Polylactic acid foaming method

A technology of polylactic acid foaming and polylactic acid resin, which is applied in the field of polylactic acid foaming, can solve problems such as difficulty in obtaining high foaming ratio foaming materials, inability to wrap foaming agent to escape, and difficulty in foaming molding, etc., to achieve foaming Controllable magnification, uniform cell size, and high foaming magnification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

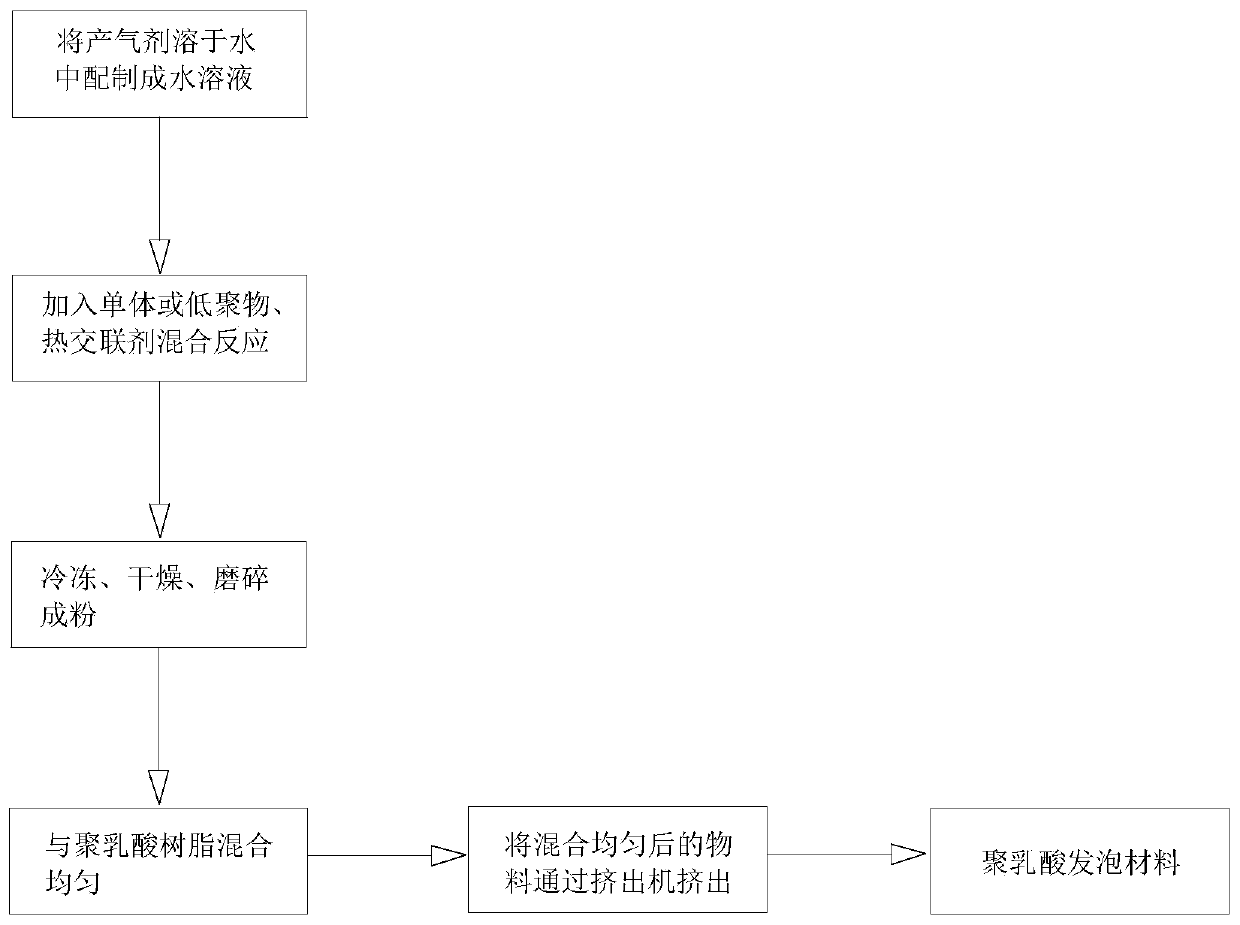

Method used

Image

Examples

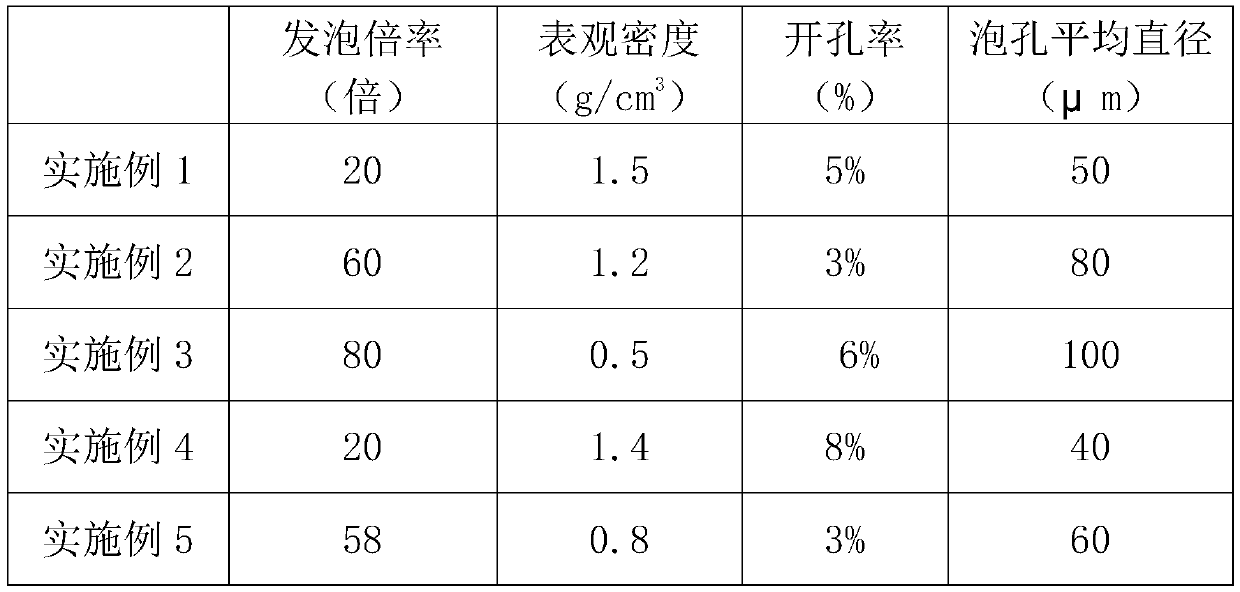

Embodiment 1

[0057] First, urea is dissolved in water to prepare an aqueous solution with a mass concentration of 1%; then acrylic acid and azobisisobutylimidazole hydrochloride are mixed with the aqueous solution of urea according to a mass ratio of 1:0.05, and acrylic acid and azobisisobutylimidazole The dosage ratio of morphine hydrochloride and the above-mentioned urea aqueous solution is 1:50; mix and react at 50°C for 1 hour to obtain an initial reaction mixture, which is freeze-dried in a freeze-drying device and then pulverized into powder; Then, 100 parts by weight of polylactic acid resin and 5 parts by weight of the above-mentioned pulverized powder are mixed uniformly; the uniformly mixed material is added to the extruder, and the temperature of the extruder is set at 150 ° C and the screw speed is 80 Rotation / min, head pressure not less than 8Mpa, material not exceeding 2 / 3 volume of the hopper, melt extrusion, heat urea to expand during the extrusion process, making the polyla...

Embodiment 2

