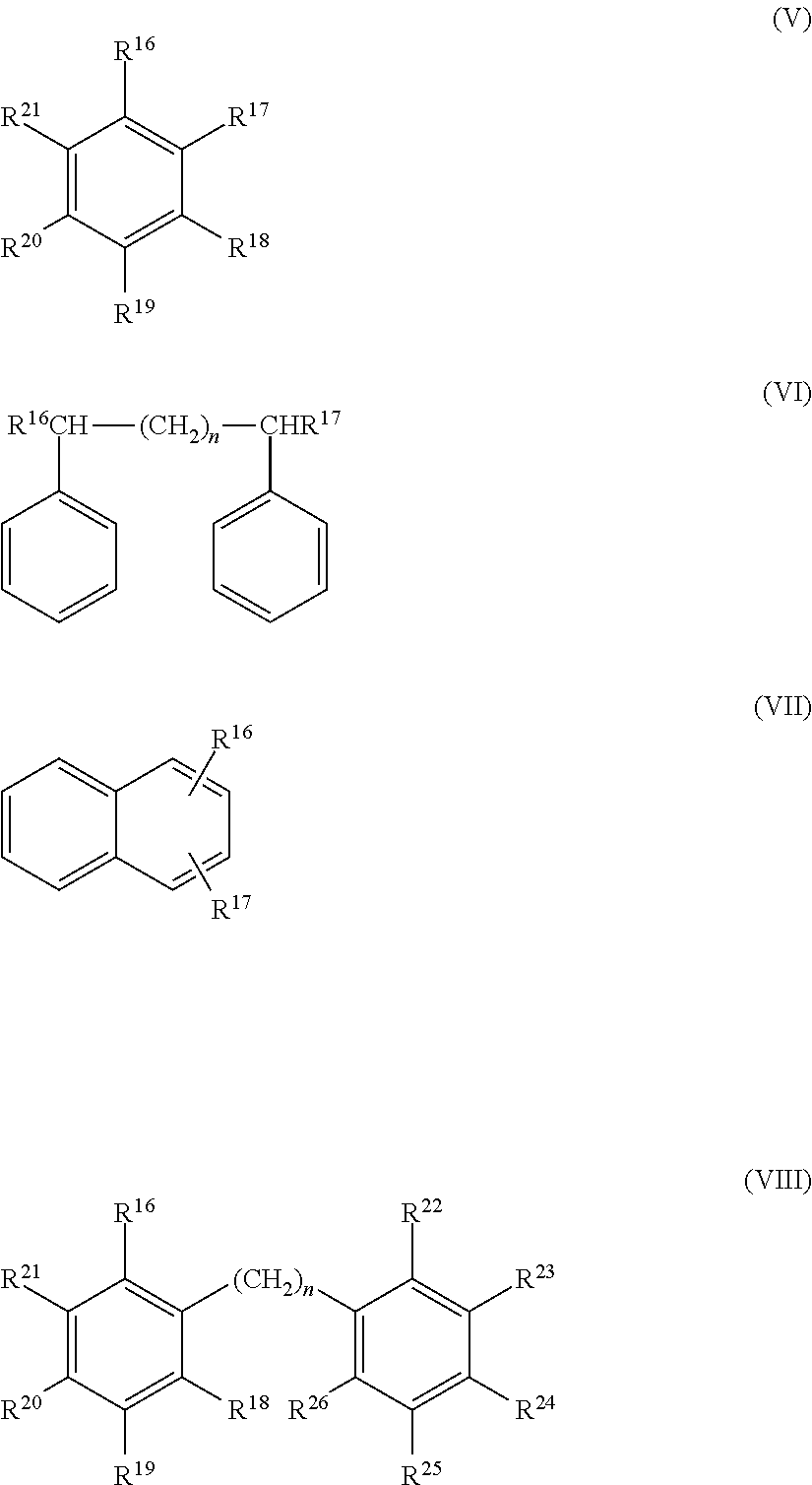

Methods of preparing silicone materials using electron beam curing are described. The materials are hot melt processed and cured in the absence of an effective amount of catalysts and initiators. Both functional and nonfunctionalized silicone materials may be used. Exemplary cured materials include silicone pressure sensitive adhesives, silicone foams, and non-tacky silicone films.

