Single-component polyurethane foaming adhesive as well as preparation method and application thereof

A polyurethane and adhesive technology, applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problems of reducing the viscosity of the system, the use of waterproof performance, and the inability to meet the foaming ratio of foamed ceramic tiles, etc. Achieve the effect of adjustable foaming ratio, lower production cost, and adjustable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

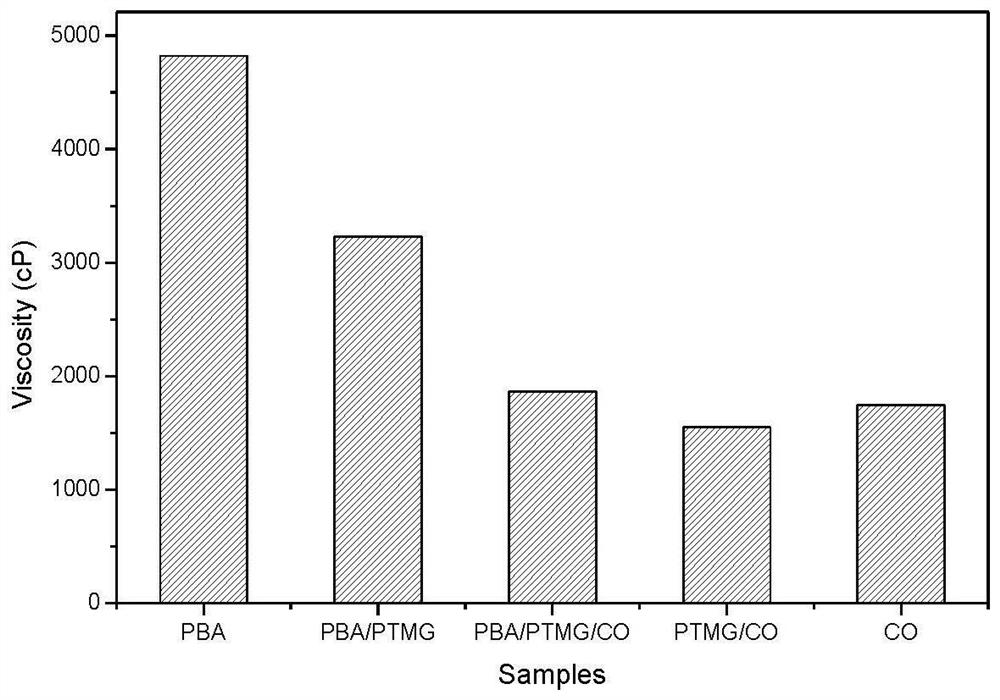

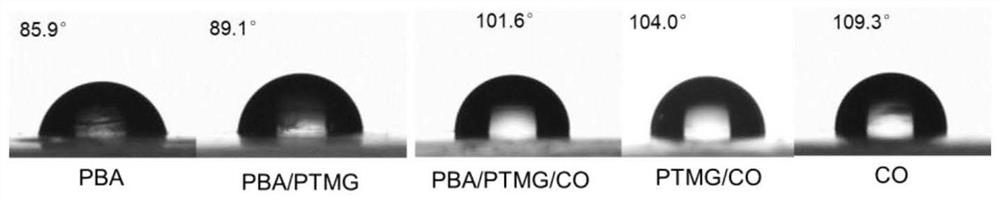

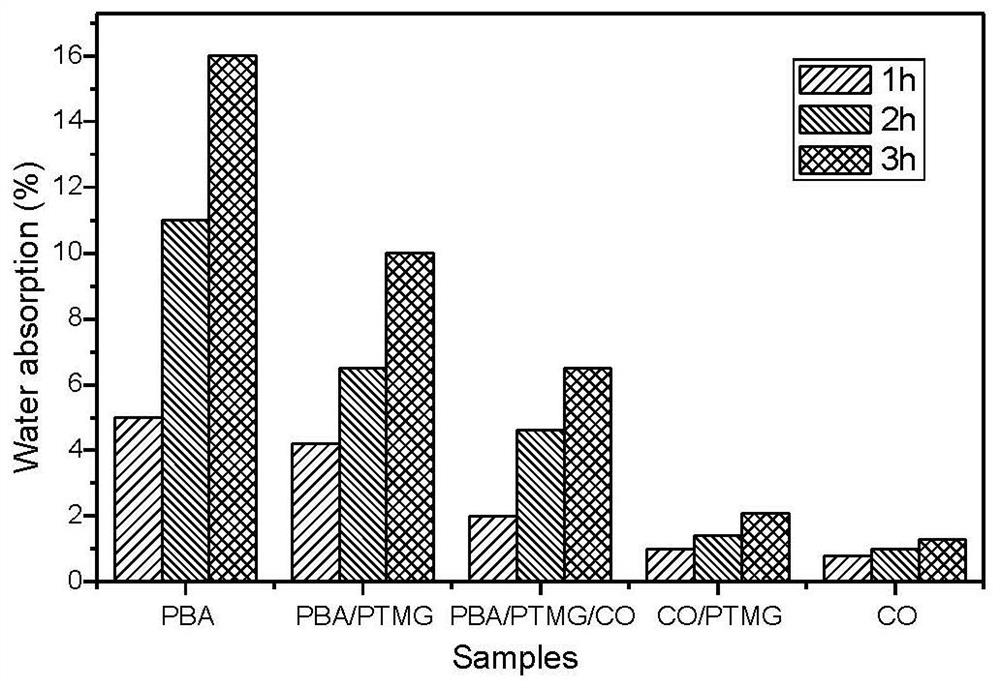

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of a single-component polyurethane foam adhesive for foamed ceramic tiles, the composition of the raw material formula is as follows:

[0031]

[0032]

[0033] According to the above ratio, mix castor oil polyol, propylene glycol polyether and poly-1,4-butylene adipate diol into a three-necked flask with a stirrer equipped with a thermometer, heat up to 110°C and vacuumize Dry for 2 hours to remove a small amount of water in the system to obtain a mixed polyol. Then the dehydrated mixed polyol and IPDI are fed according to the formula, the temperature is raised to 50°C, the stirring speed is increased and nitrogen gas is blown to start the reaction. Sampling and measuring the content of isocyanate groups in the polymer every 10 minutes, when the content of isocyanate reaches 7%-8%, cool down to 40°C, add dibutyltin dilaurate and triethanolamine (dibutyltin dilaurate The mass ratio of triethanolamine and triethanolamine is 1:2), after continu...

Embodiment 2

[0036] A preparation method of a single-component polyurethane foam adhesive for foamed ceramic tiles, the composition of the raw material formula is as follows:

[0037]

[0038]

