Patents

Literature

102 results about "Pressure Rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

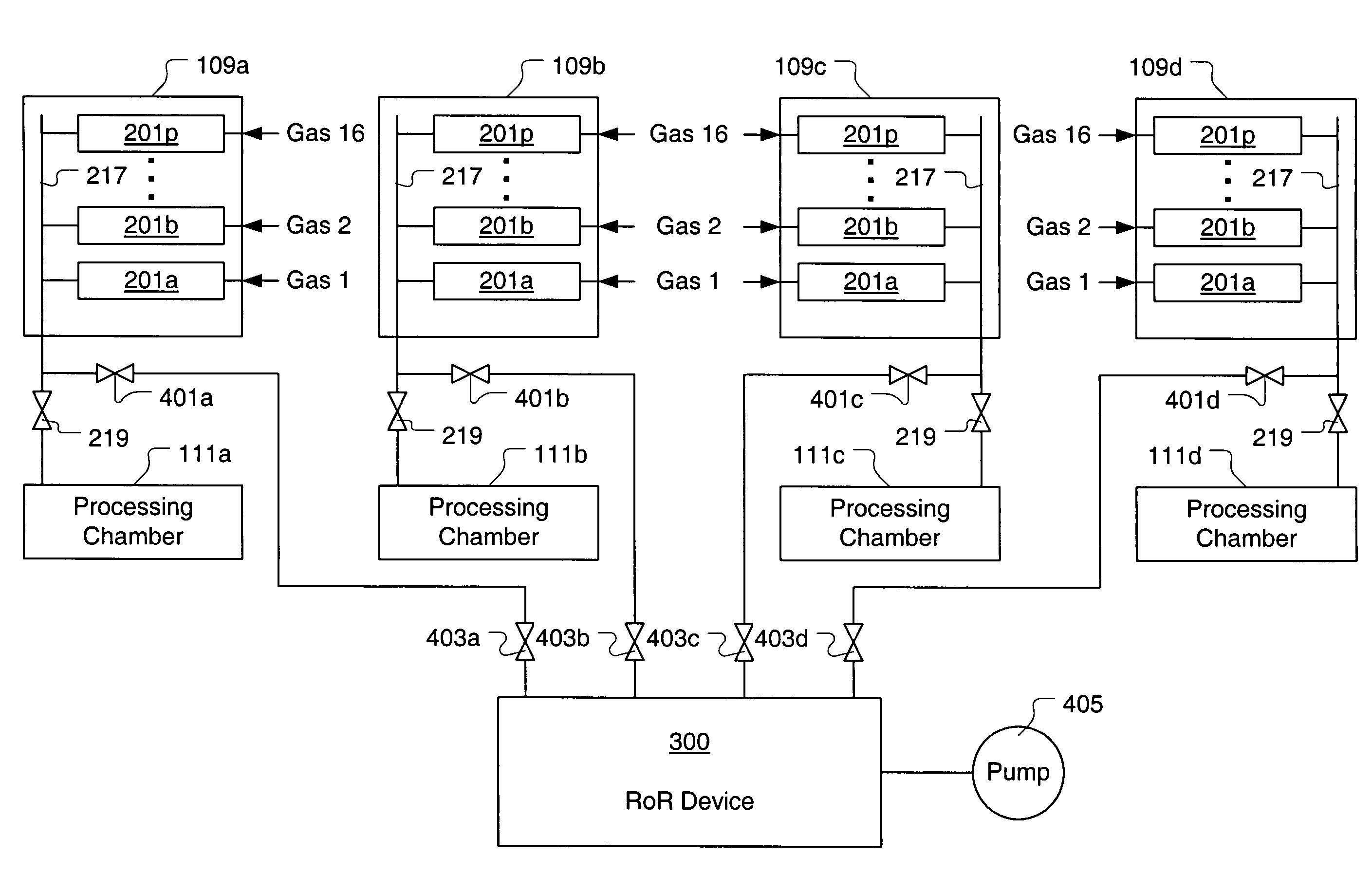

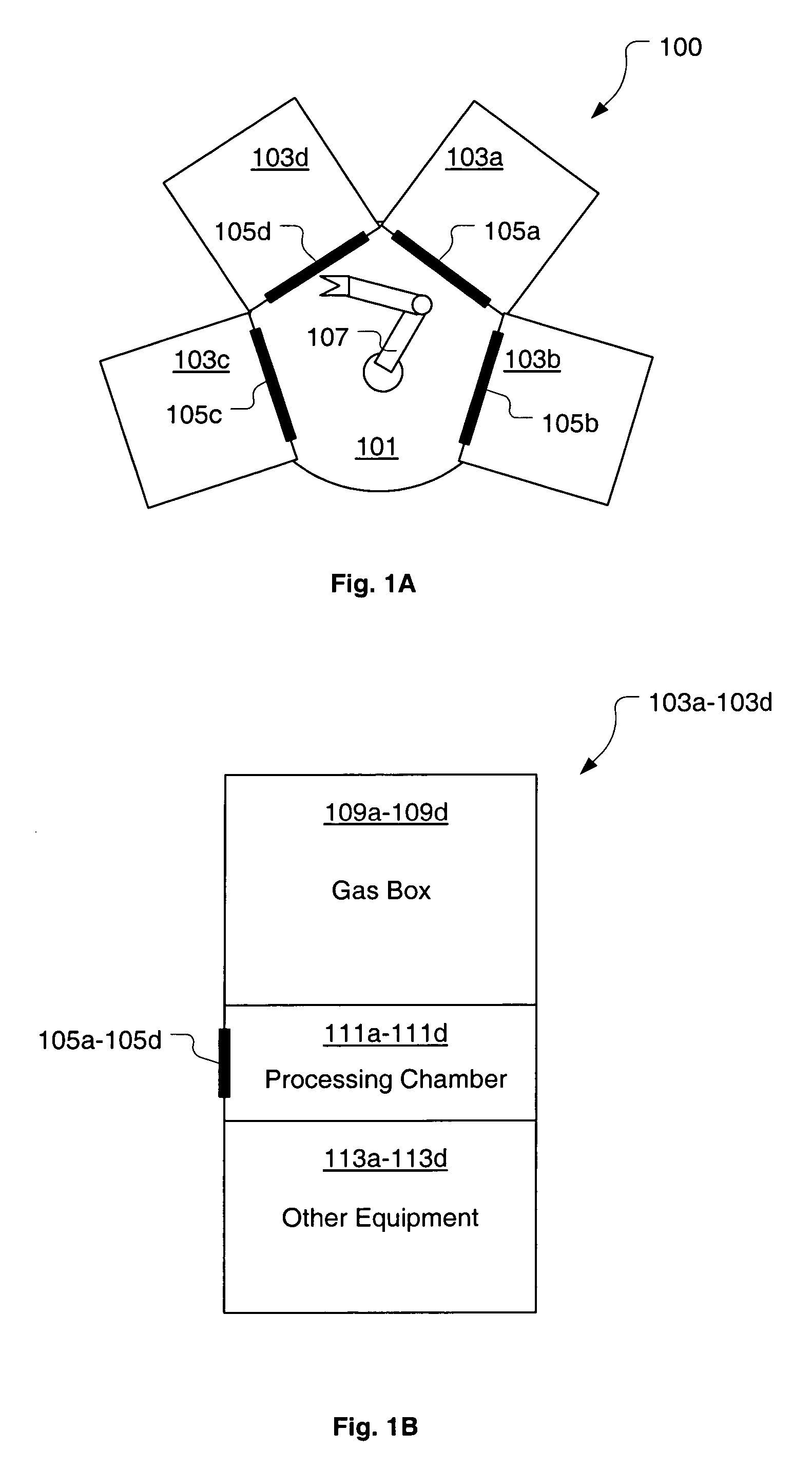

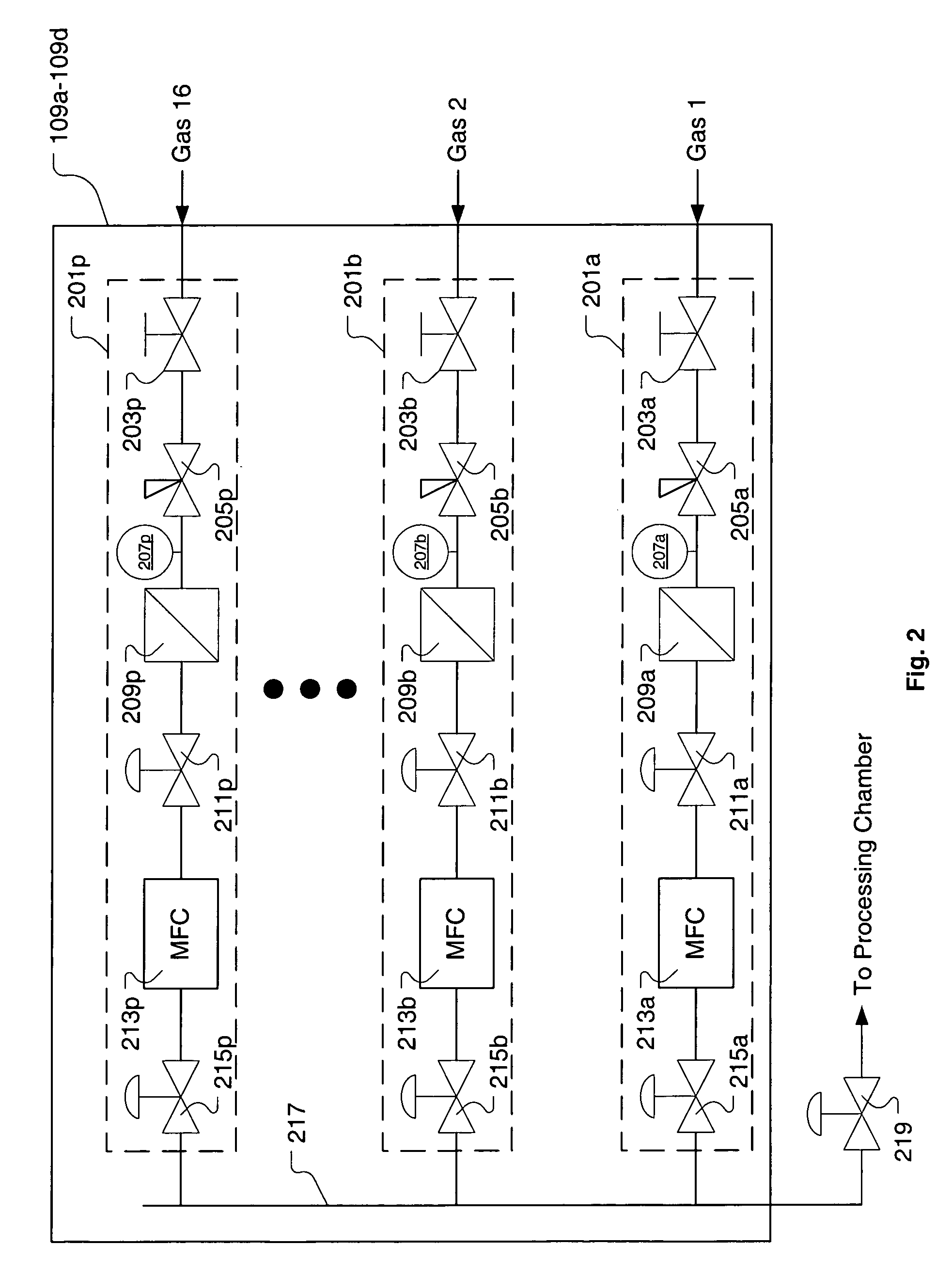

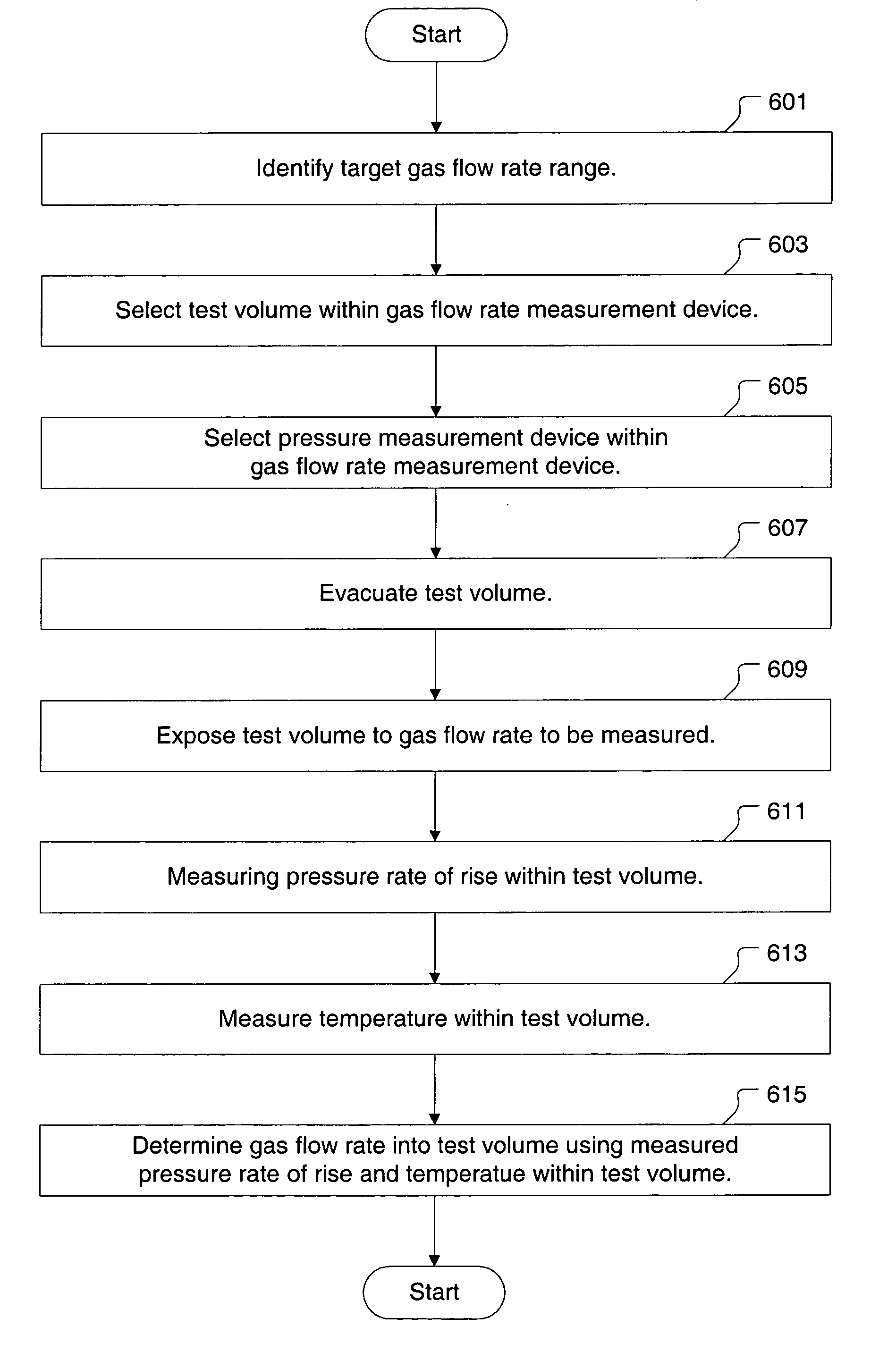

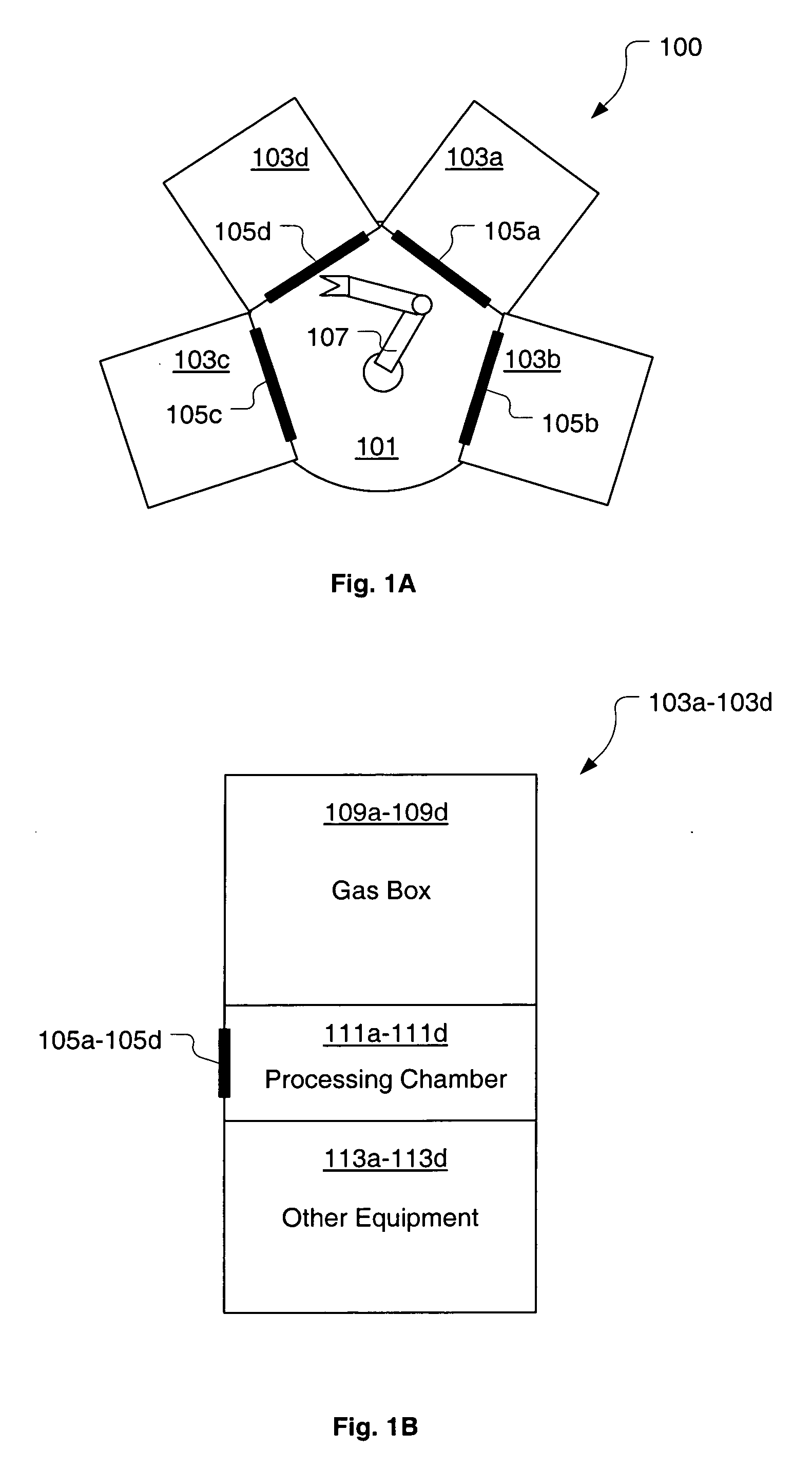

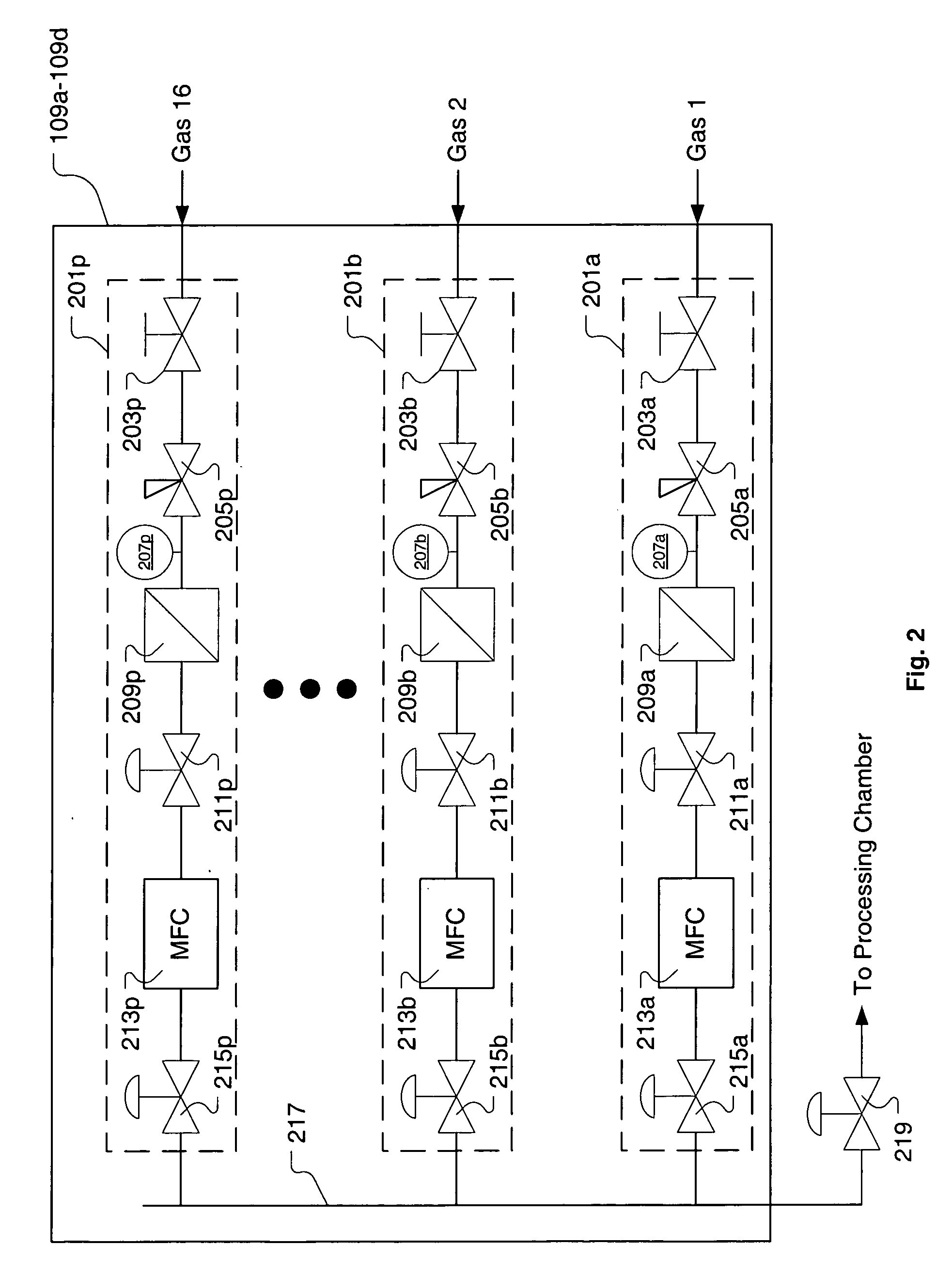

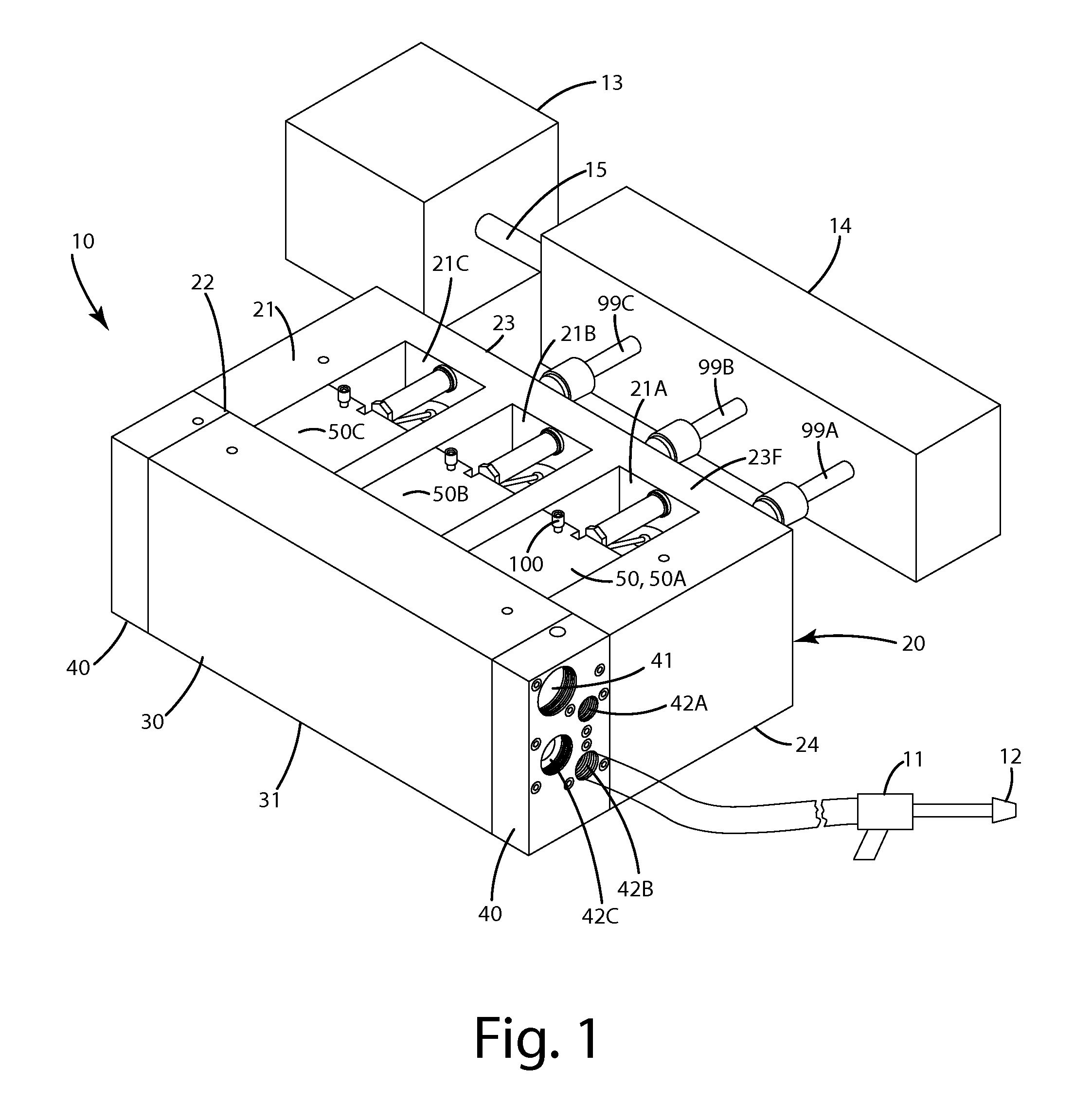

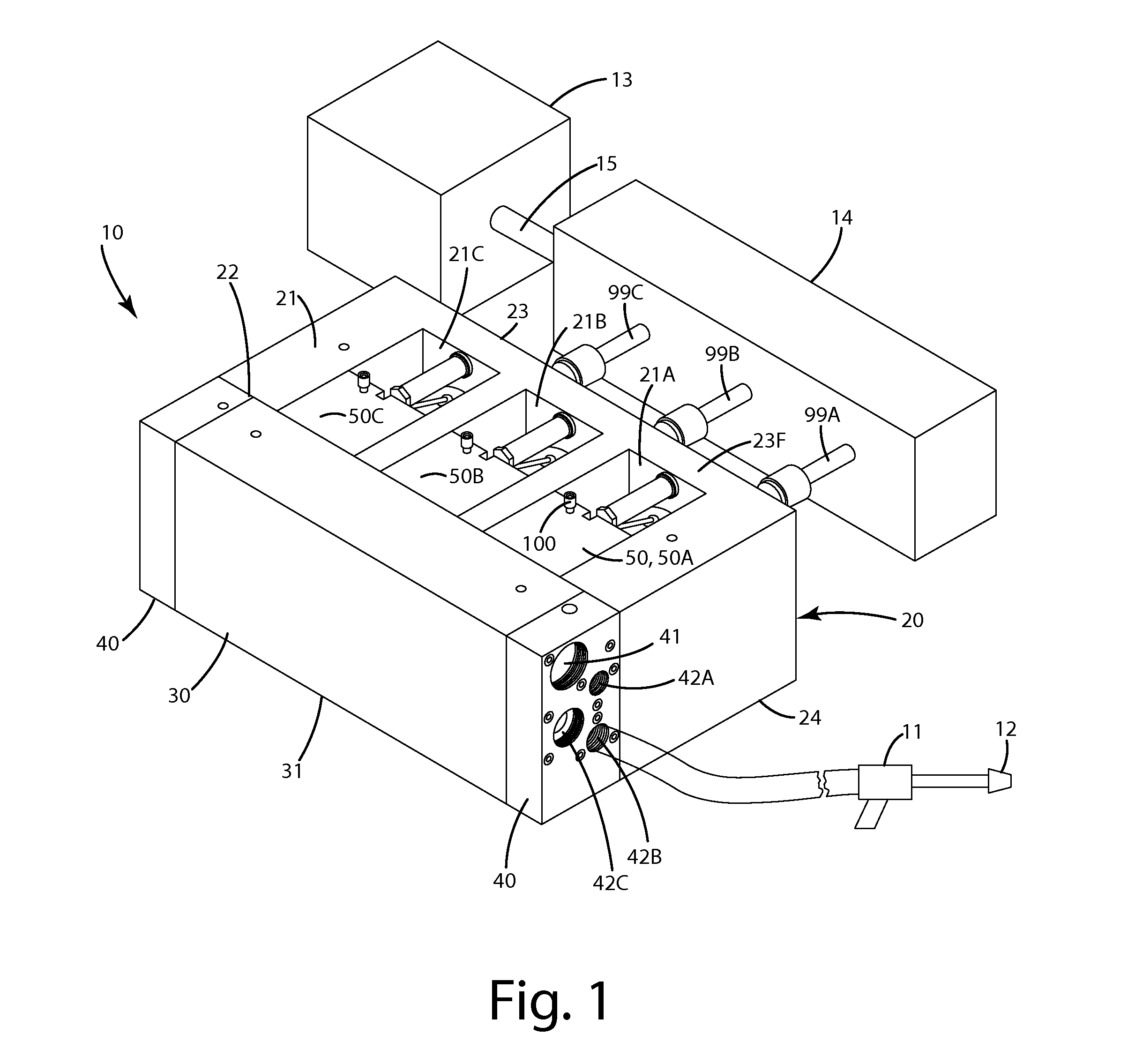

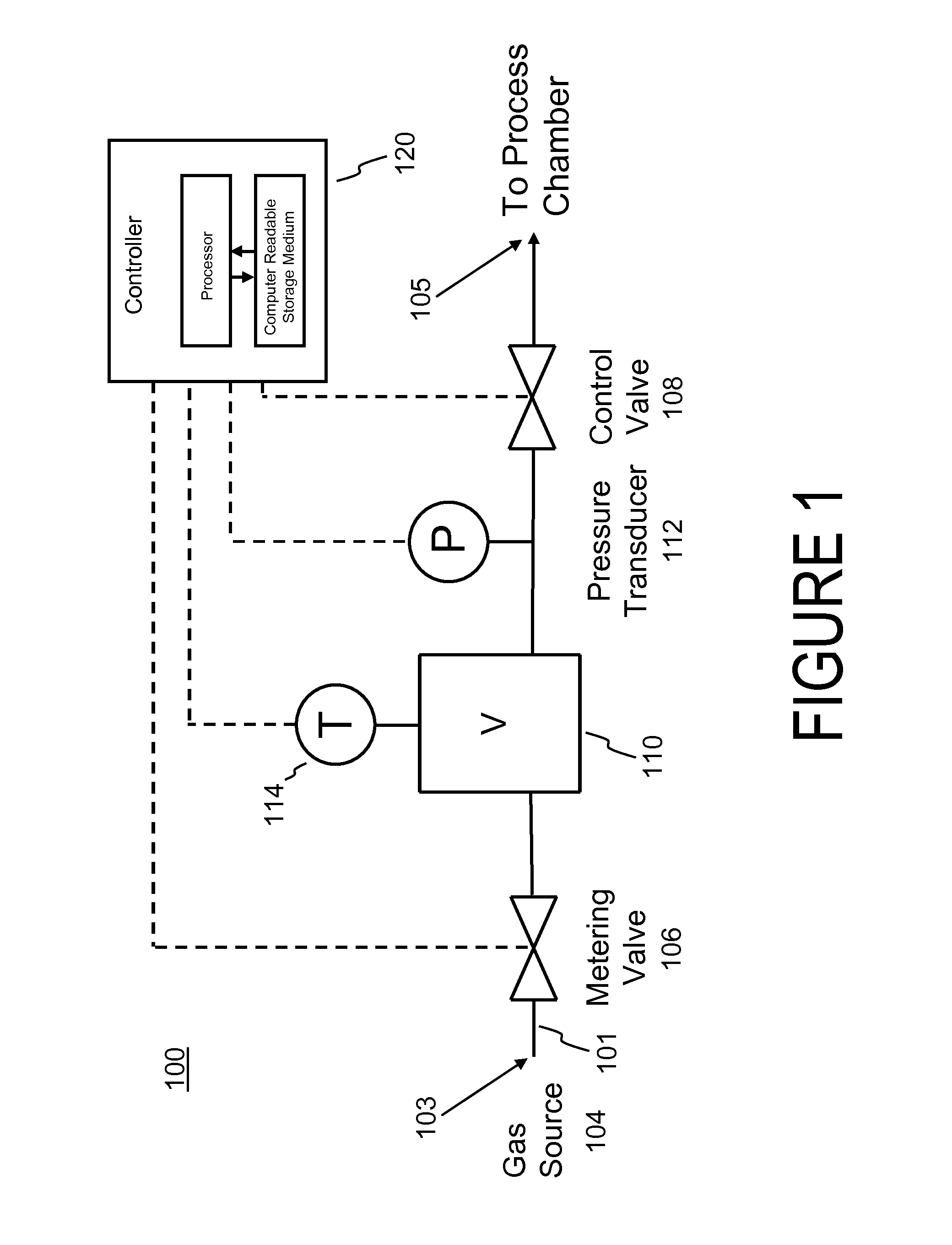

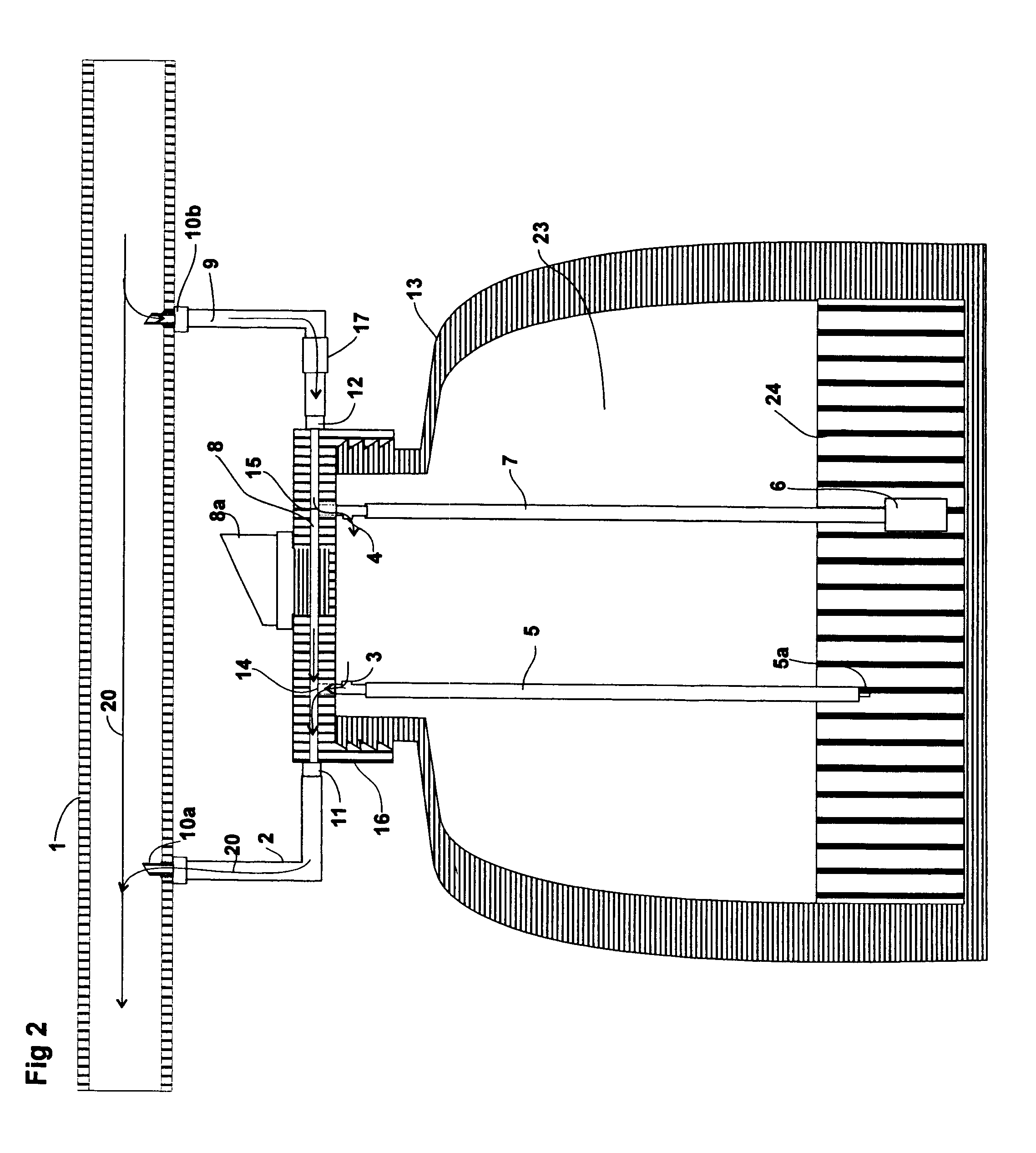

System and method for gas flow verification

A gas flow rate verification apparatus is provided for shared use in a multiple tool semiconductor processing platform. The gas flow rate verification apparatus is defined to measure a pressure rate of rise and temperature within a test volume for determination of a corresponding gas flow rate. The apparatus includes first and second volumes, wherein the second volume is larger than the first volume. The apparatus also includes first and second pressure measurement devices, wherein the second pressure measurement device is capable of measuring higher pressures. Based on the target gas flow rate to be measured, either the first or second volume can be selected as the test volume, and either the first or second pressure measurement device can be selected to measure the pressure in the test volume. Configurability of the apparatus enables accurate measurement of gas flow rates over a broad range and in an time efficient manner.

