Preparation method of open-cell propylene polymer foamed beads

An expanded bead and propylene technology, which is applied in the field of preparation of open-cell propylene polymer expanded beads, can solve the problems of cumbersome process and high equipment requirements, and achieves simple process, high equipment requirements and high expansion ratio. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

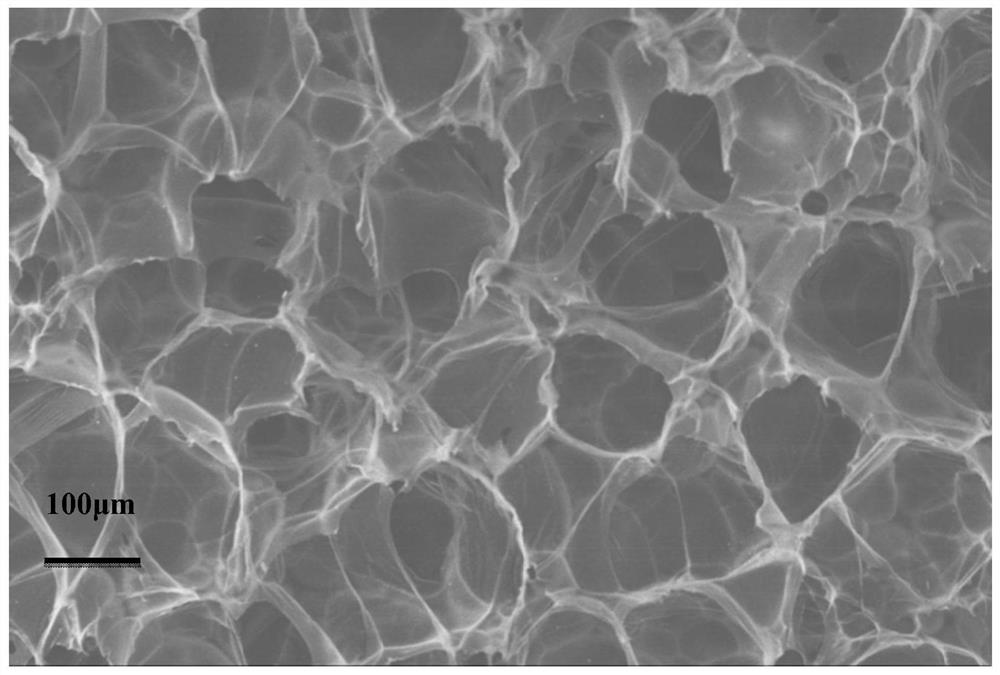

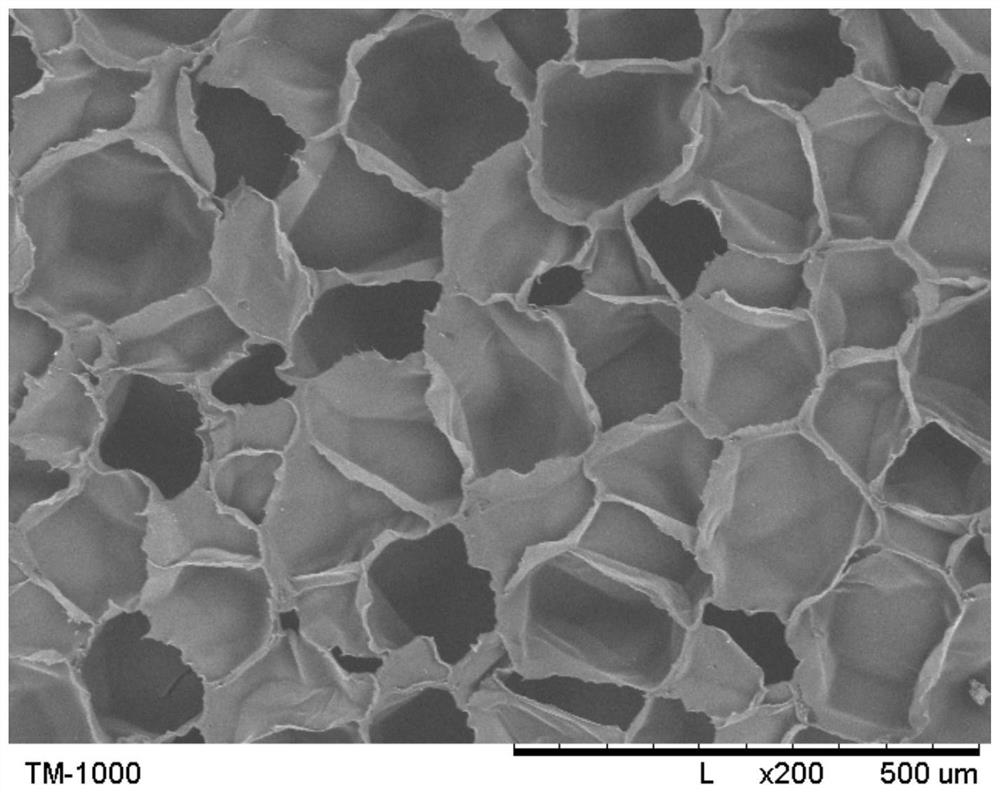

Image

Examples

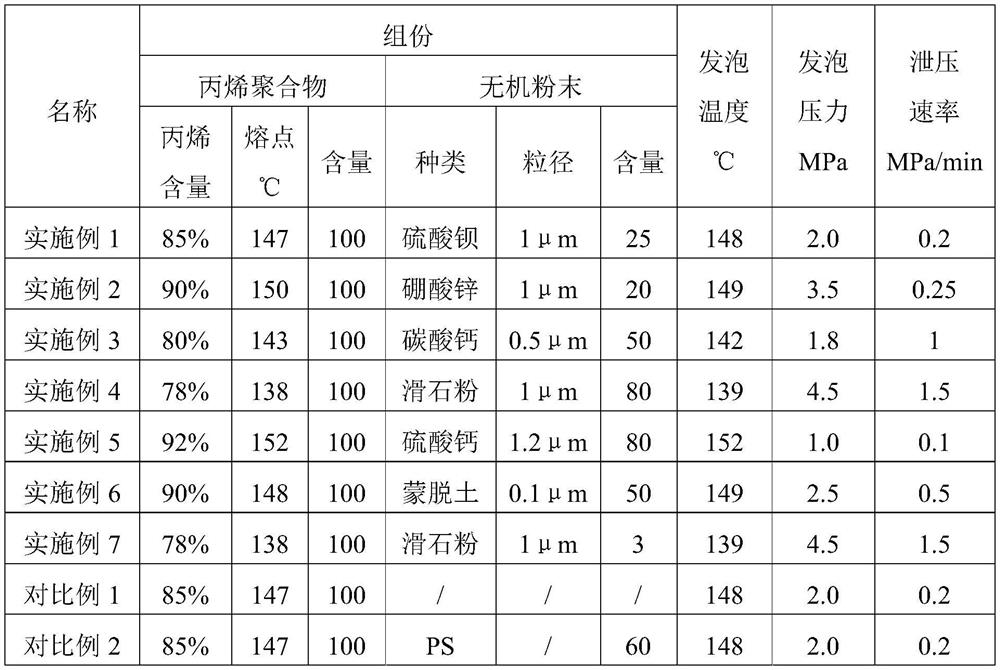

Embodiment 1

[0079] Weigh 100 parts by weight of propylene polymer (85% by weight of propylene) and 25 parts by weight of barium sulfate, wherein the melting point of the propylene polymer is 147° C. and the particle size of barium sulfate is 1 μm.

[0080] The above-mentioned raw materials were mixed by a high-mixer and then added to a twin-screw extruder, and then pulled and pelletized by a pelletizer to obtain blended particles with a diameter of 1.0 mm and a length of 1.5 mm (length-diameter ratio of 1.5).

[0081] 1kg of the above-mentioned blended particles was placed in a 50L autoclave, 30L of water was added, 2.0MPa of carbon dioxide was introduced, and the reactor jacket was heated to 148°C with steam, and the opening of the unloading valve was controlled to 0.2MPa / The microparticles were released to atmospheric pressure at a pressure release rate of min, and cooled with water, dried, and dried in an oven at 80 °C for 8 hours. The obtained open-cell propylene polymer foam beads we...

Embodiment 2

[0083] Weigh 100 parts by weight of a propylene polymer (90% by weight of propylene) and 20 parts by weight of zinc borate, wherein the melting point of the propylene polymer is 150° C. and the particle size of the zinc borate is 2 μm.