Owner:3M INNOVATIVE PROPERTIES CO

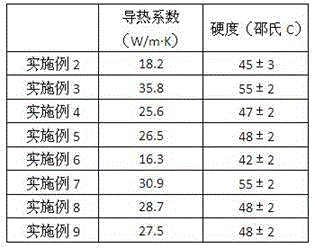

Heat-conductive and temperature-resistant silicone foam material and preparation method thereof

InactiveCN107141808AImprove thermal conductivity and temperature resistanceImprove temperature resistanceHeat-exchange elementsPolymer scienceFoaming agent

The invention relates to a heat-conductive and temperature-resistant silicone foam material and a preparation method thereof. The preparation method of the heat-conductive and temperature-resistant silicone foam material comprises the following steps: performing open milling on 20-45 parts of silicon rubber, 10-25 parts of silicon resin and 5-15 parts of a reinforcing agent for 10-30 minutes at normal temperature in an open mill, then adding 0-1 part of pigment, 2-5 parts of a heat-conductive filler, 3-10 parts of a curing agent and 5-15 parts of a foaming agent, continuing performing open milling till a uniform state, pressing the open-milled material into a sheet with a certain thickness by using hot pressing equipment, heating the sheet in a 180 DEG C drying tunnel for 3-5 minutes to completely foam the sheet, and then performing moulding calendering treatment in calendering equipment to obtain the silicone foam with the thickness of 0.3-5 MM. The silicone foam prepared by the preparation method provided by the invention has high heat conductivity and buffer resistance, can resist the temperature from -60 DEG C to 260 DEG C, and can be applied to a hot pressing occasion with a relatively high buffer need.

Owner:CHANGZHOU CHIKE PHOTOELECTRICITY TECH CO LTD

Silicone Foam Control Compositions And Process For Making Thereof

InactiveUS20140364515A1Limitation efficient use of equipmentReduce processOther chemical processesMixing methodsChemical compoundSilicone foam

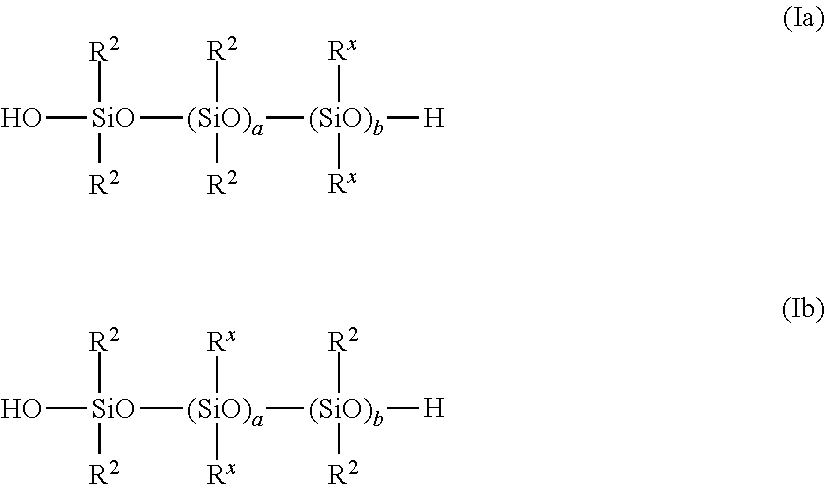

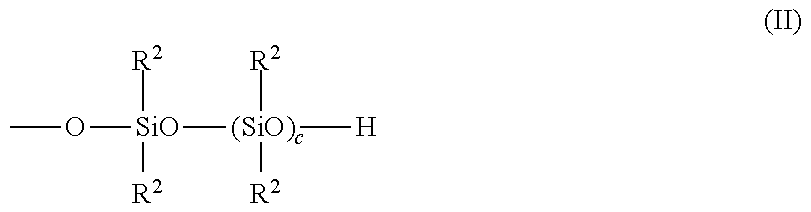

A silicone foam control composition comprises a finely divided filler, an organosilicon compound that contains at least two silicon-bonded hydroxy groups in each molecule, an organosilicon compound having at least two silicon-bonded aminoxy groups in each molecule, and optionally an inert fluid. At least (B) and (C) react so the silicone foam control composition has a viscosity of from 1,000 mPa·s to 1,000,000 mPa·s at 25° C. An oil-in-water silicone emulsion composition comprising the silicone foam control composition, a process for making the silicone foam control composition, and a method of using the composition, are also disclosed.

