High-elasticity polyurethane modified epoxy-silicone ablation resistance paint

A technology for modification of epoxy silicone and polyurethane, applied in polyurea/polyurethane coatings, coatings, etc. Process and other issues, to meet the needs of ablation, excellent thermal stability, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

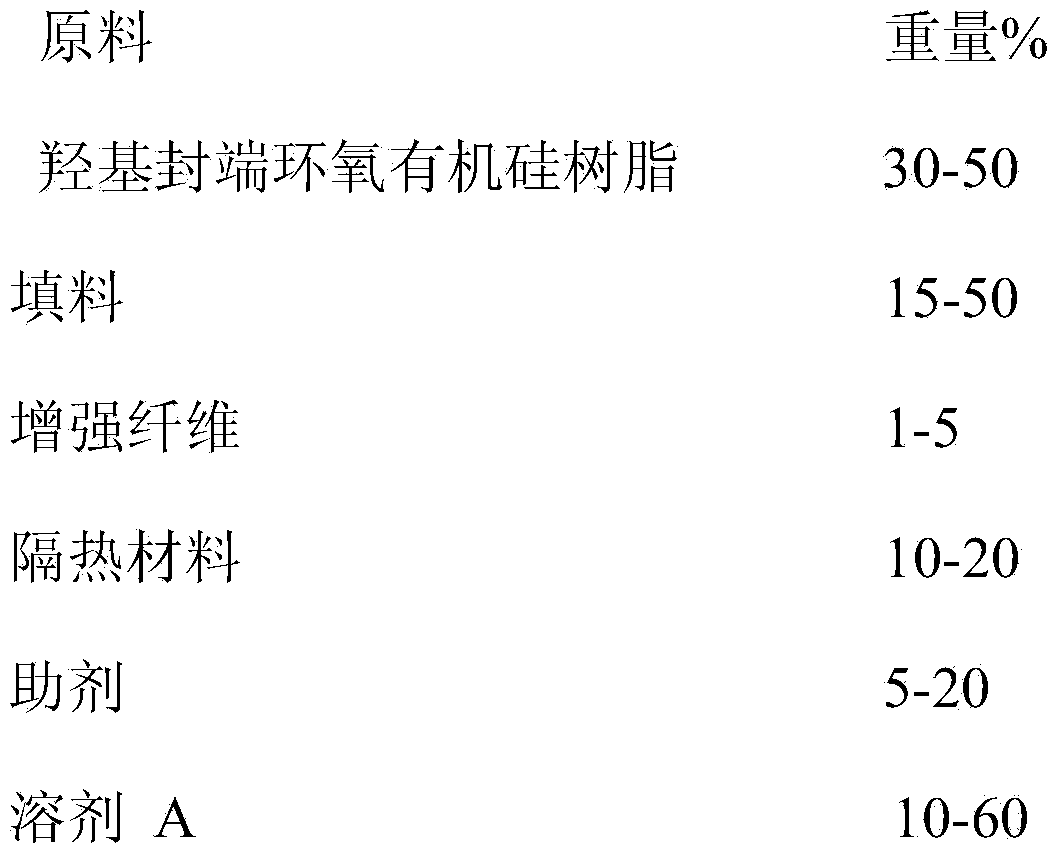

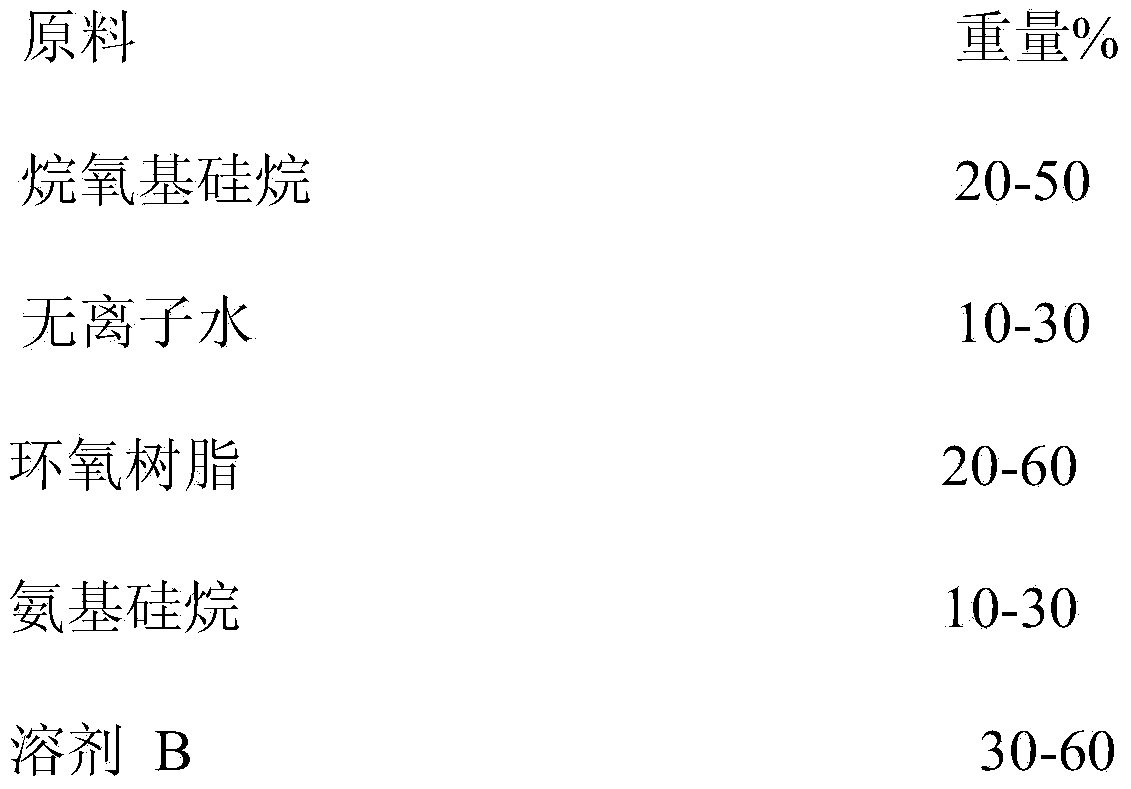

Method used

Image

Examples

Embodiment 1

[0036] Add 240g of phenyltriethoxysilane and 544g of diphenyldiethoxysilane into the three-necked reaction flask, start stirring, and evenly drop 21g of water into the reaction flask with a dropping funnel, and control the reaction temperature at 38°C for about 1h The dropwise addition is complete. Keep warm for 0.5h. Heat up to 80°C. The ethanol produced by the reaction reaches 88g. It takes 1.5h to raise the temperature to 133°C. After 1.5h, the amount of ethanol collected is 108g, and the temperature is lowered to 60°C. The ethoxy content is 30.3%, and the refractive index D20 is obtained: 1.512 silicone intermediates. Put 697g of organosilicon intermediate, 1162g of cyclohexanone, 581g of xylene, and 1046g of E-20 epoxy resin into a three-necked reaction flask in sequence, slowly raise the temperature, pass CO2 gas and turn on cooling water to cool, and raise the temperature to 160°C. After 6 hours of heat preservation, samples were taken to measure the gel time of the re...

Embodiment 2

[0046] Add 240g of phenyltriethoxysilane and 440g of phenylmethyldiethoxysilane into the three-necked reaction flask, start stirring, and evenly drop 31g of water into the reaction flask with a dropping funnel, control the reaction temperature at 38°C, about 1h dropwise addition is