[0084] The above-mentioned raw materials are mixed with a high-mixer and then added to a twin-screw extruder for heating and extrusion, and are pulled and pelletized by a pelletizer to obtain a total diameter of 0.9mm and a length of 1.3mm (length-diameter ratio is 1.44). Mixed particles.

[0085] 1kg of the above-mentioned particles was placed in a 50L autoclave, 30L of water was added, the carbon dioxide of 3.5MPa was introduced, and the water vapor was heated to 149° C. through the reactor jacket. The pressure rate of the particles was released to atmospheric pressure, and the particles were cooled by water, dried, and dried in an oven at 80 ° C for 8 hours. The obtained open-cell propylene polymer foam beads were recorded as sample 2#, and...

Embodiment 3

[0087] Weigh 100 parts by weight of a propylene polymer (80% by weight of propylene) and 50 parts by weight of calcium carbonate, wherein the melting point of the propylene polymer is 143° C. and the particle size of the calcium carbonate is 0.5 μm.

[0088] The above-mentioned raw materials are mixed with a high-speed mixer and then added to a twin-screw extruder for heating and extrusion, and are pulled and pelletized by a pelletizer to obtain a blended particle with a diameter of 1mm and a length of 1.5mm (length-diameter ratio is 1.5). .

[0089] 1kg of the above-mentioned particles was placed in a 50L autoclave, 30L of water was added, 1.8MPa of carbon dioxide was introduced, and the water vapor was heated to 142° C. by the reactor jacket. The pressure rate of the particles was released to atmospheric pressure, and the particles were cooled with water, dried, and dried in an oven at 80 ° C for 8 hours. The obtained open-cell propylene polymer foam beads were recorded as s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com