Owner:DOW CORNING TORAY CO LTD +1

Foamed Silicone in Wound Care

ActiveUS20190001019A1Adapt quicklyEasy to controlNon-adhesive dressingsIntravenous devicesChemical reactionWound care

The present invention relates to a silicone foam that is produced in-situ at a wound site, e.g. in a wound cavity, through a multi-component system, based on a physical foaming process, wherein the gas required to form the foam structure is provided through the blowing agent independently of the curing reaction of the polyorganosiloxane components of the multi-component system. Therefore, in accordance with the present invention, the blowing agent is provided as a distinct entity of the multi-component system that is, in particular, not the result of any chemical reaction taking place in the multi-component system. The present invention also relates to a device for producing the foam and the corresponding negative pressure wound therapy kit.

Owner:MOLNLYCKE HEALTH CARE AB

Composition for flame-retardant flexible polyurethane foam

Owner:DIAHACHI CHEMICAL INDUSTRY CO LTD

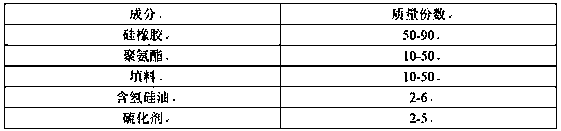

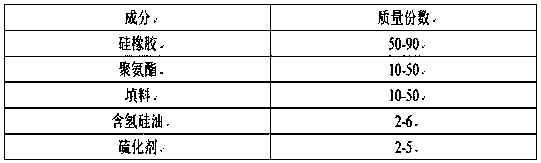

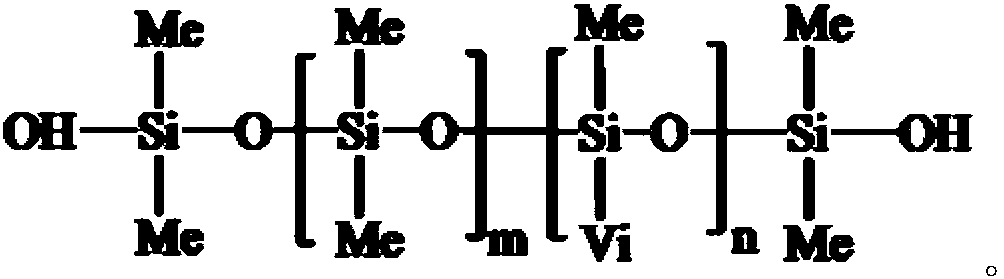

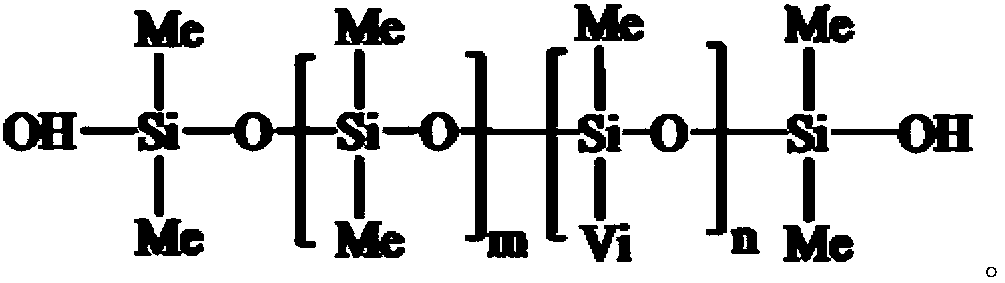

Medical silicone rubber with high mechanical property and preparation method thereof

The invention relates to medical silicone rubber with high mechanical property and a preparation method thereof. The silicone rubber comprises the following raw materials, by weight: 50-90 parts of silicone rubber, 10-50 parts of polyurethane, 10-50 parts of a filling material, 2-6 parts of hydrogen-containing silicone oil, and 2-5 parts of a vulcanizing agent. The preparation method includes thefollowing steps: evenly mixing white carbon black with silicone rubber and polyurethane in an internal mixer, placing the mixed polyurethane on an open type rubber mixer, and adding the hydrogen-containing silicone oil, silicone rubber and vulcanizing agent in a small amount and a plurality of batches; and finally vulcanizing the rubber compound on a flat rubber vulcanizer at 150-190 DEG C for 5-15 min to obtain the medical silicone rubber with high mechanical property. The medical silicone rubber with high mechanical property has the characteristics of good mechanical property, no irritation,high safety and the like.