Owner:LAM RES CORP

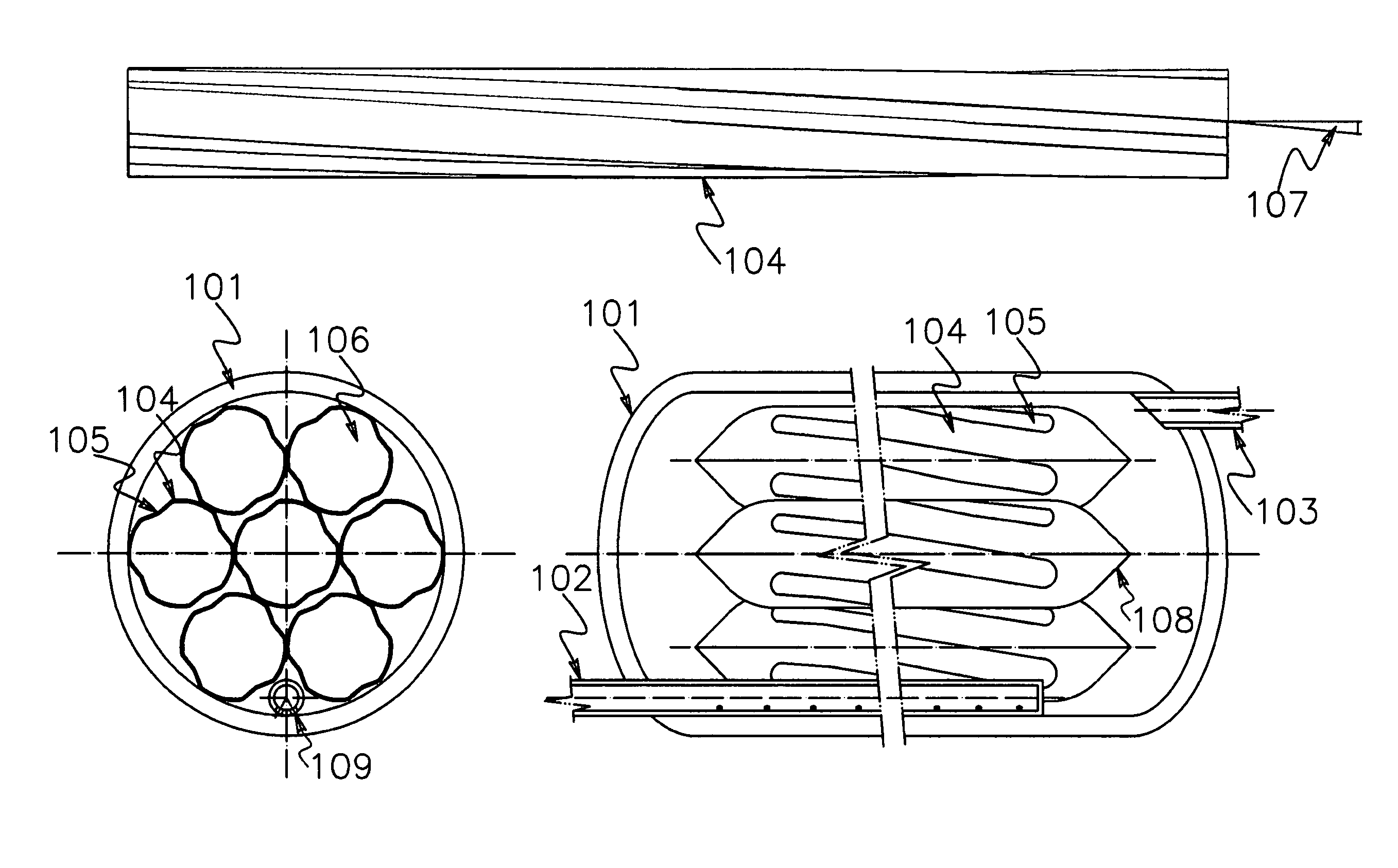

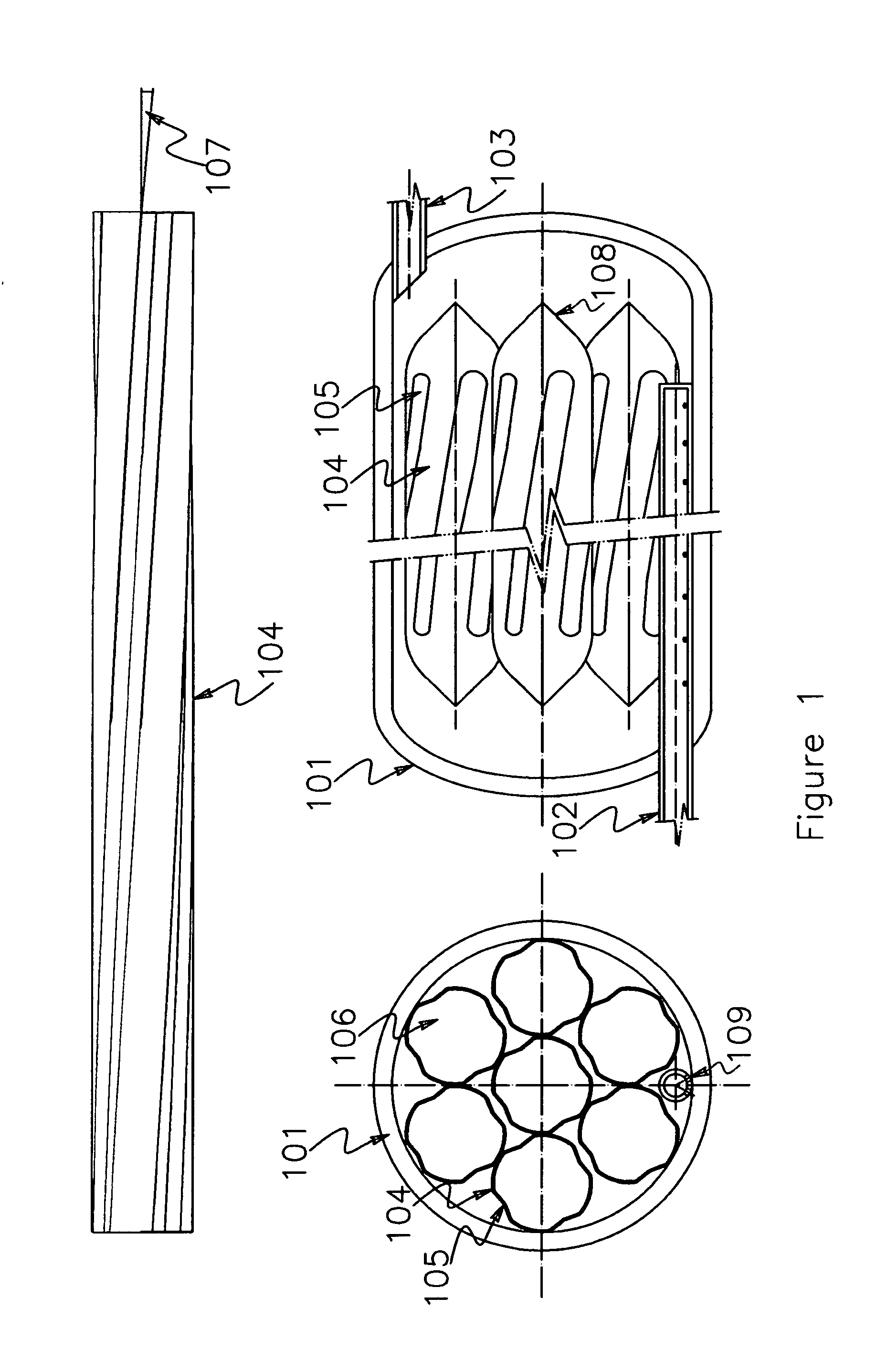

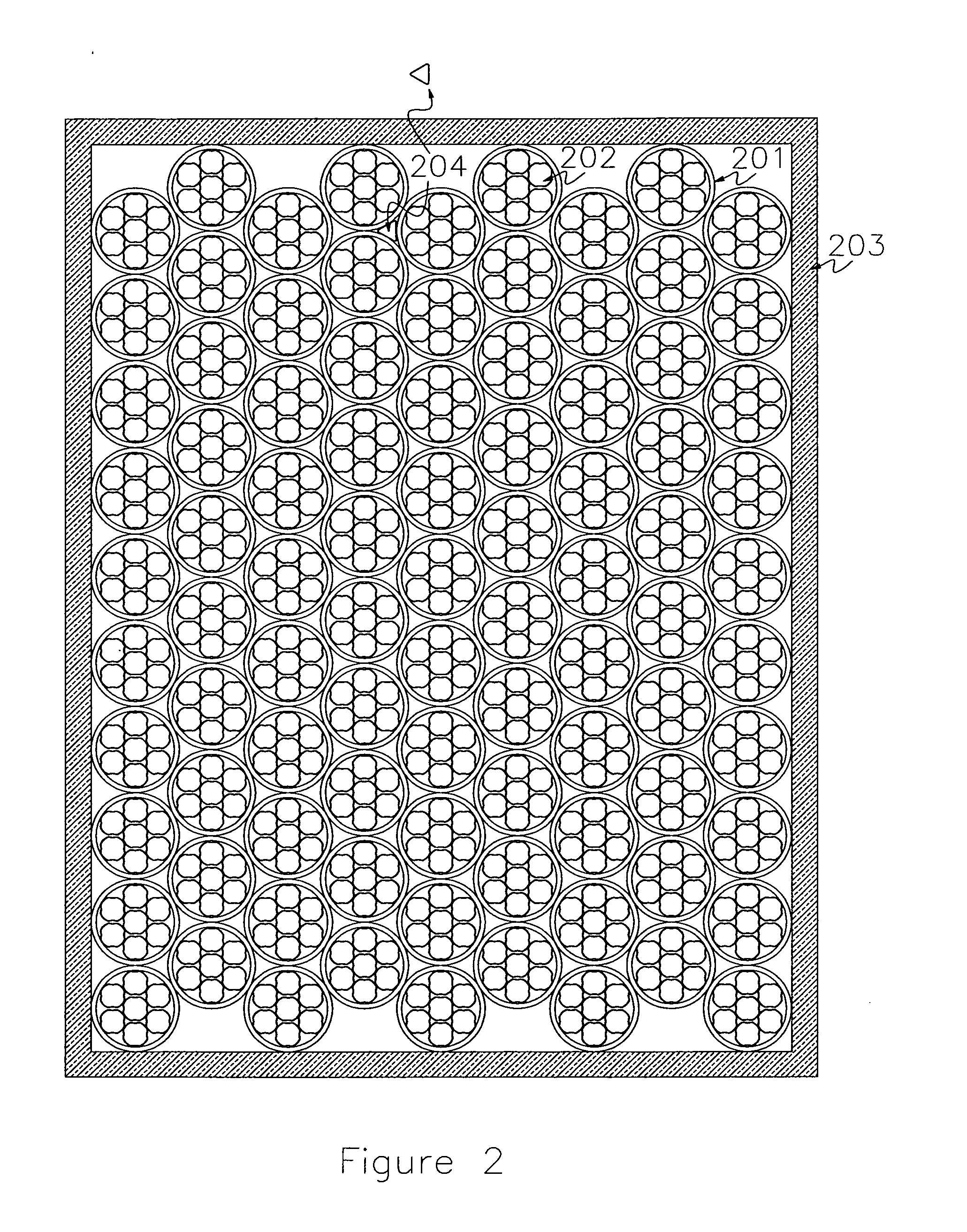

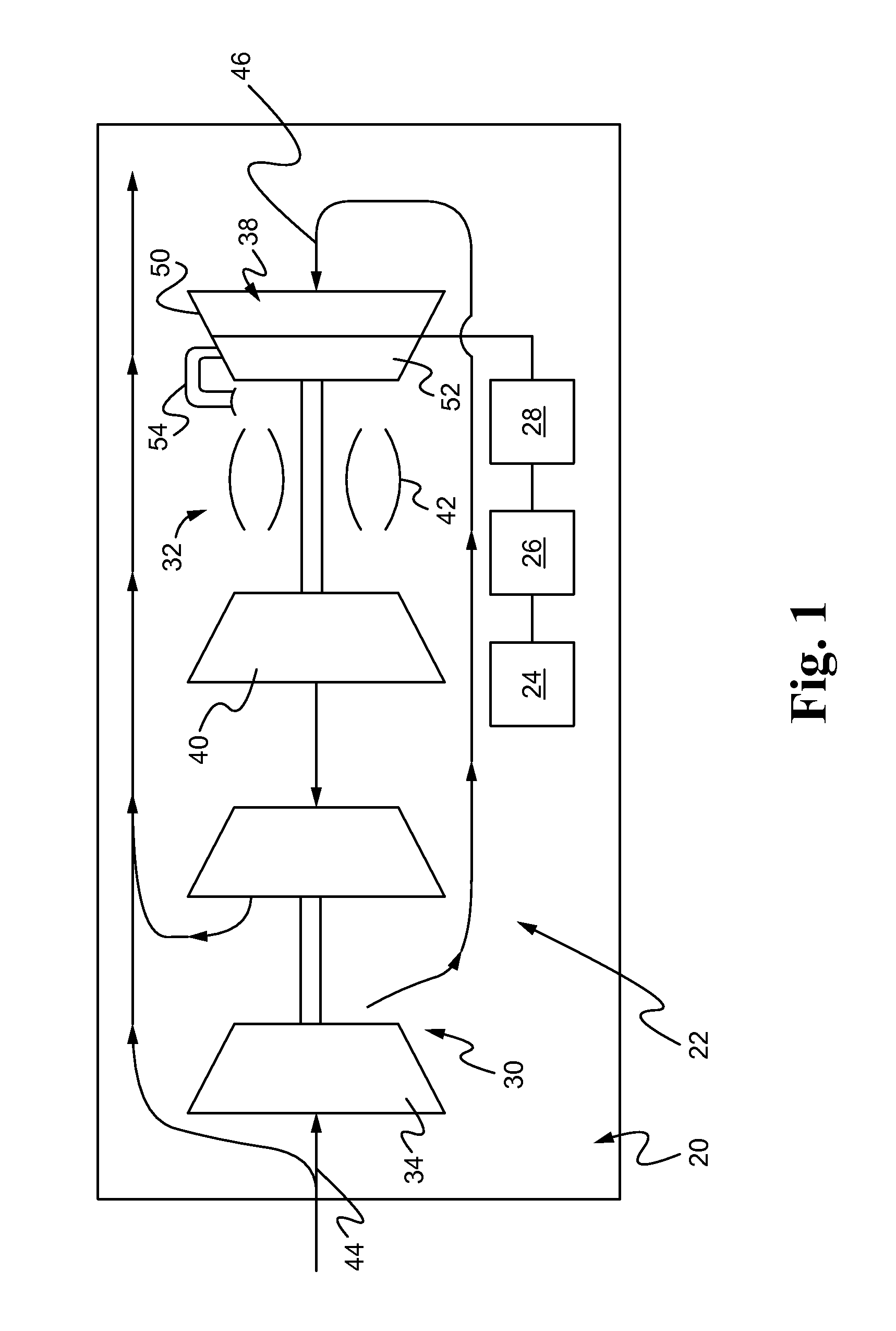

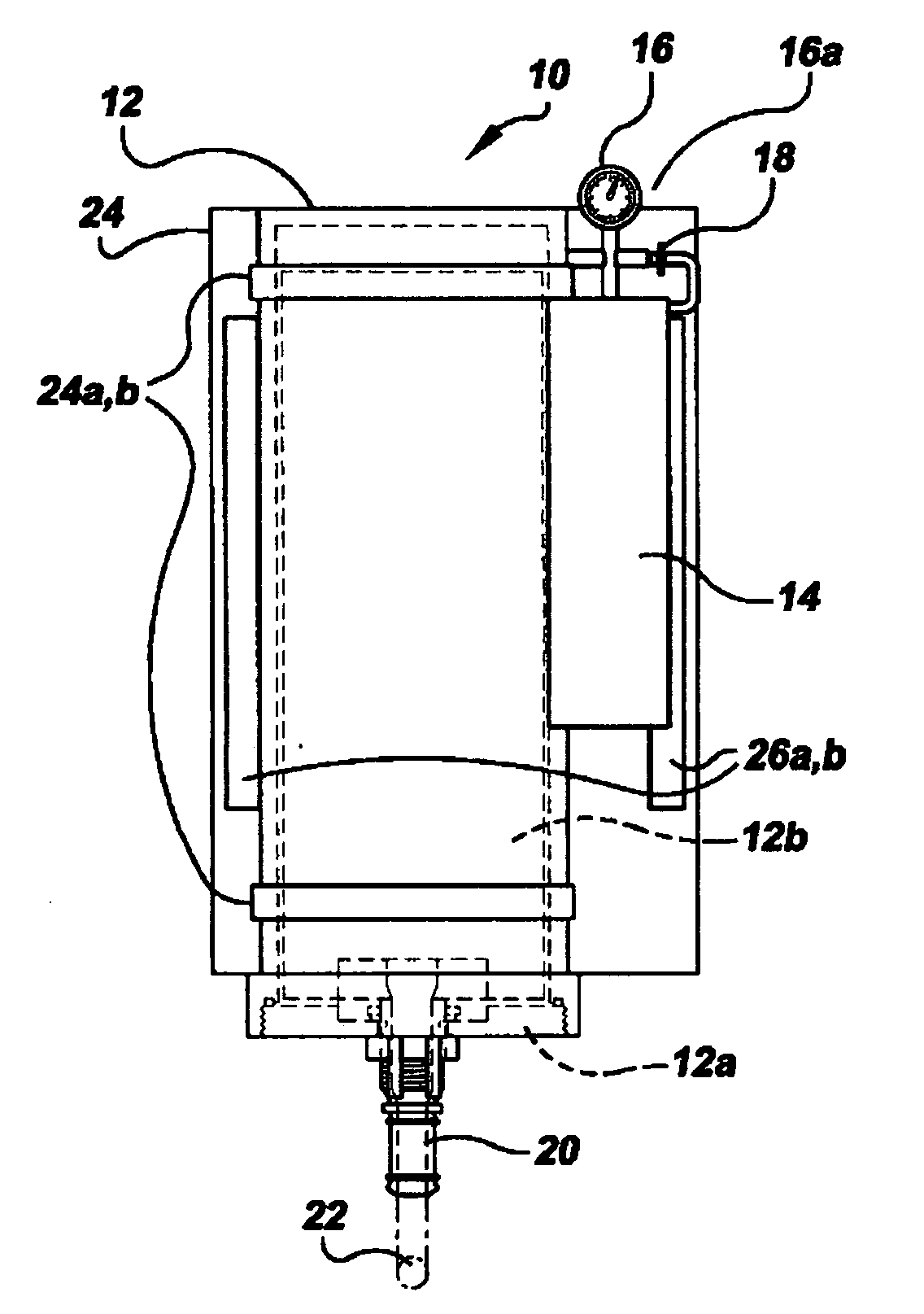

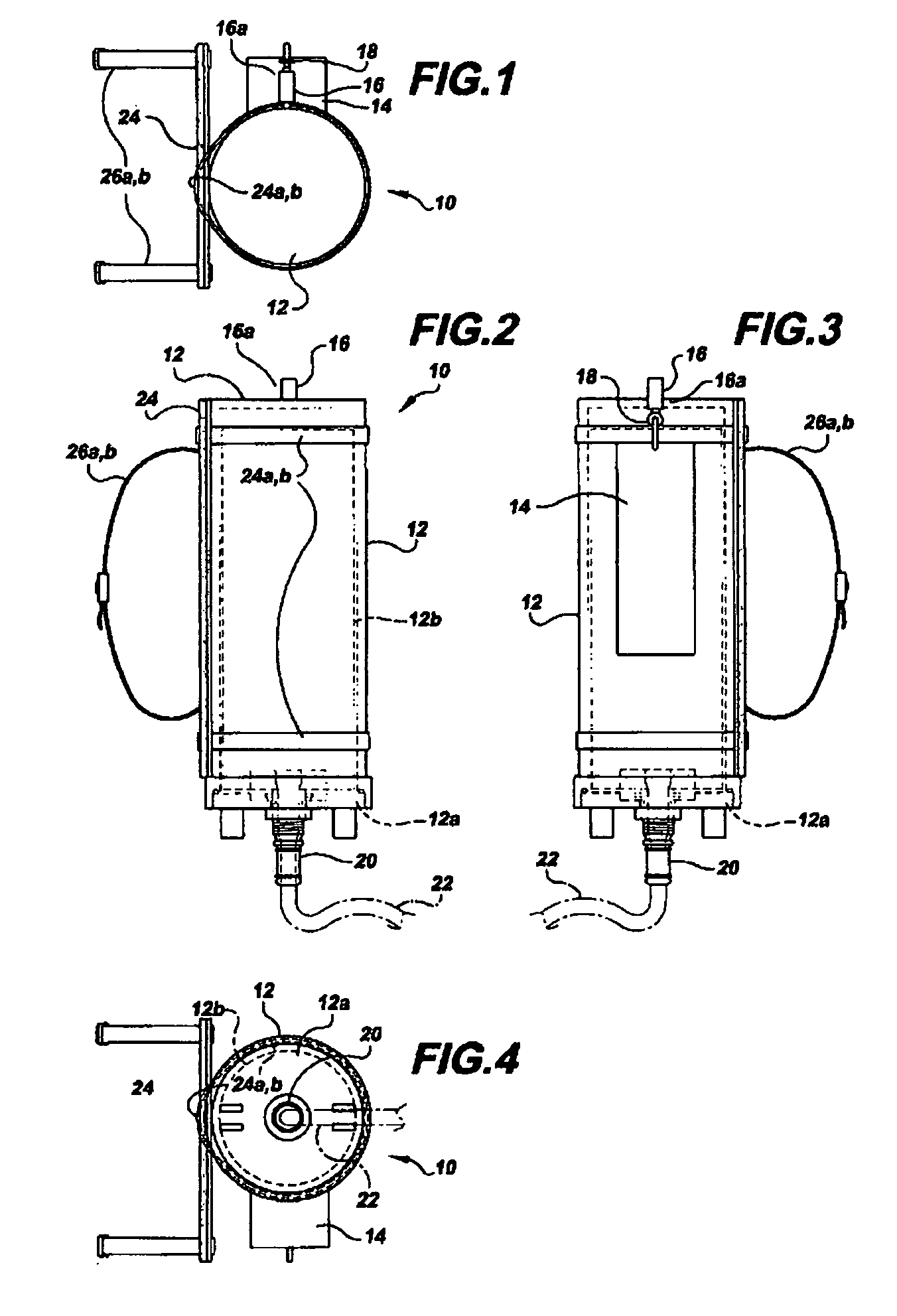

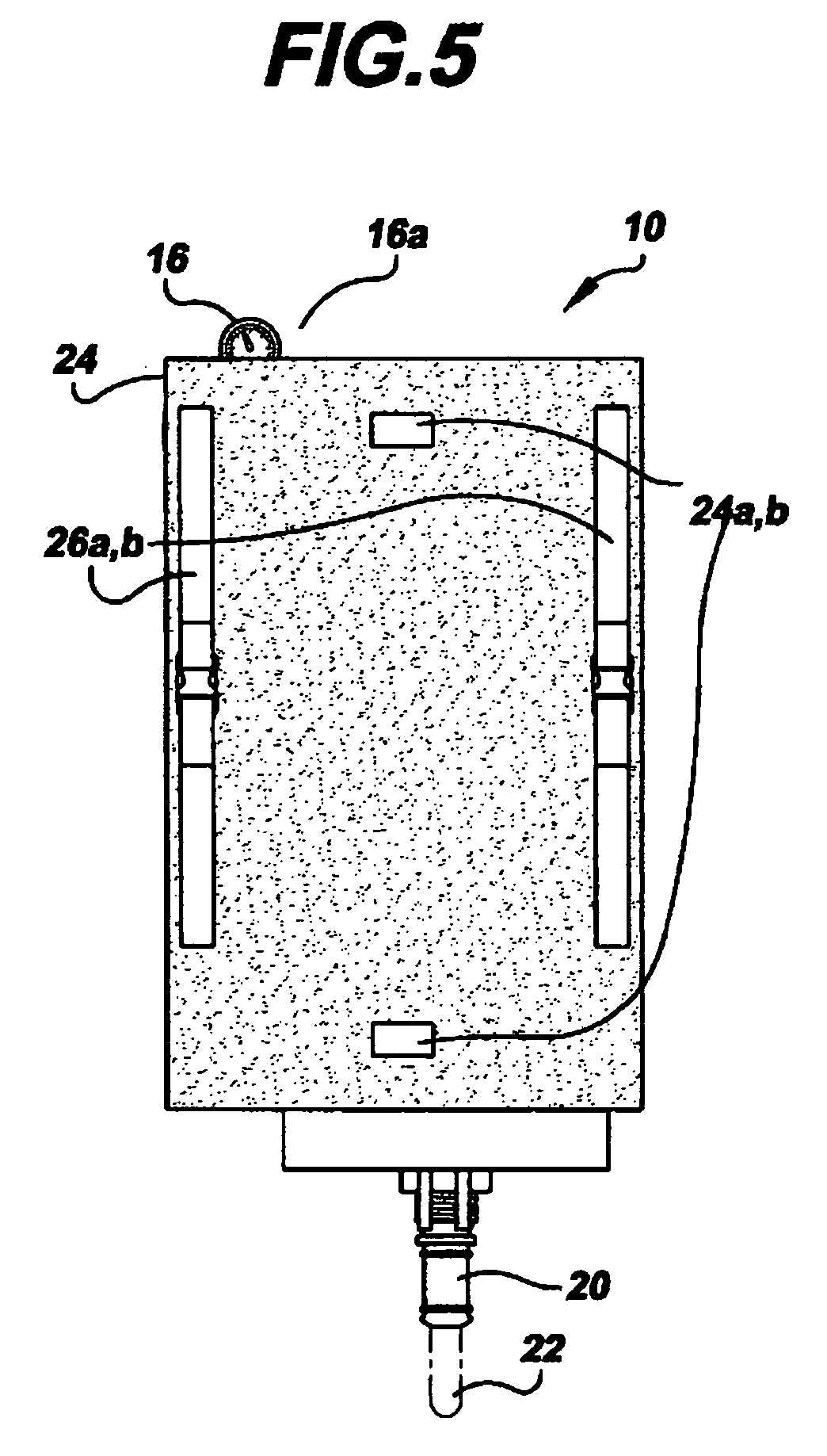

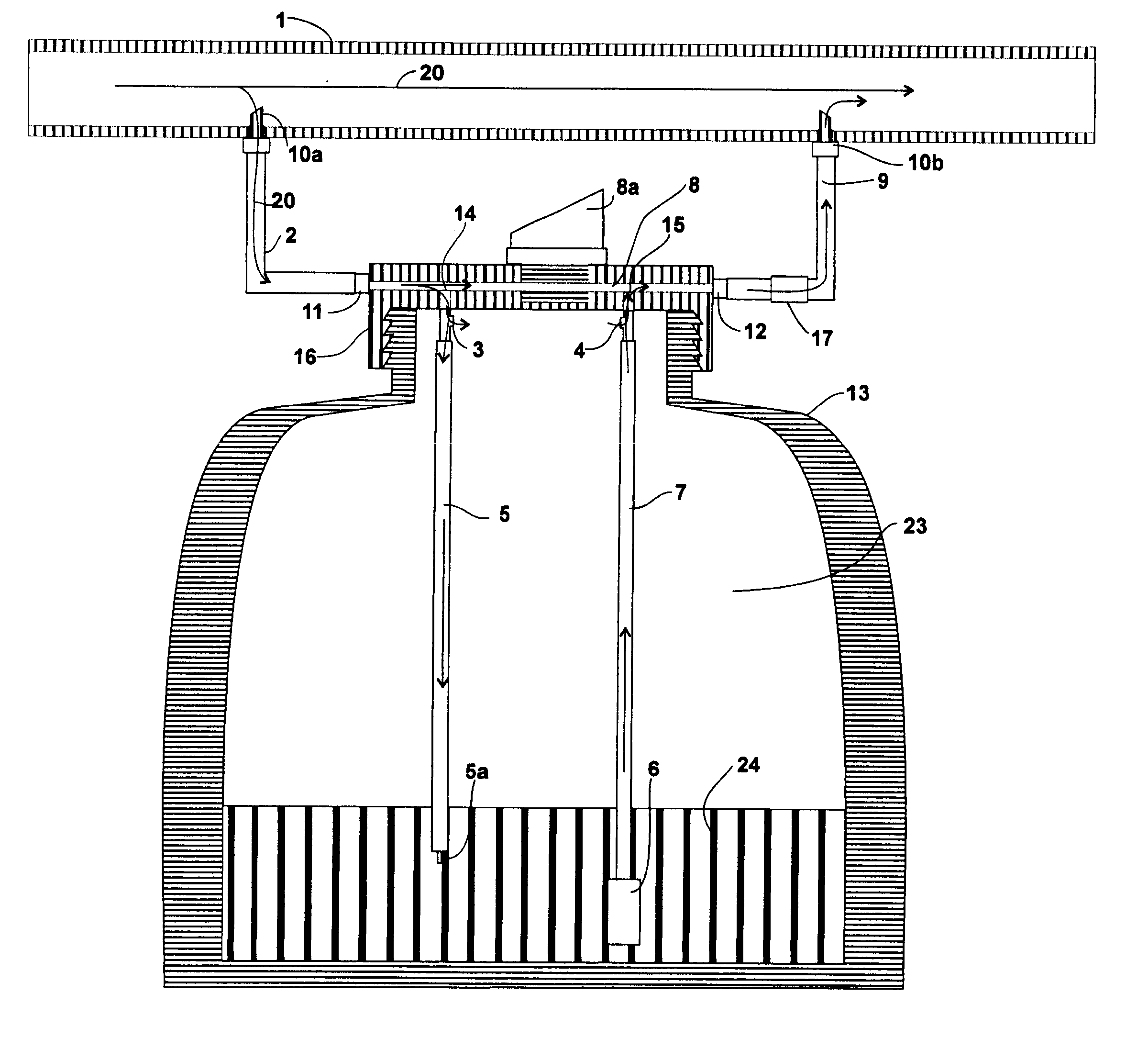

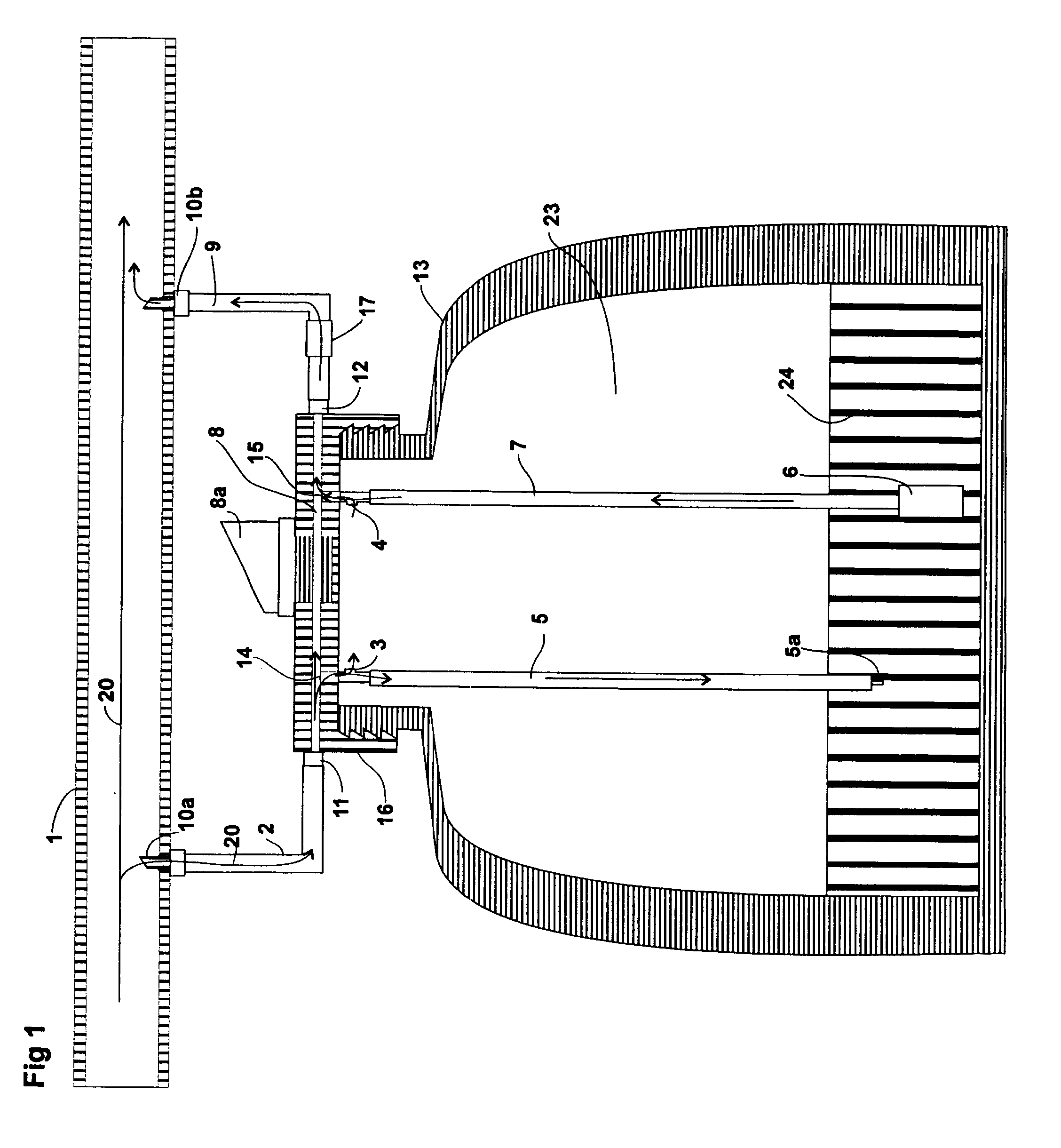

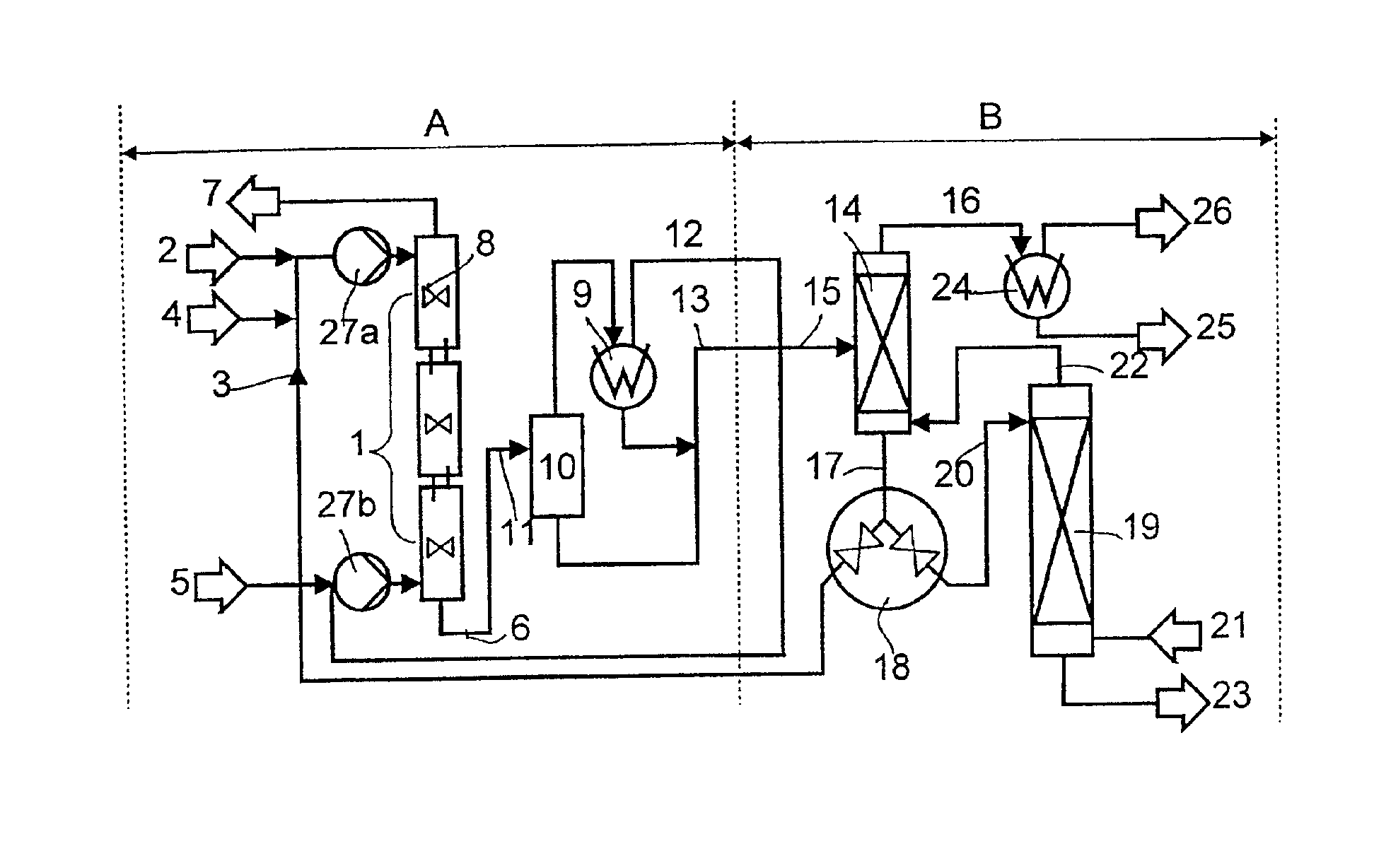

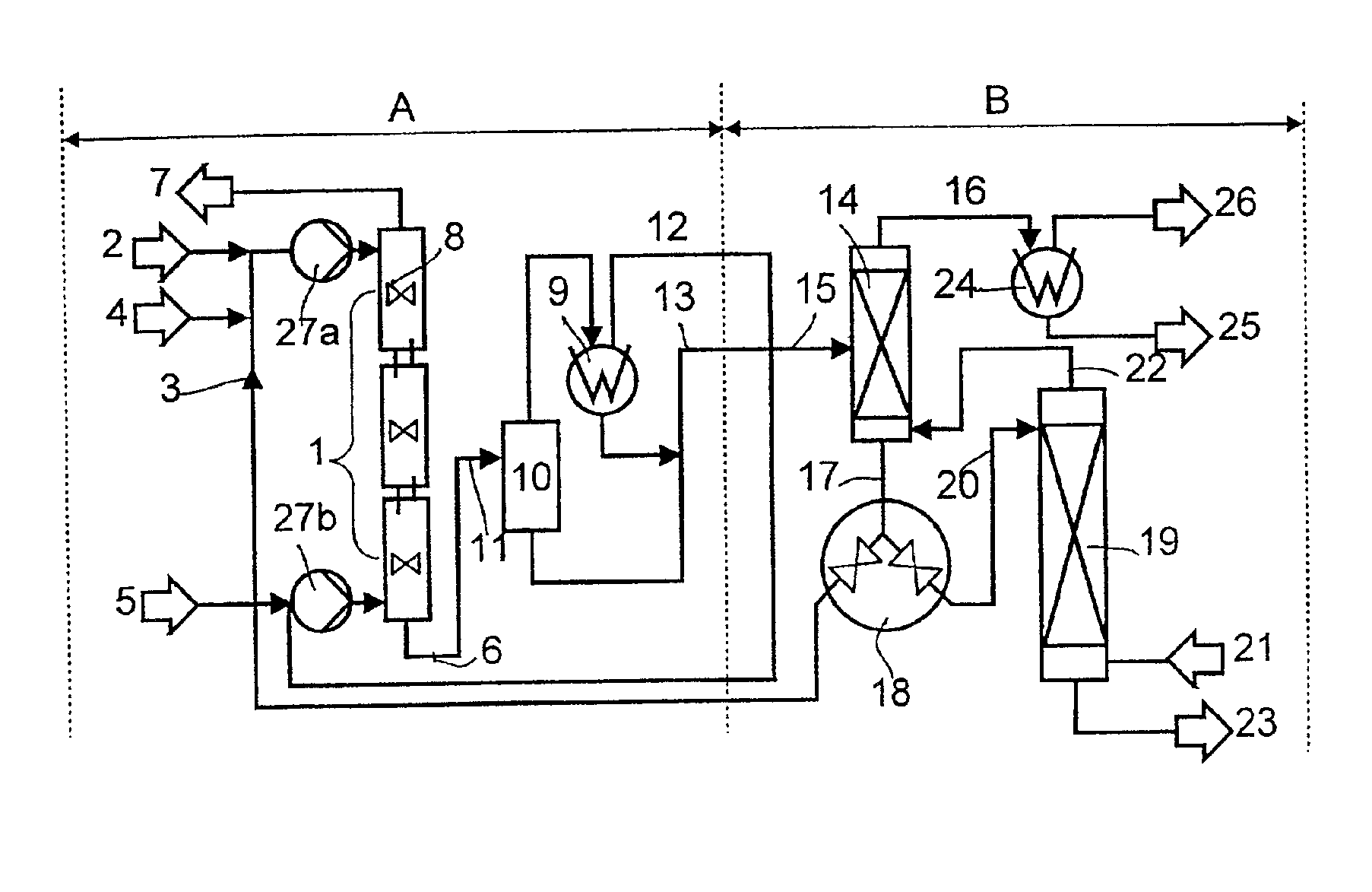

High temperature thermal energy storage system

InactiveUS20120055661A1Large lengthFrom solar energyHeat storage plantsThermal energyThermal energy storage

