Silicone rubber insulating adhesive composition and preparation method thereof

A silicone rubber insulation and composition technology, which is applied in the field of silicone rubber, can solve the problems of high density of insulating silicone rubber products, high specific gravity of aluminum hydroxide, and reduced physical and mechanical properties of silicone rubber, and achieves reduction in specific gravity, electrical insulation and resistance. Good aging and improved physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

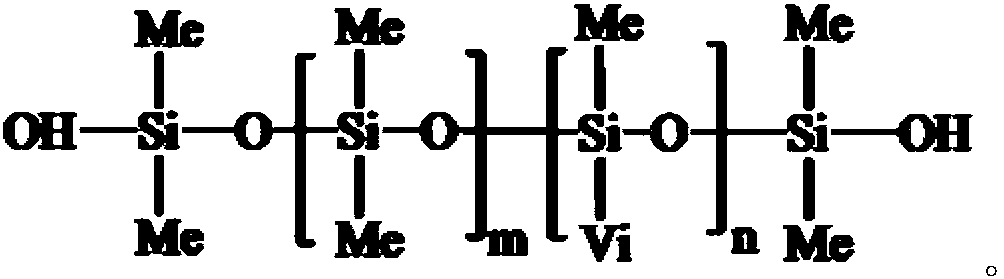

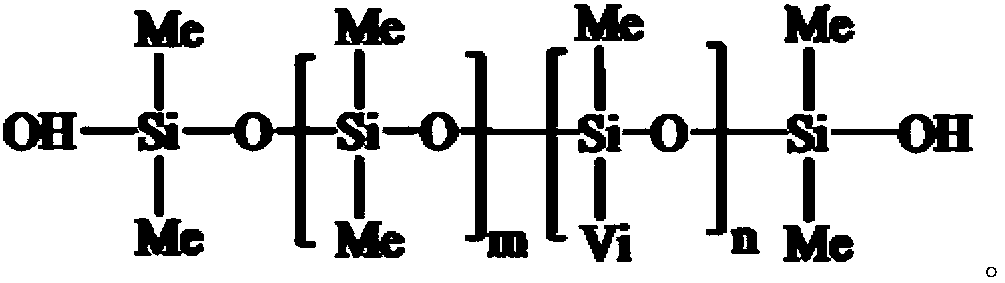

[0035] 1) In terms of parts by mass, in a vacuum mixer, add 90 parts of methyl vinyl silicone rubber (Dongjue Organic Co., Ltd. Silicon (Nanjing) Co., Ltd.), 10 parts of dimethylvinyl-terminated, molecular weight of 550,000, vinyl molar content of 0.2% methyl vinyl silicone rubber (Dongjue Silicone (Nanjing) Co., Ltd.), 5 parts of vinyl MQ silicone resin (vinyl content is 1.2-2.7%, M:Q=1, powder product, Hubei Jiayun Chemical Technology Co., Ltd.), 3 parts of hydroxyl silicone oil with a kinematic viscosity of 35cst (Wuxi Quanli Chemical Industry Co., Ltd. Co., Ltd., hydroxyvinyl silicone oil with a vinyl content of 5%), 1 part of hydrogen-containing silicone oil with a hydrogen content of 1.53% (Wuxi Quanli Chemical Co., Ltd.), 0.1 part of zinc stearate, and mix them uniformly in a kneader.

[0036] 2) In step 1), add 15 parts of specific surface area is 200m 2 / g of hydrophobic fumed silica (Guangzhou Jibisheng Technology Industrial Co., Ltd.), 40 parts of magnesium aluminu...

Embodiment 2

[0041] 1) In terms of parts by mass, in a vacuum mixer, add 70 parts of methyl vinyl silicone rubber (Dongjue Organic Co., Ltd. Silicon (Nanjing) Co., Ltd.), 30 parts of dimethylvinyl-terminated, molecular weight of 550,000, vinyl molar content of 0.23% methyl vinyl silicone rubber (Dongjue Silicone (Nanjing) Co., Ltd.), 6 parts of vinyl MQ silicone resin (vinyl content is 1.2-2.7%, M:Q=1, powder product, Hubei Jiayun Chemical Technology Co., Ltd.), 3 parts of hydroxy vinyl silicone oil with a kinematic viscosity of 33cst (Wuxi Quan Li Chemical Co., Ltd., hydroxyvinyl silicone oil, vinyl content is 5%), 1 part of hydrogen-containing silicone oil with a hydrogen content of 1.53% (Wuxi Quanli Chemical Co., Ltd.), 0.5 part of zinc stearate, mixed in a kneader uniform.

[0042] 2) In step 1), add 12 parts of specific surface area is 200m 2 Hydrophobic fumed silica (Guangzhou Jibisheng Technology Industrial Co., Ltd.), 70 magnesium aluminum hydrotalcite (Nantong Advan Chemical Co...

Embodiment 3

[0047] 1) In terms of parts by mass, add 60 parts of methyl vinyl silicone rubber (Dongjue Organic Co., Ltd. Silicon (Nanjing) Co., Ltd.), 40 parts of dimethylvinyl-terminated, molecular weight is 550,000, and the molar content of vinyl is 0.25% methyl vinyl silicone rubber (Dongjue Silicone (Nanjing) Co., Ltd.), 5 parts of vinyl MQ silicone resin (vinyl content is 1.2-2.7%, M:Q=1, powder product, Hubei Jiayun Chemical Technology Co., Ltd.), 4 parts of hydroxy vinyl silicone oil with a kinematic viscosity of 35cst (Wuxi Quan Li Chemical Co., Ltd., hydroxyvinyl silicone oil, vinyl content is 5%), 0.6 parts of hydrogen-containing silicone oil with a hydrogen content of 1.53% (Wuxi Quanli Chemical Co., Ltd.), 0.2 parts of zinc stearate, mixed in a kneader uniform

[0048] 2) Add 10 parts in step 1) with a specific surface area of 200m 2 / g of hydrophobic fumed silica (Guangzhou Jibisheng Technology Industrial Co., Ltd.), 100 parts of magnesium aluminum hydrotalcite (Nantong A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com