Owner:SHANDONG BRANDEN MEDICAL DEVICE

Silicone rubber insulating adhesive composition and preparation method thereof

ActiveCN108239402ALight weightImprove flame retardant performanceRubber insulatorsElectric power transmissionPolymer science

The invention discloses a silicone rubber insulating adhesive composition and a preparation method thereof. The silicone rubber insulating adhesive composition comprises the following components in parts by weight: 100 parts of methyl vinyl silicone rubber, 10-30 parts of gas-phase method white carbon black, 40-100 parts of magnesium aluminum hydrotalcite, 5-20 parts of coated ammonium polyphosphate, 5-10 parts of vinyl MQ silicone resin, 1-3 parts of hydroxyl silicone oil, 0.1-1 part of hydrogen-containing silicone oil, 0.05-1 part of an inner mold-releasing agent, and 0.3-2 parts of a vulcanizing agent. The insulating silicone rubber composition provided by the invention has the advantages of low specific gravity, excellent physical properties, good flame retardance, high insulation performance and the like, and can be applied to fields such as electric engineering, electrical engineering and electric power transmission.

Owner:DONGJUE SILICONE NANJING CO LTD

Low-content graphene-modified organic silicone flame-retardant foamed composite material and preparation method thereof

The invention relates to the technical field of organic silicon. In order to solve the problems that a flame retardant with a very high content needs to be added to achieve a flame retardant effect incurrent organic silicone foam, and some flame retardants do harm to human health and pollutes the environment, the invention provides a low-content graphene-modified organic silicone green flame-retardant foamed composite material and a preparation method thereof. The composite material is prepared from the following raw materials in parts by weight: 40-98 parts of organic silicone oil, 0.2-10 parts of a foaming agent, 0.01-10 parts of a flame retardant, 0.0002-0.02 part of a catalyst and 0.1-5.0 parts of an inhibitor. The composite material provided by the invention not only has excellent flame-retardant self-extinguishing properties, but also has good elastic properties, compression properties and hydrophobic properties.

Owner:HANGZHOU NORMAL UNIVERSITY

Real leather silicone rubber polymer synthetic leather and manufacturing technology thereof

ActiveCN108823340AOvercome the disadvantage of not being able to coat silicone rubber polymersEasy to operateCoatingsLeather surface finishingManufacturing technologyPolymer science

The invention discloses a real leather silicone rubber polymer synthetic leather, which comprises real leather. A priming silicone rubber layer is painted on the real leather. A matte hand-feeling oilsurface layer is painted on the priming silicone rubber layer. The priming silicone rubber layer is composed of following raw materials in parts by weight: 100 to 200 parts of vinyl silicone rubber based glue, 5 to 10 parts of polyvinyl silicone oil, 1 to 3 parts of tackifier, 1 to 3 parts of silane coupling agent, 5 to 20 parts of hydrogen containing silicone oil, 0.5 to 2 parts of platinum catalyst, 5 to 20 parts of color paste pigment, and 0.05 to 0.2 part of inhibitor. The invention also discloses a manufacturing technology of the real leather silicone rubber polymer synthetic leather. The shortage that silicone rubber polymer cannot be painted on real leather is overcome; provided is a method that can paint silicone rubber polymer on real leather; the method is simple and easy to perform, the operation is simple, at the same time, the processing cost is low, and the production is simple, convenient, environmentally friendly, and pollution-free.