Owner:FEHER PETER

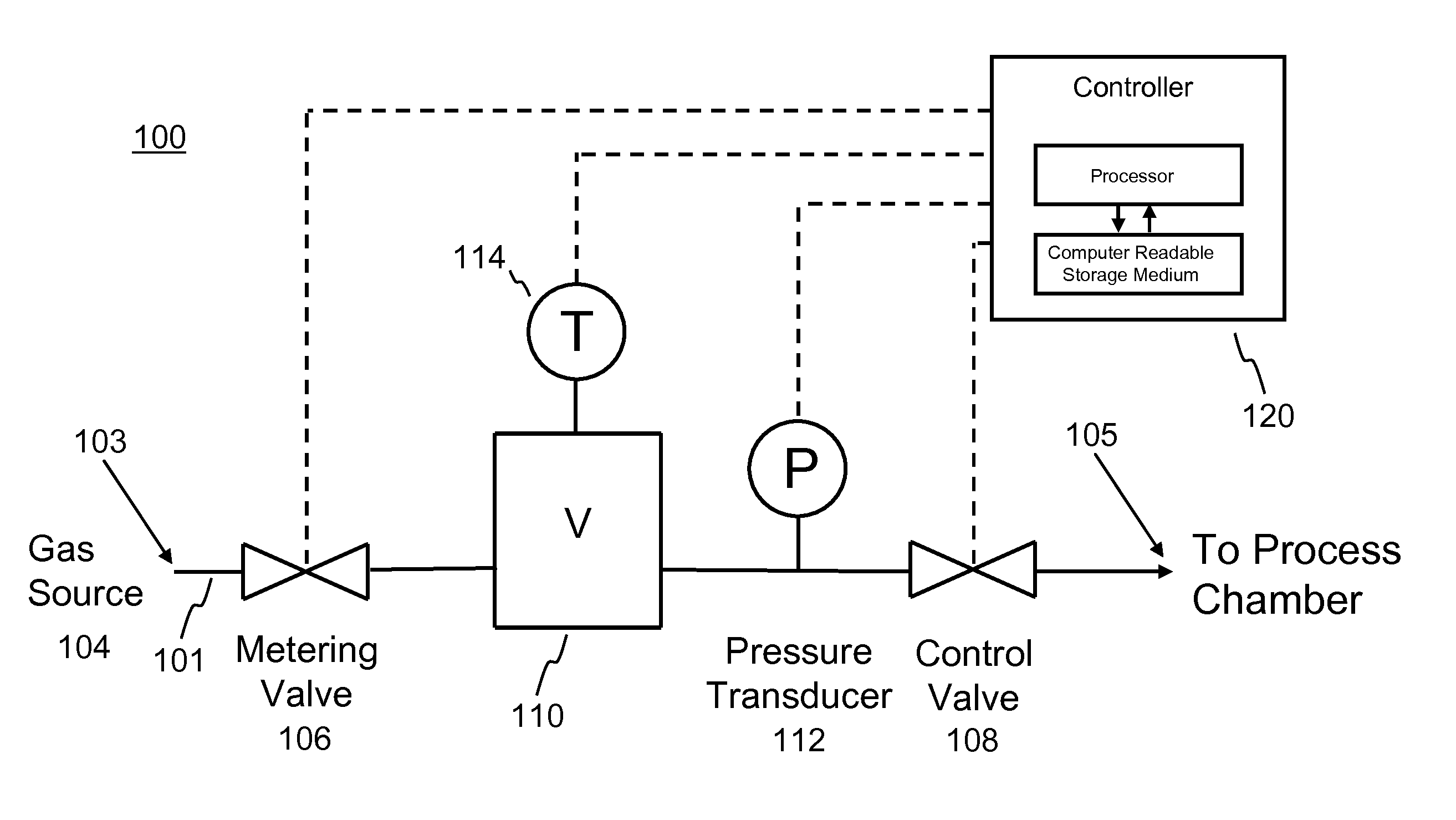

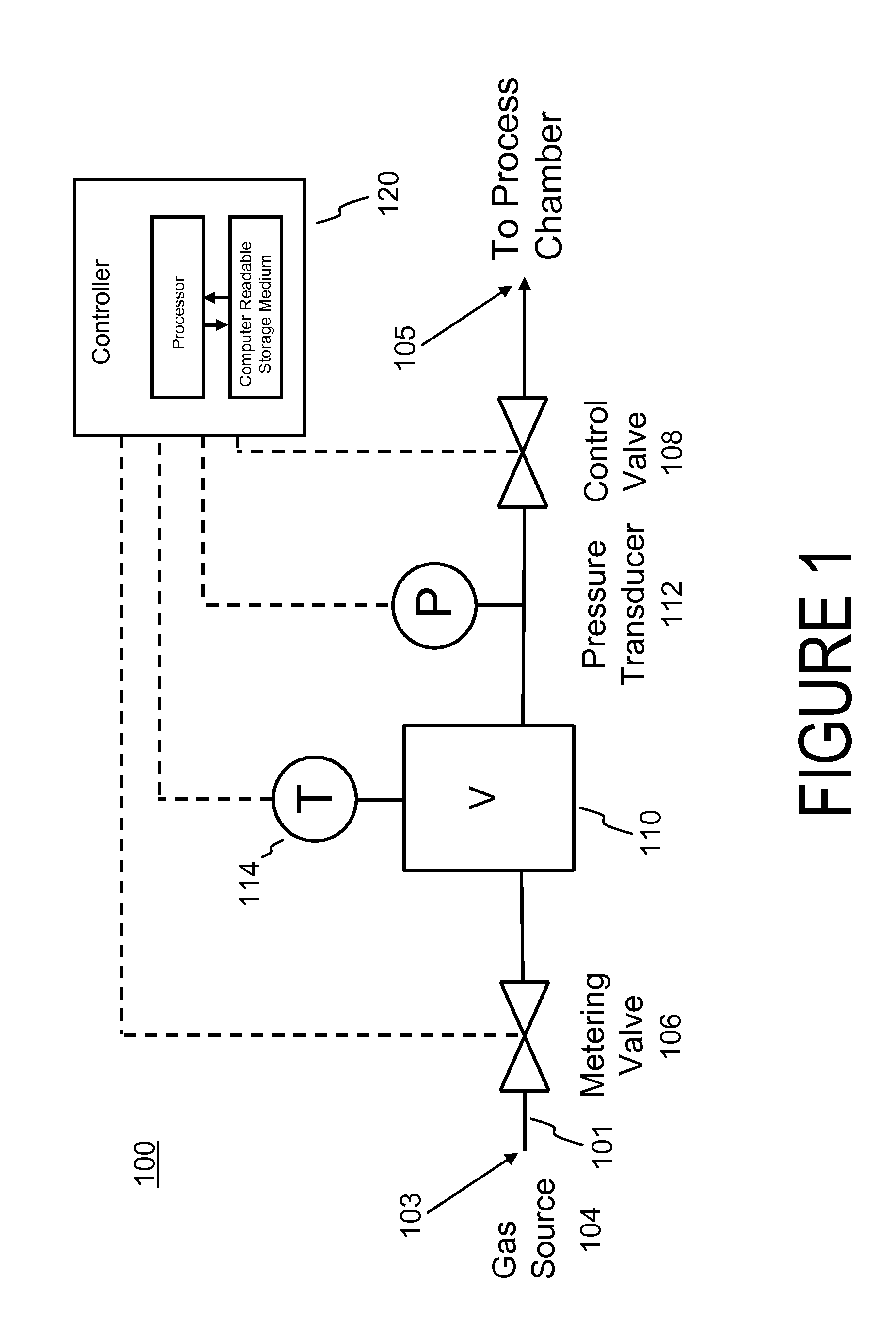

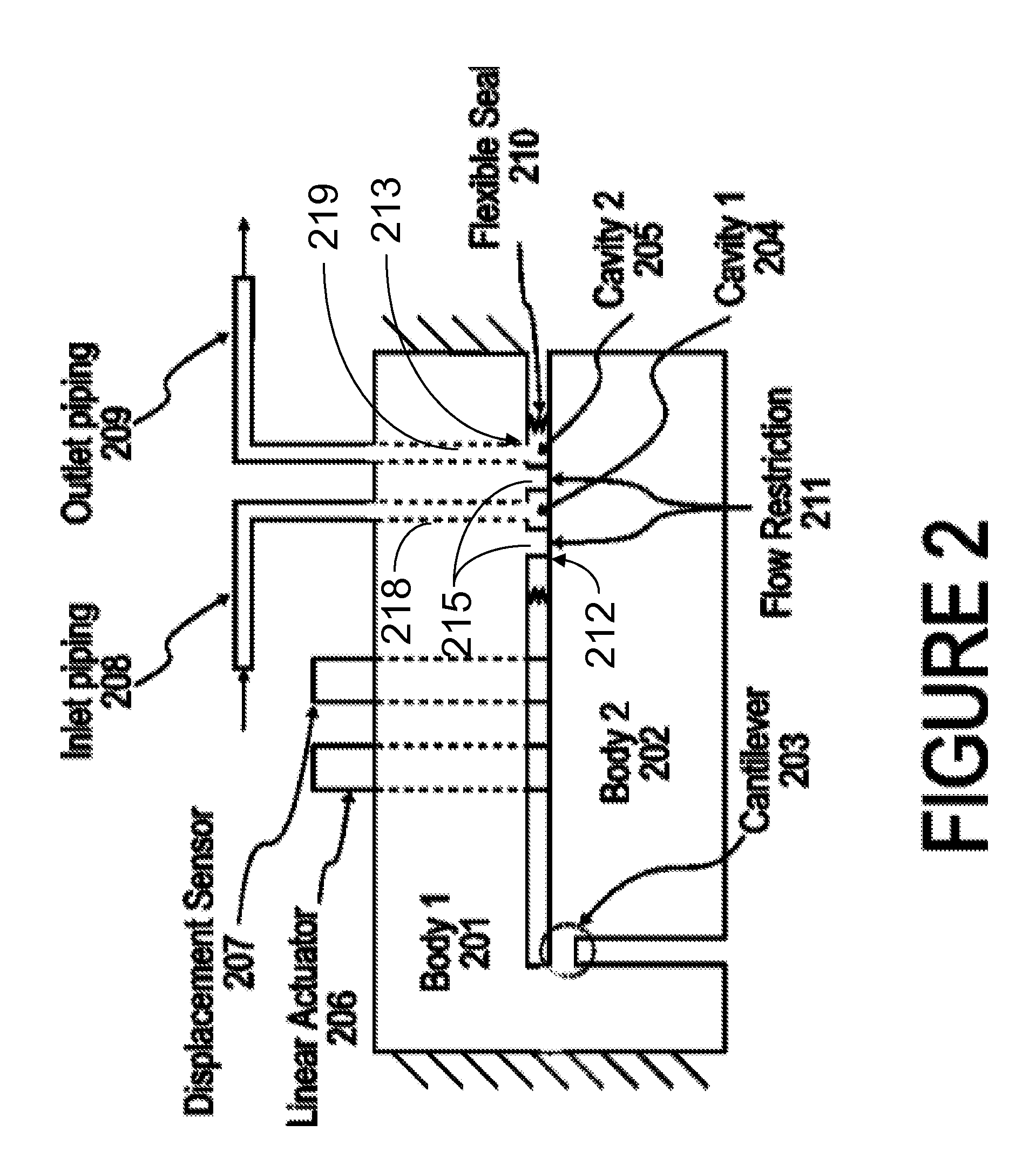

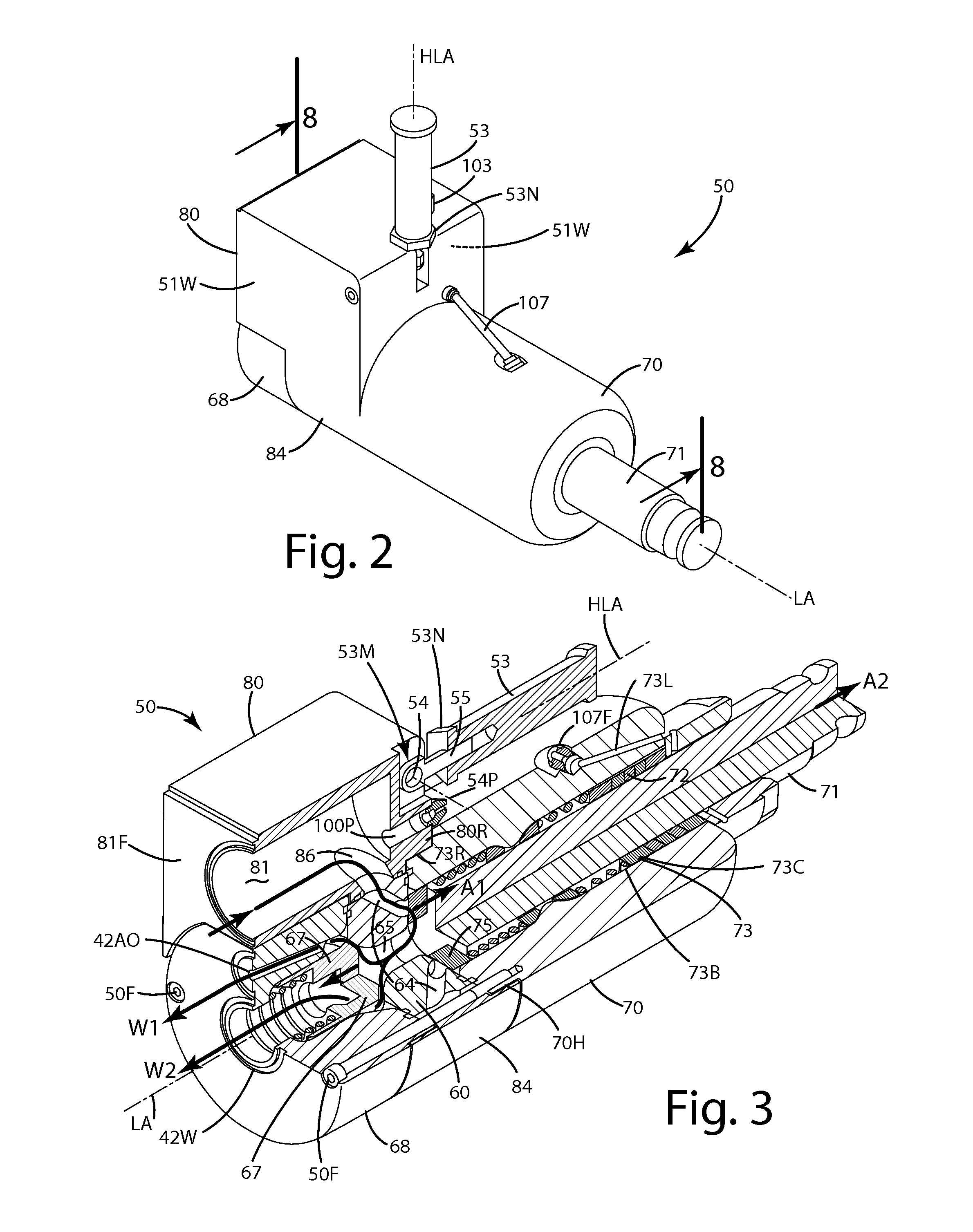

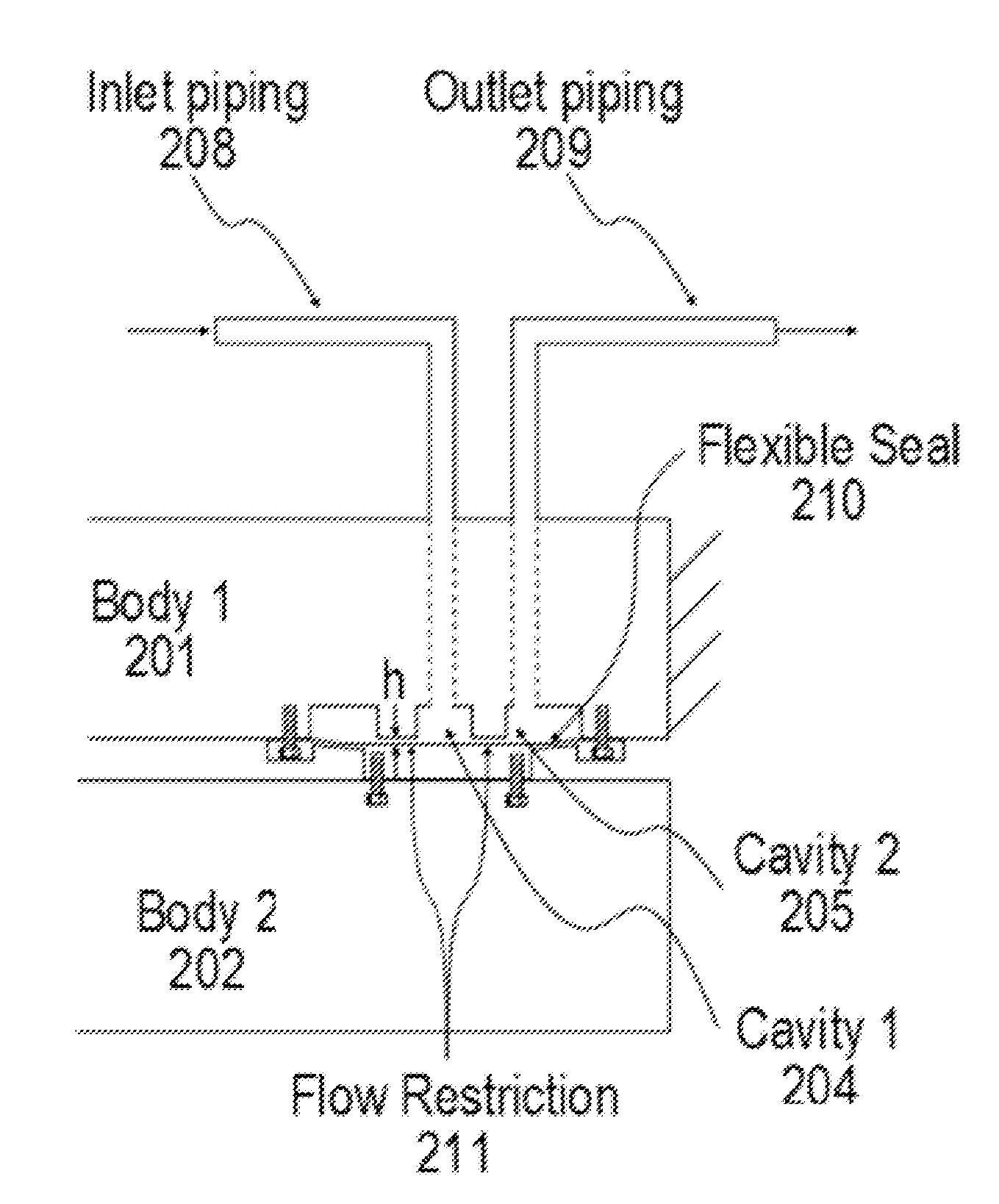

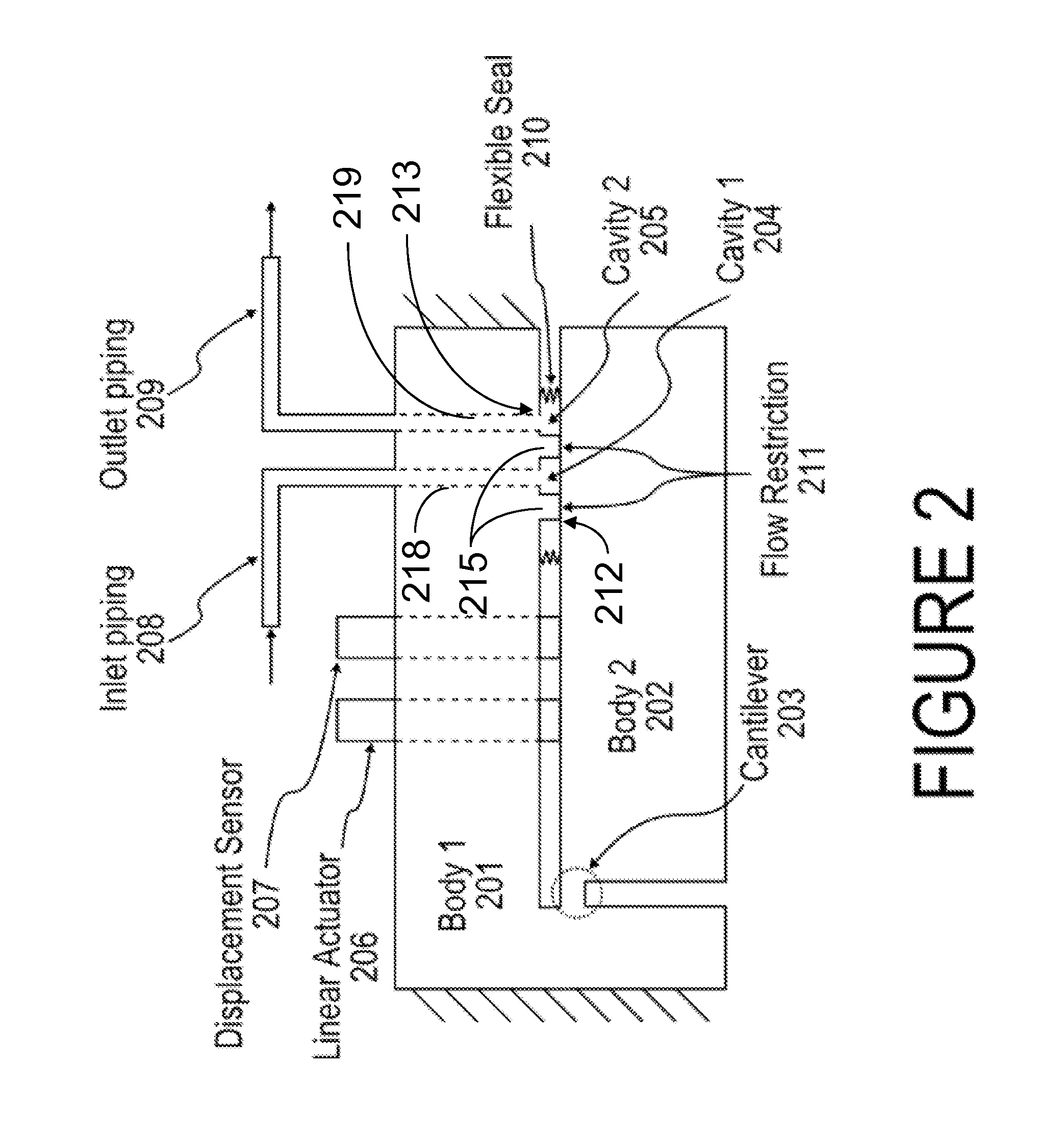

Method and apparatus for gas flow control

InactiveUS20110108126A1High precisionDiaphragm valvesOperating means/releasing devices for valvesEngineeringStreamflow

A method and apparatus for self-calibrating control of gas flow. The gas flow rate is initially set by controlling, to a high degree of precision, the amount of opening of a flow restriction, where the design of the apparatus containing the flow restriction lends itself to achieving high precision. The gas flow rate is then measured by a pressure rate-of-drop upstream of the flow restriction, and the amount of flow restriction opening is adjusted, if need be, to obtain exactly the desired flow.

