Biodegradable pearl cotton and preparation method thereof

A biodegradable and pearl cotton technology, applied in the field of packaging materials, can solve the problems of high production cost, residual foaming agent, complicated process, etc., and achieve the effects of high production efficiency, increased strength and resilience, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] After the wheat straw is harvested, it is naturally air-dried and air-dried to reduce the moisture content to below 15%, and then it is preliminarily sorted to ensure that there is no mildew or deterioration, mixed with sand, stones or other sundries; then the straw is further dried with hot air, It is crushed with a rotary knife type plant straw grinder until the particle diameter is less than 70 microns, and dried until the water content is lower than 2%, so as to obtain the straw powder filling material.

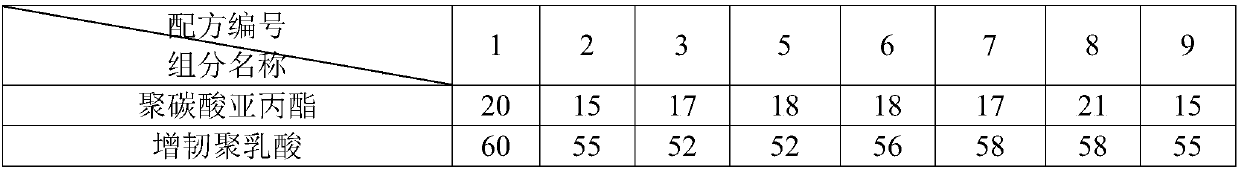

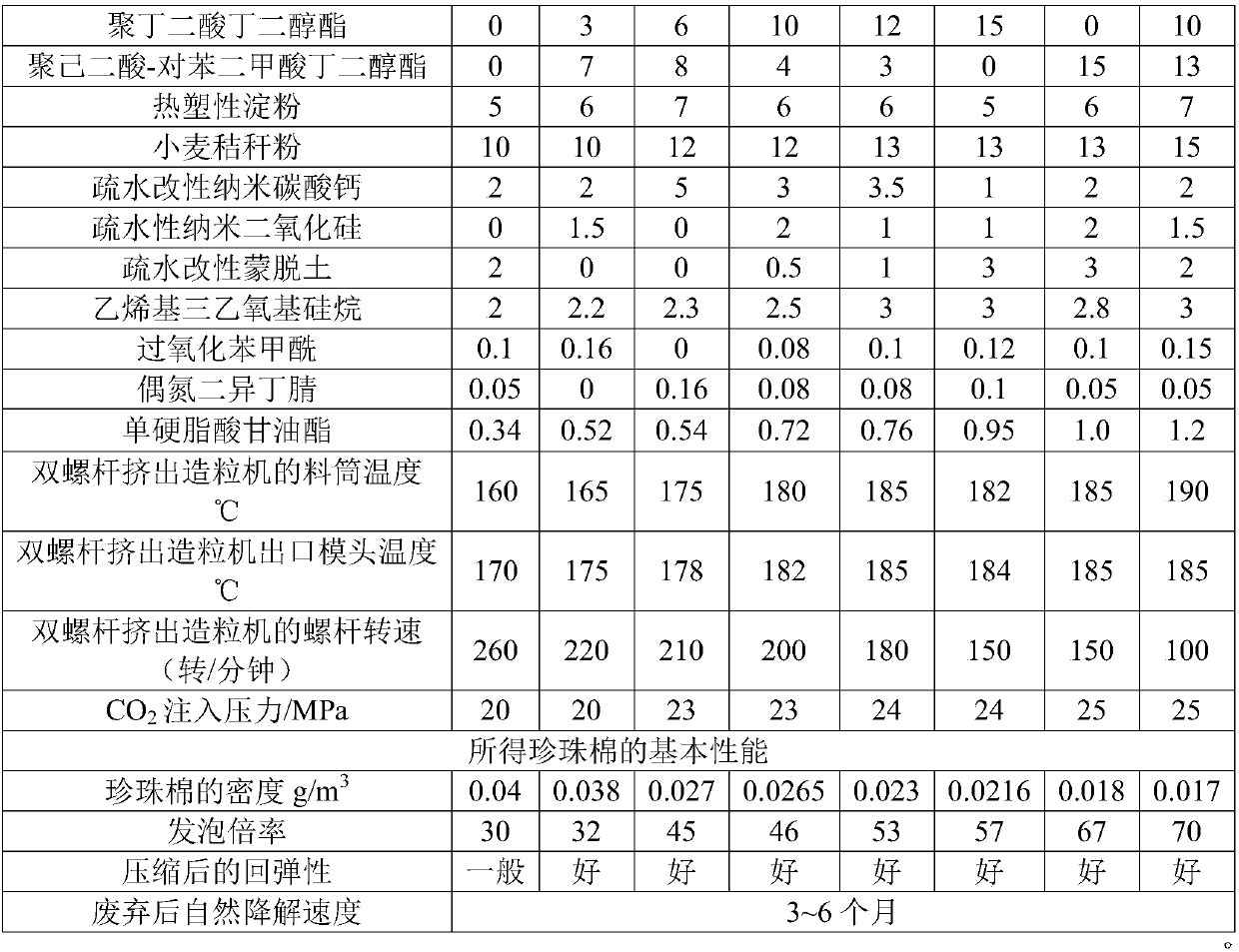

[0033] According to the formula ratio in Table 1:

[0034] (1) Weighing the biodegradable polymer main material, straw powder filler and nucleating agent, adding them to the mixer, stirring and mixing evenly to obtain the premix;

[0035] (2) Select a parallel twin-screw extrusion granulator with a screw length-to-diameter ratio of 35:1 to 45:1, and add the premix obtained in step (1) into the hopper of the twin-screw extrusion granulator, Set the barrel temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com