Electron beam cured silicone materials

A technology of organosilicon and electron beam irradiation, which is applied in thin material processing, film/sheet adhesive, transportation and packaging, etc., and can solve problems such as benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

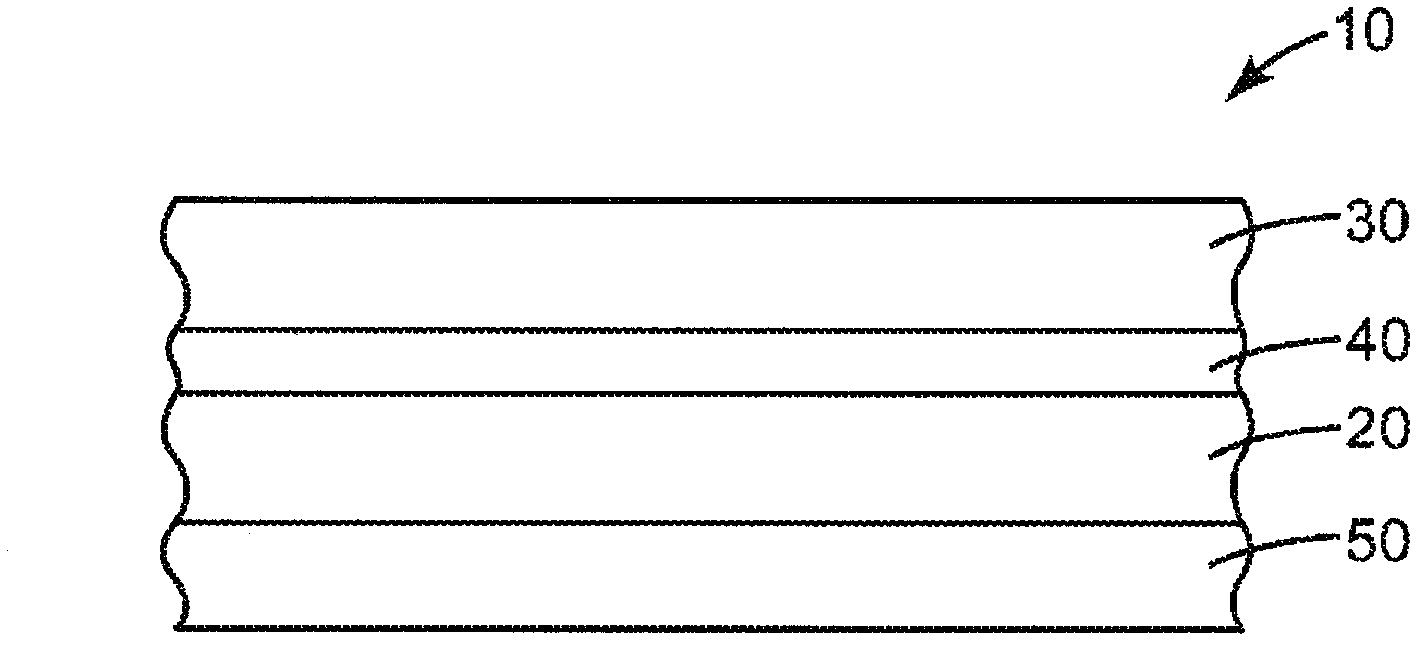

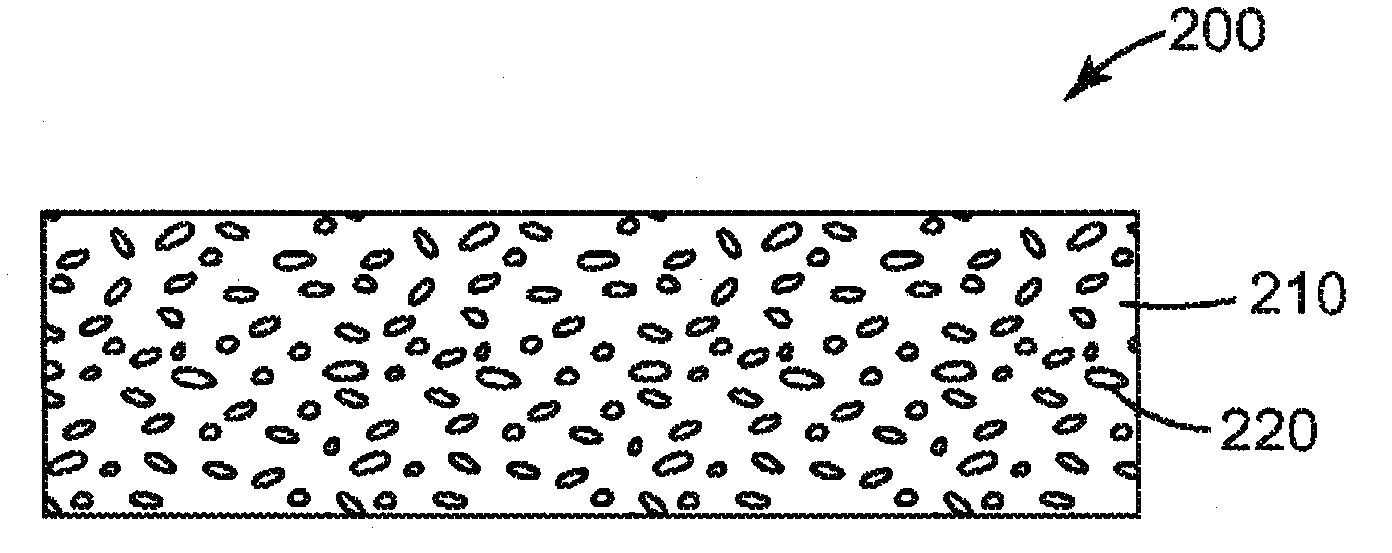

[0029] The pressure-sensitive adhesive of the present invention can be prepared by mixing silicone materials (such as silicone colloids or elastomers) with suitable tackifying resins, hot-melt coating the resulting combination, and using electron beam (E-beam ) to cure by irradiation. In general, any known additives useful in pressure sensitive adhesive formulations (such as dyes, pigments, fillers, flame retardants, rheology modifiers, flow agents, surface active agents, microspheres (such as expandable microspheres, etc.).

[0030] In general, any known tackifying resin can be used, for example, in some embodiments, a silicate tackifying resin can be used. In some exemplary adhesive compositions, a variety of silicate tackifying resins can be used to achieve desired properties.

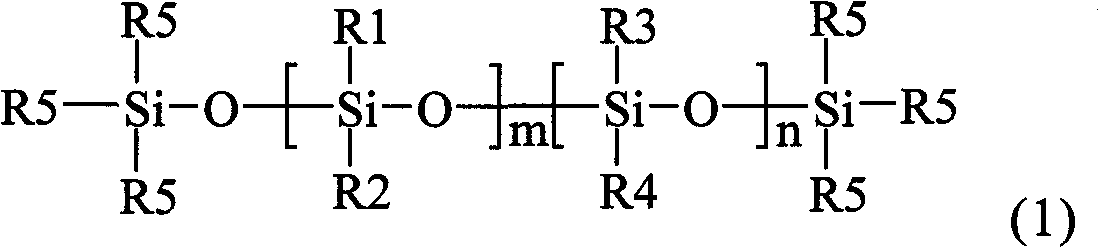

[0031] Suitable silicate tackifying resins include resins composed of the following structural units: M (i.e., monovalent R' 3 SiO 1 / 2 unit), D (ie, divalent R' 2 SiO 2 / 2 unit), T (ie, trivale...

example