Owner:PIVOTAL SYST CORP

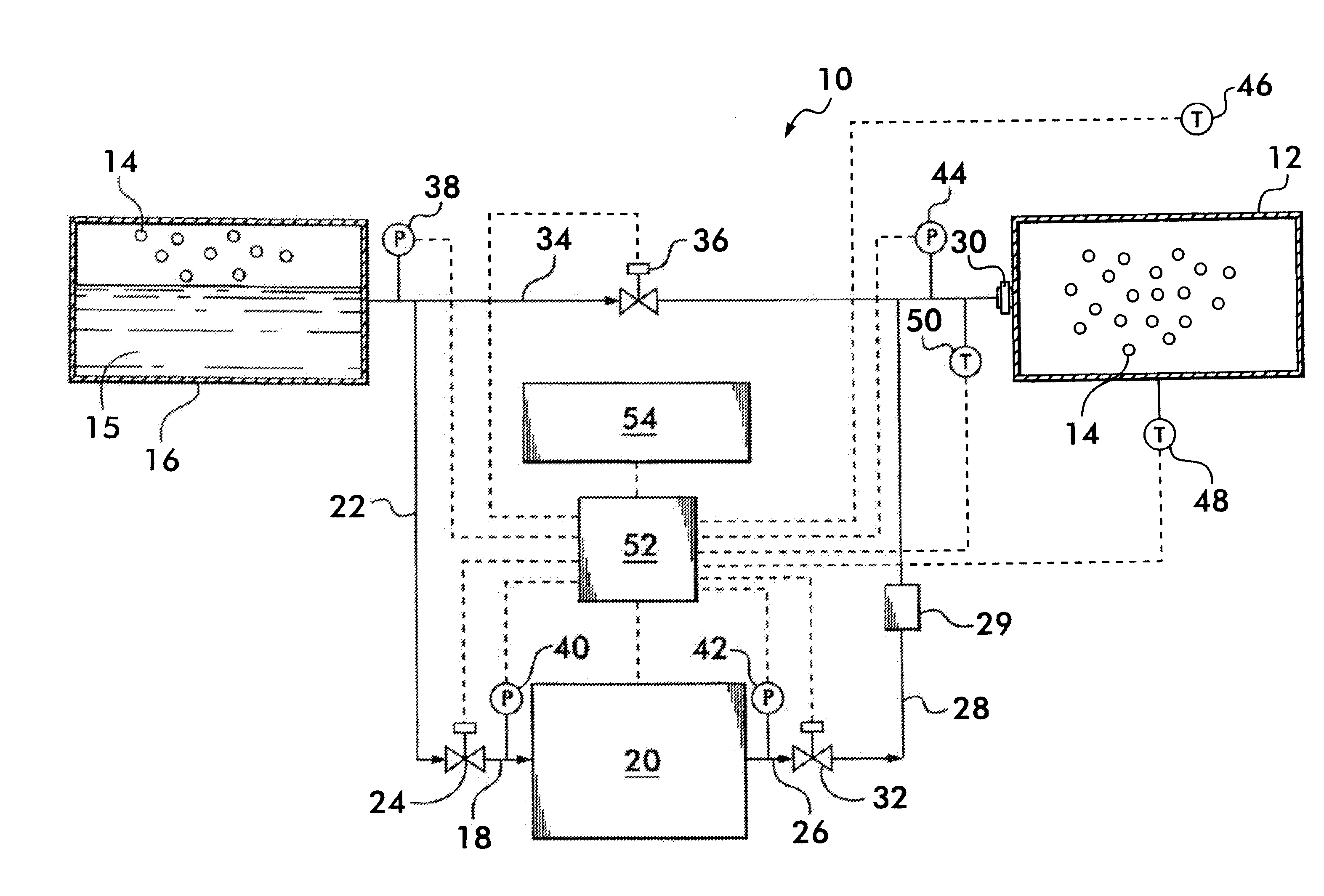

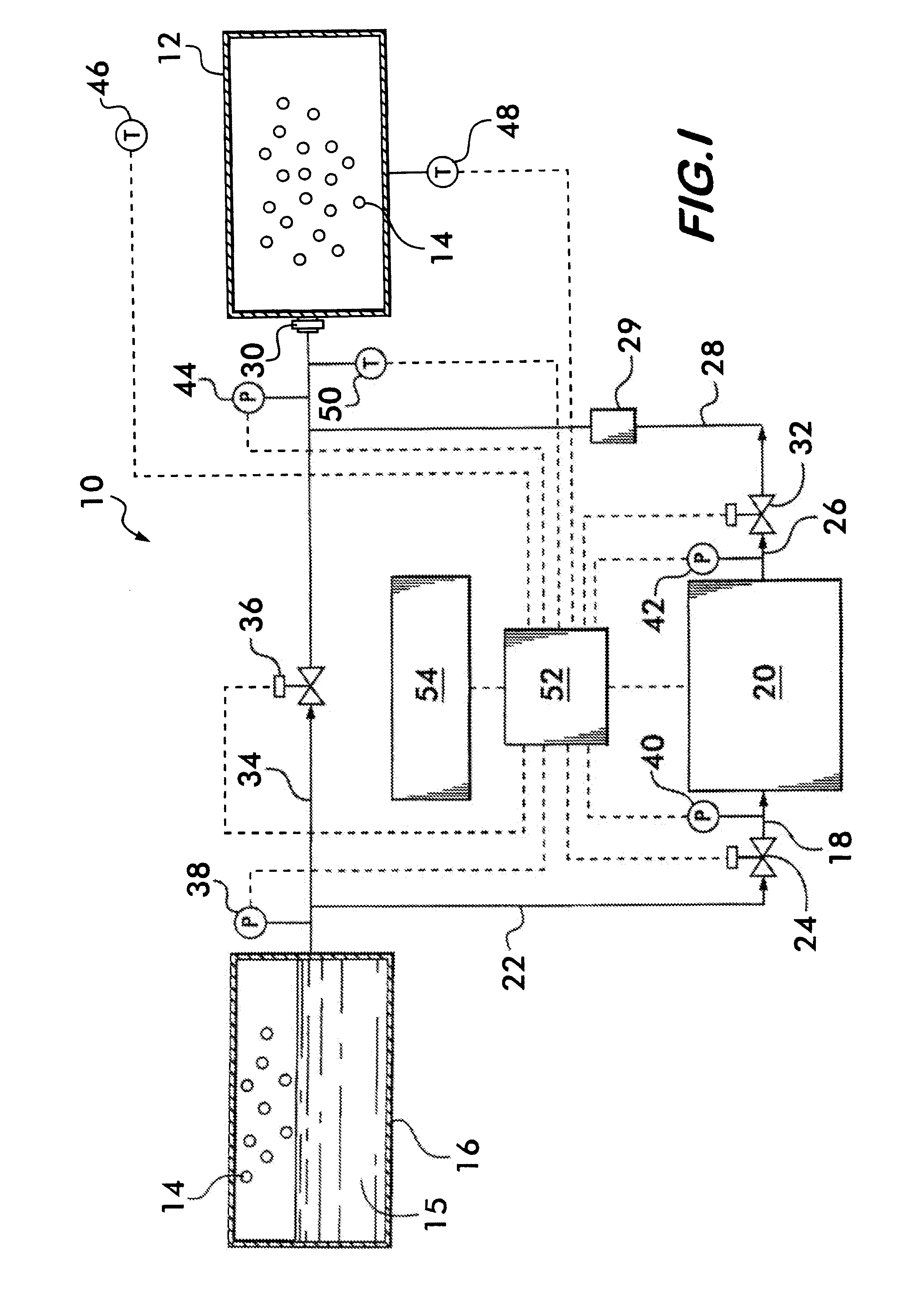

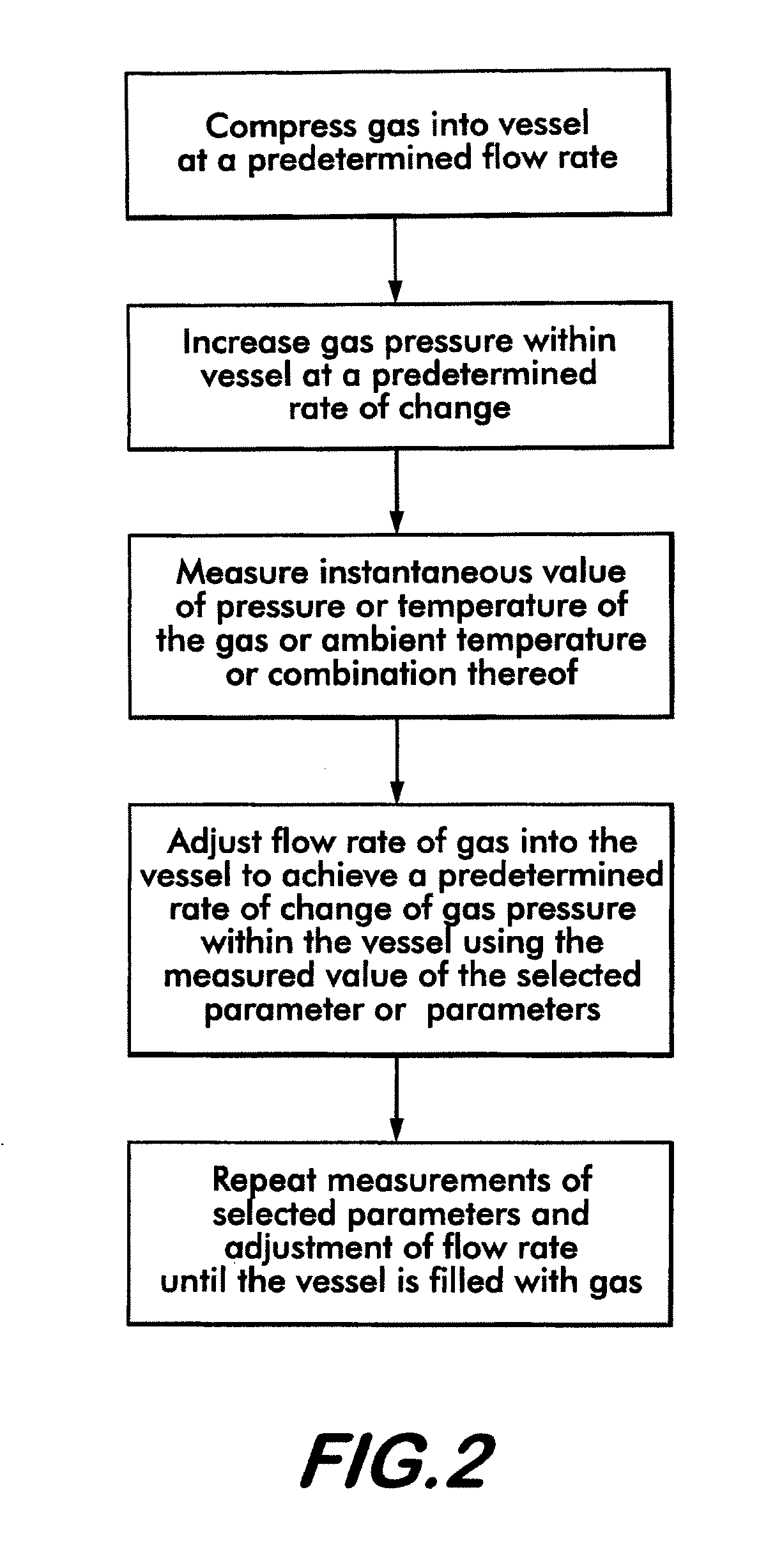

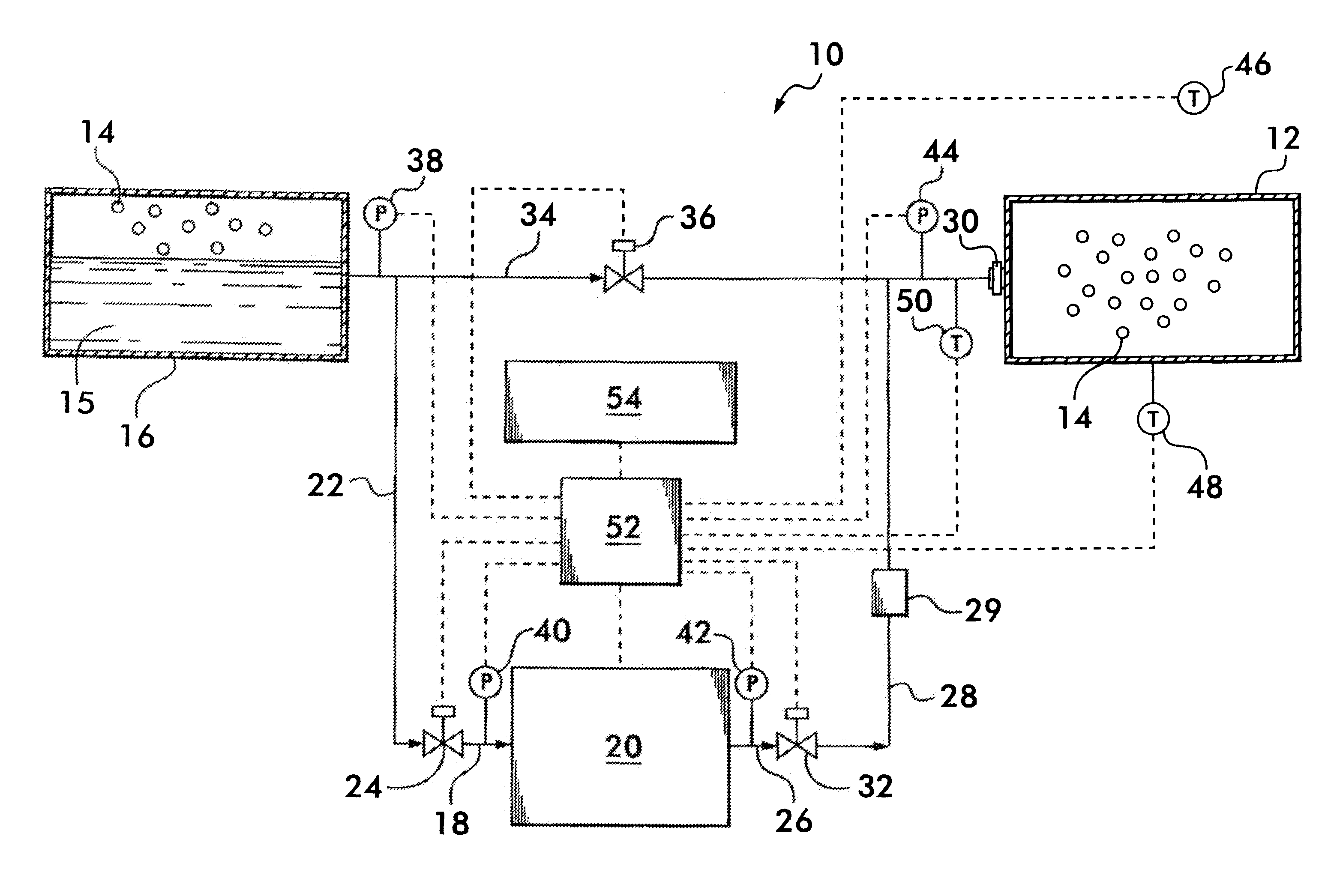

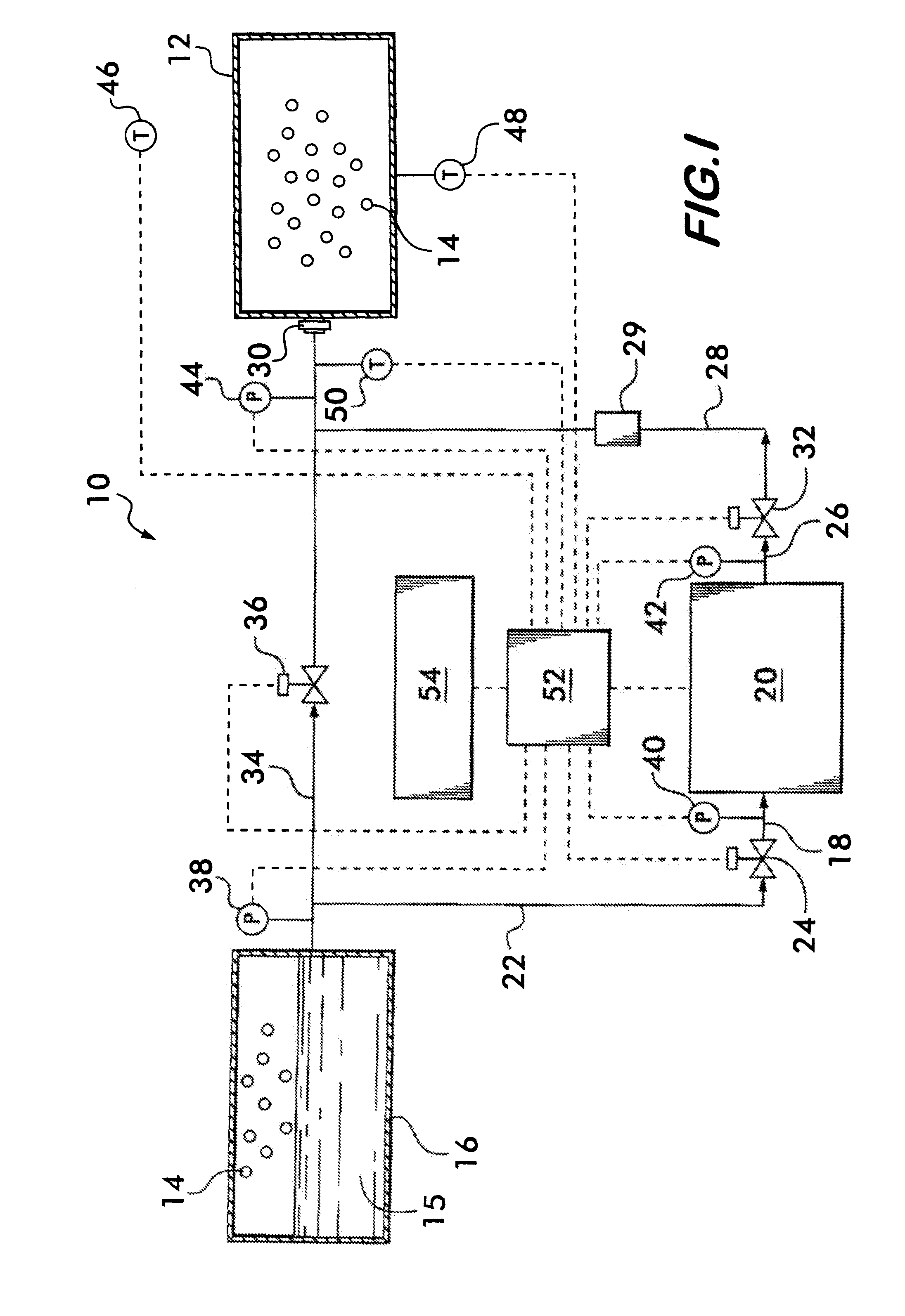

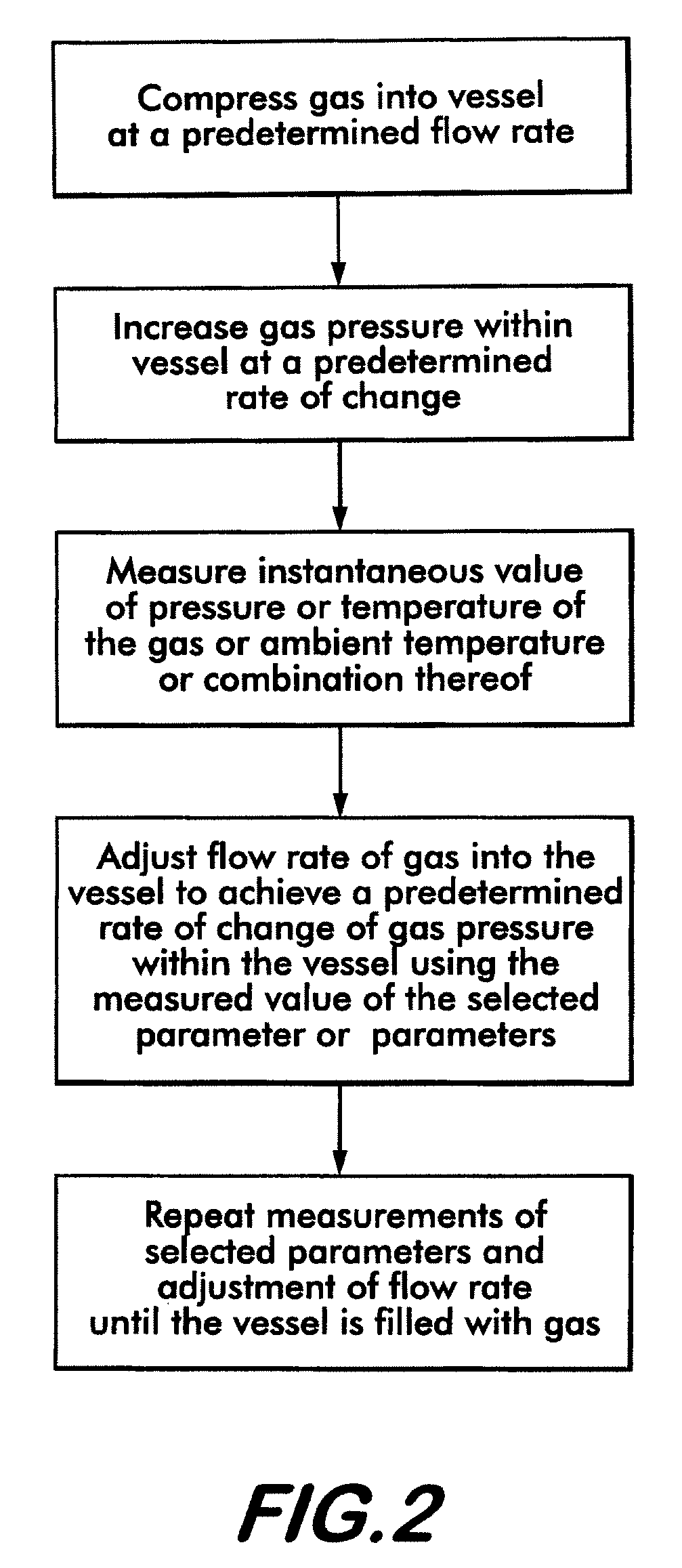

Compressor Fill Method And Apparatus

A method an apparatus for filling a vessel with compressed gas is disclosed. Gas is compressed into the vessel at a predetermined flow rate using a variable speed pump or compressor. The flow rate is adjusted to increase the gas pressure at a predetermined rate of change. The flow rate is adjusted based upon the instantaneous value of a measured parameter such as gas temperature or pressure or ambient temperature. The parameter is measured by a transducer and the value is fed back to a controller which adjusts the speed of the compressor or pump to produce the flow rate needed to achieve the predetermined pressure rate of change.

Owner:AIR PROD & CHEM INC

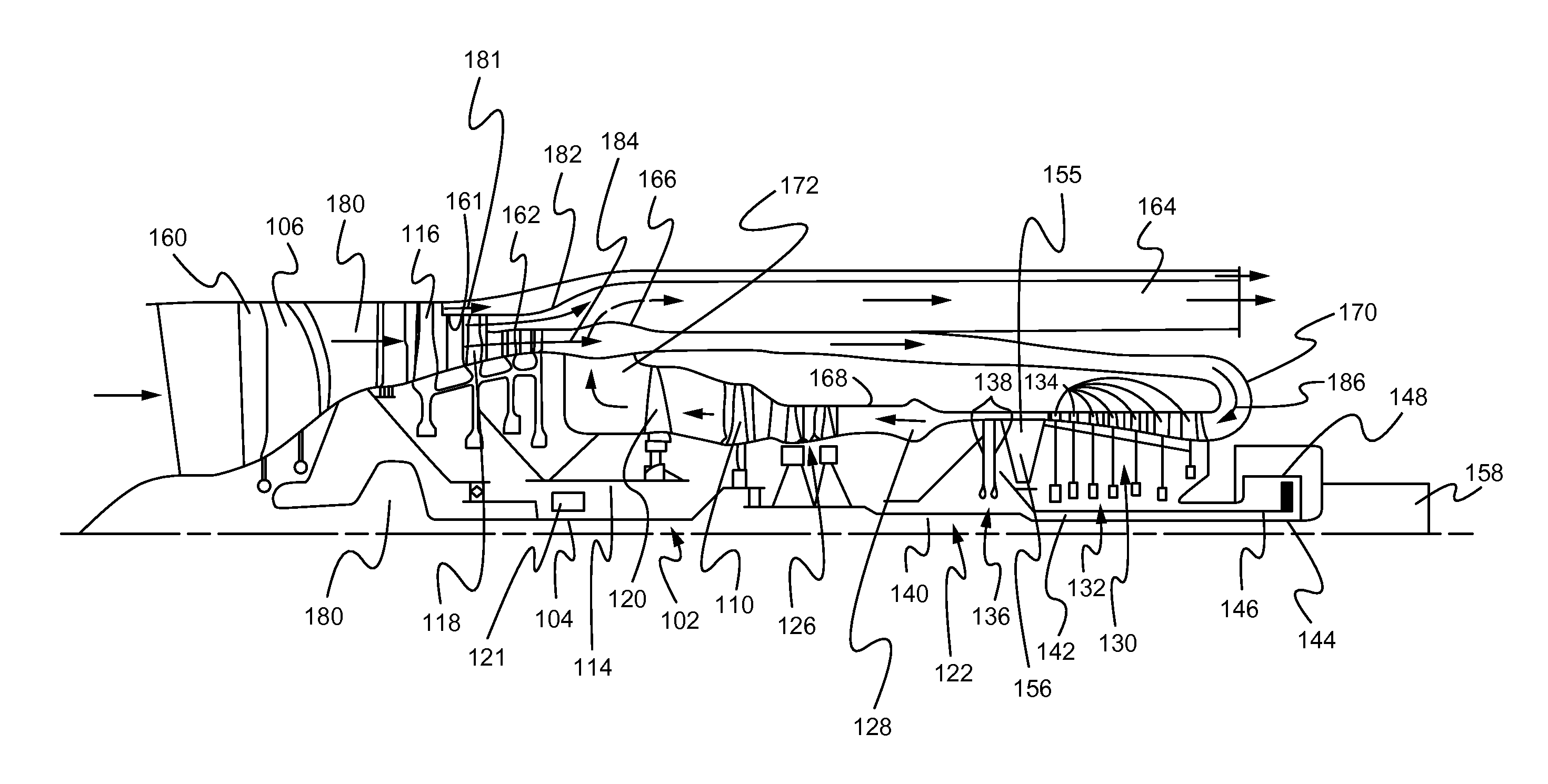

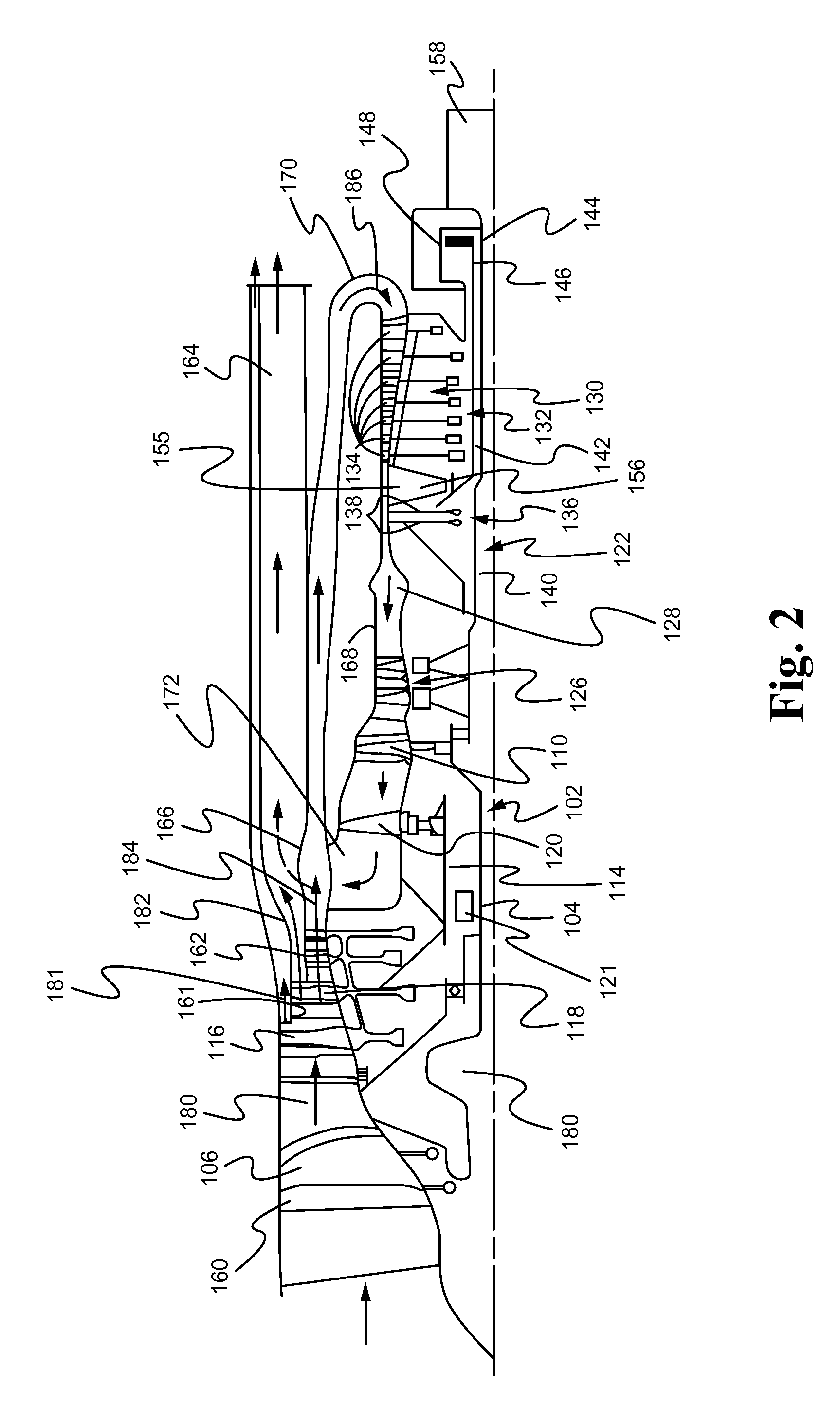

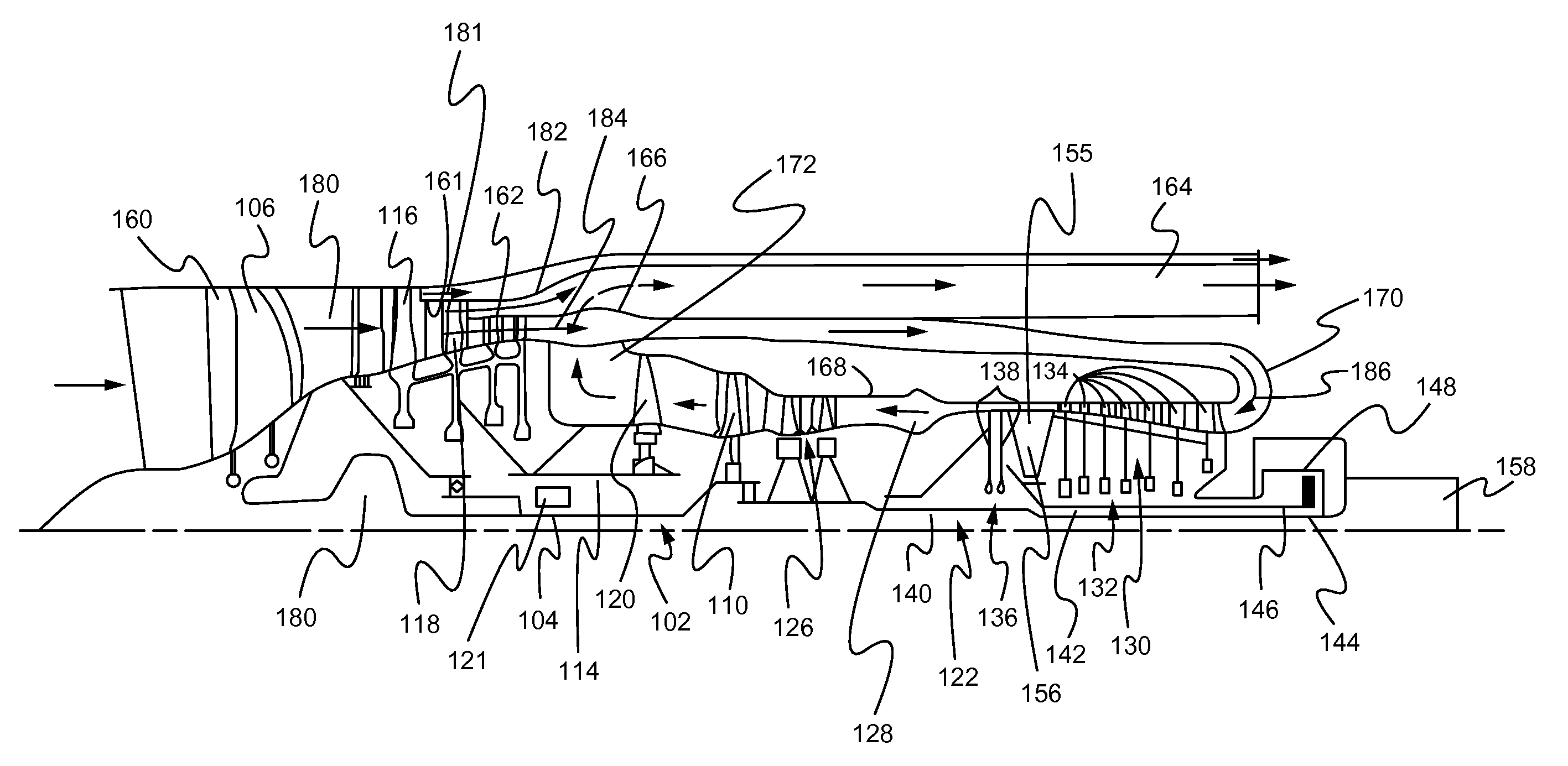

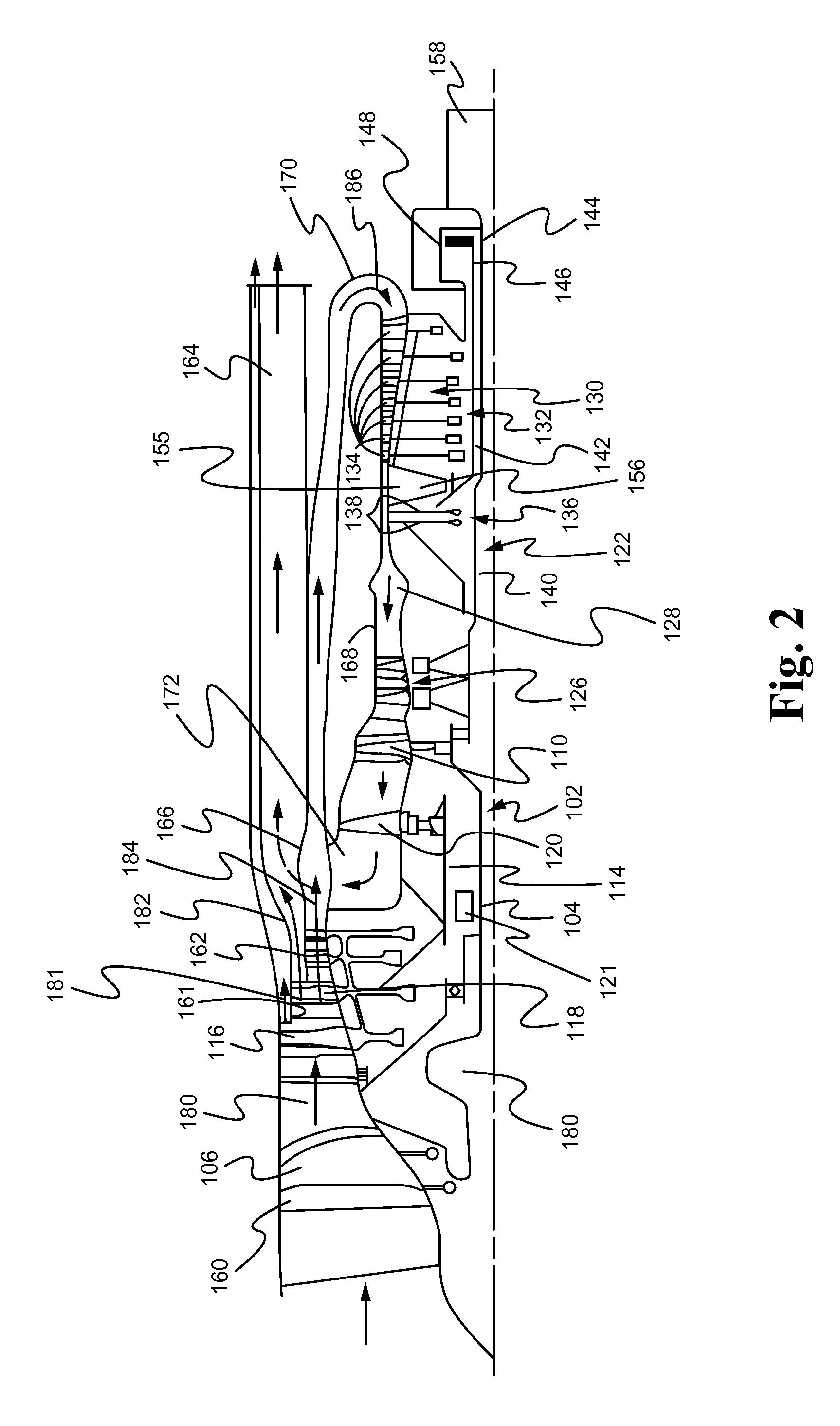

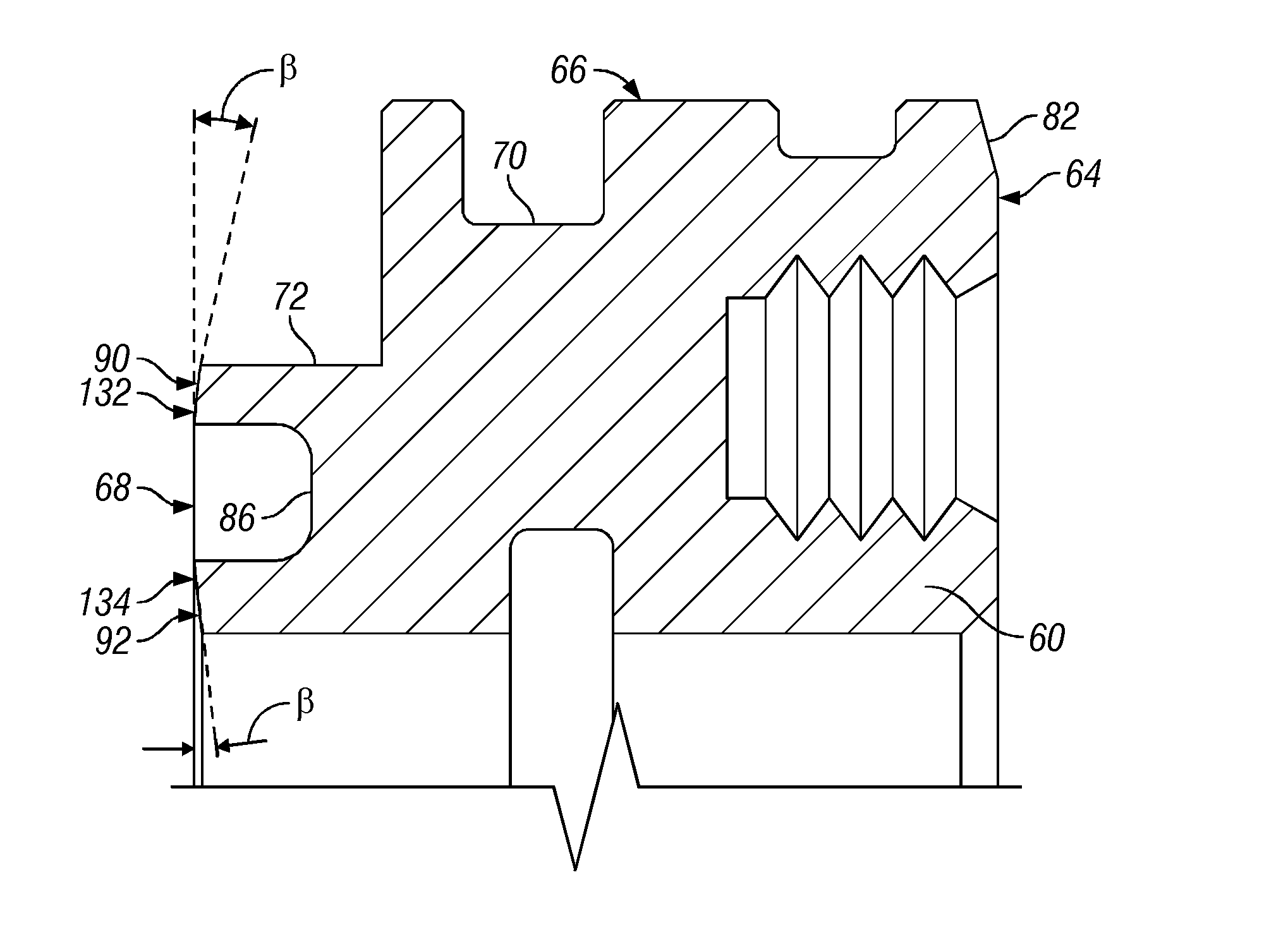

Gas Turbine Engine with Variable Overall Pressure Ratio

A gas turbine engine has a variable overall pressure rate (“OPR”). The engine includes a high pressure compressor having at least a primary stage having a set of primary rotors and a secondary stage having a set of secondary rotors. A clutch is provided to selectively engage the secondary rotors with the primary rotors. Engagement of the clutch may be controlled based on the vehicle travel mode, such as disengaging during a takeoff mode to reduce turbine entry temperature and engaging during a loiter mode to increase OPR.

Owner:RTX CORP +1

Compressor fill method and apparatus

A method an apparatus for filling a vessel with compressed gas is disclosed. Gas is compressed into the vessel at a predetermined flow rate using a variable speed pump or compressor. The flow rate is adjusted to increase the gas pressure at a predetermined rate of change. The flow rate is adjusted based upon the instantaneous value of a measured parameter such as gas temperature or pressure or ambient temperature. The parameter is measured by a transducer and the value is fed back to a controller which adjusts the speed of the compressor or pump to produce the flow rate needed to achieve the predetermined pressure rate of change.

