Double-component fireproof silicone foamed material with ultra-low density and preparation technology thereof

An ultra-low density, silicone foam technology, applied in the field of polymer fireproof materials, can solve the problems of complicated operation methods, difficulty in preparing complex-shaped foamed silicone rubber, and high production conditions, and achieve simple preparation process and easy construction And the effect of easy replacement and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Each component in this embodiment is measured in parts by mass.

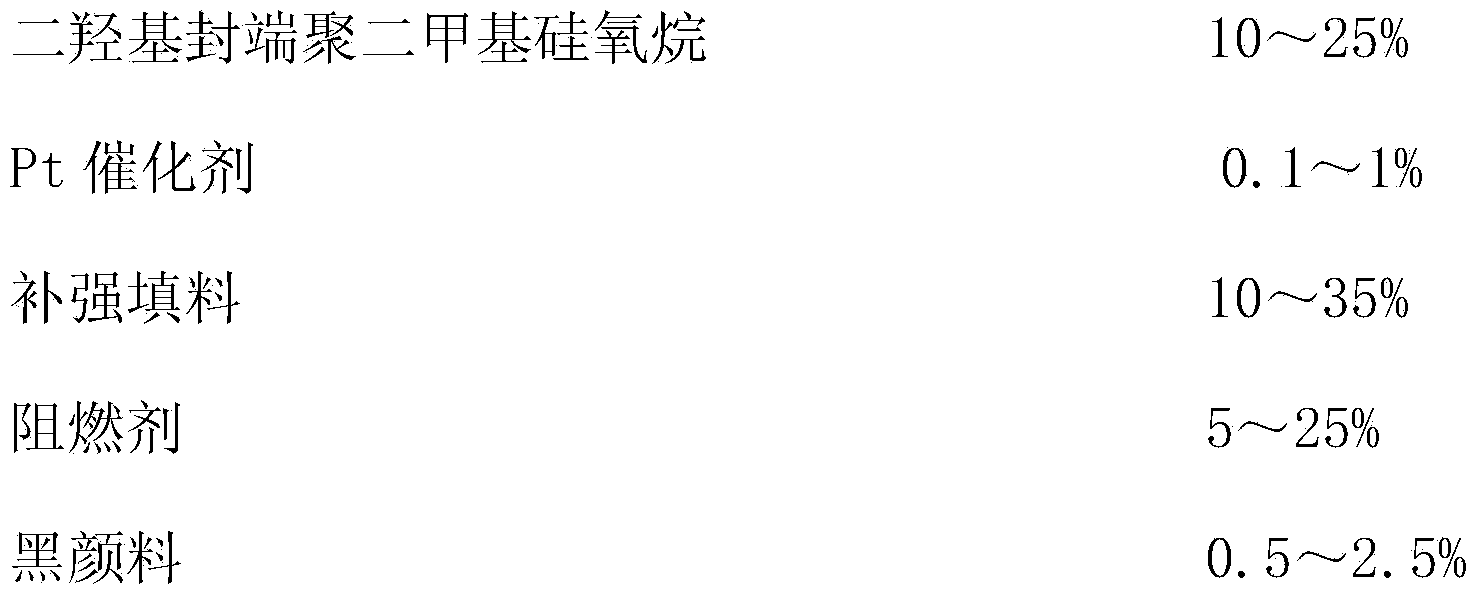

[0034] First, add 50 parts of 1000mPa vinyl-terminated polydimethylsiloxane and 13 parts of 15000mPa dihydroxyl-terminated polydimethylsiloxane into a multifunctional dispersing mixer for mixing. Mixing temperature: 30°C, mixing time : 75min; then add 15 parts of 1500 mesh fumed silica, 10 parts of 1500 mesh wollastonite powder, 6 parts of 1000 mesh aluminum hydroxide, 5 parts of 1000 mesh magnesium hydroxide and stir and mix, mixing time: 45min; then add 0.5 parts of Pt Catalyst, 0.5 parts of carbon black powder were stirred and dispersed, stirring time: 45min; after that, vacuum degassed, time: 90min, to obtain A component;

