Air-permeable elastomeric bra cup

a technology of air-permeable elastomeric and bra cups, which is applied in the field of bra cups, can solve the problem that the bra cups can be used for a long time, and achieve the effect of improving the air-permeability and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

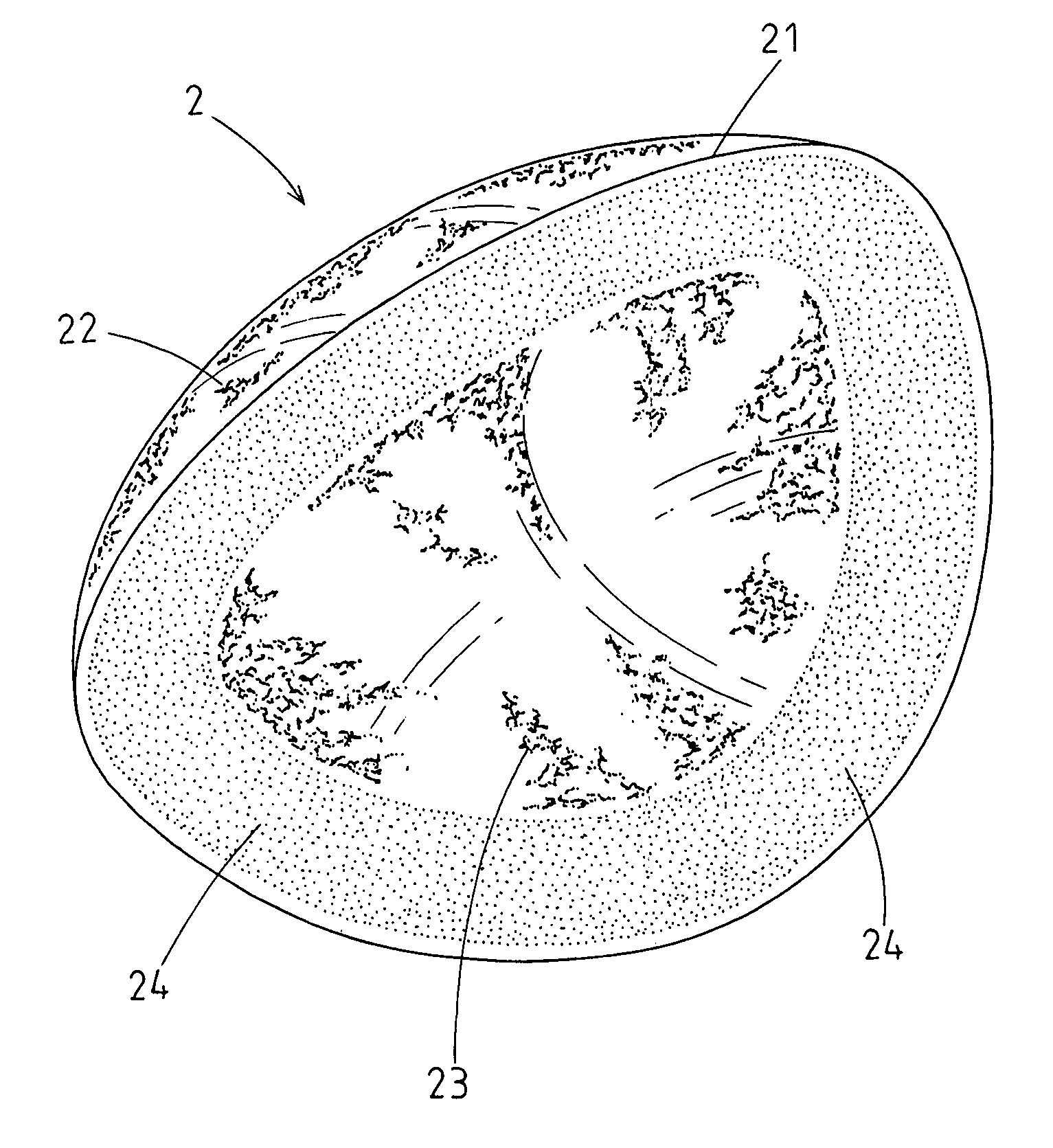

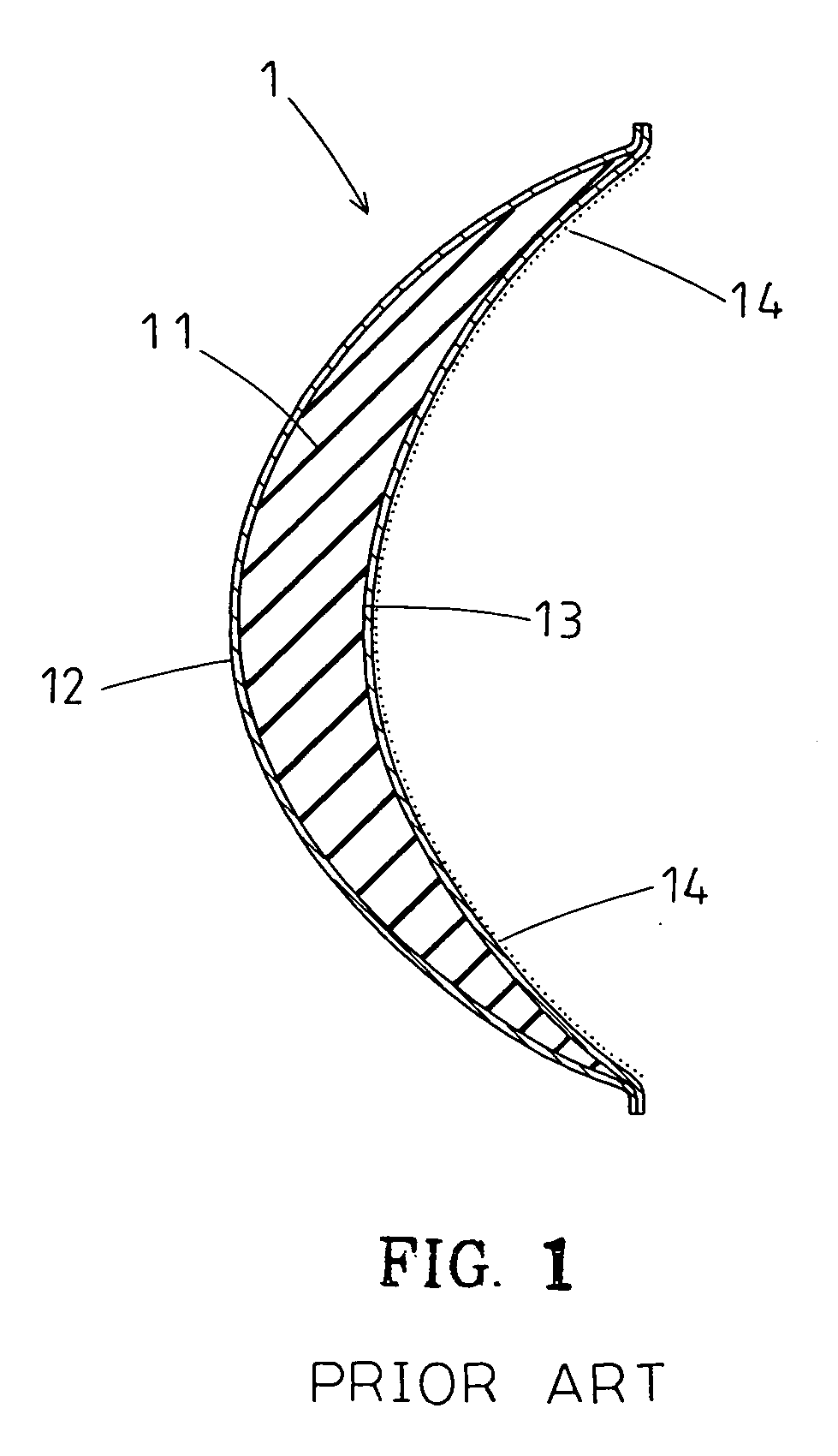

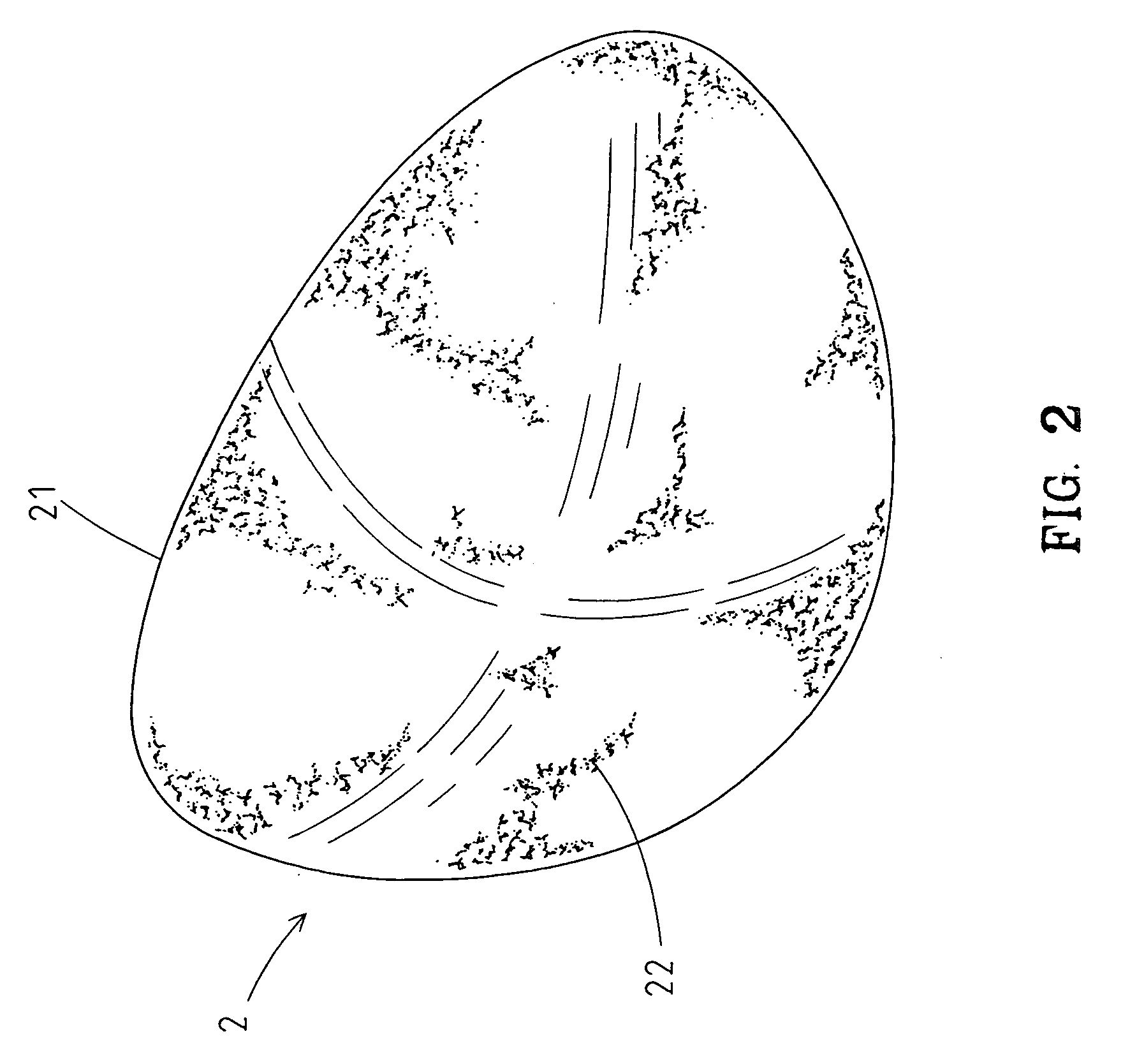

[0027] Referring to FIGS. 2 through 4, a bra cup 2 in accordance with the present invention comprises a body 21 that is convexo-concave to suit the profile of the bosom of a user. The body 21 includes an outer face 22 and an inner face 23. Adhesive 24 is applied to at least a peripheral portion of the inner face 23, allowing the body 21 to be directly adhered to the bosom of the user.

[0028] In this embodiment, the body 21 is made of silicone foamed elastomer. The body 21 includes a plurality of densely distributed holes in the interior and the surface of the body 21, providing a highly air-permeable, highly elastomeric structure.

[0029] In manufacture, a first silicon oil containing OH functional group (such as HO(Me2SiO)nH) and a second silicon oil containing H functional group (such as (CH3)3SiO((SiHCH3)O)nSi(CH3)3) are filled into a mold for a bra cup and dehydrating crosslinking reaction is carried out under catalyzing by platinum catalyst at room temperature to form a foamed e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| elastomeric | aaaaa | aaaaa |

| durable | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com