Owner:AIR PROD & CHEM INC

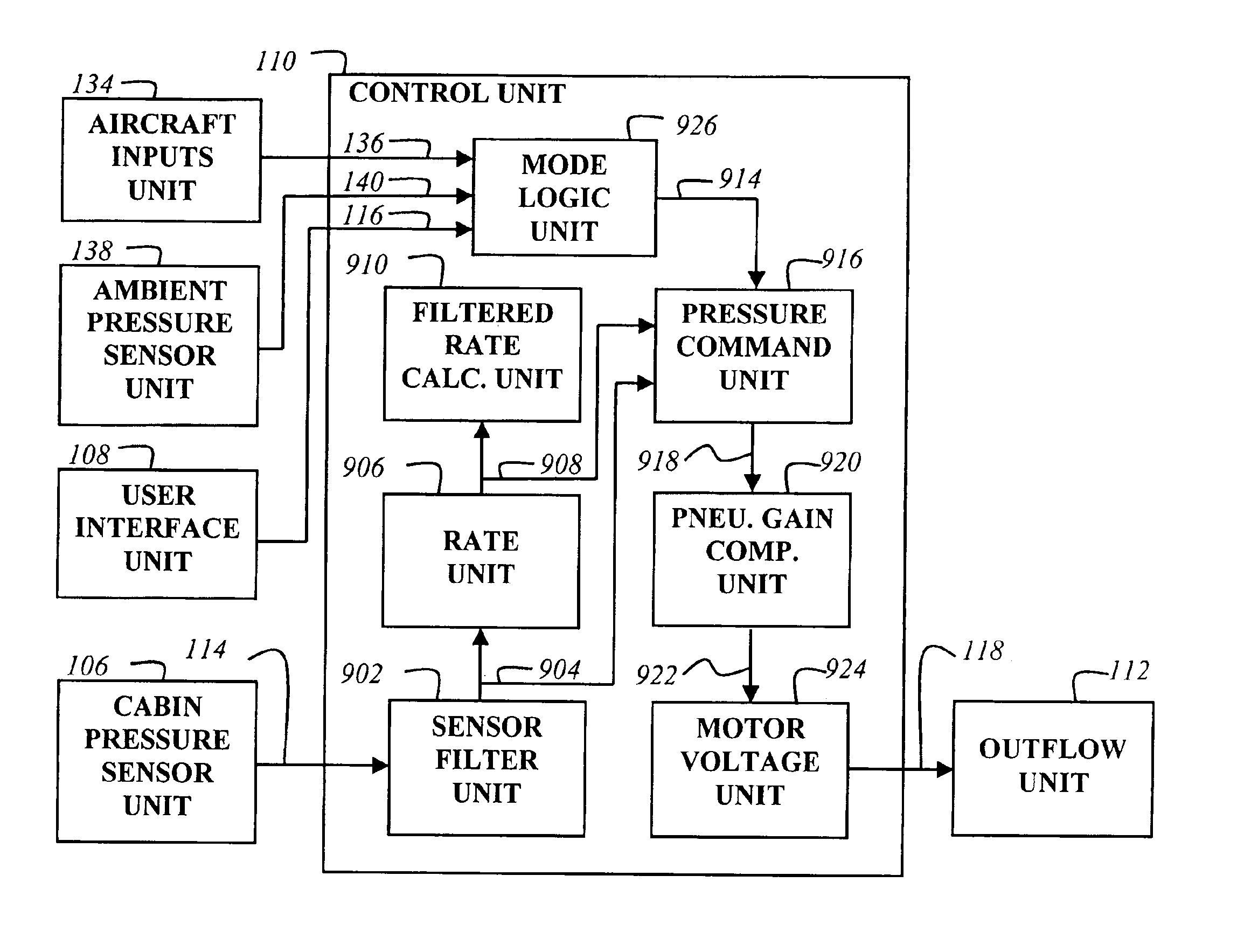

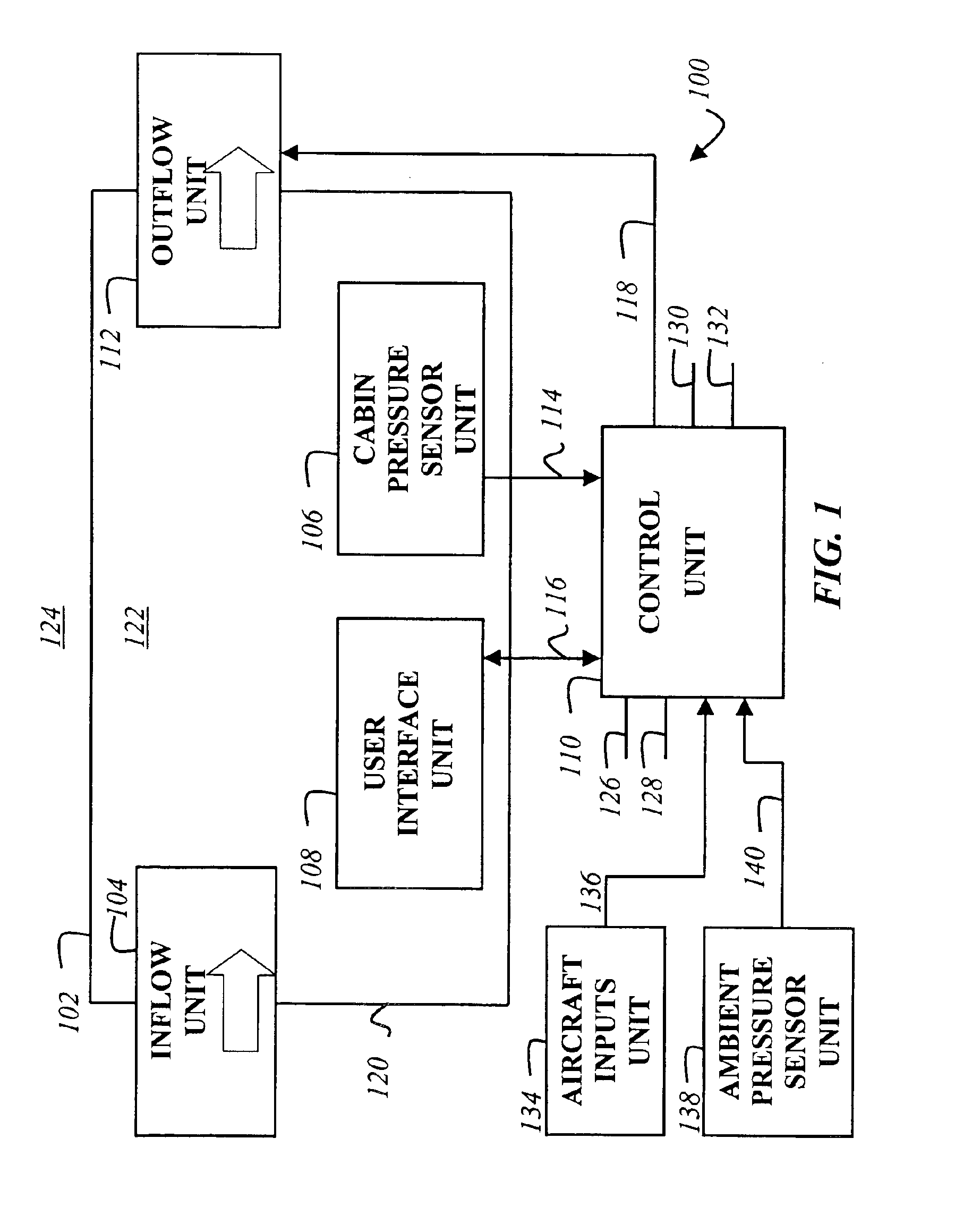

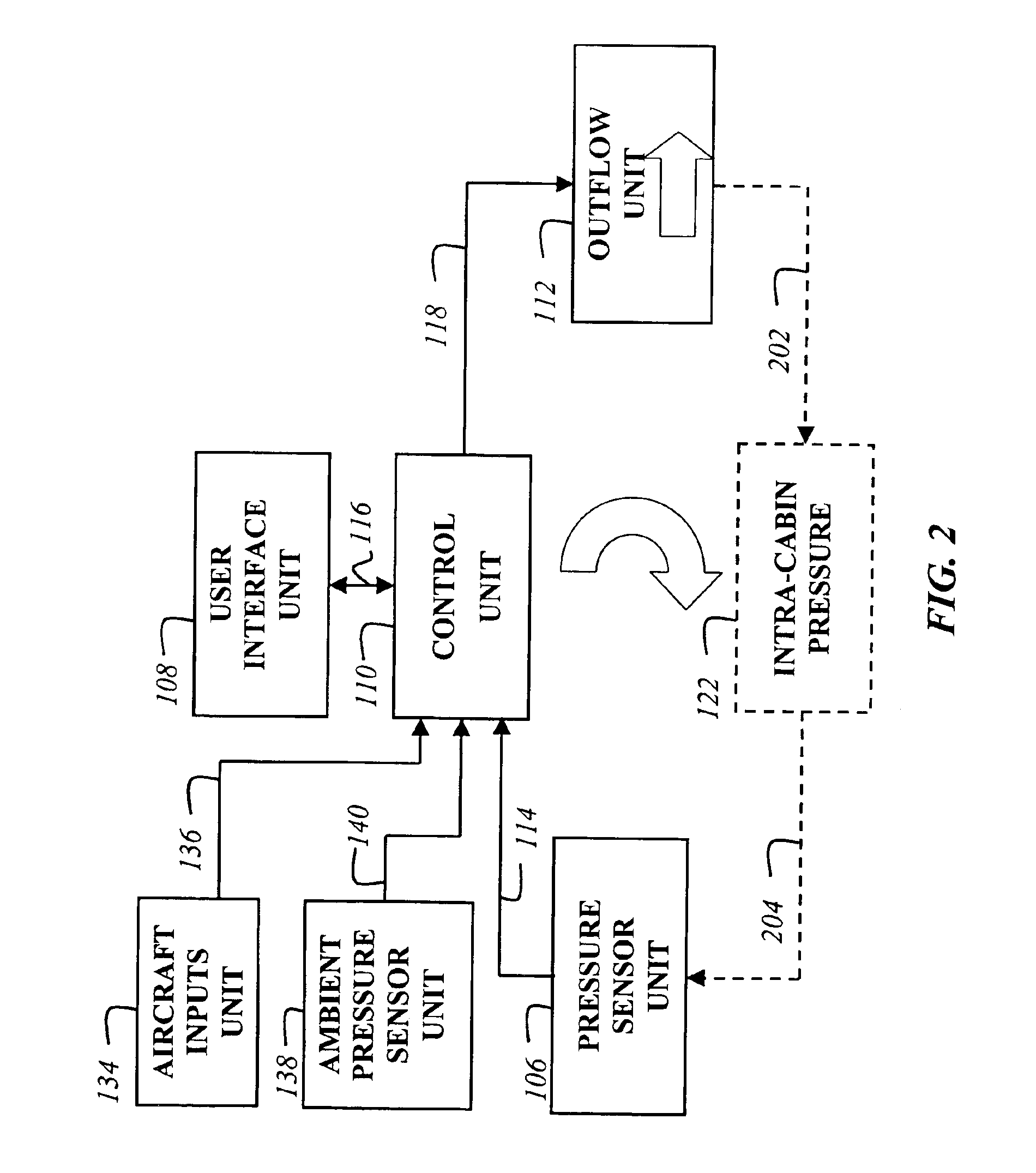

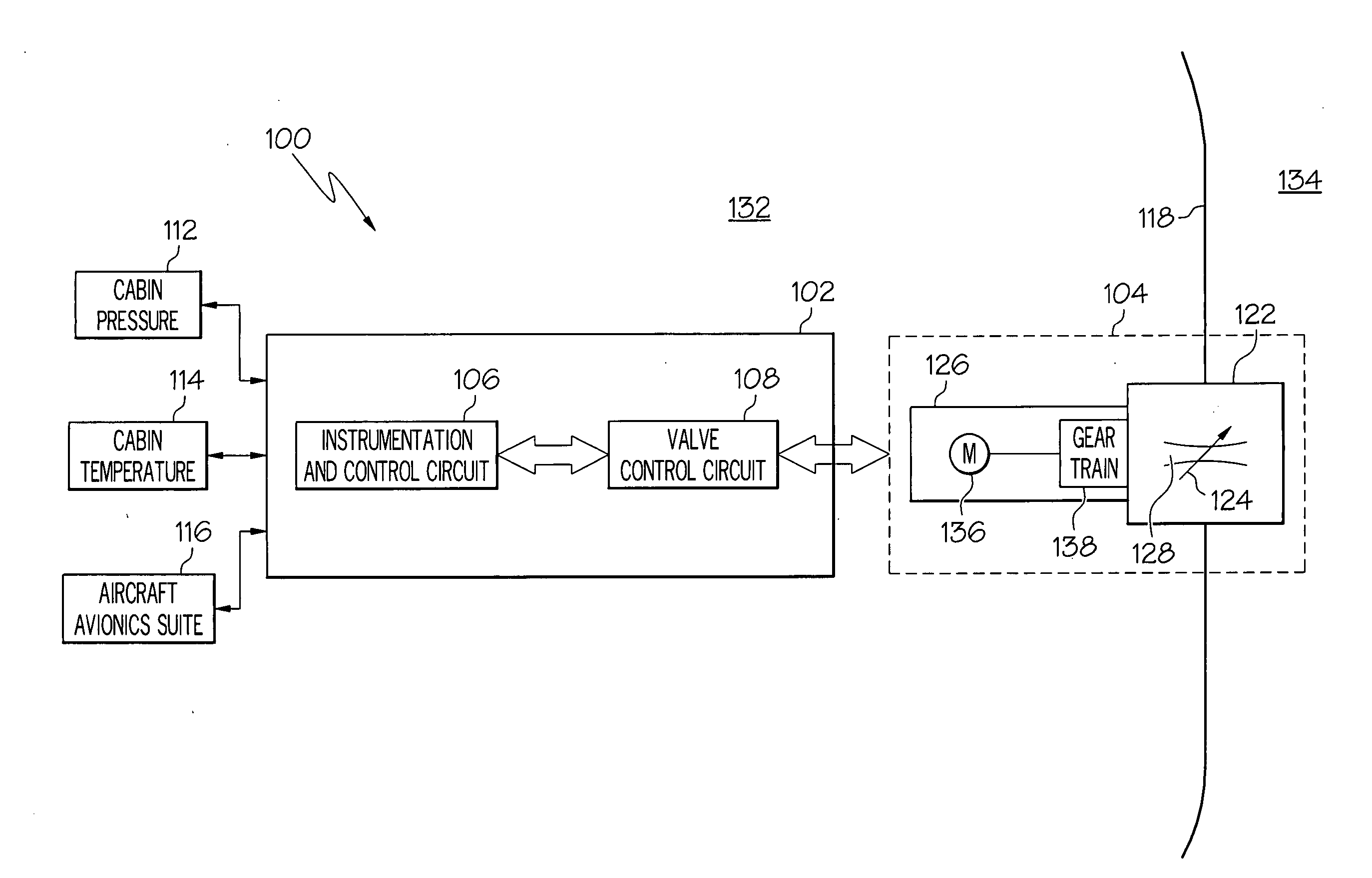

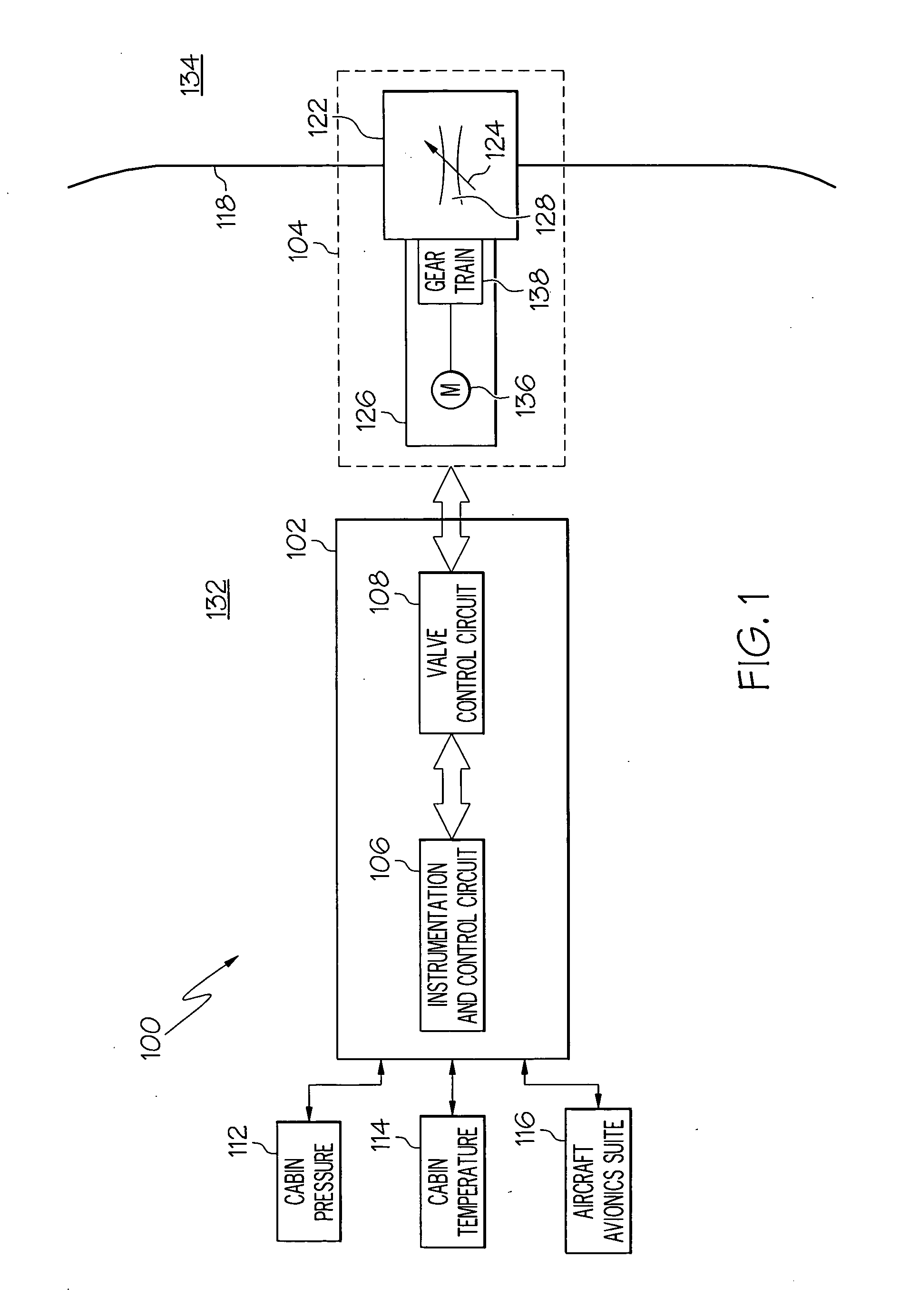

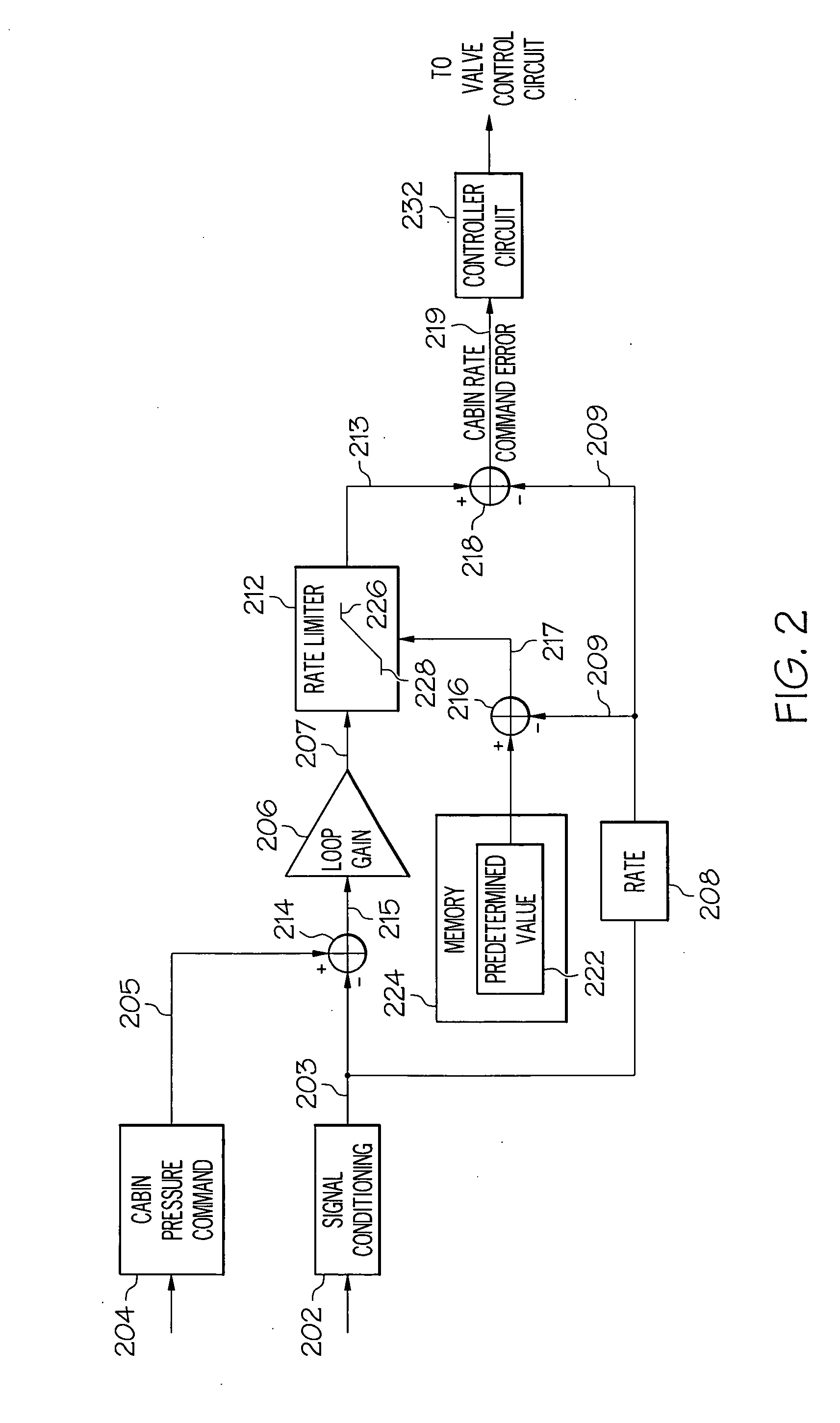

Cabin pressure control method and apparatus using all-electric control without outflow valve position feedback

ActiveUS6979257B2Air-treatment apparatus arrangementsFluid pressure control using electric meansMotor speedControl signal

A pressure control system including an inflow unit for admitting pressurized air into a cabin, an outflow unit including a motor for operating a valve to discharge air from the cabin at a predetermined rate based on an motor control signal that sets the motor speed, a control unit, and an air pressure sensor within the cabin for determining a pressure signal. The control unit receives the pressure signal and computes a pressure rate of change error signal to set the motor control signal. The outflow unit, control unit, and air pressure sensor form a feedback control loop independent of motor speed, valve speed, or valve position feedback.

Owner:HONEYWELL INT INC

Back pack applicator for coatings or sealants

InactiveUS20070235471A1Easy to useEasy to cleanLiquid surface applicatorsLiquid transferring devicesAutomatic controlEngineering

A machine for delivering liquid coating or sealant from a flexible walled package to an applicator, package fitment will accommodate sealing of compressed gas in canister and seal the product in pouch for dispensing, a light weight pressure rated canister for the package and compressed gas can be added external to the package and internal to the canister for application, a compressor for delivering compressed gas to the canister, a safety relief valve set below canister rated pressure, an adjustable pressure switch to control the on / off function of the compressor automatically, a dispensing tube that is flexible and sized to handle the required flow rate with minimal pressure drop and convenient in length for application, an adjustable valve with an operator button on applicator handle for optimized product flow during application, a back pack harness or side harness to hold the canister for mobility and hands free operation.

Owner:RADERMACHER MARTY EDWARD

System and method for gas flow verification

ActiveUS20060212233A1Increase pressureTesting/calibration apparatusFlow propertiesMeasurement deviceTime efficient

A gas flow rate verification apparatus is provided for shared use in a multiple tool semiconductor processing platform. The gas flow rate verification apparatus is defined to measure a pressure rate of rise and temperature within a test volume for determination of a corresponding gas flow rate. The apparatus includes first and second volumes, wherein the second volume is larger than the first volume. The apparatus also includes first and second pressure measurement devices, wherein the second pressure measurement device is capable of measuring higher pressures. Based on the target gas flow rate to be measured, either the first or second volume can be selected as the test volume, and either the first or second pressure measurement device can be selected to measure the pressure in the test volume. Configurability of the apparatus enables accurate measurement of gas flow rates over a broad range and in an time efficient manner.

