Low-content graphene-modified organic silicone flame-retardant foamed composite material and preparation method thereof

A technology of graphene modification and composite materials, which is applied in the field of organic silicon, which can solve the problems of environmental pollution and flame retardants endangering human health, and achieve the effects of uniform cell structure, excellent flame retardant and self-extinguishing, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Take a total of 100g of hydrogen-containing silicone oil with a viscosity of 25mPa.s, a hydrogen content of 0.3%, and a hydroxyl silicone oil with a viscosity of 10Pa.s, and add 1gKH550 functionalized graphene, 2g of 3,5-dimethyl-1-hexyne-3- Alcohol and 5g of AC foaming agent were thoroughly mixed by mechanical stirring to prepare component A; at the same time, take 30g of vinyl silicone oil with a viscosity of 5Pa.s, add 0.30g of chloroplatinic acid-isopropanol solution containing 1500ppm, and pass Mechanical stirring is used to mix thoroughly and evenly to prepare component B.

[0040] Then components A and B were mixed uniformly by mechanical stirring for 30 seconds at a mass ratio of 1:1, and then cured at 80°C for 5 minutes and then treated at a high temperature of 180°C for 15 minutes to prepare a silicone flame-retardant foam composite sample 1.

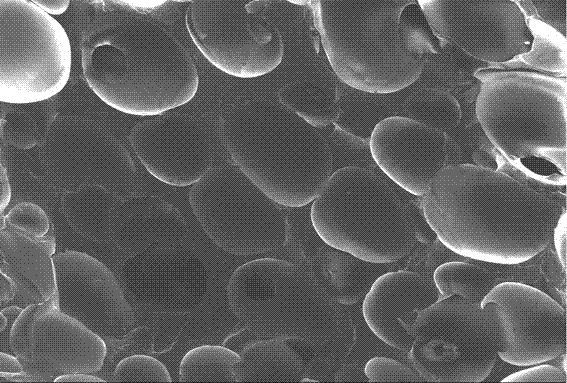

[0041] The cells of spline 1 are visually uniform, and the scanning electron microscope picture is as follows figure...

Embodiment 2

[0043] Take a total of 40g of hydrogen-containing silicone oil with a viscosity of 30mPa.s, a hydrogen content of 0.2%, and a hydroxyl silicone oil with a viscosity of 5Pa.s, and add 0.5g of graphene powder and 1.5g of 3,5-dimethyl-1-hexyne to it -3-alcohol and 1.6g of water were mixed thoroughly by mechanical stirring to prepare component A; at the same time, take 20g of vinyl silicone oil with a viscosity of 5Pa.s, add 0.25g of chloroplatinic acid-isopropanol solution containing 1500ppm, Prepare component B after mixing thoroughly and uniformly by mechanical stirring.

[0044] Then components A and B were mixed uniformly by mechanical stirring for 30s at a mass ratio of 1:1, and then cured at 40°C for 10 minutes and then treated at a high temperature of 180°C for 20 minutes to prepare silicone flame-retardant foam composite sample 2.

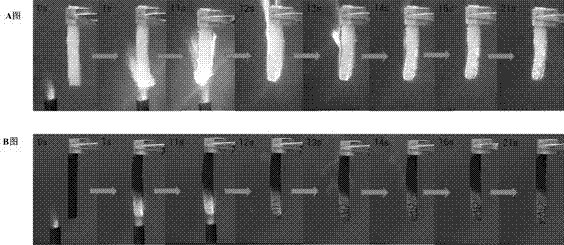

[0045] Such as figure 2As shown, after passing the vertical burning test, comparing the combustion results, it can be known that: the silic...

Embodiment 3

[0047] Take a total of 30g of hydrogen-containing silicone oil with a viscosity of 25mPa.s, a hydrogen content of 0.5%, and a hydroxyl silicone oil with a viscosity of 12Pa.s, and add 0.4g KH560 functionalized graphene, 0.45g 3-methylbutynol-3 and 1.4g Polyethylene glycol, prepared by mechanical stirring and mixing well to obtain component A; at the same time, take 60g of vinyl silicone oil with a viscosity of 10Pa.s, add 0.25g of Castel platinum catalyst containing 2000ppm, and mix well by mechanical stirring Then prepare component B.

[0048] Then components A and B were mixed uniformly by mechanical stirring for 30s at a mass ratio of 1:1, and then cured at 90°C for 5 minutes and then treated at a high temperature of 150°C for 20 minutes to prepare a silicone flame-retardant foam composite sample 3.

[0049] After passing the vertical burning test, the results of comparative combustion show that the silicone foam added with KH560 functionalized graphene is not easy to burn ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com