Thermoplastic polyurethane elastomer foam material having density gradient, and preparation method thereof

A thermoplastic polyurethane and foaming material technology, which is applied in the field of thermoplastic polyurethane elastomer foaming material and its preparation, can solve the problems of coarse cells, low product density, complicated preparation process, etc., and achieve the effect of fine internal cell structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

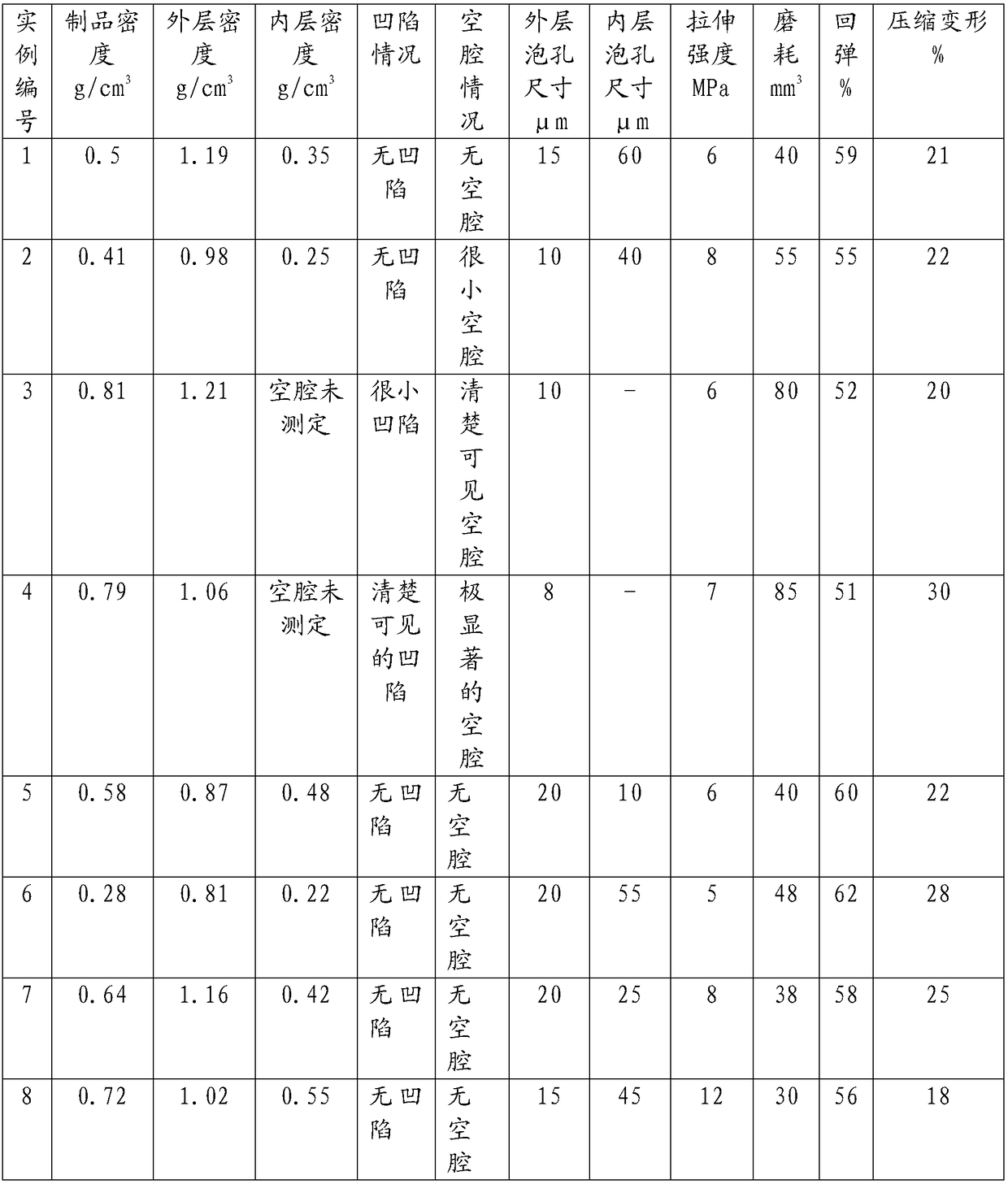

Examples

Embodiment 1

[0033] A preparation of a thermoplastic polyurethane elastomer foaming material with a density gradient, comprising the following steps:

[0034] Step 1: Weigh 100 parts by weight of the brand as E180 thermoplastic polyurethane elastomer (TPU) and 2 parts by weight of white oil were stirred evenly in a high mixer, and dried at 80° C. for 6 hours to obtain the first mixture.

[0035]Step 2: In the first mixture that step 1 obtains, add the sodium bicarbonate and silicon dioxide mixture that the mass ratio of 1 weight part is 9:1, wherein, the mesh number of silicon dioxide is 1200 mesh, adopts high mixer to mix After 3 minutes, stir evenly to obtain the second mixture.

[0036] Step 3: Set the temperature of the feed section, compression section, metering section and nozzle of the injection molding machine to 100°C, 155°C, 160°C, and 155°C respectively, and the mold temperature to 25°C. The mixture is put into an injection molding machine for injection molding processing to ...

Embodiment 2

[0039] A preparation of a thermoplastic polyurethane elastomer foaming material with a density gradient, comprising the following steps:

[0040] Step 1: Weigh 100 parts by weight of the brand as E185 thermoplastic polyurethane elastomer (TPU) and 2 parts by weight of white oil were stirred evenly in a high mixer, and dried at 80° C. for 6 hours.

[0041] Step 2: Add 1 weight part of sodium bicarbonate and calcium oxide mixture with a mass ratio of 7:3 to the first mixture obtained in step 1, wherein the calcium oxide has a mesh number of 1200 mesh, and mix it for 3 minutes with a high mixer , and stir evenly to obtain the second mixture.

[0042] Step 3: Set the temperature of the feed section, compression section, metering section and nozzle of the injection molding machine to 100°C, 160°C, 165°C, and 160°C respectively, and the mold temperature to 25°C, and put the mixture obtained in step 2 into Injection molding is performed in an injection molding machine to obtain a ...

Embodiment 3

[0045] A preparation of a thermoplastic polyurethane elastomer foaming material with a density gradient, comprising the following steps:

[0046] Step 1: Weigh 100 parts by weight of the brand as E190 thermoplastic polyurethane elastomer (TPU) and 2 parts by weight of white oil were stirred evenly in a high mixer, and dried at 80° C. for 6 hours.

[0047] Step 2: Add 1 part by weight of azodicarbonamide and silicon dioxide mixture with a mass ratio of 8.5:1.5 to the first mixture obtained in step 1, wherein the mesh number of silicon dioxide is 1200 mesh, using high-mixing Machine mixing for 3 minutes, stirring evenly to obtain the second mixture.

[0048] Step 3: Set the temperature of the feed section, compression section, metering section and nozzle of the injection molding machine to 100°C, 165°C, 170°C, and 165°C respectively, and the mold temperature to 25°C, and put the mixture obtained in step 2 into Injection molding is performed in an injection molding machine to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com