Owner:LAM RES CORP

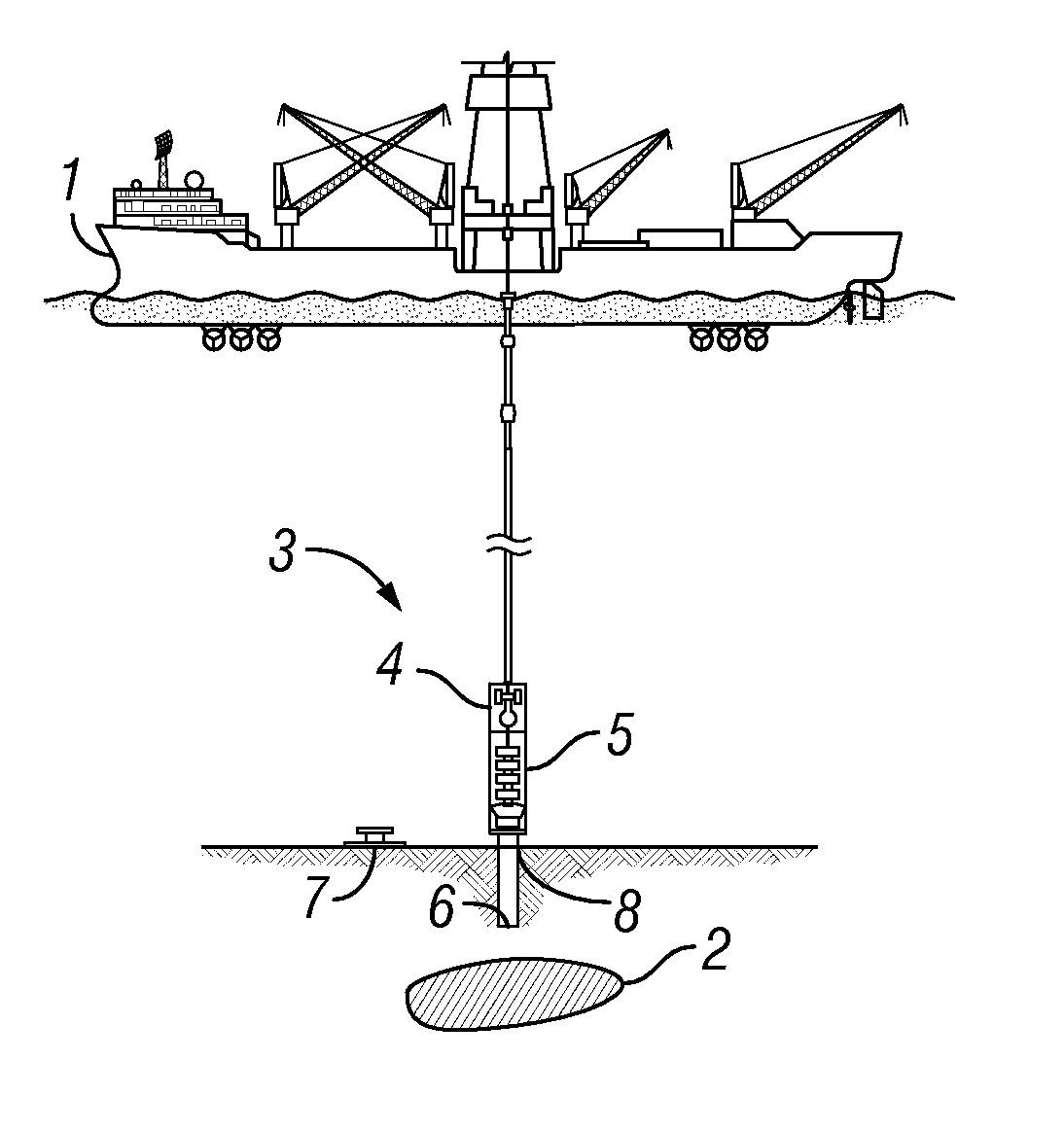

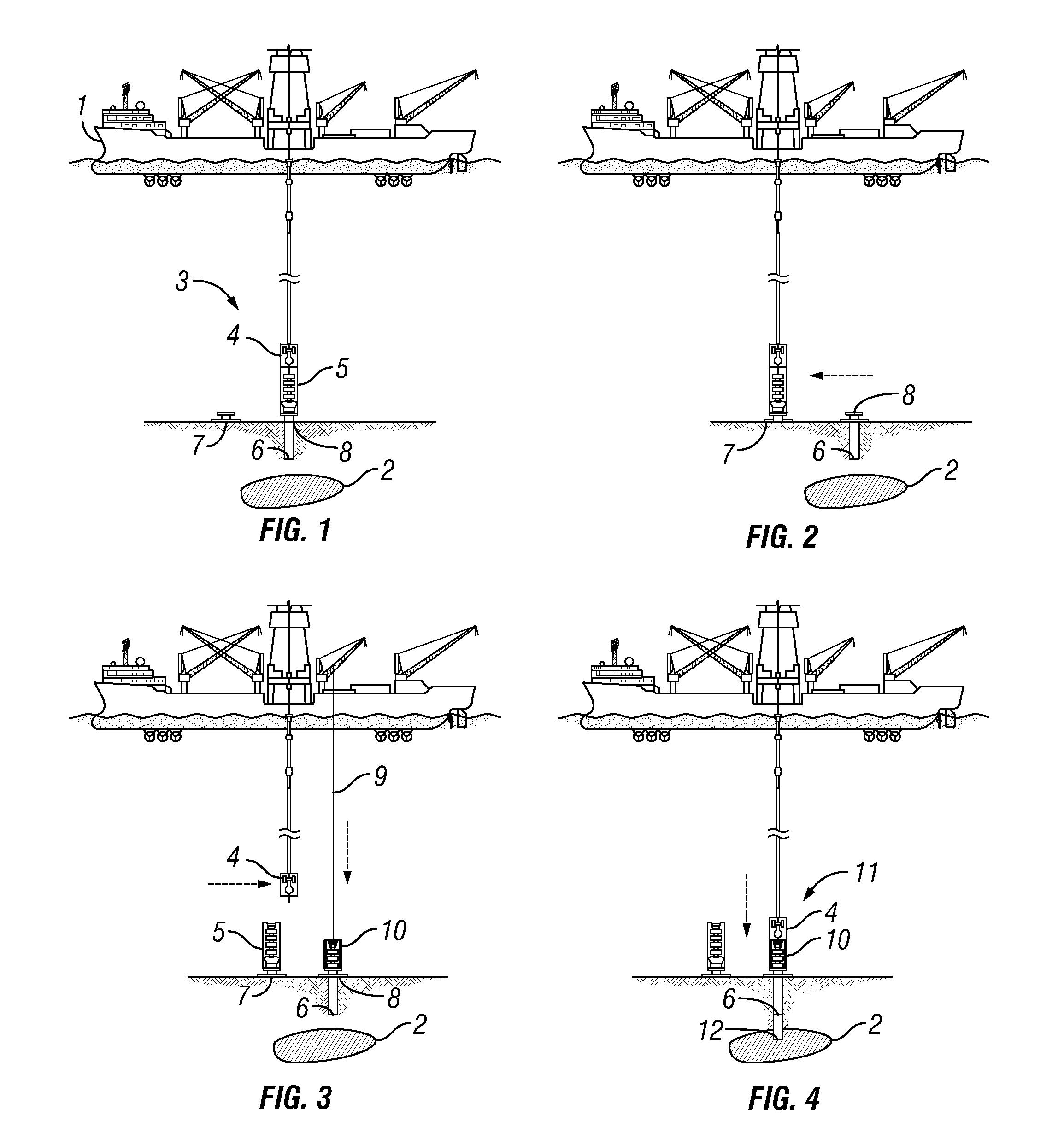

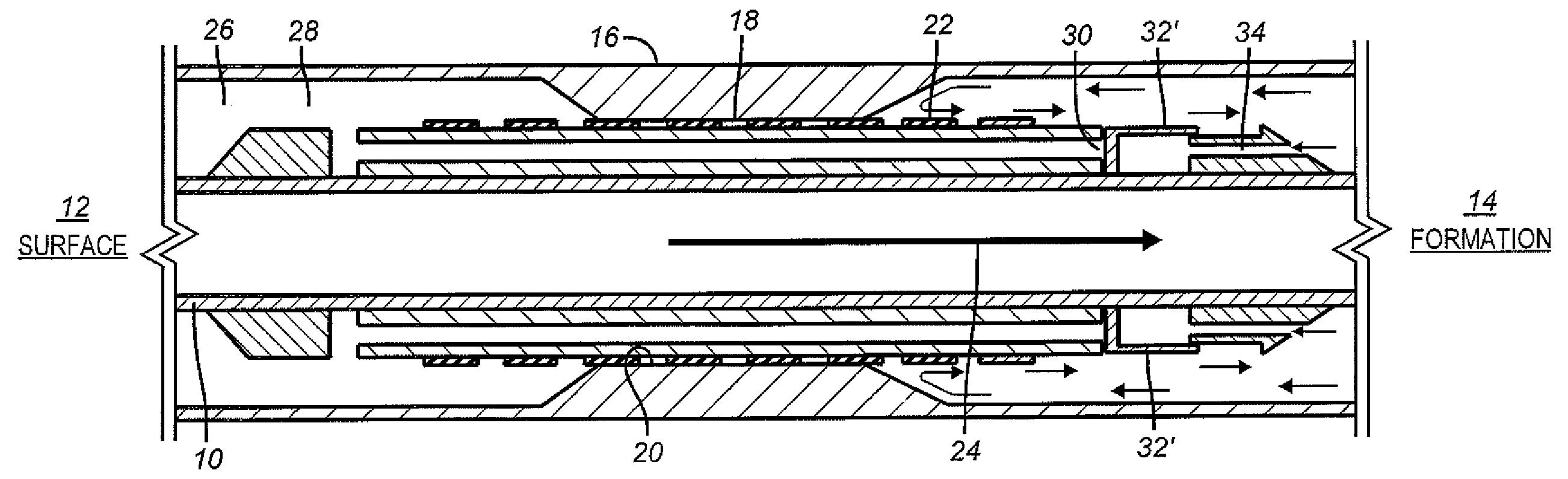

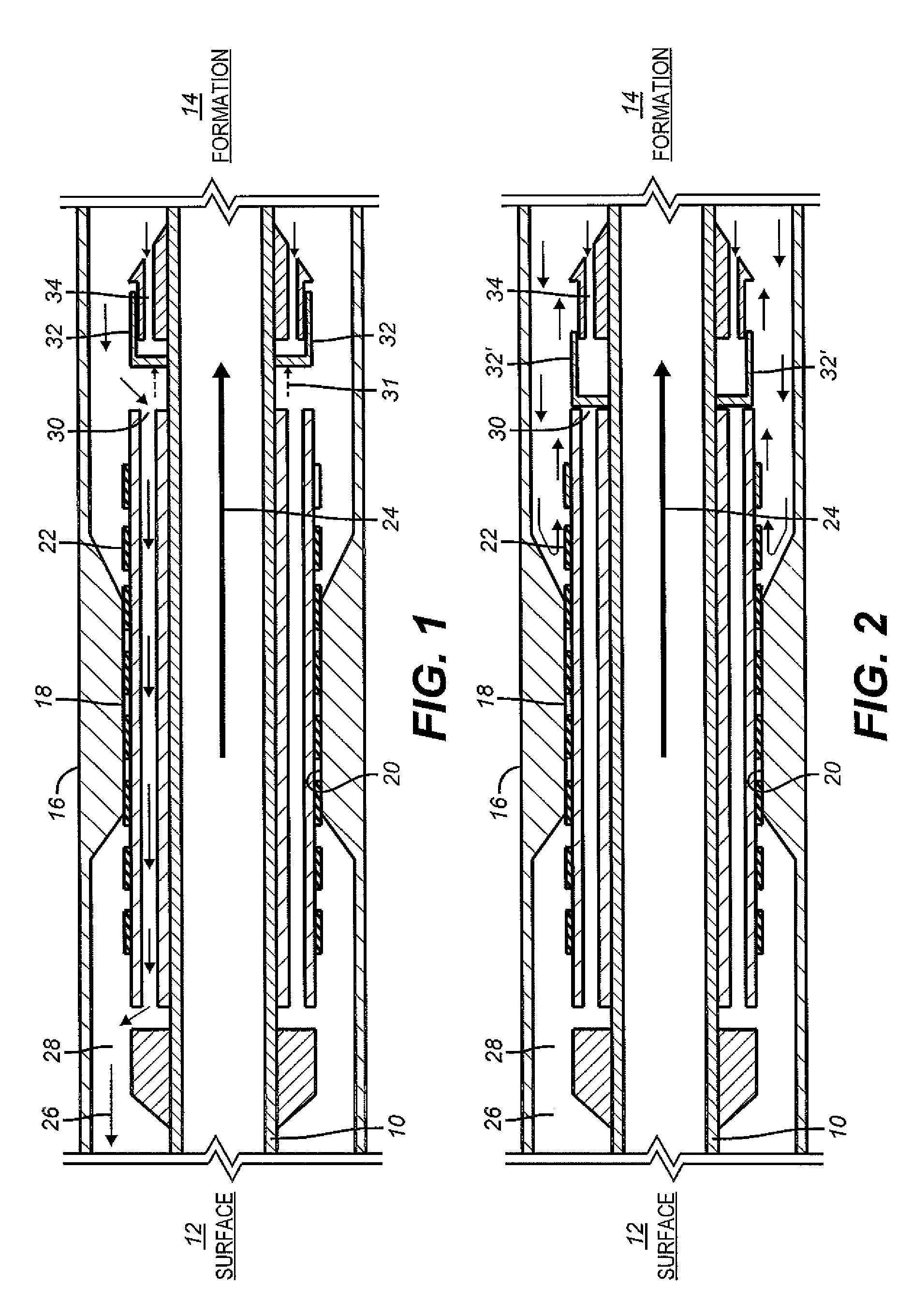

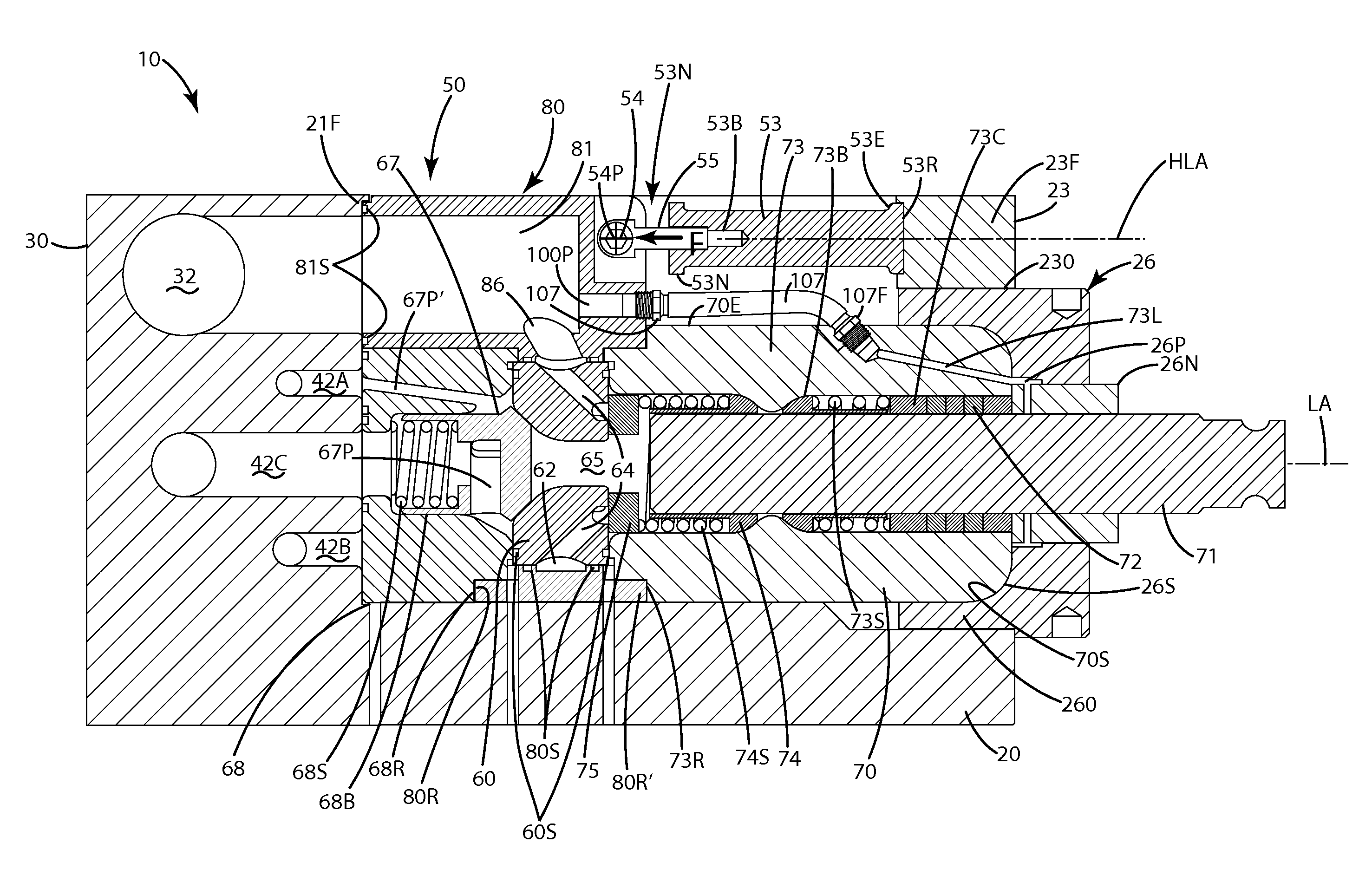

Dual-bop and common riser system

Owner:TRANSOCEAN OFFSHORE DEEPWATER DRILLING

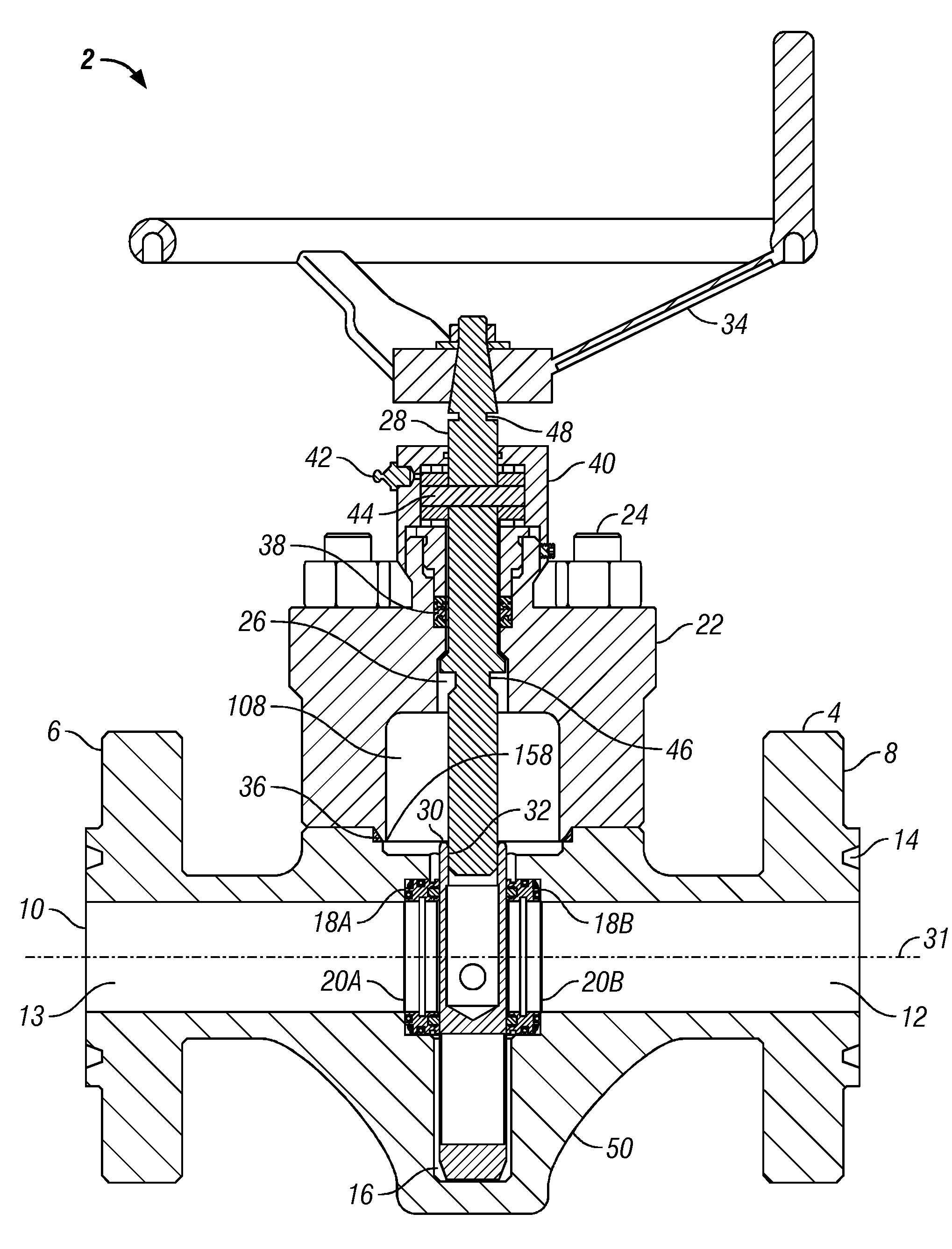

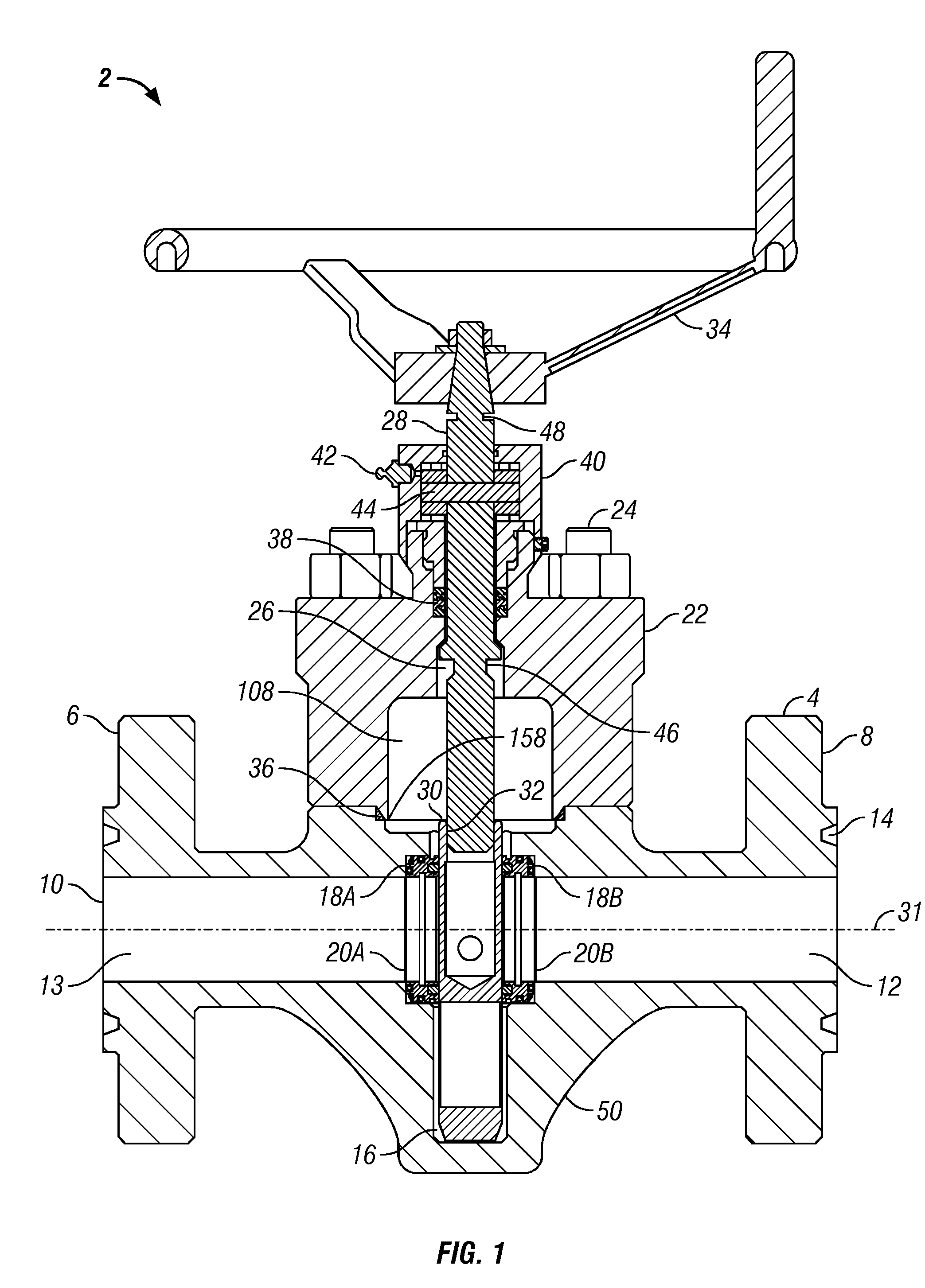

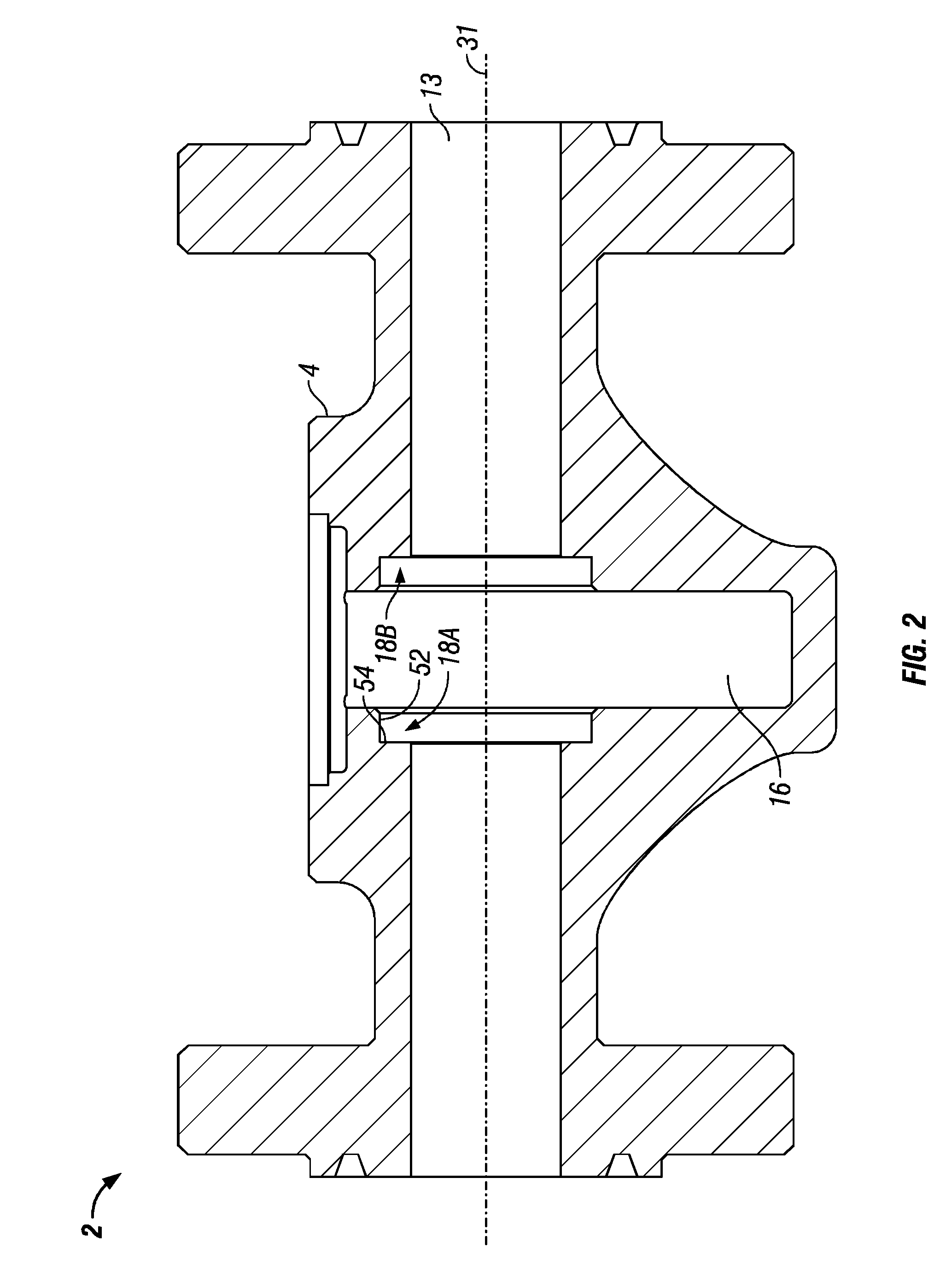

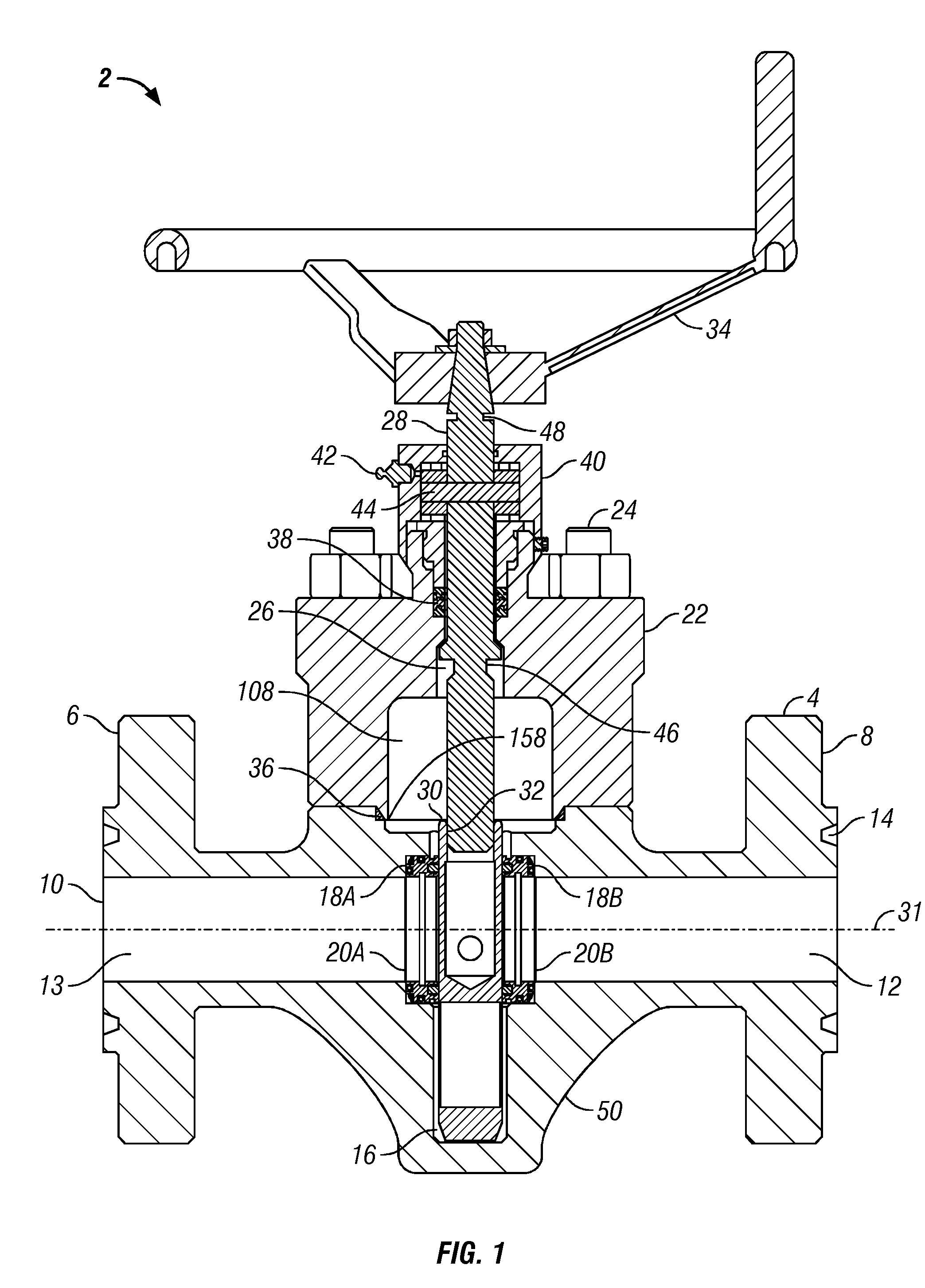

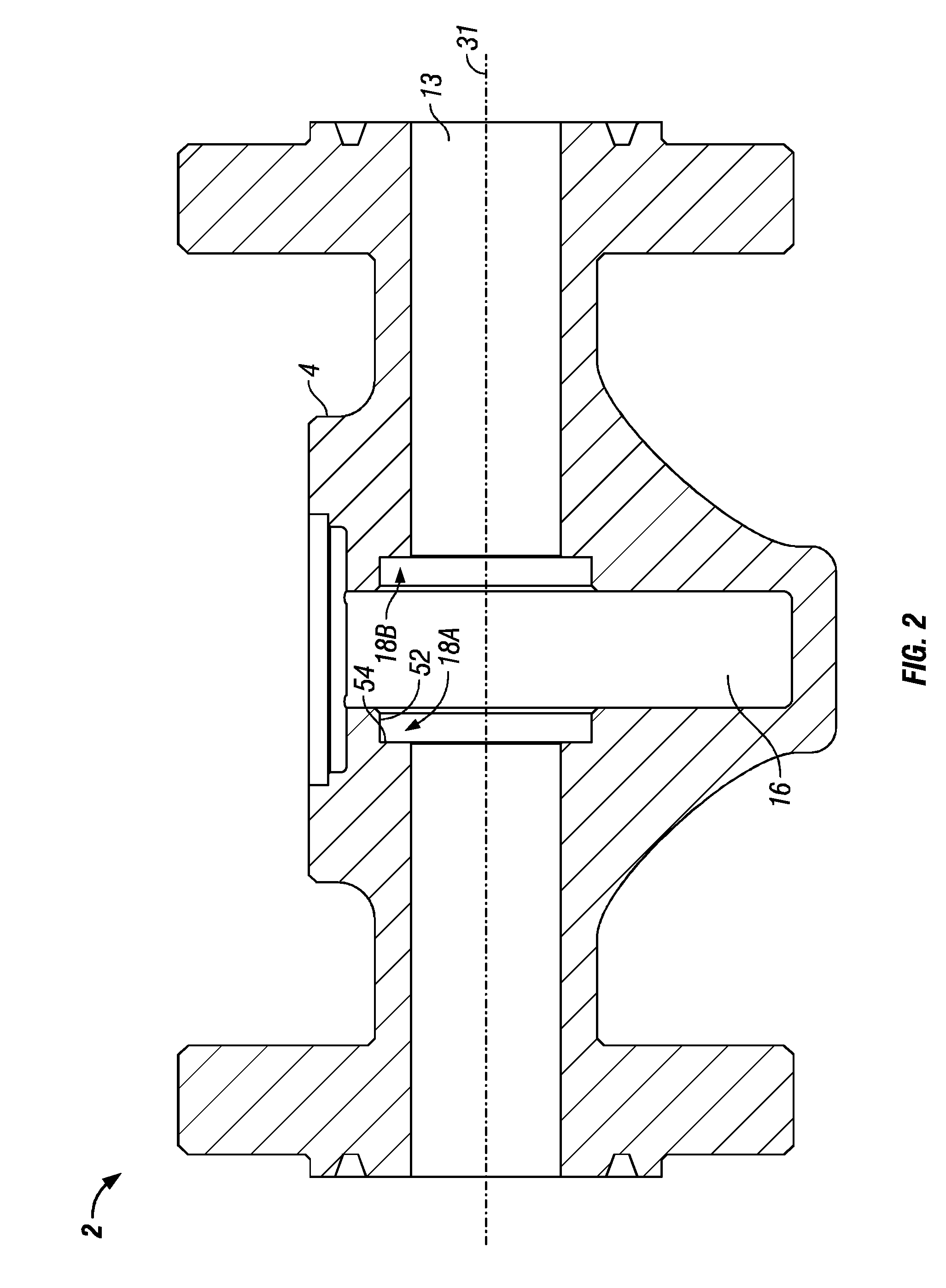

Pressure rated oil field gate valve

ActiveUS20090095934A1Minimal increase in priceMinimizes weight increaseSlide valveOil fieldEngineering

The disclosure provides an efficient design for a pressure rated oil field gate valve that meets the challenges of providing a quality product with minimal increase in price due to the design. It minimizes weight increase in the valve body over valves not meeting strict pressure specifications, due to strengthening ribs at strategic places without having to increase the overall body size as in commonplace in the industry. It provides redundancy of seals with minimal costs and no change in seat pockets over valves not capable of meeting the higher standards. It provides multiple shear points along a valve stem that can still allow a user to operate the valve from external to the valve bonnet. It further provides for additional sealing of the valve bonnet to the valve body by using elasticity in metal over long lengths to maintain a compression seal between the bonnet and the body.

Owner:T 3 PROPERTY HLDG

Annular pressure monitoring during hydraulic fracturing

Owner:BAKER HUGHES INC

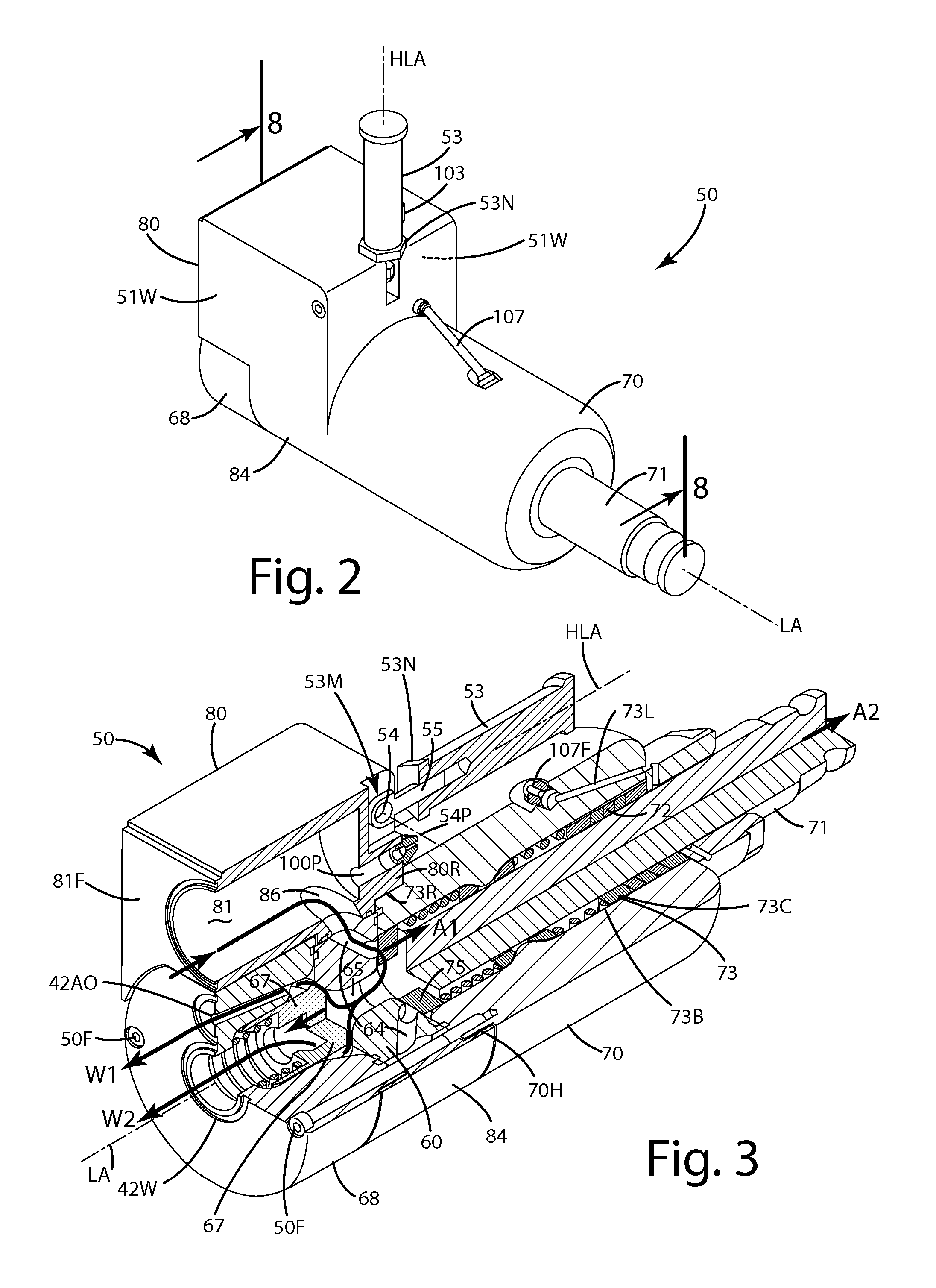

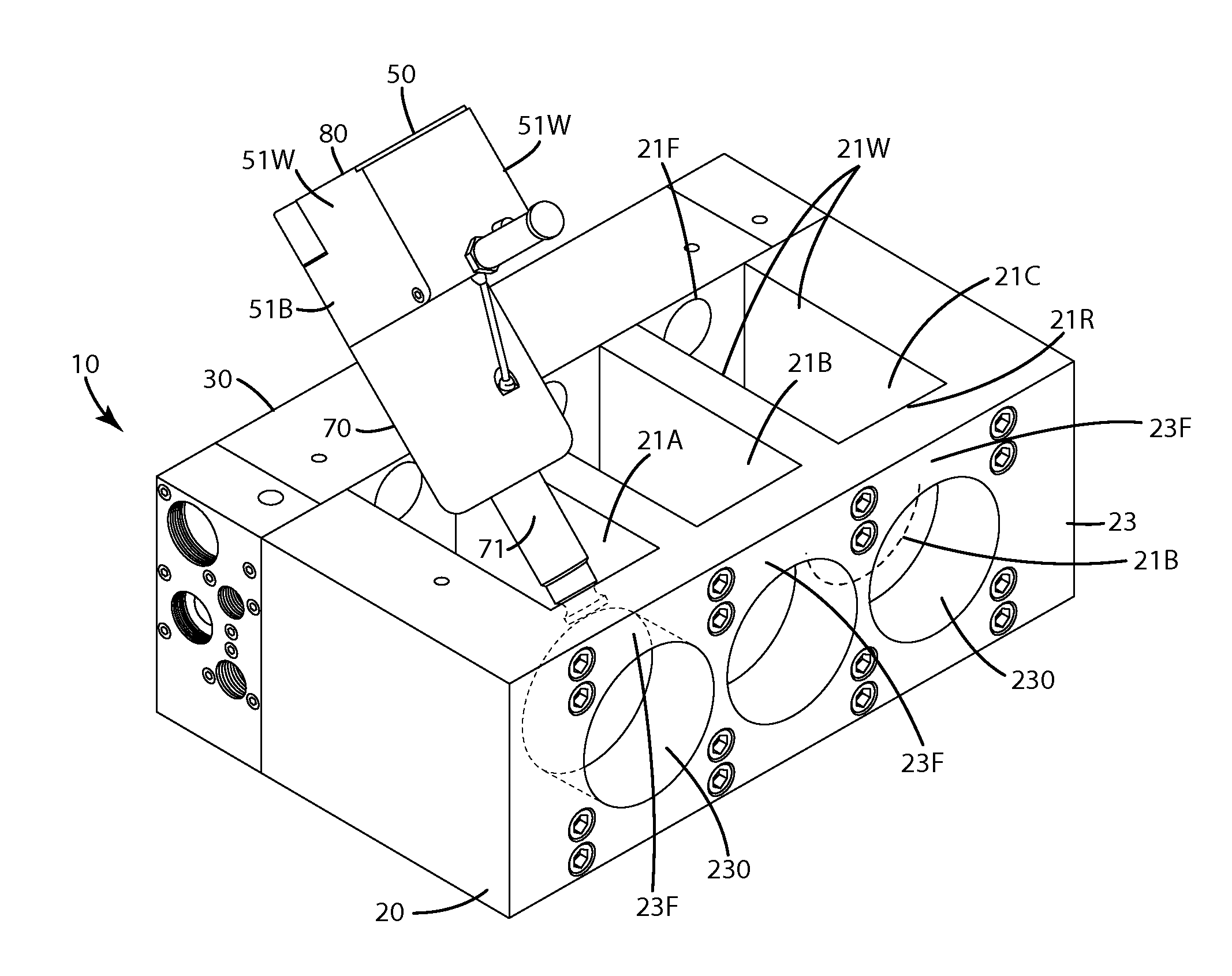

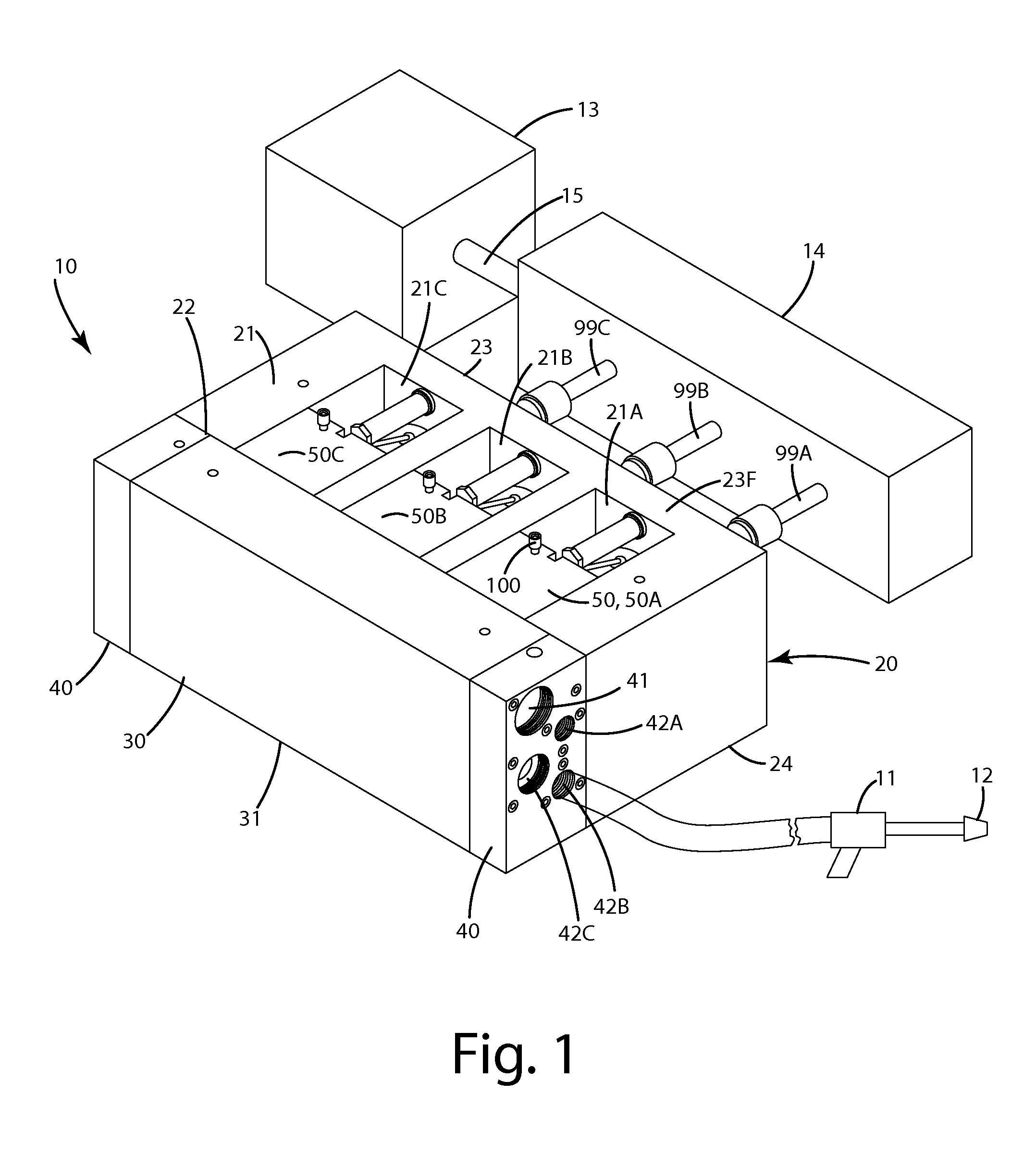

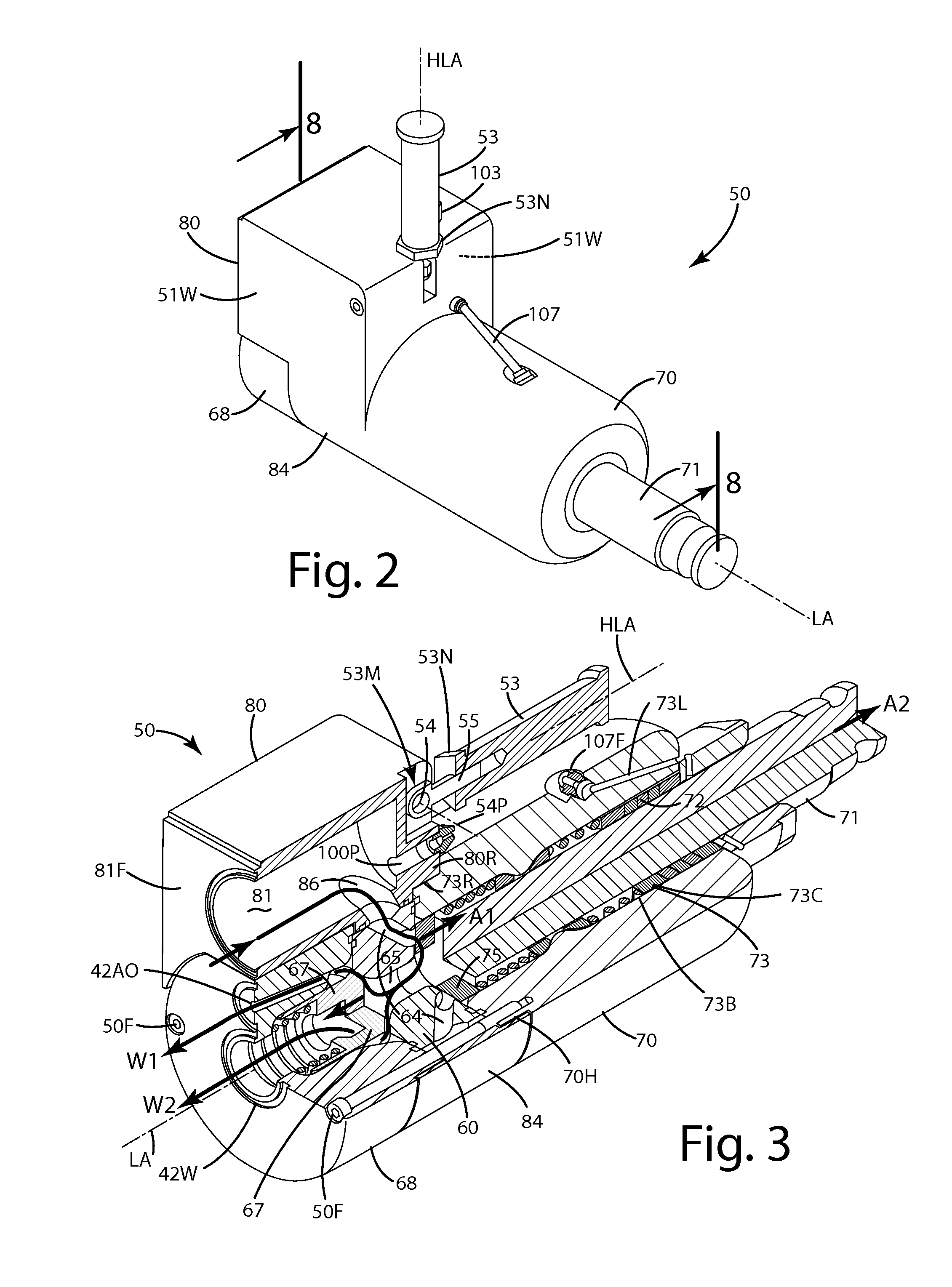

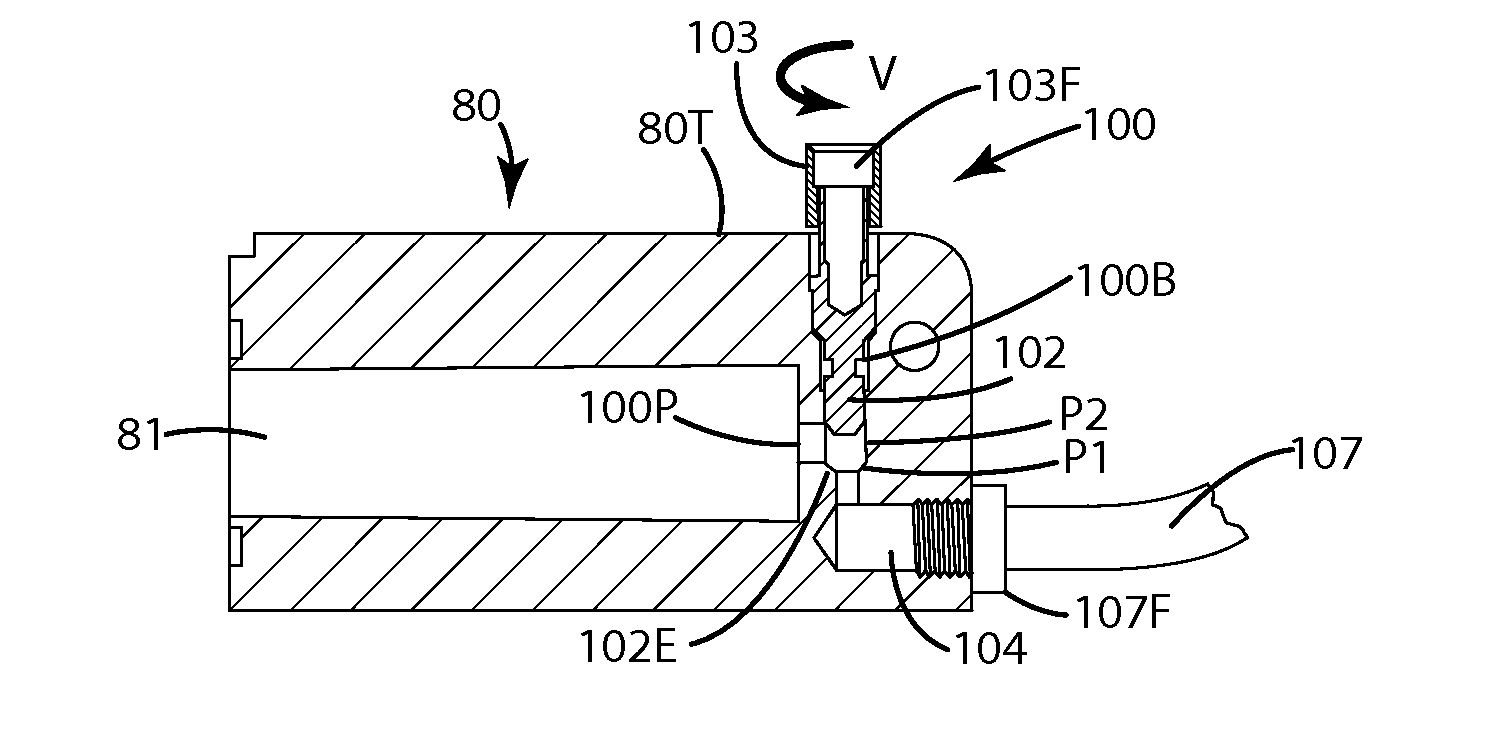

High pressure fluid system

ActiveUS9285040B2Easy to replaceMinimize the possibilityPlug valvesPositive displacement pump componentsCamHigh pressure

Owner:PSI PRESSURE SYST

High pressure fluid system

ActiveUS20150101681A1Easy to replaceMinimize the possibilityPlug valvesPositive displacement pump componentsHigh pressureCam

A high pressure fluid system including enhanced safety, maintenance and servicing features. The system can include a CAM assembly module, having a valve seat assembly, seal cartridge assembly and inlet manifold, that is easily installed in and removed from a frame and / discharge manifold as a single unit. A discharge manifold can isolate different pressure rated passageways of the system, and multiple rupture discs associated with the same. A discharge manifold end plate can be included to provide ease of repair of discharge outlets and to establish a plumbing system for the rupture discs. A quick coupler can facilitate connection between a plunger of the seal cartridge assembly and a cross head stub connected to a power frame. A lubrication valve assembly can provide and meter lubrication from a high pressure inlet source to a plunger and packing of the seal cartridge assembly.