complete. Keep warm for 0.5h, heat up to 80°C, the ethanol produced by the reaction reaches 130g, take 1.5h to heat up to 133°C, collect 158g of ethanol after 2h, cool down to 60°C, and obtain ethoxy content of 30.3%, refractive index D20: 1.512 Silicone intermediates. Put 553g of organosilicon intermediate, 939g of cyclohexanone, 444g of xylene, and 830g of E-20 epoxy resin into a three-necked reaction bottle in sequence, slowly raise the temperature, pass CO2 gas and turn on cooling water to cool, and raise the temperature to 160°C. After 5.5 hours of heat preservation, samples were taken to measure the gelation time of the resin. When the gelation time was 2 minutes at 250 ° C, the temperature w...

Embodiment 3

[0056] Add 240g of phenyltriethoxysilane and 297g of dimethyldiethoxysilane into the three-necked reaction flask, start stirring, and evenly drop 40.8g of water into the reaction flask with a dropping funnel, and control the reaction temperature at 37°C for about 1h The dropwise addition is complete. Insulate for 0.5h. Heat up to 80°C. The ethanol produced by the reaction reaches 170g. It takes 1.5h to raise the temperature to 133°C. After 2h, the amount of ethanol collected is 206g, and the temperature is lowered to 60°C. The ethoxy content is 30.1%, and the refractive index D20: 1.511 Silicone intermediates. Put 372g of organosilicon intermediate, 613g of cyclohexanone, 307g of xylene, and 552g of E-20 epoxy resin into a three-necked reaction bottle in sequence, slowly raise the temperature, pass CO2 gas and turn on cooling water to cool, and raise the temperature to 160°C. After 6 hours of heat preservation, samples were taken to measure the gel time of the resin. When the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com