Owner:GUANGDONG TIANYUE NEW MATERIAL CO LTD

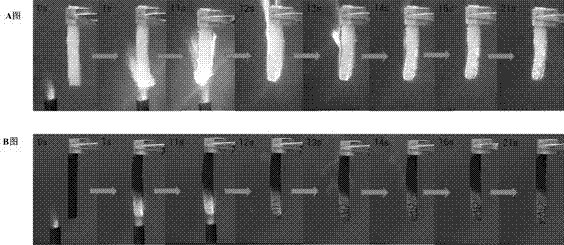

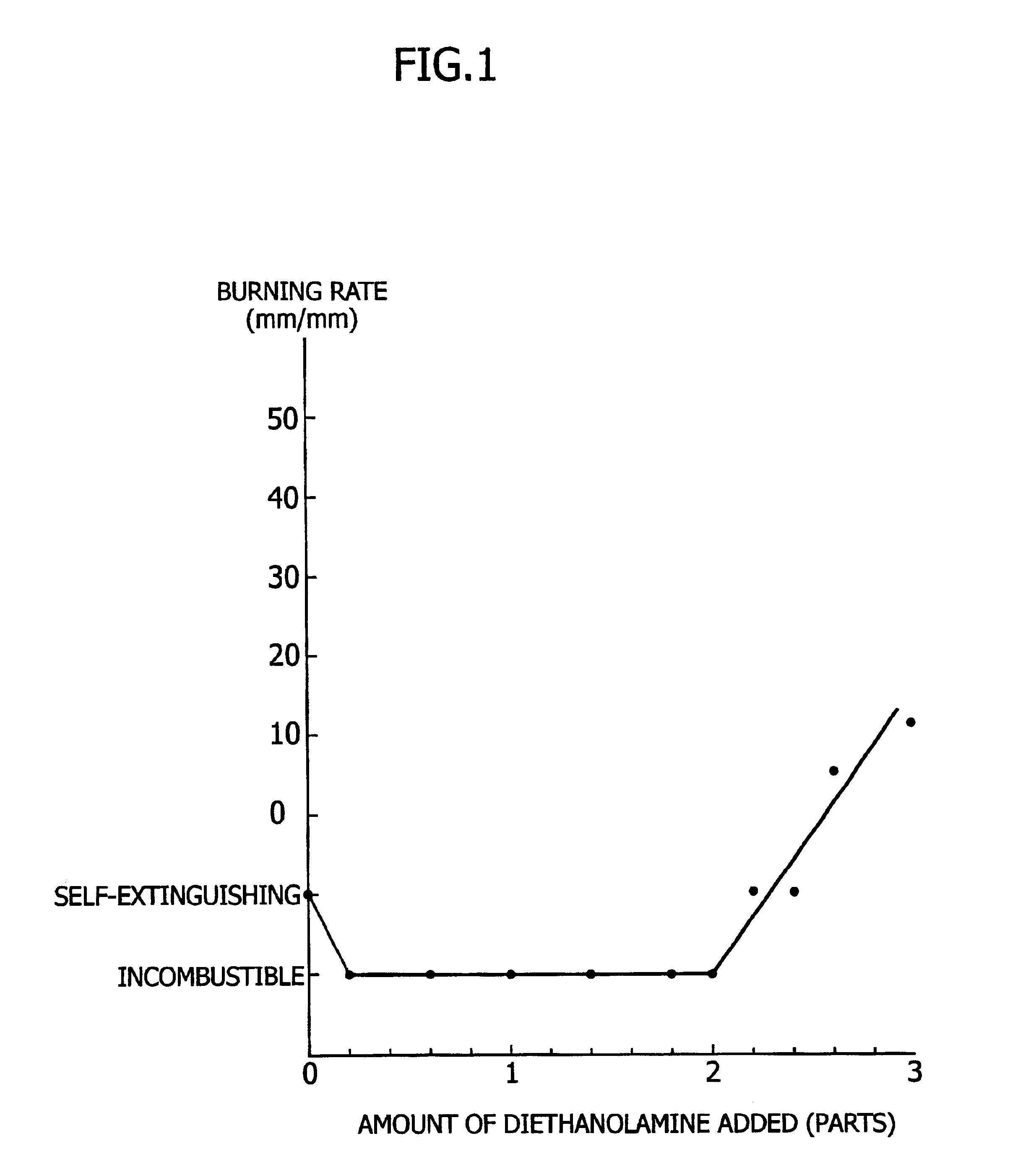

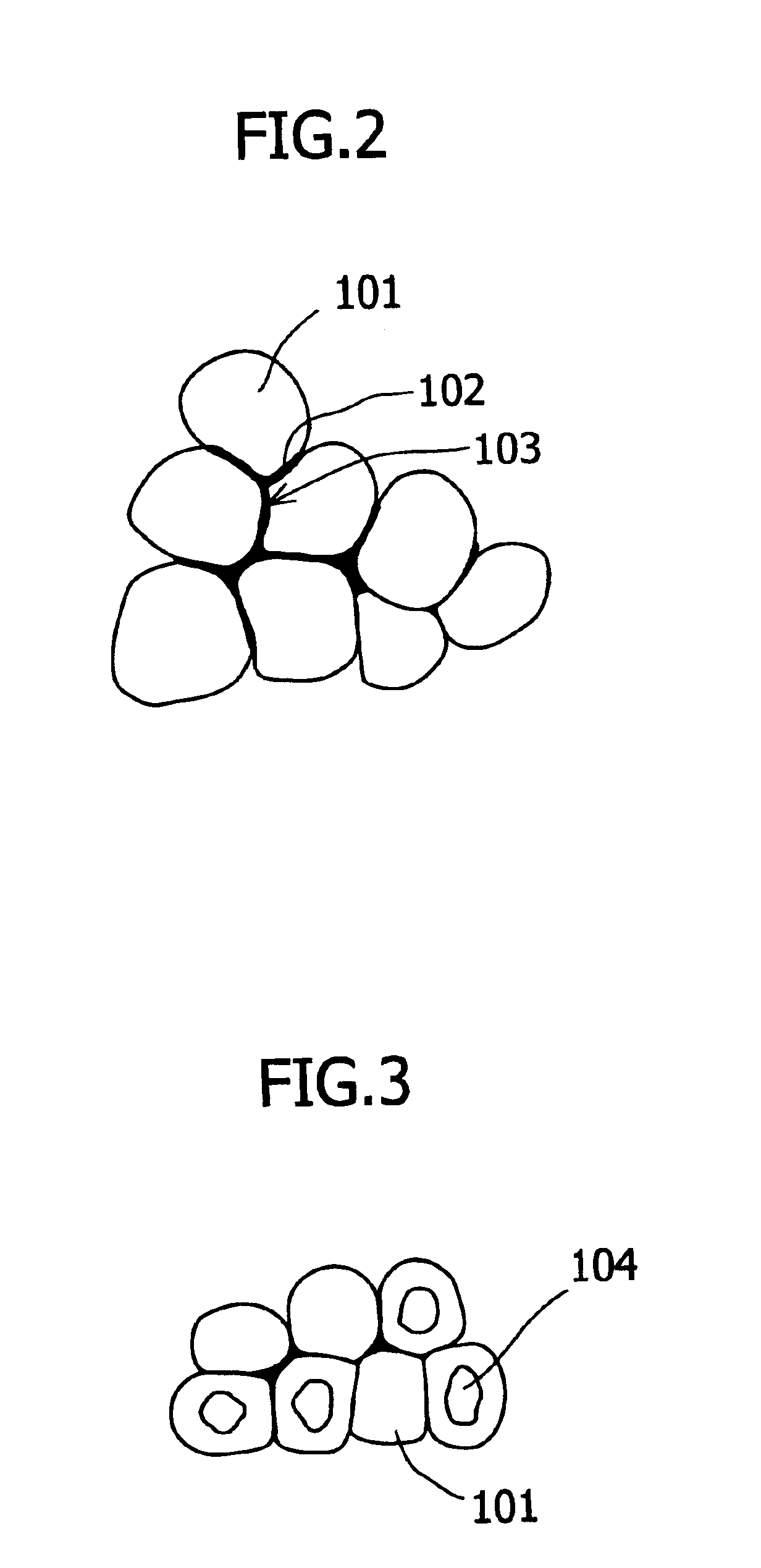

Process for the production of a lightweight cold urethane

In a process for the production of a lightweight cold urethane wherein raw materials are injected into a mold in one shot, diethanolamine is added in an amount of 0.1 to 2.0 parts by weight per 100 parts by weight of the polyol. When principal raw materials including a polyol and an isocyanate, and an auxiliary ingredient mixture prepared by previously mixing auxiliary ingredients other than the polyol and the isocyanate, are injected into a mold from separate storage vessels, a water-soluble silicone foam stabilizer is added to the auxiliary ingredient mixture.

Owner:SUZUKI MOTOR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com