Preparation method for tungsten trioxide nanowire electrochromic film

A technology of tungsten trioxide and rice noodle electricity, applied in the direction of tungsten oxide/tungsten hydroxide, nanotechnology, coating, etc., can solve problems such as hindering practical application, low coloring efficiency, slow discoloration speed, etc., and achieve controllable hydrothermal process. , Improve the adhesion performance, the effect of fast discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

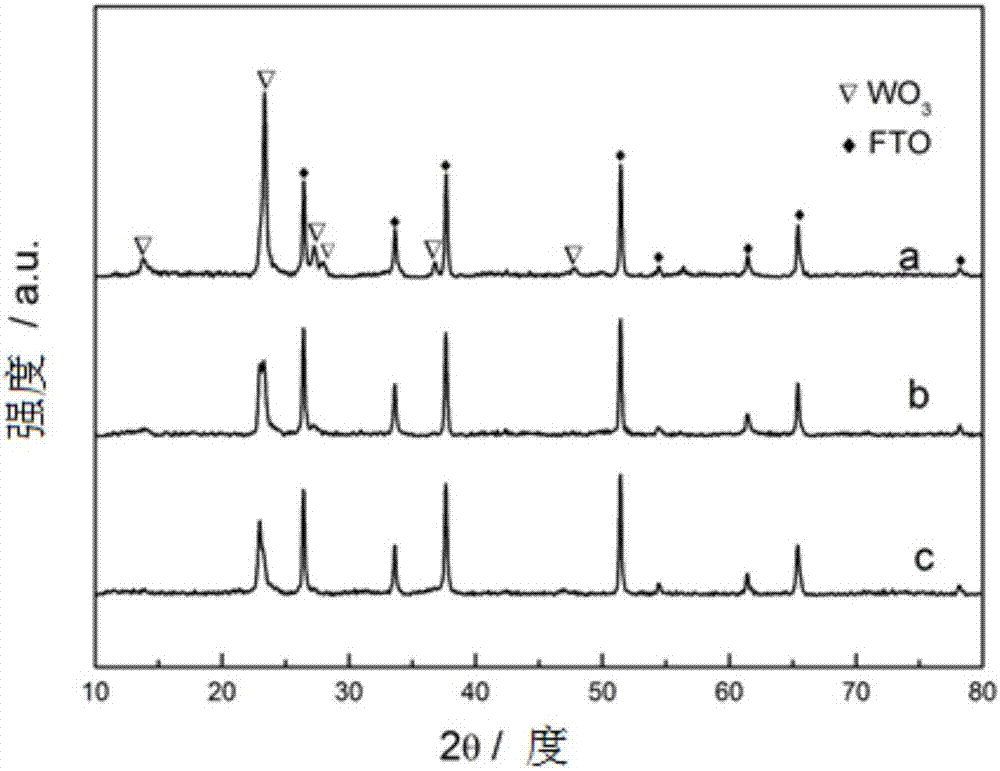

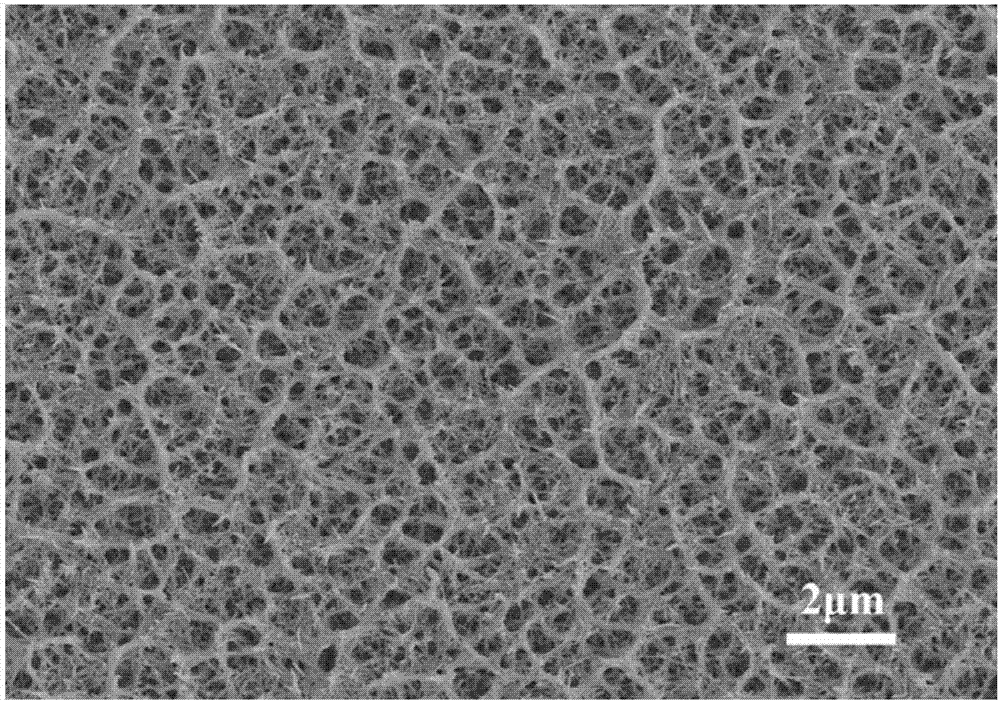

Embodiment 1

[0037] (1) Clean the FTO conductive glass sequentially with acetone, ethanol, and deionized water ultrasonically, each cleaning time is 20 minutes, and dry it for later use;