[0059] First, urea is dissolved in water to prepare an aqueous solution with a mass concentration of 10%; then acrylic acid and azobisisobutylimidazoline hydrochloride are mixed with the aqueous solution of urea in a mass ratio of 1:3, and acrylic acid and azobisisobutylimidazoline The dosage ratio of hydrochloride and the above-mentioned urea aqueous solution is 1:70; mix and react at 50°C for 2 hours to obtain the initial reaction mixture, which is freeze-dried in a freeze-drying device and then ground into powder; then Mix 100 parts by weight of polylactic acid resin and 15 parts by weight of the above-mentioned pulverized powder; add the uniformly mixed material into the extruder, set the temperature of the extruder to 180°C, and the screw speed to 90 rpm / min, the head pressure is not lower than 8Mpa, and the material does not exceed 2 / 3 of the volume of the hopper. Melt extrusion is carried out. During the extrusion process, the urea is heated to expand, so that the polyl...

Embodiment 3

[0061] First, urea is dissolved in water to prepare an aqueous solution with a mass concentration of 20%; then, acrylic acid and azobisisobutylimidazole hydrochloride are mixed with the aqueous solution of urea according to a mass ratio of 1:5, and acrylic acid and azobisisobutylimidazole The dosage ratio of morphine hydrochloride and the above-mentioned urea aqueous solution is 1:100; mix and react at 80°C for 1.5 hours to obtain the initial reaction mixture, which is freeze-dried in a freeze-drying device and then ground into powder ; Then the polylactic acid resin of 100 weight parts and the above-mentioned pulverized powder of 30 weight parts are mixed uniformly; The material mixed homogeneously is joined in the extruder, the temperature of setting extruder 200 ℃, screw speed are 110 rpm, head pressure not less than 8Mpa, material not exceeding 2 / 3 of the volume of the hopper, melt extrusion, heat urea to expand during the extrusion process, so that the polylactic acid melt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com