Fireproof and irradiation-resisting room temperature vulcanization two-component silicone foam sealant used in nuclear power station and preparation process thereof

A technology of room temperature vulcanization and silicone foam, which is applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of lack of radiation resistance, and achieve the effect of short preparation time, simple preparation process and excellent radiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited by the examples.

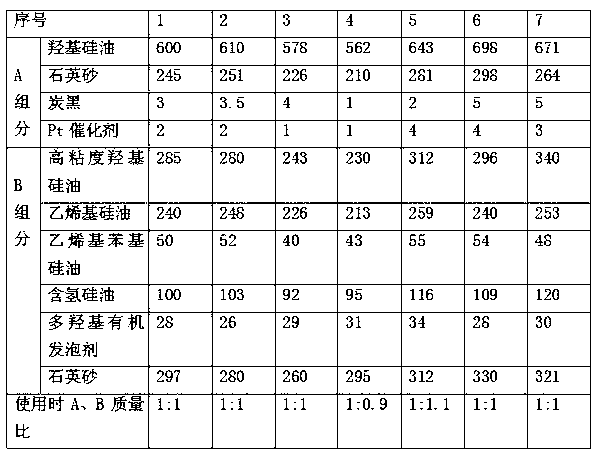

[0068] The two-component silicone foam used in nuclear power plants in this embodiment includes component A and component B, wherein the specific composition of component A and component B is shown in Table 1 in parts by weight.

[0069] Table 1 The specific proportions of component A and component B in this example

[0070]

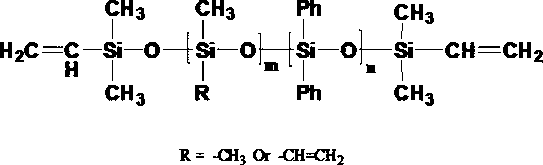

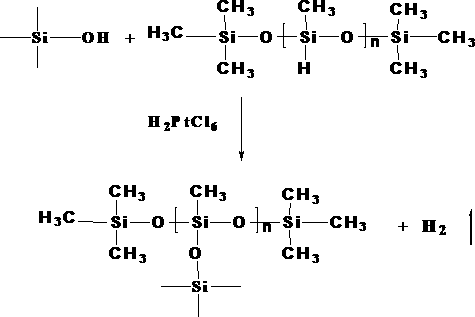

[0071] The radiation-resistant sealing foam prepared in this example is a microporous spongy foam formed by foaming and vulcanizing at room temperature with hydroxyl silicone oil as the base material, vinyl silicone oil as the auxiliary, and hydrogen-containing silicone oil as the foaming agent. Elastic foam. Its reaction formula is as follows:

[0072]

[0073] Under the component distribution ratio of above-mentioned table 1, research is carried out for each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com