Owner:PSI PRESSURE SYST

Machining method of super-austenite stainless steel plate coil

InactiveCN107419194AImprove board qualityHigh yieldTemperature control deviceMetal rolling arrangementsLaminar coolingHigh pressure water

A method for processing super austenitic stainless steel coils. The mass composition of super austenitic stainless steel coils is as follows: C: ≤0.020%, Si: ≤1.00%, Mn: ≤2.00%, P: ≤0.045%, S: ≤0.035%, N: ≤0.1%, Cr: 19.0~23.0%, Cu: 1.2‑2.0%, Mo: 4.0~5.0%, Ni: 23.0~28.0%, and the balance is Fe; the process flow of this processing method is: Heating → high-pressure water dephosphorization → rough rolling → finish rolling → laminar cooling → coiling; the thermal processing method of the present invention, by controlling the heating temperature, rolling temperature, rolling pass and rolling pressure rate of the slab, can Super austenitic stainless steel hot-rolled coils without edge cracks and surface cracks are produced, and the surface quality and yield of the plates are improved.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

Aircraft cabin pressure control system and method that improves cabin pressurization during take-off

ActiveUS20070102576A1Quickly and consistentlyFaster rateAir-treatment apparatus arrangementsEnergy efficient board measuresControl systemSimulation

A cabin pressure control system and method improves cabin pressurization during aircraft take-off operations. The cabin pressure control system sets a cabin pressurization rate limit based on a cabin pressurization rate error. The cabin pressurization rate error is derived from a comparison of a sensed cabin pressure rate-of-change value and a predetermined cabin pressurization rate value.

Owner:HONEYWELL INT INC

High pressure fluid system

ActiveUS20150101679A1Faster and easy to convertLess componentsPlug valvesPositive displacement pump componentsComputer moduleEngineering

Owner:PSI PRESSURE SYST

Gas turbine engine with variable overall pressure ratio

Owner:RTX CORP +1

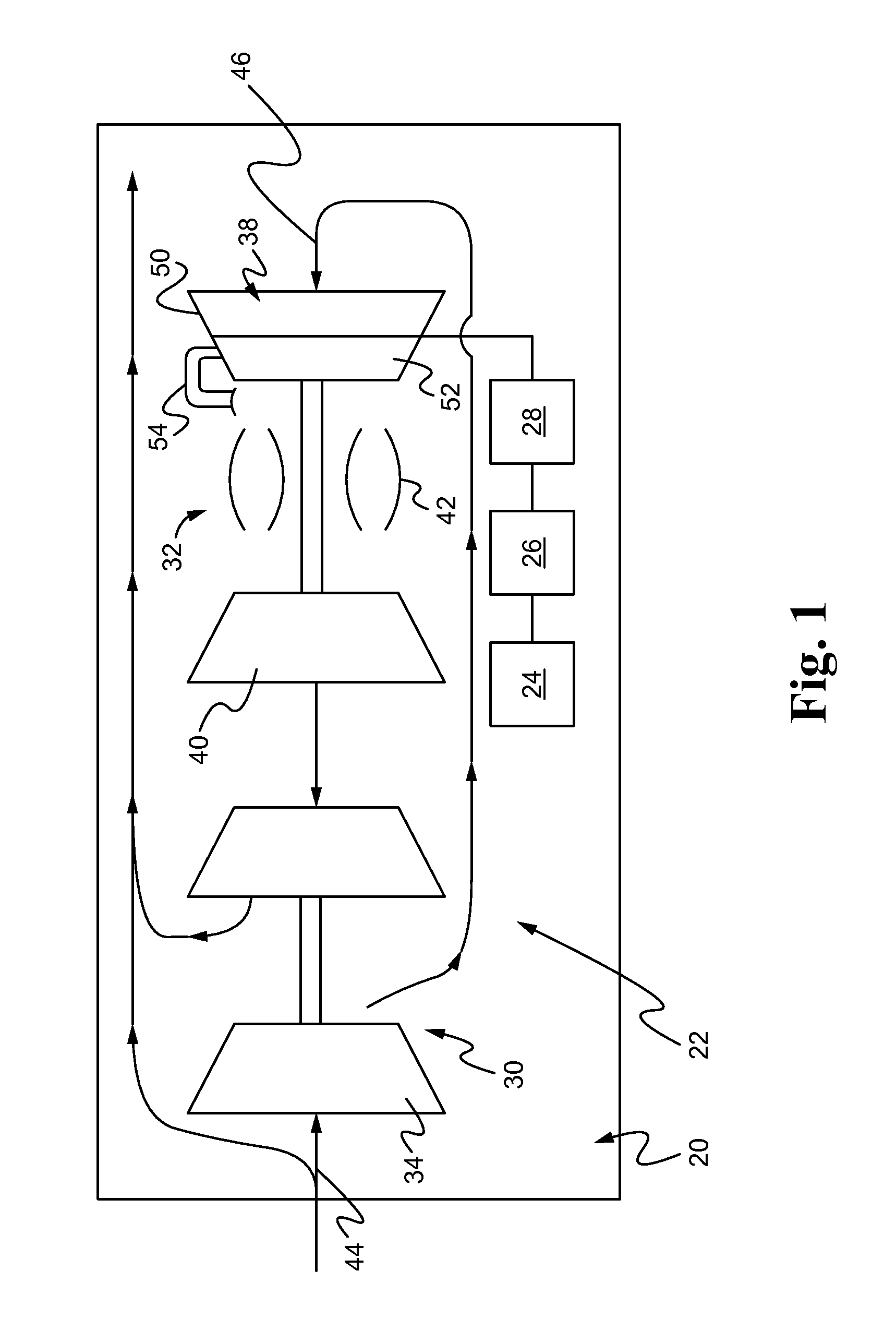

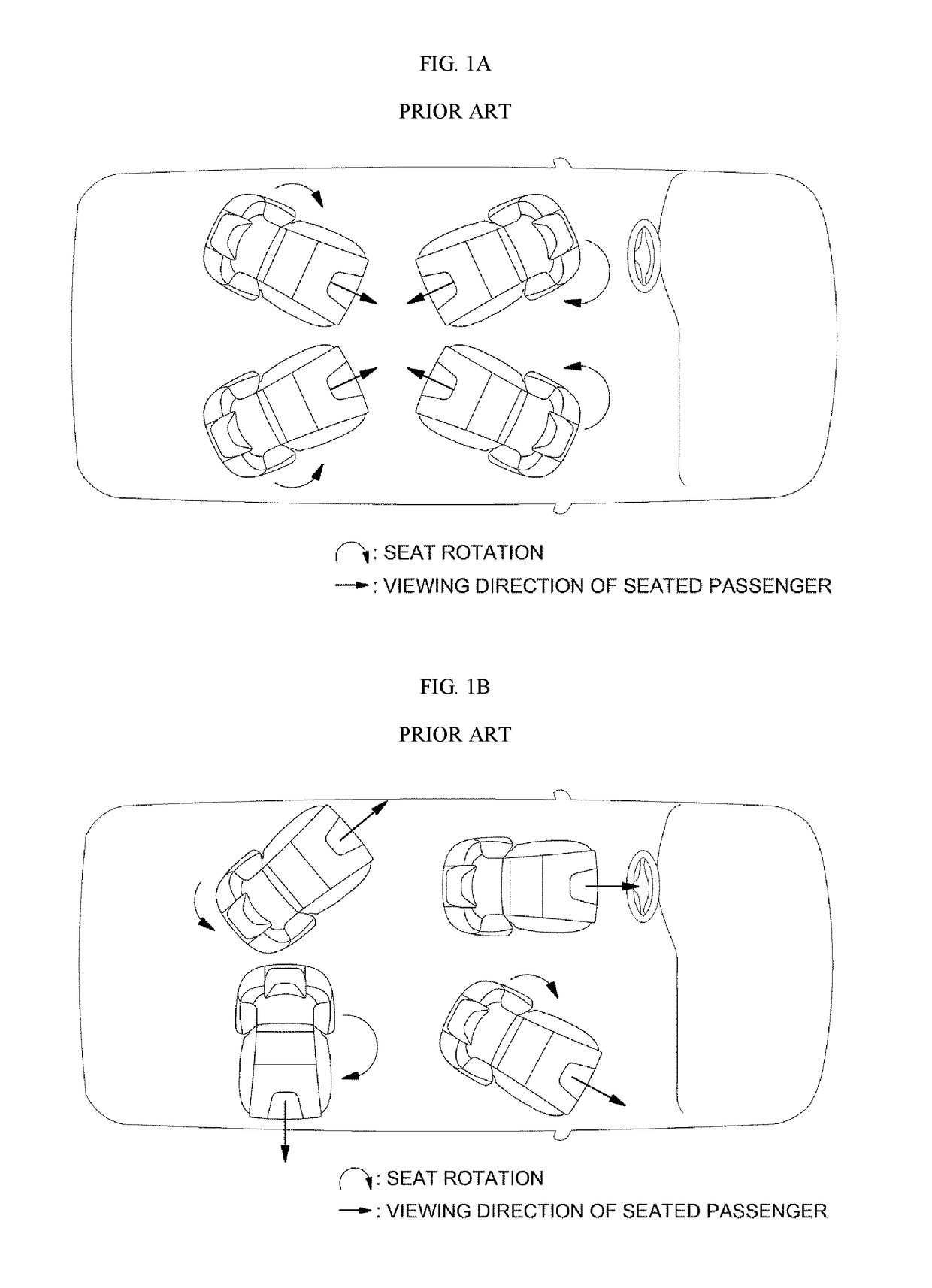

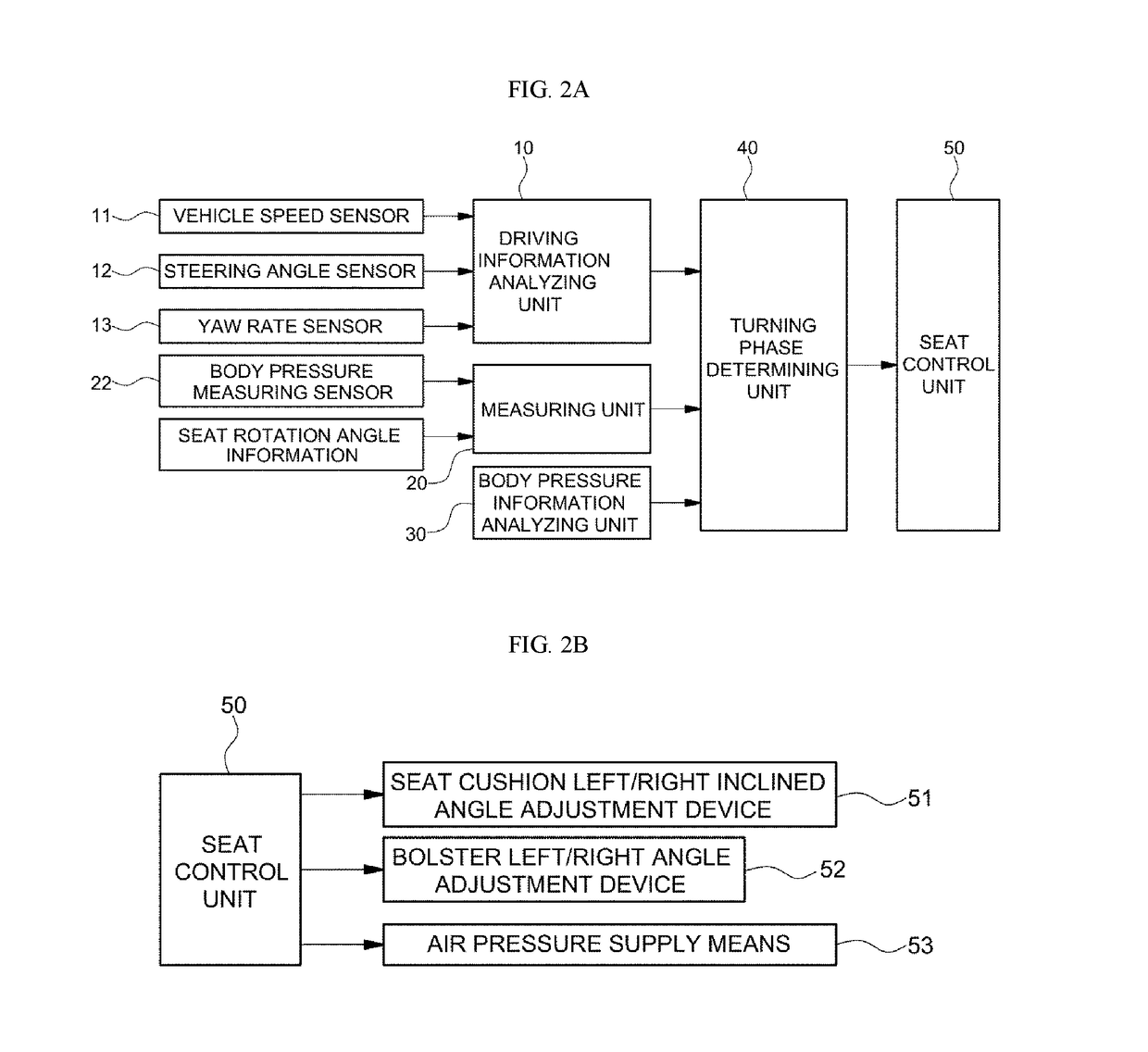

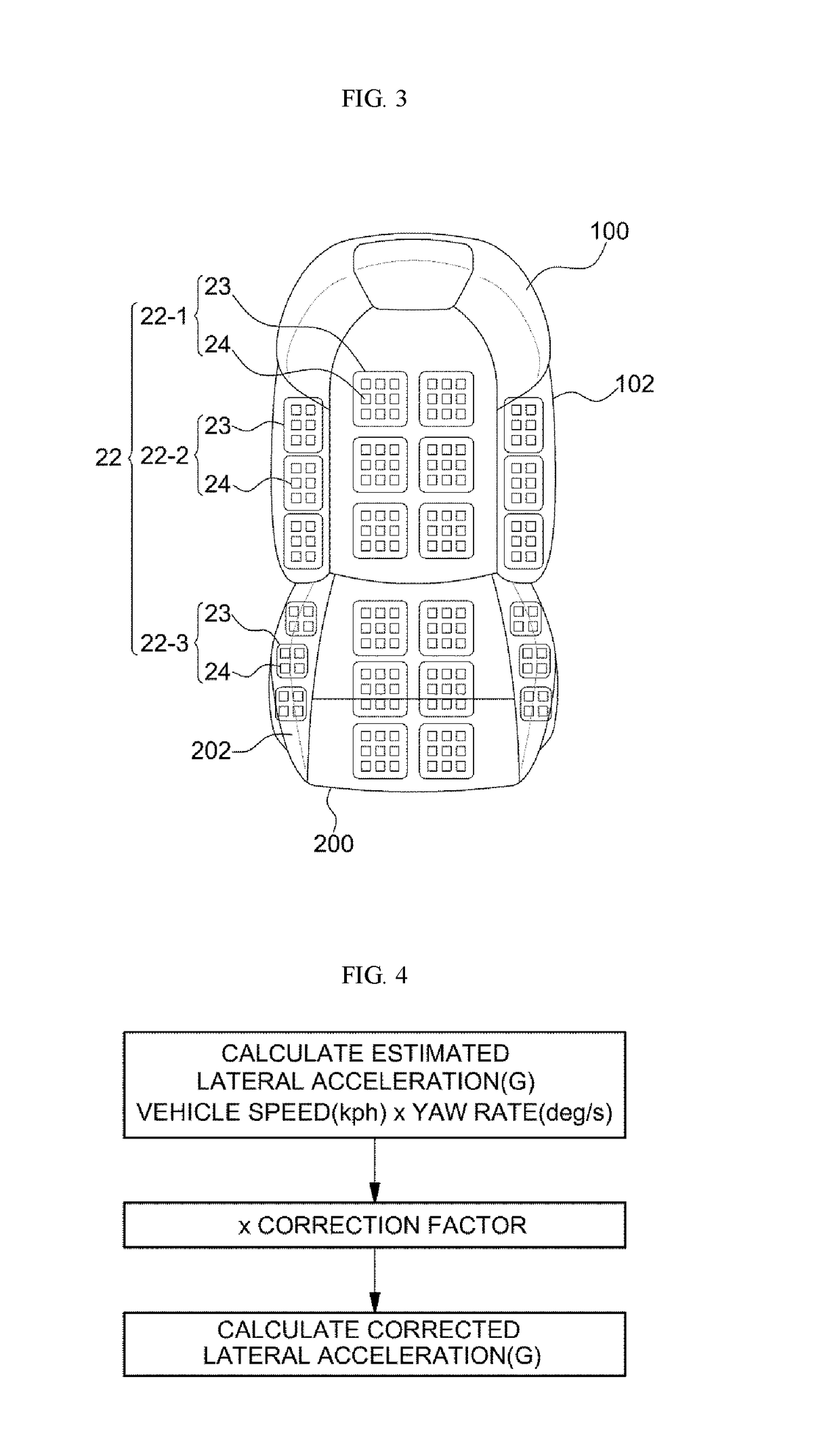

System and method for controlling rotating type seat of self-driving vehicle

A system and a method are provided for controlling a rotating type seat of a self-driving vehicle. In particular, seat position and bolster volume are adjusted based on a pressure rate in response to a vehicle turning when seat of the self-driving vehicle is rotationally adjusted in a desired direction. Accordingly, body displacement due to a centrifugal force and inertia is supported and a stable seating feeling is provided to the passenger.

Owner:HYUNDAI MOTOR CO LTD +1

Grinding method for high-grade stainless steel frosted plate surface

InactiveCN101168243AImprove yieldImprove hit rateBelt grinding machinesUltrasound attenuationSheet steel

Provided is a grinding method of the surface of a high-grade stainless steel frosted plate. The steps of grinding method include that, (1) throwing pills, firstly, after a steel plate is annealed, cooled and scale broken, the steel plate is taken into a pill throwing machine, new steel pills are stopped from being added at the time of five hours earlier of the steel plate being taken into the pill throwing machine, then, when narrow materials throws pills, throwing head speed is 1850-2000 revolutions per minute, and when broad materials throws pills, throwing head speed is 1600-1700 revolutions per minute, (2) rolling overall pressure rate of a cold rolling being equals to or over 65%, (3) starting a first upper grinding head, a second upper grinding head and a third grinding head in the grinding time, firstly, the grain size of a abrasive band is polished, the new abrasive band is firstly ground to be attenuated on other steel coils, an abrasive band of the attenuation equal to or over 100 minutes and an abrasive band of the attenuation equals to or over 200 minutes, secondly, the abrasive band of the attenuation which equals to or over 100 minutes is mounted on the first upper grinding head, and then two abrasive bands of the attenuation equal to or over 200 minutes are installed on the second upper grinding head and the third grinding head to be precisely ground. The grinding method improves the surface quality of the frosted plate of the cold rolling and reduces the surface defects of the steel plate.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Method and apparatus for gas flow control

ActiveUS20140367596A1Diaphragm valvesOperating means/releasing devices for valvesEngineeringProduct gas

Owner:PIVOTAL SYST CORP

Fluid injector with vent/proportioner ports

A fluid injector made of pressure rated components that attach to a fluid flow line so that flow is transferred from the flow line, into the injection unit and back to the fluid flow line. The inlet flow is used to pressurize the storage tank and provide a solution to mix with injection solutions in the tank to provide an accurate preset or adjustable injection rate into the fluid flow line. Vent / proportioner ports provide back flow protection, prevent fluid from siphoning from the storage tank, provide an internal air release port and set injection ratios. A mixing control valve adjusts the injection ratios by mixing outgoing injection solutions with incoming fluid from the fluid flow line. Flexible bladders isolate one or more injection solutions within one storage container which are injected simultaneously at independent injection rates.

Owner:E Z FLO INJECTION SYST

Pressure rated oil field gate valve

The disclosure provides an efficient design for a pressure rated oil field gate valve that meets the challenges of providing a quality product with minimal increase in price due to the design. It minimizes weight increase in the valve body over valves not meeting strict pressure specifications, due to strengthening ribs at strategic places without having to increase the overall body size as in commonplace in the industry. It provides redundancy of seals with minimal costs and no change in seat pockets over valves not capable of meeting the higher standards. It provides multiple shear points along a valve stem that can still allow a user to operate the valve from external to the valve bonnet. It further provides for additional sealing of the valve bonnet to the valve body by using elasticity in metal over long lengths to maintain a compression seal between the bonnet and the body.

Owner:T 3 PROPERTY HLDG

Method for the continuous production of methyl formate

InactiveUS6921833B1High yieldCheap preparationPressurized chemical processOrganic compound preparationAlkaline earth metalAtmospheric pressure

A description is given of a process for preparing methyl formate by reacting excess methanol with carbon monoxide under superatmospheric pressure and at elevated temperature in the presence of alkali metal methoxide or alkaline earth metal methoxide as catalyst in a pressure-rated reactor, in which the use of at least two reactor elements, preferably operated in countercurrent, at about 100° C. and a pressure of about 100 bar in combination with a solids-free desalting of the reaction product makes possible very economical, largely trouble-free production of methyl formate in any desired quality and with a very good production capacity.Furthermore, the process for solids-free desalting and apparatuses for carrying out this process are described.

Owner:BASF AG

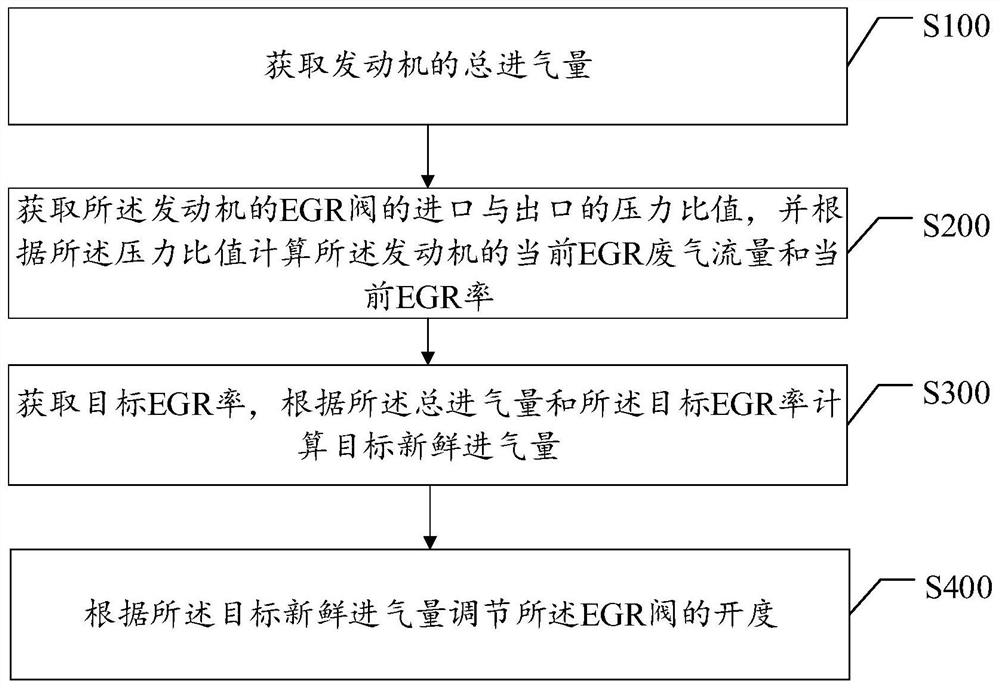

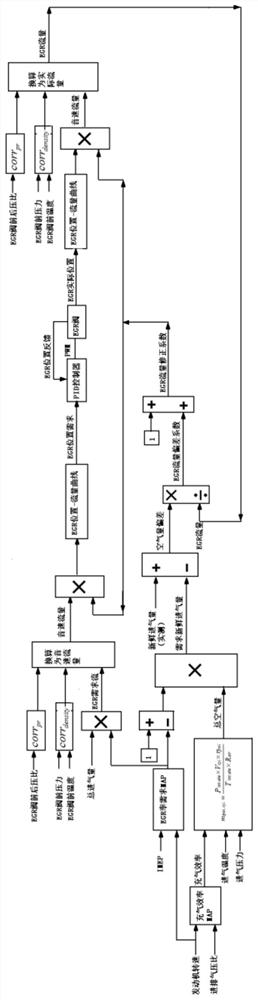

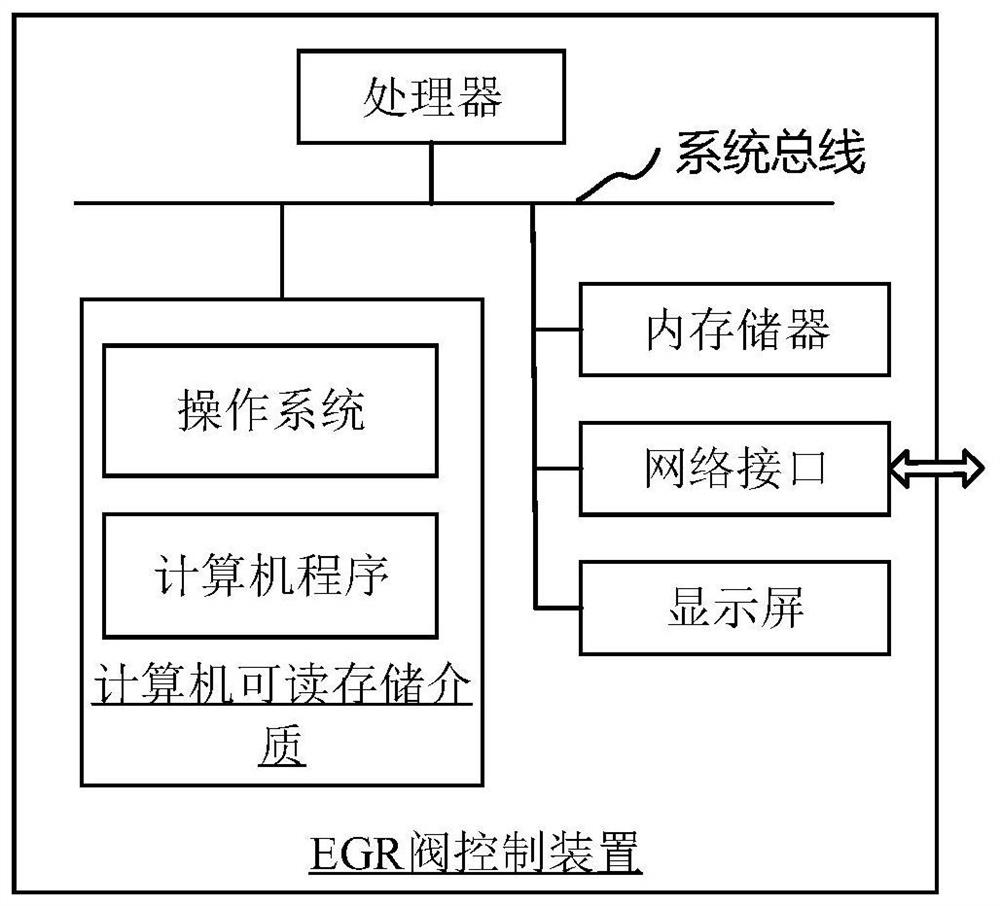

EGR valve control method and device and computer readable storage medium

InactiveCN112594071AReal-time calculation of target fresh air intakeElectrical controlMachines/enginesThermodynamicsFresh air

The invention discloses an EGR valve control method and device and a computer readable storage medium. The method comprises the steps of obtaining the total air inflow of an engine; obtaining a pressure ratio of an inlet to an outlet of an EGR valve of the engine, and calculating the current EGR waste gas flow and a current EGR rate of the engine according to the pressure ratio; obtaining a targetEGR rate, and calculating the target fresh air inflow according to the total air inflow and the target EGR rate; and adjusting the opening degree of the EGR valve according to the target fresh air inflow. The total air inflow of the engine is obtained, the current EGR waste gas flow is calculated through the pressure ratio of the front portion and the rear portion of the EGR valve, the target fresh air inflow is calculated in real time according to the total air inflow of the engine and the target EGR rate, and then the actual fresh air inflow reaches the target fresh air inflow by adjustingthe EGR opening degree, so that the current EGR rate reaches the target EGR rate.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

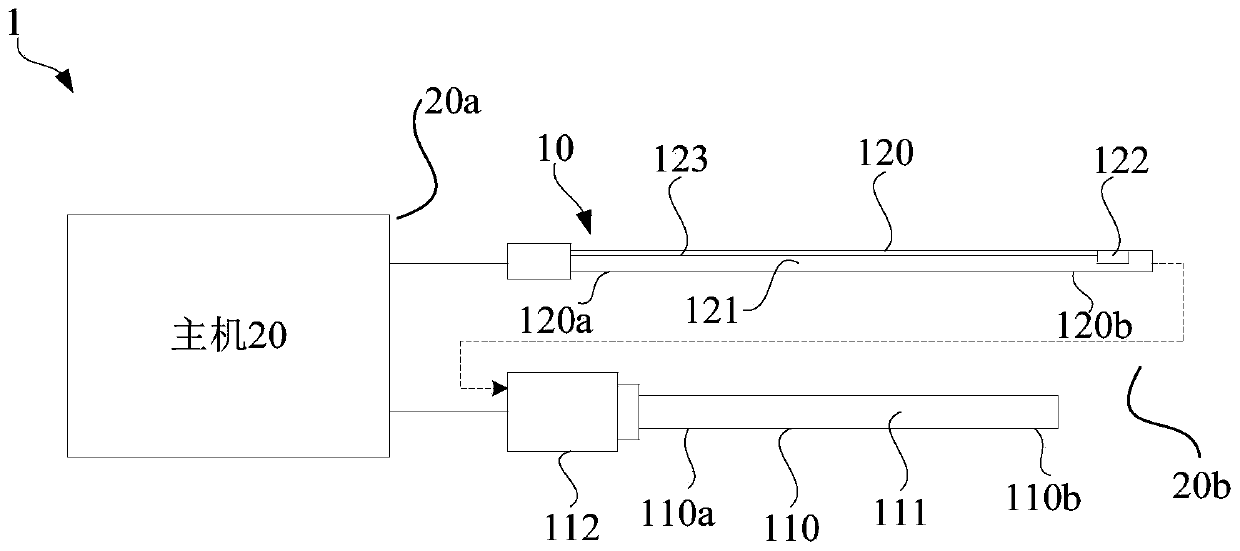

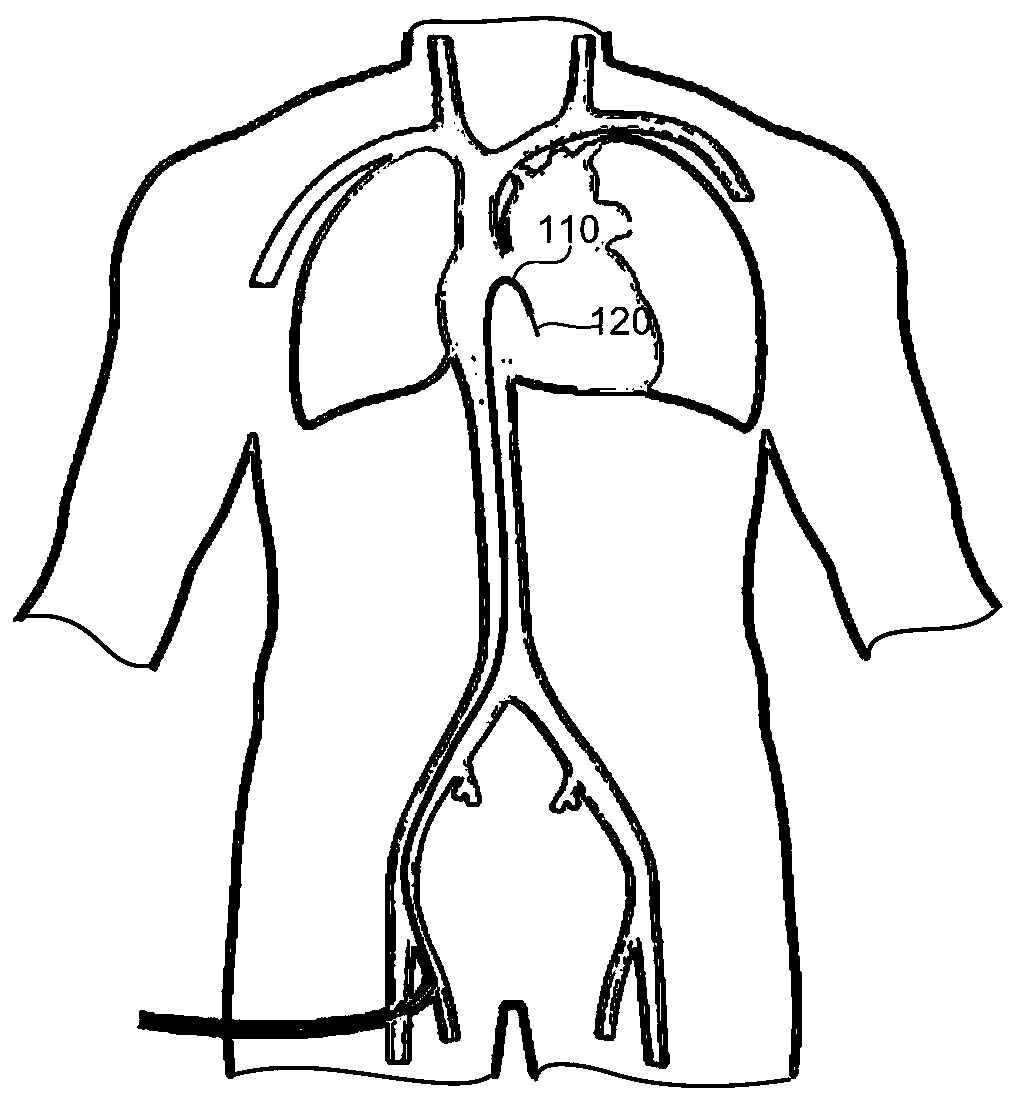

System and method for tracking cardiac cycle event by using blood pressure

The invention relates to a system for tracking a cardiac cycle event by using blood pressure. The system comprises a pressure measuring device and a host, wherein the pressure measuring device is configured to measure the pressure close to the proximal side in a blood vessel and the pressure far away from the proximal side in the blood vessel respectively and generate a first pressure signal and asecond pressure signal; the host is connected with the pressure measuring device and receives the first pressure signal and the second pressure signal; the host distinguishes various cardiac cycles based on the first pressure signal and the second pressure signal, calculates the ratio of the pressure value of the second pressure signal to the pressure value of the first pressure signal corresponding to the pressure value of the second pressure signal to obtain a pressure ratio value and generates a target pressure waveform; the host acquires a target derivative waveform based on the target pressure waveform, and determines a target period in any cardiac cycle based on the target derivative waveform, and thus, an average value of the corresponding pressure ratio value in the target periodis obtained; and the target period is a period in which the derivative value of the target derivative waveform in the cardiac cycle changes within a preset numerical range.