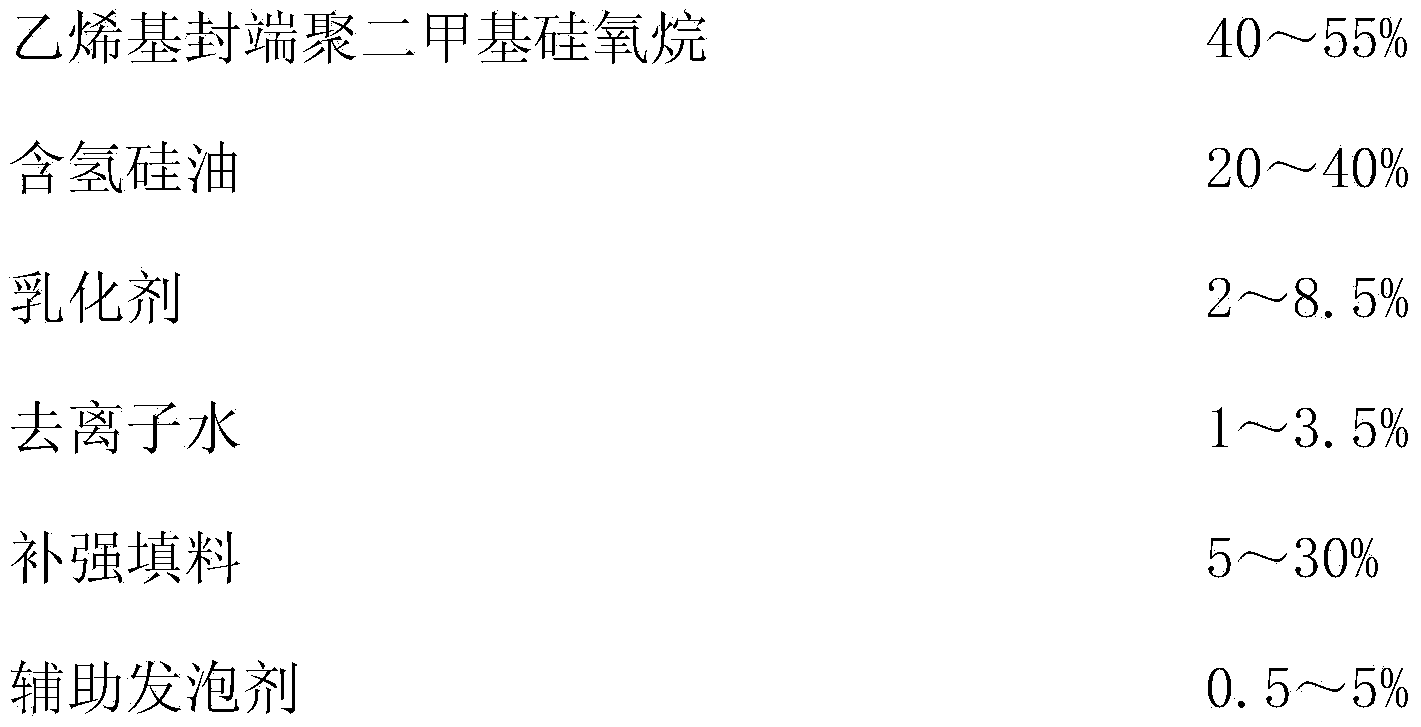

[0035] Next, add 55 parts of 5000mPa vinyl-terminated polydimethylsiloxane, 26 parts of hydrogen-containing silicone oil (hydrogen content 1.5%), 0.9 part of ethylene glycol, and 0.1 part of glycerol into the multifunctional dispersion mixer Mixing, mixing temperature 30°C, mixing...

Embodiment 2

[0038] Each component in this embodiment is measured in parts by mass.

[0039] First, add 45 parts of 2000mPa vinyl-terminated polydimethylsiloxane and 15 parts of 12000mPa dihydroxyl-terminated polydimethylsiloxane into a multifunctional dispersing mixer and mix them. Mixing temperature: 40°C, mixing time : 80min; then add 5 parts of 600 mesh aluminum hydroxide, 5 parts of 600 mesh zinc carbonate, 29 parts of 500 mesh light calcium carbonate and stir and mix, mixing time: 35min; then add 0.1 part of Pt catalyst, 0.5 part of colloidal graphite powder, 0.4 Part of iron oxide black powder was stirred and dispersed, stirring time: 40min; then vacuum degassed, time: 80min, to obtain A component;

[0040] Next, add 45 parts of 4000mPa vinyl-terminated polydimethylsiloxane, 28 parts of hydrogen-containing silicone oil (2% hydrogen content) and 0.5 parts of ethylene glycol into a multifunctional dispersing mixer and mix at a mixing temperature of 25°C , mixing time: 80min; then add...

Embodiment 3

[0043] Each component in this embodiment is measured in parts by mass.

[0044] First, add 65 parts of 2000mPa vinyl-terminated polydimethylsiloxane and 10 parts of 11000mPa dihydroxyl-terminated polydimethylsiloxane to a multifunctional dispersing mixer and mix them. The mixing temperature is 38°C and the mixing time is : 100min; then add 5 parts of chlorinated paraffin, 7 parts of magnesium hydroxide, 10 parts of 2500 mesh fumed silica, 5 parts of 2500 mesh silicon powder and stir and mix, mixing time: 50min; then add 0.5 parts of Pt catalyst, 1.5 parts of carbon Stir and disperse the black powder and 1 part of colloidal graphite powder, stirring time: 38min; then vacuum degassing, time: 85min, to obtain component A;

[0045] Next, add 41 parts of 1000mPa vinyl-terminated polydimethylsiloxane, 36 parts of hydrogen-containing silicone oil (2.5% hydrogen content) and 2.6 parts of ethylene glycol into a multifunctional dispersing mixer and mix at a mixing temperature of 38°C ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com