[0038] (2) Weigh 0.25g tungstic acid and dissolve it in 15mL hydrogen peroxide solution with a mass fraction of 30%, then add 50mL deionized water, continue stirring for 8h, after forming a preliminary sol, continue aging for 24h to obtain tungsten acid sol, and then the tungstic acid sol was spin-coated on the FTO conductive glass at a rate of 3000rpm, and the spin-coating time was 20s, and then the FTO conductive glass was annealed at 400°C for 40min to obtain a 3FTO conductive glass of the seed layer;

[0039] (3) Weigh 1.32g of sodium tungstate dihydrate and dissolve it in 18mL of deionized water, add 2.5mL of 3mol / L hydrochloric acid solution to adjust the pH value to about 2, then add 1.056g of ammonium sulfate and 12mL of ethylene glycol, and continue stirring for 30min. Obtain a stable tungsten ...

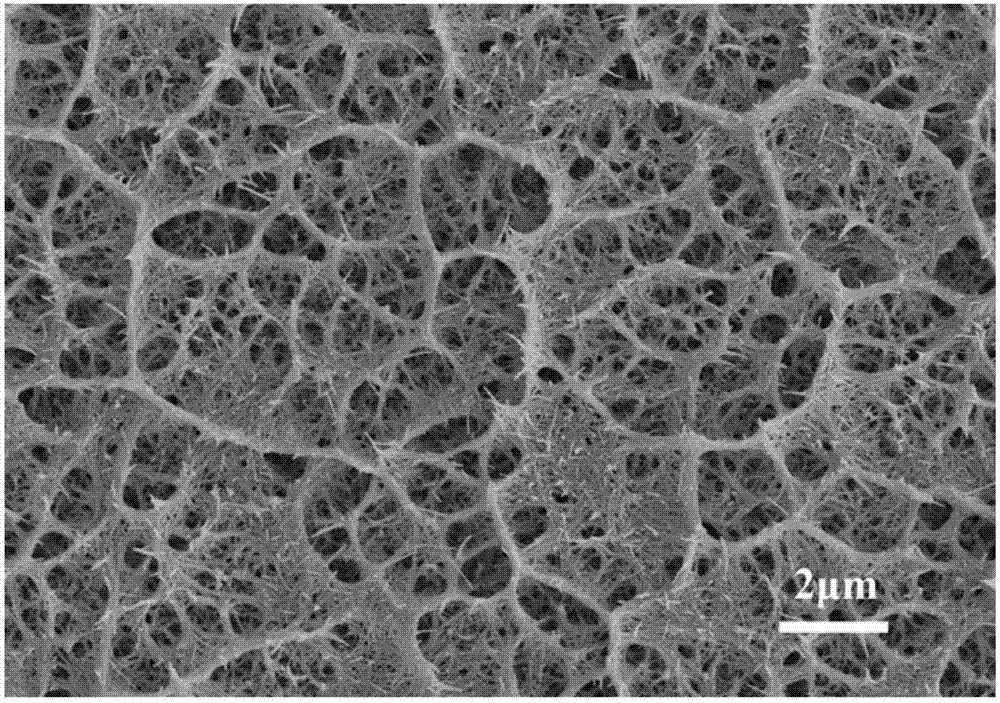

Embodiment 2

[0051] (1) Clean the FTO conductive glass sequentially with acetone, ethanol, and deionized water ultrasonically, each cleaning time is 20 minutes, and dry it for later use;

[0052] (2) Weigh 0.25g tungstic acid and dissolve it in 15mL hydrogen peroxide solution with a mass fraction of 30%, then add 50mL deionized water, continue stirring for 8h, after forming a preliminary sol, continue aging for 24h to obtain tungsten acid sol, and then the tungstic acid sol was spin-coated on the FTO conductive glass at a rate of 3000rpm, and the spin-coating time was 20s, and then the FTO conductive glass was annealed at 400°C for 40min to obtain a 3 FTO conductive glass of the seed layer;

[0053] (3) Weigh 1.32g of sodium tungstate dihydrate and dissolve it in 22mL of deionized water, add 2.5mL of 3mol / L hydrochloric acid solution to adjust the pH value to about 2, then add 1.056g of ammonium sulfate and 8mL of ethylene glycol, and continue stirring for 30min. Obtain a stable tungsten ...

Embodiment 3

[0064] (1) Clean the FTO conductive glass sequentially with acetone, ethanol, and deionized water ultrasonically, each cleaning time is 20 minutes, and dry it for later use;

[0065] (2) Weigh 0.25g tungstic acid and dissolve it in 15mL hydrogen peroxide solution with a mass fraction of 30%, then add 50mL deionized water, continue stirring for 8h, after forming a preliminary sol, continue aging for 24h to obtain tungsten acid sol, and then the tungstic acid sol was spin-coated on the FTO conductive glass at a rate of 3000rpm, and the spin-coating time was 20s, and then the FTO conductive glass was annealed at 400°C for 40min to obtain a 3 FTO conductive glass of the seed layer;

[0066] (3) Weigh 1.32g of sodium tungstate dihydrate and dissolve it in 26mL of deionized water, add 2.5mL of 3mol / L hydrochloric acid solution to adjust the pH value to about 2, then add 1.056g of ammonium sulfate and 4mL of ethylene glycol, and continue stirring for 30min. Obtain a stable tungsten ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com