Owner:SHENZHEN INSIGHT MED CO LTD

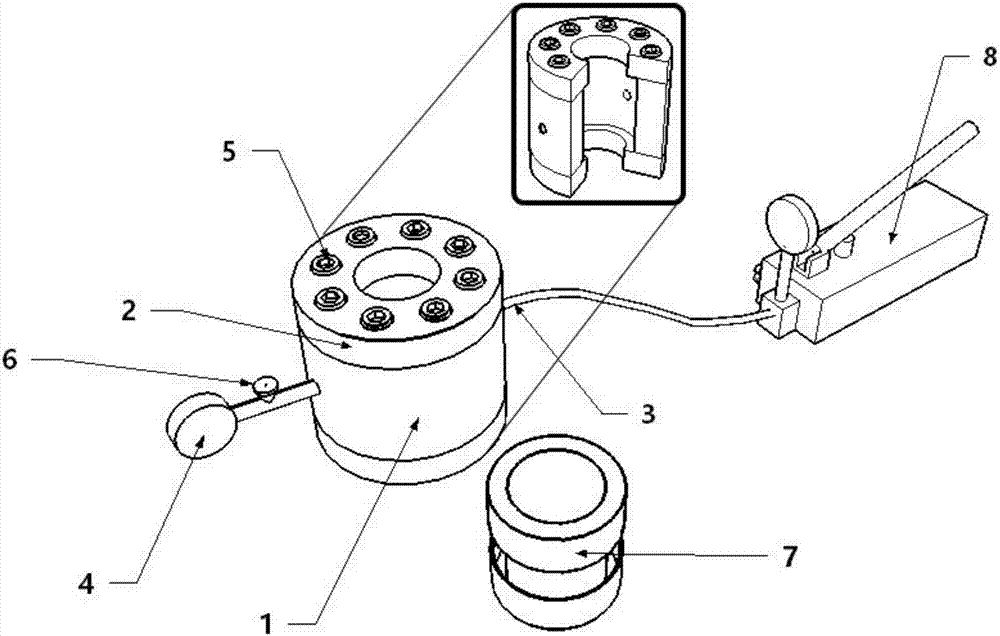

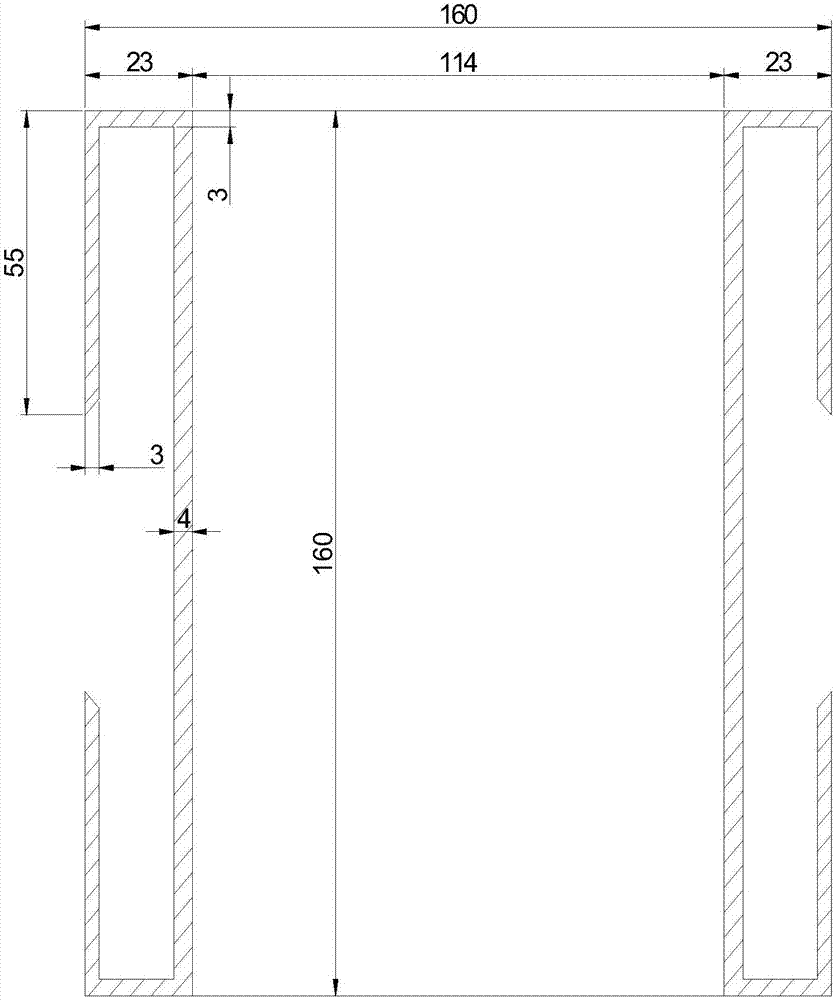

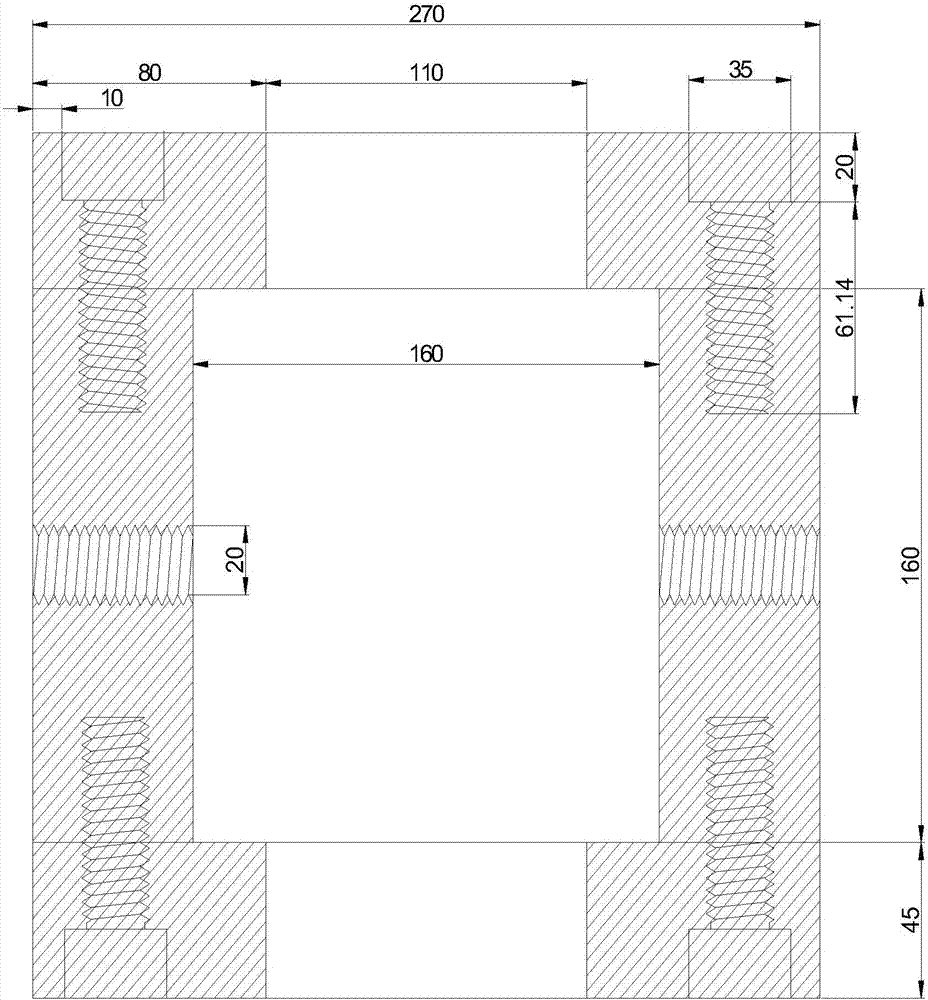

Hollow inclusion crustal stress measurement self-sealing multi-aperture universal high pressure confining pressure rate meter

InactiveCN107101875AEasy to operateStable confining pressureMaterial strength using tensile/compressive forcesRock coreEngineering

The invention provides a hollow inclusion crustal stress measurement self-sealing multi-aperture universal high pressure confining pressure calibration instrument, and belongs to the technical field of rock strength measurement. The high pressure confining pressure calibration instrument cabin of the high pressure confining pressure calibration instrument is provided with an oil inlet, an exhaust port and an oil pressure gauge, both ends of the cabin are provided with cabin covers with different diameters, cabin cover plates are matched according to rock core sizes, a back double groove universal self-sealing high strength polyurethane rubber leather sheath is arranged in the cabin, hydraulic oil is fully filled between the leather sheath and the high pressure confining pressure calibration instrument cabin, and a test rock sample is put and extruded into the back double groove universal self-sealing high strength polyurethane rubber leather sheath. The whole system adopts a hydraulic oil self sealing principle, the cabin cover plates are matched according to the rock core sizes, the oil inlet is connected with a high pressure hand pump by a high pressure oil pipe, the rubber leather sheath is adopted to realize stable loading of confining pressure 80MPa, and the confining pressure in the high pressure confining pressure calibration instrument can be in real time monitored. The high pressure confining pressure calibration instrument can simulate the crustal stress in a deep rock mass and monitor deformation before the rock sample is loaded and destroyed, the operation is simple, and the confining pressure is stable.

Owner:UNIV OF SCI & TECH BEIJING

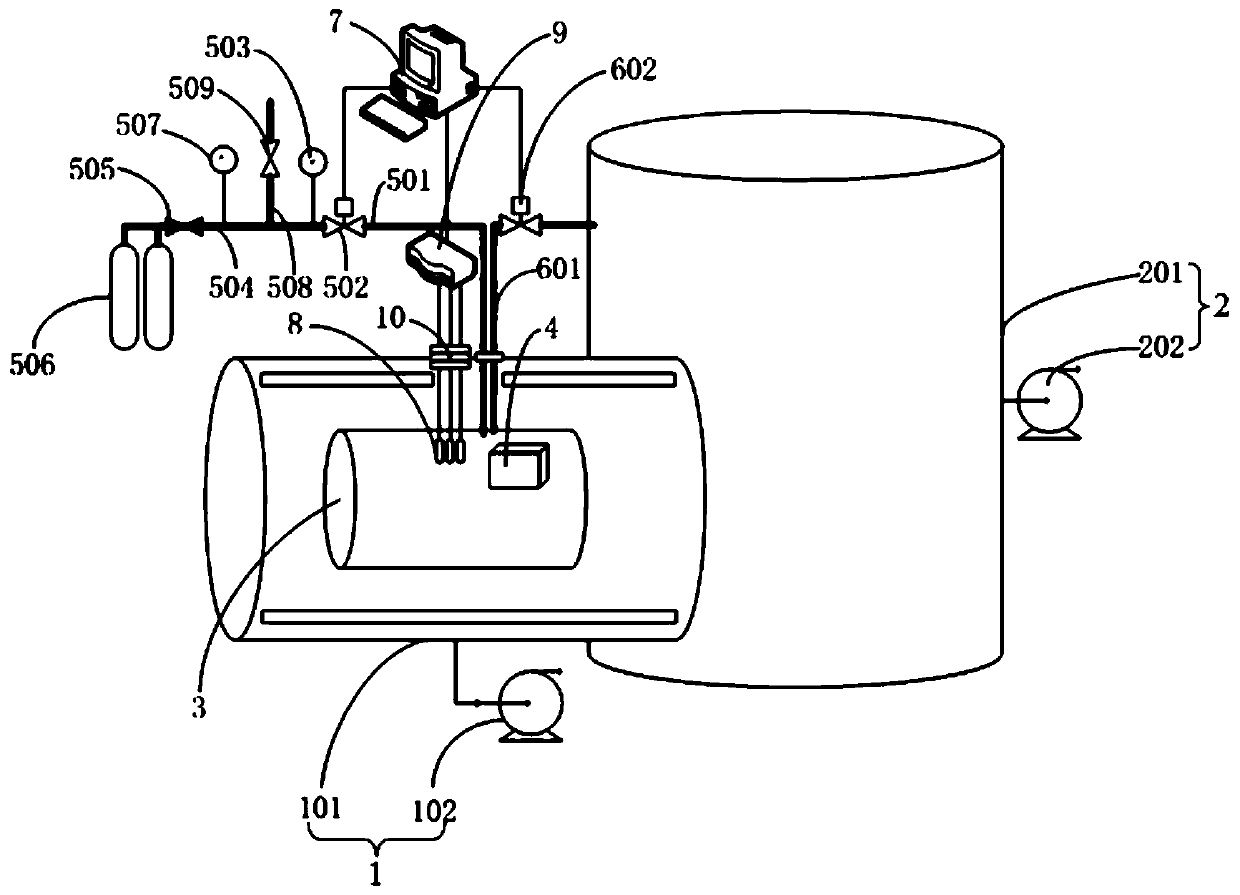

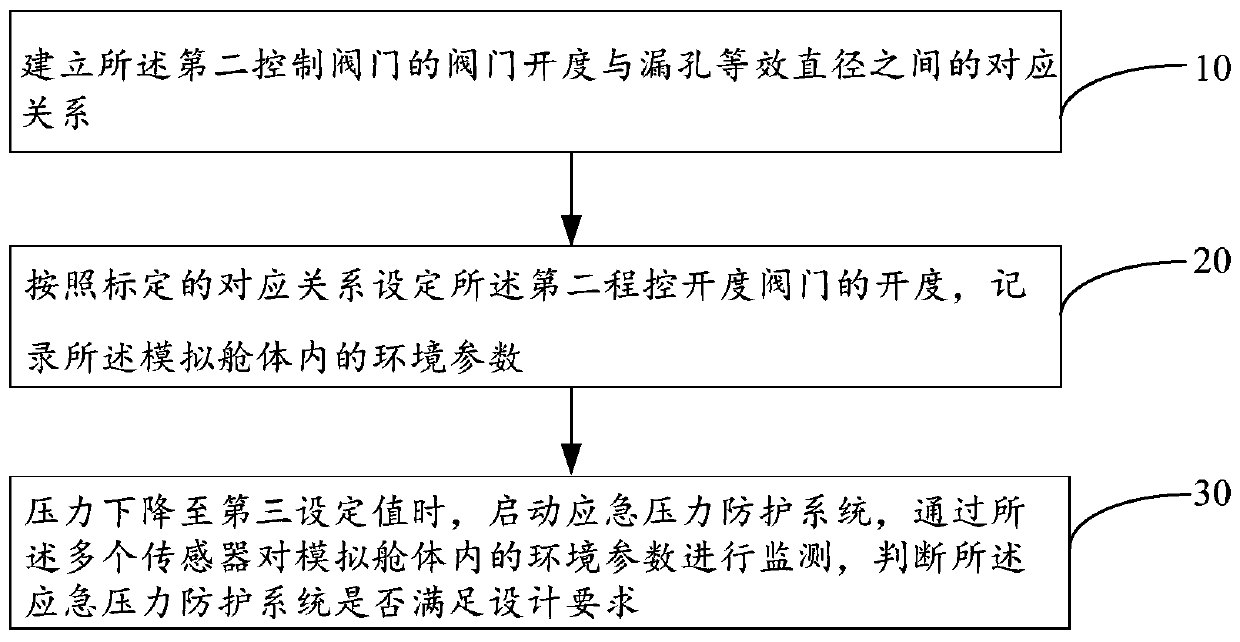

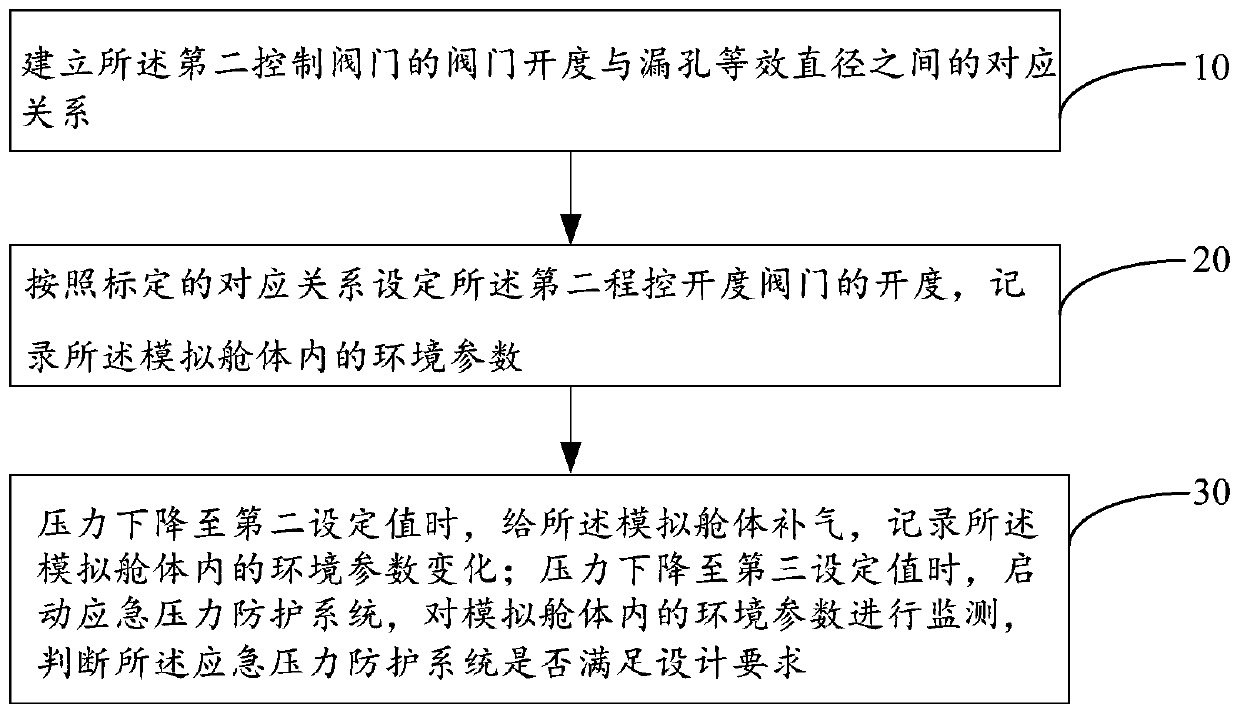

Test system and test method for pressure protection system of spacecraft sealed cabin

ActiveCN110525698AThe test result is validCosmonautic condition simulationsFluid pressure measurementSpace environmentEngineering

The application discloses a test system and a test method for a pressure protection system of a spacecraft sealed cabin. The test system comprises a first space environment simulation device, a secondspace environment simulation device, a simulation cabin body, an emergency pressure protection system, an air inlet pipeline assembly and a pressure relief pipeline assembly, wherein the pressure relief pipeline assembly comprises a pressure relief pipeline, a second program-controlled opening valve is arranged on the pressure relief pipeline, the air inlet pipeline assembly comprises an air inlet pipeline, and the air inlet pipeline is provided with a first program-controlled opening valve; wherein the second program-controlled opening valve controls the pressure relief rate of the pressurerelief pipeline to the second space environment simulation equipment to realize the simulation of different leakage holes of different spacecrafts in orbit, and the first program-controlled opening valve controls the re-pressure rate of the air inlet pipeline to the simulation cabin body for calibrating the equivalent diameters of the leakage holes. According to the test system and the test method, the working process of the pressure protection system in the cabin is simulated when the spacecraft loses pressure in orbit, and the performance of the pressure protection system is evaluated to provide support for the safety of future manned spacecraft.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

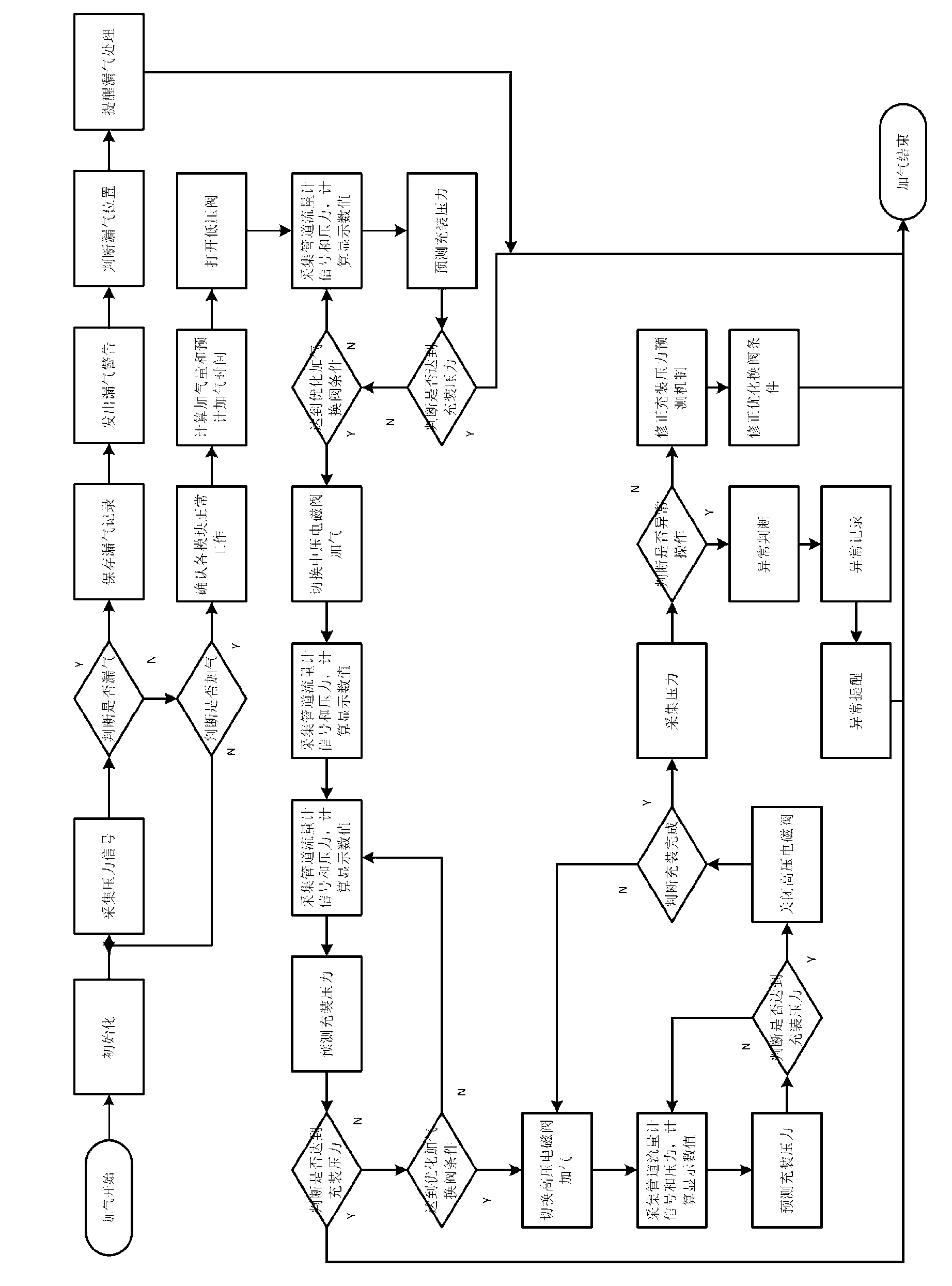

Self-feedback control method of gas dispenser

InactiveCN103267224ARealization of self-feedback controlAchieving Self-Learning ImprovementsContainer filling methodsContainer discharging methodsSelf feedbackElectron

The invention relates to the field of control of a gas dispenser and particularly relates to a self-feedback control method of a gas dispenser. The self-feedback control method comprises the following steps of: initializing a system and calculating an instantaneous pressure changing rate; when the instantaneous pressure changing rate is greater than a pre-set value, maintaining the gas leakage of the inner part of a pipeline of the gas dispenser; if the inner part of the pipeline of the gas dispenser does not leak gas, setting a gas dispensing amount or a gas dispensing volume and a charging pressure rated value; sampling a flow of a mass flow meter and a pressure value of a pressure-limited sensing device in real time; calculating a predicated charging pressure value of a terminal by an electric controller through using a predicated charging pressure algorithm; comparing the predicated charging pressure value with a pre-set charging pressure rated value; if the predicated charging pressure value is equal to the pre-set charging pressure rated value, finishing the gas dispensing; reading a pressure value of the terminal by the pressure-limited sensing device when the gas dispensing is finished and comparing the pressure value with the pre-set charging pressure rated value; and revising a weighted value of an output layer of the predicated charging pressure algorithm according to the error of the values and the flow when the gas dispensing is stopped. According to the self-feedback control method disclosed by the invention, the adaptive capacity of the gas dispenser to a pipeline environment is improved and the self-feedback control of the gas dispenser is realized.

Owner:BEIJING DFDADAO ENERGY EQUIP

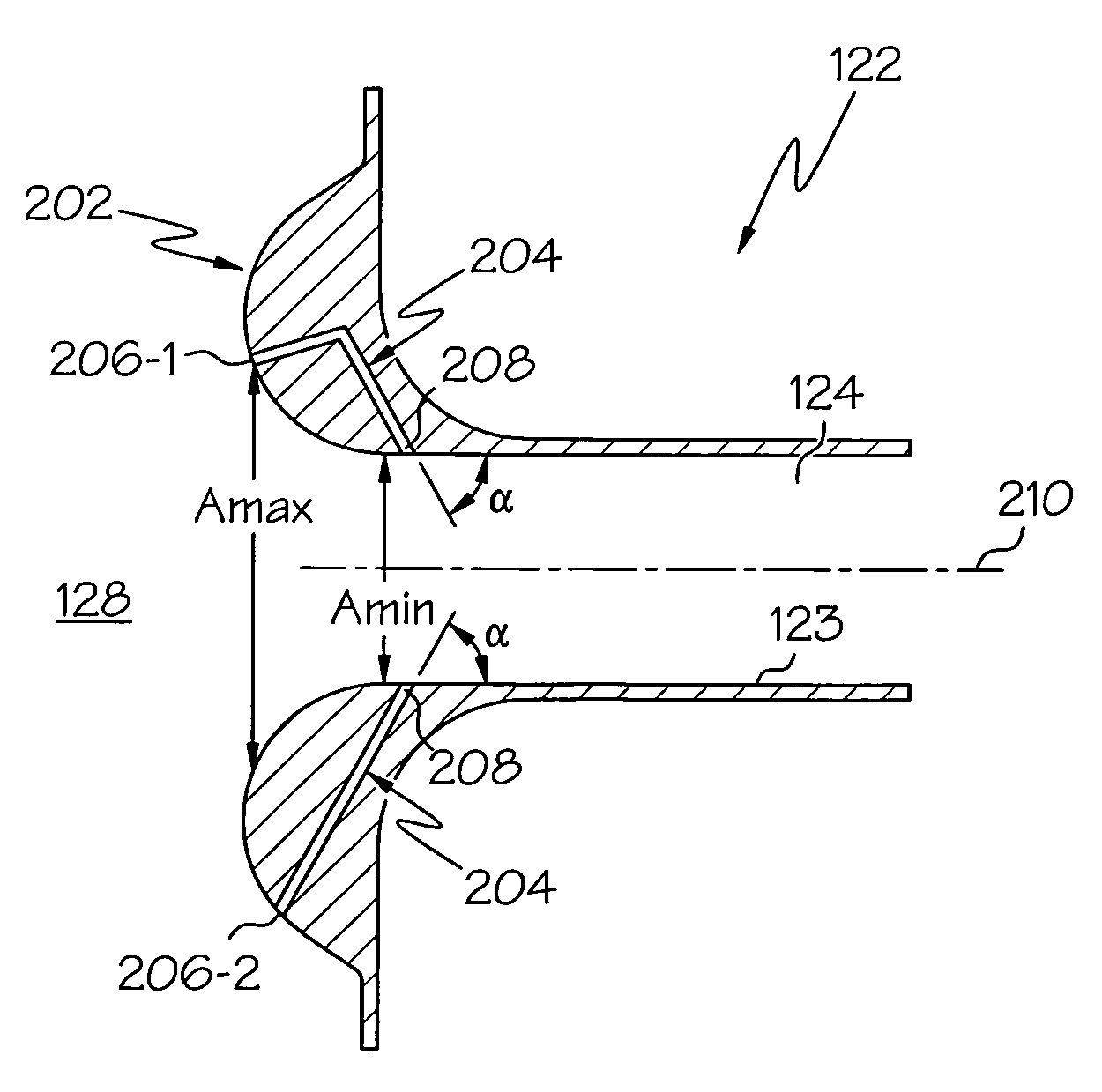

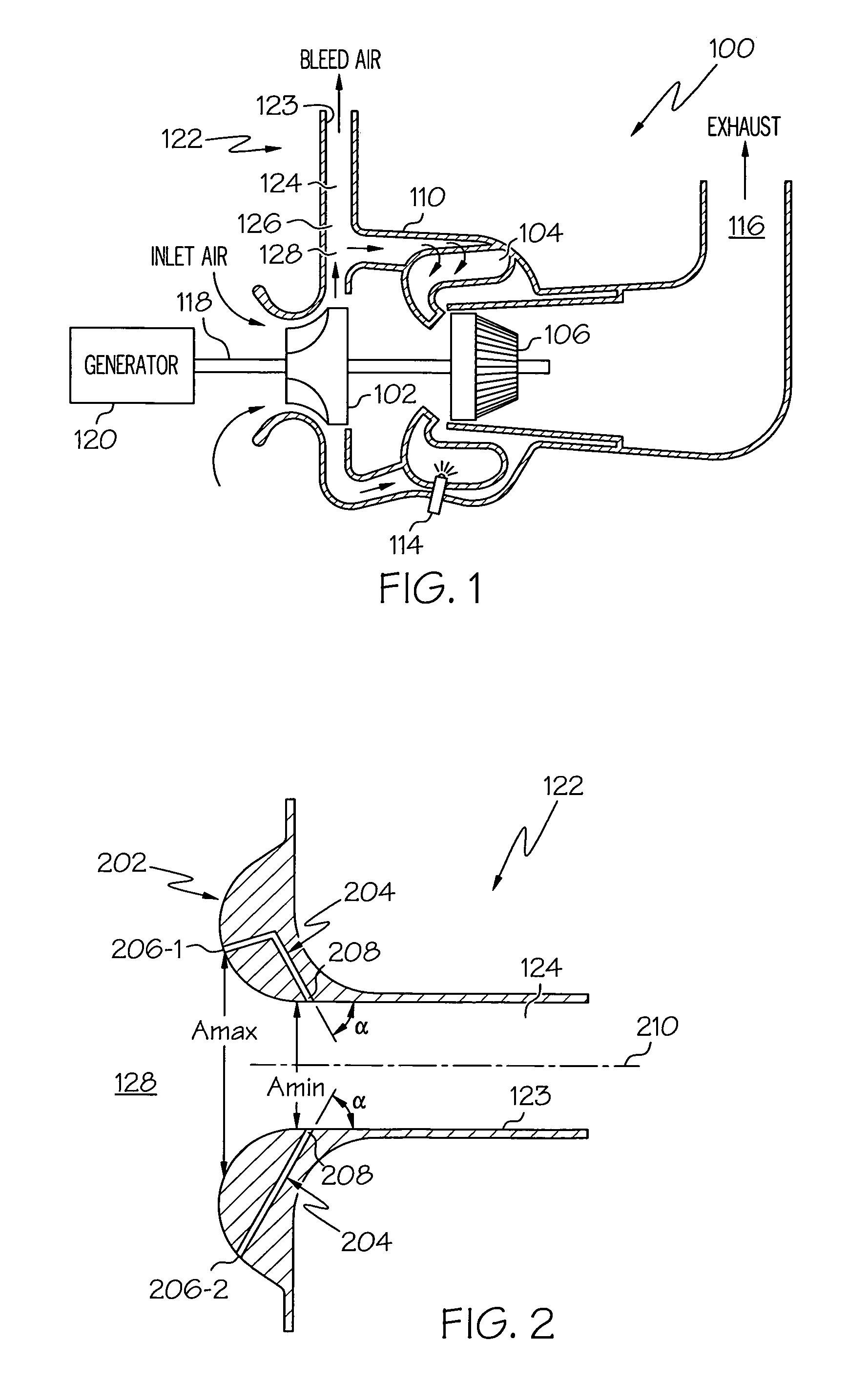

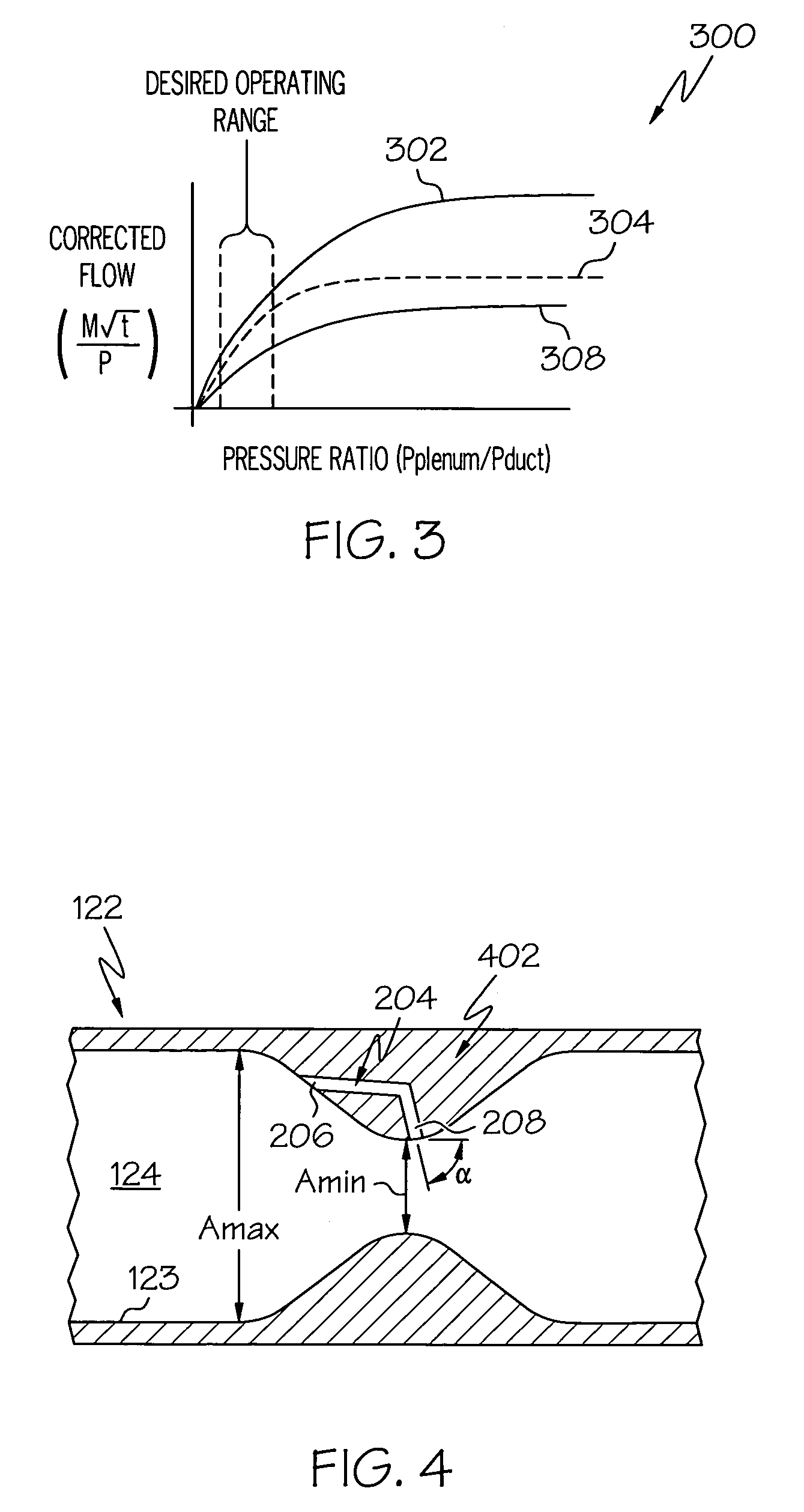

Low loss flow limited feed duct

A duct that preferably includes a low loss inlet section is configured to include one or more flow limiting passages that extend through a portion of the low loss inlet section. The flow limiting passages are located and configured such that in the desired operating flow range of the duct, the fluid exiting the flow limiting passages has minimal effect on fluid flow into and through the duct. However, at relatively high pressure ratios, the fluid exiting the flow limiting passages will disturb the fluid entering the duct, causing mixing and shock losses, which will limit the fluid flow rate into and through the duct.

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com