Foaming method of polypropylene foamed microparticles

A technology of polypropylene and microparticles, which is applied in the field of polypropylene foam materials, can solve problems such as poor mechanical properties, low production process efficiency, and low expansion ratio of polypropylene foam particles, and achieve excellent compression resistance and energy absorption performance, mechanical properties Excellent performance and the effect of avoiding pollution of volatile organic compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

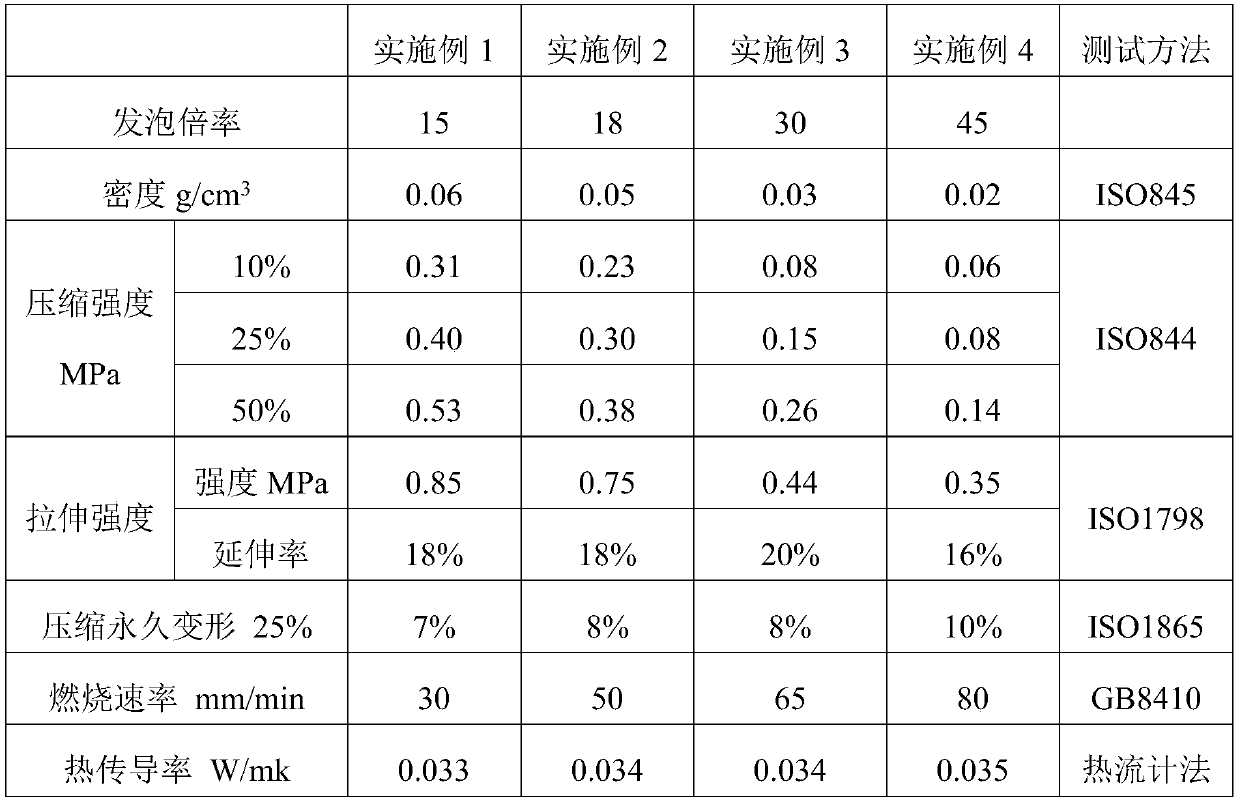

Examples

Embodiment 1

[0037] The foaming method of the polypropylene expanded particle of the present embodiment comprises the following steps:

[0038] (1) Mix the polypropylene raw material granules and the first additive evenly, heat it with electricity to make it melt from solid to liquid in the extruder, extrude through the small hole in the mold after melting, and compress to a cross-sectional diameter of about 0.7mm The compressed filaments become solid filaments after being cooled by the water tank. The filaments are cut into granules, and the granules are screened by a vibrating screen to obtain evenly sized polypropylene particles for foaming. This process Generally, it is controlled at about 240°C; the melt index of polypropylene raw material particles is 3.37g / 10min, the first additive is talcum powder, and the weight of talc powder is 3% of the weight of polypropylene raw material particles.

[0039] (2) Add polypropylene particles, the second auxiliary agent, and water into the autocl...

Embodiment 2

[0047] The foaming method of the polypropylene expanded particle of the present embodiment comprises the following steps:

[0048] (1) Mix the polypropylene raw material particles and the first additive evenly, heat it with electricity to make it melt from solid to liquid in the extruder, extrude through the small hole in the mold after melting, and compress to a cross-sectional diameter of about 0.8mm The compressed filaments become solid filaments after being cooled by the water tank. The filaments are cut into granules, and the granules are screened by a vibrating screen to obtain evenly sized polypropylene particles for foaming. This process It is generally controlled at about 240°C; the melt index of polypropylene raw material particles is 3.6g / 10min, the first additive is talcum powder, and the weight of talc powder is 5% of the weight of polypropylene raw material particles.

[0049] (2) Add polypropylene particles, the second auxiliary agent, and water into the autocla...

Embodiment 3

[0057] The foaming method of the polypropylene expanded particle of the present embodiment comprises the following steps:

[0058] (1) Mix the polypropylene raw material granules and the first additive evenly, heat it with electricity to make it melt from solid to liquid in the extruder, extrude through the small hole in the mold after melting, and compress into a cross-sectional diameter of about 1mm Filamentous, the compressed filaments become solid filaments after being cooled in a water tank, the filaments are cut into granules, and the granules are screened out by a vibrating screen to obtain evenly sized polypropylene particles for foaming. This process is generally The temperature is controlled at about 240°C; the melt index of the polypropylene raw material granules is 3.8g / 10min, the first additive is talcum powder, and the weight of the talc powder is 8% of the weight of the polypropylene raw material granules.

[0059] (2) Add polypropylene particles, the second aux...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com