[0039] According to the above ratio, mix castor oil polyol, polytetrahydrofuran diol and poly-1,4-butylene adipate diol into a three-necked flask with a stirrer equipped with a thermometer, heat up to 110°C and vacuumize Dry for 2 hours to remove a small amount of water in the system to obtain a mixed polyol. Then the dehydrated mixed polyol and IPDI are fed according to the formula, the temperature is raised to 50°C, the stirring speed is increased and nitrogen gas is blown to start the reaction. Sampling and measuring the content of isocyanate groups in the polymer every 10 minutes, when the content of isocyanate reaches 10%-11%, cool down to 40°C, add dibutyltin dilaurate and dimethylethanolamine (dilauric acid The mass ratio of dibutyltin and triethanolamine is 1:1.5), after continuing t...

Embodiment 3

[0042] A preparation method of a single-component polyurethane foam adhesive for foamed ceramic tiles, the composition of the raw material formula is as follows:

[0043]

[0044]

[0045] According to the above ratio, mix castor oil polyol, polytetrahydrofuran diol and poly-1,4-butylene adipate diol into a three-necked flask with a stirrer equipped with a thermometer, heat up to 110°C and vacuumize Dry for 2 hours to remove a small amount of water in the system to obtain a mixed polyol. Then the dehydrated mixed polyol and IPDI are fed according to the formula, the temperature is raised to 50°C, the stirring speed is increased and nitrogen gas is blown to start the reaction. Sampling and measuring the content of isocyanate groups in the polymer every 10 minutes, when the content of isocyanate reaches 8%-9%, cool down to 40°C, add dibutyltin dilaurate and dimethylethanolamine (dilauric acid The mass ratio of dibutyltin and triethanolamine is 1:1.5), after continuing to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface dry time | aaaaa | aaaaa |

| Surface dry time | aaaaa | aaaaa |

| Hard work time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com