[0047] The following examples illustrate the inventors' surprising discovery that a variety of silicone chemistries can be cured using electron beam (E-Beam) irradiation to obtain pressure sensitive adhesives. The performance of these e-beam cured adhesives was comparable to the same adhesives cured by conventional methods, although the catalysts or initiators required for conventional curing were not used.

[0048] For comparison, three samples were prepared for each of the silicone chemistries. A reference example in which the silicone was not cured, a comparative example in which the silicone was cured by an appropriate conventional method using a catalyst, and an example of the present invention in which the silicone was cured by electron beam irradiation in the absence of a catalyst and an initiator . The peel adhesion and static shear of the samples were determined according to the tests described below.

[0049] Peel Adhesion Test. Peel adhesion was measured using an...

example 2A、2B

[0063] Examples 2A, 2B, and 2C. DC-7355 was coated as is onto PET-3SAC film using a knife coater with a gap of 127 microns. The coated samples were then dried in an oven at 70°C for 15 minutes. The dried samples were passed through an electron beam chamber with an oxygen content <50 ppm having 250 keV and various dose levels: 1 Mrad (EX-2A), 5 Mrad (EX-2B), and 9 Mrad Ladd (EX-2C).

[0064] Series 3: Q2-7735

[0065] See example RE-3. Q2-7735 was coated as is onto PET-3SAC film using a knife coater with a gap of 127 microns. The coated samples were then dried in an oven at 70°C for 15 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com