Preparation method of interface heat conduction material silicone rubber pad

An interface thermal conductive material and silicone rubber technology, which is applied in the field of thermally conductive polymer composite materials, can solve the problems of not meeting the requirements of thermal conductivity, failing to reflect graphene, and being unfavorable for industrial production, so as to improve the thermal conductivity and speed up the vulcanization rate. , the effect of enhancing physical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

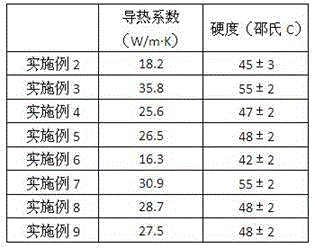

Examples

Embodiment 1

[0032] A method for preparing a silicone rubber mat, which is a thermal interface material, includes the following steps:

[0033] (1) Add 10-300 parts by weight of inorganic thermally conductive powder, 1-10 parts by weight of catalyst, and 1-10 parts by weight of a mixture of dimethyl silicone oil and hydrogen-containing silicone oil into 100 parts by weight of silicone rubber, and knead After homogenization, the rubber compound is obtained;

[0034] (2) Take 10-90 parts by weight of a carbon material with a three-dimensional network structure, and evenly fill the mixed rubber obtained in step (1) into the carbon material to obtain a composite material; wherein the carbon material with a three-dimensional network structure is graphene Or carbon fiber, and when it is graphene, the thickness of graphene is 0.5-10mm;

[0035] (3) Put the composite material into an oven to vulcanize, the vulcanization temperature is 120-180℃, and the vulcanization time is 0.5-2h. After vulcanization, ...

Embodiment 2

[0043] A method for preparing a silicone rubber mat, which is a thermal interface material, includes the following steps:

[0044] (1) Prepare materials, prepare 100g of raw silicone rubber, 10g of metal aluminum powder, 1g of tert-butyl peroxybenzoate and 1g of a mixture composed of dimethyl silicone oil and hydrogen-containing silicone oil. After the preparation is completed, the silicone rubber and inorganic thermal conductivity The powder, the catalyst, and the mixture composed of dimethyl silicone oil and hydrogen-containing silicone oil are added to a kneader for kneading, and the mixed rubber is obtained after uniform kneading. Among them, simethicone with a viscosity of 500mPa·s is added to the catalyst, and the mass percentage of the catalyst and simethicone is 1:10; in the mixture of simethicone and hydrogen-containing silicone oil, hydrogen-containing silicone oil and The mass percentage of simethicone is 1:20, the hydrogen content in hydrogen-containing silicone oil i...

Embodiment 3

[0048] A method for preparing a silicone rubber mat, which is a thermal interface material, includes the following steps:

[0049] (1) Prepare materials, prepare 100g of raw silicone rubber, 300g of metal aluminum powder, 10g of tert-butyl peroxybenzoate and 10g of a mixture composed of dimethyl silicone oil and hydrogen-containing silicone oil. After the preparation is completed, the silicone rubber and inorganic thermal conductivity Powder, catalyst, and a mixture of simethicone and hydrogen-containing silicone oil are added to the kneader and kneaded. After uniform kneading, a rubber compound is obtained; among them, dimethyl silicone oil with a viscosity of 5000 mPa·s is added to the catalyst. The mass percentage of simethicone is 10:100; in the mixture of simethicone and hydrogen-containing silicone oil, the mass percentage of hydrogen-containing silicone oil and simethicone is 20:100, and the hydrogen content in hydrogen-containing silicone oil It is 0.5%, and the viscosity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com